Surface Engineering of Woodworking Tools, a Review

Abstract

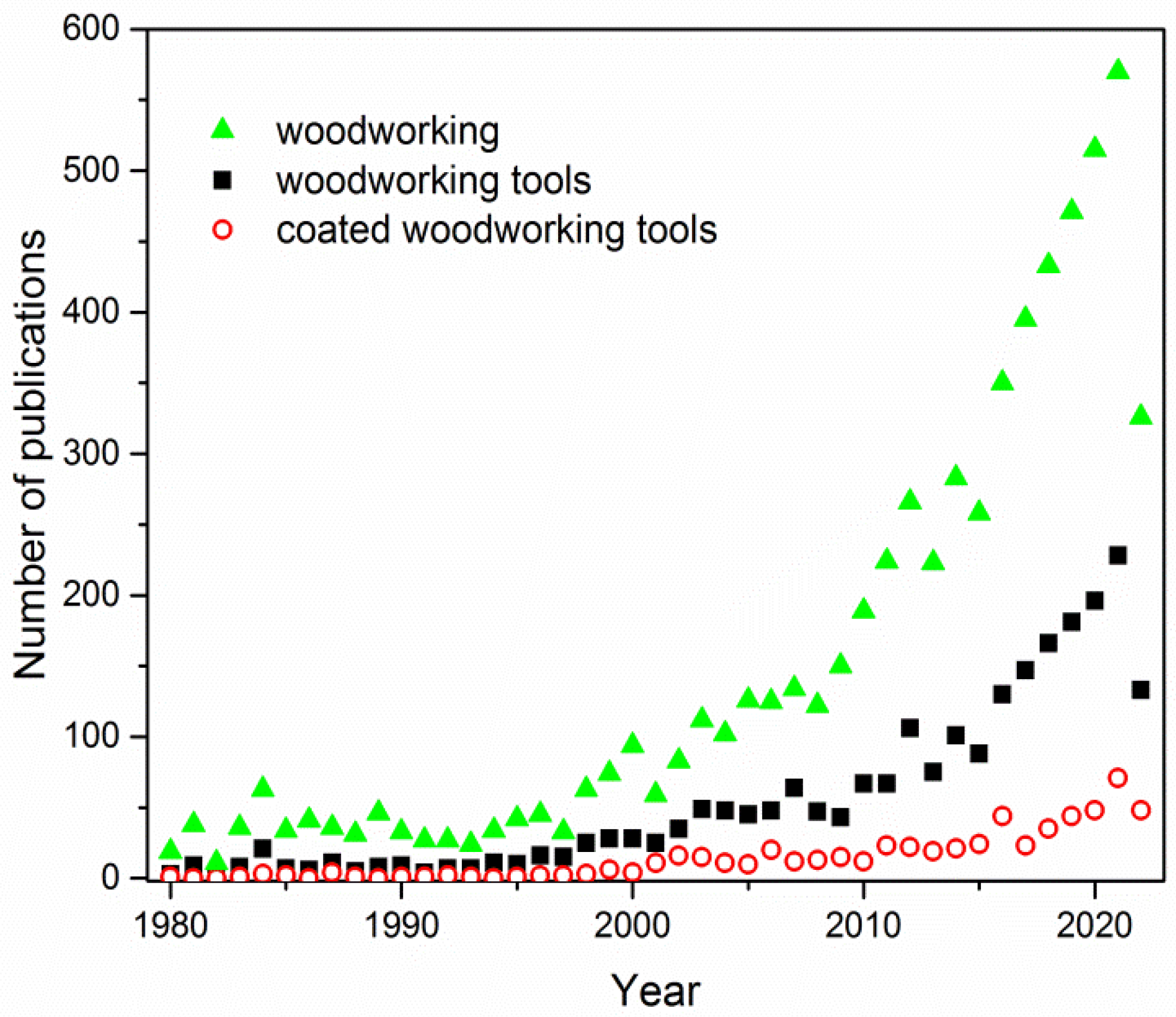

1. Introduction

2. Tool materials

3. The Areas for Improving the Efficiency of Work Tools

- Application of appropriate cooling and lubricating agents;

4. Surface Technologies

5. Coatings Used for Woodworking Tools

5.1. Binary Coatings

5.2. Binary Coatings Doped with Various Elements

5.3. Multilayer Coatings

- A comparison of the wear resistance of single-layer coatings was presented by Kazlauskas et al. [85]. Binary CrN and ternary AlCrN and TiCN coatings deposited on WC-Co tools (substrates) during the milling of oak wood showed improved wear resistance of cutters by factors of 3.0, 1.9, and 1.7, respectively. They also found that CrN was characterized by the best adhesion among the tested coatings and a low and stable coefficient of friction. They stated that low-friction coatings exhibited better wear resistance;

- Ti-based coatings have inferior wear resistance compared to Cr-based coatings. This applies to both magnetron- and arc-formed coatings. The Ti-W-N/Ti-W coating is characterized by twice the tool wear area compared to the Cr-W-N/Cr-W coating in the milling of OSB and particle board [41]. The wear of the tool covered by TiCN and CrN coating is smaller by 1.6 and 2.0, respectively [57,65]. The above conclusions are confirmed by Kazlauskas et al. [85];

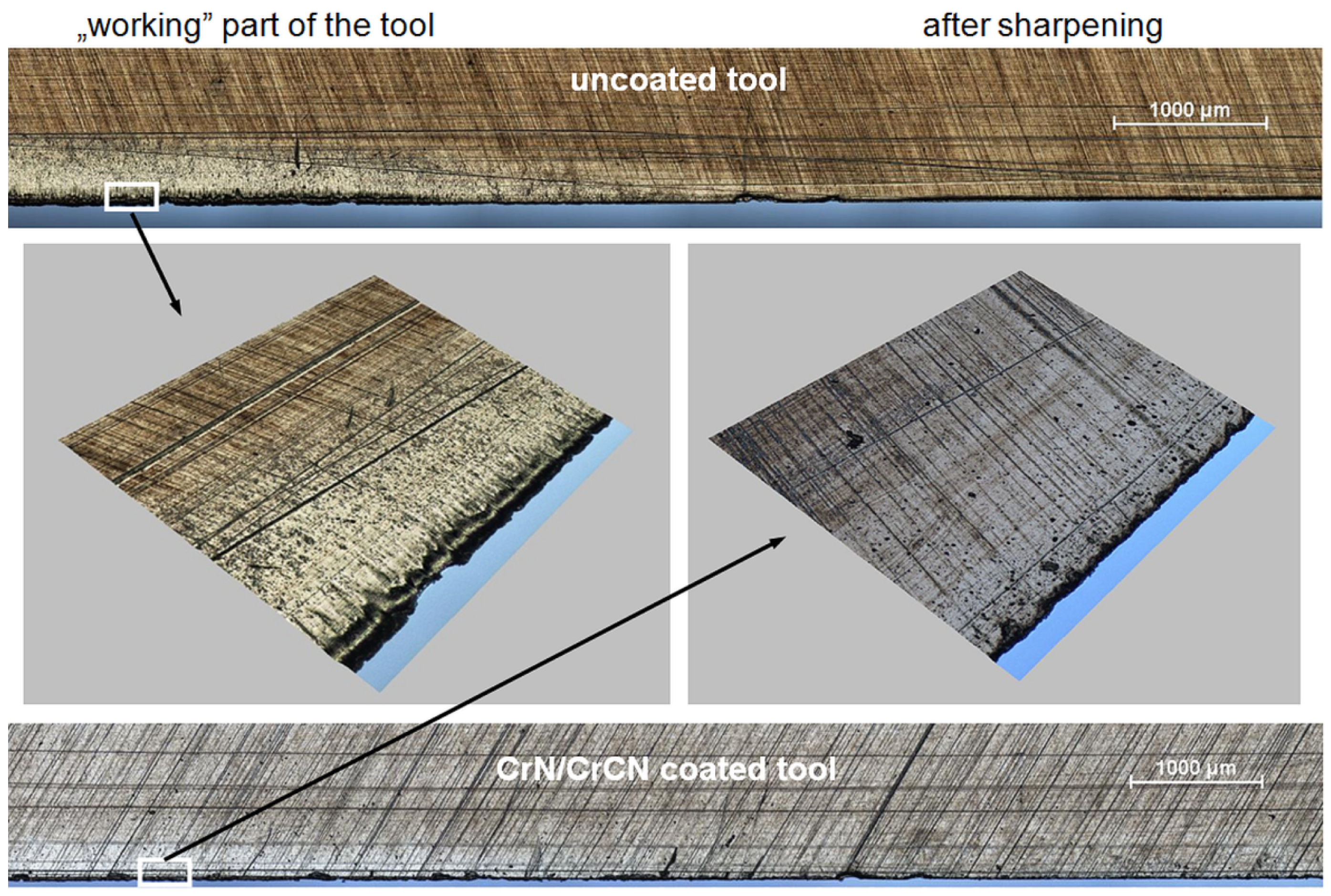

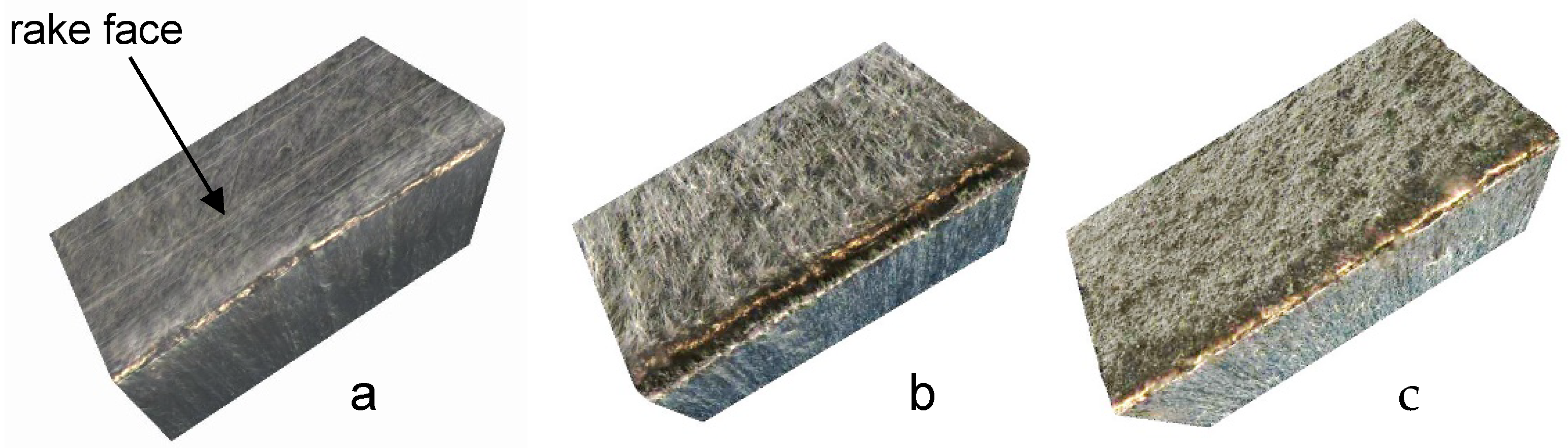

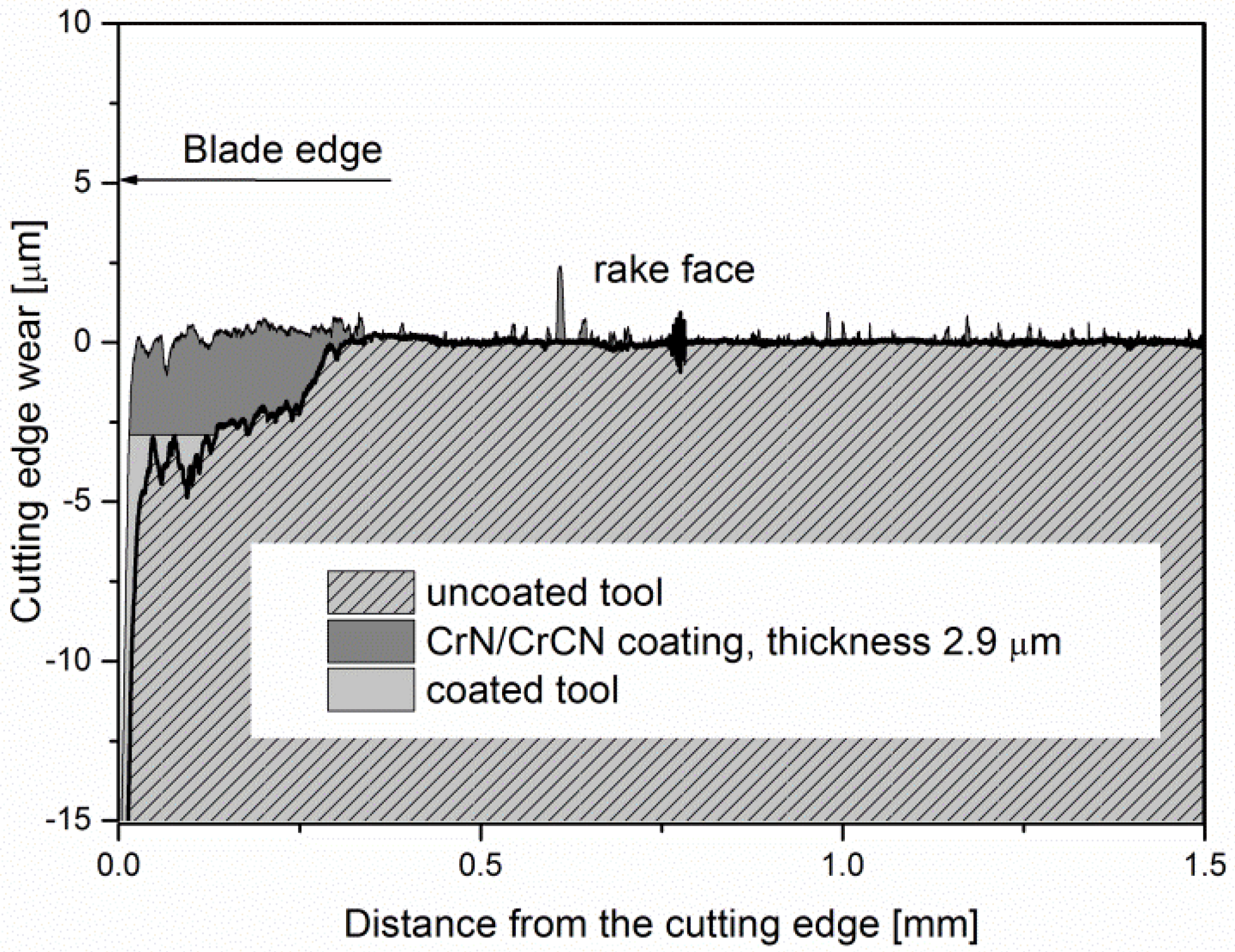

- Multilayer coatings have better properties compared to single-layer coatings. CrN and CrN/CrCN coatings were deposited on a substrate made of M2 steel and cemented carbide and the timber boles were rounded [54]. Two significant effects were observed:

- (a)

- The multilayer coating was characterized by a greater wear resistance of about 170%, while in the case of CrN coatings the increase was about 100%. These results relate to the tests carried out on the M2 steel tool coating system. Cemented carbide tools with coatings were characterized by a slightly lower durability of approx. 110% (CrN/CrCN) and 100% (CrN). It should be noted, however, that uncoated tools made of M2 steel rounded 15 boles, and cemented carbide tools 188 boles;

- (b)

- The comparison of these coatings shows that in M2 steel tools with CrN/CrCN coatings the service time is about 33% higher compared to the CrN coating, and in the case of a cemented carbide tool the increase is about 7% [54]. This confirms the reports of many authors about the importance of the substrate;

- A comparison of the edge recession of tungsten carbide tools with TiAlN monolayer coating and TiAlN/TiSiN and TiAlN/TiBON multilayer coatings in milling different wood composites indicates a greater edge recession of the TiAlN and TiAlN/TiSiN coatings [81]. Among the tested coatings, the smallest edge recession was demonstrated by the TiAlN/TiBON multilayer coating, despite the fact that its hardness was the lowest among the tested coatings, 2700 HV. The TiAlN/TiSiN coating, with a hardness of 3600 HV and the highest coefficient of friction (0.9), showed greater edge recession than the TiAlN single-layer coating. The results of these tests confirm that a lower coefficient of friction is more important than hardness.

5.4. Substrates Used for Testing the Properties of the Coatings

5.5. Scientific Centers

6. Conclusions

- Many articles are related to the processing of fiberboard or very dense homogeneous wood, the most homogeneous and isotropic materials. The processing of other materials, softwood and wood-based materials, does not give unequivocal results in the durability of the tools. It seems that the most important factors in modifying a wood knife are low friction value, good abrasion resistance, good coating adhesion, and thermal resistance. Most of the tested coatings belong to the simplest, two- or three-element systems. Only in some cases have more complex coatings, such as quaternary systems or multi-layer coatings with different structures, been investigated. The test results indicate that the latter have better wear resistance, but standardized tests should be performed to confirm this.

- A comparison of various coatings operating in the same conditions shows the advantage of CrN both in the treatment of beech wood and OSB. This is probably due to the lower brittleness of the CrN coatings, relatively low coefficient of friction, and very good adhesion to the substrate;

- Chromium-based coatings have better wear resistance compared to titanium-based coatings;

- Multilayer coatings are characterized by better wear resistance compared to single-layer coatings. This may be related to the reduction of crack propagation at the phase and grain boundaries. As in the case of a single-layer coating, higher wear resistance is found in coatings that exhibit a lower friction coefficient and are less brittle. The results of the tests confirm that a lower coefficient of friction is more important than hardness;

- The type of tool material used, and its possible thermochemical treatment, have a great influence on tool life. Increasing the hardness of the tool increases its productivity, although not always its durability.

Future Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| MDF | medium density fiberboard |

| OSB | Oriented Strand Board |

| ta-C | tetragonal carbon |

| WPC | wood plastic composite |

| LVL | laminated veneer lumber |

| GRC | Glass-reinforced concrete |

Appendix A

| Coating/ Structure | Substrate | Type of Machining | Machining Material | Results | Year | Reference |

|---|---|---|---|---|---|---|

| W-C:H (DLC with WC precipitations) CrN | 60SMD8 | peeling | beech wood | reduction of the knives’ edges by 38% (W-C:H) and 52% (CrN) | 1999 | [53] |

| CrN W–C:H(DLC) | 60SMD8 | peeling | beech wood | cutting edge reduction up to: DLC—60%, CrN—130%. | 1999 | [26] |

| CrN Cr2N | Carbide | cutting | OSB | reduction of the knives’ edges 52% (CrN) and 40% (Cr2N) | 2000 | [84] |

| CrN Cr2N | Carbide | cutting | OSB | service life four times higher (CrN), about 1.8 times higher (Cr2N) | 2001 | [24] |

| CrN | 32CrMoV13 Nitrided | peeling | beech wood | increase the service of the tool by a factor of 1.3 | 2003 | [23] |

| CrN | Carbide | routing | OSB | decrease in nose width about 64% | 2003 | [51] |

| CrN | 90MCV8 | peeling | MDF | reduction in the wear of the edge by about 50% | 2005 | [14] |

| CrN | different carbidess | milling | OSB | dependent on type of substrates | 2005 | [52] |

| CrAlN | Carbide | routing | MDF | increase up to 2.5 times more than unmodified ones | 2007 | [66] |

| CrAlN | 90CrMoV8 | peeling | beech wood | reduction in the wear of the edge by about 50% | 2009 | [37] |

| AlCrN | WC-2% Co | routing | MDF, (M) standard, and (E) fireproof | max decrease in nose width about 25%—MDF(M), 40% MDF(E) and 44% MDF | 2009 | [83] |

| CrSiN | WC-2% Co | routing | MDF | max decrease in nose width about 33% | 2009 | [38] |

| Ti-W-N/Ti-W Cr-W-N/Cr-W | WC+4%Co | milling | OSB | reduction in average wear area: Ti based coatings—to 54%, Cr—to 100%, | 2009 | [41] |

| Ti-W-N/Ti-W Cr-W-N/Cr-W | WC+4%Co | milling | particle board | reduction in average wear area: Ti based coatings—to 215%, Cr—to 460% | 2009 | [41] |

| TiAlN TiAlN/aCN | Carbide | cutting | chipboard | max. increase by 23% (TiAlN/aCN) | 2020 | [89] |

| TiN/AlTiN TiAlN/a-C:N | Different carbides | cutting | chipboard | max. increase by 56% (TiN/TiAlN) | 2021 | [90] |

| Coating/ Structure | Substrate | Type of Machining | Machining Material | Results | Year | Reference |

|---|---|---|---|---|---|---|

| TiN (Ti,Zr)N | 60SMD8 90WDCV | peeling | beech wood | cutting edge reduction up to: Ti based coatings 17%, | 1999 | [26] |

| CrN/CrCN | HS6-5-2 | planing | pine wood | reduction in average wear area to 170% | 2011 | [71] |

| Cr2N/CrN | HS6-5-2 | cutting | pine wood | reduction in average wear area of 60% | 2011 | [69] |

| TiCN CrN DLC | K01–K20 | milling | wood panel oaken scantlings glued by polyvinyl acetate | wear compared to the uncoated cutters. TiCN—smaller by 1.6 × DLC—smaller by 1.9 × CrN—smaller twice | 2015 | [65] |

| ZrN MoN | WC + Co | milling | particle board | reduction in volume wear to 150% (MoN) and 110% (ZrN) | 2016 | [93] |

| TiAlN | K10 | cutting | mersawa wood fiberboard, particleboard, GRC | edge recession reduction by factor: 0.27 0.60 0.33 0.38 | 2016 | [40] |

| TiAlN/TiSiN | K10 | cutting | mersawa wood fiberboard particleboard GRC | edge recession reduction by factor: 0.38 0.78 0.43 0.54 | 2016 | [40] |

| TiAlN/TiBON | K10 | cutting | mersawa wood fiberboard particleboard GRC | edge recession reduction by factor: 0.62 1.13 0.83 1.10 | 2016 | [40] |

| CrN CrN/CrCN | M2 steel | cutting | timber | improvement in the tool durability of 170% (CrN/CrCN), 100% (CrN) | 2018 | [54] |

| CrN CrN/CrCN | cemented carbide | rounding | timber | improvement in the tool durability of 110% (CrN/CrCN), 100% (CrN) | 2018 | [54] |

| TiAlN | K10 tungsten carbide tool | milling | asbestos WPC LVL OSB | edge recession reduction by factor: 2.12 1.09 1.5 1.54 | 2019 | [81] |

| TiAlN/TiSiN | K10 tungsten carbide tool | milling | asbestos WPC LVL OSB | edge recession reduction by factor: 1.08 0.84 1.35 1.33 | 2019 | [81] |

| TiAlN/TiBON | K10 tungsten carbide tool | milling | asbestos WPC LVL OSB | edge recession reduction by factor: 2.33 3.18 4.0 3.67 | 2019 | [81] |

| CrN/CrCN | HS6-5-2 | planing | pine wood | improvement in the tool durability of 142% | 2020 | [91] |

| AlCrBN | HS6-5-2 | planing | pine wood | improvement in the life service by 205% | 2021 | [92] |

| Coating/ Structure | Substrate | Type of Machining | Machining Material | Results | Year | Reference |

|---|---|---|---|---|---|---|

| ta-C | cemented tungsten carbide | milling | melamine laminated particle board | 2.5-fold lifetime increase | 1999 | [49] |

| TiN | SKH 51 | sawing | oil palm afina sugi | tool wear 10% decrease 25% increase 64% increase | 2006 | [47] |

| TiN | P30 | cutting | hardboard, cement board | life time increase 30–45% | 2008 | [48] |

| TiAlN/TiBN, TiAlN/TiSiN, TiAlN/CrAIN TiAlN | K10 | milling | particle board | multilayer-coated tools experienced a smaller amount of delamination wear than the monolayer-coated tool. The best multilayer coating was TiAlN/CrAlN | 2010 | [68] |

| CrN, AlTiN, TiAlN, TiCN, and CrN | WC-Co | milling | oak wood | improvement in wear resistance by factors of: 3.0 (CrN), 1.9 (AlCrN), 1.7 (TiCN) | 2022 | [85] |

References

- Available online: www.Kadur.com (accessed on 31 August 2022).

- Dembiński, C.; Potok, Z.; Kučerka, M.; Kminiak, R.; Očkajová, A.; Rogoziński, T. The Flow Resistance of the Filter Bags in the Dust Collector Operating in the Line of Wood-Based Furniture Panels Edge Banding. Appl. Sci. 2022, 12, 5580. [Google Scholar] [CrossRef]

- Dong, W.; Xiong, X.; Ma, Y.; Yue, X. Woodworking Tool Wear Condition Monitoring during Milling Based on Power Signals and a Particle Swarm Optimization-Back Propagation Neural Network. Appl. Sci. 2021, 11, 9026. [Google Scholar] [CrossRef]

- Mračková, E.; Schmidtová, J.; Marková, I.; Jad’ud’ová, J.; Tureková, I.; Hitka, M. Fire Parameters of Spruce (Picea abies Karst. (L.)) Dust Layer from Different Wood Technologies Slovak Case Study. Appl. Sci. 2022, 12, 548. [Google Scholar] [CrossRef]

- Orlowski, K.A.; Dudek, P.; Chuchala, D.; Blacharski, W.; Przybylinski, T. The Design Development of the Sliding Table Saw Towards Improving Its Dynamic Properties. Appl. Sci. 2020, 10, 7386. [Google Scholar] [CrossRef]

- Pędzik, M.; Rogoziński, T.; Majka, J.; Stuper-Szablewska, K.; Antov, P.; Kristak, L.; Kminiak, R.; Kučerka, M. Fine Dust Creation during Hardwood Machine Sanding. Appl. Sci. 2021, 11, 6602. [Google Scholar] [CrossRef]

- Sporek, M.; Sporek, K.; Stebila, J.; Kučerka, M.; Kminiak, R.; Lubis, M.A.R. Assessment of the Mass and Surface Area of the Scots Pine (Pinus sylvestris L.) Needles. Appl. Sci. 2022, 12, 8204. [Google Scholar] [CrossRef]

- Sydor, M.; Mirski, R.; Stuper-Szablewska, K.; Rogoziński, T. Efficiency of Machine Sanding of Wood. Appl. Sci. 2021, 11, 2860. [Google Scholar] [CrossRef]

- Sydor, M.; Pinkowski, G.; Kučerka, M.; Kminiak, R.; Antov, P.; Rogoziński, T. Indentation Hardness and Elastic Recovery of Some Hardwood Species. Appl. Sci. 2022, 12, 5049. [Google Scholar] [CrossRef]

- Norrby, N.; Johansson, M.P.; M’Saoubi, R.; Odén, M. Pressure and temperature effects on the decomposition of arc evaporated Ti0.6Al0.4N coatings in continuous turning. Surf. Coat. Technol. 2012, 209, 203–207. [Google Scholar] [CrossRef]

- Grobelny, T. Thermo-Mechanical Condition of the Tool Blade in the Process of Milling Wood and Wood Materials. Ph.D. Thesis, SGGW, Warsaw, Poland, 1999. [Google Scholar]

- Lopez De Lacalle, L.N.; Lamikiz, A.; De Larrinova, J.F.; Azkona, I. Advanced Cutting Tools. In Machining of Hard Materials; Davim, J.P., Ed.; Springer-Verlag: London, UK, 2011; pp. 33–85. [Google Scholar]

- Yates, J.M. Is there life after tungsten carbide? Wood Wood Prod. 1987, 92, 77–87. [Google Scholar]

- Boyle, G.R. PCD replacing carbide in woodworking applications. Cut. Tool Eng. 1983, 35, 60–61. [Google Scholar]

- Aytacoglu, M.E. PCD cutting tools gaining momentum. Cut. Tool Eng. 1983, 35, 49–50. [Google Scholar]

- Heimbrand, E. Machining wood products with PCD. Ind. Diam. Rev. 1985, 45, 187–190. [Google Scholar]

- Herbert, S. Wood products latch on to PCD. Ind. Diam. Rev. 1984, 44, 159–162. [Google Scholar]

- Klamecki, B.E. A review of wood cutting tool wear literature. Holz Als Roh-Und Werkst. 1979, 37, 265–276. [Google Scholar] [CrossRef]

- Thibaut, B.; Denaud, L.; Collet, R.; Marchal, R.; Beauchene, J.; Mothe, F.; Méausoone, P.J.; Martin, P.; Larricq, P.; Eyma, F. Wood machining with a focus on French research in the last 50 years. Ann. For. Sci. 2016, 73, 163–184. [Google Scholar] [CrossRef]

- Rudnicki, J.; Beer, P.; Sokołowska, A.; Marchal, R. Low-temperature ion nitriding used for improving the durability of the steel knives in the wood rotary peeling. Surf. Coat. Technol. 1998, 107, 20–23. [Google Scholar] [CrossRef]

- Nouveau, C.; Steyer, P.; Mohan Rao, K.R.; Lagadrillere, D. Plasma nitriding of 90CrMoV8 tool steel for the enhancement of hardness and corrosion resistance. Surf. Coat. Technol. 2011, 205, 4514–4520. [Google Scholar] [CrossRef]

- Chekour, L.; Nouveau, C.; Chala, A.; Djouadi, M.A. Duplex treatment of 32CrMoV13 steel by ionic nitriding and triode sputtering: Application to wood machining. Wear 2003, 255, 1438–1443. [Google Scholar] [CrossRef]

- Nouveau, C.; Djouadi, M.A.; Decès-Petit, C.; Beer, P.; Lambertin, M. Influence of CrxNy coatings deposited by magnetron sputtering on tool service life in wood processing. Surf. Coat. Technol. 2001, 142–144, 94–101. [Google Scholar] [CrossRef]

- Labidi, C.; Collet, R.; Nouveau, C.; Beer, P.; Nicosia, S.; Djouadi, M.A. Surface treatments of tools used in industrial wood machining. Surf. Coat. Technol. 2005, 200, 118–122. [Google Scholar] [CrossRef]

- Anon, J.C.R. Modern cutting tools adapt to changing woodworking needs. Wood Wood Prod. 1984, 89, 201–203. [Google Scholar]

- Djouadi, M.A.; Beer, P.; Marchal, R.; Sokolowska, A.; Lambertin, M.; Precht, W.; Nouveau, C. Antiabrasive coatings: Application for wood processing. Surf. Coat. Technol. 1999, 116–119, 508–516. [Google Scholar] [CrossRef]

- Naylor, A.; Hackney, P. A Review of Wood Machining Literature with a Special Focus on Sawing. BioResources 2013, 8, 3122–3135. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y. Effect of Cutting Edge Geometry on Thermal Stresses and Failure of Diamond Coated Tools. Procedia Manuf. 2015, 1, 663–674. [Google Scholar] [CrossRef]

- Sheikh-Ahmad, J.Y.; Morita, T. Tool coatings for wood machining: Problems and prospects. For. Prod. J. 2002, 52, 43–51. [Google Scholar]

- Gogolewski, P.; Klimke, J.; Krell, A.; Beer, P. Al2O3 tools towards effective machining of wood-based materials. J. Mater. Process. Technol. 2009, 209, 2231–2236. [Google Scholar] [CrossRef]

- Guo, X.L.; Cao, P.X.; Liu, H.N.; Teng, Y.; Guo, Y.; Wang, H. Tribological Properties of Ceramics Tool Materials in Contact with Wood-Based Materials. Adv. Mat. Res. 2013, 764, 65–69. [Google Scholar] [CrossRef]

- Zhu, Z.; Guo, X.; Na, B.; Liang, X.; Ekevad, M.; Ji, F. Research on cutting performance of ceramic cutting tools in milling high density fiberboard. Wood Res. 2017, 62, 125–138. [Google Scholar]

- Eblagon, F.; Ehrle, B.; Graule, T.; Kuebler, J. Development of silicon nitride/silicon carbide composites for wood-cutting tools. J. Eur. Ceram. Soc. 2007, 27, 419–428. [Google Scholar] [CrossRef]

- Ugulino, B.; Hernandez, R.E. Assessment of surface properties and solvent-borne coating performance of red oak wood produced by peripheral planing. Eur. J. Woo Prod. 2017, 75, 581–593. [Google Scholar] [CrossRef]

- Blugan, G.; Strehler, V.; Vetterli, M.; Ehrle, B.; Duttlinger, R.; Blösch, P.; Kuebler, J. Performance of lightweight coated oxide ceramic composites for industrial high speed wood cutting tools: A step closer to market. Ceram. Int. 2017, 43, 8735–8742. [Google Scholar] [CrossRef]

- Beer, P.; Gogolewski, P.; Klimke, J.; Krell, A. Tribological Behaviour of Sub-micron Cutting-ceramics in Contact with Wood-based Materials. Tribol. Lett. 2007, 27, 155–158. [Google Scholar] [CrossRef]

- Beer, P.; Rudnicki, J.; Ciupinski, L.; Djouadi, M.A.; Nouveau, C. Modification by composite coatings of knives made of low alloy steel for wood machining purposes. Surf. Coat. Technol. 2003, 174–175, 434–439. [Google Scholar] [CrossRef]

- Benlatreche, Y.; Nouveau, C.; Aknouche, H.; Imhoff, L.; Martin, N.; Gavoille, J.; Rousselot, C.; Rauch, J.Y.; Pilloud, D. Physical and Mechanical Properties of CrAlN and CrSiN Ternary Systems for Wood Machining Applications. Plasma Process. Polym. 2009, 6, S113–S117. [Google Scholar] [CrossRef]

- Faga, M.G.; Settineri, L. Innovative anti-wear coatings on cutting tools for wood machining. Surf. Coat. Technol. 2006, 201, 3002–3007. [Google Scholar] [CrossRef]

- Fahrussiam, F.; Praja, I.A.; Darmawan, W.; Wahyudi, I.; Nandika, D.; Usuki, H.; Koseki, S. Wear characteristics of multilayer-coated cutting tools in milling wood and wood-based composites. Tribol. Ind. 2016, 38, 66–73. [Google Scholar]

- Pinheiro, D.; Vieira, M.T.; Djouadi, M.A. Advantages of depositing multilayer coatings for cutting wood-based products. Surf. Coat. Technol. 2009, 203, 3197–3205. [Google Scholar] [CrossRef]

- Vahlas, C. Chemical vapor deposition of metals: From unary systems to complex metallic alloys. In Surface Properties and Engineering of Complex Metallic Alloys; Belin-Ferre, E., Ed.; World Scientific Publishing Company Co., Pte. Ltd.: Singapore, 2010; Volume 3, pp. 49–82. [Google Scholar]

- Gulbiński, W. Physical vapor deposition of thin film coatings. In Surface Properties and Engineering of Complex Metallic Alloys; Belin-Ferre, E., Ed.; World Scientific Publishing Company Co., Pte. Ltd.: Singapore, 2010; Volume 3, pp. 83–92. [Google Scholar]

- Bendikiene, R.; Keturakis, G.; Pilkaite, T.; Pupelis, E. Wear Behaviour and Cutting Performance of Surfaced Inserts for Wood Machining. Stroj.Vestn.-J. Mech. E. 2015, 61, 459–464. [Google Scholar] [CrossRef]

- Valleti, K.; Rejin, C.; Joshi, S.V. Factors influencing properties of CrN thin films grown by cylindrical cathodic arc physical vapor deposition on HSS substrates. Mater. Sci. Eng. A 2012, 545, 155–161. [Google Scholar] [CrossRef]

- Osenius, S.; Korhonen, A.S.; Sulonen, M.S. Performance of TiN-coated tools in wood cutting. Surf. Coat. Technol. 1987, 33, 141–151. [Google Scholar] [CrossRef]

- Okai, R.; Tanaka, C.; Iwasaki, Y. Influence of mechanical properties and mineral salts in wood species on tool wear of high-speed steels and stellite-tipped tools—Consideration of tool wear of the newly developed tip-inserted band saw. Holz Als Roh-Und Werkst. 2006, 64, 45–52. [Google Scholar] [CrossRef]

- Darmawan, W.; Usuki, H.; Quesada, J.; Marchal, R. Clearance wear and normal force of TiN-coated P30 in cutting hardboards and wood-chip cement boards. Holz Als Roh-Und Werkst. 2008, 66, 89–97. [Google Scholar] [CrossRef]

- Endler, I.; Bartsch, K.; Leonhardt, A.; Scheibe, H.J.; Ziegele, H.; Fuchs, I.; Raatz, C. Preparation and wear behaviour of woodworking tools coated with superhard layers. Diam. Relat. Mater. 1999, 8, 834–839. [Google Scholar] [CrossRef]

- Kusiak, A.; Battaglia, J.L.; Marchal, R. Influence of CrN coating in wood machining from heat flux estimation in the tool. Int. J. Thermal Sci. 2005, 44, 289–301. [Google Scholar] [CrossRef]

- Nouveau, C.; Djouadi, M.A.; Decès-Petit, C. The influence of deposition parameters on the wear resistance of CrxNy magnetron sputtering coatings in routing of oriented strand board. Surf. Coat. Technol. 2003, 174–175, 455–460. [Google Scholar] [CrossRef]

- Nouveau, C.; Jorand, E.; Decès-Petit, C.; Labidi, C.; Djouadi, M.A. Influence of carbide substrates on tribological properties of chromium nitride coatings: Application to wood machining. Wear 2005, 258, 157–165. [Google Scholar] [CrossRef]

- Beer, P.; Djouadi, M.A.; Marchal, R.; Sokolowska, A.; Lambertin, M.; Czyzniewski, A.; Precht, W. Antiabrasive coatings in a new application—Wood rotary peeling process. Vacuum 1999, 53, 363–366. [Google Scholar] [CrossRef]

- Kong, Y.; Tian, X.; Gong, C. Enhancement of toughness and wear resistance by CrN/CrCN multilayered coatings for wood processing. Surf. Coat. Technol. 2018, 344, 204–213. [Google Scholar] [CrossRef]

- Niedzielski, P.; Miklaszewski, S.; Beer, P.; Sokolowska, A. Tribological properties of NCD coated cemented carbides in contact with wood. Diam. Rel. Mater. 2001, 10, 1–6. [Google Scholar] [CrossRef]

- Pancielejko, M.; Czyzniewski, A.; Gilewicz, A.; Zavaleyev, V.; Szymański, W. The cutting properties and wear of the knives with DLC and W-DLC coatings. deposited by PVD methods. applied for wood and wood-based materials machining. Arch. Mater. Sci. Eng. 2012, 58, 235–244. [Google Scholar]

- Kaczorowski, W.; Batory, D.; Szamanski, W.; Niedzielski, P. Carbon-based layers for mechanical machining of wood-based materials. Wood Sci. Technol. 2012, 46, 1085–1096. [Google Scholar] [CrossRef]

- Olaya, J.J.; Wei, G.; Rodil, S.E.; Muhl, S.; Bhushan, B. Influence of the ion–atom flux ratio on the mechanical properties of chromium nitride thin films. Vacuum 2007, 81, 610–618. [Google Scholar] [CrossRef]

- Odén, M.; Ericsson, C.; Håkansson, G.; Ljungcrantz, H. Microstructure and mechanical behavior of arc-evaporated Cr–N coatings. Surf. Coat. Technol. 1999, 114, 39–51. [Google Scholar] [CrossRef]

- Oden, M.; Almer, J.; Hakansson, G.; Olsson, M. Microstructure property relationships in arc-evaporated CrN coatings. Thin Solid Films 2000, 377–378, 407–412. [Google Scholar] [CrossRef]

- Navinsek, B.; Panjan, P.; Milosev, I. Industrial applications of CrN (PVD) coatings. deposited at high and low temperatures. Surf. Coat. Technol. 1997, 97, 182–191. [Google Scholar] [CrossRef]

- Rebholz, C.; Ziegele, H.; Leyland, A.; Matthew, A. Structure, mechanical and tribological properties of nitrogen-containing chromium coatings prepared by reactive magnetron sputtering. Surf. Coat. Technol. 1999, 115, 222–229. [Google Scholar] [CrossRef]

- Wiklund, U.; Gunnars, J.; Hogmark, S. Influence of residual stresses on fracture and delamination of thin hard coatings. Wear 1999, 232, 262–269. [Google Scholar] [CrossRef]

- Castanho, J.M.; Vieira, M.T. Effect of ductile layers in mechanical behaviour of TiAlN thin coatings. J. Mater. Proc. Technol. 2003, 143–144, 352–357. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Keturakis, G. Wear of TiCN, CrN and DLC coated tungsten carbide router cutters during oak wood milling. In Proceedings of the 20th International Scientific Conference: Mechanika 2015, Kaunas University of Technology, Kaunas, Lithuania, 23–24 April 2015. [Google Scholar]

- Nouveau, C.; Labidi, C.; Ferreira Martin, J.P.; Collet, R.; Djouadi, M.A. Application of CrAlN coatings on carbide substrates in routing of MDF. Wear 2007, 263, 1291–1299. [Google Scholar] [CrossRef]

- Nouveau, C.; Labidi, C.; Collet, R.; Benlatreche, Y.; Djouadi, M.A. Effect of surface finishing such as sand-blasting and CrAlN hard coatings on the cutting edge’s pelling tools’ wear resistance. Wear 2009, 267, 1062–1067. [Google Scholar] [CrossRef]

- Darmawan, W.; Usuki, H.; Rahayu, I.S.; Gottlöber, C.; Marchal, R. Wear Characteristics of Multilayer-Coated Cutting Tools when Milling Particleboard. For. Prod. J. 2010, 60, 615–621. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Ratajski, J. Cr2N/CrN multilayer coatings for wood machining tools. Tribol. Int. 2011, 244, 1076–1082. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A.; Kuklinski, Z.; Myslinski, P. Hard CrCN/CrN multilayer coatings for tribological applications. Surf. Coat. Technol. 2010, 204, 2289–2293. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B.; Myslinski, P.; Szymanski, W. Anti-wear multilayer coatings based on chromium nitride for wood machining tools. Wear 2010, 210, 32–38. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Multilayer coatings on tools for woodworking. Wear 2011, 271, 2812–2820. [Google Scholar] [CrossRef]

- Gilewicz, A.; Warcholinski, B.; Szymanski, W.; Grimm, W. CrCN/CrN + ta-C multilayer coating for applications in wood processing. Tribol. Int. 2013, 57, 1–7. [Google Scholar] [CrossRef]

- Kot, M.; Rakowski, W.A.; Major, Ł.; Major, R.; Morgiel, J. Effect of bilayer period on properties of Cr/CrN multilayer coatings produced by laser ablation. Surf. Coat. Technol. 2008, 202, 3501–3506. [Google Scholar] [CrossRef]

- Chang, Y.Y.; Yang, S.J.; Wang, D.Y. Structural and mechanical properties of TiAlN/CrN coatings synthesized by a cathodic-arc deposition process. Surf. Coat. Technol. 2006, 201, 4209–4214. [Google Scholar] [CrossRef]

- Salje, E.W.; Stuehmeier, W. Milling particleboard with high hard cutting materials. In Proceedings of the Ninth International Wood Machining Seminar, Richmond, VA, USA, 10–12 October 1988; pp. 211–228. [Google Scholar]

- Fuch, I.; Raatz, C. Study of wear behavior of specially coated (CVD.PACVD) cemented carbide tools while milling of wood-based materials. In Proceedings of the 13th International Wood Machining Seminar, Vancouver, BC, Canada, 17–19 June 1997; pp. 709–715. [Google Scholar]

- Sheikh-Ahmad, J.Y.; Stewart, J.S. Performance of different PVD coated tungsten carbide tools in the continuous machining of particleboard. In Proceedings of the 12th International Wood Machining Seminar, Kyoto, Japan, 2–4 October 1995; pp. 282–291. [Google Scholar]

- Li, Y.; Liu, Y.H.; Tian, Y.B.; Wang, Y.; Wang, J.L. Application of improved fireworks algorithm in grinding surface roughness online monitoring. J. Manuf. Process. 2022, 74, 400–412. [Google Scholar] [CrossRef]

- Li, Y.; Liu, Y.H.; Wang, J.L.; Wang, Y.; Tian, Y.B. Real-time monitoring of silica ceramic composites grinding surface roughness based on signal spectrum analysis. Ceram. Int. 2022, 48, 7204–7217. [Google Scholar] [CrossRef]

- Pangestu, K.P.T.; Darmawan, W.; Nandika, D.; Usuki, H. Cutting performance of multilayer coated tungsten carbide in milling of wood composites. Int. Wood Prod. J. 2019, 10, 78–85. [Google Scholar] [CrossRef]

- Warcholinski, B.; Gilewicz, A. Coating for better endurance. In FMD ASIA Solid Wood Panel Technology; 2012; pp. 26–29. [Google Scholar]

- Warcholiński, B.; Gilewicz, A.; Szymański, W.; Pinkowski, G. Improvment of durability of engineering tools for wood. Surf. Eng. 2011, 2, 73–80. (In Polish) [Google Scholar]

- Djouadi, M.A.; Nouveau, C.; Beer, P.; Lambertin, M. CrxNy hard coatings deposited with PVD method on tools for wood machining. Surf. Coat. Technol. 2000, 133–134, 478–483. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Jankauskas, V.; Kreivaitis, R.; Tuckute, S. Wear behaviour of PVD coating strengthened WC-Co cutters during milling of oak-wood. Wear 2022, 498–499, 204336. [Google Scholar] [CrossRef]

- Benlatreche, Y.; Nouveau, C.; Marchal, R.; Ferreira Martins, J.P.; Aknouche, H. Applications of CrAlN ternary system in wood machining of medium density fibreboard (MDF). Wear 2009, 267, 1056–1061. [Google Scholar] [CrossRef]

- Kato, C.; Bailey, J.A. Wear Characteristics of a Woodworking Knife with a Vanadium Carbide Coating only on the Clearance Surface (Back Surface). Key Eng. Mater. 1998, 138–140, 479–520. [Google Scholar] [CrossRef]

- Makala, R.S.; Yoganand, S.N.; Jagannadham, K.; Lemaster, R.L.; Bailey, J. Diamond Coated WC Tools for Machining Wood and Particle Board. MRS Online Proc. Libr. 2001, 697, 819. [Google Scholar] [CrossRef]

- Czarniak, P.; Szymanowski, K.; Kucharska, B.; Krawczyńska, A.; Sobiecki, J.R.; Kubacki, J.; Panjan, P. Modification of tools for wood based materials machining with TiAlN/a-CN coating. J. Mater. Sci. Eng. B 2020, 257, 114540. [Google Scholar] [CrossRef]

- Kucharska, B.; Sobiecki, J.R.; Czarniak, P.; Szymanowski, K.; Cymerman, K.; Moszczyńska, D.; Panjan, P. Influence of Different Types of Cemented Carbide Blades and Coating Thickness on Structure and Properties of TiN/AlTiN and TiAlN/a-C:N Coatings Deposited by PVD Techniques for Machining of Wood-Based Materials. Materials 2021, 14, 2740. [Google Scholar] [CrossRef]

- Nadolny, K.; Kapłonek, W.; Sutowska, M.; Sutowski, P.; Myśliński, P.; Gilewicz, A. Experimental Studies on Durability of PVD-Based CrCN/CrN-Coated Cutting Blade of Planer Knives Used in the Pine Wood Planing Process. Materials 2020, 13, 2398. [Google Scholar] [CrossRef] [PubMed]

- Nadolny, K.; Kapłonek, W.; Sutowska, M.; Sutowski, P.; Myśliński, P.; Gilewicz, A.; Warcholiński, B. Moving towards sustainable manufacturing by extending the tool life of the pine wood planing process using the AlCrBN coating. SM&T 2021, 28, e00259. [Google Scholar]

- Chayeuski, V.; Zhylinski, V.; Grishkevich, A.; Rudak, P.; Barcik, S. Influence of high energy treatment on wear of edges knives of wood-cutting tool. MM Sci. J. 2016, 6, 1519–1523. [Google Scholar] [CrossRef][Green Version]

- Latushkina, S.D.; Rudak, P.V.; Kuis, D.V.; Rudak, O.G.; Posylkina, O.I.; Piskunova, O.Y.; Kováč, J.; Krilek, J.; Barcík, S. Protective Woodcutting Tool Coatings. Acta Univ. Agric. Silvic. Mendel. Brun. 2016, 64, 835–839. [Google Scholar] [CrossRef]

- Chayeuski, V.; Zhylinski, V.; Cernashejus, O.; Visniakov, N.; Mikalauskas, G. Structural and Mechanical Properties of the ZrC/Ni-Nanodiamond Coating Synthesized by the PVD and Electroplating Processes for the Cutting Knifes. J. Mater. Eng. Perform. 2019, 28, 1278–1285. [Google Scholar] [CrossRef]

- Kuleshov, A.K.; Uglov, V.V.; Rusalsky, D.P.; Grishkevich, A.A.; Chayeuski, V.V.; Haranin, V.N. Effect of ZrN and Mo-N coatings and sulfacyyanization on wear of wood-cutting knives. J. Frict. Wear. 2014, 35, 201–209. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Jankauskas, V.; Tuckute, S. Research on tribological characteristics of hard metal WC-Co tools with TiAlN and CrN PVD coatings for processing solid oak wood. Coating 2020, 10, 632. [Google Scholar] [CrossRef]

- Kazlauskas, D.; Jankauskas, V. Woodworking tools: Tribological problems and directions of solutions. In Proceedings of the 9th International Conference BALTTRIB’2017, Kaunas, Lithuania, 16–17 November 2017. [Google Scholar]

- Kazlauskas, D.; Keturakis, G.; Jankauskas, V.; Andriušis, A. Investigation of TiCrN-Coated High Speed Steel Tools Wear during Medium Density Fiberboard Milling. J. Frict. Wear 2021, 42, 124–129. [Google Scholar] [CrossRef]

- Castanho, J.M.; Pinheiro, D.; Vieira, M.T. New Multilayer Coatings for Secondary Wood Products Cutting. Mater. Sci. Forum. 2004, 455–456, 619–622. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Warcholinski, B.; Gilewicz, A. Surface Engineering of Woodworking Tools, a Review. Appl. Sci. 2022, 12, 10389. https://doi.org/10.3390/app122010389

Warcholinski B, Gilewicz A. Surface Engineering of Woodworking Tools, a Review. Applied Sciences. 2022; 12(20):10389. https://doi.org/10.3390/app122010389

Chicago/Turabian StyleWarcholinski, Bogdan, and Adam Gilewicz. 2022. "Surface Engineering of Woodworking Tools, a Review" Applied Sciences 12, no. 20: 10389. https://doi.org/10.3390/app122010389

APA StyleWarcholinski, B., & Gilewicz, A. (2022). Surface Engineering of Woodworking Tools, a Review. Applied Sciences, 12(20), 10389. https://doi.org/10.3390/app122010389