Compressive and Tensile Fracture Failure Analysis of Asphalt Mixture Subjected to Freeze–Thaw Conditions by Acoustic Emission and CT Scanning Technologies

Abstract

1. Introduction

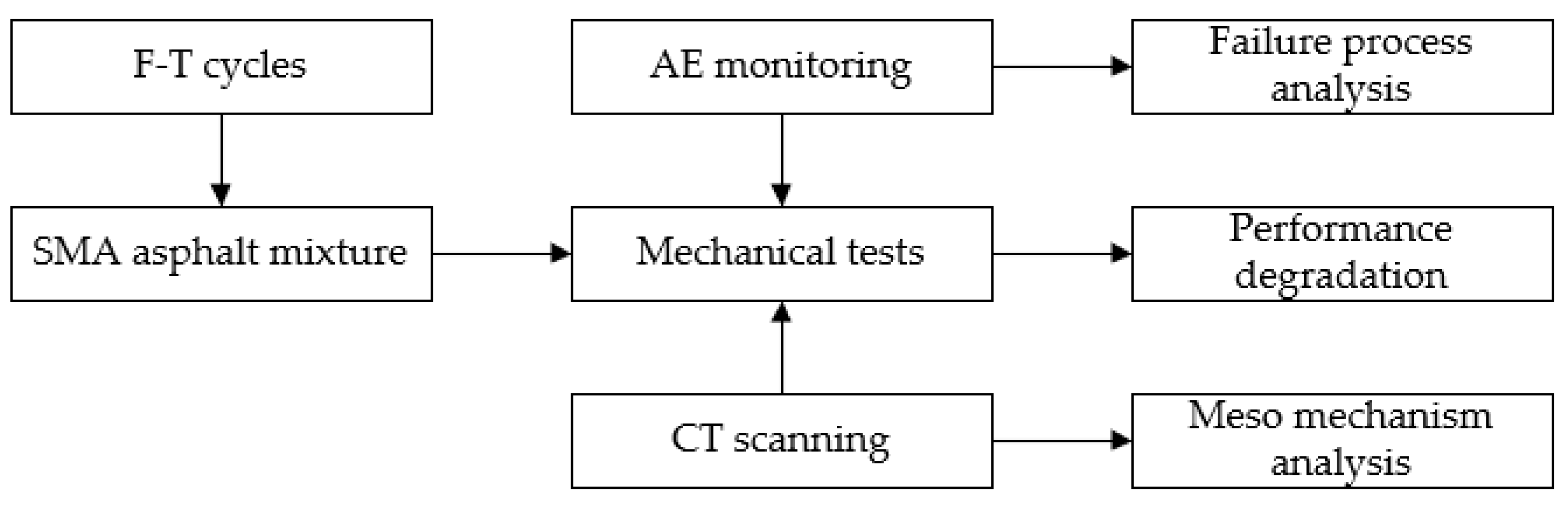

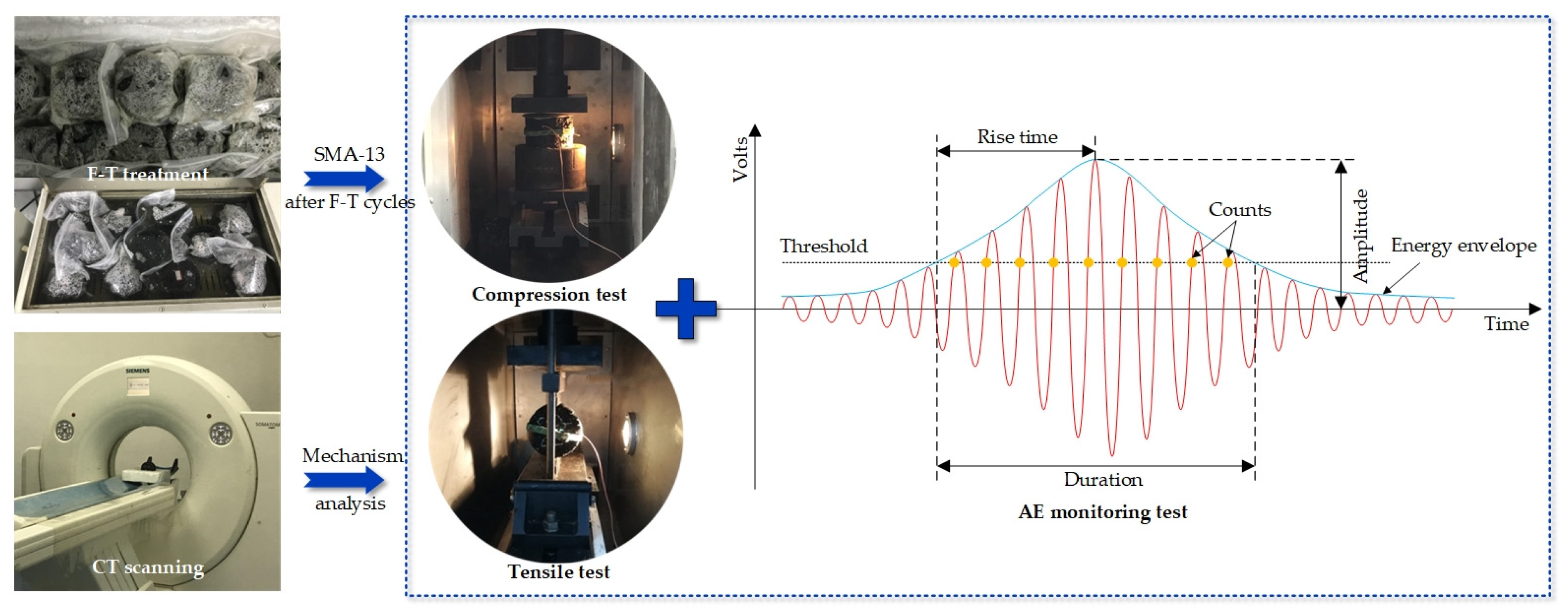

2. Materials and Methods

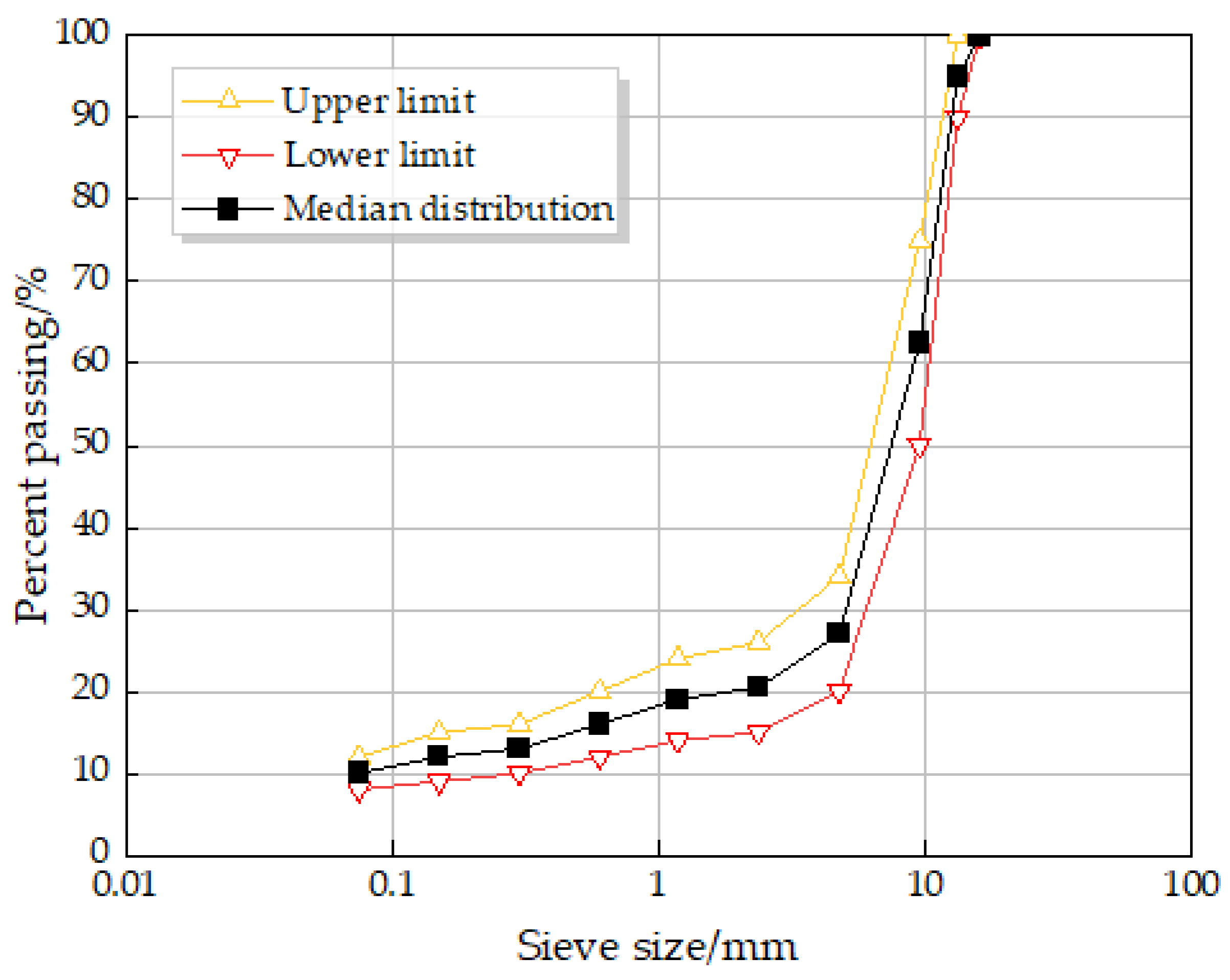

2.1. Raw Materials and Specimen Preparation

2.2. Experimental Procedure

3. Results and Discussion

3.1. Compressive and Tensile Response Analysis Subjected to F-T Conditions

3.2. Fracture Failure Process Analysis Subjected to F-T Conditions

3.2.1. Fracture Failure Evaluation by AE Index

- (1)

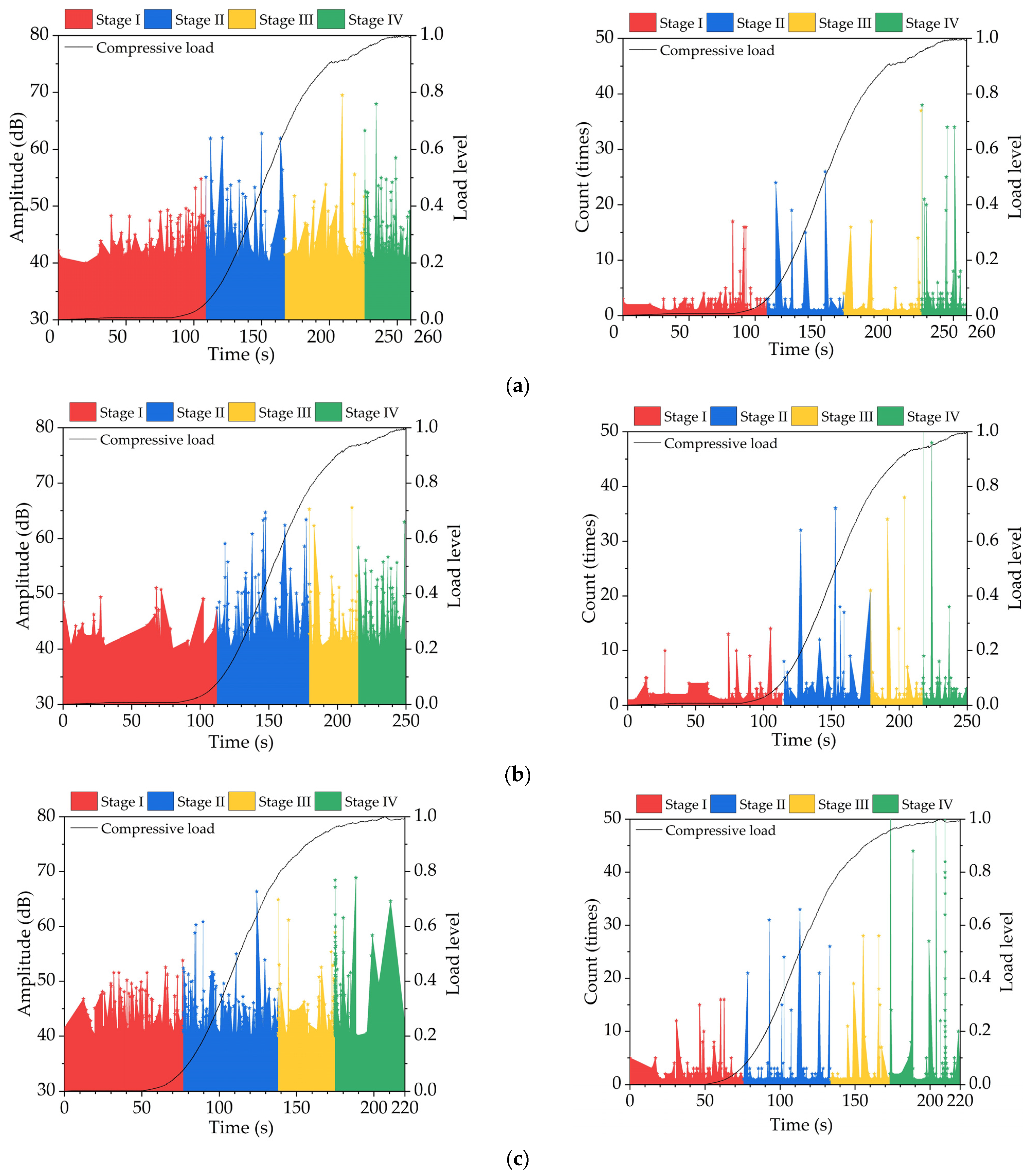

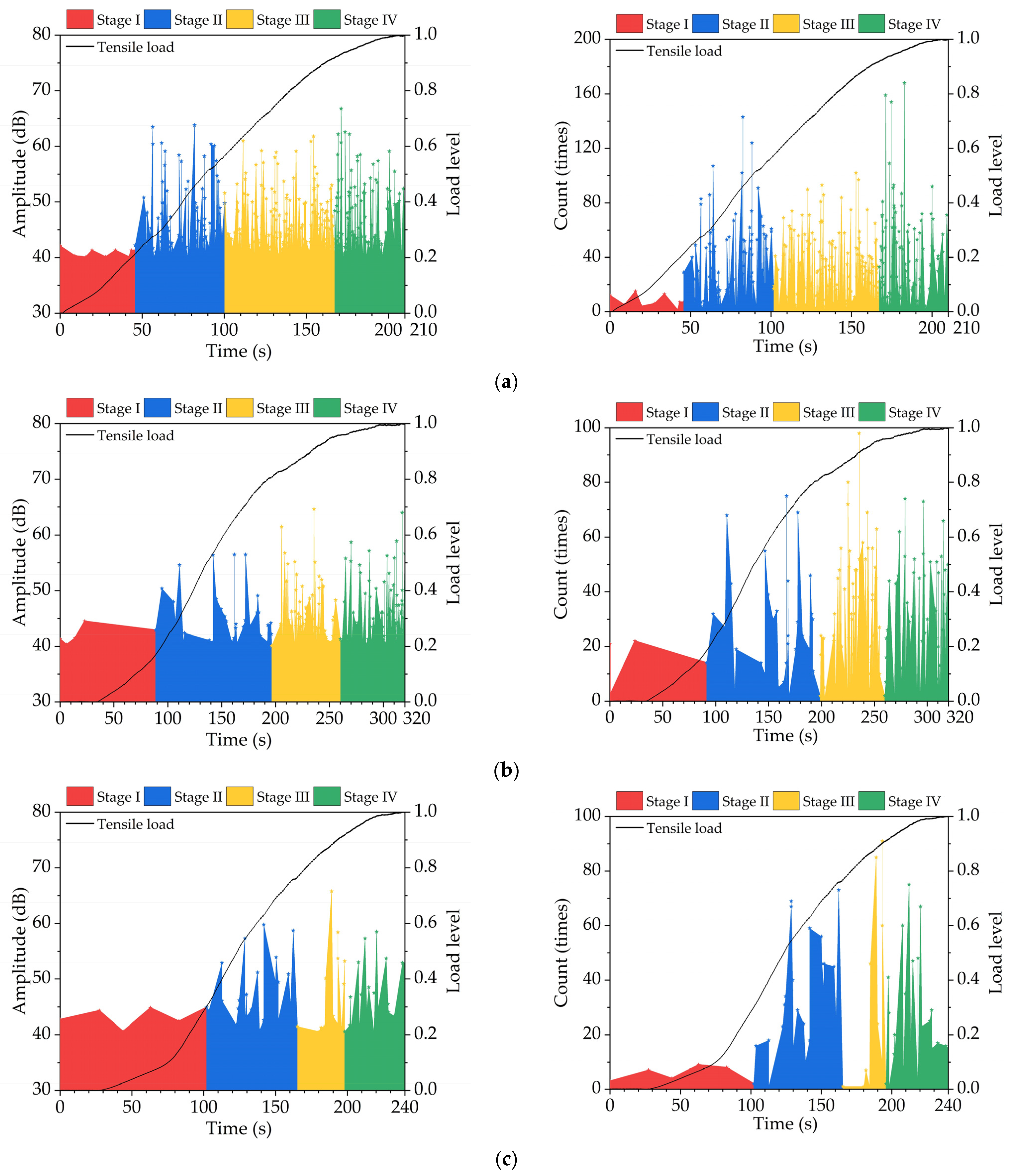

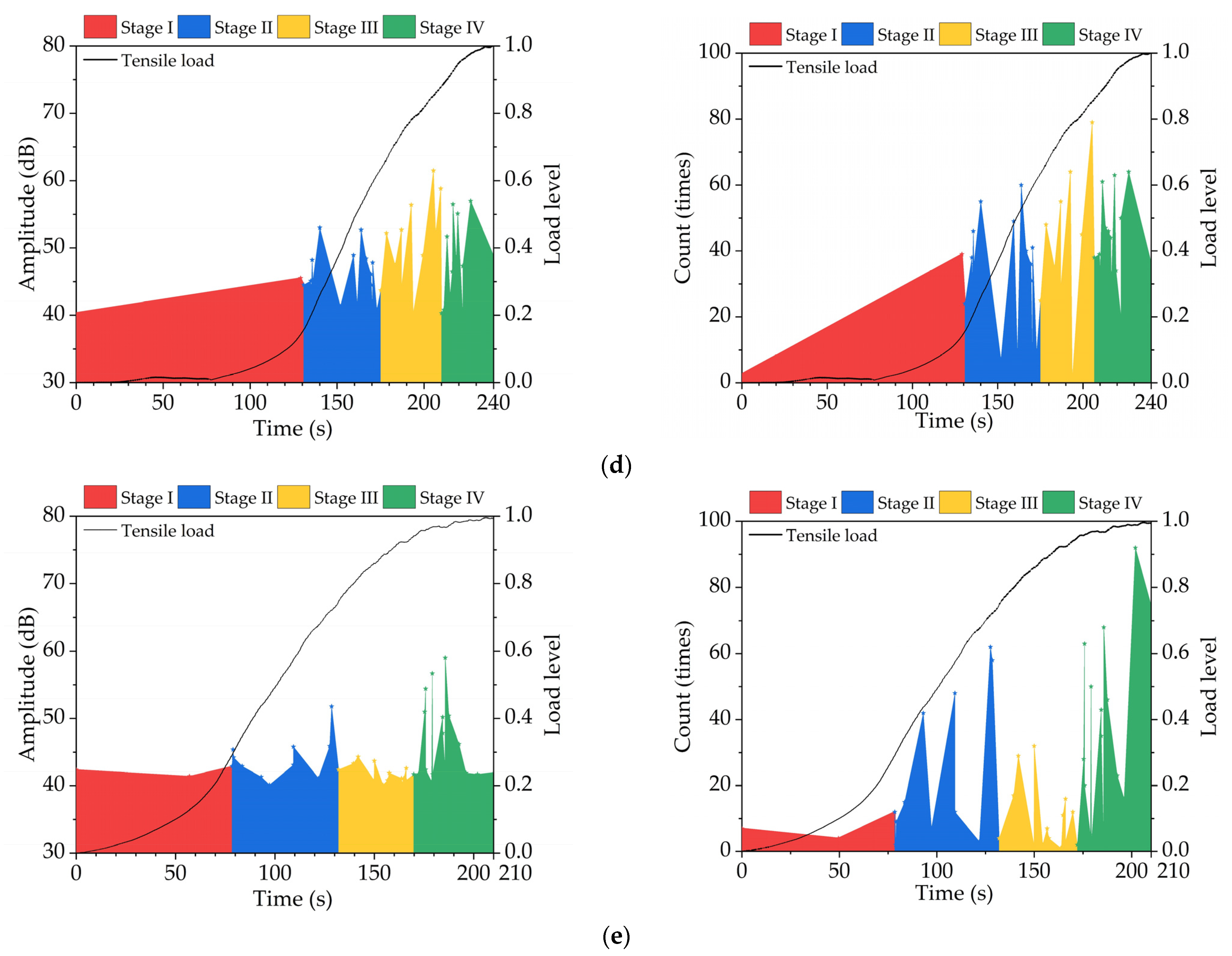

- Compressive fracture failure analysis under F-T cycles

- Stage I—micro-crack initiation:

- Stage II—micro-crack accumulation:

- Stage III—damage development:

- Stage IV—macro-crack generation:

- (2)

- Tensile fracture failure analysis under F-T conditions

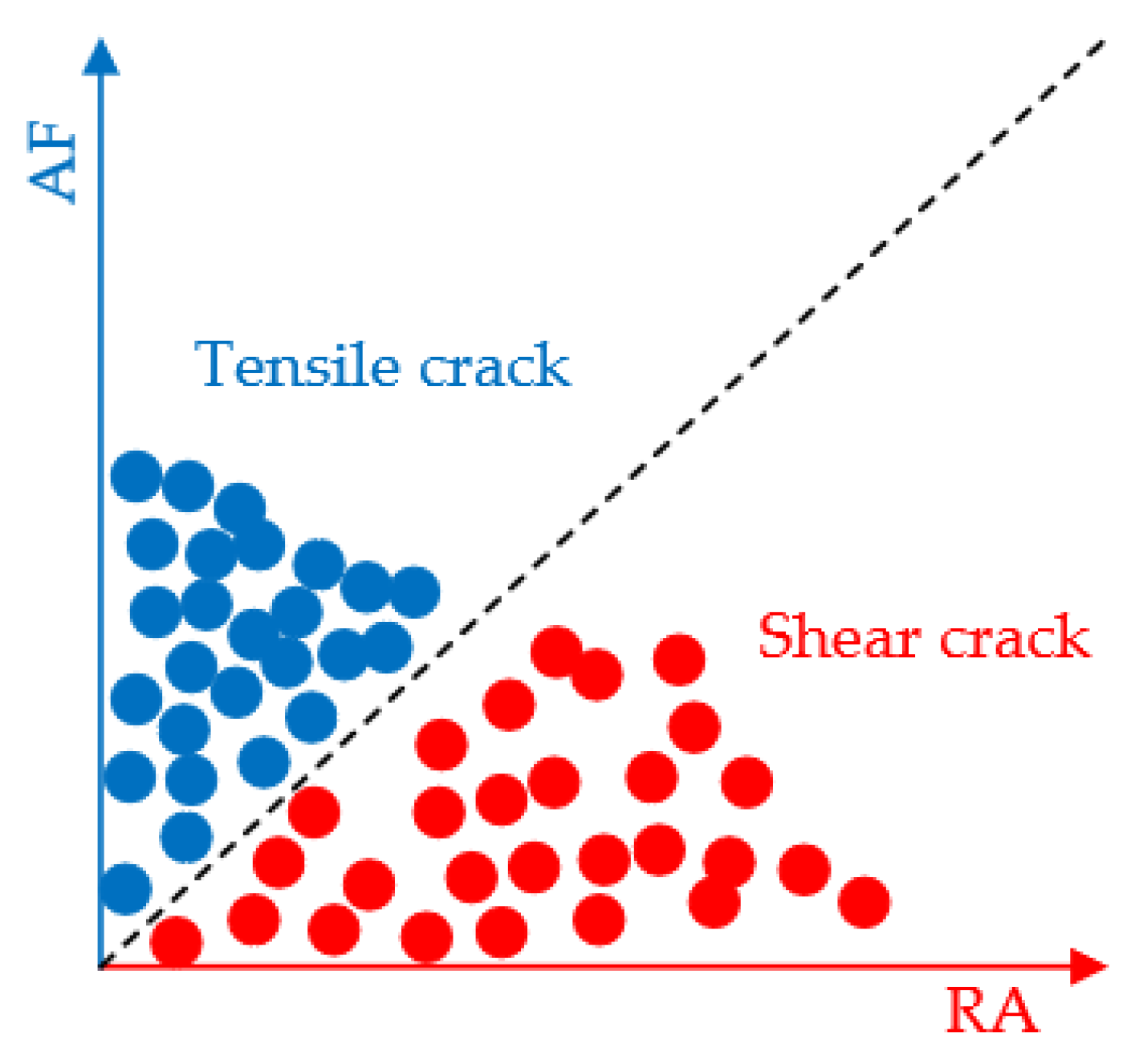

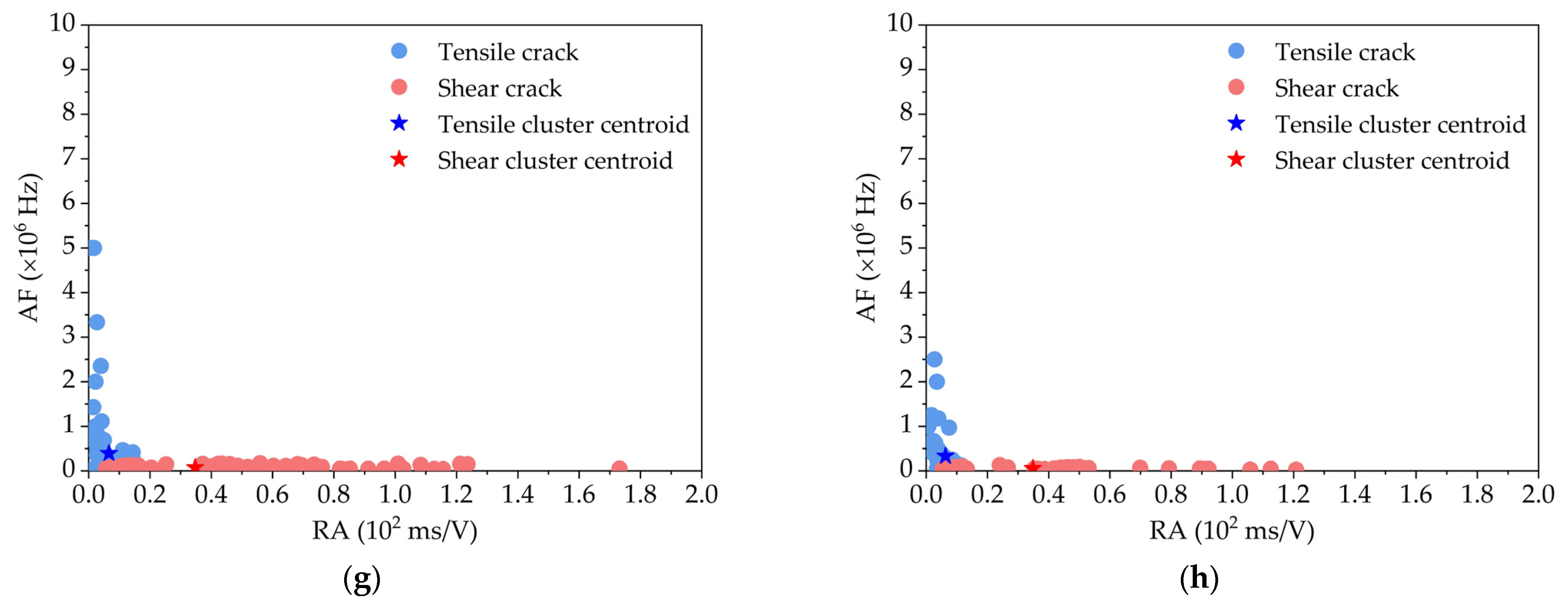

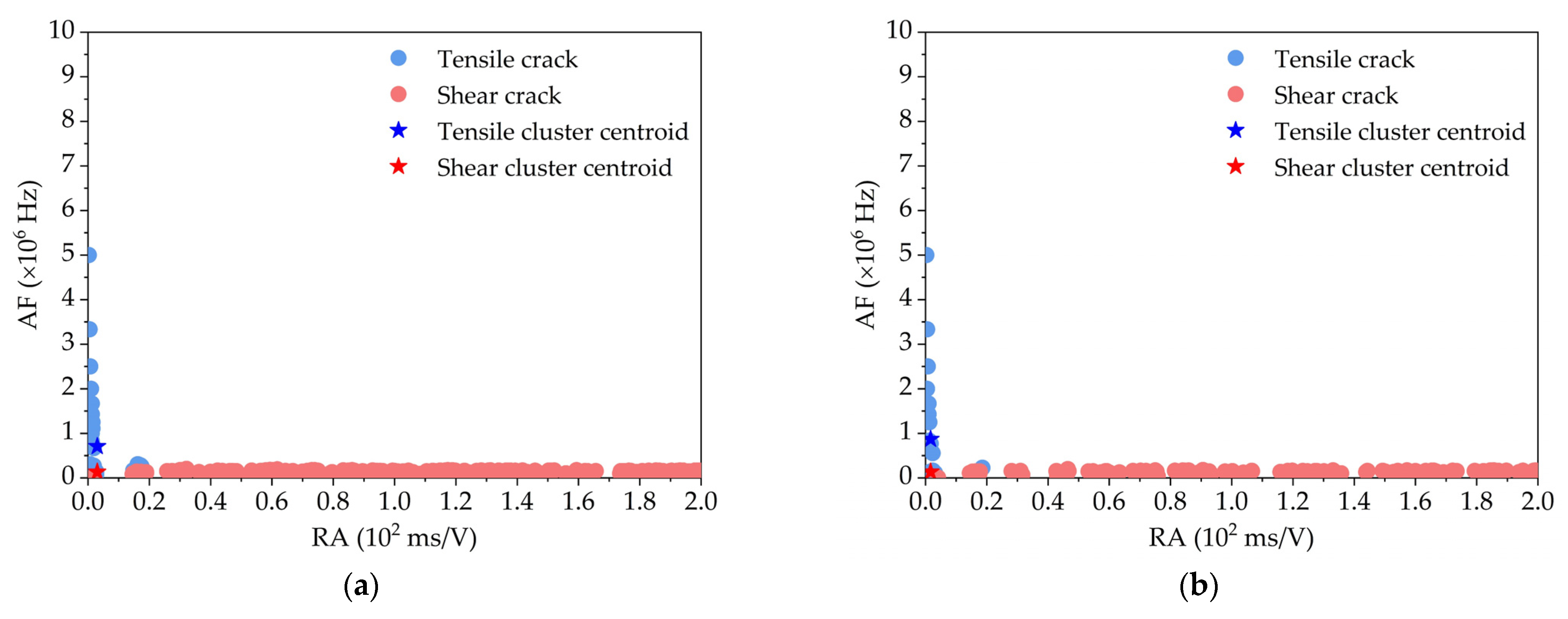

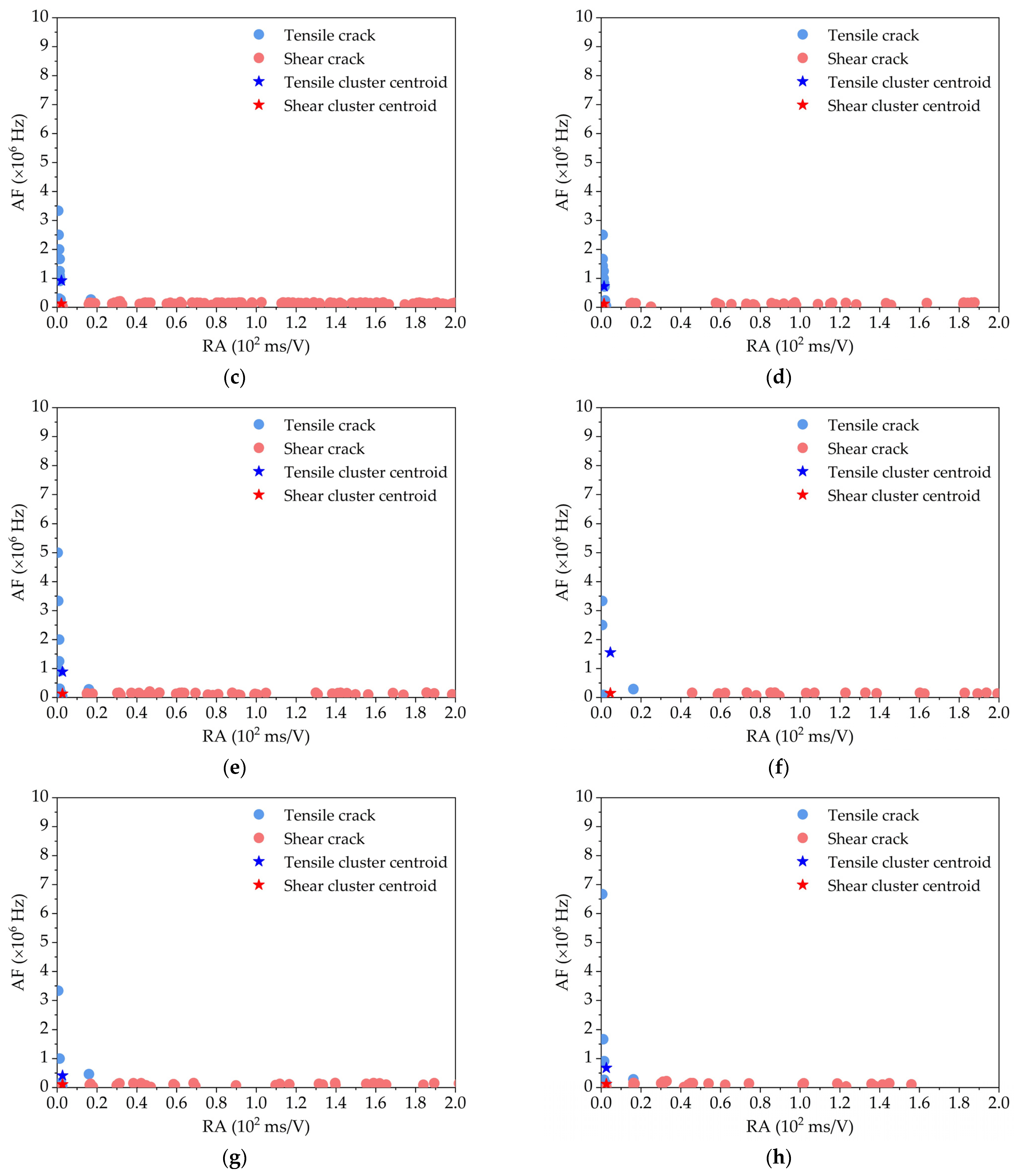

3.2.2. Fracture Failure Process Analysis Based on AE Signal Indirect Parameters

- (1)

- Compressive fracture failure analysis under F-T conditions

- (2)

- Tensile fracture failure analysis under F-T conditions

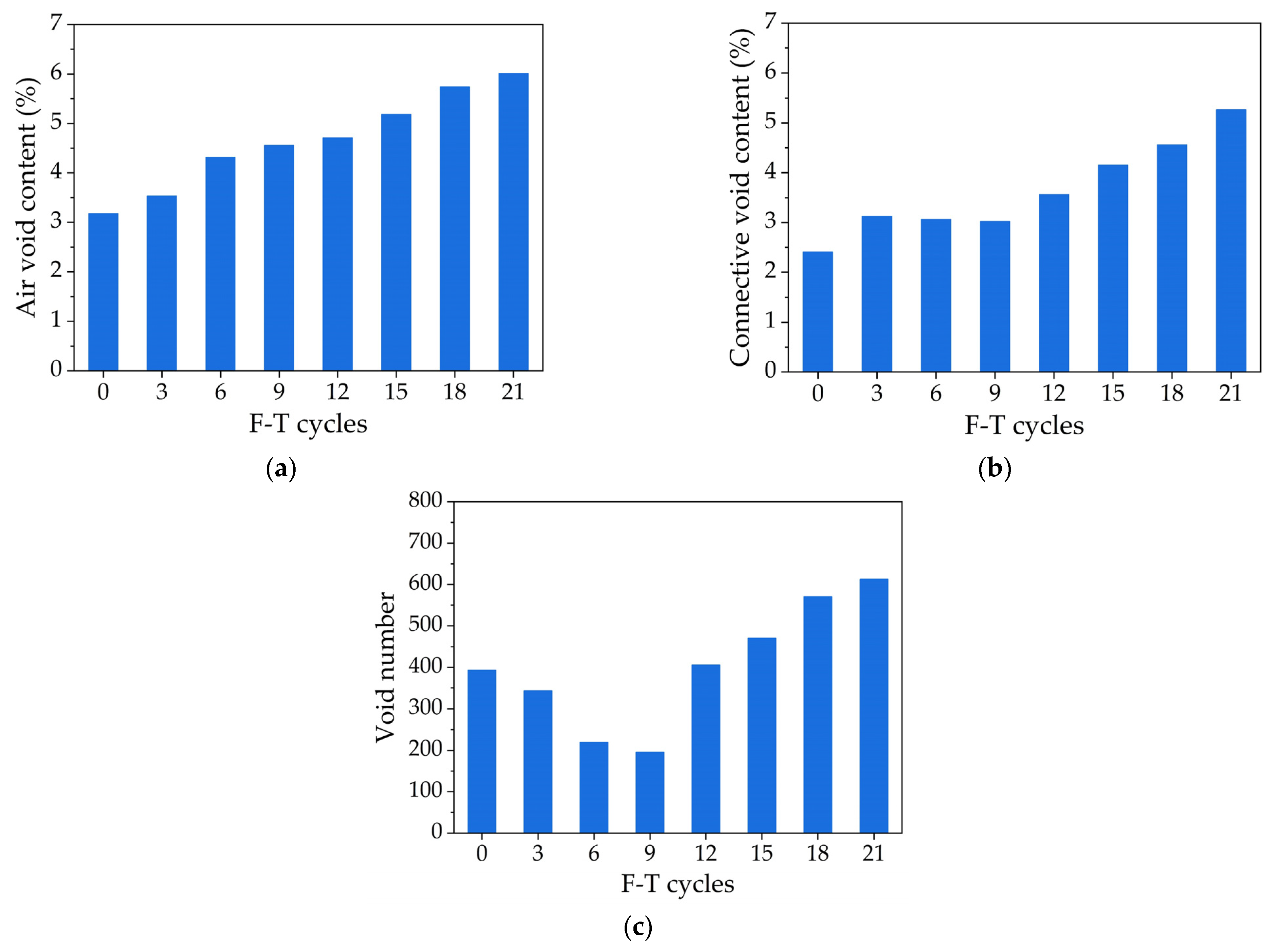

3.3. Fracture Damage Analysis Based on Meso-Characteristic Parameters

4. Conclusions

- (1)

- As the F-T condition continues, uniaxial compressive strength and tensile strength gradually decrease. When F-T cycles reached 21, the loss rate of the high-temperature uniaxial compressive strength at 50 °C for bitumen incorporating basalt fiber was 24.05%, and the tensile strength decreased by 31.56%, with the most serious loss. The F-T condition had a significant influence on asphalt pavement.

- (2)

- Under the action of compression and tensile load modes, the fracture failure process can be divided into four stages combined with signal index as well as loading level. In the loading pre-treatment, smaller values of amplitude and count are observed, which could be regarded as the micro-crack initiation stage. Then, the first and second inflection points occur in the load level, and the AE signal values of amplitude and count change obviously, which are called the micro-crack accumulation stage and damage development stage. Finally, the load level gradually becomes gentle, and obvious macroscopic cracks appear.

- (3)

- The time history of the AE signal values of amplitude and count shows stage features of fracture failure procedure for bitumen. According to the AE indirect index, fracture mode variation under compressive and tensile loading is related to failure, showing that the coupling interactions between tensile and shear cracks has a catalytic influence. AE technology could be used to characterize the performance change of asphalt mixtures.

- (4)

- Asphalt mixtures have different behaviours for the compressive and tensile strength and fracture failure characteristics based on AE when exposed to F-T conditions, which is attributed to different internal void topologies. During F-T conditions, new voids and cracks formed rapidly, and voids as well as cracks opened gradually.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, S.C.; Guo, N.S.; Wang, L.; You, Z.P.; Tan, Y.Q.; Guo, Z.X.; Luo, X.D.; Chen, Z. Effect of freeze-thaw cycles on the pavement performance of sbs modified and composite crumb rubber modified asphalt mixtures. Constr. Build. Mater. 2022, 342, 127799. [Google Scholar] [CrossRef]

- Wang, W.S.; Tan, G.J.; Liang, C.Y.; Wang, Y.; Cheng, Y.C. Study on viscoelastic properties of asphalt mixtures incorporating sbs polymer and basalt fiber under freeze-thaw cycles. Polymers 2020, 12, 1804. [Google Scholar] [CrossRef]

- Haghighatpour, P.J.; Aliha, M.R.M. Assessment of freezing and thawing cycle (ftc) effects on mixed mode i/iii fracture toughness and work of fracture of hma asphalt mixtures. Theor. Appl. Fract. Mec. 2022, 118, 103261. [Google Scholar] [CrossRef]

- Rafiq, W.; Musarat, M.A.; Altaf, M.; Napiah, M.; Sutanto, M.H.; Alaloul, W.S.; Javed, M.F.; Mosavi, A. Life cycle cost analysis comparison of hot mix asphalt and reclaimed asphalt pavement: A case study. Sustainability 2021, 13, 4411. [Google Scholar] [CrossRef]

- Wang, W.S.; Cheng, Y.C.; Ma, G.R.; Tan, G.J.; Sun, X.; Yang, S.T. Further investigation on damage model of eco-friendly basalt fiber modified asphalt mixture under freeze-thaw cycles. Appl. Sci. 2019, 9, 60. [Google Scholar] [CrossRef]

- Xu, G.; Yu, Y.H.; Cai, D.G.; Xie, G.Y.; Chen, X.H.; Yang, J. Multi-scale damage characterization of asphalt mixture subject to freeze-thaw cycles. Constr. Build Mater. 2020, 240, 117947. [Google Scholar] [CrossRef]

- Lou, B.W.; Sha, A.M.; Barbieri, D.M.; Liu, Z.Z.; Zhang, F.; Jiang, W.; Hoff, I. Characterization and microwave healing properties of different asphalt mixtures suffered freeze-thaw damage. J. Clean Prod. 2021, 320, 128823. [Google Scholar] [CrossRef]

- Tan, G.J.; Wang, W.S.; Cheng, Y.C.; Wang, Y.; Zhu, Z.Q. Establishment of complex modulus master curves based on generalized sigmoidal model for freeze-thaw resistance evaluation of basalt fiber-modified asphalt mixtures. Polymers 2020, 12, 1698. [Google Scholar] [CrossRef] [PubMed]

- Meng, A.X.; Xu, H.N.; Feng, X.L.; Tan, Y.Q. Feasibility of freeze-thaw damage analysis for asphalt mixtures through dynamic nondestructive testing. Constr. Build Mater. 2020, 233, 117220. [Google Scholar] [CrossRef]

- Guo, Z.X.; Wang, L.; Feng, L.; Guo, Y.Y. Research on fatigue performance of composite crumb rubber modified asphalt mixture under freeze thaw cycles. Constr. Build Mater. 2022, 323, 126603. [Google Scholar] [CrossRef]

- Badeli, S.; Carter, A.; Dore, G.; Saliani, S. Evaluation of the durability and the performance of an asphalt mix involving aramid pulp fiber (apf): Complex modulus before and after freeze-thaw cycles, fatigue, and tsrst tests. Constr. Build Mater. 2018, 174, 60–71. [Google Scholar] [CrossRef]

- Huang, T.; Qi, S.; Yang, M.; Lv, S.T.; Liu, H.F.; Zheng, J.L. Strength criterion of asphalt mixtures in three-dimensional stress states under freeze-thaw conditions. Appl. Sci. 2018, 8, 1302. [Google Scholar] [CrossRef]

- Cheng, Y.C.; Yu, D.; Tan, G.J.; Zhu, C.F. Low-temperature performance and damage constitutive model of eco-friendly basalt fiber-diatomite-modified asphalt mixture under freeze-thaw cycles. Materials 2018, 11, 2148. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.F.; Bi, H.P.; Tian, Z.H.; Tan, G.J. Pavement performance investigation of nano-tio2/caco3 and basalt fiber composite modified asphalt mixture under freeze-thaw cycles. Appl. Sci. 2018, 8, 2581. [Google Scholar] [CrossRef]

- You, L.Y.; You, Z.P.; Dai, Q.L.; Xie, X.F.; Washko, S.; Gao, J.F. Investigation of adhesion and interface bond strength for pavements underlying chip-seal: Effect of asphalt-aggregate combinations and freeze-thaw cycles on chip-seal. Constr. Build Mater. 2019, 203, 322–330. [Google Scholar] [CrossRef]

- Wu, H.N.; Li, P.; Nian, T.F.; Zhang, G.H.; He, T.; Wei, X.Y. Evaluation of asphalt and asphalt mixtures’ water stability method under multiple freeze-thaw cycles. Constr. Build Mater. 2019, 228, 117089. [Google Scholar] [CrossRef]

- Lovqvist, L.; Balieu, R.; Kringos, N. A micromechanical model of freeze-thaw damage in asphalt mixtures. Int. J. Pavement Eng. 2021, 22, 1017–1029. [Google Scholar] [CrossRef]

- Liu, P.F.; Hu, J.; Falla, G.C.; Wang, D.W.; Leischner, S.; Oeser, M. Primary investigation on the relationship between microstructural characteristics and the mechanical performance of asphalt mixtures with different compaction degrees. Constr. Build Mater. 2019, 223, 784–793. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Yuan, Z.K.; Suo, Z.; Xu, Y.; Li, P.F.; You, Z.P. Moisture susceptibility of warm mix asphalt (wma) with an organic wax additive based on x-ray computed tomography (ct) technology. Adv. Civ. Eng. 2019, 2019, 7101982. [Google Scholar] [CrossRef]

- Ahmad, K.A.; Hassan, N.A.; Abdullah, M.E.; Bilema, M.A.M.; Usman, N.; Al Allam, A.M.; Bin Hainin, M.R. Image processing procedure to quantify the internal structure of porous asphalt concrete. Multidiscip. Model Mater. 2019, 15, 206–226. [Google Scholar] [CrossRef]

- Carpinteri, A.; Lacidogna, G.; Puzzi, S. Prediction of cracking evolution in full scale structures by the b-value analysis and yule statistics. Phys. Mesomech. 2008, 11, 260–271. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.X.; Xu, W.Y.; Yang, Q.; Wang, F.; Yuan, J. Diagnosis of damage evolution process for asphalt mixtures using pattern recognition with acoustic emission signals. Constr. Build Mater. 2021, 280, 122536. [Google Scholar] [CrossRef]

- Qiu, X.; Xu, J.X.; Xiao, S.L.; Yang, Q. Acoustic emission parameters and waveforms characteristics of fracture failure process of asphalt mixtures. Constr. Build Mater. 2019, 215, 135–147. [Google Scholar] [CrossRef]

- Jiao, Y.B.; Zhang, Y.; Zhang, M.S.; Fu, L.X.; Zhang, L.D. Investigation of fracture modes in pervious asphalt under splitting and compression based on acoustic emission monitoring. Eng. Fract. Mech. 2019, 211, 209–220. [Google Scholar] [CrossRef]

- Islam, S.K.S.; Singh, S.K.; Ransinchung, R.N.G.D.; Ravindranath, S.S. Performance deterioration of sbs-modified asphalt mix: Impact of elevated storage temperature and sbs concentration of modified binder. J. Mater. Civil Eng. 2022, 34, 04021475. [Google Scholar] [CrossRef]

- Tan, G.J.; Wang, W.S.; Cheng, Y.C.; Wang, Y.; Zhu, Z.Q. Master curve establishment and complex modulus evaluation of sbs-modified asphalt mixture reinforced with basalt fiber based on generalized sigmoidal model. Polymers 2020, 12, 1586. [Google Scholar] [CrossRef] [PubMed]

- Awan, H.H.; Hussain, A.; Javed, M.F.; Qiu, Y.J.; Alrowais, R.; Mohamed, A.M.; Fathi, D.; Alzahrani, A.M. Predicting marshall flow and marshall stability of asphalt pavements using multi expression programming. Buildings 2022, 12, 314. [Google Scholar] [CrossRef]

- Wang, W.S.; Cheng, Y.C.; Zhou, P.L.; Tan, G.J.; Wang, H.T.; Liu, H.B. Performance evaluation of styrene-butadiene-styrene-modified stone mastic asphalt with basalt fiber using different compaction methods. Polymers 2019, 11, 1006. [Google Scholar] [CrossRef] [PubMed]

- Liang, C.Y.; Ma, J.C.; Zhou, P.L.; Ma, G.R.; Xu, X. Fracture damage properties of sbs-modified asphalt mixtures reinforced with basalt fiber after freeze-thaw cycles using the acoustic emission approach. Appl. Sci. 2020, 10, 3301. [Google Scholar] [CrossRef]

- Tan, G.J.; Zhu, Z.Q.; Wang, W.S.; Wu, C.L.; Ou, J.; Cui, G.J.; Zhang, D.M. Flexural ductility and crack-controlling capacity of polypropylene fiber reinforced ecc thin sheet with waste superfine river sand based on acoustic emission analysis. Constr. Build Mater. 2021, 277, 122321. [Google Scholar] [CrossRef]

| Index | Unit | Results |

|---|---|---|

| Penetration | 0.1 mm (@ 25 °C, 100 g, 5 s) | 72 |

| Ductility | cm (@ 15 °C, 5 cm/min) | 45 |

| Softening point | °C | 60.5 |

| Density | g/cm3 | 1.018 |

| Flash point | °C | 262 |

| RTFOT | ||

| Mass loss | % | −0.094 |

| Penetration ratio | % (@ 25 °C) | 66.9 |

| Index | Unit | Results | Standard Limits | |

|---|---|---|---|---|

| Crushing value | % | 13.6 | ≤26 | |

| Los Angeles abrasion value | % | 17.9 | ≤28 | |

| Apparent Specific Gravity | 13.2 mm | - | 2.836 | ≥2.6 |

| 9.5 mm | 2.805 | |||

| 4.75 mm | 2.726 | |||

| Water Absorption | 13.2 mm | % | 0.6 | ≤2.0 |

| 9.5 mm | 0.28 | |||

| 4.75 mm | 0.7 | |||

| Index | Unit | Results | Standard Limits |

|---|---|---|---|

| Apparent specific gravity | - | 2.723 | ≥2.5 |

| Water absorption | % | 0.64 | - |

| Angularity (flow time) | s | 39.9 | ≥30 |

| Sand equivalent | % | 68 | ≥60 |

| Index | Unit | Results | Standard Limits | |

|---|---|---|---|---|

| Apparent density | t/m3 | 2.712 | ≥2.5 | |

| Hydrophilic coefficient | - | 0.63 | <1 | |

| Water content | % | 0.3 | ≤1 | |

| Plastic index | % | 2 | <4 | |

| Granular composition | <0.6 mm | % | 100 | 100 |

| <0.15 mm | 92.5 | 90~100 | ||

| <0.075 mm | 81.8 | 75~100 | ||

| Index | Unit | Results |

|---|---|---|

| Length | mm | 6 |

| Diameter | µm | 13 |

| Specific gravity | g/cm3 | 2.55~2.65 |

| Tensile strength | MPa | ≥3000 |

| Elongation at break | % | 3.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Xia, W.; Liang, J. Compressive and Tensile Fracture Failure Analysis of Asphalt Mixture Subjected to Freeze–Thaw Conditions by Acoustic Emission and CT Scanning Technologies. Appl. Sci. 2022, 12, 10707. https://doi.org/10.3390/app122110707

Wang W, Xia W, Liang J. Compressive and Tensile Fracture Failure Analysis of Asphalt Mixture Subjected to Freeze–Thaw Conditions by Acoustic Emission and CT Scanning Technologies. Applied Sciences. 2022; 12(21):10707. https://doi.org/10.3390/app122110707

Chicago/Turabian StyleWang, Wensheng, Wenlei Xia, and Jiaxiang Liang. 2022. "Compressive and Tensile Fracture Failure Analysis of Asphalt Mixture Subjected to Freeze–Thaw Conditions by Acoustic Emission and CT Scanning Technologies" Applied Sciences 12, no. 21: 10707. https://doi.org/10.3390/app122110707

APA StyleWang, W., Xia, W., & Liang, J. (2022). Compressive and Tensile Fracture Failure Analysis of Asphalt Mixture Subjected to Freeze–Thaw Conditions by Acoustic Emission and CT Scanning Technologies. Applied Sciences, 12(21), 10707. https://doi.org/10.3390/app122110707