A New Multi-Objective Optimization Design Method for Directional Well Trajectory Based on Multi-Factor Constraints

Abstract

:1. Introduction

2. Optimization Model

2.1. Well Track Length

2.2. Cost of Drilling

2.3. Target Error of First Target

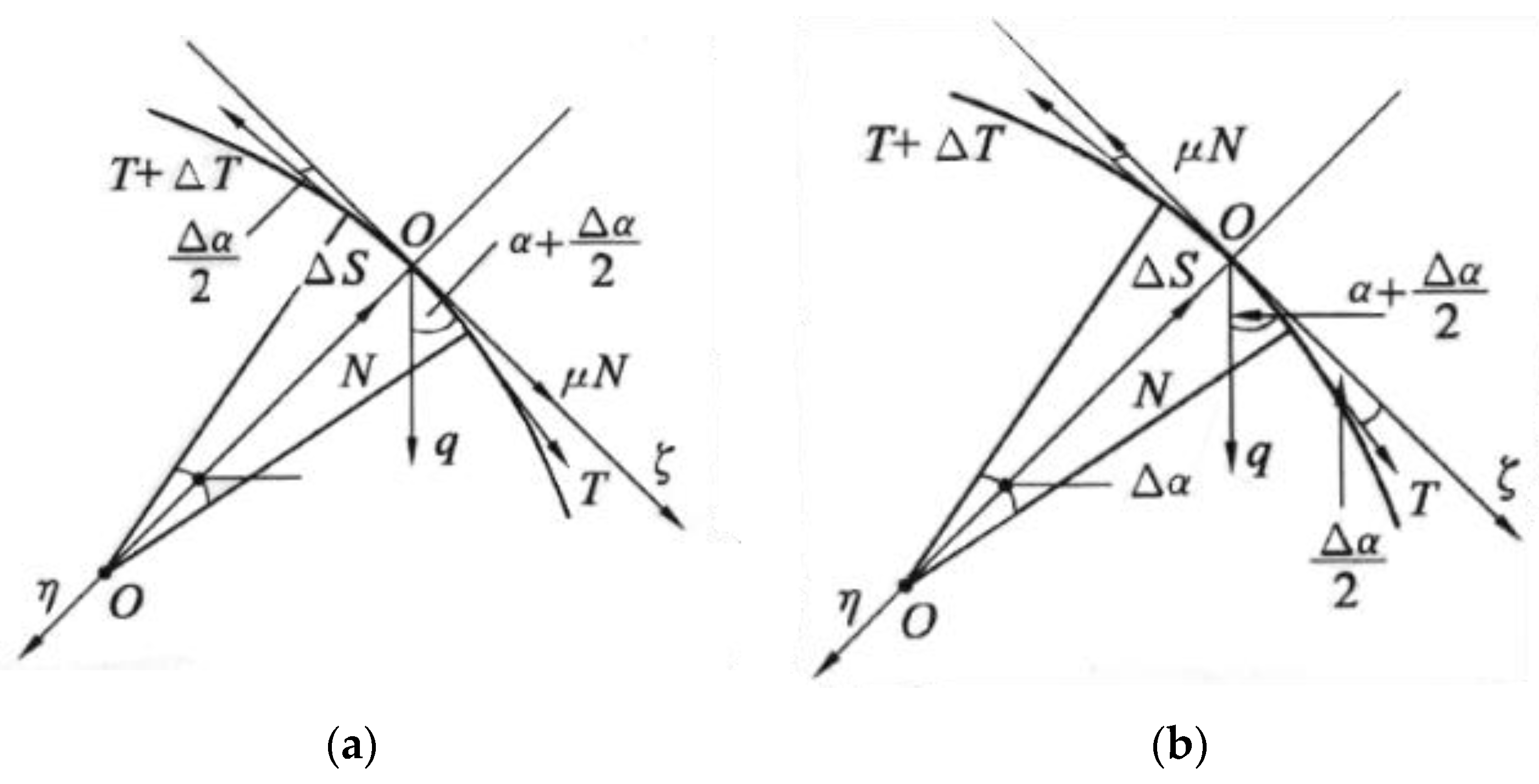

2.4. Friction

- (1)

- Hold section

- (2)

- Build-up section

- (3)

- Drop-off section

2.5. Torque

- (1)

- Hold sectionwhere is the diameter of the pipe string, mm.

- (2)

- Build-up section

- (3)

- Drop-off section

2.6. Open-Hole Extension Capability of Extended Reach Wells

2.7. Constraints

- (1)

- The velocity of wellbore trajectory change can be controlled by the build-up rate. When the build-up rate is low, the length of the well orbit required to reach the target increases, thus extending the drilling cycle. When the build-up rate is large, the construction speed is fast, which may lead to stuck bit and increased construction difficulty [40]. The build-up rate should be between the maximum build-up rate and minimum build-up rate of the deflecting tool. For conventional directional wells, the build-up rate is generally (2.1–4.2) (°)/30 m, and the drop-off rate is generally less than 2.5 (°)/30 m [41]. There is a lot of feed for extended reach wells in the inclined section. Controlling the build-up rate below 3 (°)/30 m is beneficial to reduce friction and casing wear and prevent fatigue damage to drilling tools during rotation. The range constraint expression of build-up rate k is shown in Formula (23). In order to prevent track loss and landing, the building slope of the offshore platform is generally (2.5–3) (°)/30 m.

- (2)

- According to the calculation of the safety density window, the stable inclination should be between the maximum stable inclination angle and minimum stable inclination angle under the condition of wellbore stability. According to the law of rock carrying, the inclination angle between 48° and 68° is the most unfavorable to rock carrying. For directional wells, if the angle of inclination is less than 15°, the borehole orientation is unstable and drift is easy to occur. If the deviation value is more than 45°, it is not conducive to wellbore torsion, and logging and completion operations are relatively difficult.

- (3)

- When the stratum strength is low, the dip force generated by the BHA is small, restricting the build-up rate’s rise. When the stratum strength is high, the inclination-building effect of the inclination-building force generated by the bottom hole assembly decreases, which restricts the improvement of the build-up rate. Therefore, it is necessary to combine the formation strength factors to select the location of the inclination-making point, and it should be located in the medium-soft to medium-hard stratum, which is most conducive to the inclination making [42,43]. To establish the constraint conditions considering the influencing factors of formation strength, the uniaxial compressive strength value of formation can be input into the program, and the function of formation strength and vertical depth can be established. Through the program call, the constraint range of formation strength can be determined according to Table 1 [44], and the appropriate depth can be selected. Then, the expression can be expressed as

- (4)

- When the vertical depth of the kickoff point is shallow, the length of the build-up section will be increased,; then the drilling operation cycle will be extended, and the drilling operation will be more difficult. When the vertical depth of the kickoff point is deep, the build-up rate will be increased, thus increasing the difficulty of construction [45]. The constraint expression of the vertical depth range of the first kickoff point is shown in Formula (26). According to the requirements of the offshore cluster well standard, in order to quickly make the surface separation and reduce the risk of collision prevention, the position of the first kickoff point ZA is generally chosen at one to two pillars after the catheter shoe.

- (5)

- The vertical depth and plane error of the second target should be less than the specified range, and the constraint conditions can be expressed aswhere J is the allowable error in the plane, and H is the allowable error in the vertical.

- (6)

- In order to prevent errors in program calculation, geometric constraints should be considered, and the length of the steady slope section should not be less than zero. Then, the expression is

3. Optimize the Design Model

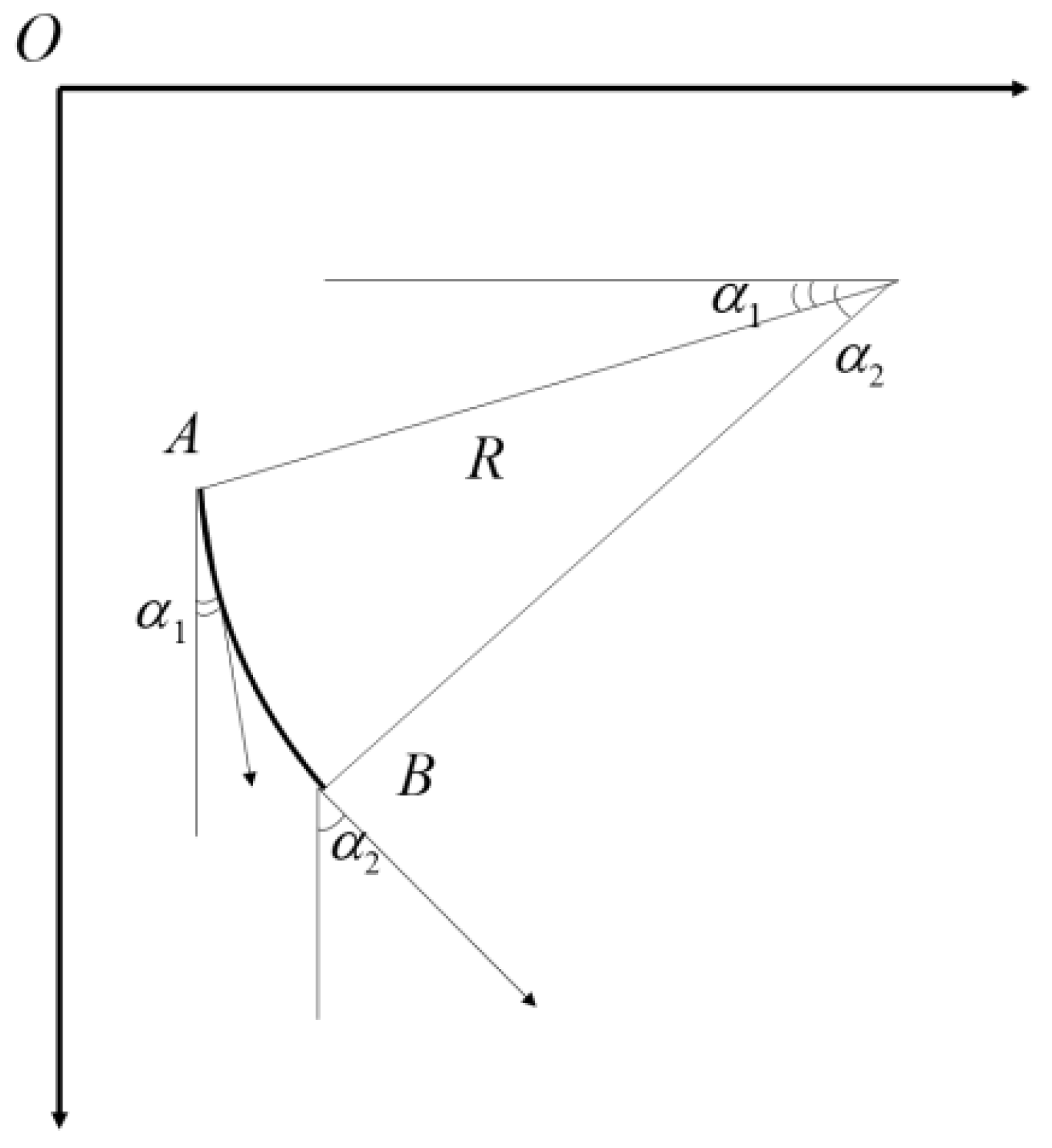

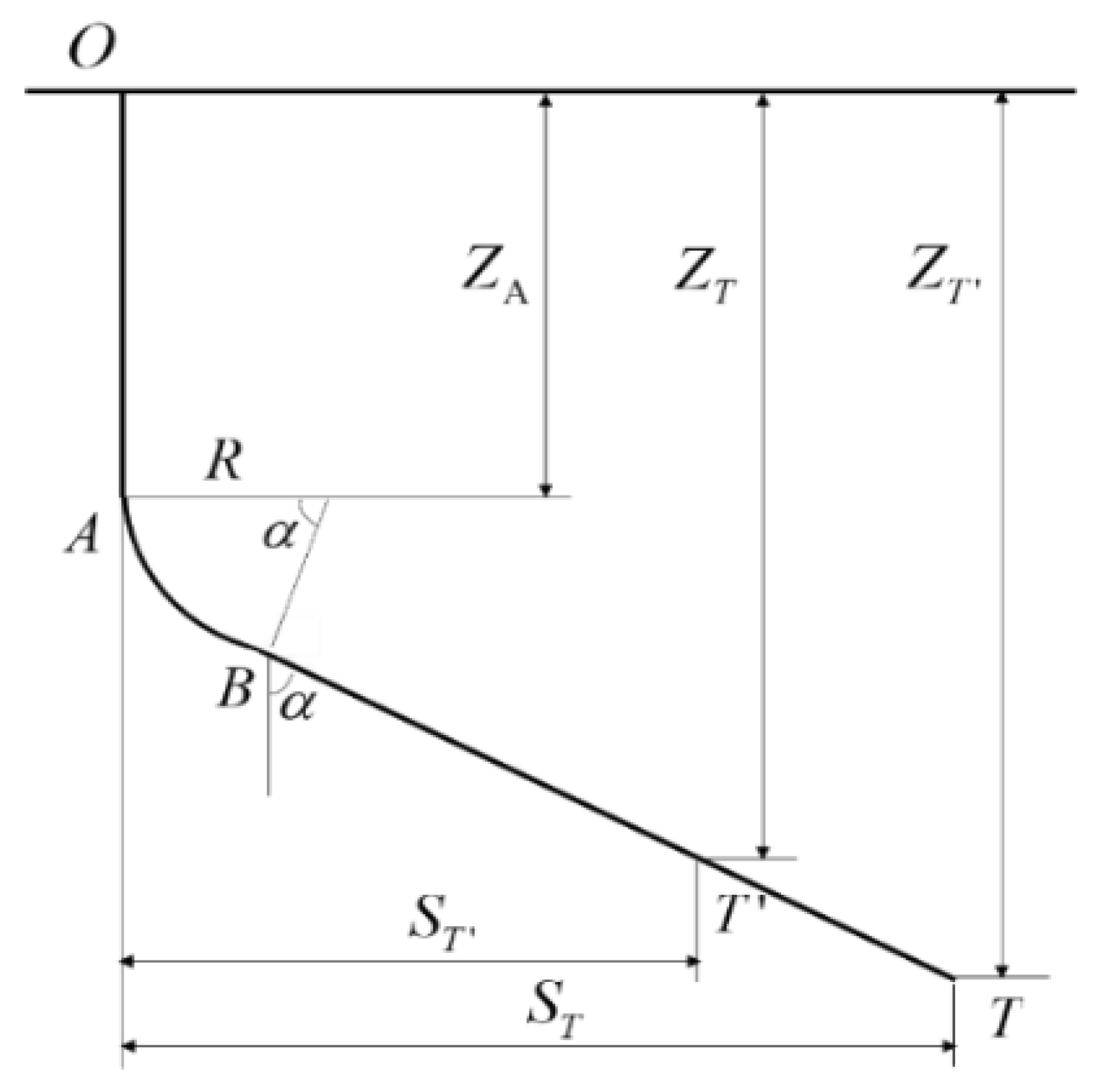

3.1. Three-Stage

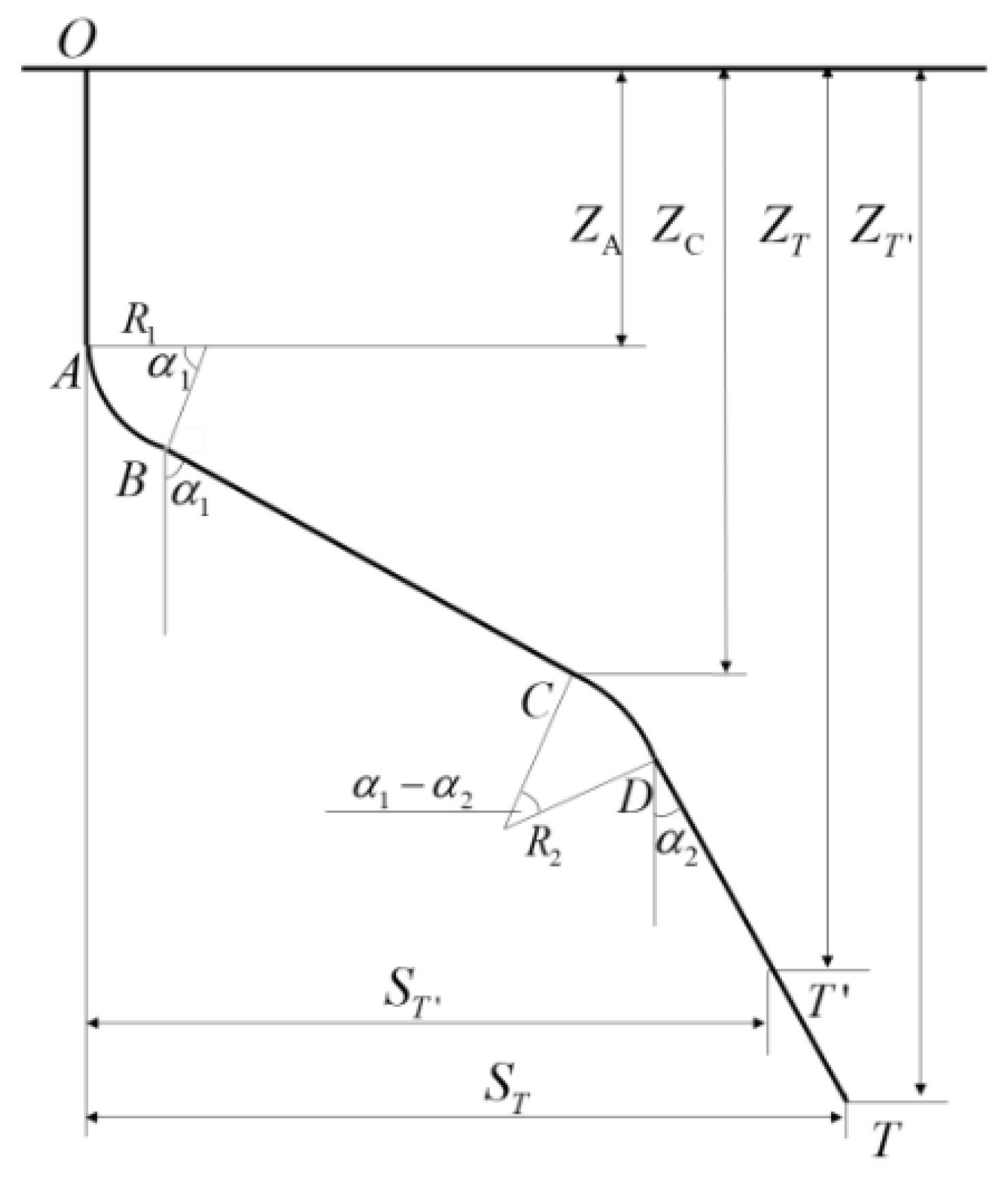

3.2. Five-Stage

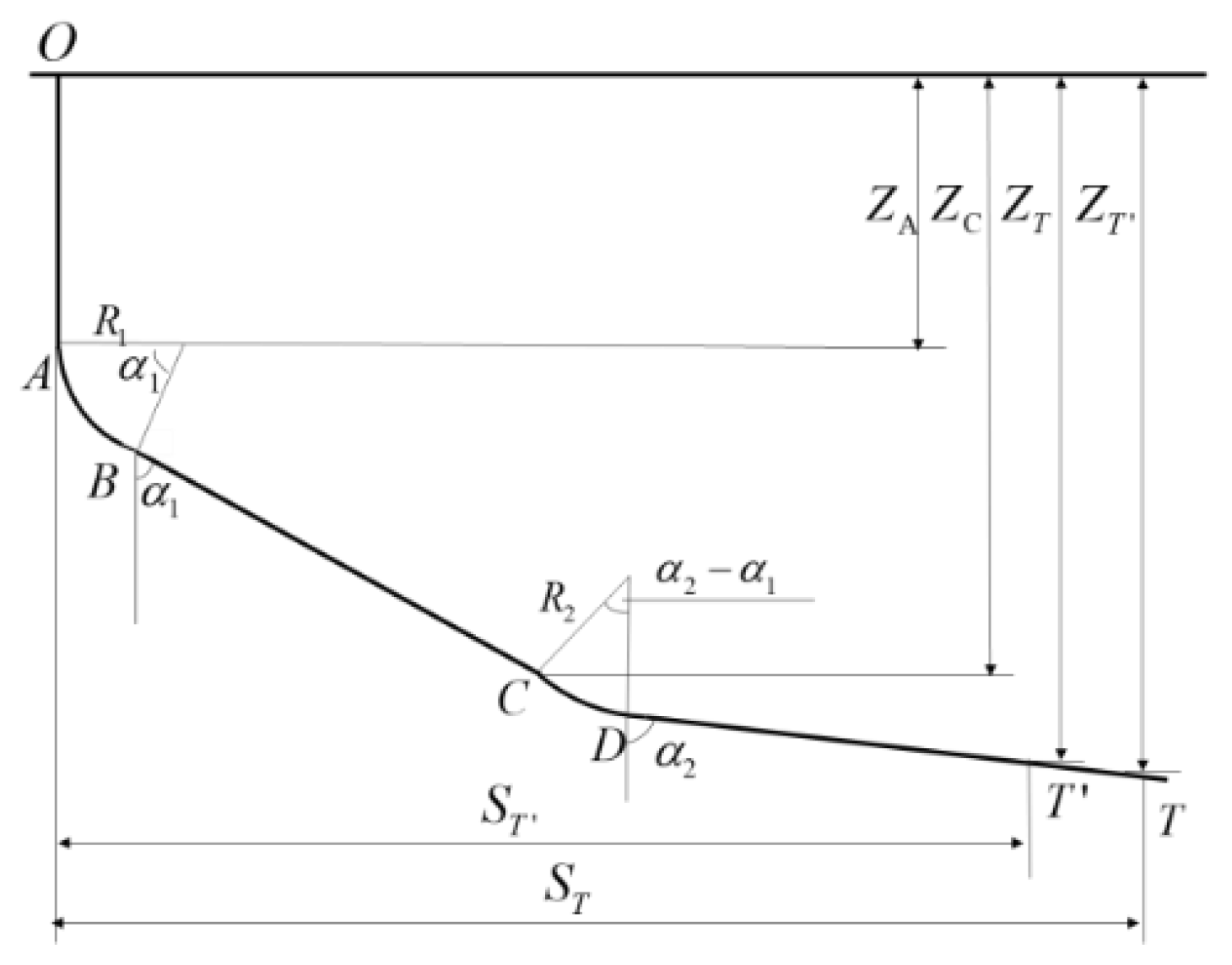

3.3. Extended Reach Well with Double Increasing Profile

4. Case Analysis

4.1. Objective Function

4.2. Multi-Objective Function Optimization

- (1)

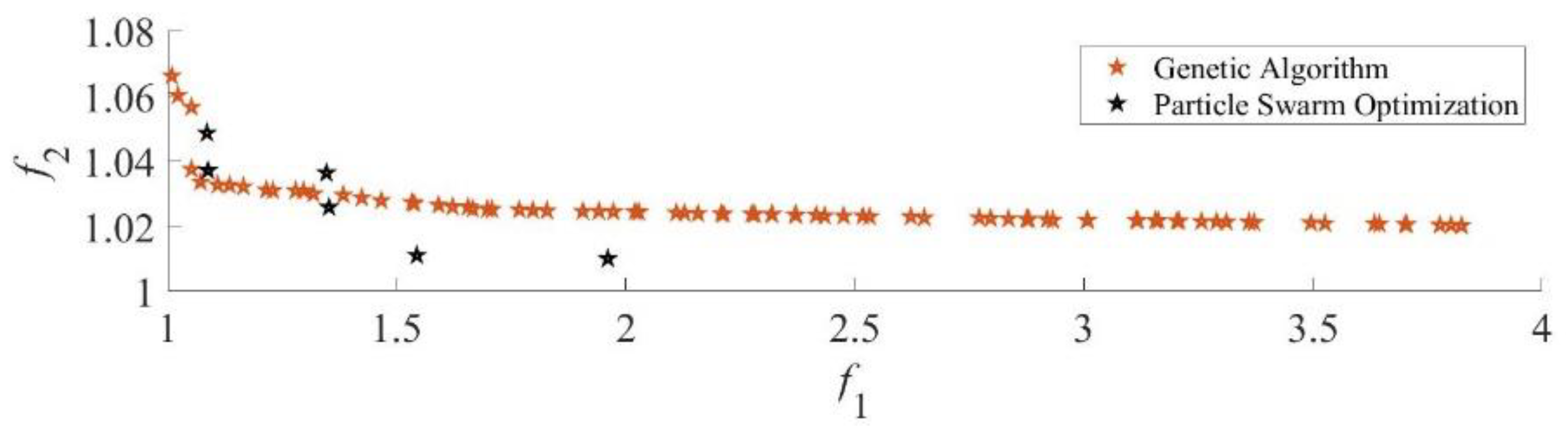

- Simplified as double-objective function

- (2)

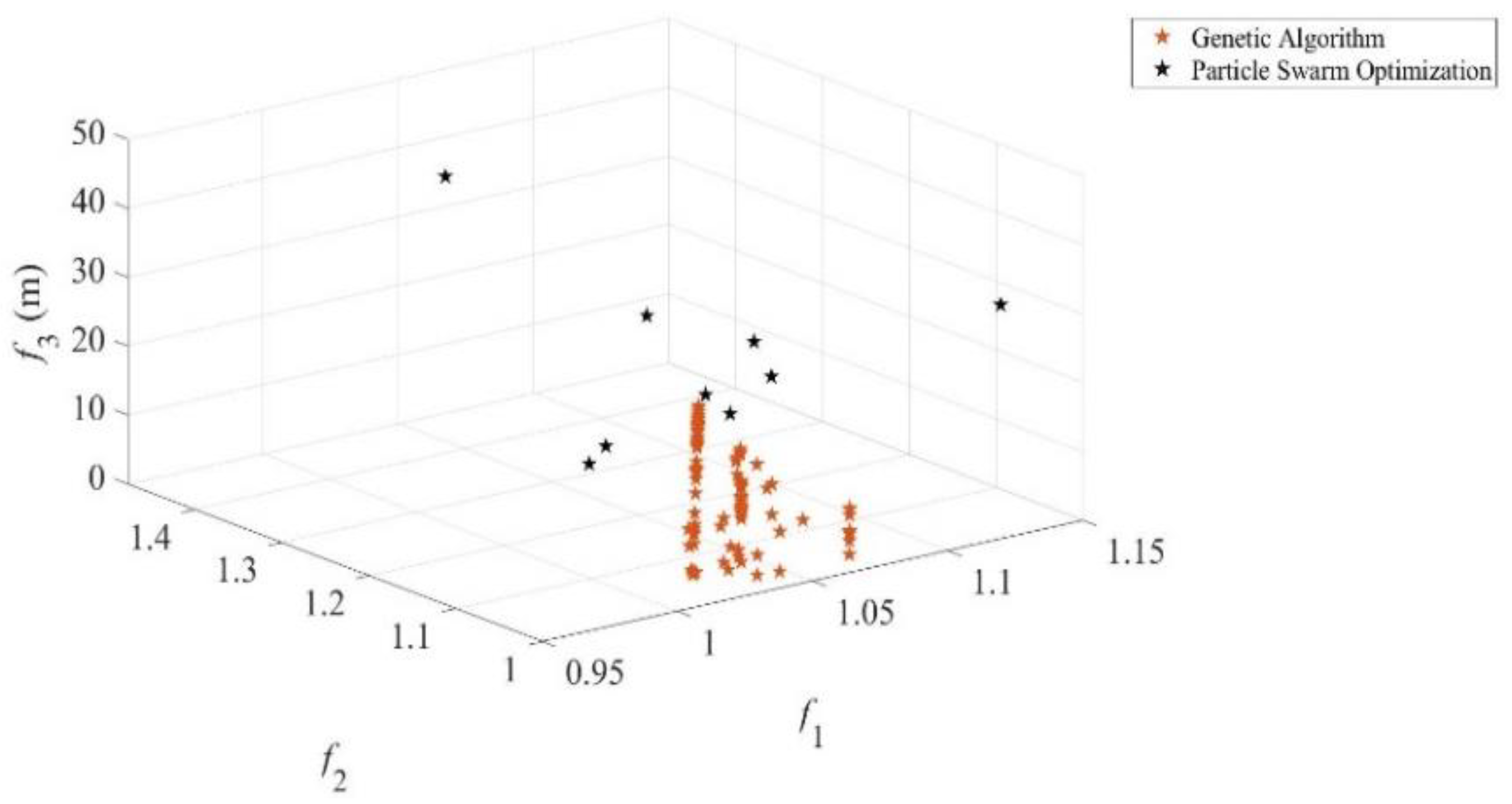

- Simplifies to three objective functions

- (3)

- Simplifies to four objective functions

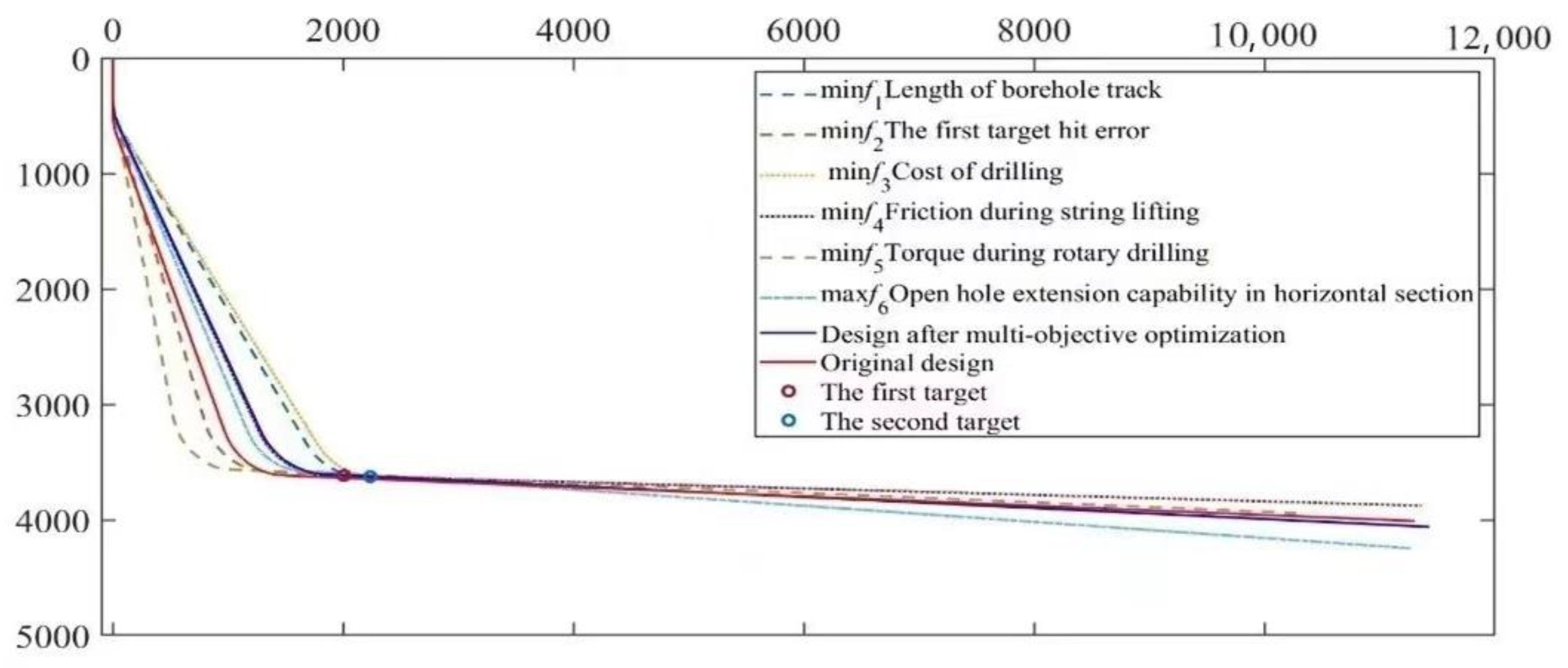

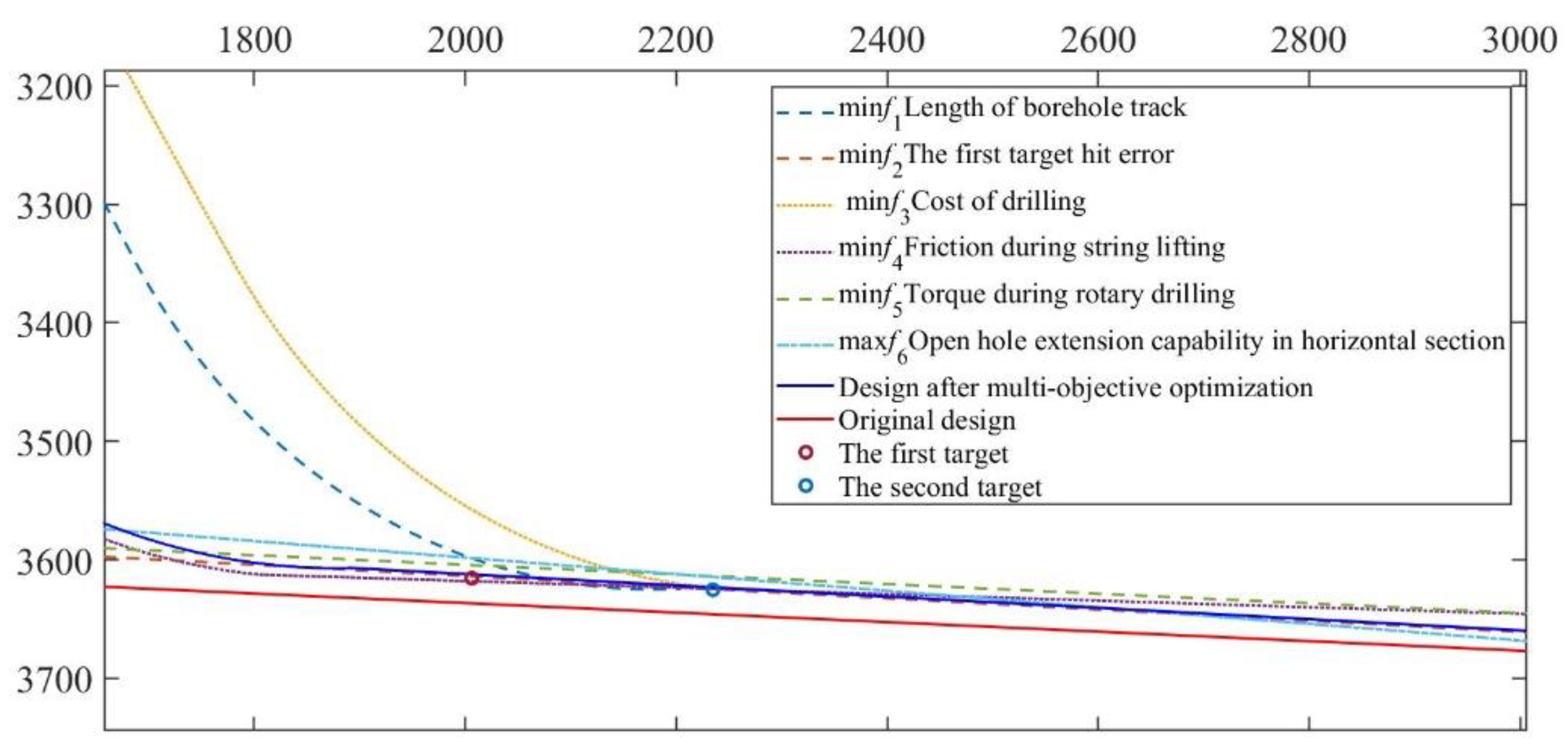

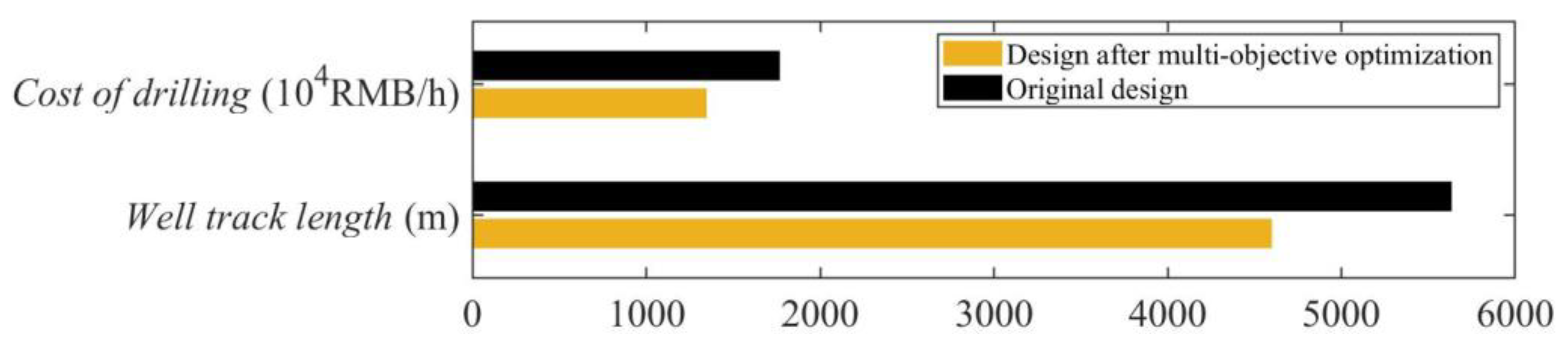

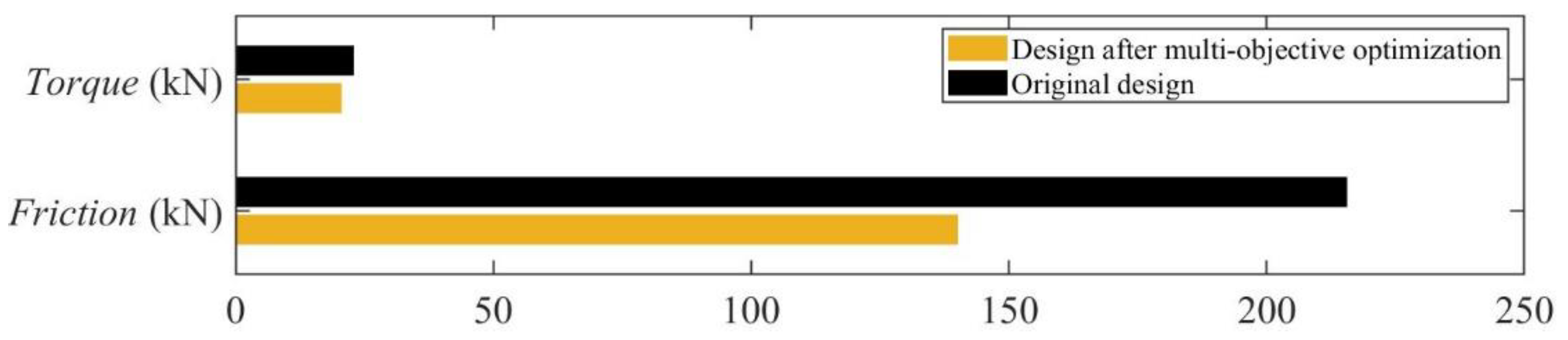

4.3. Comparison of Results

5. Conclusions and Future Works

- (1)

- For the three-segment, five-segment, and double-profile extended reach wells, taking into account the formation wellbore stability, formation strength, and deflection tool work to determine the well deflection angle, deflection point location, and target hitting range and other constraints; the optimization objective function of the shortest total length of the borehole; the smallest error of the second target hitting; the lowest cost; and the smallest friction resistance of the pipe string, the smallest rotary drilling torque is established, and the objective function of the longest open-hole extension limit in the horizontal section is established for extended reach wells.

- (2)

- Taking the extended section well as an example, two objective functions are used to solve the nondominated solution, whose results verify that the friction objective functions of lifting and lowering strings are highly correlated, and one of the minimum friction conditions is taken as the objective function.

- (3)

- Taking the optimization model of dual profile extended reach well in block 14-8 of the Lufeng Oilfield in the east of the South China Sea as an example and comparing it with the original well trajectory, the well trajectory optimized by multi-objective function can avoid the shortcomings of large target error and poor expansion ability; reduce the track length, friction, and torque; reduce the drilling cost; and achieve the goal of cost reduction and efficiency increase. It is proved that the multi-objective function optimization is practical in application and can provide a certain reference value for the design of well trajectory in field application.

- (4)

- In the optimization design of well trajectory, in order to reduce costs and more effectively improve productivity, it is also necessary to establish an optimization model based on the three-dimensional trajectory model, optimize the well trajectory by considering more factors, and optimize the well trajectory by using more advanced and richer computer systems and optimization procedures so that the optimization design of well trajectory is closer to reality.

Author Contributions

Funding

Conflicts of Interest

References

- Chen, X.; Yang, J.; Gao, D.; Hong, Y.; Zou, Y.; Du, X. Unlocking the deepwater natural gas hydrate’s commercial potential with extended reach wells from shallow water: Review and an innovative method. Renew. Sustain. Energy Rev. 2020, 134, 110388. [Google Scholar] [CrossRef]

- Chen, X.; Du, X.; Yang, J.; Gao, D.; Zou, Y.; He, Q. Developing offshore natural gas hydrate from existing oil & gas platform based on a novel multilateral wells system: Depressurization combined with thermal flooding by utilizing geothermal heat from existing oil & gas wellbore. Energy 2022, 258, 124870. [Google Scholar]

- Biswas, K.; Vasant, P.M.; Vintaned, J.A.G.; Watada, J. Cellular automata-based multi-objective hybrid Grey Wolf Optimization and particle swarm optimization algorithm for wellbore trajectory optimization. J. Nat. Gas Sci. Eng. 2021, 85, 103695. [Google Scholar] [CrossRef]

- Abdollahzadeh, B.; Gharehchopogh, F.S. A multi-objective optimization algorithm for feature selection problems. Eng. Comput. 2022, 38, 1845–1863. [Google Scholar] [CrossRef]

- Akyol, S.; Altas, B. Plant intelligence based metaheuristic optimization algorithms. Artif. Intell. Rev. 2017, 47, 417–462. [Google Scholar] [CrossRef]

- Hosseini, F.; Gharehchopogh, F.S.; Masdari, M. A Botnet Detection in IoT Using a Hybrid Multi-objective Optimization Algorithm. N. Gener. Comput. 2022, 40, 809–843. [Google Scholar] [CrossRef]

- Helmy, M.W.; Khalaf, F.; Darwish, T.A. Well design using a computer model. SPE Drill. Complet. 1998, 13, 42–46. [Google Scholar] [CrossRef]

- Shengzong, J.; Xilu, W.; Limin, C.; Kunfang, L. A new method for designing 3D trajectory in sidetracking horizontal wells under multi-constraints. In SPE Asia Pacific Improved Oil Recovery Conference; OnePetro: Richardson, TX, USA, 1999. [Google Scholar]

- Zhang, Y.; Wu, S.; Liu, K.; Cao, L.; Yu, L. Research on optimization design method of directional well trajectory. Pet. Drill. Tech. 1999, 27, 3. [Google Scholar]

- Sui, M.; Zhang, D.; Cheng, W. Optimization design of well trace curve in horizontal Wells. J. Jianghan Pet. Inst. 2000, 22, 25–26. [Google Scholar]

- Liu, N. Optimization design method of directional well trajectory. J. Jianghan Pet. Inst. 2001, 29, 3. [Google Scholar]

- Yu, G.; Xing, Y.; Lu, G. Optimization calculation method of trajectory design for oil drilling. J. Shenyang Inst. Aeronaut. Technol. 2003, 20, 3. [Google Scholar]

- Liu, H.; Meng, Y. Study on optimal trajectory of directional well. T’ien Jan Ch’i K. Yeh 2004, 24, 4. [Google Scholar]

- Shokir, E.E.M.; Emera, M.K.; Eid, S.M.; Wally, A.W. A new optimization model for 3D well design. Oil Gas Sci. Technol. 2004, 59, 255–266. [Google Scholar] [CrossRef] [Green Version]

- Lu, G.; Tong, C.; Xing, Y. Three-dimensional multi-target well trajectory design model based on constraint optimization method. Acta Pet. 2005, 26, 3. [Google Scholar]

- Yan, T.; Liu, W.; Bi, X.; Bi, C. Trajectory optimization design of stepped horizontal Wells. Pet. Drill. Tech. 2007, 29, 3. [Google Scholar]

- Sun, T. Integrated Method of Horizontal Well Drilling Trajectory Design and Control. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2013. [Google Scholar]

- Jia, J.; Han, L.; Dou, Y.; Yan, Z.; Huang, G.; Ma, Q. Extended reach well trajectory design method based on multi-objective optimization. J. Guangxi Univ. Nat. Sci. Ed. 2014, 39, 7. [Google Scholar]

- Atashnezhad, A.; Wood, D.A.; Fereidounpour, A.; Khosravanian, R. Designing and optimizing deviated wellbore trajectories using novel particle swarm algorithms. J. Nat. Gas Sci. Eng. 2014, 21, 1184–1204. [Google Scholar] [CrossRef]

- Mansouri, V.; Khosravanian, R.; Wood, D.A.; Aadnoy, B.S. 3-D well path design using a multi objective genetic algorithm. J. Nat. Gas Sci. Eng. 2015, 27, 219–235. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D.; Yang, J. Design and calculation of complex directional-well trajectories on the basis of the minimum-curvature method. SPE Drill. Complet. 2019, 34, 173–188. [Google Scholar] [CrossRef]

- Wood, D.A. Hybrid bat flight optimization algorithm applied to complex wellbore trajectories highlights the relative contributions of metaheuristic components. Nat. Gas Sci. Eng. 2016, 32, 211–221. [Google Scholar] [CrossRef]

- Wang, Z.; Gao, D.; Liu, J. Multi-objective sidetracking horizontal well trajectory optimization in cluster wells based on DS algorithm. J. Pet. Sci. Eng. 2016, 147, 771–778. [Google Scholar] [CrossRef]

- Sha, L.; Pan, Z. FSQGA based 3D complexity wellbore trajectory optimization. Ind. Eng. Chem. Res. 2018, 73, 79. [Google Scholar] [CrossRef]

- Huang, W.; Wu, M.; Chen, L. Multi-Objective Drilling Trajectory Optimization with a Modified Complexity Index. In Proceedings of the 37th Chinese Control Conference (CCC), Wuhan, China, 25–27 July 2018. [Google Scholar]

- Khosravanian, R.; Mansouri, V.; Wood, D.A.; Alipour, M.R. A comparative study of several metaheuristic algorithms for optimizing complex 3-D well-path designs. J. Pet. Explor. Prod. Technol. 2018, 8, 1487–1503. [Google Scholar] [CrossRef] [Green Version]

- Li, W. Multi-Objective Optimization Technology for Complex Borehole Trajectory. Master’s Thesis, Xi’an Shiyou University, Xi’an, China, 2019. [Google Scholar]

- Zheng, J.; Lu, C.; Gao, L. Multi-objective cellular particle swarm optimization for wellbore trajectory design. Appl. Soft Comput. 2019, 77, 106–117. [Google Scholar] [CrossRef]

- Wang, L.; Wei, L.; Gao, Y.; Zhang, Y.; Chen, L.; Zhang, M. Research on 3d horizontal well trajectory optimization design based on multi-objective constraints. Drill. Prod. Technol. 2020, 1, 17–20. [Google Scholar]

- Khodadadi, N.; Soleimanian Gharehchopogh, F.; Mirjalili, S. MOAVOA: A new multi-objective artificial vultures optimization algorithm. Neural. Comput. Appl. 2022, 1–39. [Google Scholar] [CrossRef]

- Gharehchopogh, F.S. An Improved Tunicate Swarm Algorithm with Best-random Mutation Strategy for Global Optimization Problems. J. Bionic Eng. 2022, 19, 1177–1202. [Google Scholar] [CrossRef]

- Liu, X. Research on catenary Track Design Method. T’ien Jan Ch’i K. Yeh 2007, 7, 73–75. [Google Scholar]

- Liu, X.; Zhou, D.; Li, S.; Gu, L. Design principle and method of parabolic directional well profile. J. Northeast Pet. Univ. 1989, 4, 29–37. [Google Scholar]

- Wiśniowski, R.; Łopata, P.; Orłowicz, G. Numerical Methods for Optimization of the Horizontal Directional Drilling (HDD) Well Path Trajectory. Energies 2020, 13, 3806. [Google Scholar] [CrossRef]

- Liu, X. Borehole Trajectory Geometry; Petroleum Industry Press: Beijing, China, 2006. [Google Scholar]

- Gao, D. Pipe String Mechanics and Engineering in Oil and Gas Wells; China University of Petroleum Press: Beijing, China, 2016. [Google Scholar]

- Li, X.; Gao, D.; Zhou, Y.; Zhang, H.; Yang, Y. Study on the prediction model of the open-hole extended-reach limit in horizontal drilling considering the effects of cuttings. J. Nat. Gas Sci. Eng. 2017, 40, 159–167. [Google Scholar] [CrossRef]

- Li, X.; Gao, D.; Zhou, Y.; Cao, W. General approach for the calculation and optimal control of the extended-reach limit in horizontal drilling based on the mud weight window. J. Nat. Gas Sci. Eng. 2016, 35, 964–979. [Google Scholar] [CrossRef]

- Li, X.; Gao, D.; Zhou, Y.; Zhang, H. A model for extended-reach limit analysis in offshore horizontal drilling based on formation fracture pressure. J. Pet. Sci. Eng. 2016, 146, 400–408. [Google Scholar] [CrossRef]

- Holt, F.; Lane, H.; Lisnas. Rock Mechanics in Petroleum Engineering: English-Chinese Reference; Petroleum Industry Press: Beijing, China, 2010. [Google Scholar]

- Chen, J.; Liu, Z. Drilling Engineering Design Method for Deepwater Exploration Wells; Petroleum Industry Press: Beijing, China, 2014. [Google Scholar]

- Runar, N.; Robin, H. Steering Response for Directional Well in Soft Formation in Deep Water Development; Offshore Technology Conference: Houston, TX, USA, 2008. [Google Scholar]

- Zheng, D.; Zhang, H.; Zhu, Y.; Sun, W. Influence mechanism of rock mechanical properties on well trajectory. Pet. Drill. Tech. 2014, 42, 5. [Google Scholar]

- Zhao, W. Research and Application of Drilling Technology in the Tuo Putai Block of Tahe Oilfield. Master’s Thesis, China University of Petroleum (east China), Qingdao, China, 2018. [Google Scholar]

- Meng, Q. Optimization of Horizontal Well Trajectory in Dibeilla Block, Niger. Master’s Thesis, China University of Petroleum (Beijing), Beijing, China, 2020. [Google Scholar]

| Layer | Drillability | Compressive Strength (MPa) |

|---|---|---|

| Dead-soft | Level 1–2 | <25 |

| Soft | Level 3 | 25–50 |

| Medium-soft | Level 4 | 50–75 |

| Medium | Level 4–5 | 75–100 |

| Medium-hard | Level 5–6 | 100–150 |

| Hard | Level 5–6 | 150–200 |

| Extrahard | More than 7 | >200 |

| Drilling Open Time | Bit Size (in) | Footage Per Bit (m) |

|---|---|---|

| 1 | 24 | 273 |

| 2 | 16 | |

| 3 | 12-1/4 | |

| 4 | 8-1/2 |

| Parameter | Value | Unit |

|---|---|---|

| Drilling fluid density | 1.3 | g/cm3 |

| Solid density of drilling fluid | 2.5 | g/cm3 |

| Solids loading | 0.05 | |

| Consistency coefficient | 0.6565 | Pa∙sn |

| Liquidity index | 0.5365 | |

| Displacement | 26 | L/s |

| Open-hole sliding friction coefficient | 0.25 | |

| Open-hole rolling friction coefficient | 0.15 | |

| Dimensions of drill pipe | 5-7/8 | in |

| Nominal weight of drill pipe | 23.4 | lb/ft |

| Speed of drill pipe | 50 | rpm |

| Torque-on-bit | 5 | kN∙m |

| Drilling bit weight | 8 | T |

| Name of Parameter | Symbols for Parameter | Value | Unit |

|---|---|---|---|

| Upper limit of build-up rate | kmax | 3 | °/30 m |

| Lower limit of build-up rate | min | 2.5 | °/30 m |

| Upper limit of the first stable inclination angle | α1max | 5 | ° |

| Lower limit of the first stable inclination angle | α1min | 60 | ° |

| Upper limit of the second stable inclination angle | α2max | 86 | ° |

| Lower limit of the second stable inclination angle | α2min | 93 | ° |

| Upper limit of formation strength at the first kickoff point | UCSAmax | 150 | MPa |

| Lower limit of formation strength at the first kickoff point | UCSAmin | 0 | MPa |

| Upper limit of formation strength at the second kickoff point | UCSCmax | 150 | MPa |

| Lower limit of formation strength at the second kickoff point | UCSCmin | 50 | MPa |

| Upper vertical depth limit of the first kickoff point | hmax | 346 | m |

| Lower vertical depth limit of the first kickoff point | hmin | 306 | m |

| Plane allowable error | J | 30 | m |

| Vertical allowable error | H | 1 | m |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, J.; Liu, L.; Xue, L.; Chen, X.; Weng, C. A New Multi-Objective Optimization Design Method for Directional Well Trajectory Based on Multi-Factor Constraints. Appl. Sci. 2022, 12, 10722. https://doi.org/10.3390/app122110722

Qin J, Liu L, Xue L, Chen X, Weng C. A New Multi-Objective Optimization Design Method for Directional Well Trajectory Based on Multi-Factor Constraints. Applied Sciences. 2022; 12(21):10722. https://doi.org/10.3390/app122110722

Chicago/Turabian StyleQin, Jianyu, Luo Liu, Liang Xue, Xuyue Chen, and Chengkai Weng. 2022. "A New Multi-Objective Optimization Design Method for Directional Well Trajectory Based on Multi-Factor Constraints" Applied Sciences 12, no. 21: 10722. https://doi.org/10.3390/app122110722