Experimental Research to Determine the Effect of Ultrasound in Drying Bo Chinh Ginseng by Ultrasound-Assisted Heat Pump Drying Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Material and Equipment

2.1.1. Experimental Material

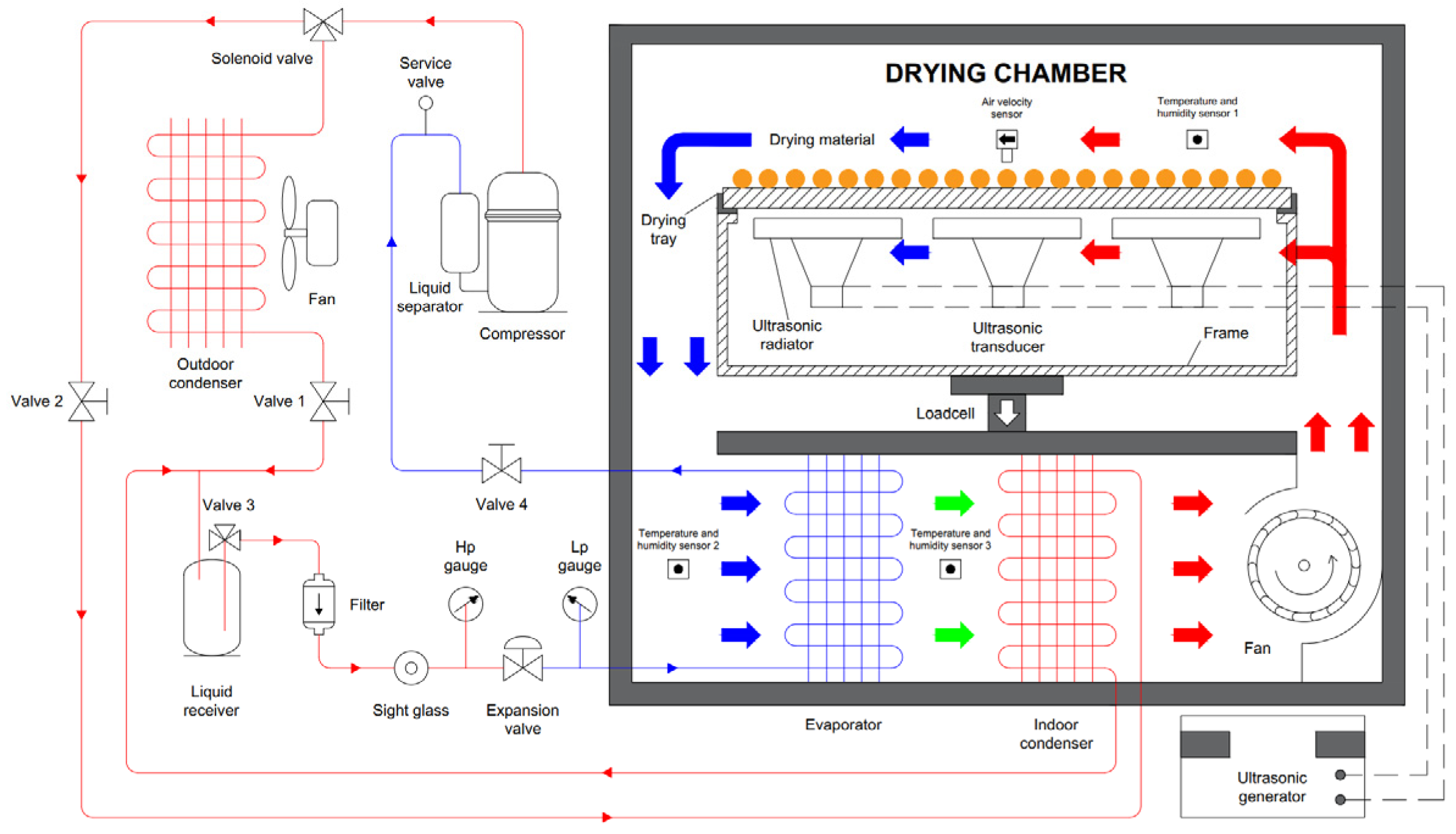

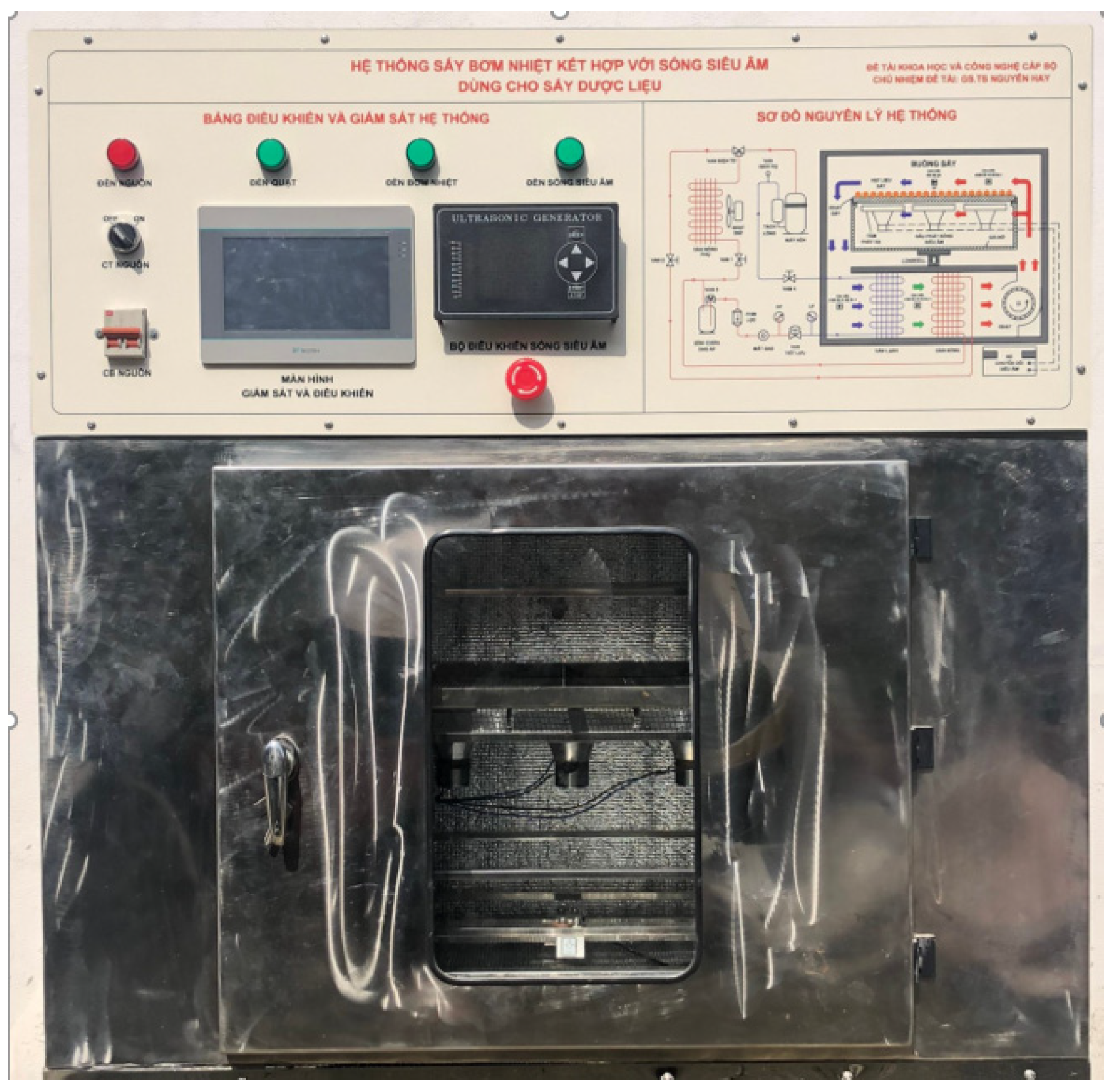

2.1.2. Experimental Equipment

2.2. Experimental Method

2.3. Moisture Effective Diffusion Coefficient of Material: Deff

2.4. Saponin Content

2.5. Color Change

2.6. Scanning Electron Microscopy of Material (SEM)

3. Results and Discussion

3.1. Experimental Results

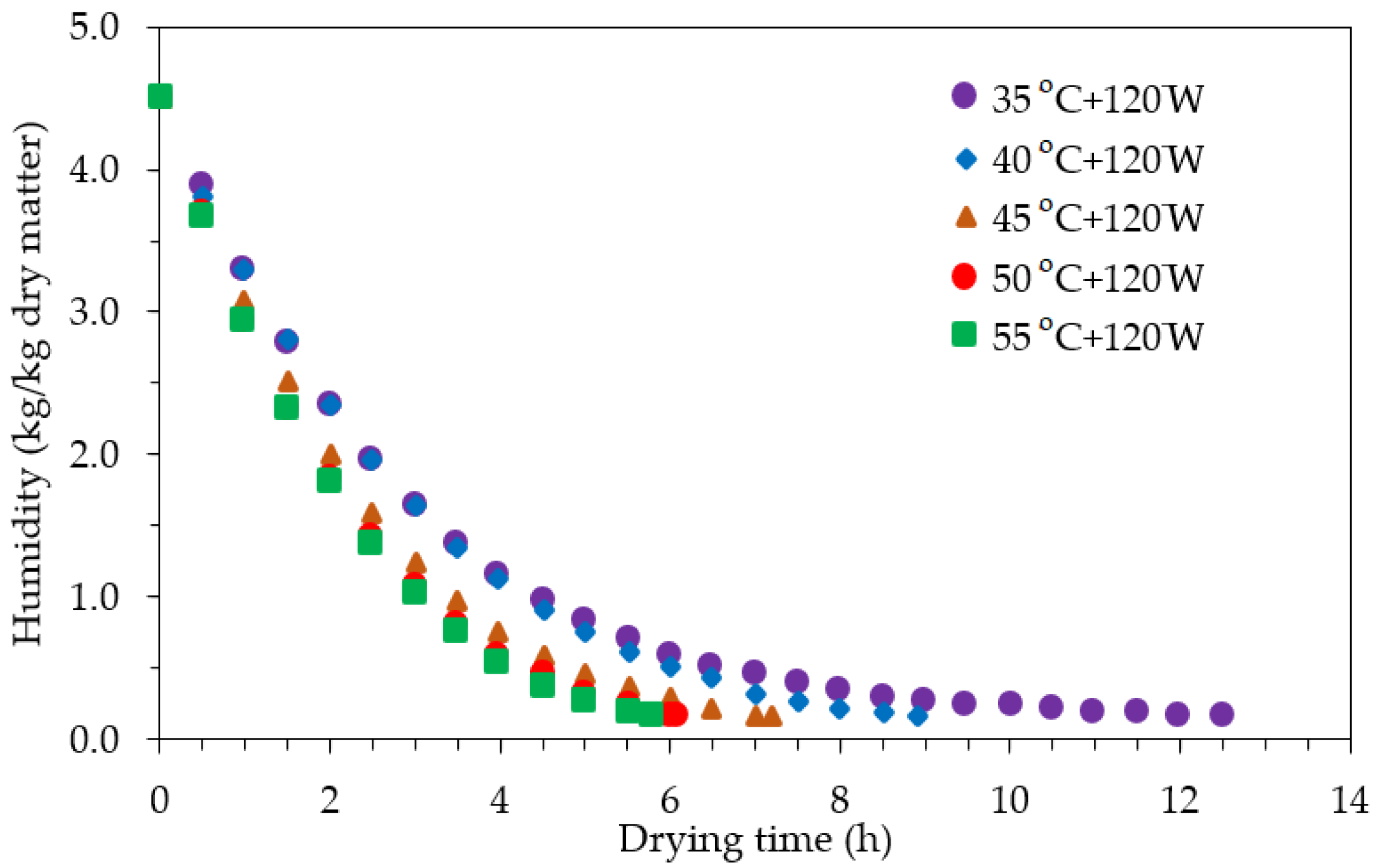

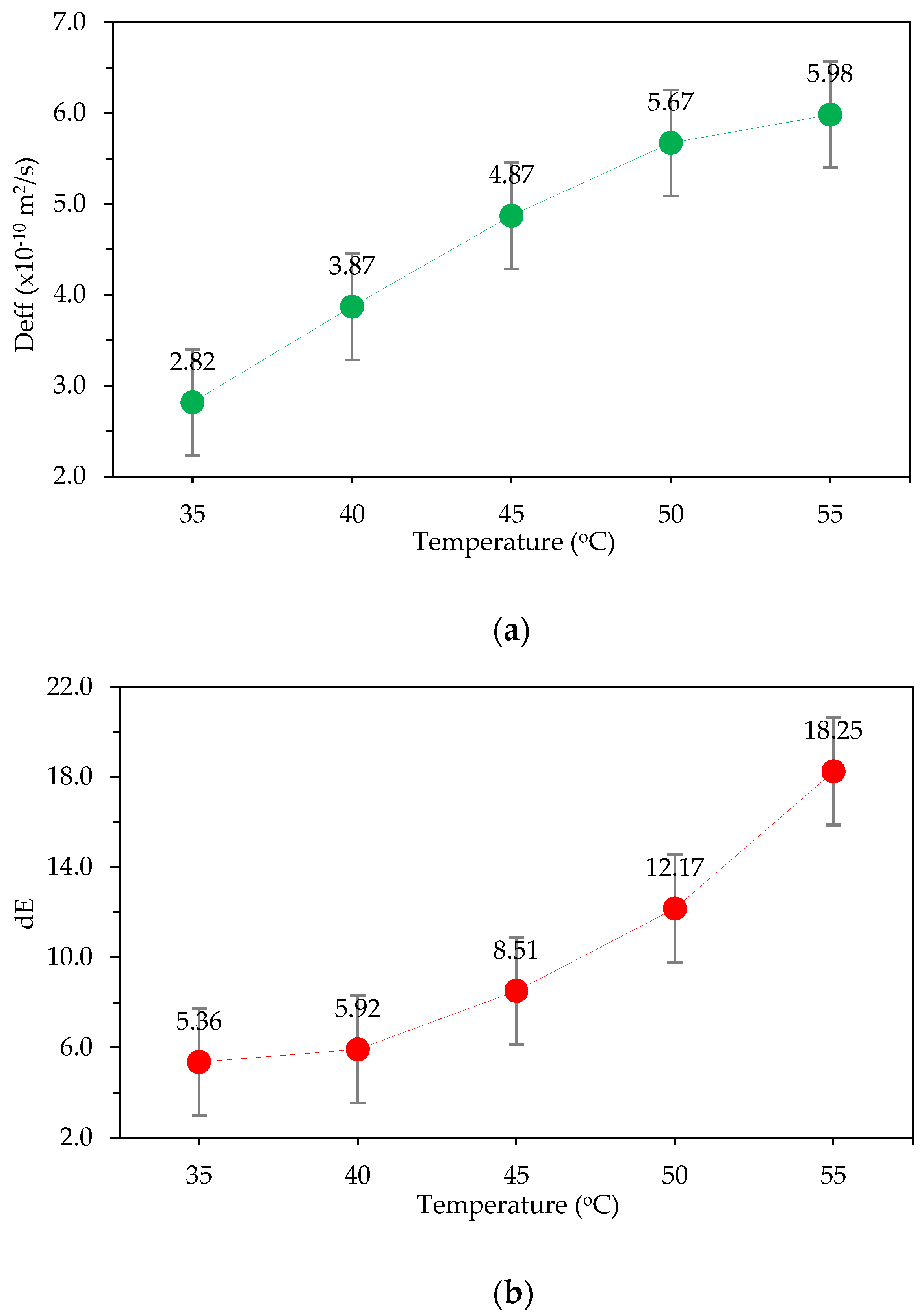

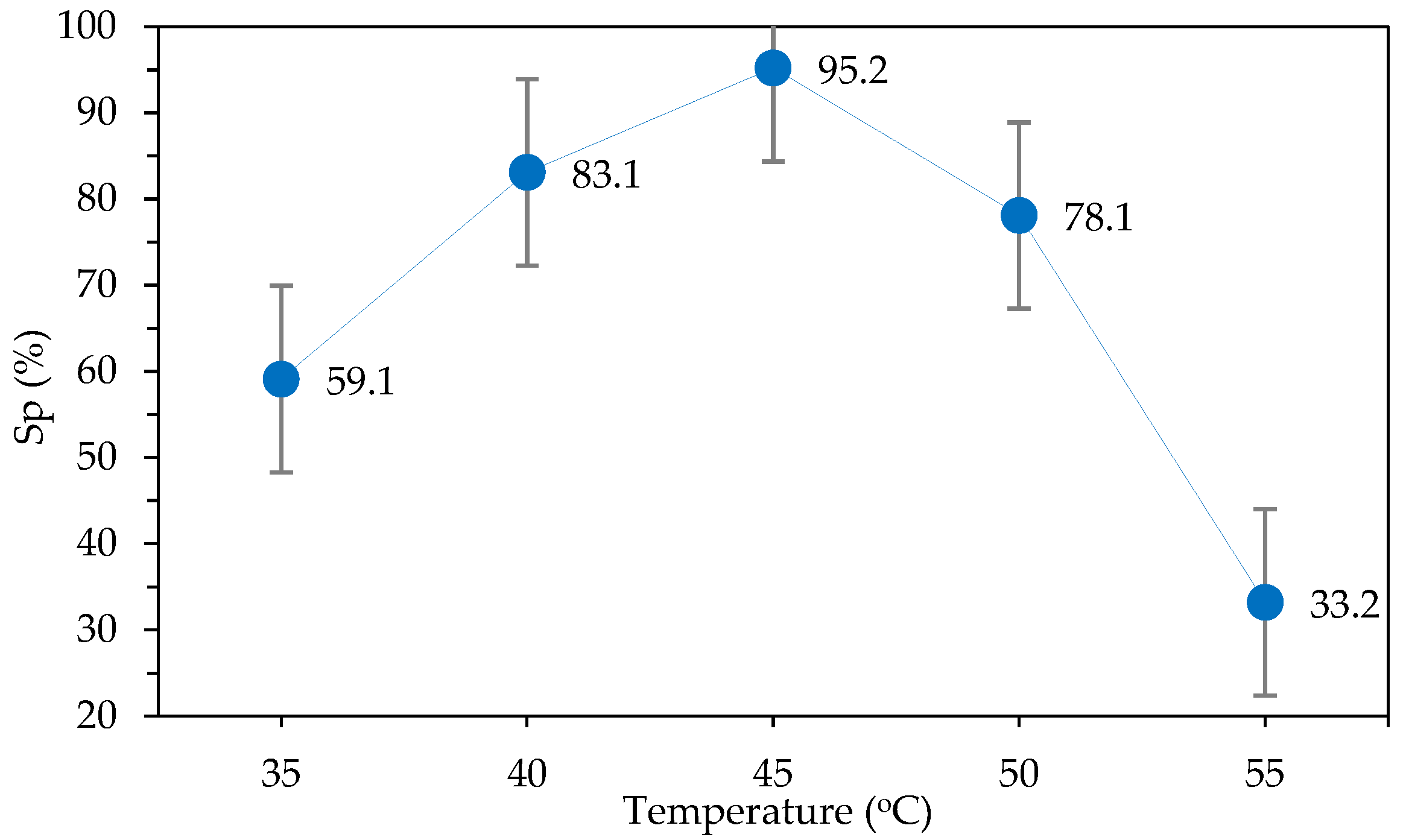

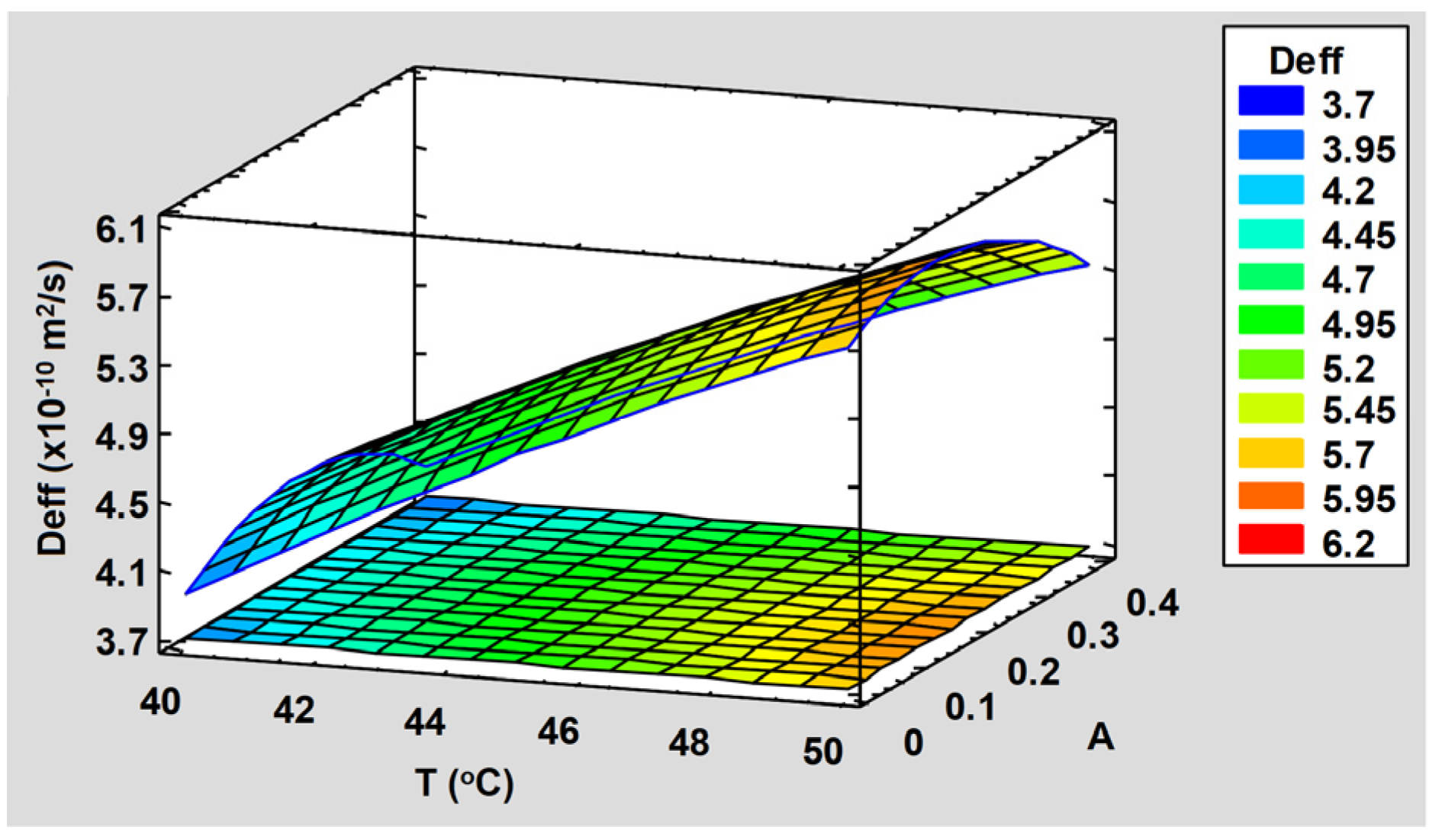

3.1.1. Effect of Drying Temperature (T) on Moisture Effective Diffusion Coefficient, Color Change and Saponin Content of Dried Materials

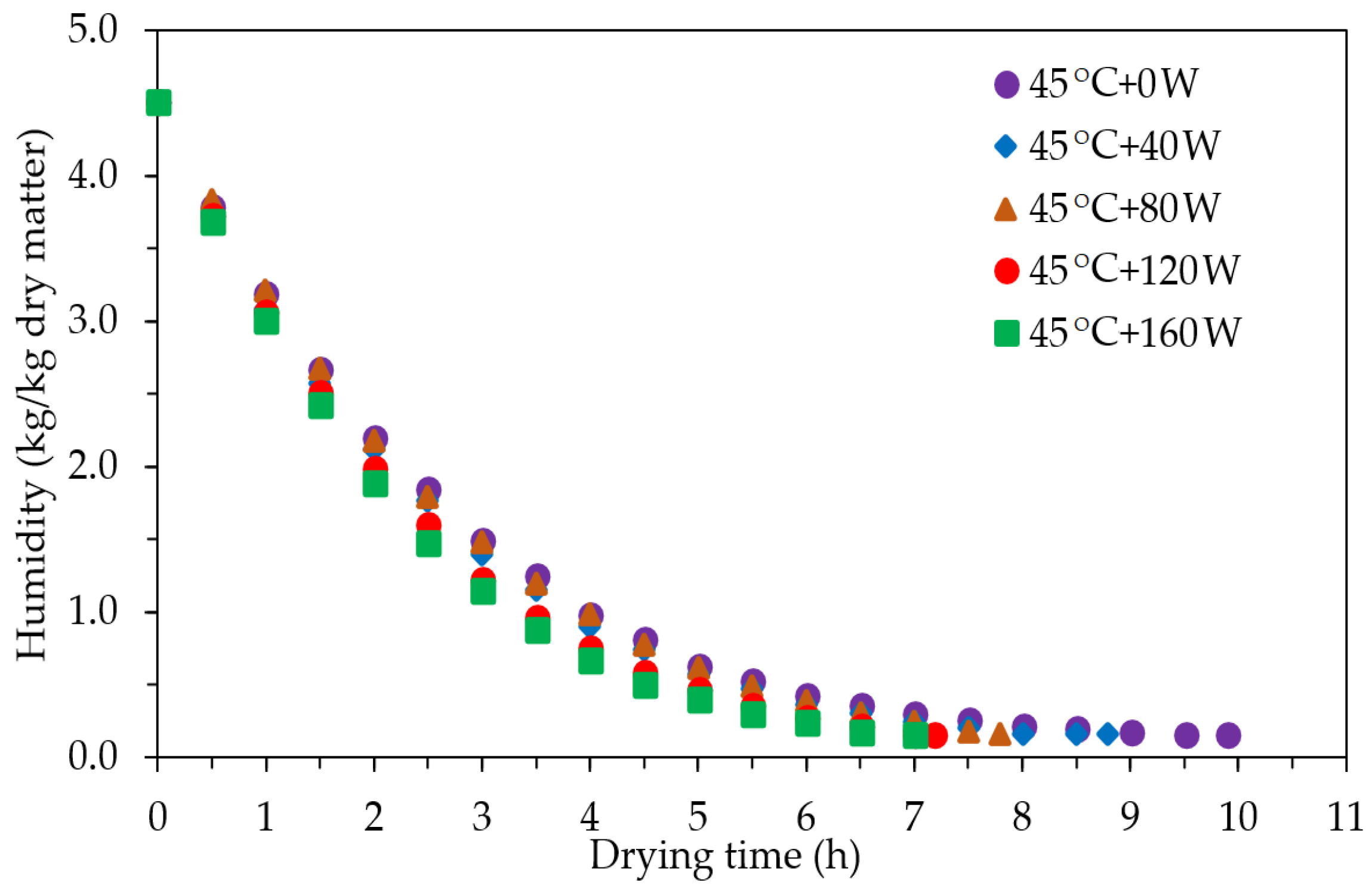

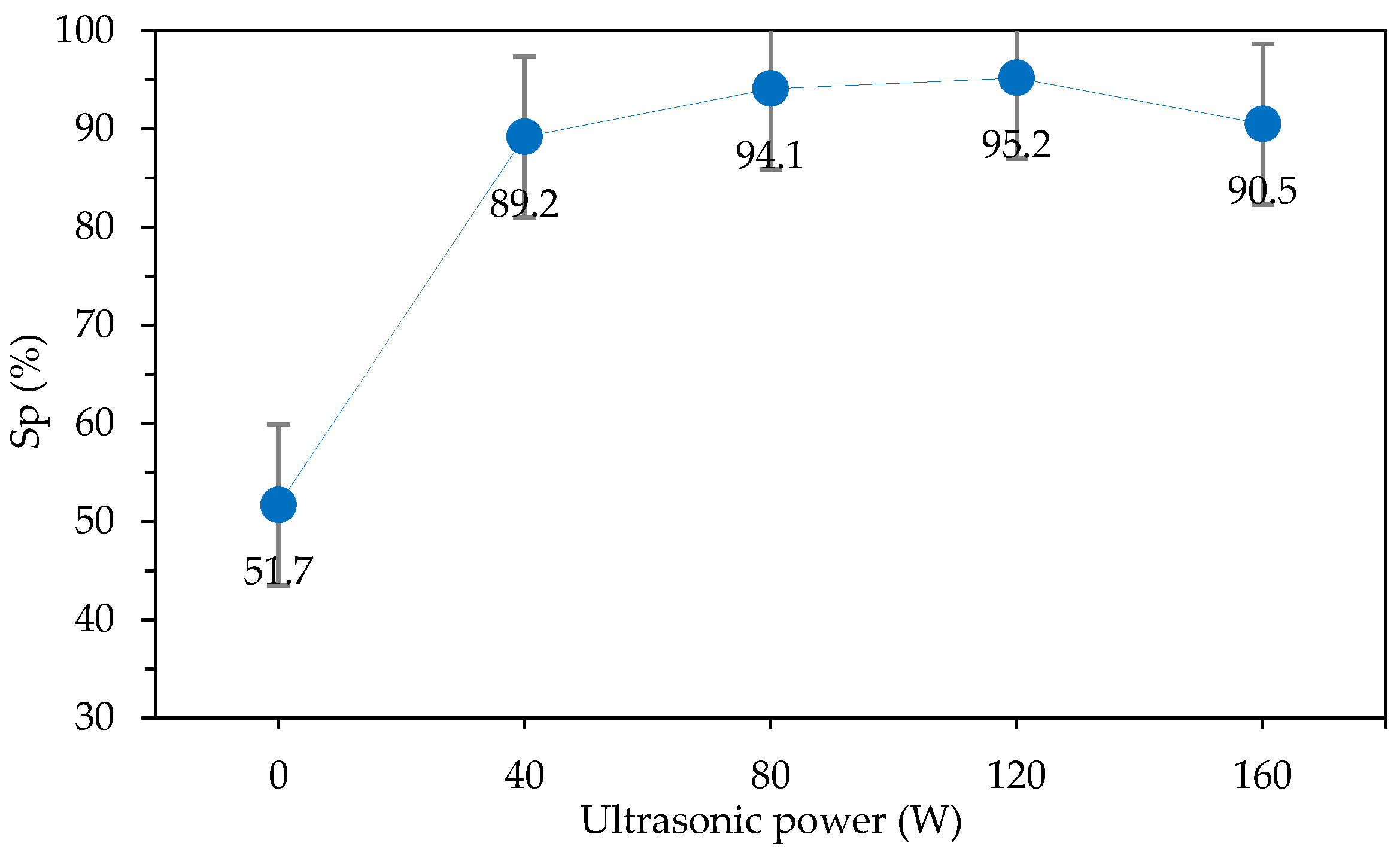

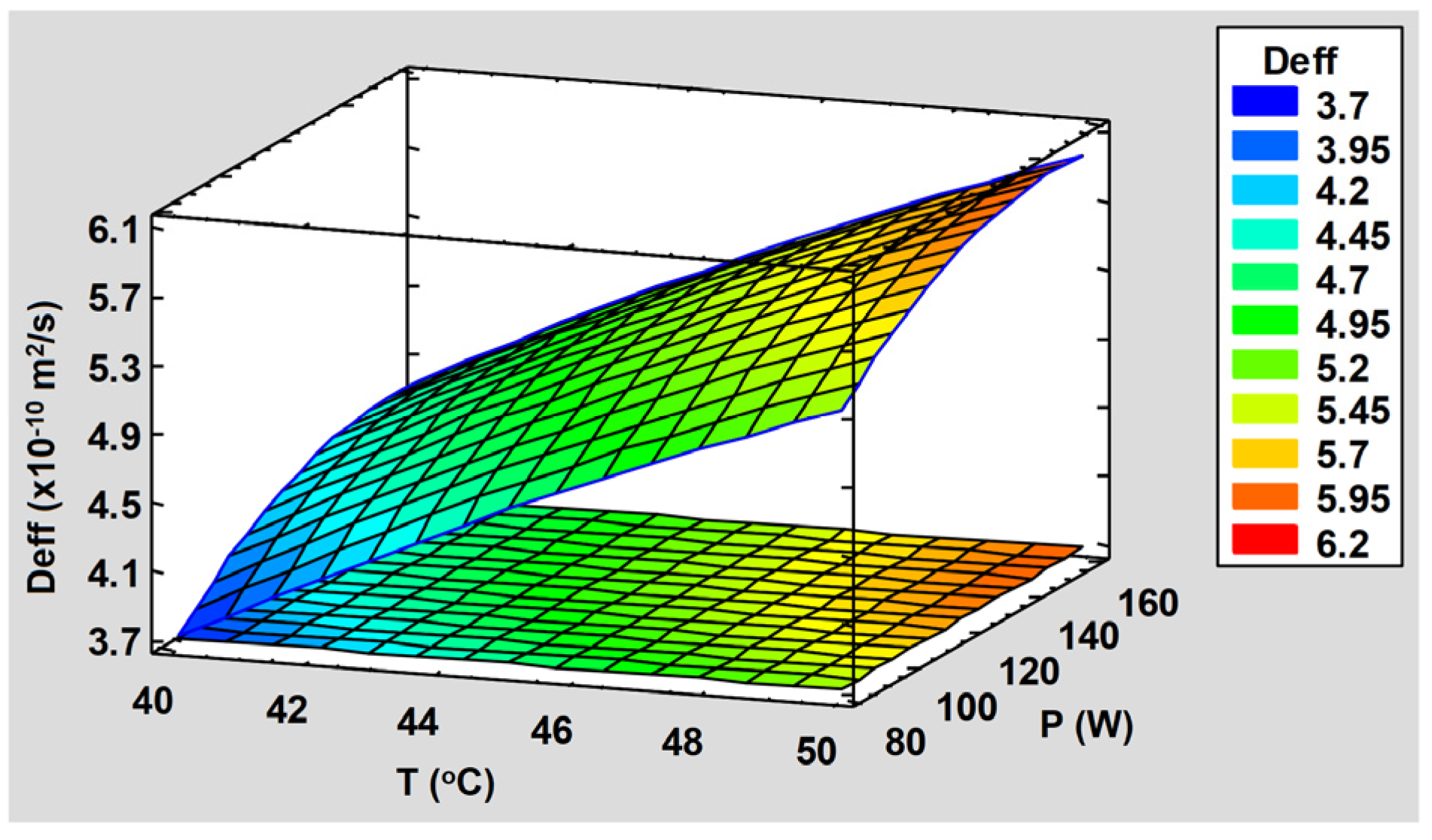

3.1.2. Effect of Ultrasonic Power (P) on Moisture Diffusion Coefficient, Color Change and Saponin Content of Dried Materials

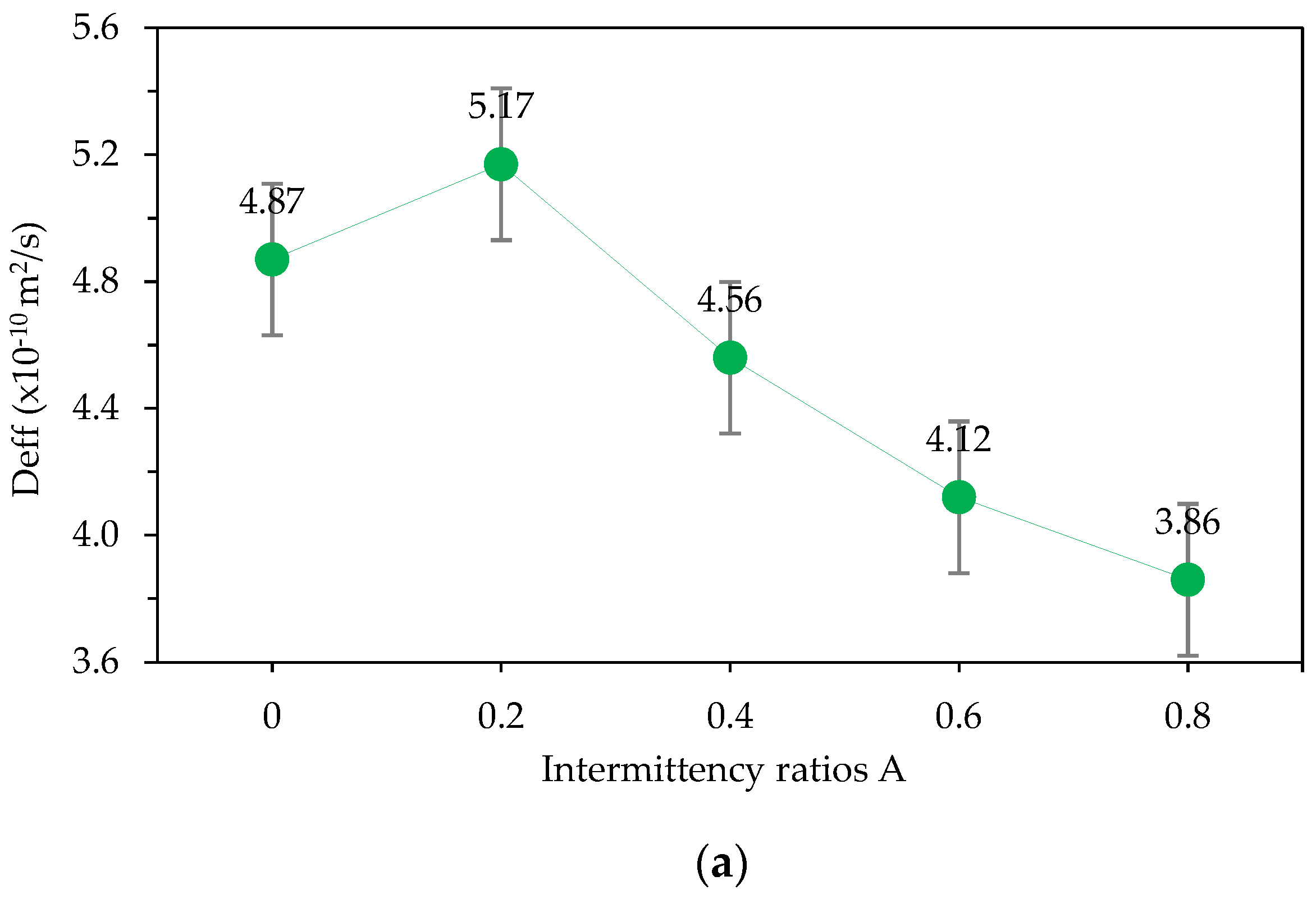

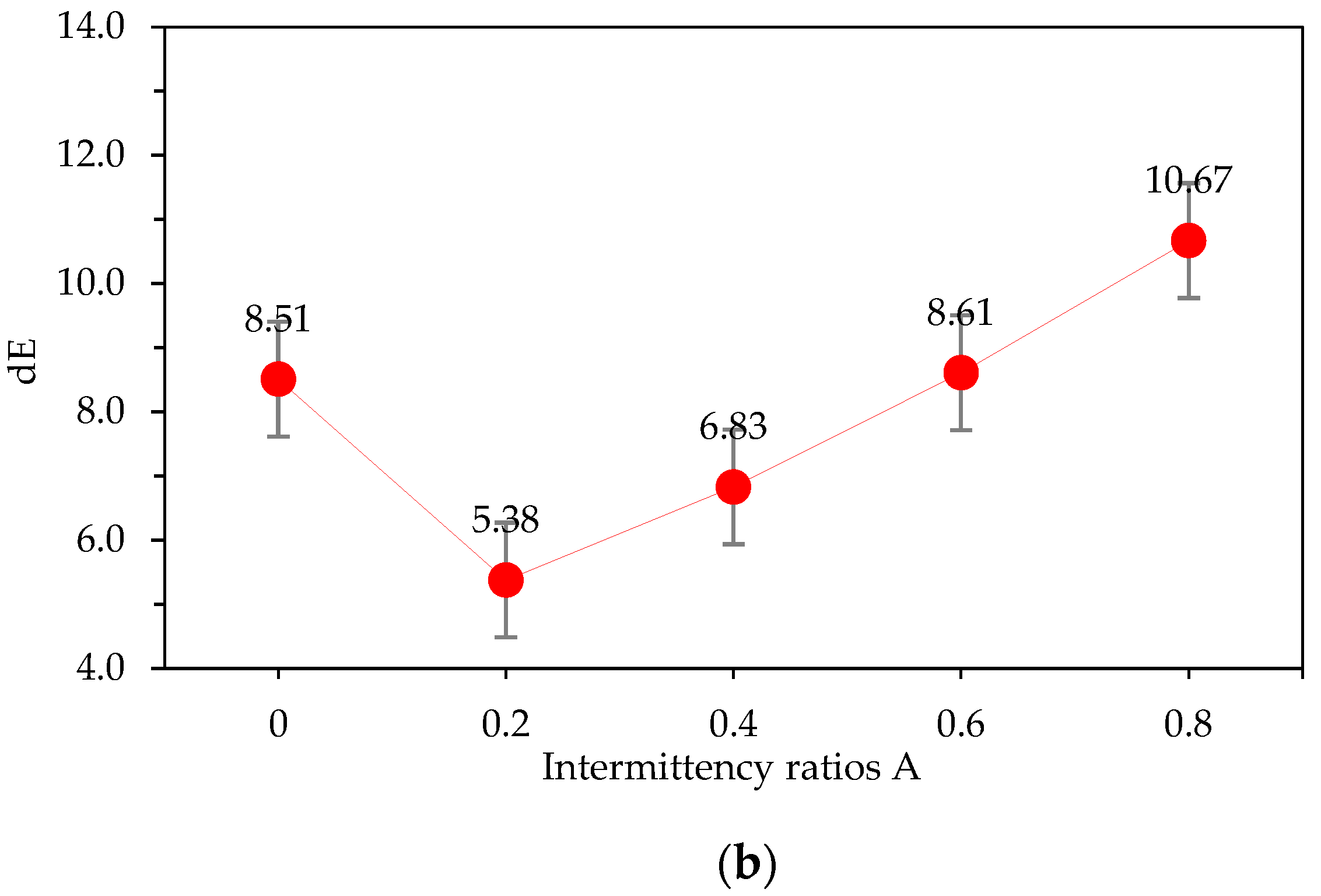

3.1.3. Effect of Intermittency Ratio (A) on Moisture Diffusion Coefficient, Color Change and Saponin Content of Dried Materials

3.2. Multifactorial Experiment

3.2.1. Experimental Design and Results

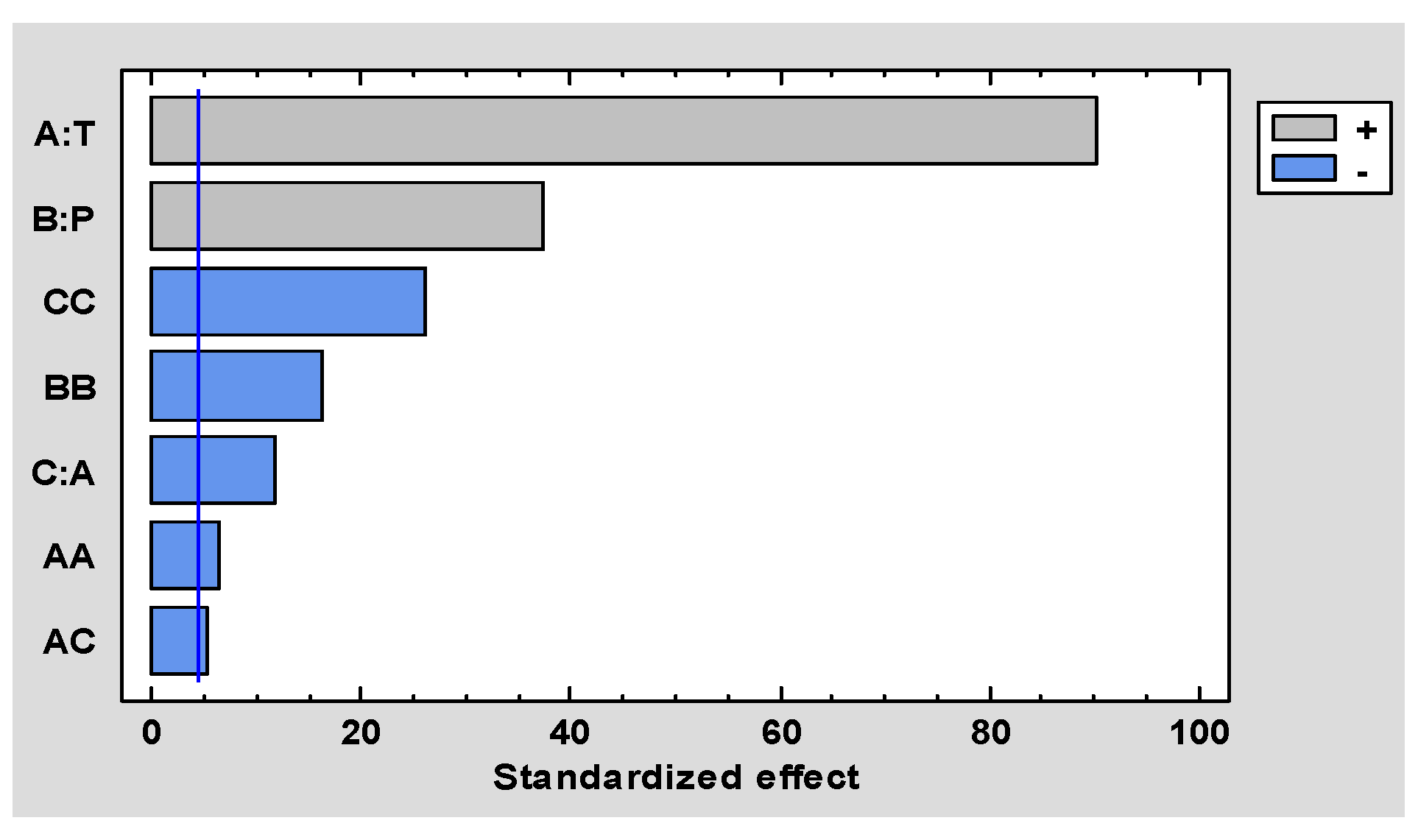

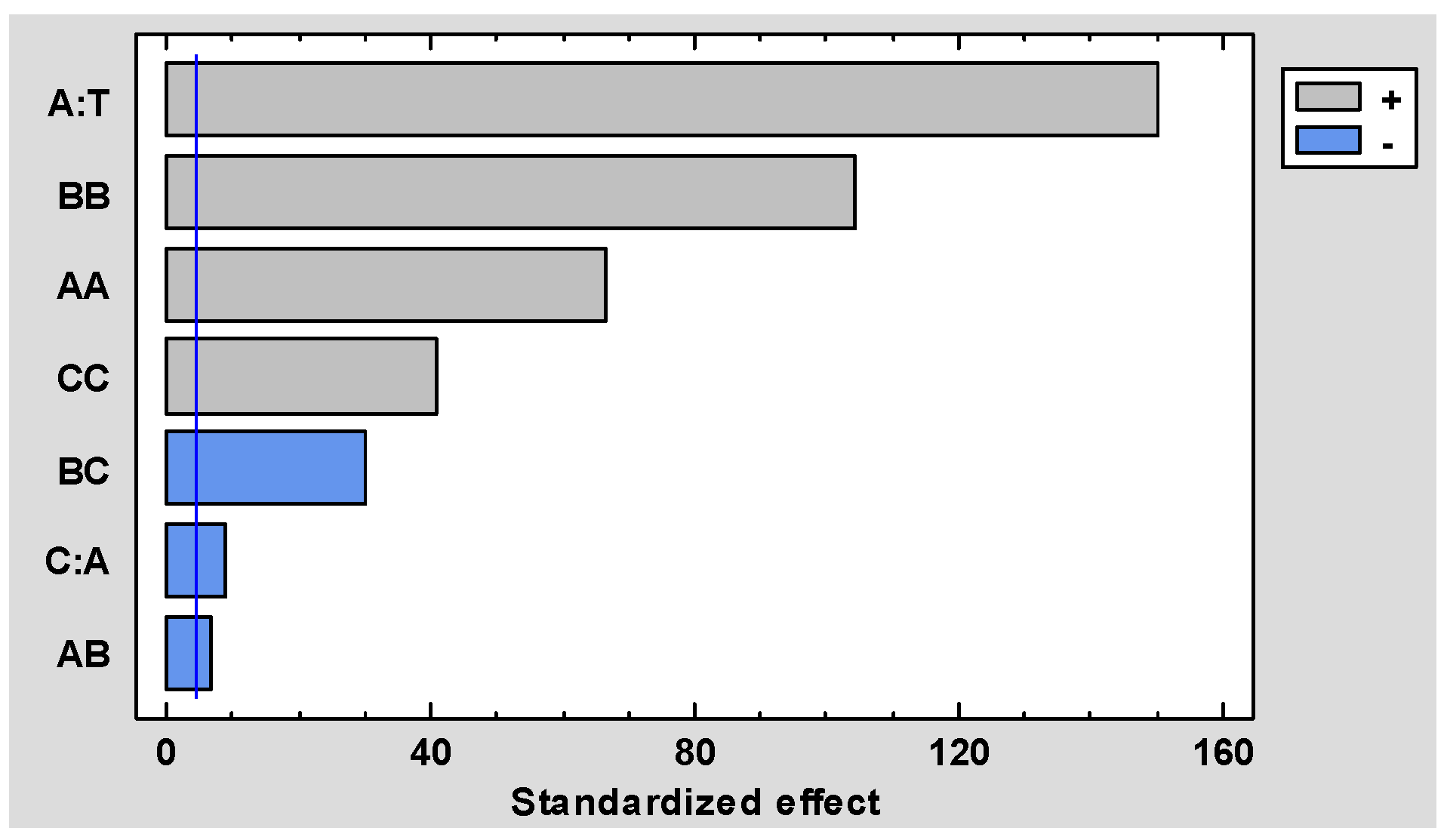

3.2.2. Regression Model Deff, Sp, dE

Function of Moisture Diffusion Coefficient Deff (×10−10 m2/s)

0.000133073P2 − 8.51042A2

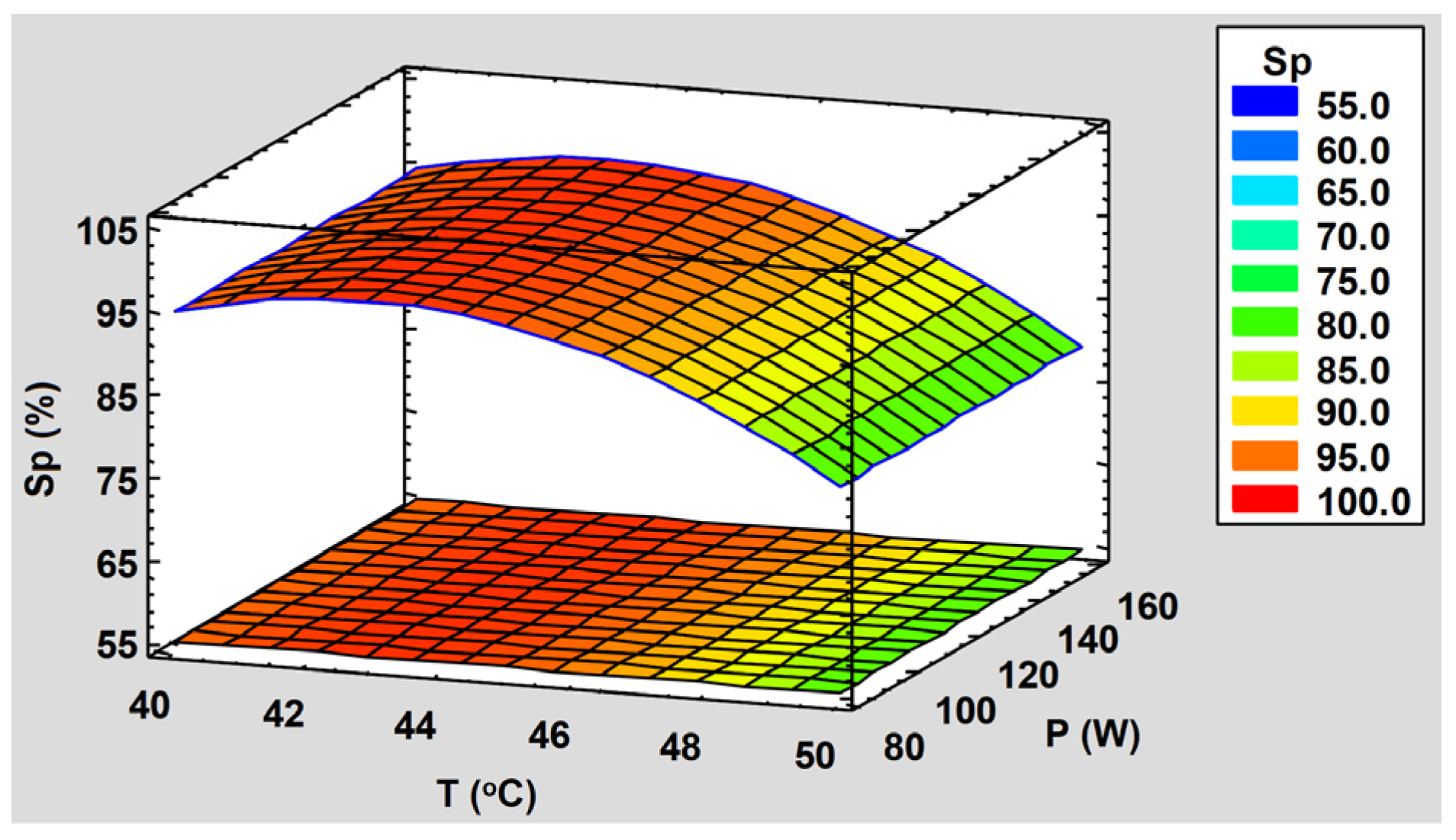

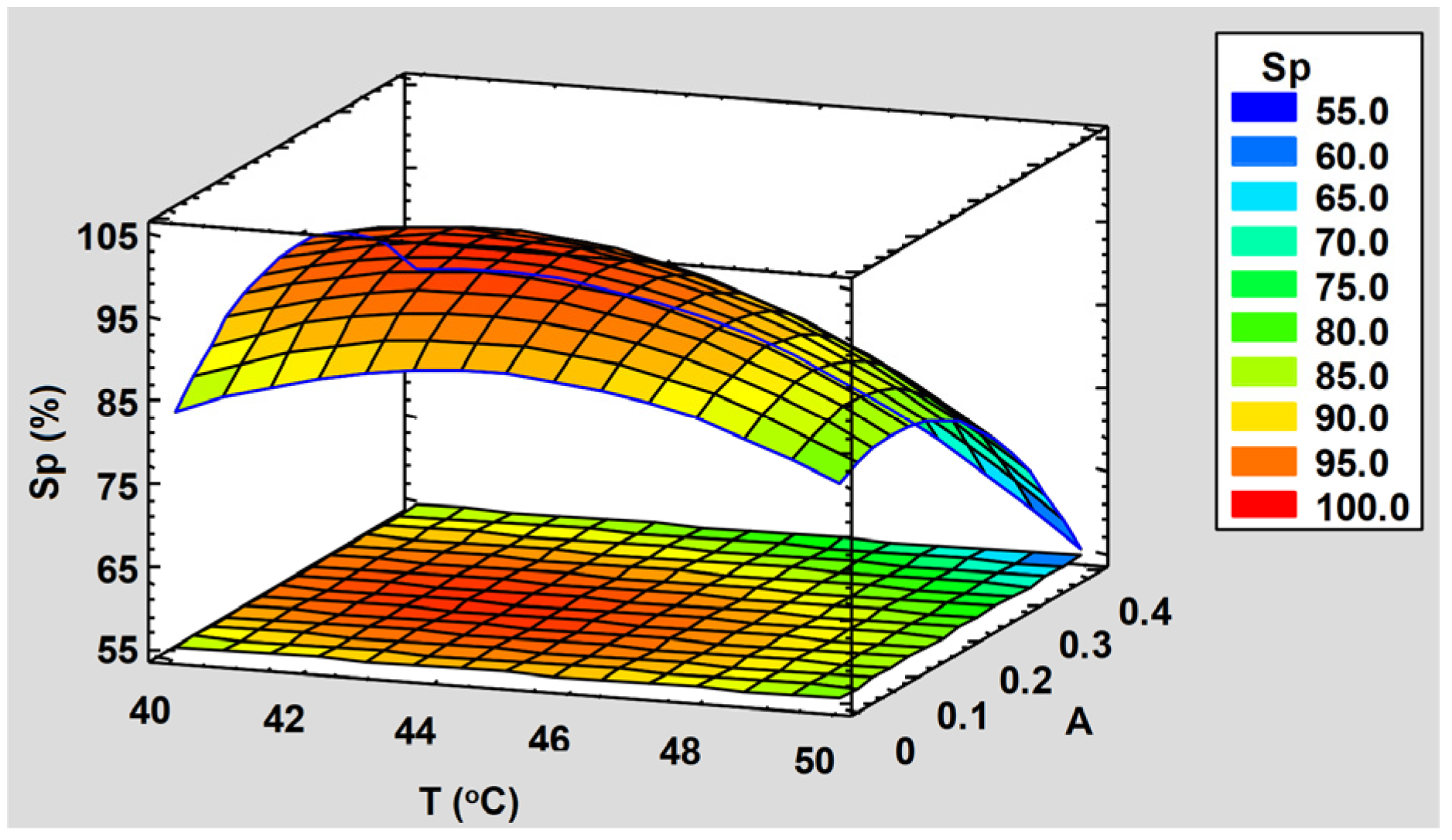

Function of Saponin Content Sp (%)

0.615625PA − 285.433A2

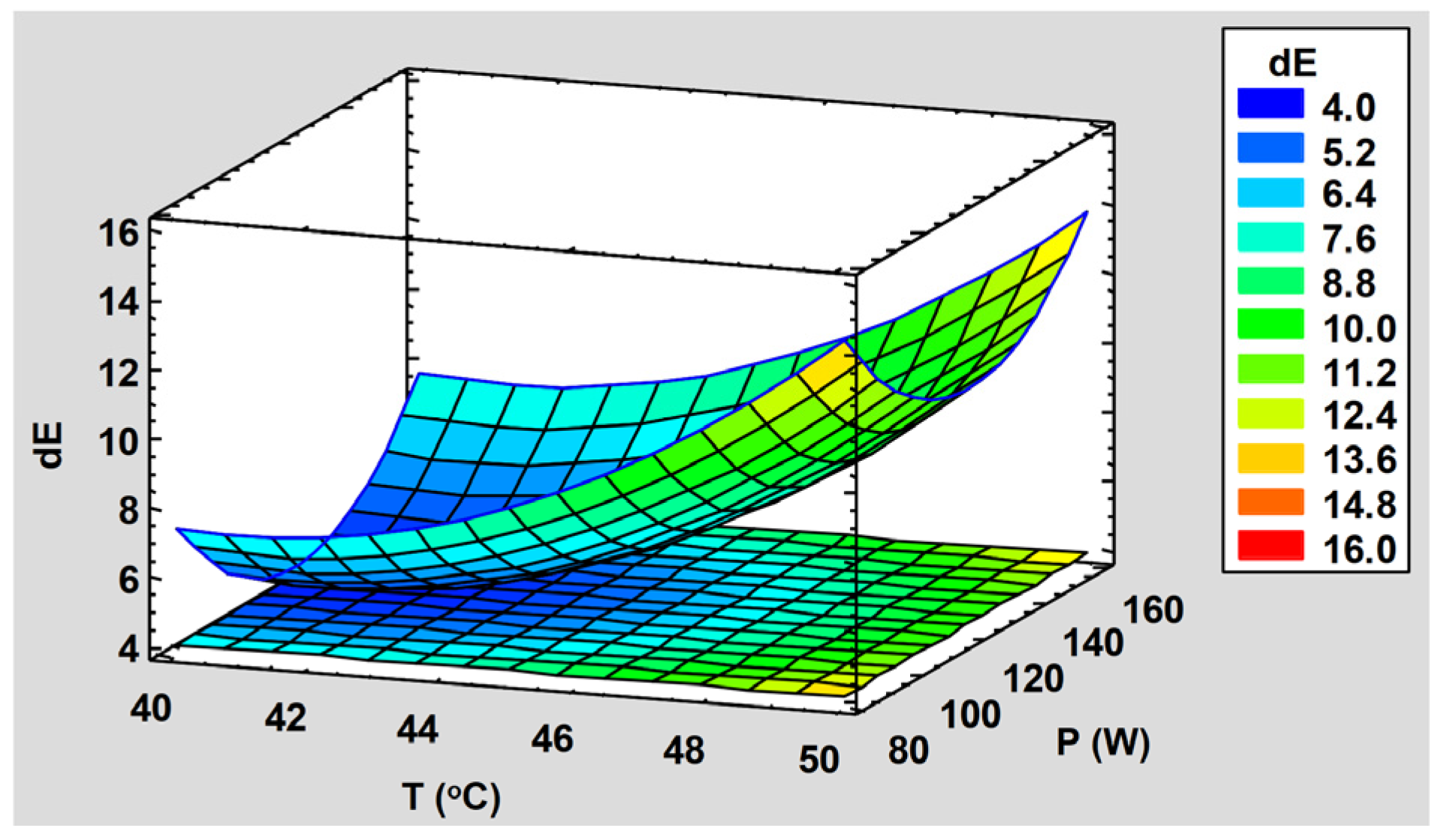

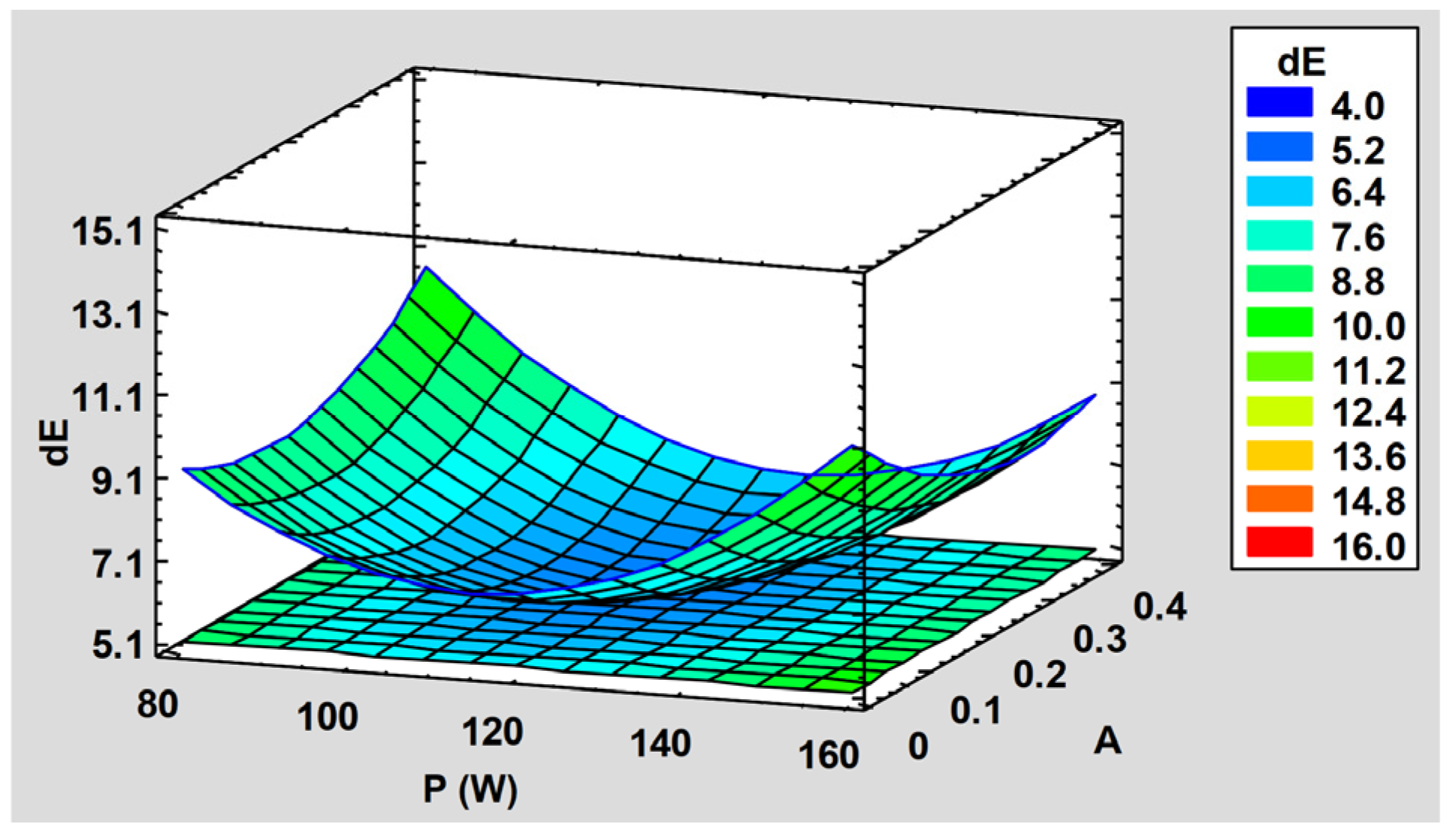

Function of Color Change (dE)

0.00207292P2 − 0.115313PA + 32.4792A2

3.3. Optimization of Deff, Sp and dE

3.3.1. Optimal Parameters and Indicators

- Drying temperature: T = 45.2 °C;

- Ultrasonic power: P = 127.7 W;

- Intermittency ratio: A = 0.18;

- Moisture diffusion coefficient: Deff = 5.23 × 10−10 m2/s;

- Saponin content: Sp = 96.4%;

- Color change: dE = 5.66;

3.3.2. Drying at Optimal Mode

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mierzwa, D.; Szadzińska, J.; Pawłowski, A.; Pashminehazar, R.; Kharaghani, A. Nonstationary convective drying of raspberries, assisted by microwaves and ultrasound. Dry. Technol. 2019, 37, 988–1001. [Google Scholar] [CrossRef]

- Szadzińska, J.; Mierzwa, D.; Pawłowski, A.; Musielak, G.; Pashminehazar, R.; Kharaghani, A. Ultrasound- and microwave-assisted intermittent drying of red beetroot. Dry. Technol. 2019, 38, 93–107. [Google Scholar] [CrossRef]

- Schössler, K.; Jäger, H.; Knorr, D. Effect of continuous and intermittent ultrasound on drying time and effective diffusivity during convective drying of apple and red bell pepper. J. Food Eng. 2012, 108, 103–110. [Google Scholar] [CrossRef]

- Schössler, K.; Jäger, H.; Knorr, D. Novel contact ultrasound system for the accelerated freeze-drying of vegetables. Innov. Food Sci. Emerg. Technol. 2012, 16, 113–120. [Google Scholar] [CrossRef]

- Ning, X.; Feng, Y.; Gong, Y.; Chen, Y.; Qin, J.; Wang, D. Drying features of microwave and far-infrared combination drying on white ginseng slices. Food Sci. Biotechnol. 2019, 28, 1065–1072. [Google Scholar] [CrossRef] [PubMed]

- Colucci, D.; Fissore, D.; Rossello, C.; Carcel, J.A. On the effect of ultrasound-assisted atmospheric freeze-drying on the antioxidant properties of eggplant. Food Res. Int. 2018, 106, 580–588. [Google Scholar] [CrossRef] [PubMed]

- Huang, D.; Men, K.; Li, D.; Wen, T.; Gong, Z.; Sunden, B.; Wu, Z. Application of ultrasound technology in the drying of food products. Ultrason. Sonochem. 2020, 63, 104950. [Google Scholar] [CrossRef] [PubMed]

- Tao, Y.; Zhang, J.; Jiang, S.; Xu, Y.; Show, P.-L.; Han, Y.; Ye, X.; Ye, M. Contacting ultrasound enhanced hot-air convective drying of garlic slices: Mass transfer modeling and quality evaluation. J. Food Eng. 2018, 235, 79–88. [Google Scholar] [CrossRef]

- Liu, Y.; Zeng, Y.; Wang, Q.; Sun, C.; Xi, H. Drying characteristics, microstructure, glass transition temperature, and quality of ultrasound-strengthened hot air drying on pear slices. J. Food Process. Preserv. 2019, 43, e13899. [Google Scholar] [CrossRef]

- Szadzińska, J.; Łechtańska, J.; Kowalski, S.J.; Stasiak, M. The effect of high power airborne ultrasound and microwaves on convective drying effectiveness and quality of green pepper. Ultrason. Sonochem. 2017, 34, 531–539. [Google Scholar] [CrossRef] [PubMed]

- Kroehnke, J.; Szadzińska, J.; Stasiak, M.; Radziejewska-Kubzdela, E.; Biegańska-Marecik, R.; Musielak, G. Ultrasound- and microwave-assisted convective drying of carrots—Process kinetics and product’s quality analysis. Ultrason. Sonochem. 2018, 48, 249–258. [Google Scholar] [CrossRef] [PubMed]

- Ning, X.; Han, C. Drying characteristics and quality of taegeuk ginseng (Panax ginseng C.A. Meyer) using far-infrared rays. Int. J. Food Sci. Technol. 2012, 48, 477–483. [Google Scholar] [CrossRef]

- Ning, X.; Lee, J.; Han, C. Drying characteristics and quality of red ginseng using far-infrared rays. J. Ginseng Res. 2015, 39, 371–375. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Merone, D.; Colucci, D.; Fissore, D.; Sanjuan, N.; Carcel, J. Energy and environmental analysis of ultrasound-assisted atmospheric freeze-drying of food. J. Food Eng. 2020, 283, 110031. [Google Scholar] [CrossRef]

- Yang, Z.; Yang, Z.; Yu, F.; Tao, Z. Ultrasound-assisted heat pump intermittent drying of adzuki bean seeds: Drying characteristics and parameter optimization. J. Food Process Eng. 2020, 43, e13501. [Google Scholar] [CrossRef]

- Zhang, Y.; Abatzoglou, N. Review: Fundamentals, applications and potentials of ultrasound-assisted drying. Chem. Eng. Res. Des. 2020, 154, 21–46. [Google Scholar] [CrossRef]

- Ministry of Public Health. Vietnamese Pharmacopoeia, 5th ed.; Medical Publshing House: Ha Noi, Vietnam, 2017.

- Cuevas, M.; Martínez-Cartas, M.L.; Pérez-Villarejo, L.; Hernández, L.; García-Martín, J.F.; Sánchez, S. Drying kinetics and effective water diffusivities in olive stone and olive-tree pruning. Renew. Energy 2018, 132, 911–920. [Google Scholar] [CrossRef]

- Crank, J. The Mathermatics of Diffusion, 2nd ed.; Oxford University Press: Oxford, UK, 1975. [Google Scholar]

- Kowalski, S.J.; Mierzwa, D.; Stasiak, M. Ultrasound-assisted convective drying of apples at different process conditions. Dry. Technol. 2017, 35, 939–947. [Google Scholar] [CrossRef]

| Number | Input Parameter | Output Parameter | ||||

|---|---|---|---|---|---|---|

| T (°C) | P (W) | A | Sp (%) | Deff (×10−10 m2/s) | dE | |

| 1 | 45 | 120 | 0.2 | 96.4 | 5.17 | 5.38 |

| 2 | 45 | 120 | 0.2 | 94.6 | 5.14 | 5.3 |

| 3 | 45 | 120 | 0.2 | 96.4 | 5.12 | 5.42 |

| 4 | 45 | 160 | 0.4 | 85.7 | 4.85 | 9.05 |

| 5 | 40 | 160 | 0.2 | 94.6 | 4.33 | 7.75 |

| 6 | 45 | 80 | 0.4 | 69.6 | 4.02 | 10.67 |

| 7 | 40 | 120 | 0.0 | 83.1 | 3.87 | 5.92 |

| 8 | 50 | 160 | 0.2 | 78.6 | 5.92 | 13.89 |

| 9 | 40 | 120 | 0.4 | 85.7 | 3.9 | 5.19 |

| 10 | 50 | 120 | 0.4 | 55.4 | 5.43 | 11.84 |

| 11 | 40 | 80 | 0.2 | 92.9 | 3.81 | 7.3 |

| 12 | 45 | 80 | 0.0 | 94.1 | 4.39 | 9.07 |

| 13 | 45 | 160 | 0.0 | 90.5 | 5.1 | 11.14 |

| 14 | 50 | 80 | 0.2 | 83.9 | 5.32 | 14.25 |

| 15 | 50 | 120 | 0.0 | 78.1 | 5.67 | 12.17 |

| Drying Regime at Optimum Parameter T = 45.2 °C; P = 127.7 W; A = 0.18 | |||

|---|---|---|---|

| Optimum Criteria | Theory | Experiment | Error (%) |

| Deff (×10−10 m2/s) | 5.23 | 5.05 | 3.44 |

| Sp (%) | 96.4 | 94.1 | 2.39 |

| dE | 5.66 | 5.40 | 4.59 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nguyen, H.; Le, Q.-H.; Le, T.-D.; Pham, V.-K. Experimental Research to Determine the Effect of Ultrasound in Drying Bo Chinh Ginseng by Ultrasound-Assisted Heat Pump Drying Method. Appl. Sci. 2022, 12, 11525. https://doi.org/10.3390/app122211525

Nguyen H, Le Q-H, Le T-D, Pham V-K. Experimental Research to Determine the Effect of Ultrasound in Drying Bo Chinh Ginseng by Ultrasound-Assisted Heat Pump Drying Method. Applied Sciences. 2022; 12(22):11525. https://doi.org/10.3390/app122211525

Chicago/Turabian StyleNguyen, Hay, Quang-Huy Le, Thanh-Dat Le, and Van-Kien Pham. 2022. "Experimental Research to Determine the Effect of Ultrasound in Drying Bo Chinh Ginseng by Ultrasound-Assisted Heat Pump Drying Method" Applied Sciences 12, no. 22: 11525. https://doi.org/10.3390/app122211525

APA StyleNguyen, H., Le, Q.-H., Le, T.-D., & Pham, V.-K. (2022). Experimental Research to Determine the Effect of Ultrasound in Drying Bo Chinh Ginseng by Ultrasound-Assisted Heat Pump Drying Method. Applied Sciences, 12(22), 11525. https://doi.org/10.3390/app122211525