A Novel Fluorescent-Material-Based Simple Method for Sunscreen Evaluation

Abstract

1. Introduction

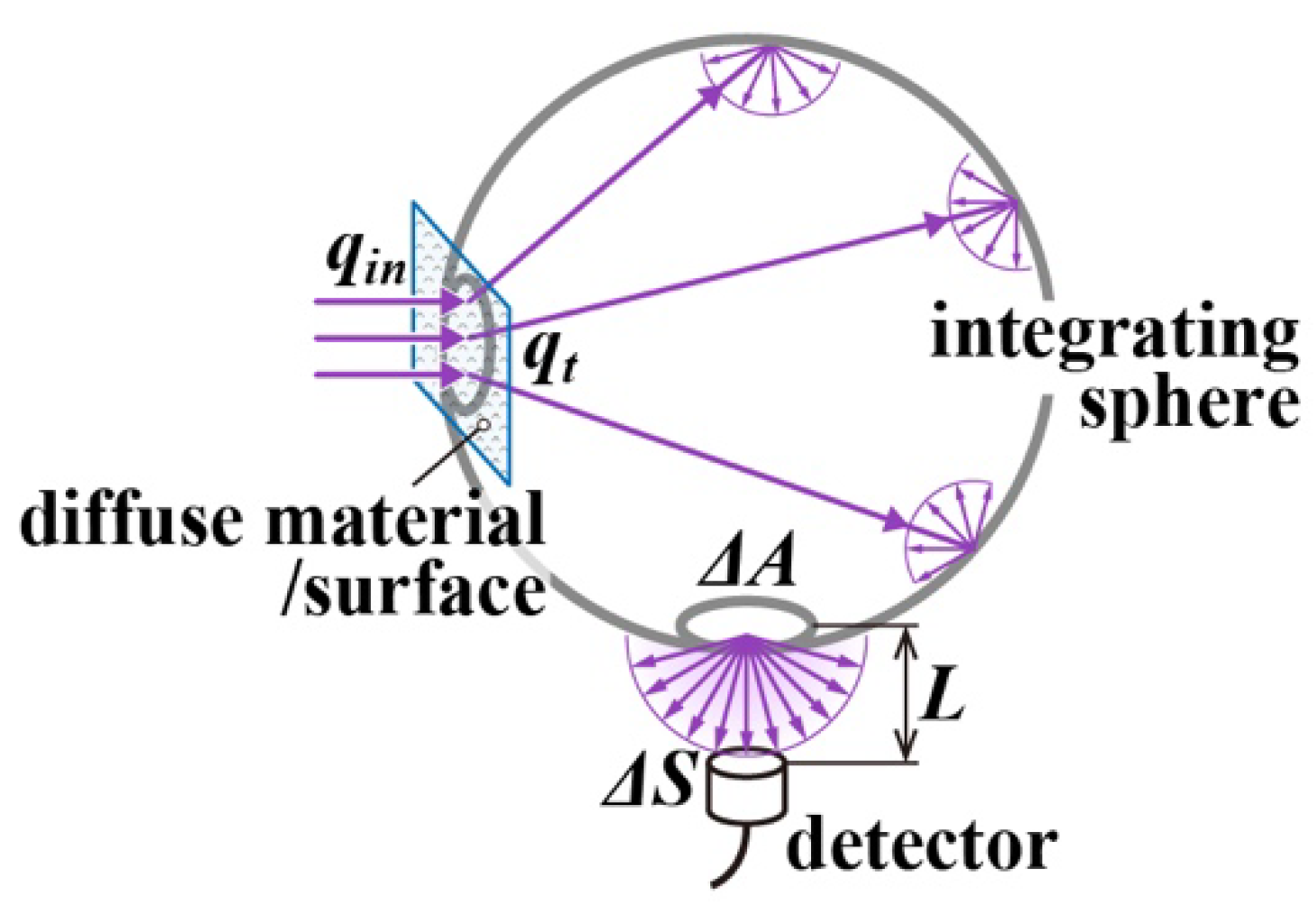

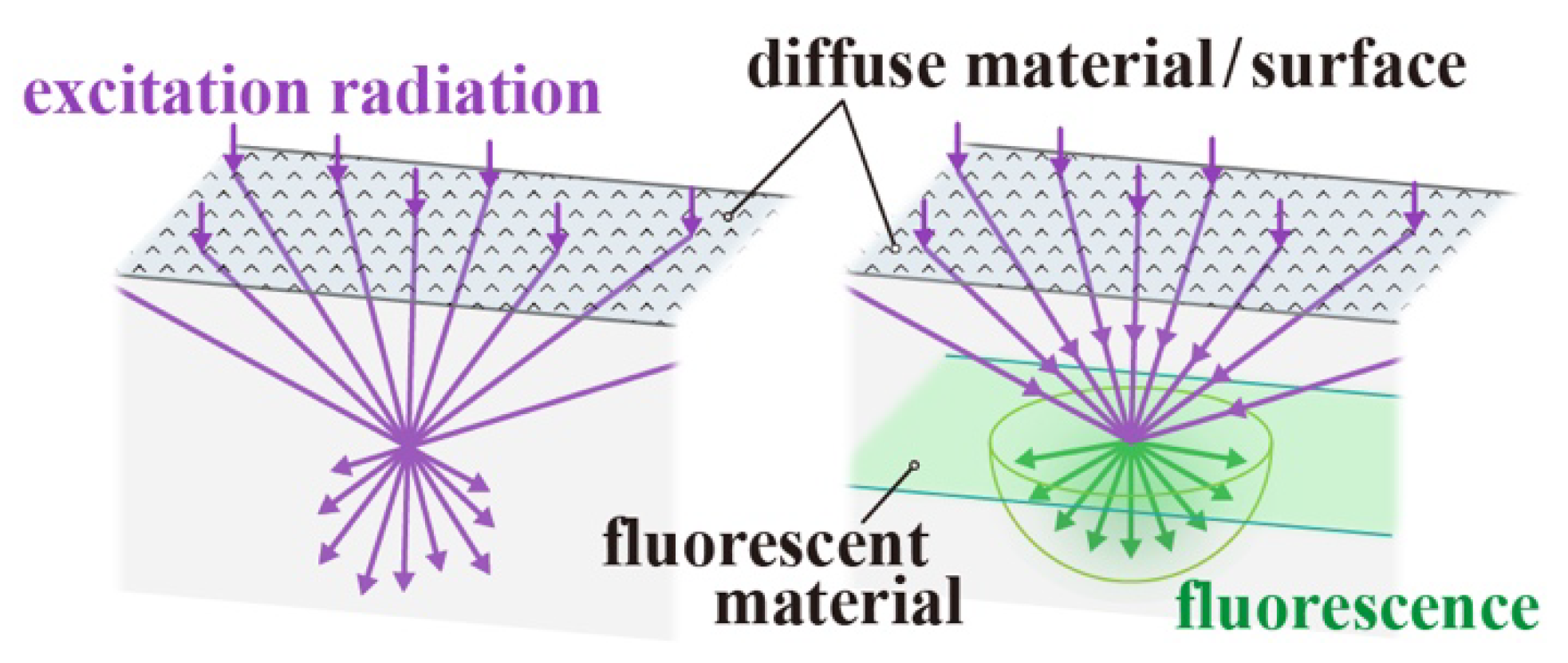

2. Concept of Proposed Measurement Method

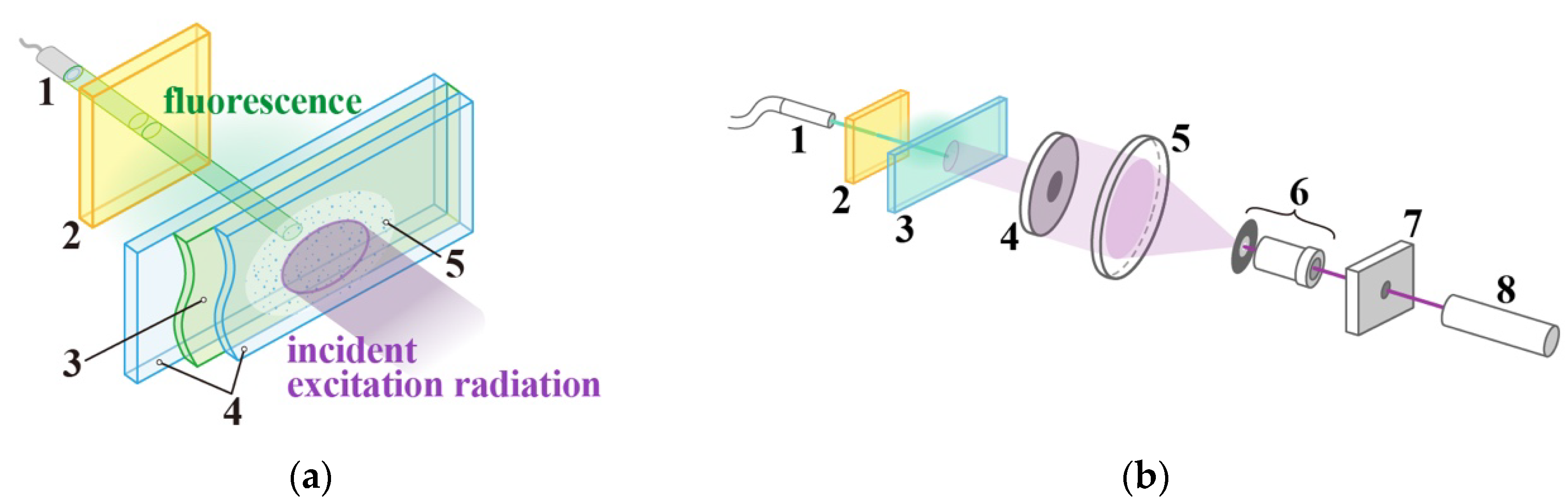

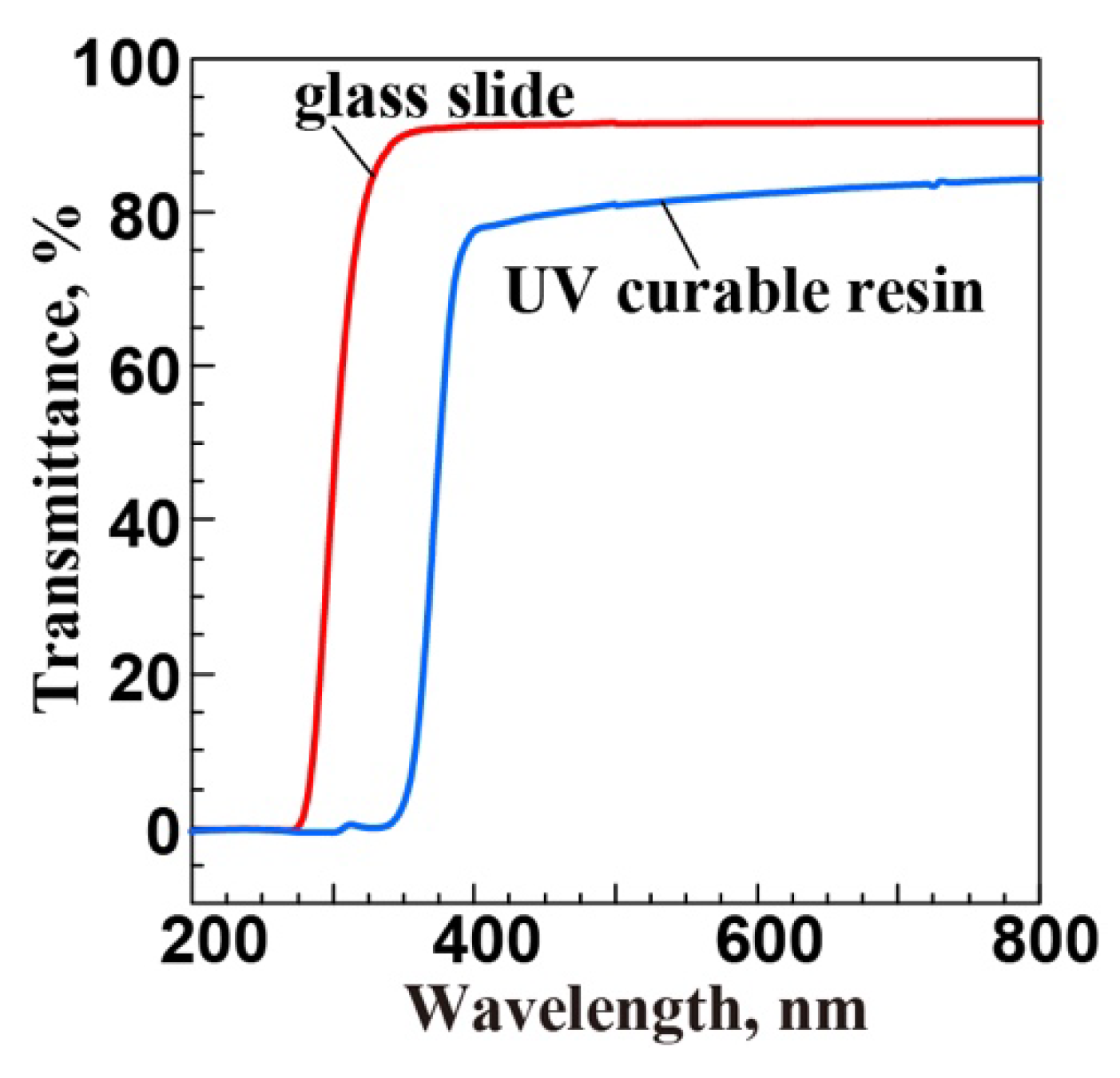

3. Measurement System

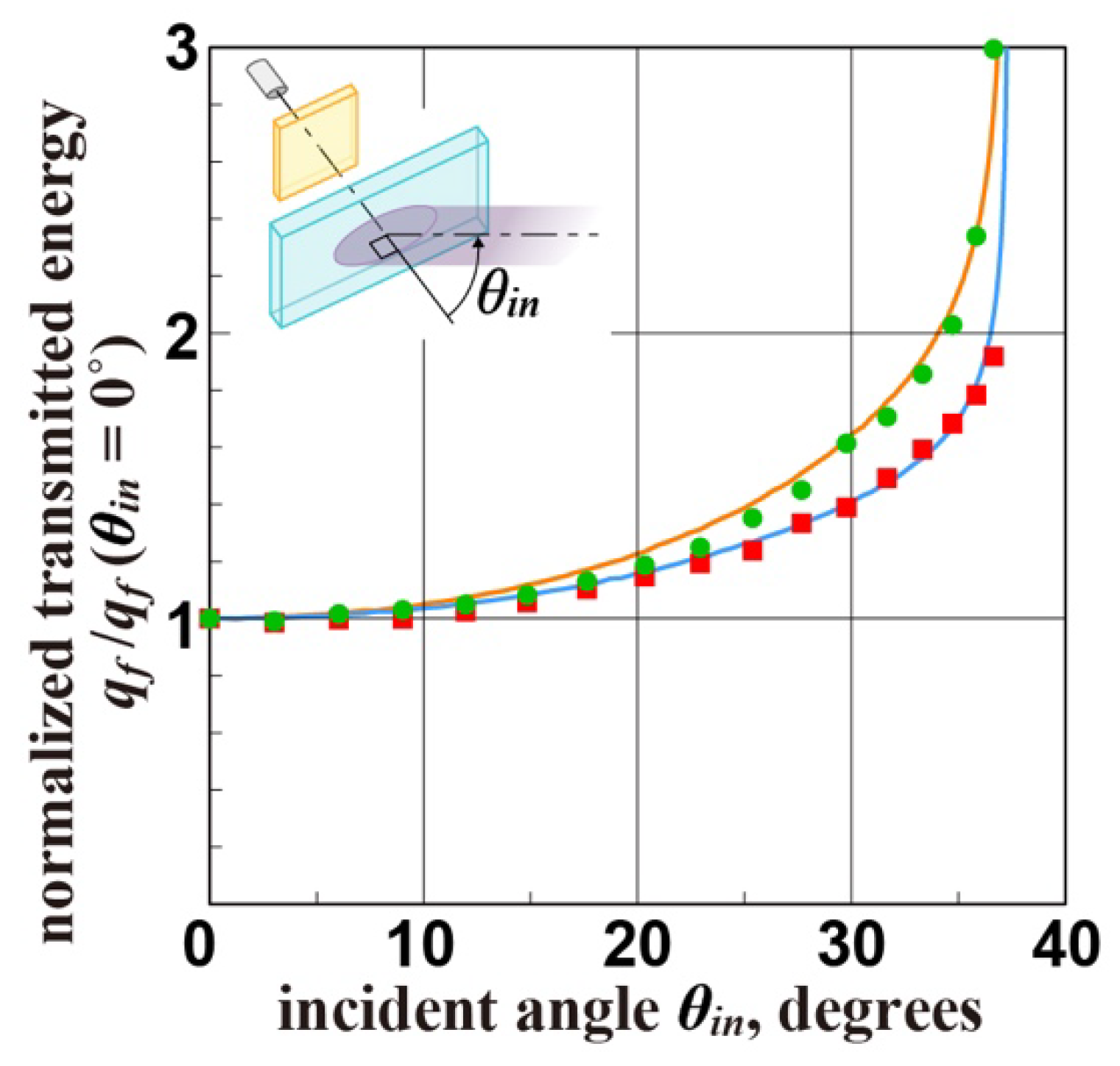

4. Validation of Proposed Method

4.1. Validation Procedures

4.2. Experiments

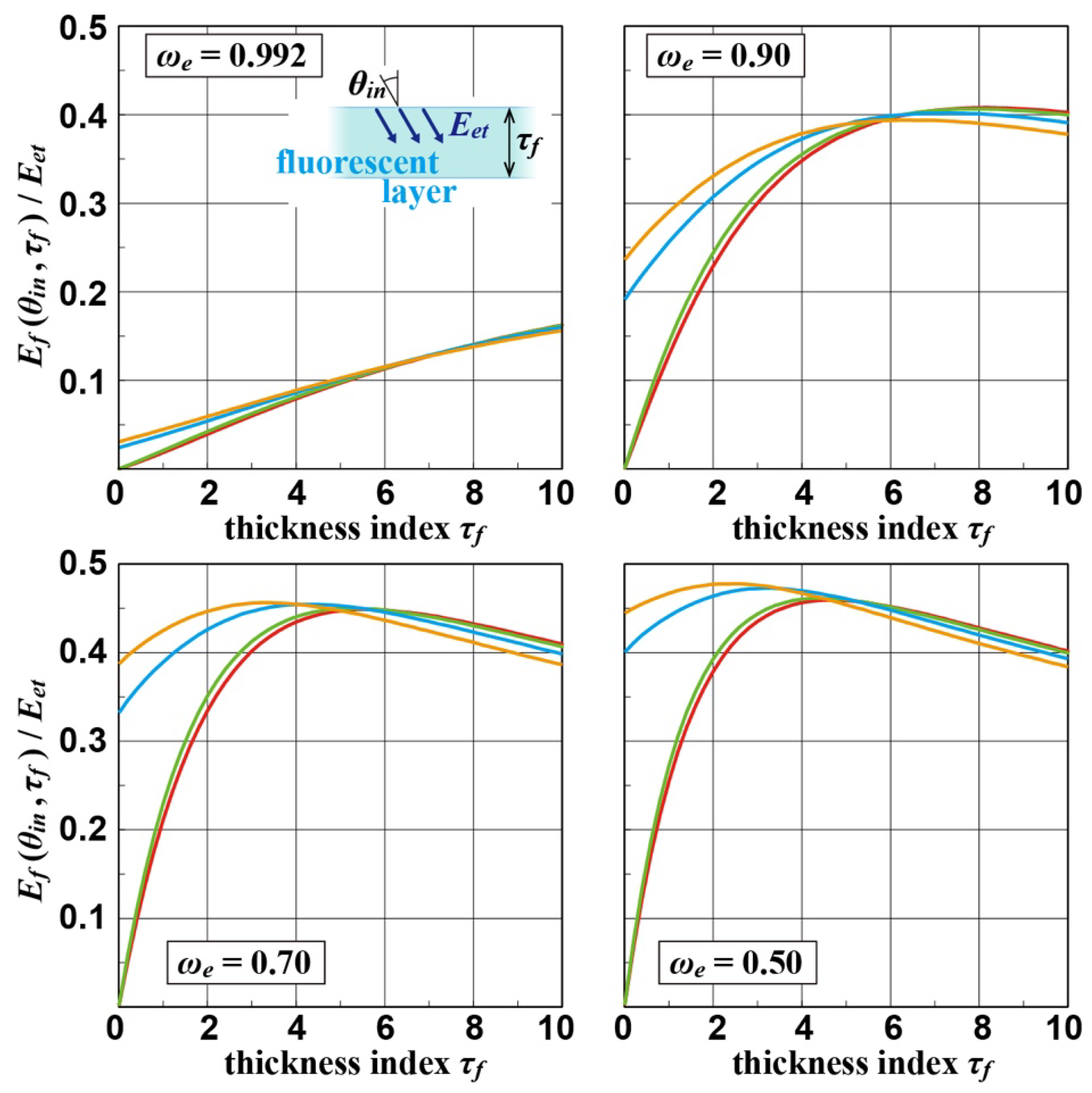

4.3. Numerical Analysis

5. Results and Discussions

5.1. Regarding the Validation

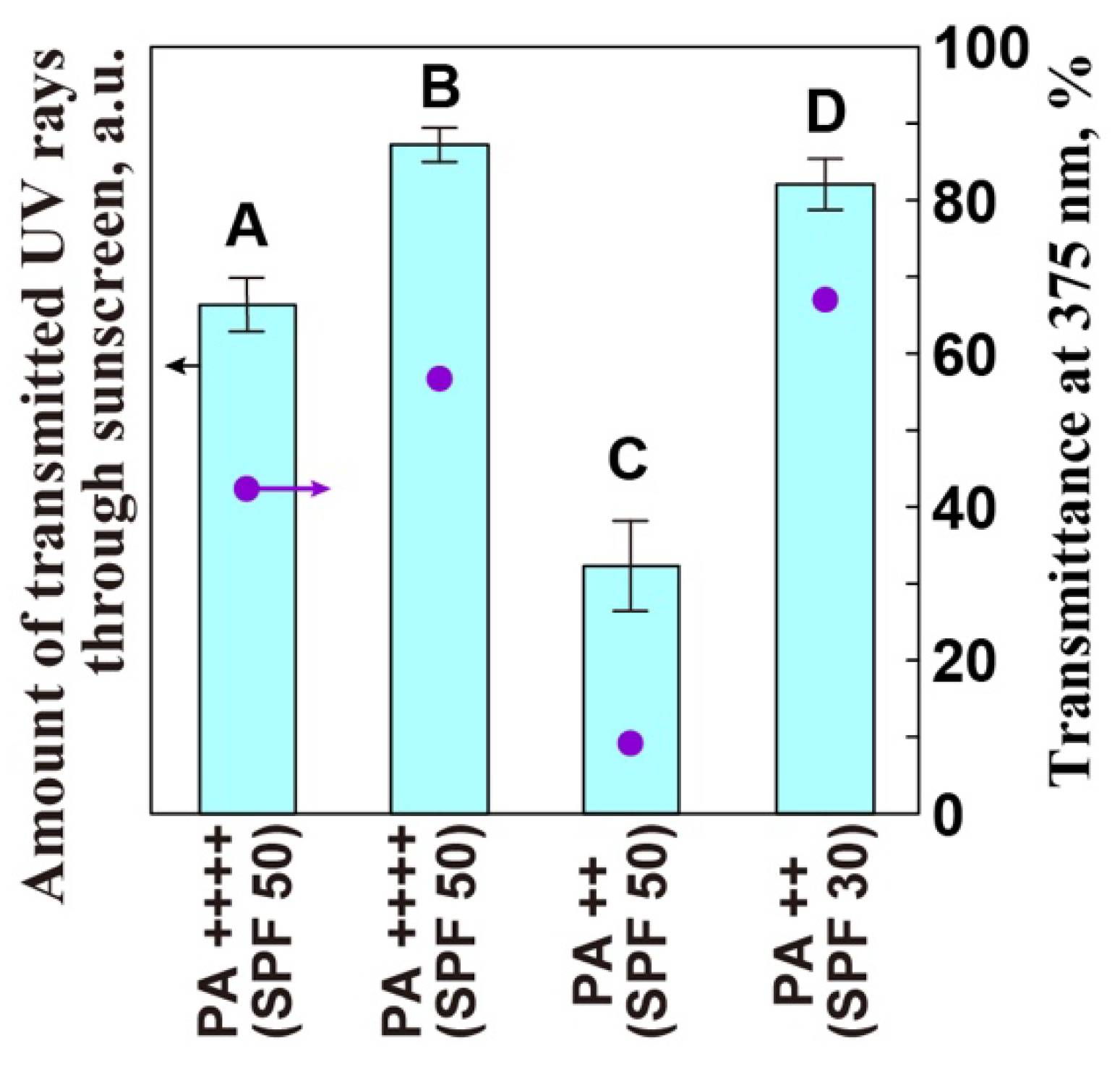

5.2. Evaluation of Sunscreens

6. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| q | radiative flux, W·m−2 |

| I | radiative intensity, W·m−2·sr−1 |

| E | radiation energy, W |

| Φ | scattering phase function |

| Ω | solid angle, sr |

| θ | polar angle, degrees |

| φ | azimuthal angle, degrees |

| n | refractive index |

| τ | coordinate along the direction of the distance and thickness indices of the fluorescent layer |

| ω | albedo |

| β | extinction coefficient, mm−1 |

| σ | scattering coefficient, mm−1 |

| α | absorbing coefficient, mm−1 |

| x | actual distance, mm |

| Q | fluorescent yield |

| R | hemispherical reflectance |

| T | hemispherical transmittance |

| Subscripts | |

| s | scattering/absorbing sample |

| e | excitation light |

| f | fluorescent |

| t | transmitted |

| in | incident |

References

- Moyal, D. UVA protection labeling and in vitro testing methods, Photochem. Photobiol. Sci. 2010, 9, 516–523. [Google Scholar] [CrossRef] [PubMed]

- Sato, K. Sun protection test methods–Current situation and future issues of measurement and labeling of SPF and PA. J. Jpn. Cosmet. Sci. Soc. 2017, 41, 44–48. (In Japanese) [Google Scholar] [CrossRef]

- Gollavilli, H.; Hegde, A.R.; Managuli, R.S.; Bhaskar, K.V.; Dengale, S.J.; Reddy, M.S.; Kalthur, G.; Mutalik, S. Naringin nano-ethosomal novel sunscreen creams: Development and performance evaluation. Colloids Surf. B 2022, 193, 111122. [Google Scholar] [CrossRef]

- Ionescu, M.A.; Gougerot, A. Sun protection and sunscreen labeling—An update. Acta Dermatovenerol. Croat 2007, 15, 92–95. [Google Scholar]

- Code of Federal Regulations. Available online: https://www.ecfr.gov/current/title-21/chapter-I/subchapter-C/part-201/subpart-G/section-201.327#p-201.327(c) (accessed on 1 September 2022).

- ISO 24444:2019(en) Cosmetics—Sun Protection Test Methods—In Vivo Determination of the Sun Protection Factor (SPF). Available online: https://www.iso.org/obp/ui/#iso:std:iso:24444:ed-2:v1:en (accessed on 13 September 2022).

- ISO 24442:2022(en) Cosmetics—Sun Protection Test Methods—In Vivo Determination of Sunscreen UVA Protection. Available online: https://www.iso.org/obp/ui/#iso:std:iso:24442:ed-2:v1:en (accessed on 13 September 2022).

- Lakhdar, H.; Zouhair, K.; Khadir, K.; Essari, A.; Richard, A.; Seité, S.; Rougier, A. Evaluation of the effectiveness of a broad-spectrum sunscreen in the prevention of chloasma in pregnant women. J. Eur. Acad. Dermatol. Venereol. 2007, 21, 738–742. [Google Scholar] [CrossRef]

- Ohkubo, K. Integrating sphere theory for measuring optical radiation. J. Light Visual Environ. 2010, 34, 111–122. [Google Scholar] [CrossRef][Green Version]

- Clarke, F.J.J.; Larkin, J.A. Measurement of total reflectance, transmittance and emissivity over the thermal ir spectrum. Infrared Phys. 1985, 25, 359–367. [Google Scholar] [CrossRef]

- Pickering, J.W.; Prahl, S.A.; Wieringen, N.; Beek, J.F.; Sterenborg, H.J.C.M.; Gemert, M.J.C. Double-integrating-sphere system for measuring the optical properties of tissue. Appl. Opt. 1993, 32, 399–410. [Google Scholar] [CrossRef]

- Roos, A. Use of an integrating sphere in solar energy research. Sol. Energy Mater Sol. Cells 1993, 30, 77–94. [Google Scholar] [CrossRef]

- Yaroslavsky, I.V.; Yaroslavsky, A.N.; Goldbach, T.; Schwarzmaier, H.J. Inverse hybrid technique for determining the optical properties of turbid media from integrating-sphere measurements. Appl. Opt. 1996, 35, 6797–6809. [Google Scholar] [CrossRef]

- Chin, J.; Byrd, E.; Embree, N.; Garver, J.; Dickens, B.; Finn, T.; Martin, J. Accelerated UV weathering device based on integrating sphere technology. Rev. Sci. Instrum. 2004, 75, 4951–4959. [Google Scholar] [CrossRef]

- Gaigalas, A.K.; Wang, L. Measurement of the fluorescence quantum yield using a spectrometer with an integrating sphere detector. J. Res. Natl. Inst. Stand. Technol. 2008, 113, 17–28. [Google Scholar] [CrossRef] [PubMed]

- Zhong, M.; Jang, M. Light absorption coefficient measurement of SOA using a UV-Visible spectrometer connected with an integrating sphere. Atmospheric Environ. 2011, 45, 4263–4271. [Google Scholar] [CrossRef]

- Rehman, A.; Ahmad, I.; Qureshi, S.A. Biomedical applications of integrating sphere: A review. Photodiagnosis Photodyn. Ther. 2020, 31, 101712. [Google Scholar] [CrossRef] [PubMed]

- Pettit, R.B. Hemispherical transmittance properties of solar glazings as a function of averaging procedure and incident angle. So. Energy Mater. 1979, 1, 125–140. [Google Scholar] [CrossRef]

- Zerlaut, G.A.; Anderson, T.E. Multiple-integrating sphere spectrophotometer for measuring absolute spectral reflectance and transmittance. Appl. Opt. 1981, 20, 3797–3804. [Google Scholar] [CrossRef]

- Kessel, J. Transmittance measurements in the integrating sphere. Appl. Opt. 1986, 25, 2752–2756. [Google Scholar] [CrossRef]

- Hanssen, L.M. Effects of non-Lambertian surfaces on integrating sphere measurements. Appl. Opt. 1996, 35, 3597–3606. [Google Scholar] [CrossRef]

- Prokhorov, A.V.; Mekhontsev, S.N.; Hanssen, L.M. Monte Carlo modeling of an integrating sphere reflectometer. Appl. Opt. 2003, 42, 3832–3842. [Google Scholar] [CrossRef]

- Foschum, F.; Bergmann, F.; Kienle, A. Precise determination of the optical properties of turbid media using an optimized integrating sphere and advanced Monte Carlo simulations. Appl. Opt. 2020, 59, 3203–3215. [Google Scholar] [CrossRef]

- Brewster, M.Q. Thermal Radiative Transfer and Properties, 1st ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 1992; pp. 39–53. [Google Scholar]

- Hernández-Rivera, D.; Torres-Landa, S.D.; Rangel-Ayala, M.; Agarwal, V. Fluorescent films based on PVDF doped with carbon dots for evaluation of UVA protection of sunscreens and fabrication of cool white LEDs. RSC Adv. 2021, 11, 32604–32614. [Google Scholar] [CrossRef] [PubMed]

- Garoli, D.; Pelizzo, M.G.; Nicolosi, P.; Peserico, A.; Tonin, E.; Alaibac, M. Effectiveness of different substrate materials for in vitro sunscreen tests. J. Dermatol. Sci. 2009, 56, 89–98. [Google Scholar] [CrossRef] [PubMed]

- Siegel, R.; Howell, J.R. Thermal Radiation Heat Transfer, 3rd ed.; Taylor & Francis: Oxfordshire, UK, 1992; pp. 513–588. [Google Scholar]

- Wakabayashi, M.; Okano, K.; Mukawa, T.; Maezawa, D.; Masaki, H.; Kuroda, A.; Asakura, K. Problems on the Evaluation of the Critical Wavelength of Sunscreens for “Broad Spectrum” Approval Brought on by Viscous Fingering During Sunscreen Application. Photochem. Photobiol. 2016, 92, 637–643. [Google Scholar] [CrossRef] [PubMed]

| Fluorescent Material Concentration in Fluorescent Layer | ||

|---|---|---|

| 20 wt% | 30 wt% | |

| ωe | 0.992 | 0.992 |

| τf | 0.18 | 0.35 |

| g | 0.75 | 0.65 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nakamura, K.; Kono, T.; Rajagopalan, U.M.; Yamada, J. A Novel Fluorescent-Material-Based Simple Method for Sunscreen Evaluation. Appl. Sci. 2022, 12, 11521. https://doi.org/10.3390/app122211521

Nakamura K, Kono T, Rajagopalan UM, Yamada J. A Novel Fluorescent-Material-Based Simple Method for Sunscreen Evaluation. Applied Sciences. 2022; 12(22):11521. https://doi.org/10.3390/app122211521

Chicago/Turabian StyleNakamura, Kae, Takahiro Kono, Uma Maheswari Rajagopalan, and Jun Yamada. 2022. "A Novel Fluorescent-Material-Based Simple Method for Sunscreen Evaluation" Applied Sciences 12, no. 22: 11521. https://doi.org/10.3390/app122211521

APA StyleNakamura, K., Kono, T., Rajagopalan, U. M., & Yamada, J. (2022). A Novel Fluorescent-Material-Based Simple Method for Sunscreen Evaluation. Applied Sciences, 12(22), 11521. https://doi.org/10.3390/app122211521