Abstract

The present study assessed the Bailey Bridge’s condition and investigated its adaptation as a permanent structure, targeted the Acrow Bailey Bridge in Japan. Field diagnostic loading experiments were performed under various loading conditions, such as dynamic and static loading tests. The onsite data were obtained using a transducer, friction strain gauge, target measurements for the image processing approach, and accelerometer. From the field measurements, the deflection and stresses of the bridge were found to operate within the linear elastic region. The bridge was then accurately modeled based on the in situ geometric configuration of the bridge, and Finite Element Analysis was performed. The model’s accuracy was validated with the onsite data under the linear elastic domain. The model was deployed to check for resistance of critical members. A nonlinear analysis based on the linear and nonlinear buckling method was performed to determine the subject bridge’s Serviceability Limit State and Ultimate Limit State. The results showed that the first out-of-plane eigenvalue buckling analysis could monolithically assess bridge members. Further, the study established digital twin models resolve for historical data through in situ modeling measurements. Therefore, the findings obtained in this study highlight the bridge’s Structural Health Condition, bearing capacity, and propose a framework for adaptation as a permanent structure.

1. Introduction

1.1. Background

A Bailey Bridge is a prefabricated truss bridge type whose symmetrically bending moments vary from maximum to zero from the center span to the end posts. This aspect is fundamental during their design because the end bays are not entirely used, exposing the center bays to maximum stress [1]. Bailey Bridges were initially meant for military use. However, their benefits have been diversified from temporary to semi-permanent or permanent due to their ease of transportation, low cost, flexible structural form, onsite fabrication, and versatility in accommodating various loading requirements [2]. The panel elements are interchangeable, making them easy to assemble by pinning the components under different configurations. It takes at least 40 min for a simple combination of double truss employing the cantilever launching method short of falsework [3]. Structural degradation due to loss of parts is expected; primarily, loose pins that readjust during the dynamic movement of traffic have been reported. Additionally, they are subject to maintenance issues and lack of historical data [4], such as the bearing capacity. Therefore, it is advisable to assess their structural integrity.

To verify the load-bearing performance of an actual Bailey Bridge, Yi et al. [4] King et al. [5] and Khounsida et al. [2,6] are hereafter worth mentioning. The authors [2,4,6] exploited the Diagnostic load test using Dynamic and Static Loading (DSL) to certify the bearing capacity for both in-service [2,6] and out-of-service bridges [4]. Diagnostic load testing is meant to assess the structural response of a bridge, and update or calibrate an analytical model for decision-making. The calibrated model is then deployed to evaluate the load rating factors, particularly to determine load rating and safety. Conventionally, the loads applied are below the bridge’s capacity—similar to serviceability limit state conditions; hence larger loads are extrapolated. Consequently, Yi et al. established that the design drawing was unavailable during the load rating of the ‘Engineers Bridge’ pinned arch bridge. Three targets were selected, ¼ span, mid-span, and ¾ span, to establish deflection using a total station with an accuracy of 0.2 mm. The author modeled the bridge using existing onsite geometry for the bridge to be analytically examined and compared the deflection results with field measurements. The author went further and established the load rating based on the serviceability and ultimate limit of the bridge using the current codes, demonstrating an approach for establishing the bearing capacity [4]. On the other hand, King et al. found that to evaluate the structural response of a Bailey-type Bridge, actual loading conditions should be tested, and a numerical model employed to examine the nonlinear response. Under laboratory testing the author used a 130-t Universal dynamic Servo-hydraulic Tester to simulate various loading conditions and Linear Variable Differential Transformer (LVDT) displacement sensor to monitor deflections [5]. Further, Khounsida et al. determined the Bailey Bridge response through onsite experimentations and structural analysis of a bridge in Laos [6]. The author acquired on-site data statically by displacement transducers and total station, and dynamically using an accelerometer positioned at optimum locations along the girders for maximum deflection. In each of these studies, the evaluation of load-bearing performance by linear or nonlinear finite element analysis of digital twins is based on actual and on-site member measurements. Therefore, it is thought that appropriate maintenance and management of a permanent bridge can be performed by clarifying the bearing capacity and ensuring the conversion from a temporary bridge to a permanent bridge.

The present study aims to assess a Bailey Bridge’s condition and investigate its adaptation as a permanent structure. The Sukumo bridge was targeted, the only Bailey Bridge type in Uchiko Town, Shikoku Island, Japan. First, diagnostic loading field experiments were performed through DSL tests to examine the static and dynamic behavior of the Sukumo bridge. The structural responses were determined both statically and dynamically. The LVDT displacement transducer and image processing approach assessed the deflection on static loading conditions, while the Micro-electromechanical Systems (MEMs) accelerometer for dynamic loading deflection [7,8]. Frictional strain gauges [9,10] accounted for the strains. Then, the bridge’s Finite Element Analysis (FEA) model (digital twin) was developed, and its validation was confirmed compared to the field measurement results. Further, nonlinear analysis was performed using the validated model to examine the load bearing capacity of the Sukumo Bailey Bridge. Based on these, the possibility of adaptation of the Sukumo bridge as a permanent structure was evaluated.

1.2. Bailey Bridge Structural Characteristics

Numerous bridges have been made from the typical Bailey Bridge panel using different designs and material strengths:

1.2.1. First Generation

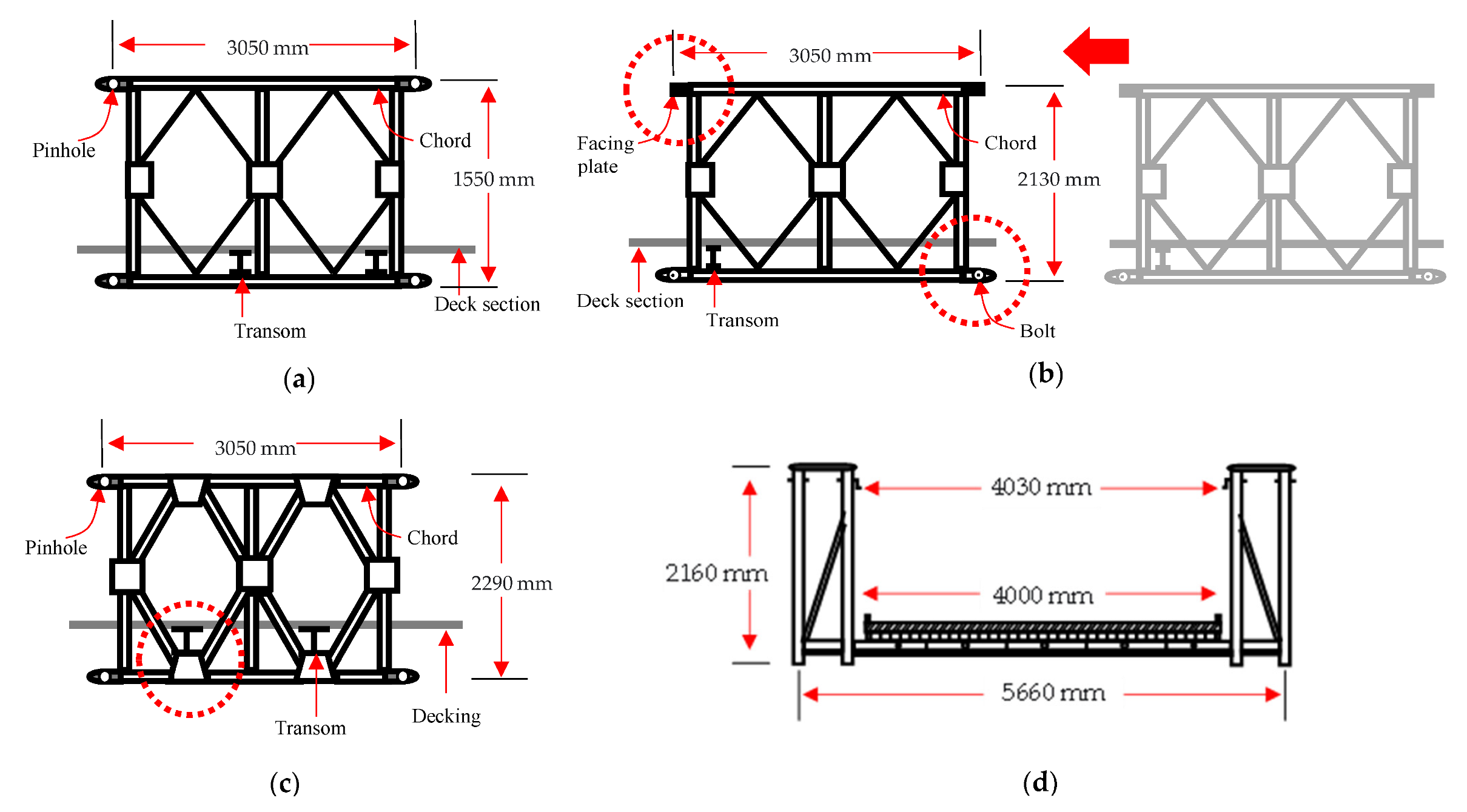

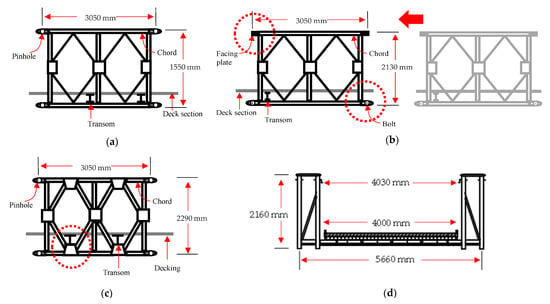

The Bailey Bridge was designed by Sir Donald Bailey and patented in 1943 [3,4]. It was the basis for the current modular bridge. The bridge was a transportable, prefabricated truss bridge realized by developing new construction methods and panel connection systems from the Callender-Hamilton Bridge [11,12]. Each member of the Bailey Bridge is standardized, as shown in Figure 1a. Depending on the span length and the number of lanes, the strength of the girders can be increased by stacking multiple panels of typical dimensions 3050 mm × 1550 mm or connecting them vertically. In addition, it uses hollow high-grade, lightweight steel material that can be transported manually and does not require special tools. The first-generation Bailey Bridges are classified into M1, M2, and M3. Bailey M1 is the initial type, while the predecessor Bailey M2 was designed by widening the road by 12% feet, and Bailey M3 was an improvement of Bailey M2 [13].

Figure 1.

(a) Typical Bailey Bridge, (b) Mabey Bailey Bridge, (c) Acrow Bailey Bridge and (d) M2 typical end shear/post.

1.2.2. Second Generation

After the Bailey Bridge patent expired in 1970, Thos Storey Engineers Ltd. and Mabey Johnson Ltd. introduced the Acrow 1, Acrow 500, and Mabey Super Bailey & Compact 100 in that order. The Acrow 1 Bailey Bridge had a diamond panel configuration with the transom moving in the diamond panel. It was conspicuous due to its method of eliminating stress related to pinhole sag and global deflection due to the diamond configuration. The design could accommodate two transoms per panel. On the other hand, the Acrow 500, introduced in 1987, used a single universal transom at each bay, retaining its panel dimension illustrated in Figure 1c. The Mabey Super Bailey was introduced in 1967 with improved detail and strength than the typical Bailey but with similar panel dimensions [11]. The lower chords panel used bolts and facing plates on the top chord for strength. Its predecessor, the Mabey Compact 100 [13,14], used high-grade steel and channel sections as bracing frames with one transom per panel. The second generation of the Bailey Bridge is lighter than the original Bailey Bridge and uses the same end post configuration with varying dimension as the M2-type typical Bailey Bridge demonstrated in Figure 1d—measurements from site.

1.2.3. Third Generation

The Mabey Compact 200 and Acrow 700 came with increased panel depth, approximately 50% higher panel height, and 20% more potent in shear than the original Bailey Bridge demonstrated in Figure 1b,c. The depth improved its stability and potential to accommodate a wider roadway of 7.3 m. Mabey Compact 200 was used during the construction of the Baker bridge in 2009 in Cambria, Britain. The Acrow 500 was replaced with the Acrow 700, later adopted as Acrow 700XS [11]. The Acrow 700XS were assembled for recovery efforts at ground zero of the World Trade Center, during the terrorist attack, in record time. The structure was erected on prefabricated piers, moving a record 1.8 million tons of debris. Additionally, it was also operational during the rebuilding process. On the other hand, New Jersey Turnpike Authority employed the 700 series to create a diversion during the upgrade of the existing bridge in a record 15 min [11].

2. Field Experiment

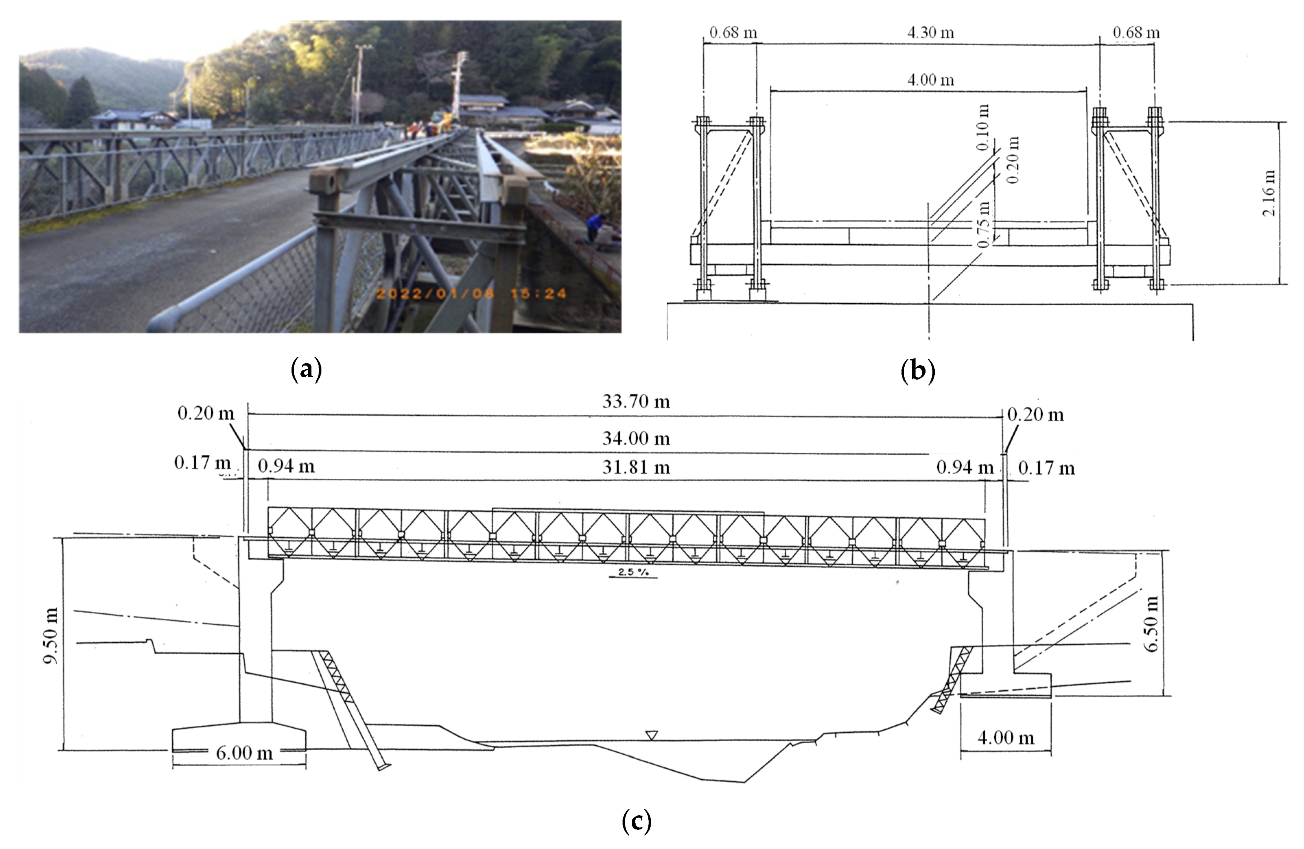

2.1. Target Bailey Bridge

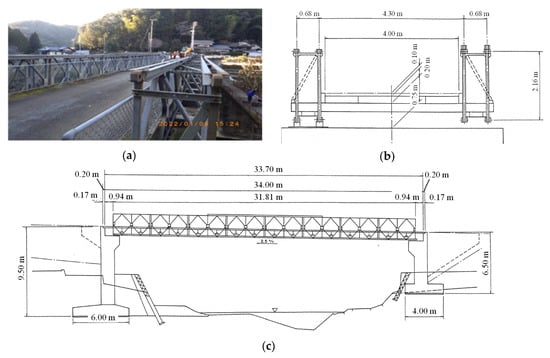

Figure 2 shows the target Bailey Bridge referred to as the Sukumo Bailey Bridge. The bridge is in Uchiko Town, Kita District, Ehime Prefecture, along the junction of Route 56 highway. The bridge was built in 1997 as a temporary structure to serve as an access for constructing one of the Matsuyama Expressway (E56) piers across the Nakayama River. The bridge spans 31.81 m, having a carriage width of 4.0 m, as shown in Figure 2a–c. The bridge has an alleged loading capacity of 25 T, sourced from interviews with Uchiko Town municipal offices. It is a third-generation Bailey Bridge Acrow type Double Single Reinforced (DSR), with a panel of 3.976 and 2.134 m, length, and height, respectively.

Figure 2.

(a) Sukumo bridge. (b) The front view—end shears/posts. (c) The side view—panel sections.

2.2. Load Test

Load tests were performed statically and dynamically to examine the static and dynamic behavior of the Sukumo Bridge. Before the loading tests, three types of loading cases were selected, not to exceed the Sukumo bridge’s presumed loading capacity (i.e., 25 Tons). It was assumed that the loads chosen were within the elastic region.

Equation (1) summarizes the approach for load selection. A bridge (Bailey) has an elasticity range that departs from its linear elastic region when the applied loads exceed its bearing capacity. This principle is critical in the structure’s bearing capacity that dictates its capacity—Serviceability Limit State (SLS). Hence, it refrains the structure from plastically deforming (aid in predicting various effects of load on a structure) when the loads are beyond the design capacity—Ultimate Limit State (ULS). The decking joints are critical, considering they receive the full effect of dynamic hammering of loads; it is prudent not to exceed the design tolerance [5,6]. Therefore, the choice of loads was dictated by the principle of superposition summarized in Equation (1), where δi-n denoted displacement (mm), Fi-n denoted Load (Tons), and m denoted slope.

Table 1 shows the three types of loading cases. Loading cases are 1 was a car whose weight was 1.57 Tons, 2 was a Truck whose weight was 12.24 Tons, and 3 was a crane whose weight was 19.66 Tons, excluding the average weight of the driver weighing 55 kg. These weights were loaded statically and dynamically onto the bridge. After this, the loading conditions are explained in detail.

Table 1.

Three types of loading cases.

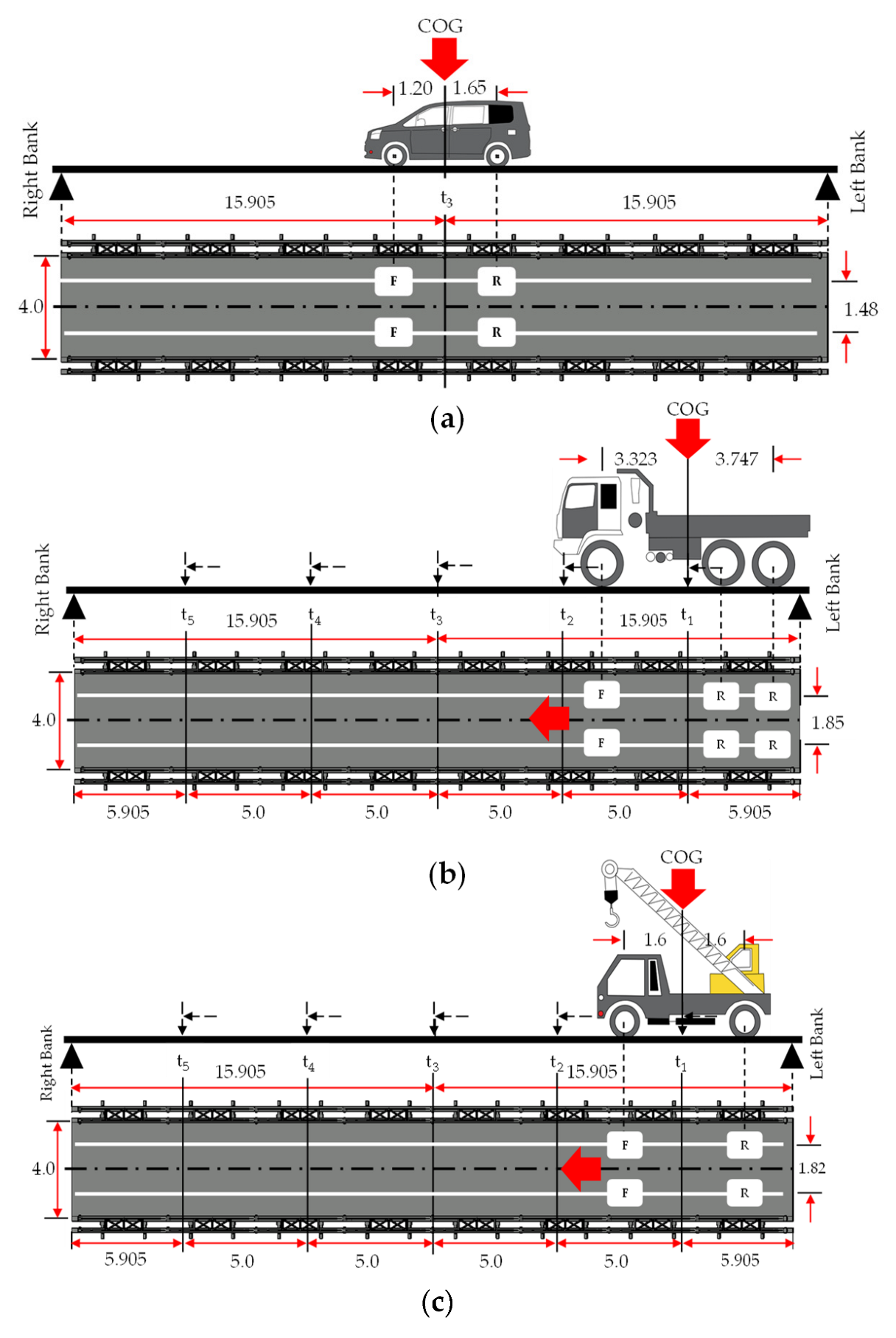

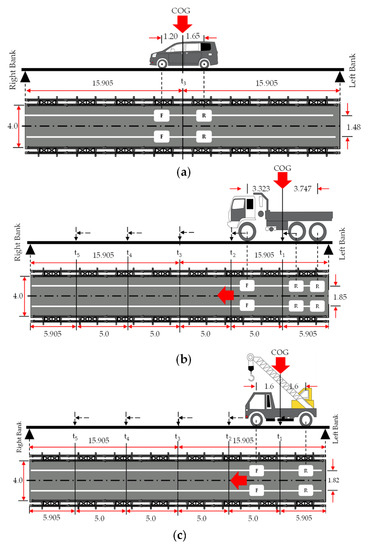

2.2.1. Static Loading Condition

Figure 3 shows the static loading conditions. Due to the constrained width of the structure, 4.0 m; symmetrical loading was limited. Hence, the Load’s Center of Gravity (COG) was established from the load axles for optimum positioning of the load cases, as shown in Figure 3. The bridge deck was demarcated widthwise 0.74, 0.93, and 0.91 m from the center of the lane, as illustrated in Figure 3. The dimensions were based on the loading cases. Lengthwise, the structure was divided into 6 sections with 5 targets at 5.0–5.905 m along the bridge t1 to t5. Loading case 1 was set at the mid-span of the Sukumo Bridge (t3), while loading cases 2 and 3 were set at targets t1 to t5, ensuring the axles COG coincides with the target axis as indicated in Figure 3a–c.

Figure 3.

Static loading conditions (unit: m): (a) Loading case 1; the target set at midspan (t3) for measurement of displacement; Metadata: Car, wheel spacing of 1.48 m and axle spacing of 2.85 m. (b) Loading case 2; targets are set along the bridge span t1–t5; metadata: Truck, wheel spacing of 1.85 m and axle spacing of 5.7 or 1.37 m. (c) Loading case 3; targets are set along the bridge span t1–t5; metadata: Crane, wheel spacing of 1.82 m, and axle spacing of 3.20 m.

2.2.2. Dynamic Loading Condition

The dynamic load test under ambient conditions was conducted such that the car, truck, and crane drove over the bridge from the left to right banks of the span portrayed in Figure 3. RL and LR denoted the situation from the Right bank to the Left bank and vice versa. During the dynamic loading test, a minimum velocity of 3 km/h and a maximum of 20 km/h was maintained to establish the global dynamic behavior of the bridge.

2.3. Measurement Plan

The underlying reason for instrumenting [15] the bridge was to examine the response of the bridge under various loading conditions. The global deformation or deflection of the bridge is a measure of its stiffness [16,17]. On the other hand, stresses will give us the local behavior of elements that might prompt fatigue evaluation of the various elements [15]. Measurement instruments at our disposal were limited to the LVDT—displacement transducers, Friction strain gauge, image processing, and MEMs accelerometer. The transducers and image processing determined the deflection angle and deformation. On the other hand, the strain gauges determined the local strains during loading, while the accelerometer established the structural dynamic response during loading.

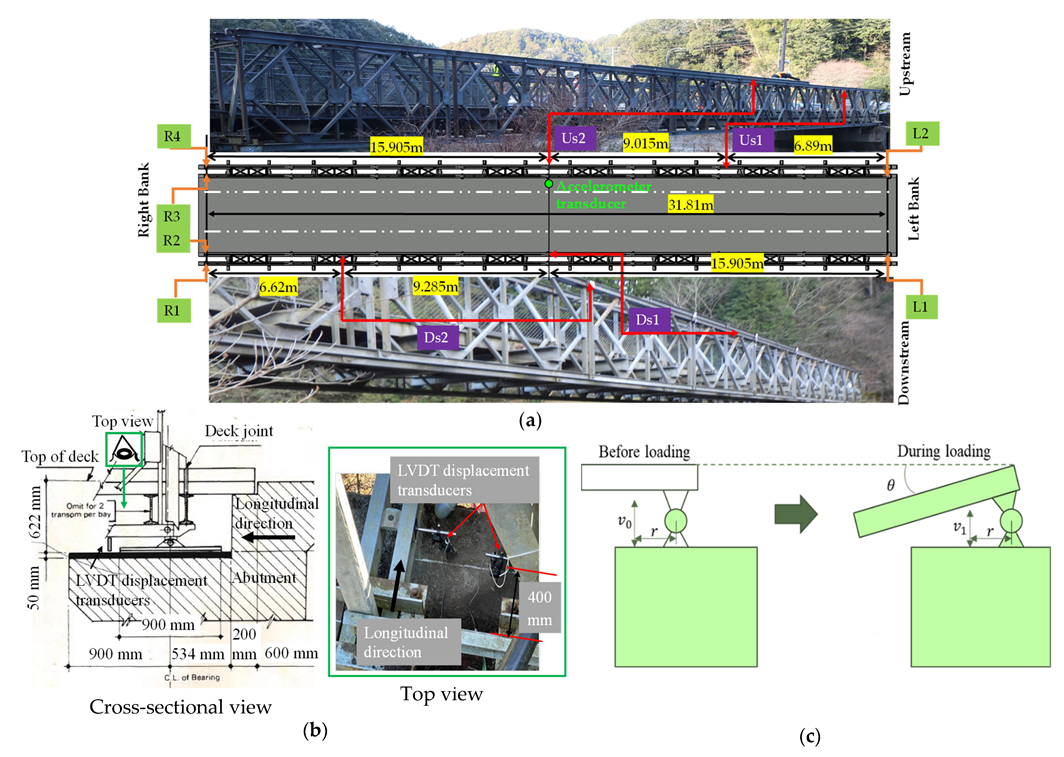

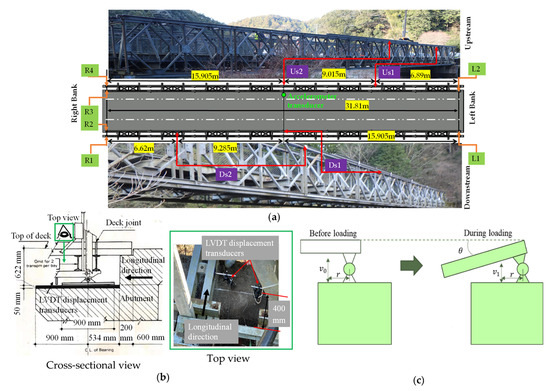

2.3.1. LVDT Displacement Transducer Setting

Figure 4a shows the set locations of the LVDT—displacement transducers. CDP-type [18] LVDT displacement transducers were exploited with a capacity of 25–100 mm, due to their stability, nonlinearity of 0.1% Rated Output, sensitivity of 100–500 (×10−6 strain/mm), and accuracy of ±0.1%. They were set at the end of the right and left end shears/post, attached to the bottom chord by a rigid magnet, demonstrated in Figure 4b,c, denoted as R1, R2, R3, R4, L1, and L2 to achieve a good deflection profile. The deflection is attributed to the composite actions between the panels’ chords and the respective members. Additionally, the transducers exclusively determined the displacement measurements under static loading conditions. To achieve the profile along both spans at intervals of approximately 5.0 m, the deflection angle from a point normal to the bearing on the base plate was determined from Equation (2). The latter was diagrammatically summarized in Figure 4d. LVDT displacement transducers were set on the abutment from a point 400 mm from a point normal to the bearing on the base plate presented in Figure 4b,c. They were then connected to a data logger DC-204R for recording voltage output emanating from the LVDT Transducer. It, in this way, acted as a link to the PC, controlled by DC-7630 Tokyo Sokki as the system interface with multichannel capabilities.

where θ—Deflection angle, V0—Initial transducer reading, V1—Transducer reading after loading, r—Distance between LVDT displacement transducer shaft to a point on the base plate and normal to the bearing.

Figure 4.

(a) Measurement instruments setup, (b) LVDT displacement transducer setup, (c) Determination of the deflection angle.

2.3.2. Frictional Strain Gauge Setting

Figure 4a,d also show the location of the Frictional strain gauges [9] attached. The location was chosen to understand the symmetrically bending moments of the Sukumo bridge. Bailey Bridges have maximum compressive stresses at the center bays’ top chord [1,2,14]. Hence, the gauges were placed on the top chords and both sides of the inner bridge panels’ web section. They were denoted in relation to the flow of the stream where Us and Ds meant Up-stream and Down-stream likewise. As a result, they were symmetrically skewed along the center line, Us2 and Ds1. On the other hand, Us1 and Ds2 were placed approximately 9.015–9.285 m from the center line completing the skew symmetry as detailed in Figure 4a. Their placement on the top girder ensured maximum global response. The magnetic frictional strain gauges were the FGMH series with a gauge length of 1.0 mm. They consisted of a rubber layer on their contact surface and a magnetic ring pressing against the web-section on the top chord. Strains are recorded due to friction caused by the target surface because of acoustic emissions [9]. They were wired to the end shears of the bridge with insulated, low-resistance copper wires approximately 15 m long on both spans. They were then connected to a quarter bridge (for voltage input) and a microprocessor data logger DC-204R system through a converter connected to a PC as the controller—DC-7630 Tokyo Sokki for calibration, manipulation, visualization, and data extraction interface. The controller had eight channels on either side of the bridge for the strain gauge, and the LVDT displacement transducer had a shared interface.

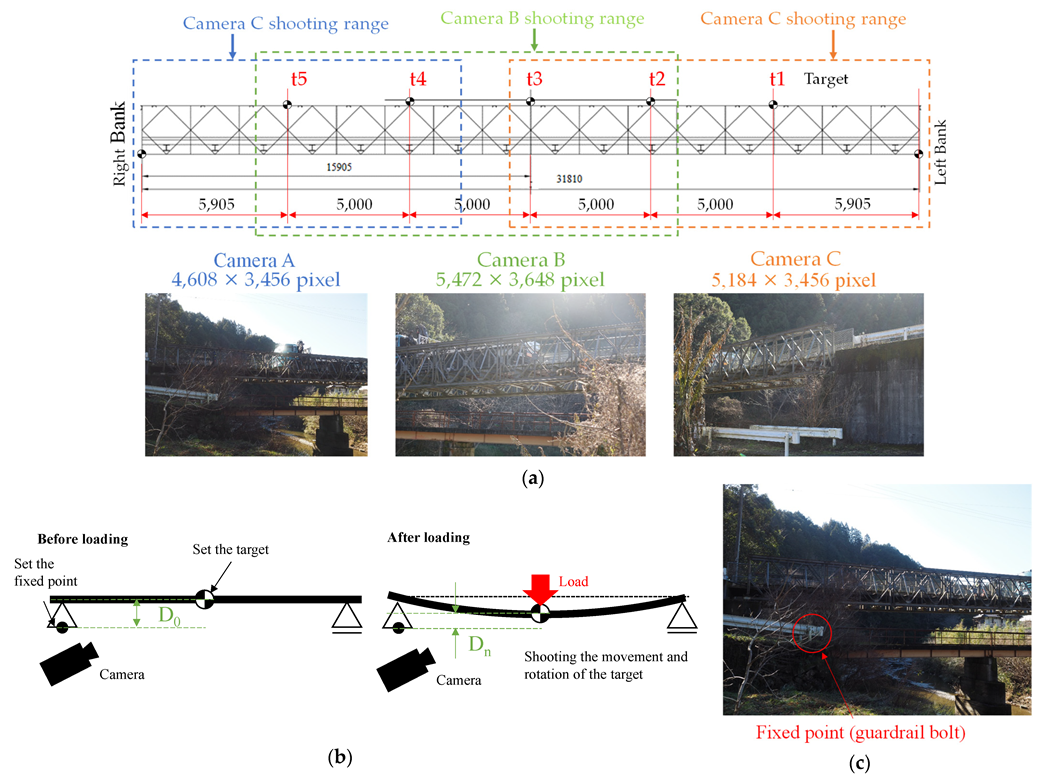

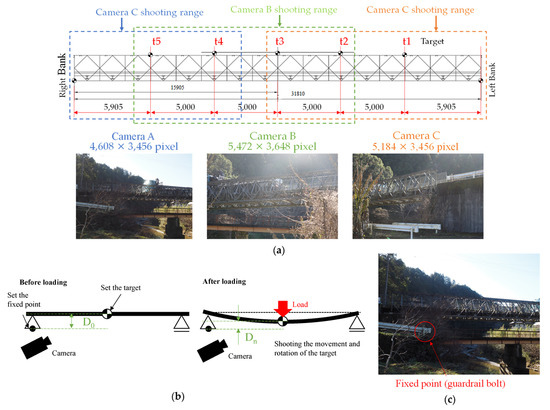

2.3.3. Target Setting for Image Processing Approach

Figure 5 shows the configuration of the image processing approach employing MOVIAS neo by Nac. Image Technology Co., Ltd. located in Akasaka, Minato City, Japan, which is widely used in automotive crash test analysis [7]. The targets were Quadrants deployed to track the frames for deflection. They were set at 5.0 m at t1 to t5 on the top chord of both the left and right spans [7]. Figure 5a presents the target setup along one of the spans. The approach is an improvement from conventional totals station that only monitors one point, leading to limited information rather than point cloud data [8,17]. The deformation of the targets was recorded from different monochrome cameras, shooting angles, and resolutions of A: 4608 × 3456 pixels, B: 5472 × 3648 pixels and C: 5184 × 345 pixels. Figure 5b illustrates how the image processing approach determined the deformation. A preselected, fixed reference point was established during the experiment for calibration using the recommended spatial resolution on the user interface—the guard rail bolt, as shown in Figure 5c. The reference point was then used to determine the displacement in reference to the target Quadrants. With a minimum resolution of 15 pixels, high center detection accuracy can be achieved on the quadrant. The target was set so that the pixel luminance information coincides with the template size [7]. Hence, the difference (Δh) is then resolved as the deflection value encapsulated in Equation (3). The instrument was only used during static loading due to scan time delays.

where, D0 Deformation/deflection reading after loading, Dn Deformation/deflection reading before loading, and Δh Deformation or deflection in mm.

Figure 5.

(a) Image processing setup, Targets are set at specific spots, and structural responses are determined from the recorded events. (b) Deflection determination was based on target/quadrant vs. fixed bolt relationship. (c) Preselected rigid reference point—the guard rail bolt.

2.3.4. Accelerometer Transducer Setting

Figure 4a also shows the set location of the MEMs accelerometer transducer, which is an INTEGRAL PLUS sensor with 15-min real-time deflection measurement capabilities. The sensor was adopted under a new technology information system within the Ministry of Land, infrastructure, transport, and Tourism Japan for inspection support. It is suitable for bridge spans less than 40 m, with a maximum running test of 40 km/h and an accuracy of 0.08 mm for steel bridges [19]. It was placed at the center span, as shown in Figure 4a, on the upstream girder side of the structure. It measured the dynamic behavior of the structure [19,20,21,22]. The measure of the vertical displacement of the structure against time under different loading conditions was meant to determine the in-service behavioral response. Such conditions illustrate the ambient condition of the structure relating to its day-in response [19].

Several parameters are employed in evaluating a structure’s dynamic condition, such as the natural frequency, vibration modes, damping, and Dynamic Amplification Factor (DAF) [23,24]. Among them, DAF is considered a critical parameter introduced in bridge design codes, for example, AASHTO 1996, 1997, and Eurocode 1-2. It establishes the structures’ inherent uncertainties that correlate with other dynamic effects, such as pavement condition and extent of deterioration. Thus, it can contribute to bridges’ structural condition. Therefore, a structural condition assessment of the Sukumo bridge was based on DAF. It was calculated using Equation (4) [25,26].

where Rdyn, Rstat, and μ denoting maximum dynamic, static response, and dynamic amplitude (deflection or deformation).

3. Results of the Field Experiment

3.1. Static Behavior

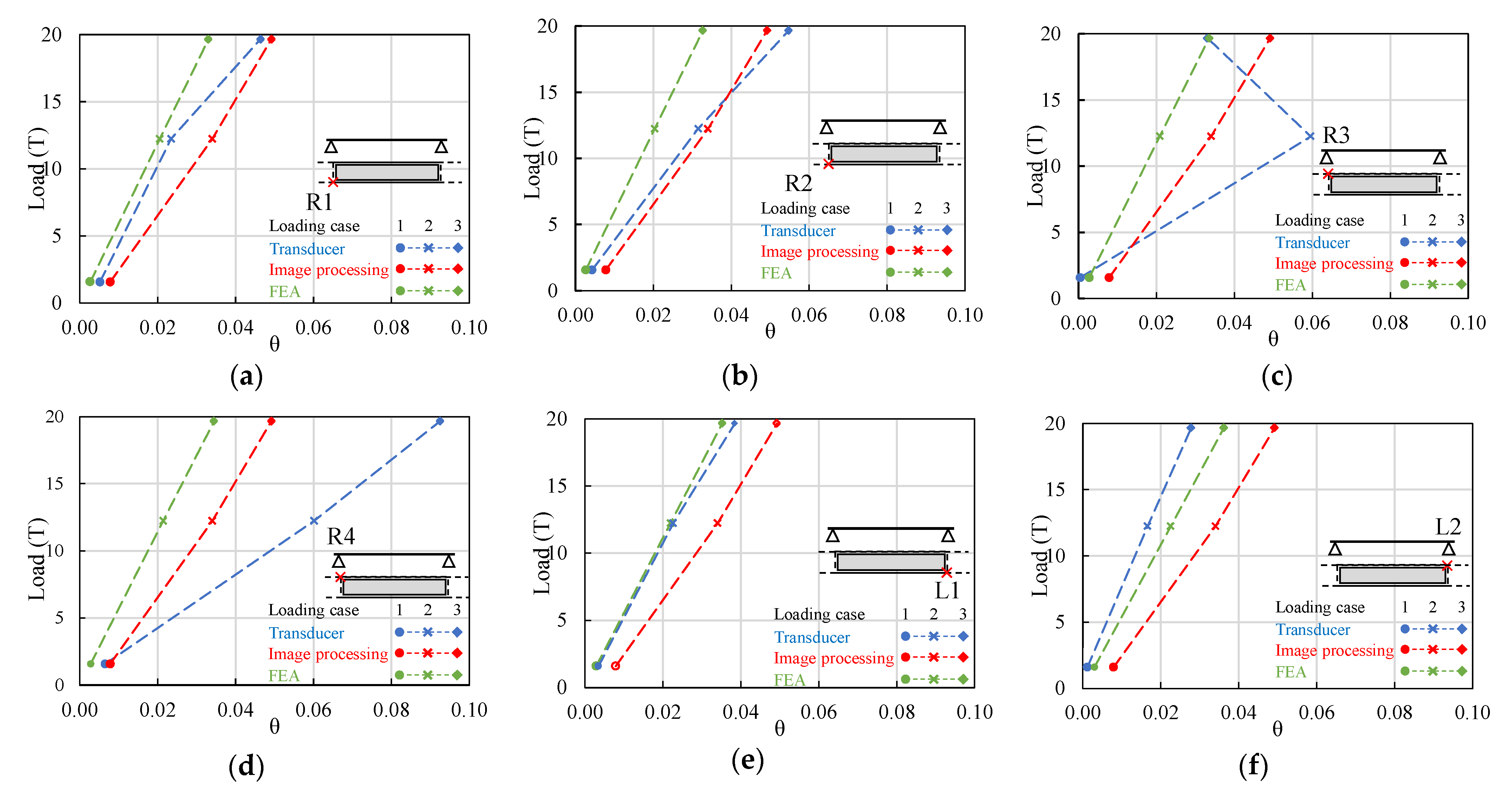

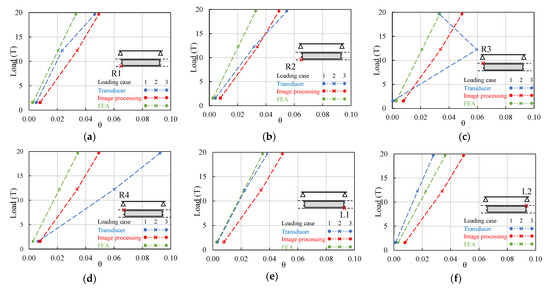

Figure 6 shows the deflection angle calculated from the transducer measurement and image processing approach. In this figure, three loading cases are shown; case 1 (1.57 Tons), case 2 (12.24 Tons), and case 3 (19.66 Tons). The deflection angle calculated from the transducer on Loading case 1 ranged from 0.0004–0.0066 with a difference of 0.01; between R4 and R3, causing a deflection ranging from 0.0030–0.0460 mm. On the other hand, Loading case 2 had a deflection angle ranging from 0.0166–0.0596 with a difference of 0.04 and deformation of 0.1160–0.4160 mm; while Loading case 3 recorded deflections from 0.0278–0.0925 with a residual of 0.06 with deformation of 0.1940–0.6460 mm. A deformation θ less than 0.1 from Equation (2) was considered reasonable. It meant the structure operated using the concept outlined in Equation (1) (principle of super-position). However, transducers R3 and R4, revealed in Figure 6c,d, exhibited higher deflections from Loading case 2. It was suspected to be due to the calibration and sensitivity of the transducer to higher loads. On the same note, the image processing approach recorded deflections increasing from Loading cases 1–3, that is, Loading case 1—0.0079 (0.0548 mm); Loading case 2—0.0340 (0.2377 mm), and Loading case 3—0.0492 (0.3435 mm), with minimal mean deviation from the transducer measurements of 0.0043, 0.0016 and 0.004 from Loading case 1 in that order, exemplified in Figure 6. Significant ∆θ residuals were observed between the displacement transducer and image processing approach. The Bailey Bridges consist of several panels [27] on each span connected with pins whose tolerances vary. As a result, the pins reset during loading [1], leading to large deflections depending on the spans’ side (left or right span). Moreover, the bending moment along the panels does not assume a perfect circular curve because the spans are an assembly of panels having approximately similar rotational angles as opposed to a single continuous beam using the second theorem () in Moment area method. Whereas t2/1 tangetial deviation, A area under the curve on a cantelever beam, centroid, EI flexural rigidity (E modulus of elasticity and I moment of inertia) [26,27]. Therefore, determining deflection from different locations will give rise to varying results, LVDT at 400 mm, and image processing method at 5.905, 10.905, and 15.905 m. Further, the image processing method’s targets were on the top chord which experienced compression during loading. On the other hand, the displacement transducer was on the lower chord, which was vulnerable to tension [2,27]. The phenomena correspondingly affect the profile hereafter presented in Figure 7.

Figure 6.

Deflection angles calculated from transducer and image processing measurements and FEA at (a) R1. (b) R2. (c) R3. (d) R4. (e) L1. (f) L2.

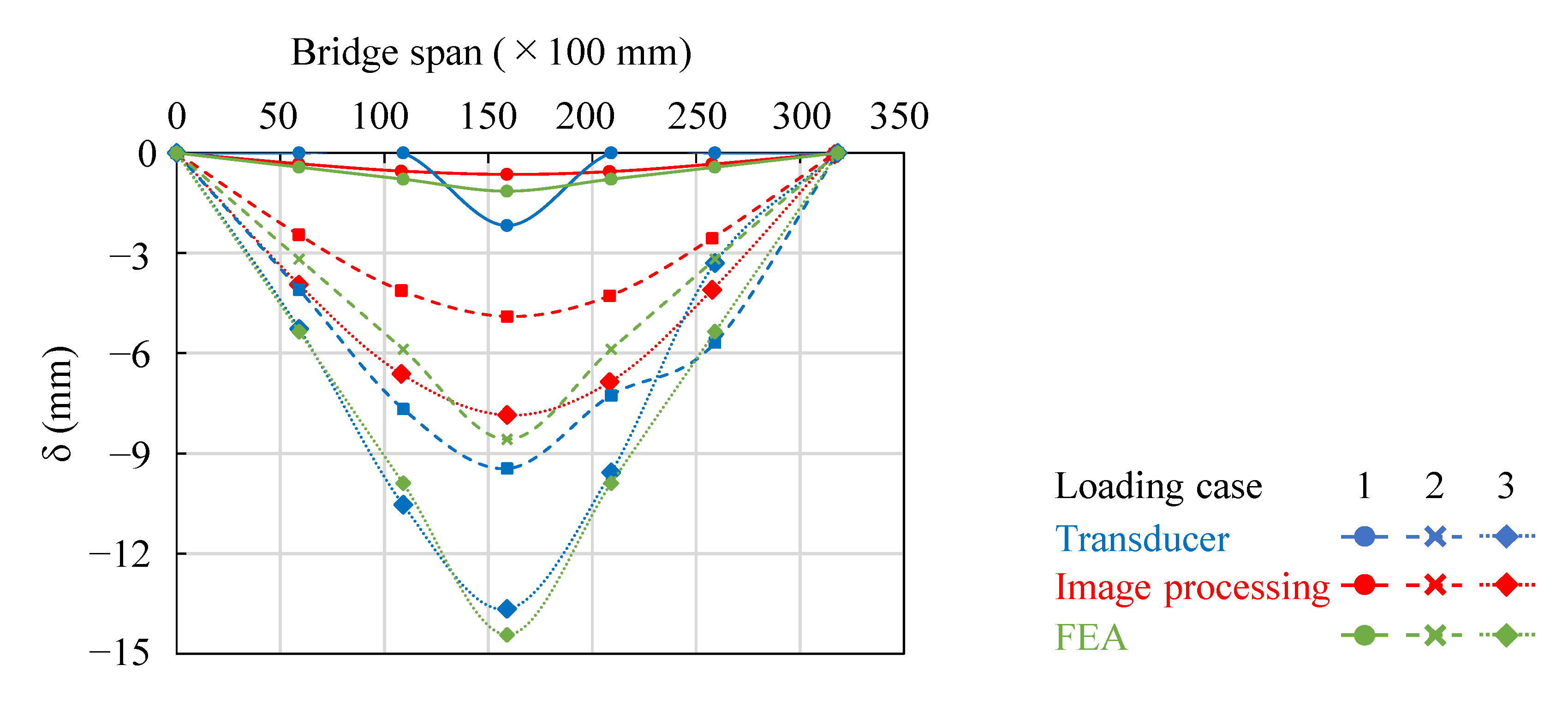

Figure 7.

Mean deformation profiles under loading cases 1, 2, and 3 along the five targets on the bridge span.

Figure 7 shows the deformation profiles along the bridge span. From the results, the profile showed symmetry at the center span, increasing with loading cases 1 to 3 on both the transducer measurement and image processing approaches. The deformation at the center span was higher with the transducer (tension members) than with the image processing approach (compression members) [2,27] with 2.18–14.42 mm. The results show a linear-elastic behavior having approximately similar characteristics in both approaches. Moreover, the deformation profile indicated an increasing bending moment from the end shears to the center of the span. The phenomena were similar in both spans. In reference to the AASHTO 2010 Bridge design specification, the permissible in-service loading is span/800 [28], translating to a maximum allowable deflection of 39.73 mm under load. Additionally, the theoretical pinhole sag () of 28.48 mm for self-weight, where d was 3.56 (constant), and n number of bays. From the experimental results, the maximum deflection obtained was 14.42 mm from the transducer’s influence line that is below the prescribed limit.

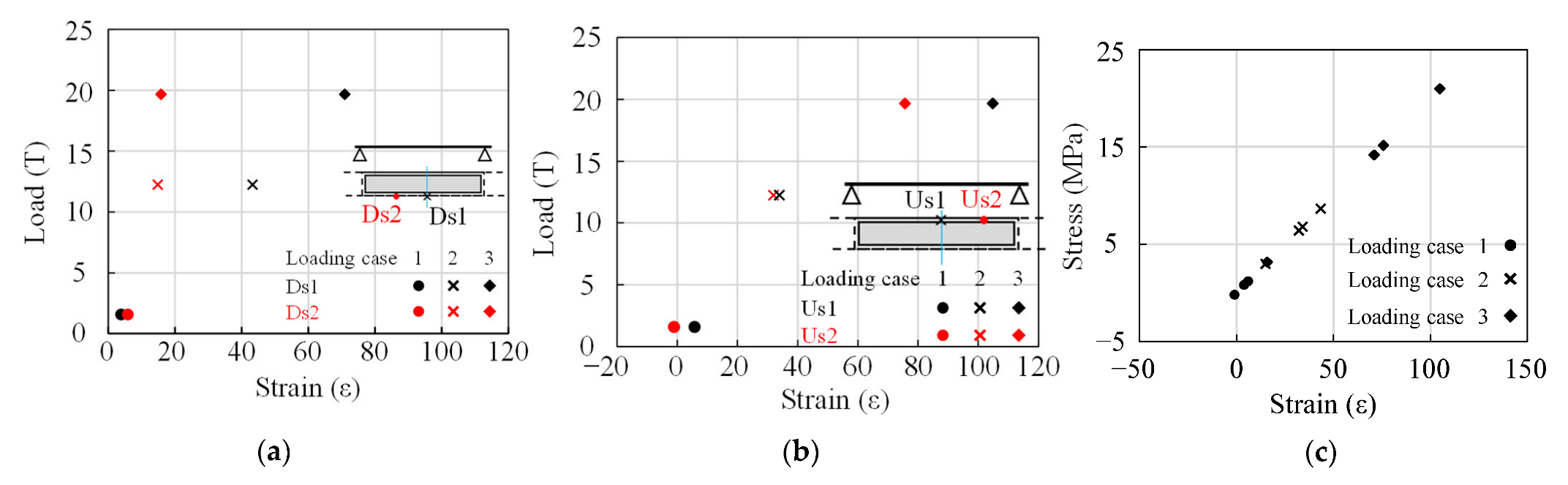

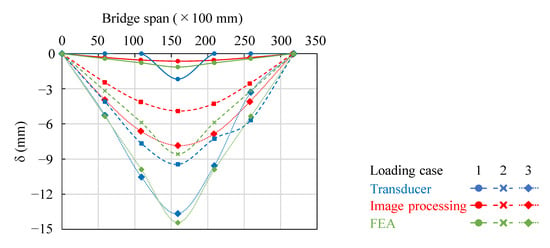

Figure 8 illustrates the load-strain and stress-strain relationship. Bailey Bridges experience significant stress at mid-span than end-shear during loading [14]. This aspect is of great importance in designing truss structures ensuring reinforcement of the critical elements at mid-span that are fully stressed. The strains were established during loading cases 1–3. Figure 8a,b indicates the effects of strain with loading. The strains increased with the loading with no anomaly to indicate underlying local issues such as fatigue. The strains had similar characteristics apart from differences due to the strain gauge placement distances, which were not precisely co-linear (Us1 & Ds1) and alternate (Us2 & Ds2). However, a symmetric relationship varies from the center, as shown in Figure 8a,b. The situation is critical for fixed-panel bridges indicating that the end posts/shears are not fully utilized. Consequently, reinforcing the center bays ensures uniform distribution of stresses. The panel stress was calculated using averaged values of Us1 and Ds1 with a modulus of elasticity of 2.0 × 105 MPa for a steel superstructure with a concrete deck to establish the linearity. Figure 8c shows the stress-strain relationship. It was clear that the bridge operated within the linear elastic range. Moreover, the stresses experienced in Loading case 3 correspond to a similar study on the same bridge [29].

Figure 8.

Load vs. strain relationship at (a) Downstream. (b) Up-stream. (c) Stress vs. strain relationship.

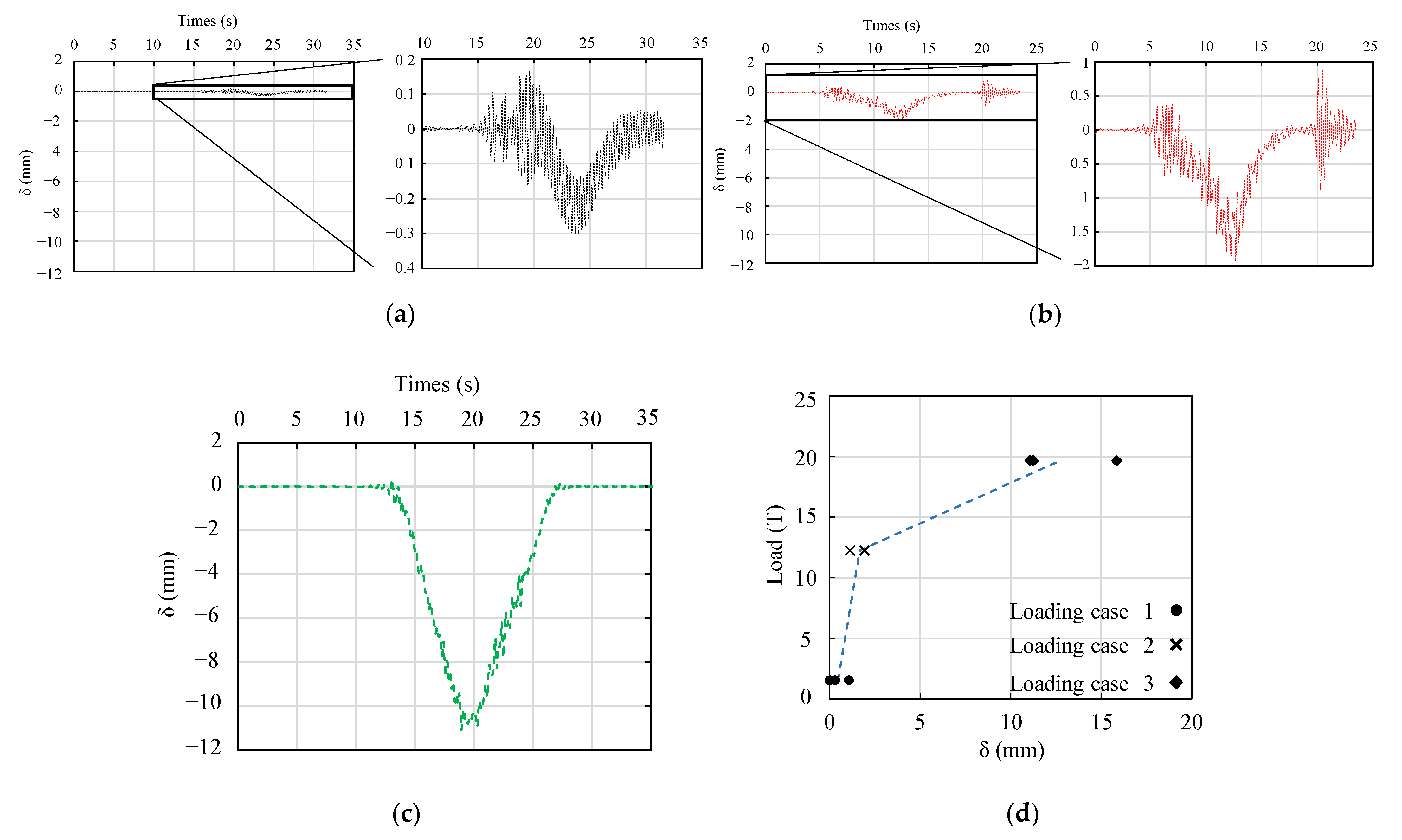

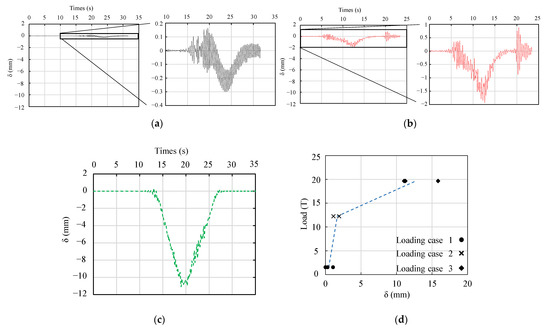

3.2. Dynamic Behaviour

Figure 9 illustrates the structural dynamic response. Figure 9a–c relay the various loading cases, indicating the structural dynamic response. Measurements were recorded from cases 1–3 with an average speed of 3–20 km/h practicable to prompt the dynamic structural effect, with 3 km/h considered the crawling speed and 20 km/h considered the average speed [19,23,30,31]. The deformation response ranged from 0–0.031, 1.30–1.932, and 11.249–15.844 mm from the loading cases, respectively, as indicated in Figure 9d. The responses were random due to their dynamic nature. Still, it was observed that the structural characteristic was linear from individual responses concerning the loading, and unloading departure from the respective negative amplitude from Figure 9a–c. Each negative peak indicated the maximum deflection and deviation from it during unloading, corresponding to a linear elastic response.

Figure 9.

Dynamic Response: (a) Loading case 1. (b) Loading case 2. (c) Loading case 3. (d) Maximum deflections at each loading case.

The maximum deflection is supposedly more prominent than the static maximum response by approximately 1.4 mm. As a result, the structure would seem nonlinear compared to the static response of 14.43 mm [30]. From Equation (3), the DAF was derived as 1.09 with a structural span of 31.81 mm of a one-lane bridge [23]. The parameter is well within the given threshold by ASSHTO 1997, indicating that the deterioration is significantly low and within maintenance margins [31]. Since DAF is a modal parameter that can reflect the dynamic performance of the bridge, it has proved to be a good indicator of the pavement condition. Consequently, it lays the foundation for a maintenance schedule concerning a well-conditioned pavement’s safe margins of 1.0–1.4 DAF. Structural failure constitutes numerous aspects, such as fatigue failure, surface wear, and corrosion, that manifest [19,20,22,32] under dynamic loading [30].

4. Structural Analysis

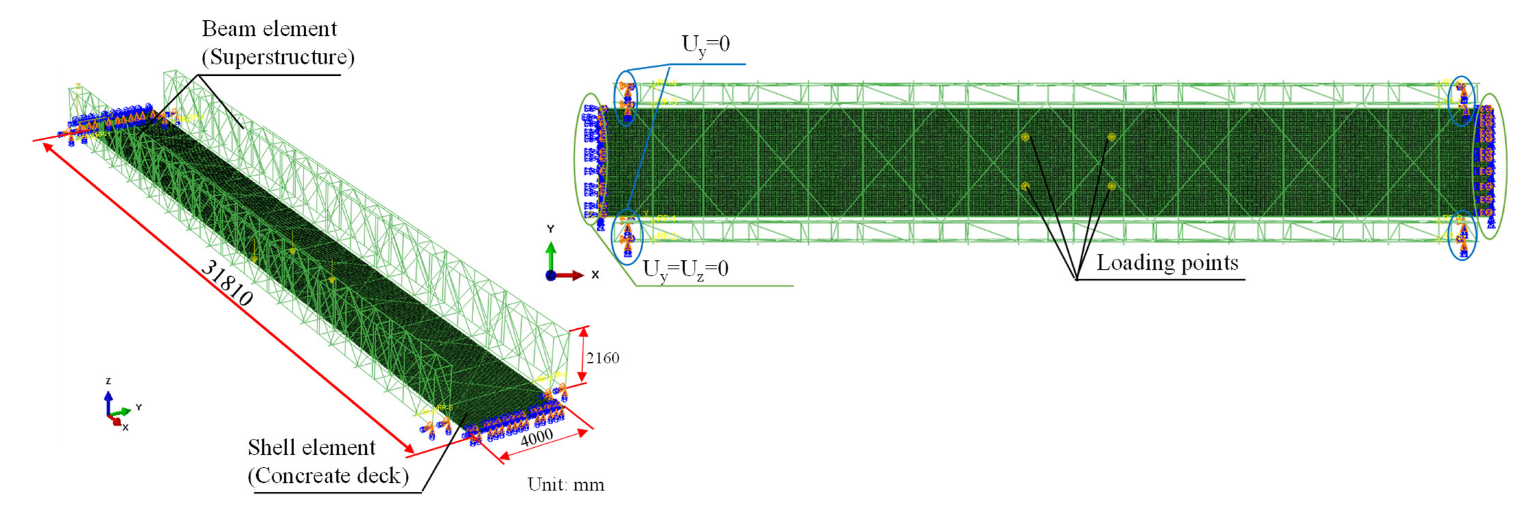

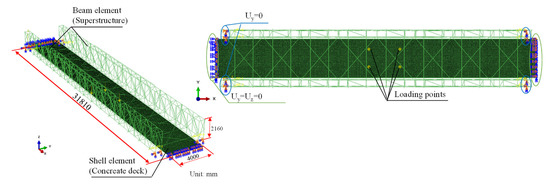

4.1. Structural Modelling

An FEA was done to validate the bridge’s structural behavior. Figure 10 shows the analytical structural model. It was modeled according to in situ geometrical dimensions, as shown in Figure 2b,c. However, the detailed design and specifications were not available. By design, modeling should adhere to reliable documentation (as-built drawings) related to its geometry and material. The geometric structural details were recorded from the site. In case structural details are still unclear even after on-site measurement, the Japanese, Philippine [33], Garden Reach Shipbuilders and Engineers Limited (GRSE) [34], and Eurocode 1 & 2 [35,36] were used to supplement each other for any unclear details. Consequently, the geometrical properties were considered with on-site dimensions provided in Table 2. A beam element with 6 degrees of freedom at the respective nodes was applied to the superstructure, employing a one-dimensional element. The beam element is mainly used for checking structural support systems. Quality is far more critical than complexity, as is commonly used in structural design [37]. As a result, increasing the computational speed beam element sufficed for the task. Some members were idealized; pin connections were modeled monolithically between the members [1]. The deck section was modeled as a shell element [37].

Figure 10.

Analytical structural model.

Table 2.

Onsite Structural Dimensions.

Loading was done at four points, considering the wheel spacing of the car, truck, and crane used in the field experiment. The support boundary condition stipulated fixed and free ends, as shown in Figure 10. Additionally, a rotational moment was allowed on the x-axis and restrained on the z and y-axis. Permanent loads, specifically, the dead load of the superstructure minus the foundation settlement, were considered with a gravity value of 9.806 × 103 N/kg. This gravity force was applied first in all cases to deal with the dead load preceded by the live load. However, it is worth noting that wind, temperature, and earthquake loads were not considered for the reasons subsequently explained.

As the span and height increase, the wind actions become more critical. Aeroelastic reactions occur because of the dynamic action of winds impacting the galloping, vortex excitation, buffering, and parametric resonance phenomena. However, the subject bridge had approximately 9 m clearance height and an aeroelastic instability of 4 & 2.16, corresponding to the span-to-width and span-to-depth ratio. Due to the consequent aeroelastic instability, it was considered not wind-sensitive [28,38,39,40,41]. Further, thermal distortions are significant when the superstructure is erected at temperatures that significantly differ from its in-service condition (∆12 °C-annually), causing deformation by internal actions on constrained sections (welded and pinned joints). However, the bridge’s flexible structural form allows thermal distortions of no serious consequence to generate a theoretical structural distortion of less than or approximately 13 mm [42,43]. On the other hand, earthquake actions relate to translational actions to the base foundation, that is, inertial forces dependent on the geographic location. Earthquake loads need not be observed unless the acceleration coefficient [42] exceeds 0.15 [44]. In that regard, the chances of an earthquake generating an acceleration coefficient of more than 0.15 are close to zero in the next 50 years [45]. This analysis was performed in ABAQUS CAE 2019 Software with a static solver, due to its ability to address linear and nonlinear material and geometric [46] aspects.

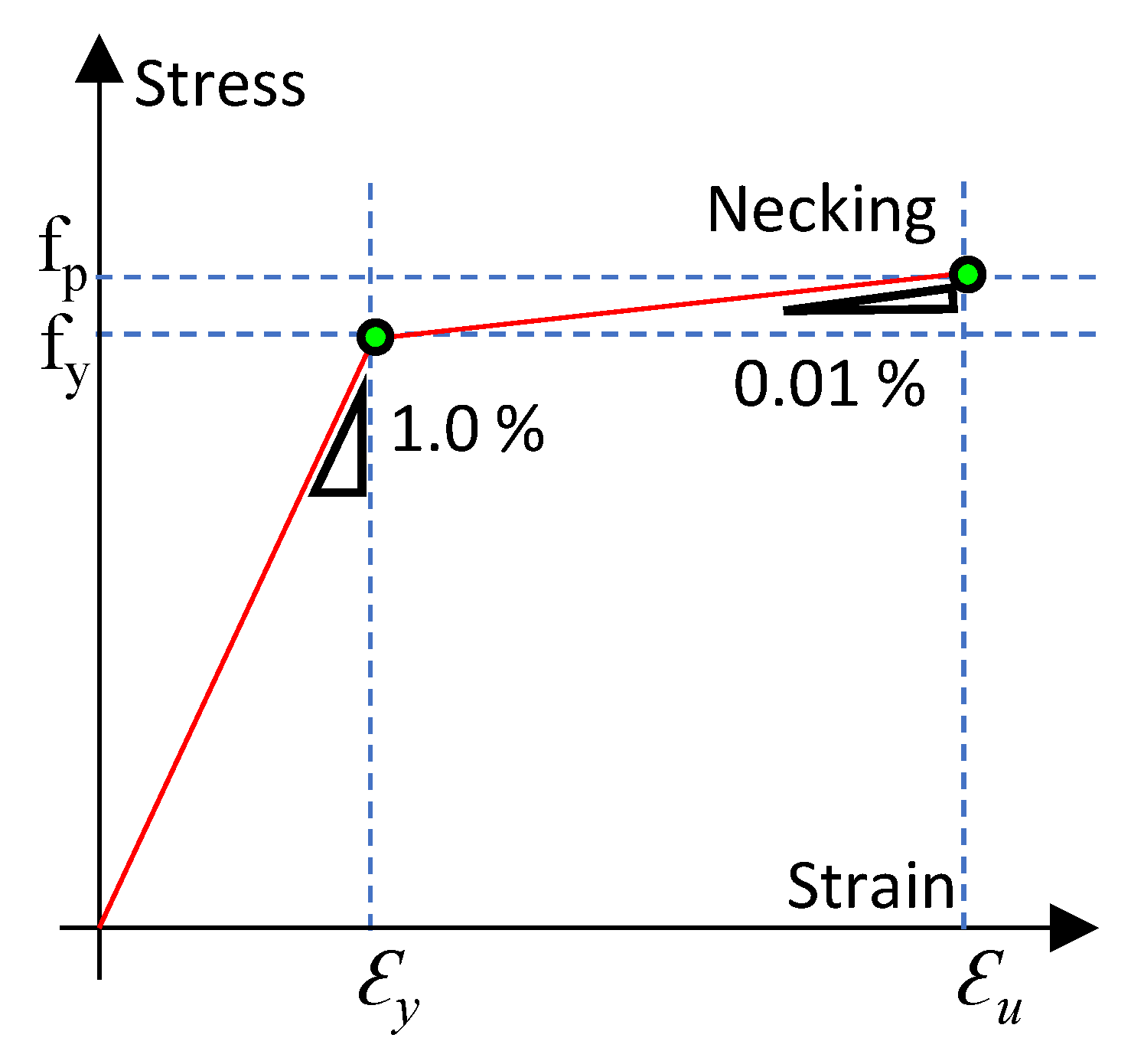

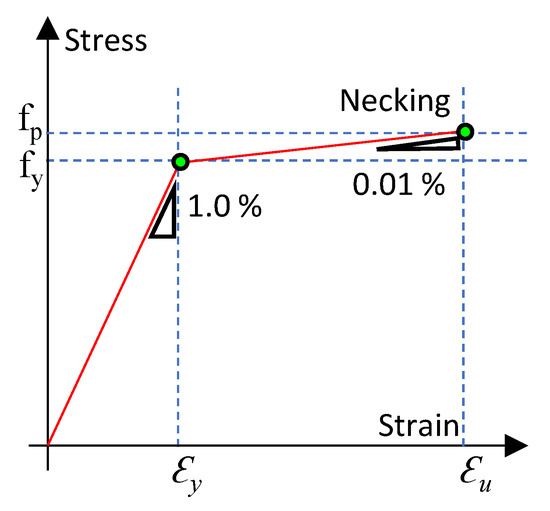

4.2. Material Modelling

Figure 11 illustrates the bilinear stress-strain model. The material properties were adopted from the Bailey Bridge manual, AASHTO 2010, and GRSE of a similar bridge design with Young’s modulus of 2.0 × 105 MPa and Poisson ratio of 0.3 [14]. Moreover, it corresponded with previous studies [2,6,29]. In the present study, a linear analysis was performed to validate the model’s accuracy, and a nonlinear analysis for the bridge’s reliability. The superstructure was set as SM490 steel with a yield strength of 325 MPa (𝑓y). The deck section was composed of concrete material. Hence, a modulus of elasticity of 30,000 MPa and a Poisson ratio of 0.2 was adopted. On the other hand, the nonlinear analysis model had a gradient of 1.0% in the elastic region with a yield strength of 325 MPa (𝑓y) and ultimate strength of 400 MPa (𝑓p) with a gradient of 0.01% [47], as shown in Figure 11. The deck section made of concrete was constantly linear elastic to grasp the nonlinear behavior of the panels and distribute the load evenly to the superstructure.

Figure 11.

Bilinear stress-strain model.

The interaction between the superstructure and concrete was not considered, serving as DSL’s carrying surface. This approach of zero interaction focuses on distributing force to corresponding elements bearing the dead load. Furthermore, the stresses throughout the model were determined using the Von mises Stress (σvm) obtained from the Cauchy stress tensor derived from Equation (5). The model is suitable for evaluating structural truss systems experiencing small deformations.

where σx, σy, σz, τxy, and τyz denotes the normal stress component in the X direction, the normal stress component in the Y direction, the normal stress component in the Z direction, the shear stress component in the Y direction applied on the plane normal to the X axis, the shear stress component in the Z direction applied on the plane normal to the X axis and is the shear stress component in the Z direction applied on the plane normal to the Y axis in that order.

4.3. Linear Elastic and Nonlinear Elastic-Plastic Analysis

4.3.1. Condition of Linear Elastic Analysis

A linear elastic analysis was done to obtain the deflection using the Newton-Raphson method [46] and to validate the model’s accuracy. The loading was prearranged such that the front and rear axles were in ratios of 4 to 3. It was considered that the front axle had a higher tonnage due to the location of the engine. The displacement control loading scheme was organized in successive and equal amplitudes of 1.75 Tons ranging from 0–26.25 Tons at a frequency of 1 s at intervals of 0.2 s in the field output request. At Loading cases 1–1.57, 2–12.24, and 3–19.66 Tons, the amplitude varied to 0.13, 0.04, and 0.47 Tons to accurately determine the deformation or deflection. The program also checked whether σvm for every element falls within the material’s linear domain (from Equation (5)). The boundary conditions were consistent, as stated in the structural modeling.

4.3.2. Condition of Nonlinear Elastic-Plastic Analysis

The bending moments and compression on bridge elements occur as whole but not as separate elements. However, Eurocode 3 recommends verifying structures in SLS and ULS as constituent members [35]. Conversely, in-situ structures interact as a whole, and their interaction should be analyzed similarly. Bailey Bridges have numerous critical points of tension (bottom chord) and compression (top chord) members. They have pronounced stresses at the center span chord, as presented in Figure 7 and Figure 8 from the field experimental data. During loading and unloading, Bailey Bridges have random dynamic and static behavior and are vulnerable to instability. The Newton-Raphson method does not account for nonlinearity for structures exhibiting buckling and material nonlinearity. Therefore, the reliability of the structure was assessed using the Arc length method. This method can check material and geometric nonlinearity [46]. In this study, it was first used to identify the linear response about the base state before the affected member fails—buckling. Moreover, the nonlinearity of systems when they exhibit numerous critical points were investigated, i.e., a body that cannot support an increase in load. Procedures of linear and nonlinear buckling analysis were detailed after this. It is worth noting that the used structural model, boundary conditions, and the material property were the same as aforementioned in Figure 10 and Figure 11.

Linear Buckling Analysis—Linear Perturbation

A four-point bending of −1 N on each loading point was applied on the deck section, coinciding with the position of the load cases used in the linear buckling analysis as the initial load. Then, the linear perturbation procedure was selected in Step and buckle as the option and subspace eigensolver. Though the number of the eigenvalue(s) required is only one—Mode 1 Eigenvalue, n = 10 was input as the minimum number of eigenvalues requested where (2n, n + 8) is the minimum number of vectors. Hence, 18 vectors were used per iteration of a maximum of ≈300. A lower number of iterations was avoided to ensure convergence. The program applies increments to the load on the load control.

Non-Linear Buckling Analysis—Static Riks

First, geometrical nonlinearity and residual stresses were introduced through equivalent geometric imperfections, as recommended in EN 1993-1-1 (EC-3), as a prerequisite for designing slender structures. The imperfection was imported from the linear perturbation step. Secondly, the step was created using the general procedure Static Riks method that exploited the arc length method to account for the nonlinearity using Nonlinear geometry (Nlgeom). The maximum number of increments was set to 1.0 × 106 with an arc length of approximately 1. The load was concentrated force set as the First Eigenvalue from Linear Perturbation Analysis with similar boundary conditions, loading point positions, and material properties. Because the method does not terminate, it was terminated when the arc length is approximately less than or equal to 1. It was assumed that the structure fails when the stress values on critical members (chords) surpass 𝑓p, corresponding to span/800 of deflection value greater than or equal to 39.763 mm. Finally, the Load Proportionality Factor (LPF) was extracted, and the product of the values by the first eigenvalue from Linear perturbation [46] was determined and plotted against the deflection and the load-displacement curve.

4.4. Validation of the Model’s Accuracy by Linear Elastic Analysis

Figure 6 shows the deflection results of instrumenting the bridge compared to the FEM model under the linear elastic domain. The validation coefficient (ɳ) was determined from the deformation or deflection obtained from the model. The residuals and coefficients present the characteristics and agreement of the model. It further details the relationship of compressive and tension members, that is, the measurement from the top and bottom chord. Dissimilar characteristics of the model versus measurement approach and anomalous validation coefficients [48] disclose a poor connection between structural members and lower structural stiffness, prompting extensive evaluation [6,48]. The mean of the measured results is presented in Table 3 with their respective residuals and validation coefficients.

Table 3.

Residuals and Validation Coefficient.

The mean deflection from transducers R1, R2, R3, R4, L1, and L2 recorded deflections ranging from 0.0035–0.0488 from Loading cases 1 to 3. On the other hand, the image processing approach recorded a mean ranging from 0.0079–0.0492 from Loading cases 1 to 3, a magnitude higher than the predecessor. The residuals had similar characteristics increasing from Loading cases 1–3. However, it was observed that compressive members had higher residuals than the corresponding tension members—the transducer measurements [2]. Therefore, the validation coefficient established the reliability of the model and structure, indicating a consistent ratio from both the transducer and image processing approach. A higher ratio was realized on the image processing approach on Loading case 1, 2.79. The ratio was peradventure informed by characteristic inaccuracies of image processing on small deformations. The coefficients show that the bridge is intact and close to the FEM model. The mean coefficient ratios of 1.45 and 1.94 for the transducer and image processing, respectively, indicate the model approximately fulfills the design requirements and operates within the elastic region. It is assumed the model idealized the in-situ bridge structure, paving the way for nonlinear analysis.

4.5. Identification of Critical Members before Determination of the Bearing Capacity

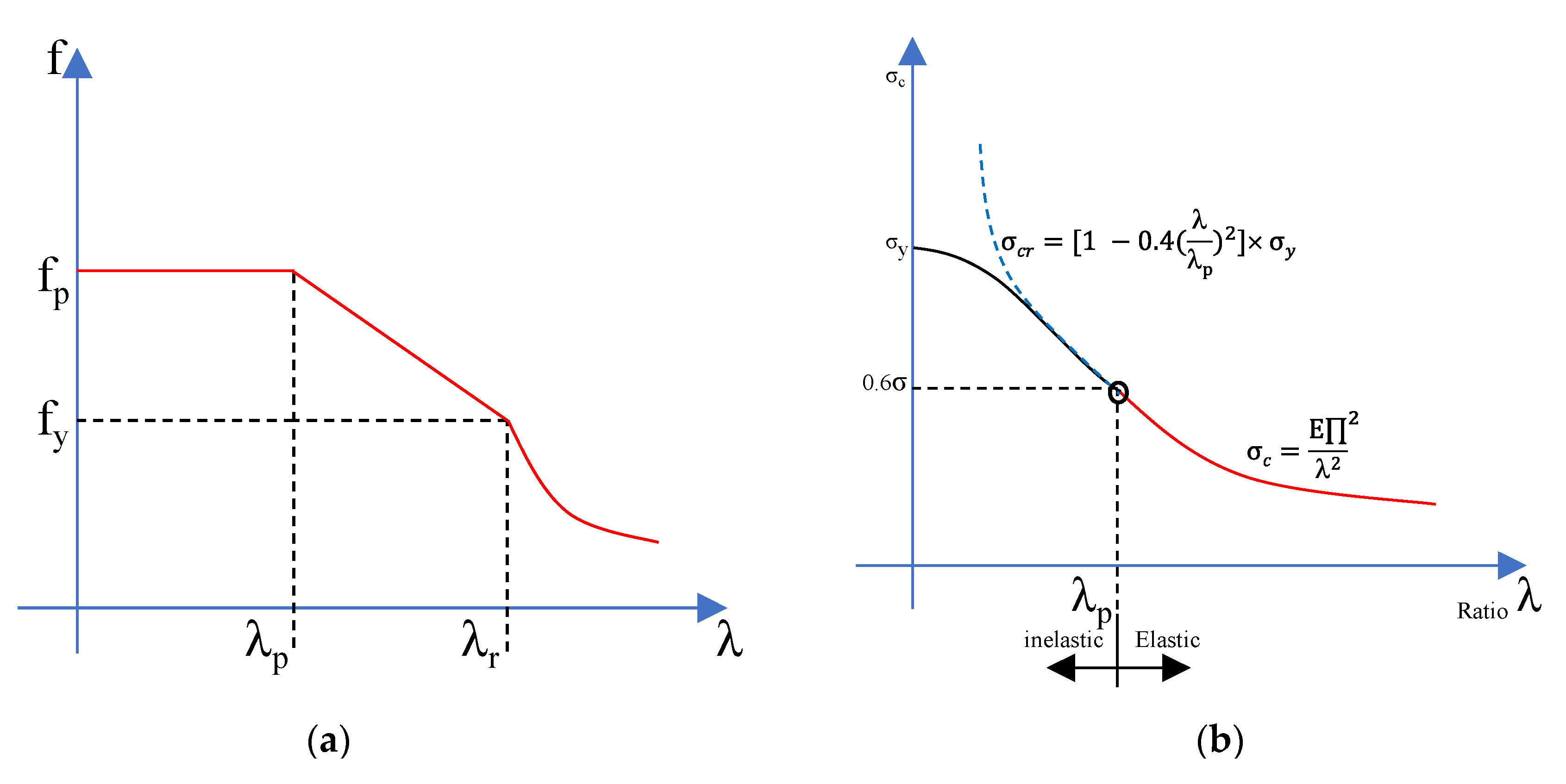

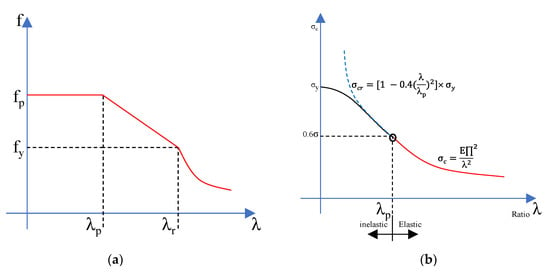

4.5.1. Identification Methods of Critical Members

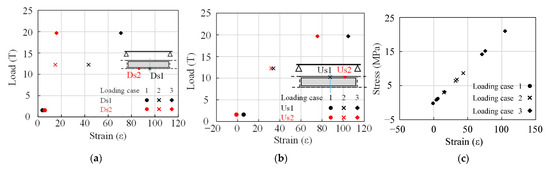

Figure 12 indicates the class limits Class 1/Plastic (λp) and Class 2/Compact (λr). An assumption was made that members only shrink due to compression and not buckle by way of explanation; global buckling occurs first rather than local buckling. Therefore, critical members were identified from previous studies [2,6,29], secondly recorded field strains, and finally, Beam cross-section classification. Compression members suffer from large strains. The strains are higher at the top chord of bailey bridges than the bottom chord under [6,29], which are generally under tension, similar to transoms identified from the linear analysis.

Figure 12.

(a) Eurocode (CEN, 2011) and (b) Japanese code (Miki, 2000). Class limits.

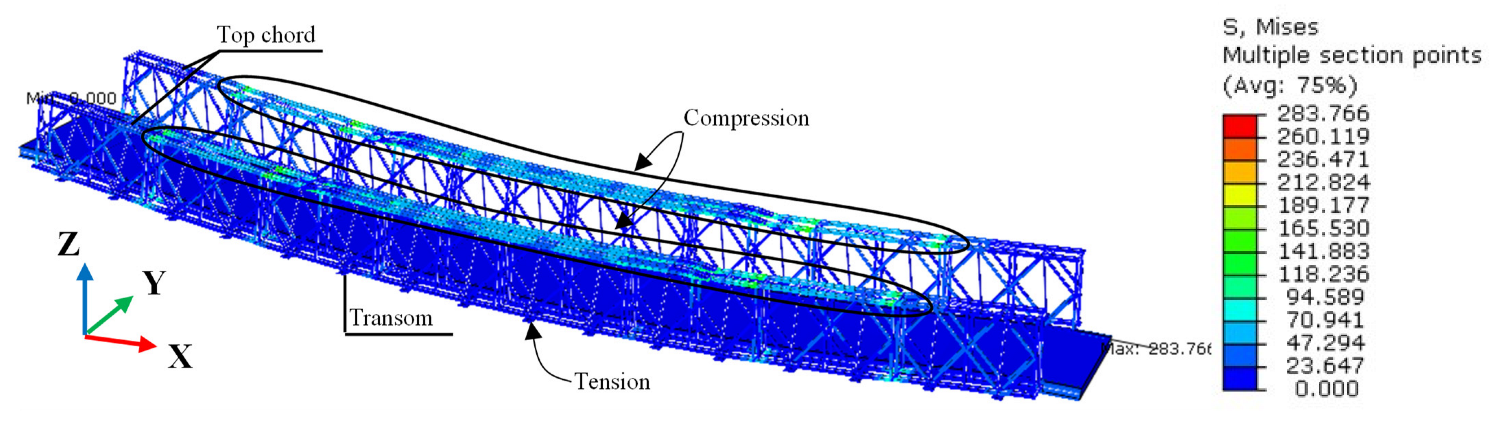

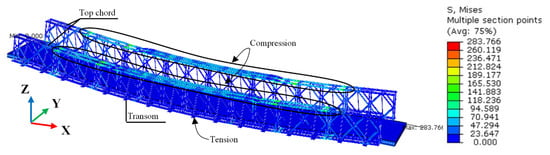

Figure 13 shows the compressive and tension members when 19.66 Tons were applied to the linear elastic analysis. It was noted that critical members of rolled steel sections are essentially slender compared to their width-thickness ratio. Due to this awareness, some members experience local buckling before plastic stress is achieved, rendering the proposed approach irrelevant from the initial assumption. Therefore, critical members were classified (Class 1–4) and checked for susceptibility to local and global buckling. The Japanese [49], Philippines [33], British, and Eurocodes [35] (Eurocode 3, Clause 5.5, 6.1, and 6.2) derived the slenderness ratio (C/t) for the Web (WLB) and Flange (FLB) Local and Global buckling.

Figure 13.

Compression and tension members—critical members.

4.5.2. Results of Identification of Critical Members

The web and flanges of the dominant critical members from the linear perturbation procedure are slender and, as such, are prone to local buckling [35]. The arc length method is deemed immaterial without checking for local buckling using the Euler formulation for beam classification. This occurrence arose because of the compressive loading of the critical members (19.66 Tons on both linear analysis and on-site experiment). The first displacement is hence considered a failure (buckling Mode 1). It is regarded as the onset of the nonlinear response of the structure that also denotes the serviceability limit. Depending on the yield strength, members were classified according to a cross-sectional relationship of width-to-thickness ratio from plastic to slender classes according to British Standards and Class 1 to Class 4—Eurocode [35,50]. These classes are because of their vulnerability to local buckling. The classes are organized from the least to most likely to succumb to buckling.

Table 4 demonstrates the class limit of both FLB and WLB. Classes were derived from Class 1/ plastic (λp) class limits and Class 2/ compact (λr). The Japanese standard had a plastic limit of 56.76 on both FLB and WLB. The Eurocode had class limits of 7.65 & 8.50 and 61.22 & 70.58 for the FLB and WLB, respectively. In that order, the British standard had λp of 8.28 and 25.76 on the FLB and WLB; likewise, λr of 9.20 and 29.44. The Philippines code indicated more significant limits than the Japanese, Eurocode, and British codes. The code had λp of 9.43 and λr of 93.27 of 24.81 and 141.40 on the FLB and WLB correspondingly.

Table 4.

Cross-sectional classification of critical members.

Likewise, the channel sections that experienced maximum compression FLB and WLB had a width-to-thickness ratio of 7.60 and 7.83 for FLB and WLB. In both cases, the stress distribution was well within the plastic limits—Class 1 (λp). Similarly, the I-section also achieved a ratio of 2.65 and 7.83 for FLB and WLB. All sections were established to be class one (Plastic) using the slenderness ratio across all the standards, as presented in Table 4 [35]. It was found that global buckling takes precedence based on computations. Therefore, the resistance of the members was considered adequate.

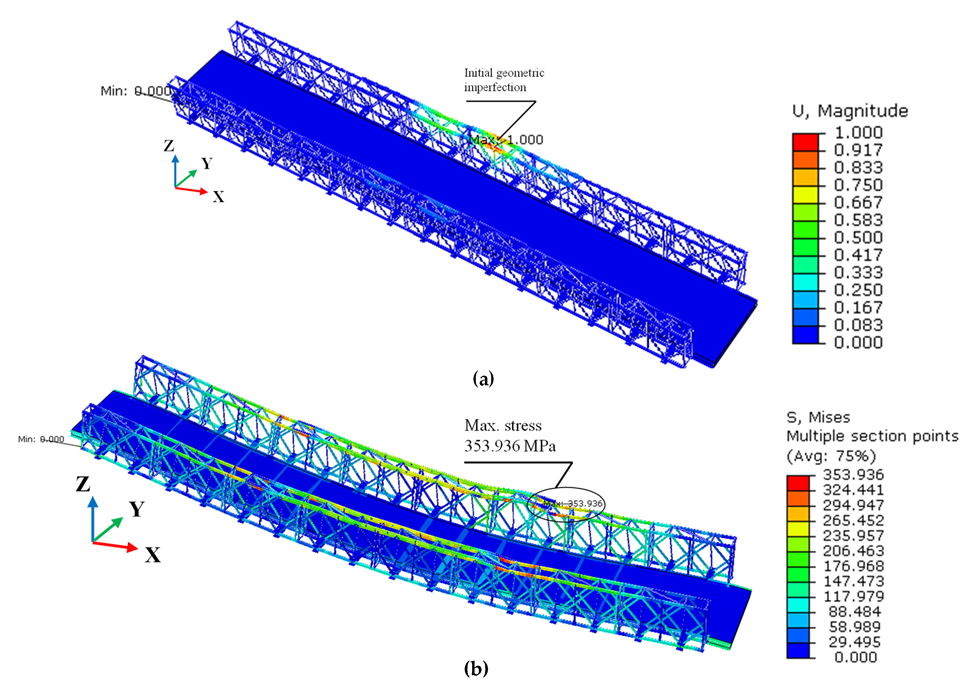

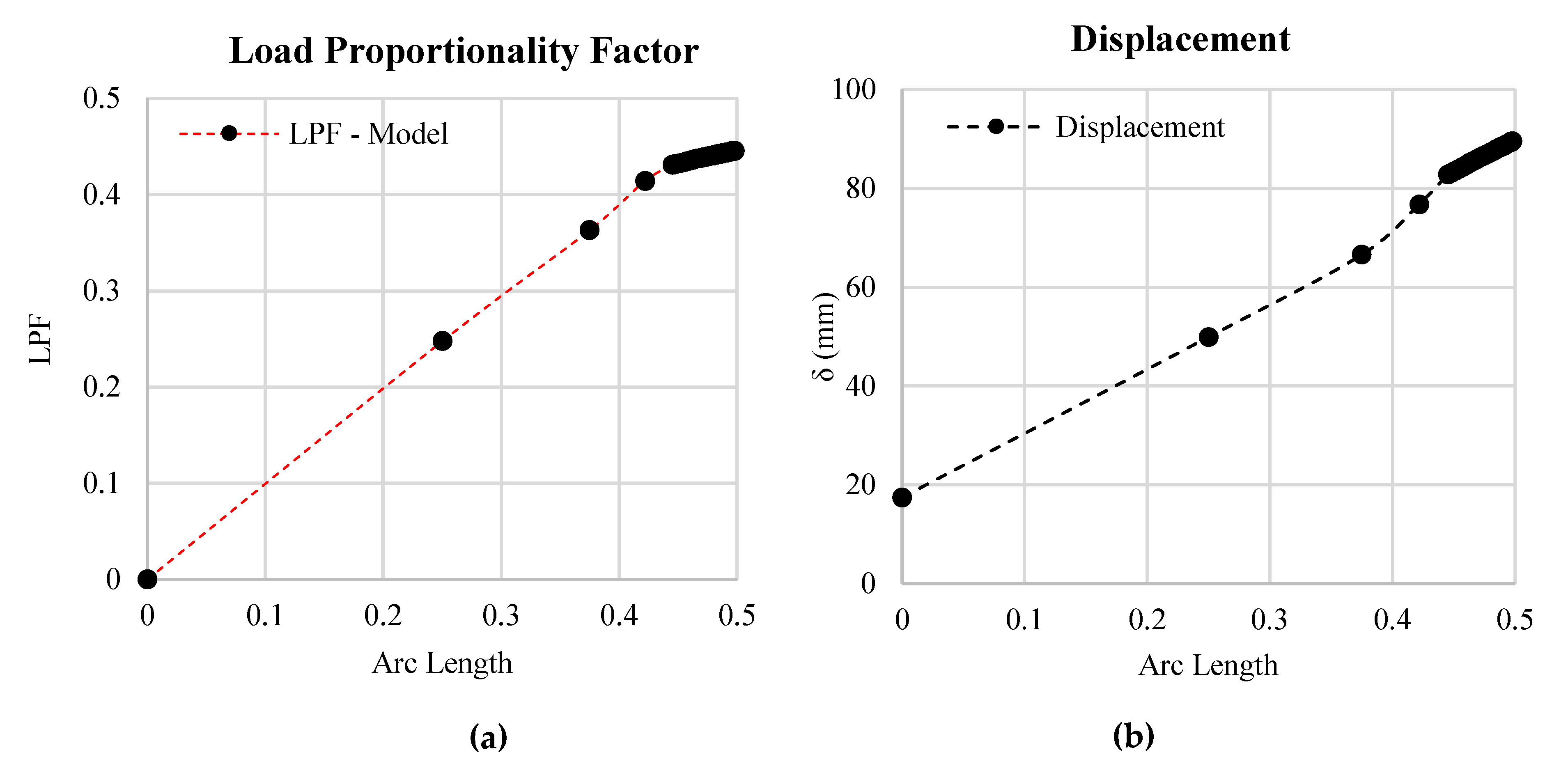

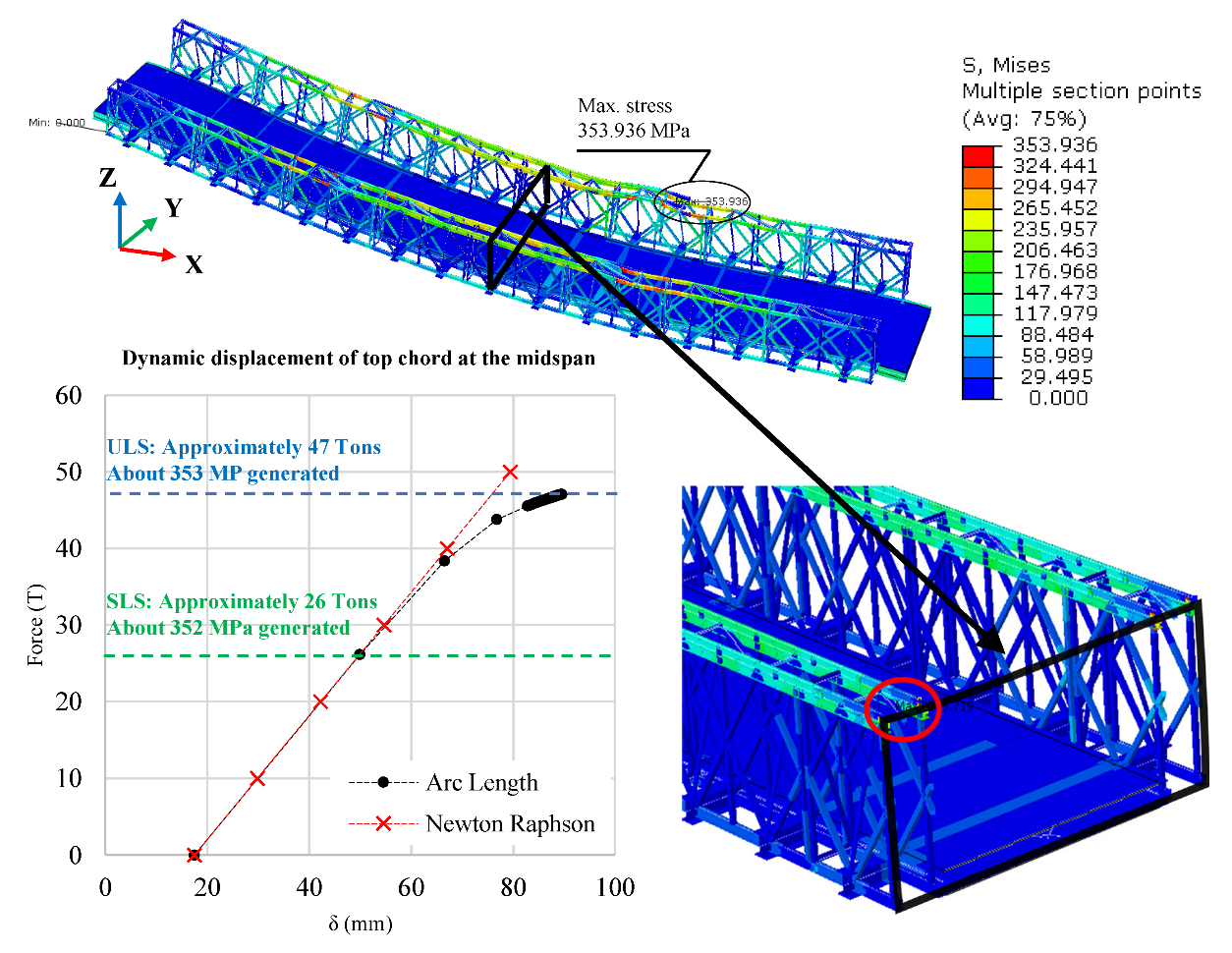

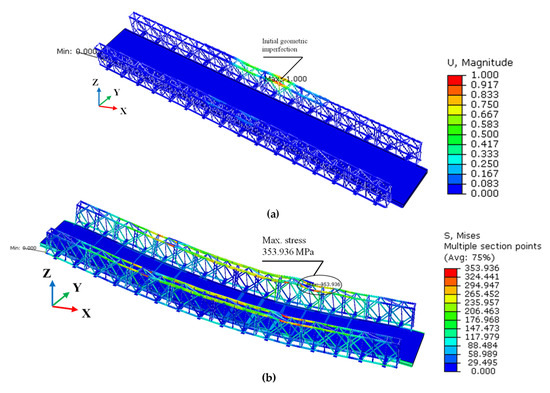

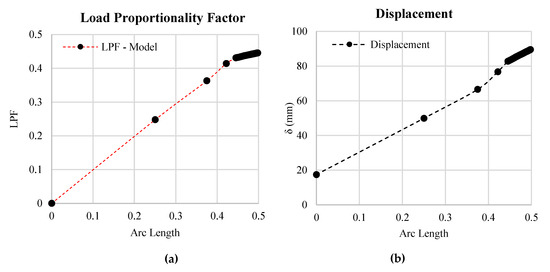

4.6. Determination of the Bearing Capacity by Nonlinear Elastic-Plastic Analysis

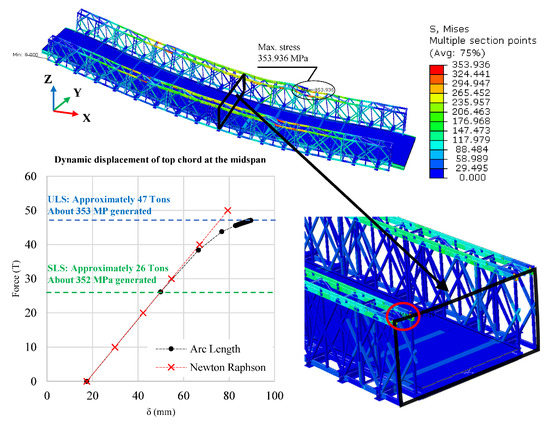

Figure 14a,b present the results of linear and nonlinear buckling analysis. They show the location of the local buckling mode one shape identified from the first out-of-plane eigenvalue and the location of maximum mises stress generation, respectively. The linear buckling process accounted for the linear response before the initial imperfection was regarded as a failure mode, one that is buckling. Hence, first, the analysis applied the weight of the concrete and superstructure preceded by the live load. Initially, the superstructure (critical members—top-chords) was linear. The loads were incremented until failure mode 1 of the superstructure corresponds to a magnitude of 1. The phase is regarded as the initial imperfection caused by an incrementing load of 1 N, as described in Figure 14a. The resultant eigenvalue mode 1 was 1.06 × 106. The value was then used as the initial load on the subsequent nonlinear buckling analysis procedure [46]. The process is like linear buckling analysis; however, the structure experiences bifurcation when the compression chord starts to buckle on stresses beyond the yield strength of 325 MPa. With the onset of buckling, the structure begins behaving nonlinearly, indicated by stresses beyond the yield strength. The superstructure deforms with no significant load varying from a deflection more than span/800 at 353.936 MPa, as illustrated in Figure 14b. Due to the consequent geometric and material nonlinearity, the superstructure releases energy related to strains. The strains are associated with the LPF extracted from the failed structure presented in Figure 15a. The proportionality factor also corresponds to the displacement of the structure with respect to the applied load that was also extracted from the nonlinear buckling analysis, as illustrated in Figure 15b.

Figure 14.

Results of linear and nonlinear buckling analysis (a) Location of local buckling mode 1 (b) Location of maximum stress generation.

Figure 15.

Relationship between Arc length and (a) LPF. (b) Displacement.

Figure 16 illustrates the location of the onset of yielding and eventual failure. Though failure occurs randomly, from the field experiment it was observed that the center span and top chord are the most vulnerable to stresses due to loading, similarly to dynamic loading [30]. In essence, the section can be used to determine the bearing capacity of the structure. A product of the LPF values by the eigenvalue mode one was considered the load or Force in Newtons (). Where Fn Force, LPF nth Load proportionality factor and X eigenvalue mode 1 (constant). On the other hand, displacement was considered as the structural deformation. The onset of nonlinearity from 26.16 Tons was observed as the SLS with a material yield stress of 325 MPa. Thus, the capacity was regarded as the minimum load that caused the initial failure of the critical member. From the bilinear model, necking denotes the ULS of 47 Tons with an ultimate strength of 353 MPa, as described in Figure 16. The estimates agreed with the suggested hearsay of 25 Tons carrying capacity. The results indicated that the bridge was intact and operated elastically during loading and unloading within the linear-elastic region. The structure was globally linear, with a bearing capacity of approximately 26 Tons [4]. The redundancy ratio between SLS and ULS was around 1.81 (). The section can be utilized to increase the bridge’s carrying capacity through structural reinforcement.

Figure 16.

SLS and ULS.

5. Conclusions

The paper presents a study on the structural health condition and adaptation of the Acrow Bailey Bridge as a permanent structure. Field experimental data were compared and validated with analytical methods for agreement. Further, an analytical model was deployed to establish the limit states (SLS and ULS) and bearing capacity using the Linear and Nonlinear Buckling (Linear perturbation and Riks) methods. The findings are presented hereunder.

Field experimental investigation:

Static loading

- Loading case 1-3 gave deflection (θ) ranging from 0.0004–0.0066, 0.0166–0.0596, and 0.0278–0.0925, correspondingly, with a validation coefficient of less than 2 on both measurement approaches that were considered within the required threshold. The maximum deformation at midspan was 14.43 mm on loading case 3.

- In that order, the image processing approach recorded deflections (θ) of 0.0079, 0.0340, and 0.0492 from Loading case 1.

- The transducer to image processing variance (Δθ) varied significantly, especially on Load case 1, by 0.0007 to 0.0050, indicating a good accuracy of the LVDT transducer on small deflections.

- Stresses were derived from an SM490 steel material with Young’s modulus of 2.0 × 105 MPa from experimental field strains that increased from Loading cases 1–3 (ε ≈ 0–104.85) within the linear elastic region.

- Static loading, under all loading conditions/cases, showed the structure operated within reasonable deflection (span/800-[39.3 mm]) and stress limits (below 325 MPa). The strain performance was also observed in typical symmetry at the center span, a trait common in Bailey Bridges.

Dynamic loading

- The results of the structural dynamic response of 3–20 km/h were 0–15.55 mm from Loading case 1, recording higher deflection than static loading by 1.4 mm at midspan, on account of the maximum recorded deflection.

- DAF (1 + μ) derived from Rdyn and Rstat resulted in 1.09. The DAF corresponded with the design criteria provided by Euro-code 1. The pavement condition was deemed ambient, with a limited deterioration range between 1.0–1.4.

Cumulatively the structure operated within the linear-elastic region.

Analytical investigation:

- DSL’s results within the linear elastic domain validated the analytical model showing good agreement with a mean validation coefficient ranging from 1.4–2.0 and similar residual characteristics across all measurement approaches.

- The response of the model compared to similar research showed a good agreement.

The validated model defines the analytical geometry, material, and loads for nonlinear analysis (material and geometric).

Analytical assessment of the bearing capacity:

- The results from the literature indicated that bridge structural elements operate in sync; therefore, their examination, espoused in Eurocode 3, gives conservative results.

- The out-of-plane eigenvalue mode one vector was established to have a first eigenmode value of 1.06 × 106 from an incrementing load of an initial magnitude of 1.

- The result of the nonlinear analysis indicated 26 Tons and 47 Tons as SLS and ULS, respectively, as the bridge’s bearing capacity with a redundancy ratio of 1.8.

- Checking for resistance of members as individuals gives conservative results. However, checking for the resistance of the whole superstructure using linear and nonlinear buckling gives non-conservative results of their interaction. These results can be deployed for evaluating structural capacity in situ without necessarily analyzing individual members, as enshrined in Eurocode 3.

The current condition of the bridge was established as good. From the research, a permanent adoption framework for the Sukumo Bailey Bridge was put forward in consideration of the local needs (use of signages to indicate the capacity) for maintaining the bridge.

The above mentioned deductions were drawn from the study providing insight for further recommendations on adoption:

- The lack of historical data can be supplemented by in situ measurement for ex situ FEM modeling. Consequently, create a digital twin of the bridge for monitoring by updating it with onsite structural data to examine its bearing capacity (digital twin models).

- A bridge operates as a monolithic structure. Thus, the 3-dimensional structural analysis of the members’ interactions is prudent for typical results. As a result, determine the ultimate resistance.

- For long-span and high bridges, wind, earthquake, and temperature loads should be considered using a case-based approach with reference to local codes and the structure’s condition, specifically abutment clearance.

Author Contributions

Conceptualization, B.A.K., T.R. and K.K.; methodology, B.A.K., Y.B. and K.K.; software, B.A.K., Y.B. and K.K.; validation, B.A.K., Y.B. and K.K.; formal analysis, B.A.K., T.R., Y.B. and K.K.; resources, B.A.K., T.R., Y.B. and K.K.; data curation B.A.K., T.R., Y.B. and K.K.; writing-original draft preparation B.A.K.; writing-review and editing B.A.K., Y.B. and K.K.; visualization, B.A.K.; supervision, Y.B. and K.K.; project administration, K.K.; funding acquisition, K.K. All authors have read the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The author is grateful to TTES for Accelerometer data processing; Inoue Kazuma of Japan Construction Method and Machinery Research Institute for his assistance in onsite measurement and image processing; JICA for initiating the Road Asset Management Program, and Uchiko Town in Ehime Prefecture, Municipality infrastructural office for the overall assistance.

Conflicts of Interest

The author declares no known competing interest in the works reported in this paper.

References

- Parivallal, S.; Narayanan, T.; Ravisankar, K.; Kesavan, K.; Maji, S. Instrumentation and Response Measurement of a Double-Lane Bailey Bridge during Load Test. Strain 2005, 41, 25–30. [Google Scholar] [CrossRef]

- Khounsida, T.; Takafumi, N.; Shozo, N.; Toshihiro, O.; Khampaseuth, T. Study on Static and Dynamic Behavior of Bailey Bridge. Adv. Struct. Eng. Mech. 2019, 46, 9425–9428. [Google Scholar] [CrossRef]

- Sindorf Trading Holland Ltd. Bailey Panel Bridge System—Triple Truss Single Storey Class 100. Available online: https://www.sindorf.nl/Portals/0/BAILEYBRIDGES.pdf (accessed on 16 November 2022).

- Yi, P.; Vaghela, G.; Andrew, B. Condition Assessment And Load Rating of Arched Bailey Bridge. In Proceedings of the Austroads Bridge Conference, Sydney, NSW, Australia, 22–24 October 2014; pp. 1–11. [Google Scholar]

- King, W.S.; Wu, S.M.; Duan, L. Laboratory Load Tests and Analysis of Bailey Bridge Segments. J. Bridg. Eng. 2013, 18, 957–968. [Google Scholar] [CrossRef]

- Khounsida, T.; Nishikawa, T.; Nakamura, S.; Okumatsu, T.; Thepvongsa, K. Experimental and Analytical Study on Dynamic Behavior of Bailey Bridge. Proc. Constr. Steel 2020, 28, 771–777. [Google Scholar]

- Motion Analysis Software MOVIAS Neo|Video Measurement|Knack. Available online: https://www.nacinc.jp/analysis/software/movias-neo/?add_list=MOVIAS+Neo (accessed on 4 November 2022).

- Jatmiko, J.; Psimoulis, P. Deformation Monitoring of a Steel Structure Using 3D Terrestrial Laser Scanner (TLS). In Proceedings of the 24th International Workshop on Intelligent Computing in Engineering, Nottingham, UK, 12 July 2017; Volume 2017, pp. 168–177. [Google Scholar]

- Tokyo Measuring Instruments Ltd. Precise and Flexible Strain Gauges; Tokyo Measuring Instruments Ltd.: Tokyo, Japan, 2020; p. 96. [Google Scholar]

- Japan Road Association. Fatigue of Steel Bridge; Japan Road Association: Tokyo, Japan, 1997; pp. 47–309. [Google Scholar]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. Prefabricated Steel Bridge Systems; FHWA SOLICITATION NO. DTFH61-03-R-00113; Structure Design and Rehabilitation, Inc.: Gaithersburg, MD, USA, 2005; Volume 1, pp. 1–261. [Google Scholar]

- Masatoshi, N.; Yuki, C.; Ichiro, A. Topological Optimum Shape of a Fundamental Module of the Periodic Structure and Cantilever Bridge. J. Struct. Eng. 2021, 67A, 90–98. [Google Scholar]

- Joiner, C.J.H. The Story of the Bailey Bridge. Proc. Inst. Civ. Eng.-Eng. Hist. Herit. 2011, 164, 65–72. [Google Scholar] [CrossRef]

- Department of the Army. Bailey Bridge; Field Manual—TM 5-277; Department of the Army: Washington, DC, USA, 1986; pp. 3–349. [Google Scholar]

- Gómez-Martínez, R.; Sánchez-García, R.; Escobar-Sánchez, J.A.; Arenas-García, L.M.; Mendoza-Salas, M.A.; Rosales-González, O.N. Monitoring Two Cable-Stayed Bridges during Load Tests with Fiber Optics. Structures 2021, 33, 4344–4358. [Google Scholar] [CrossRef]

- Umekawa, Y.; Suganuma, H. Bridge Displacement Monitoring Using Acceleration Measurement and Development of Efficient Bridge Management System. In Proceedings of the IABSE Symp. Nantes 2018 Tomorrow’s Megastructures, Nantes, France, 19–21 September 2018; pp. S6-11–S6-18. [Google Scholar] [CrossRef]

- Lichti, D.D.; Gordon, S.J.; Stewart, M.P.; Franke, J.; Tsakiri, M. Comparison of Digital Photogrammetry and Laser Scanning. ISPRS J. Photogramm. Remote Sens. 2002, 39–44. [Google Scholar]

- Tokyo Measuring Instruments Laboratory Co High Sensitive Displacement Transducer. Available online: https://tml.jp/e/product/transducers/displacement_high.html (accessed on 1 November 2022).

- Bridge Deflection Measurement Service INTEGRAL PLUS® |TTES Co., Ltd. Available online: https://ttes.co.jp/service/integral/ (accessed on 1 September 2022).

- Umekawa, Y.; Hisatada, S.; Kinoshita, K.; Ono, T. A Study on Displacement Monitoring of Bridges Using Acceleration Data Associated with Vehicle Traffic. In Proceedings of the 72nd Annual Conference of Japan Society of Civil Engineers JSCE, Kyushu, Japan, 11 September 2017; Volume 8, pp. 699–700. [Google Scholar]

- Shimosato, T.; Tai, M.; Hisatada, S.; Umekawa, Y.; Hiyama, Y. Deflection Measurement of Bridge Using TWM System. In Proceedings of the Japan Society of Civil Engineers Western Branch Okinawa Meeting, 7th Technical Research Conference, JSCE, Okinawa, Japan, 7–11 May 2018; pp. 146–147. [Google Scholar]

- Ma, M.J. Dynamic Load Test Analysis for Continuous Steel Bridge. Appl. Mech. Mater. 2013, 275–277, 1078–1081. [Google Scholar] [CrossRef]

- Paeglite, I.; Paeglitis, A.; Smirnovs, J. Dynamic Amplification Factor for Bridges With Span Length From 10 To 35 Meters. Eng. Struct. Technol. 2015, 6, 151–158. [Google Scholar] [CrossRef][Green Version]

- Bruls, A.; Calgaro, J.A.; Mathieu, H.; Prat, M. ENV1991–Part 3: The Main Models of Traffic Loads on Bridges: Background Studies; IABSE Colloquim: Delft, The Netherlands, 1996; pp. 215–228. [Google Scholar]

- Ghavami, P. Mechanics of Materials: An Introduction to Engineering Technology; Springer: New York, NY, USA, 1956; Volume 78, ISBN 9783319075716. [Google Scholar]

- Gross, D.; Ehlers, W.; Wriggers, P.; Schröder, J.; Müller, R. Mechanics of Materials-Formulas and Problems: Engineering Mechanics 2; Springer: Berlin/Heidelberg, Germany, 2016; Volume 2, pp. 1–212. [Google Scholar]

- Maros, H.; Juniar, S. Inspection and Maintenance of Steel Girders, 3rd ed.; Indian Railways Institute of Civil Engg: Pune, India, 2016; ISBN 2013206534. [Google Scholar]

- Aashto. AASHTO LRFD Bridge Design Specifications; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2010; ISBN 9781560514510. [Google Scholar]

- Yuji, I.; Nakamura, S.; Kusaba, T.; Nishikawa, T. Field Measurement and Structural Analysis of Bailey Bridge for Understanding Fundamental Load-Bearing Configuration. In Proceedings of the Japan Society of Civil Engineering-West; I-023. JSCE: Tokyo, Japan, 2022; pp. 45–46. [Google Scholar]

- Benčat, J.; Kohár, R. Bridges Subjected to Dynamic Loading. In Bridge Engineering; Intech: Rijeka, Croatia, 2018. [Google Scholar] [CrossRef]

- Kalin, J.; Žnidarič, A.; Anžlin, A.; Kreslin, M. Measurements of Bridge Dynamic Amplification Factor Using Bridge Weigh-in-Motion Data. Struct. Infrastruct. Eng. 2021, 18, 1164–1176. [Google Scholar] [CrossRef]

- Umekawa, Y.; Hisatada, S.; Kinoshita, K.; Ono, T. A Study on Displacement Response Monitoring Using Acceleration Response. In Proceedings of the JSCE Western Branch Okinawa Meeting, 6th Technical Research Presentation, Okinawa, Japan, 11–13 September 2017; JSCE: Okinawa, Japan, 2017; Volume 8, pp. 88–89. [Google Scholar]

- Association of Structural Engineers of the Philippines. National Structural Code of the Philippines; Nscp C101-15; Association of Structural Engineers of the Philippines: Quezon City, Philippines, 2015; pp. 1–1008. [Google Scholar]

- GRSE. Garden Reach Shipbuilders and Engineers Limited Kolkata—India; GRSE—Teschnical Manual; GRSE: Kolkata, India, 2016; Volume 4, pp. 1–93. [Google Scholar]

- CEN. Design of Steel Structures—Part 1-1: General Rules and Rules for Buildings; CEN: Brussels, Belgium, 2011. [Google Scholar]

- CEN. Eurocode 1: Actions on Structures—Part 2: Traffic Loads on Bridges on Bridges; CEN: Brussels, Belgium, 2003. [Google Scholar]

- Tian, Q.; Hang, C.; Wan, Z.; Zou, Y. Local Optimization Analysis of Bailey Beam Bracket Based on Multiscale Model. Key Eng. Mater. 2019, 815, 229–234. [Google Scholar] [CrossRef]

- Holmes, J.D. Wind Loading of Structures, 2nd ed.; Spon Press: New York, NY, USA, 2018; ISBN 041924610X. [Google Scholar]

- Çiftçioğlu, A.Ö.; Yildizel, S.A.; Yildirim, M.S.; Doğan, E. Wind Load Design of Hangar-Type Closed Steel Structures with Different Roof Pitches Using Abaqus CAE Software. TEM J. 2017, 6, 336–341. [Google Scholar] [CrossRef]

- LRFD Steel Girder SuperStructure Design Example-LRFD-Structures-Bridges & Structures-Federal Highway Administration. Available online: https://www.fhwa.dot.gov/bridge/lrfd/us_ds8.cfm#designstep86_5 (accessed on 19 October 2022).

- Poddaeva, O.; Fedosova, A.; Gribach, J. The Study of Wind Effects on the Bridge Constructions. E3S Web Conf. 2019, 97, 03030. [Google Scholar] [CrossRef]

- Gorenc, B.E.; Tinyou, R.; Syam, A.A. Steel Designers’ Handbook, 7th ed.; UNSW Press: Sydney, Australia, 2005. [Google Scholar]

- Ochshorn, J. Structural Elements for Architects and Builders: Design of Columns, Beams, and Tension Elements in Wood, Steel, and Reinforced Concrete; Elsevier: New York, NY, USA, 2009; ISBN 9781856177719. [Google Scholar]

- American Society of Civil Engineers. American Society of Civil Engineers Design Loads on Structures During Construction American Society of Civil Engineers Design Loads on Structures During Construction; Amer Society of Civil Engineers: Reston, VA, USA, 2003; ISBN 0784406189. [Google Scholar]

- Kumamoto, T. Seismic Hazard Maps of Japan and Computational Differences in Models and Parameters. Geogr. Rev. Jpn. Ser. B 1999, 72, 135–161. [Google Scholar] [CrossRef][Green Version]

- Dassault Systèmes. In Abaqus CAE User’s Manual; Simulia: Johnston, RI, USA, 2012; pp. 1–1174.

- Chakrabarty, J. Theory of Plasticity, 3rd ed.; Elsevier Butterworth-Heinemann: Burlington, Singapore, 2006; ISBN 0750666382. [Google Scholar]

- Sun, S.; Lei, G.; Sun, Z. Dynamic and Static Load Tests on a Large-Span Rigid-Frame Bridge. Math. Model. Eng. Probl. 2019, 6, 409–414. [Google Scholar] [CrossRef]

- Miki, C. Civil Engineering: Steel Structures, 10th ed.; Kyoritsu Publishing: Tokyo, Japan, 2000; ISBN 9784320073913. [Google Scholar]

- British Standard 5950-1:2000; Structural Use of Steel Work in Buildings Part 1. BSI: London, UK, 2001; ISBN 0 580 33238 X.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).