Performance Degradation Prognosis Based on Relative Characteristic and Long Short-Term Memory Network for Components of Brake Systems of in-Service Trains

Abstract

1. Introduction

2. Health Indicator of Components of Brake System

2.1. Brake System of Trains

2.2. Health Indicator Construction

2.3. Health Indicator Evaluation

3. LSTM-Based Method for Performance Degradation Prognosis of Components of Brake Systems

3.1. Long Short-Term Memory Network

- (1)

- Forget gate

- (2)

- Update input information

- (3)

- Update cell state

- (4)

- Network output information

3.2. Data Augmentation for the Training and Testing Sets

4. Experiment Verification

4.1. Performance Degradation Test Data Collection

4.1.1. Performance Degradation Test Data Collection

4.1.2. HI of Intake Filter

4.2. Performance Degradation Prognosis Results

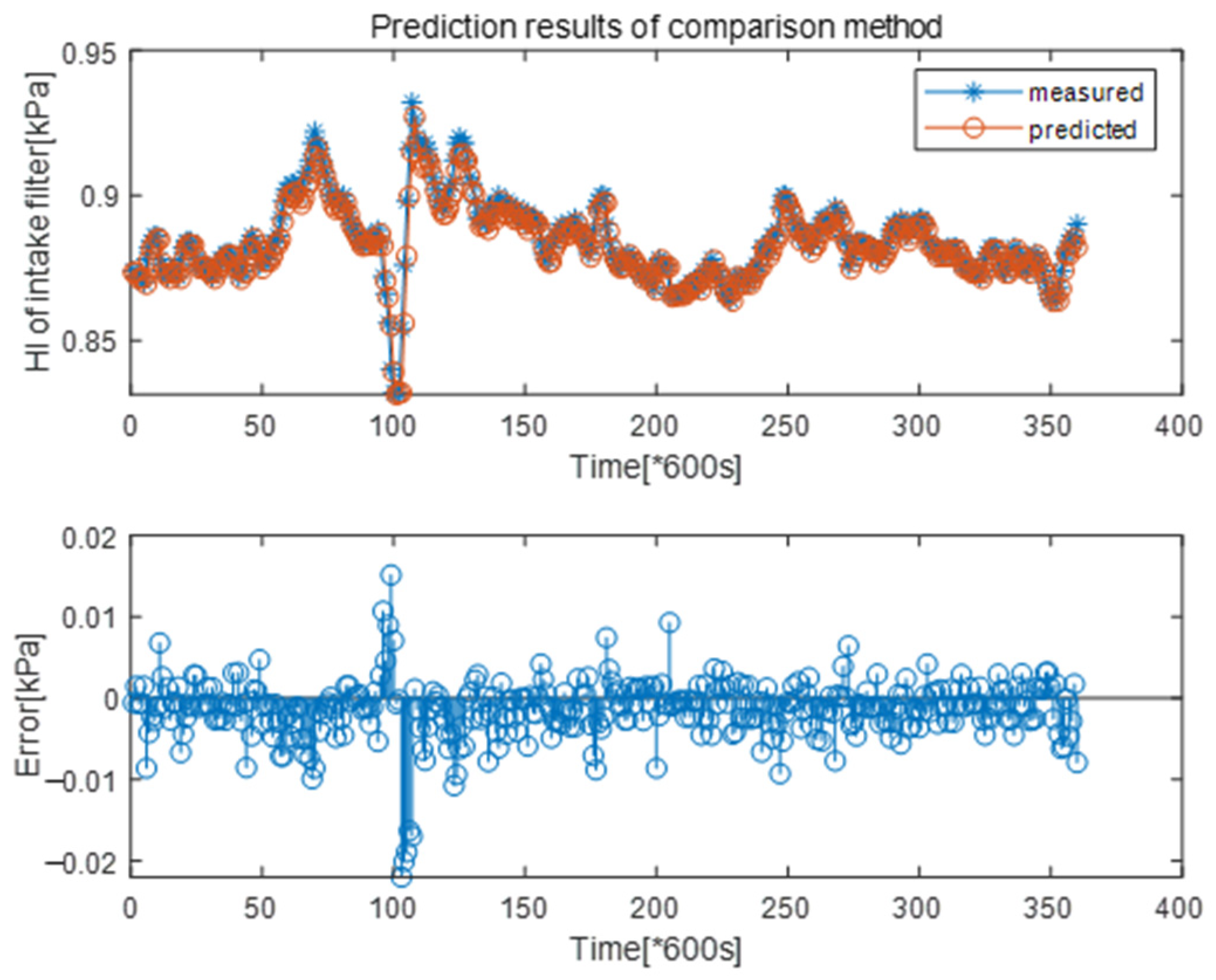

4.3. Prediction Results of the Comparison Method

4.4. The Impact of the Number of Input Nodes on Prediction Performance

5. Conclusions

- (1)

- In view of the coupling of signals between components and the variable operating conditions, the input and output signals of the components were isolated and fused. The relative characteristic that can effectively characterize the degradation state of the components was extracted as health indicators, and the validity of the health indicators was verified by calculating three evaluation indexes of monotonicity, correlation, and robustness.

- (2)

- Considering the time-memory characteristics of components during the performance degradation process, a method based on LSTM networks for trend prediction of the health indicator curves of the components was proposed.

- (3)

- A performance degradation test of the intake filter was carried out, and the validity of the performance degradation prognosis method was analyzed and verified in detail. Furthermore, the prediction results were compared with those of the prediction model based on the PSO-SVR method, verifying that the prediction model based on the LSTM network had higher prediction accuracy.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fumeo, E.; Oneto, L.; Anguita, D. Condition Based Maintenance in Railway Transportation Systems Based on Big Data Streaming Analysis. Procedia Comput. Sci. 2015, 53, 437–446. [Google Scholar] [CrossRef]

- Bai, Y.C.; An, C.; Li, M.G.; Lin, J.H.; Li, Q. Tracking Research on Service Performance of CRH3 EMU in Wuhan-Guangzhou Passenger Dedicated Line. Railw. Locomot. EMUs 2018, 1, 37–40, 43. [Google Scholar]

- Zuo, J.; Ding, J.; Hu, W.; Han, F.; Zhang, L. Performance degradation monitoring based on data fusion method for in-service train pneumatic brake system. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 1924–1938. [Google Scholar] [CrossRef]

- Liu, Z.L.; Pan, D.; Zuo, M.J.; Liang, X.L. A Review on Fault Diagnosis for Rail Vehicles. J. Mech. Eng. 2016, 52, 134–146. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.-F.; Zio, E. A SVM framework for fault detection of the braking system in a high speed train. Mech. Syst. Signal Process. 2017, 87, 401–409. [Google Scholar] [CrossRef]

- Lu, Y.; Fan, X.; Gao, D.; Cheng, Y.; Yang, Y.; Zhang, X.; Li, S.; Peng, J. A data-based approach for sensor fault detection and diagnosis of Electro-Pneumatic brake. In Proceedings of the 2019 IEEE International Conference on Prognostics and Health Management, San Francisco, CA, USA, 17–20 June 2019. [Google Scholar]

- Zuo, J.; Ding, J.; Feng, F. Latent Leakage Fault Identification and Diagnosis Based on Multi-Source Information Fusion Method for Key Pneumatic Units in Chinese Standard Electric Multiple Units (EMU) Braking System. Appl. Sci. 2019, 9, 300. [Google Scholar] [CrossRef]

- Zhou, D.; Ji, H.; He, X.; Shang, J. Fault Detection and Isolation of the Brake Cylinder System for Electric Multiple Units. IEEE Trans. Control Syst. Technol. 2018, 26, 1744–1757. [Google Scholar] [CrossRef]

- Seo, B.; Jo, S.H.; Oh, H.; Youn, B.D. Solenoid Valve Diagnosis for Railway Braking Systems with Embedded Sensor Signals and Physical Interpretation. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, Denver, CO, USA, 3–6 October 2016; pp. 337–343. [Google Scholar]

- Lei, Y.; Li, N.; Gontarz, S.; Lin, J.; Radkowski, S.; Dybala, J. A Model-Based Method for Remaining Useful Life Prediction of Machinery. IEEE Trans. Reliab. 2016, 65, 1314–1326. [Google Scholar] [CrossRef]

- An, D.; Kim, N.H.; Choi, J.-H. Practical options for selecting data-driven or physics-based prognostics algorithms with reviews. Reliab. Eng. Syst. Saf. 2015, 133, 223–236. [Google Scholar] [CrossRef]

- Baraldi, P.; Cadini, F.; Mangili, F.; Zio, E. Model-based and data-driven prognostics under different available information. Probabilistic Eng. Mech. 2013, 32, 66–79. [Google Scholar] [CrossRef]

- Zuo, J.Y.; Ding, J.X. Research progress on intelligent control and maintenance technology of railway vehicle braking system. J. Traffic Transp. Eng. 2021, 21, 50–62. [Google Scholar]

- Li, N.; Lei, Y.; Gebraeel, N.; Wang, Z.; Cai, X.; Xu, P.; Wang, B. Multi-Sensor Data-Driven Remaining Useful Life Prediction of Semi-Observable Systems. IEEE Trans. Ind. Electron. 2021, 68, 11482–11491. [Google Scholar] [CrossRef]

- Zhao, S.K.; Jiang, C.; Long, X.Y. Remaining useful life estimation of mechanical systems based on the data-driven method and bayesian theory. J. Mech. Eng. 2018, 54, 115–124. [Google Scholar] [CrossRef]

- Camci, F.; Medjaher, K.; Zerhouni, N.; Nectoux, P. Feature Evaluation for Effective Bearing Prognostics. Qual. Reliab. Eng. Int. 2013, 29, 477–486. [Google Scholar] [CrossRef]

- Qian, Y.; Hu, S.; Yan, R. Bearing performance degradation evaluation using recurrence quantification analysis and auto-regression model. In Proceedings of the IEEE Instrumentation and Measurement Technology Conference, Minneapolis, MN, USA, 6–9 May 2013; pp. 1713–1716. [Google Scholar]

- Qiu, H.; Lee, J.; Lin, J.; Yu, G. Robust performance degradation assessment methods for enhanced rolling element bearing prognostics. Adv. Eng. Inform. 2003, 17, 127–140. [Google Scholar] [CrossRef]

- Huang, R.; Xi, L.; Li, X.; Liu, C.R.; Qiu, H.; Lee, J. Residual life predictions for ball bearings based on self-organizing map and back propagation neural network methods. Mech. Syst. Signal Process. 2007, 21, 193–207. [Google Scholar] [CrossRef]

- Yu, J. Health Condition Monitoring of Machines Based on Hidden Markov Model and Contribution Analysis. IEEE Trans. Instrum. Meas. 2012, 61, 2200–2211. [Google Scholar] [CrossRef]

- Pei, H.; Hu, C.H.; Si, X.S.; Zhang, J.X.; Pang, Z.N.; Zhang, P. Review of Machine Learning Based Remaining Useful Life Prediction Methods for Equipment. J. Mech. Eng. 2019, 55, 1–13. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, B.-D.; He, B.; Peng, Y.; Ren, M.-L. Singular Spectrum Analysis and ARIMA Hybrid Model for Annual Runoff Forecasting. Water Resour. Manag. 2011, 25, 2683–2703. [Google Scholar] [CrossRef]

- Partanen, S.V.A. Forecasting electricity price and demand using a hybrid approach based on wavelet transform, ARIMA and neural networks. Int. J. Energy Res. 2014, 38, 626–637. [Google Scholar]

- Li, F.X.; Chen, G.M.; Zhu, L.; Liu, X.L.; Li, S.C. Hybrid prediction method based on empirical mode decomposition and RBF neural network. Vib. Meas. Diagn. 2012, 32, 817–822. [Google Scholar]

- You, G.-W.; Park, S.; Oh, D. Real-time state-of-health estimation for electric vehicle batteries: A data-driven approach. Appl. Energy 2016, 176, 92–103. [Google Scholar] [CrossRef]

- Gao, Y.; Li, Y. Fault Prediction Model Based on Phase Space Reconstruction and Least Squares Support Vector Machines. In Proceedings of the 2009 Ninth International Conference on Hybrid Intelligent Systems. IEEE Computer Society, Shenyang, China, 12–14 August 2009; pp. 464–467. [Google Scholar]

- Shen, Z.J.; Chen, X.F.; He, Z.J.; Sun, C.; Zhang, X.L.; Liu, Z.W. Remaining life predictions of rolling bearing based on relative features and multivariable support vector machine. J. Mech. Eng. 2013, 49, 183–189. [Google Scholar] [CrossRef]

- Tran, V.T.; Pham, H.T.; Yang, B.-S.; Nguyen, T.T. Machine performance degradation assessment and remaining useful life prediction using proportional hazard model and support vector machine. Mech. Syst. Signal Process. 2012, 32, 320–330. [Google Scholar] [CrossRef]

- Felix, O.; Heimes, B.S. Recurrent neural networks for remaining useful life estimation. In Proceedings of the 2008 International Conference on Prognostics and Health Management, Denver, CO, USA, 6–9 October 2008. [Google Scholar]

- Bengio, Y.; Simard, P.; Frasconi, P. Learning long-term dependencies with gradient descent is difficult. IEEE Trans. Neural Netw. 1994, 5, 157–166. [Google Scholar] [CrossRef] [PubMed]

- Hochreiter, S.; Schmidhuber, J. Long Short-term Memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.J.; Yang, S.P.; Liu, Y.Q.; Wen, G.L. A Method of Bearing Remaining Useful Life Estimation Based on Convolutional Long Short-term Memory Neural Network. J. Mech. Eng. 2021, 57, 88–95. [Google Scholar]

- Qi, Q.Y.; Lv, Y.B.; Ma, J.H.; Li, J. An LSTM-Based Method Considering History and Real-Time Data for Passenger Flow Prediction. Appl. Sci. 2020, 10, 3788. [Google Scholar]

- Wu, Y.; Yuan, M.; Dong, S.; Lin, L.; Liu, Y. Remaining useful life estimation of engineered systems using vanilla LSTM neural networks. Neurocomputing 2018, 275, 167–179. [Google Scholar] [CrossRef]

- Zuo, J.; Ding, J.; Liu, C.; Luo, Z. A virtual prototype for performance analysis of electropneumatic brake on metro trains. Adv. Mech. Eng. 2020, 12, 1687814020926275. [Google Scholar] [CrossRef]

| Evaluation Indicators | RMSE | MAE | MAXERROR | MAPE | MRPE | A (%) | Score |

|---|---|---|---|---|---|---|---|

| LSTM | 0.0036 | 0.0025 | 0.0197 | 0.0029 | 0.2863 | 99.94 | 359.0060 |

| PSO-SVR | 0.0041 | 0.0028 | 0.0220 | 0.0030 | 0.3151 | 99.54 | 359.0827 |

| Number of Input Nodes | RMSE | MAE | MAXERROR | MAPE | MRPE | A (%) | Score |

|---|---|---|---|---|---|---|---|

| 1 | 0.0037 | 0.0026 | 0.0182 | 0.0030 | 0.2955 | 99.85 | 361.0308 |

| 2 | 0.0036 | 0.0025 | 0.0189 | 0.0028 | 0.2811 | 99.90 | 360.0186 |

| 3 | 0.0036 | 0.0025 | 0.0197 | 0.0029 | 0.2863 | 99.94 | 359.0060 |

| 4 | 0.0037 | 0.0026 | 0.0215 | 0.0029 | 0.2941 | 99.87 | 358.0242 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ding, J.; Zuo, J. Performance Degradation Prognosis Based on Relative Characteristic and Long Short-Term Memory Network for Components of Brake Systems of in-Service Trains. Appl. Sci. 2022, 12, 11725. https://doi.org/10.3390/app122211725

Ding J, Zuo J. Performance Degradation Prognosis Based on Relative Characteristic and Long Short-Term Memory Network for Components of Brake Systems of in-Service Trains. Applied Sciences. 2022; 12(22):11725. https://doi.org/10.3390/app122211725

Chicago/Turabian StyleDing, Jingxian, and Jianyong Zuo. 2022. "Performance Degradation Prognosis Based on Relative Characteristic and Long Short-Term Memory Network for Components of Brake Systems of in-Service Trains" Applied Sciences 12, no. 22: 11725. https://doi.org/10.3390/app122211725

APA StyleDing, J., & Zuo, J. (2022). Performance Degradation Prognosis Based on Relative Characteristic and Long Short-Term Memory Network for Components of Brake Systems of in-Service Trains. Applied Sciences, 12(22), 11725. https://doi.org/10.3390/app122211725