Optimization Strategy for Modal Test Measurement Points of Large-Span Steel Beams Based on Improved Particle Swarm Optimization Algorithm with Random Weights

Abstract

1. Introduction

2. PSO Algorithm

2.1. Standard PSO Algorithms

- Initialization: At , the algorithm randomly generates particles, the dimension of each particle is and the corresponding position is ; under the limitation of the maximum velocity, take a random value and let be initialized as .

- Iterative calculation of the fitness function value: the individual optimal value of the randomly generated initial particles is , the global optimal value of the initial particle swarm is , and its fitness function value is .

- Update time: set time .

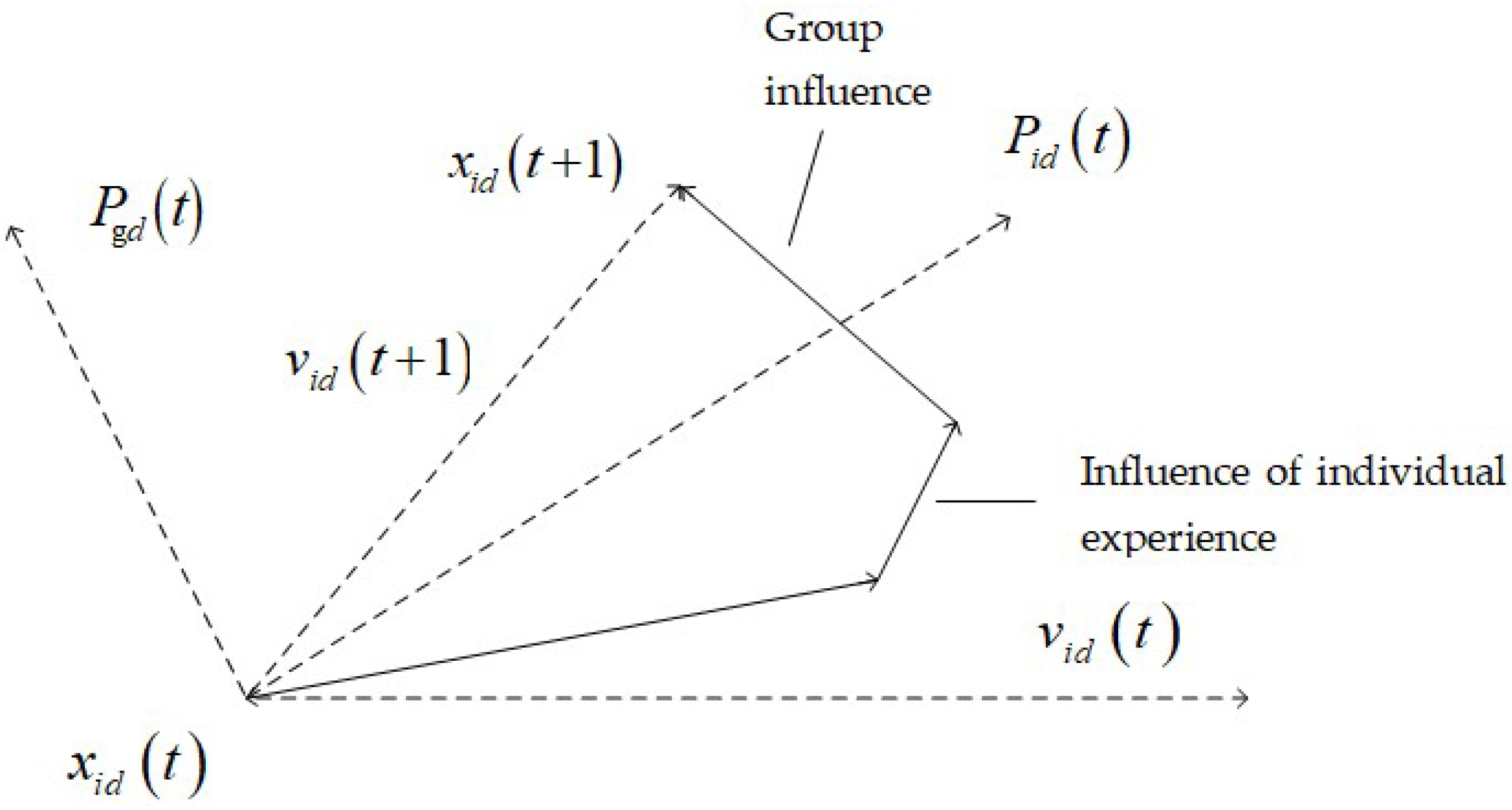

- Update velocity and position: position and velocity updates according to Equations (1) and (2), respectively.

- Update the individual optimum: compare and , make when is better than ; otherwise, is left untouched.

- Update the global optimal value: In , select the optimal and compare it with ; if is better than , then make ; otherwise, leave it untouched. Follow the above process to (6) and output the result when the end condition is met; otherwise, return to (2).

2.2. Improved PSOA (IPSOA)

- Initialize the velocity and position of each particle in the PSOA.

- Evaluate the fitness of each particle, store the current fitness value and position of each particle in the of each particle, and store the fitness value and position of the individual with the best fitness value in all in .

- Update the velocity and disarrangement of the particle using the following equation:

- Update the weights according to Equation (3).

- For each particle, compare the best position it has passed through with the fitness value, and if it is better, use it as the current best position. Compare the values of all current and and update .

- When the end condition is met, the search will stop and the results will be output; otherwise, return to (3) to continue the search.

2.3. Simulation Validation of IPSOARW

3. Measurement Point Optimization Strategy of Long-Span Steel Beam Based on the IPSOARW

3.1. Modal Assurance Criterion (MAC)

3.2. Establishment of the Fitness Function

3.3. Acquisition of Training Data for Bridge Decks Based on IPSOARW

3.4. Strategy for Optimizing the Number of Measurement Points for the Modal Test of Large-Span Steel Beams

- Construct the matrix formula.

- Set the maximum value of the non-diagonal elements of the matrix to be the function .

- Select one node at random from all the nodes as a measurement point and calculate the relationship between the number of measurement points and , select one node at random from the remaining nodes to add a measurement point, calculate the number of measurement points at this moment as a function of and repeat the superposition of measurement points.

- Using the above iterative method, the value of the function can be derived under different numbers of measurement points.

- On this basis, the most reasonable number of measurement points is determined by plotting the value of the function against the number of measurement points.

3.5. Optimization Strategy for the Location of Measurement Points on Large-Span Steel Beams Based on the IPSOARW

- Introduce the matrix

- Construct the fitness function with the maximum value of the off-diagonal elements of the matrix.

- Set IPSOARW parameters, such as population size, particle dimension, maximum number of iterations, learning factor, particle speed, etc.

- Calculate and obtain the modal shape data of the structure.

- Use the IPSOARW to optimize the position of the measurement point, calculate the current fitness value of each particle and determine the group extreme value and the individual extreme value of the particle. The loop iterates. When the maximum number of iterations is reached, the loop ends and the optimal value is output. The value is the node number of the optimal location of the measurement points.

4. Realization of the Optimization of the Measurement Points of the Deck Modal Test of STTGB

4.1. Acquisition of Training Data for the IPSOARW Based on Computational Modal Analysis

4.2. Optimization Results of the Number of Bridge Deck Measurement Points

4.3. Optimization of Bridge Deck Measurement Points Location Based on the IPSOARW

- When IPSOARW is used to optimize the location of measuring points, the fitness function value decreases with the increase in the number of iterations.

- After the number of iterations of the optimization algorithm reaches 240, when the number of iterations continues to increase, the fitness function value does not change, and the optimization algorithm reaches convergence.

- According to the criterion of modal confidence, the final convergence result of the fitness function value in the figure can reach 0.006, indicating that the proposed IPSOARW-based point distribution method of the bridge deck can meet the optimization goal of measurement point positions.

5. Validation of Optimization Strategy for STTGB Bridge Deck Measurement Points Based on Experimental Modal Analysis

5.1. The Modal Test System of the STTGB Deck

5.2. Modal Test of Bridge Deck Based on the Uniform Distribution Method

5.3. Modal Test of the Bridge Deck Based on the IPSOARW Distribution Method

5.4. Comparison of the Experiments Results of the Two-Measurement Point Arrangement Method

- The modal test on the bridge deck based on the uniform distribution method identified a total of six orders of modes, and compared to the FEA, the modal frequencies around 90 Hz were lost and a lost mode condition occurred, while the test on the bridge deck based on the IPSOARW distribution method identified a total of seven orders of modes and no lost modes.

- The mean error between the frequency obtained by the uniform distribution method and the FEA frequency of the bridge deck was 5.33%, while that of the bridge deck based on the IPSOARW distribution method was 4.06%. Obviously, the modal parameters obtained by the IPSOARW distribution method are consistent with the FEA modal parameters, and the modes of each order are basically the same.

6. Conclusions

- The number of measurement points of the bridge deck based on the uniform distribution method was 50, while the number based on the IPSOARW was 28. By contrast, the number of points was reduced by 44%. The results show that the proposed IPSOARW can effectively improve the test efficiency of the STTGB and reduce the number of sensor arrangements, which will save a lot of test costs.

- In the modal frequencies obtained based on the uniform distribution method, the mode around 90 Hz was lost, while the IPSOARW did not lose the modes. The results show that the proposed IPSOARW can effectively identify the modes in the frequency-dense segment and has the advantage of not losing the modes easily.

- The average error between the frequency obtained by the uniform distribution method and the finite element analysis frequency of the bridge deck was 5.33%, while that based on the IPSOARW distribution method was 4.06%. The results show that the proposed IPSOARW is suitable for the optimal arrangement of measurement points of the STTGB deck and that the obtained modal parameters have high accuracy. The modal parameters identified based on this optimized arrangement method have high accuracy and can accurately reflect the actual dynamic characteristics of the bridge deck.

- The experimental examples used in this paper are idealized without considering the influence of environmental factors such as wind load and vehicle load. Therefore, these factors will be taken into account in our next work to further test the applicability and effectiveness of the proposed method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Han, R.; Zhao, X. Shaking Table Tests and Validation of Multi-Modal Sensing and Damage Detection Using Smartphones. Buildings 2021, 11, 477. [Google Scholar] [CrossRef]

- Luo, J.; Huang, M.S.; Lei, Y.Z. Temperature Effect on Vibration Properties and Vibration-Based Damage Identification of Bridge Structures: A Literature Review. Buildings 2022, 12, 1209. [Google Scholar] [CrossRef]

- Seyedmilad, K.; Mahyad, K.; Ahmad, A.; José, A.L.G.; Gonzalo, R.; Jose, T. A Novel Wireless Low-Cost Inclinometer Made from Combining the Measurements of Multiple MEMS Gyroscopes and Accelerometers. Sensors 2022, 22, 5605. [Google Scholar] [CrossRef]

- Seyedmilad, K.; Fidel, L.; José, A.L.G.; Gonzalo, R.; Jose, T. Low-Cost Wireless Structural Health Monitoring of Bridges. Sensors 2022, 22, 5725. [Google Scholar] [CrossRef]

- Rosario, C.; Erica, L.; Gaetano, M.; Valerio, O.; Linda, S. Modal Identification of Structures with Interacting Diaphragms. Appl. Sci. 2022, 12, 4030. [Google Scholar] [CrossRef]

- Duvnjak, I.; Klepo, I.; Serdar, M.; Damjanović, D. Damage Assessment of Reinforced Concrete Elements Due to Corrosion Effect Using Dynamic Parameters: A Review. Buildings 2021, 11, 425. [Google Scholar] [CrossRef]

- Liu, X.L.; Zhao, S.X.; Wang, P.P.; Wang, R.J.; Huang, M. Improved Data-Driven Stochastic Subspace Identification with Autocorrelation Matrix Modal Order Estimation for Bridge Modal Parameter Extraction Using GB-SAR Data. Buildings 2022, 12, 253. [Google Scholar] [CrossRef]

- Yang, J.H.; Peng, Z.R. Improved ABC Algorithm Optimizing the Bridge Sensor Placement. Sensors 2018, 18, 2240. [Google Scholar] [CrossRef] [PubMed]

- Kammer, D.C. Sensor placement for on-orbit modal identification and correlation of large space structures. J. Guid. Control. Dyn. 1991, 14, 251–259. [Google Scholar] [CrossRef]

- Liu, W.; Gao, W.C.; Sun, Y.; Xu, M.J. Optimal sensor placement for spatial lattice structure based on genetic algorithms. J. Sound Vib. 2008, 317, 175–189. [Google Scholar] [CrossRef]

- Yin, H.; Dong, K.L.; Pan, A.; Peng, Z.R.; Jiang, Z.Y.; Li, S.Y. Optimal sensor placement based on relaxation sequential algorithm. Neurocomputing 2019, 344, 28–36. [Google Scholar] [CrossRef]

- Chai, W.H.; Yang, Y.X.; Yu, H.B.; Yang, F.L.; Yang, Z.K. Optimal sensor placement of bridge structure based on sensitivity-effective independence method. IET Circuits Devices Syst. 2022, 16, 125–135. [Google Scholar] [CrossRef]

- Liu, H.B.; Wu, C.L.; Wang, J. Sensor Optimal Placement for Bridge Structure Based on Single Parents Genetic Algorithm with Different Fitness Functions. Key Eng. Mater. 2010, 456, 115–124. [Google Scholar] [CrossRef]

- Zhang, B.Y.; Zhang, X.D.; Zhang, Z.H. Nested-Stacking Genetic Algorithm for the Optimal Placement of Sensors in Bridge. Comput. J. 2018, 61, 1269–1283. [Google Scholar] [CrossRef]

- He, C.; Xing, J.C.; Li, J.L.; Yang, Q.L.; Wang, R.H.; Zhang, X. A Combined Optimal Sensor Placement Strategy for the Structural Health Monitoring of Bridge Structures. Int. J. Distrib. Sens. Netw. 2013, 11, 477–482. [Google Scholar] [CrossRef]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN’95—International Conference on Neural Networks, Perth, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar] [CrossRef]

- Fakhouri, H.N.; Hudaib, A.; Sleit, A. Multivector particle swarm optimization algorithm. Soft Comput. 2020, 24, 11695–11713. [Google Scholar] [CrossRef]

- Yu, C.J.; Li, Y.L.; Chen, Q.; He, J.Y.; Zhao, L.Y. An advanced particle swarm optimization algorithm and its application to search flutter critical velocity of bridges. Adv. Struct. Eng. 2022, 25, 2271–2283. [Google Scholar] [CrossRef]

- Huang, M.S.; Lei, Y.Z.; Cheng, S.X. Damage identification of bridge structure considering temperature variations based on particle swarm optimization—Cuckoo search algorithm. Adv. Struct. Eng. 2019, 22, 3262–3276. [Google Scholar] [CrossRef]

- Tran, N.H.; Khatir, S.; De, R.G.; Bui, T.T.; Nguyen, N.L.; Abdel, W.M. Model Updating for Nam O Bridge Using Particle Swarm Optimization Algorithm and Genetic Algorithm. Sensors 2018, 18, 4131. [Google Scholar] [CrossRef]

- Jiang, Y.; Hu, T.S.; Huang, C.C.; Wu, X.N. An improved particle swarm optimization algorithm. Appl. Math. Comput. 2007, 193, 231–239. [Google Scholar] [CrossRef]

- Liu, H.B.; Wang, X.Q.; Jiao, Y.B.; He, X.; Wang, B.Y. Condition evaluation for existing reinforced concrete bridge superstructure using fuzzy clustering improved by particle swarm optimization. Struct. Infrastruct. Eng. 2017, 13, 955–965. [Google Scholar] [CrossRef]

- He, Z.; Liu, T.H.; Liu, H. Improved particle swarm optimization algorithms for aerodynamic shape optimization of high-speed train. Adv. Eng. Softw. 2022, 173, 103242. [Google Scholar] [CrossRef]

- Li, S.R.; Ma, D.Y.; Lu, J.X. In situ calibration of triaxial coils of a vector optically pumped magnetometers based on a particle swarm optimization algorithm. Measurement 2022, 22, 111878. [Google Scholar] [CrossRef]

- Song, Z.K.; Wang, P.; Bai, L.Q. Optimization of Pulse CVT Based on Improved Particle Swarm Algorithm. In Proceedings of the 2017 2nd International Conference on Materials Science, Machinery and Energy Engineering, Dalian, China, 13–14 May 2017. [Google Scholar] [CrossRef]

- Wang, P.; Cheng, K.; Huang, Y.; Li, B.; Ye, X.G.; Chen, X.H. Multiscale Quantum Harmonic Oscillator Algorithm for Multimodal Optimization. Comput. Intell. Neurosci. 2018, 2018, 8430175. [Google Scholar] [CrossRef] [PubMed]

| Parameters | n | Learning Factor | Number of Iterations | |||

|---|---|---|---|---|---|---|

| Value | 40 | 2 | 0.5 | 0.8 | 0.2 | 10,000 |

| Structural Steel (Q235) | |

|---|---|

| Density | 7850 kg/m3 |

| Young’s modulus | 2 × 1011 Pa |

| Poisson’s ratio | 0.3 |

| Order | Calculated Modal Frequencies [Hz] | Modal Vibration Pattern | Description of the Vibration Pattern |

|---|---|---|---|

| 1 | 18.037 |  | 1st order bending |

| 2 | 27.455 |  | 1st order twisting |

| 3 | 37.271 |  | 2nd order bending |

| 4 | 53.726 |  | 2nd order twisting |

| 5 | 79.738 |  | 3rd order twisting |

| 6 | 85.554 |  | 4th order bending |

| 7 | 95.439 |  | Combined 2nd order bending and twisting deformation |

| Population Size | Particle Dimension | Maximum Number of Iterations | Learning Factor | Particle Velocity |

|---|---|---|---|---|

| 50 | 28 | 300 | 2 2 | −20 20 |

| Number of Measurement Points | Optimization Results (Node Number) |

|---|---|

| 28 | 364274, 386971, 356881, 369766, 45758, 380325, 357042, 38894, 374472, 364668, 103815, 358666, 39530, 374055, 6193, 360275, 374735, 363356, 358739, 370854, 363740, 358884, 39414, 374296, 362180, 368224, 361438, 364724 |

| No. | X (mm) | Y (mm) | No. | X (mm) | Y (mm) |

|---|---|---|---|---|---|

| 1 | 1253.7 | 422.3 | 15 | 2482.6 | 0 |

| 2 | 6211.1 | 820.3 | 16 | 5057.4 | 898 |

| 3 | 6968.7 | 443.7 | 17 | 6640.2 | 49 |

| 4 | 3606.1 | 1327.3 | 18 | 7731 | 215.8 |

| 5 | 760.1 | 905.3 | 19 | 502.6 | 564.2 |

| 6 | 2969.8 | 815.9 | 20 | 7192.5 | 1380.8 |

| 7 | 1964.2 | 195.3 | 21 | 7886.9 | 671.4 |

| 8 | 8081.7 | 282 | 22 | 2404.5 | 818.7 |

| 9 | 2130 | 1120.8 | 23 | 6925.2 | 1218.3 |

| 10 | 6655.3 | 1360.3 | 24 | 354 | 928.7 |

| 11 | 4656.2 | 1420.1 | 25 | 896.7 | 1088.6 |

| 12 | 3973 | 360.6 | 26 | 4367.4 | 28.6 |

| 13 | 5514.4 | 645.9 | 27 | 4051.6 | 584.4 |

| 14 | 4927.2 | 338.1 | 28 | 1339.2 | 1144.6 |

| Test System Components | Test Equipment | Number |

|---|---|---|

| Motivational equipment | Large impact hammer (INV9313) | 1 |

| Rubber hammer heads | 1 | |

| Collection equipment | Channel cable wires | 2 |

| INV force sensors (110610) | 1 | |

| PCB single acceleration sensor (INV8923) | 1 | |

| Magnetic base | 1 | |

| 8-channel distributed collector (INV30600C) | 1 | |

| Analysis of components | DASP-V10 modal analysis software | 1 |

| Order | Frequency [Hz] | Modal Vibration Pattern | Description of the Vibration Pattern |

|---|---|---|---|

| 1 | 17.042 |  | 1st order bending |

| 2 | 28.156 |  | 1st order twisting |

| 3 | 40.614 |  | 2nd order bending |

| 4 | 51.152 |  | 2nd order twisting |

| 5 | 79.151 |  | 3rd order twisting |

| 6 | 93.662 |  | Combined 1st order bending and torsion deformation |

| Order | Frequency [Hz] | Modal Vibration Pattern | Description of the Vibration Pattern |

|---|---|---|---|

| 1 | 17.031 |  | 1st order bending |

| 2 | 28.091 |  | 1st order twisting |

| 3 | 40.774 |  | 2nd order bending |

| 4 | 52.112 |  | 2nd order twisting |

| 5 | 79.120 |  | 3rd order twisting |

| 6 | 90.814 |  | 4th order bending |

| 7 | 96.546 |  | Combined 1st-order bending and torsion deformation |

| Order | Frequency [Hz] | Error [%] | Mean Error [%] | ||||

|---|---|---|---|---|---|---|---|

| FEA | U (a, b) | IPSOARW | U (a, b) | IPSOARW | U (a, b) | IPSOARW | |

| 1 | 18.037 | 17.042 | 17.031 | 5.5 | 5.6 | ||

| 2 | 27.455 | 28.156 | 28.091 | 2.6 | 2.3 | ||

| 3 | 37.271 | 40.614 | 40.774 | 8.9 | 9.4 | ||

| 4 | 53.726 | 51.152 | 52.112 | 4.8 | 3.0 | 5.33 | 4.06 |

| 5 | 79.738 | 79.151 | 79.120 | 0.7 | 0.8 | ||

| 6 | 85.554 | 93.662 | 90.814 | 9.5 | 6.1 | ||

| 7 | 95.439 | - | 96.546 | - | 1.2 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, J.; Wang, K.; Wu, D.; Huang, Q.; Yu, M. Optimization Strategy for Modal Test Measurement Points of Large-Span Steel Beams Based on Improved Particle Swarm Optimization Algorithm with Random Weights. Appl. Sci. 2022, 12, 12082. https://doi.org/10.3390/app122312082

Zhao J, Wang K, Wu D, Huang Q, Yu M. Optimization Strategy for Modal Test Measurement Points of Large-Span Steel Beams Based on Improved Particle Swarm Optimization Algorithm with Random Weights. Applied Sciences. 2022; 12(23):12082. https://doi.org/10.3390/app122312082

Chicago/Turabian StyleZhao, Jian, Kun Wang, Di Wu, Qin Huang, and Ming Yu. 2022. "Optimization Strategy for Modal Test Measurement Points of Large-Span Steel Beams Based on Improved Particle Swarm Optimization Algorithm with Random Weights" Applied Sciences 12, no. 23: 12082. https://doi.org/10.3390/app122312082

APA StyleZhao, J., Wang, K., Wu, D., Huang, Q., & Yu, M. (2022). Optimization Strategy for Modal Test Measurement Points of Large-Span Steel Beams Based on Improved Particle Swarm Optimization Algorithm with Random Weights. Applied Sciences, 12(23), 12082. https://doi.org/10.3390/app122312082