Assessment of Parameters to Apply Osmotic Dehydration as Pretreatment for Improving the Efficiency of Convective Drying of Cassava Bagasse

Abstract

:1. Introduction

2. Materials and Methods

2.1. Location and Raw Material

2.2. Proximal Characterization of Cassava Bagasse

2.3. Osmotic Dehydration (OD) of Cassava Bagasse

2.4. OD as Pretreatment for Convective Drying of Cassava Bagasse

3. Results and Discussion

3.1. Proximal Characterization

3.2. Stirring Needs during OD

3.3. Adjustment of Osmotic Agent Concentration Levels and Solution to Sample Ratio

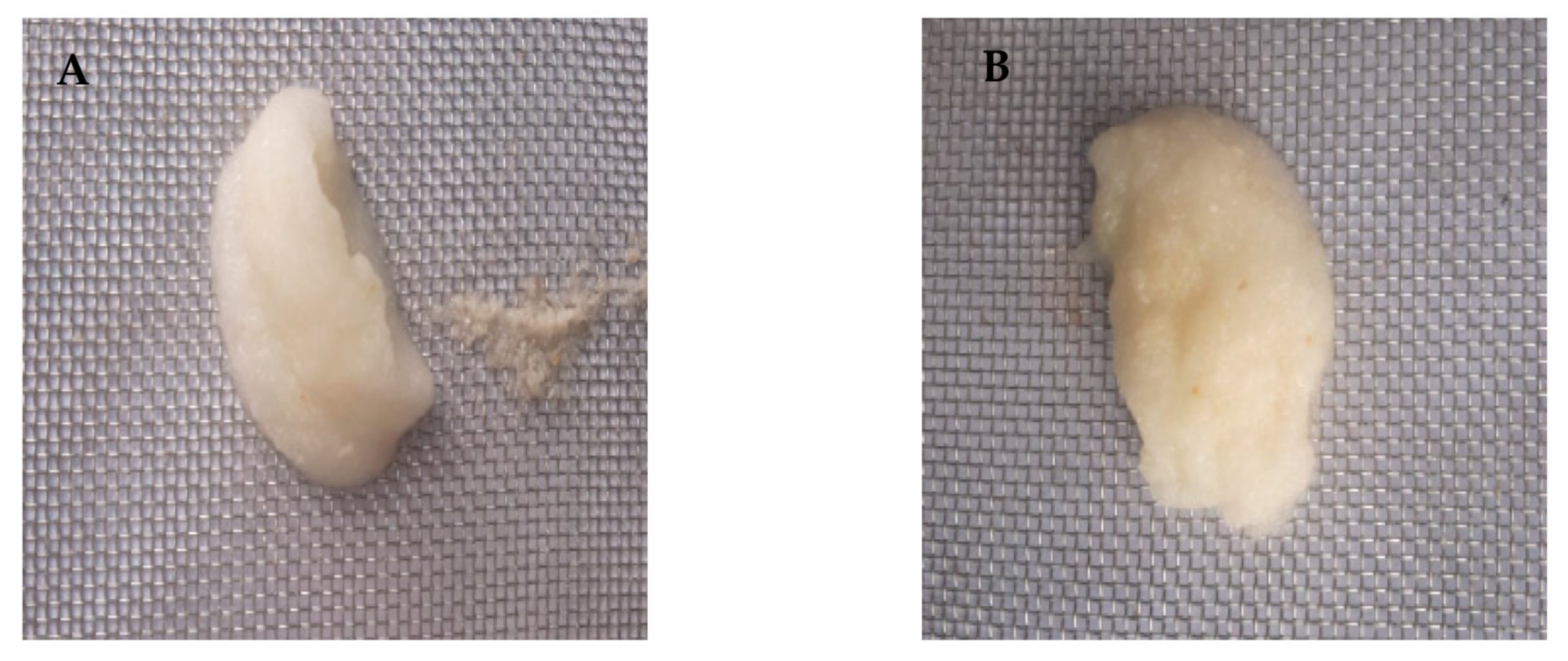

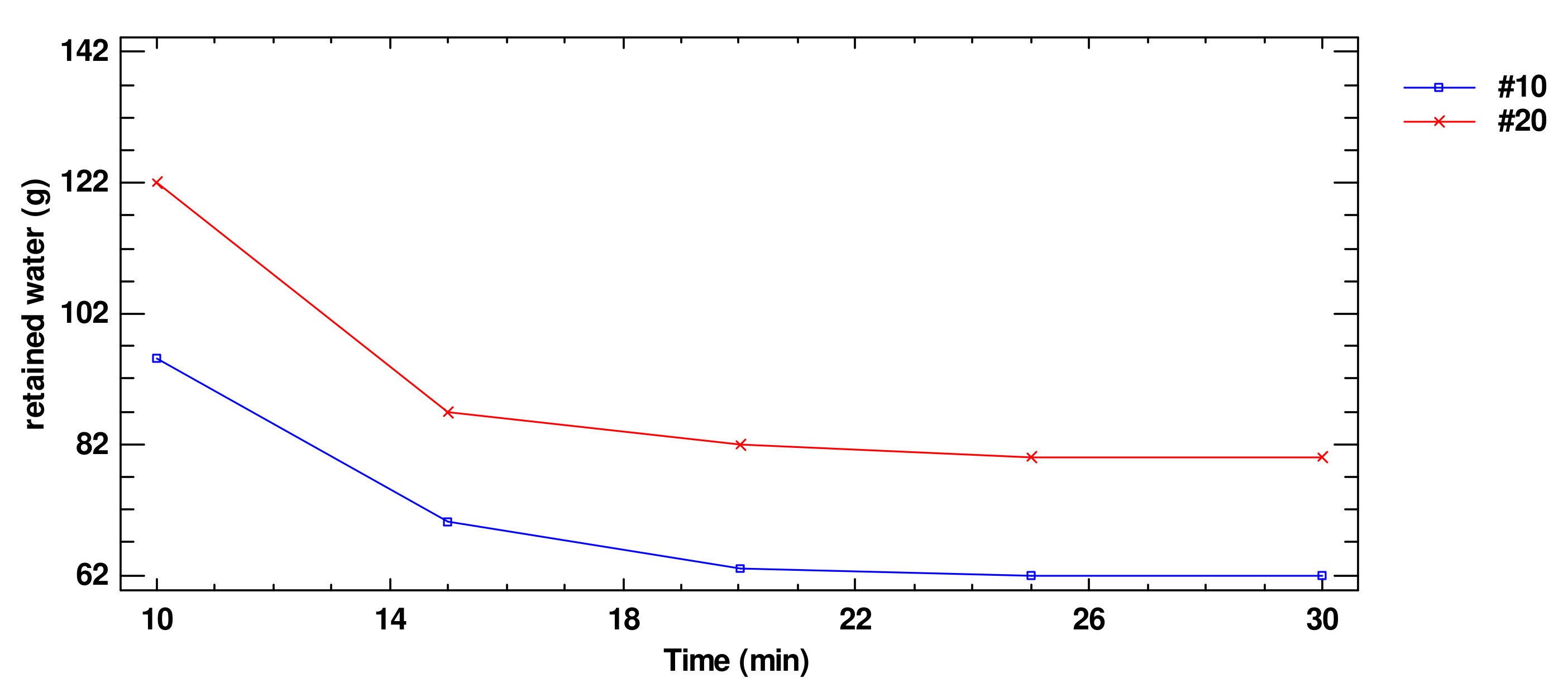

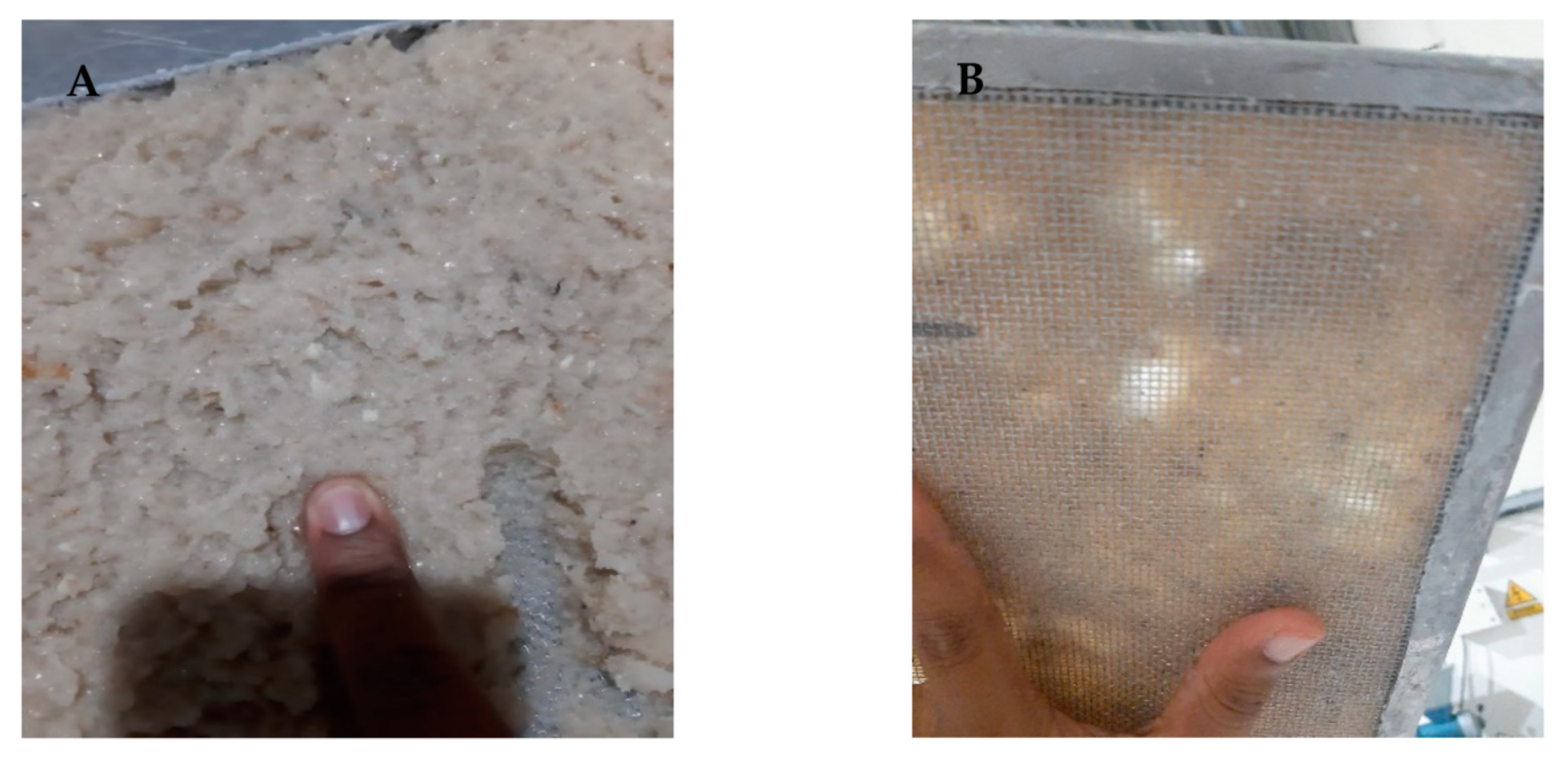

3.4. Determination of Mesh Number and Drain Time

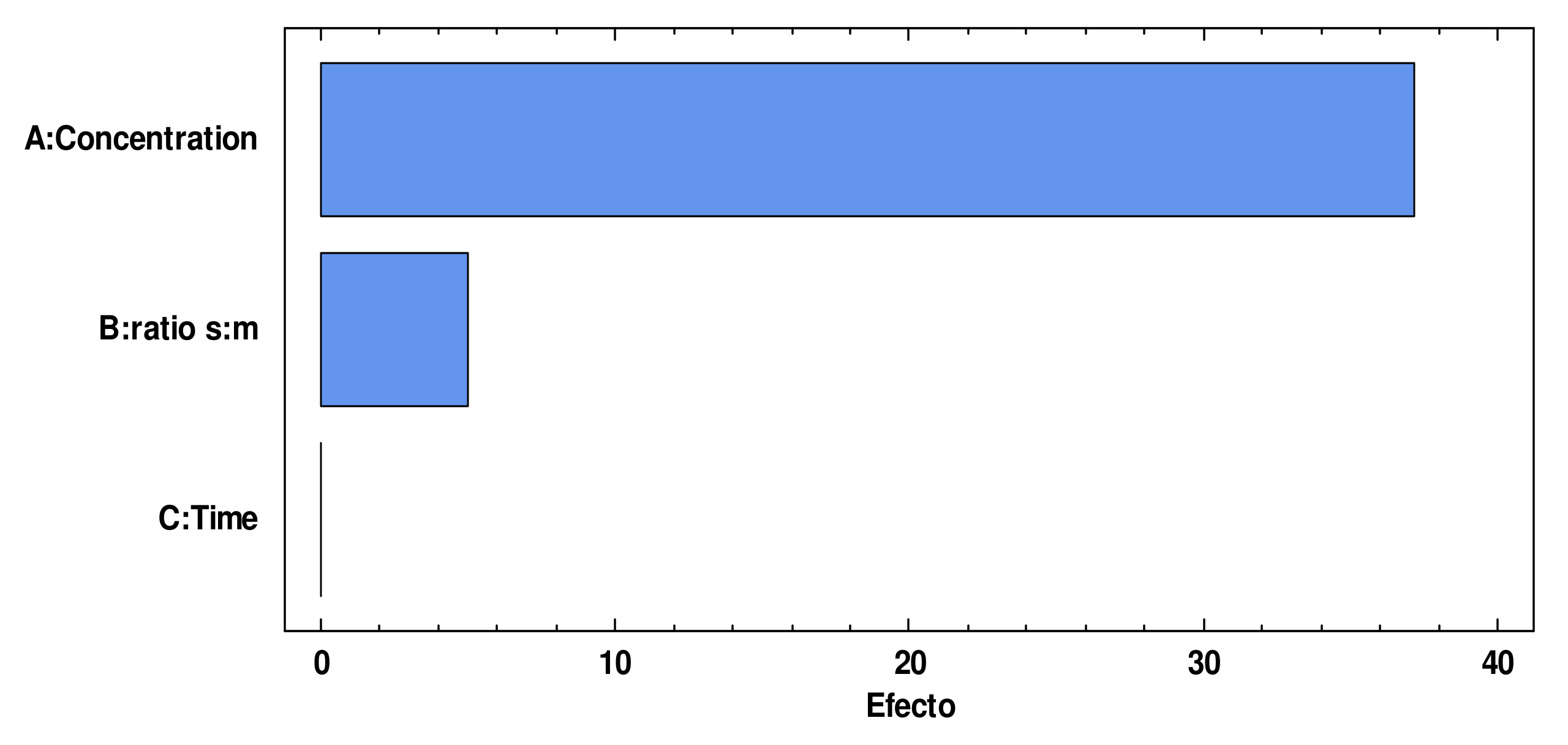

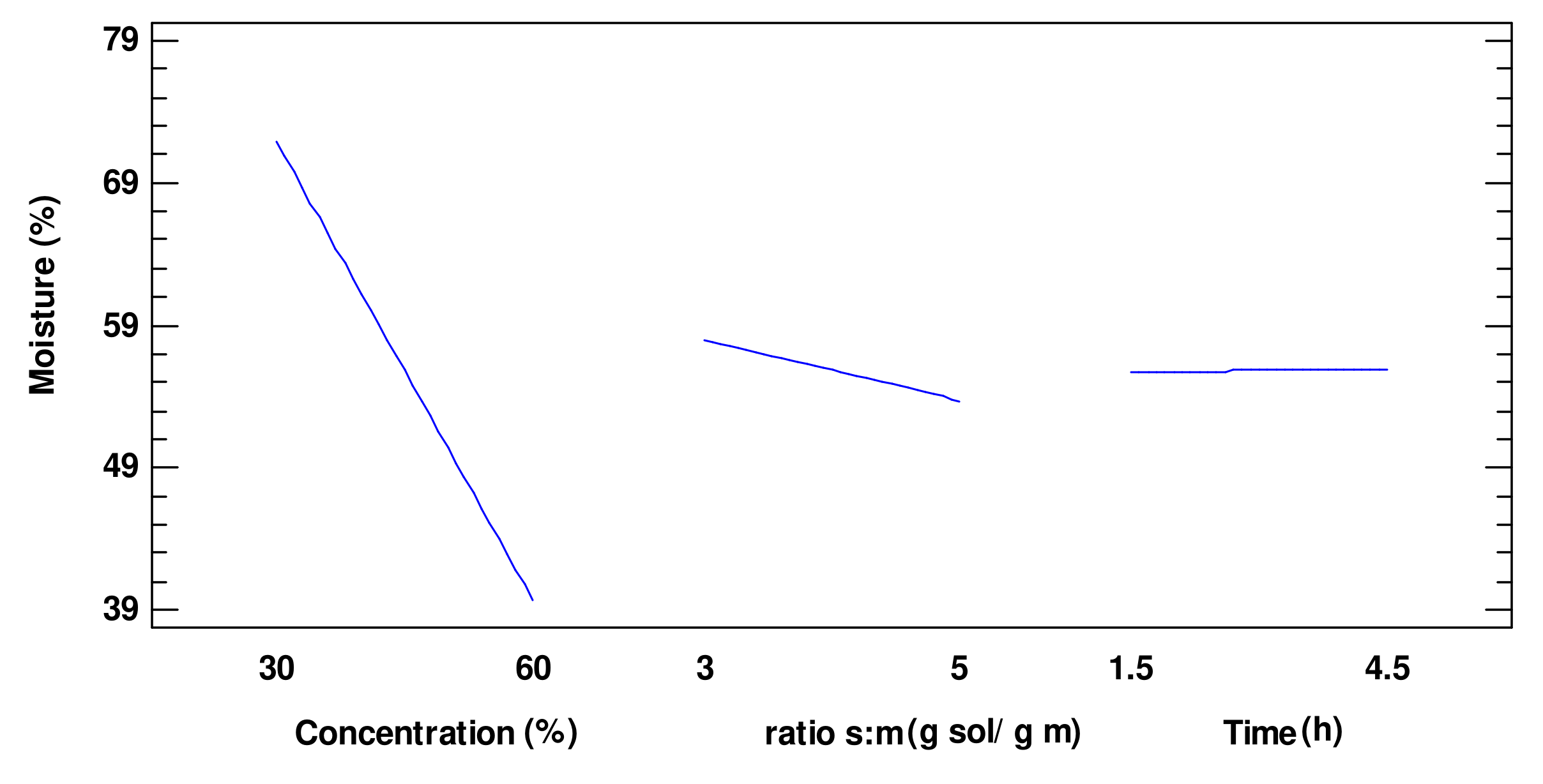

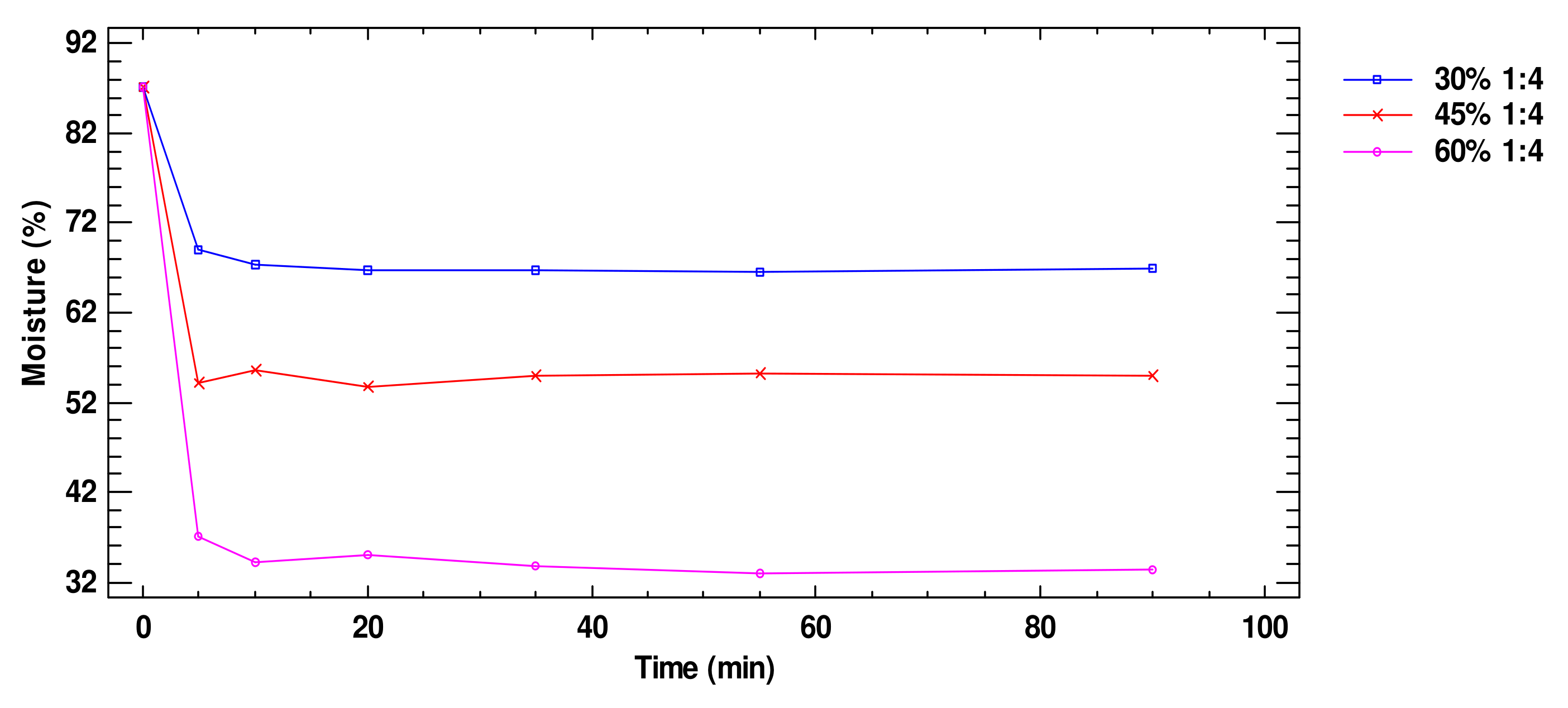

3.5. Determination of Significant Factors in Moisture Loss during the OD Operation

3.6. Determination of the Optimal Immersion Time

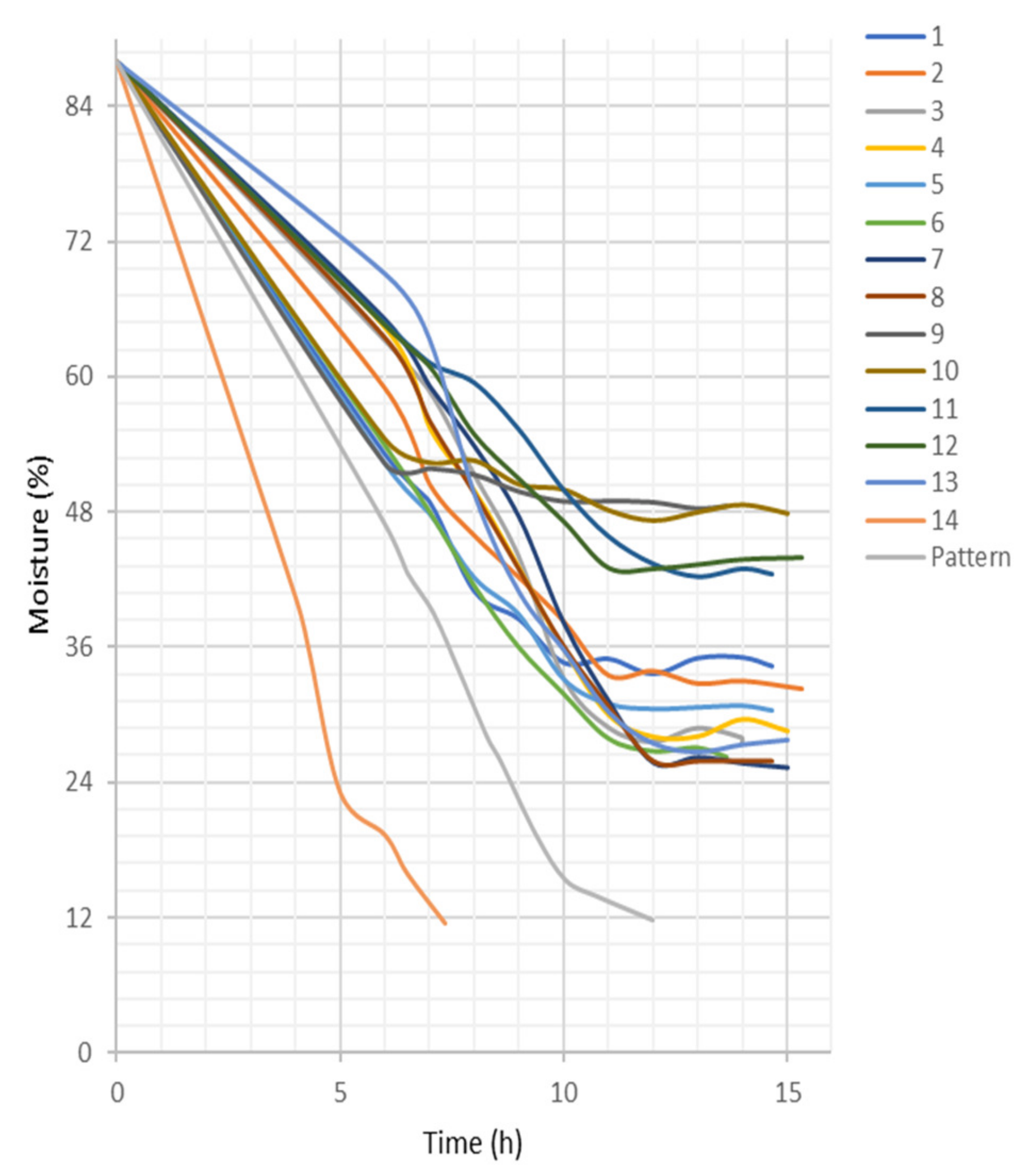

3.7. Behavior of Cassava Bagasse during Application of Combined Methods

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dermesonlouoglou, E.; Chalkia, A.; Taoukis, P. Application of osmotic dehydration to improve the quality of dried goji berry. J. Food Eng. 2018, 232, 36–43. [Google Scholar] [CrossRef]

- Yu, Y.; Jin, T.Z.; Fan, X.; Wu, J. Biochemical degradation and physical migration of polyphenolic compounds in osmotic dehydrated blueberries with pulsed electric field and thermal pretreatments. Food Chem. 2018, 239, 1219–1225. [Google Scholar] [CrossRef] [PubMed]

- Bozkir, H.; Ergün, A.R.; Serdar, E.; Metin, G.; Baysal, T. Influence of ultrasound and osmotic dehydration pretreatments on drying and quality properties of persimmon fruit. Ultrason. Sonochem. 2019, 54, 135–141. [Google Scholar] [CrossRef] [PubMed]

- Prithani, R.; Dash, K. Mass transfer modelling in ultrasound assisted osmotic dehydration of kiwi fruit. Innov. Food Sci. Emerg. Technol. 2020, 64, 102407. [Google Scholar] [CrossRef]

- Bozkir, H.; Ergün, A.R. Effect of sonication and osmotic dehydration applications on the hot air drying kinetics and quality of persimmon. LWT 2020, 131, 109704. [Google Scholar] [CrossRef]

- Dehnad, D.; Jafari, S.; Afrasiabi, M. Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci. Technol. 2016, 57, 116–131. [Google Scholar] [CrossRef]

- Rahaman, A.; Zeng, X.; Kumari, A.; Rafiq, M.; Siddeeg, A.; Manzoor, M.F.; Baloch, Z.; Ahmed, Z. Influence of ultrasound-assisted osmotic dehydration on texture, bioactive compounds and metabolites analysis of plum. Ultrason. Sonochem. 2019, 58, 104643. [Google Scholar] [CrossRef]

- Seguí, L.; Fito, P.J.; Fito, P. Analysis of structure-property relationships in isolated cells during OD treatments. Effect of initial structure on the cell behaviour. J. Food Eng. 2010, 99, 417–423. [Google Scholar] [CrossRef]

- Della Rocca, P.; Mascheroni, R. Modelos empíricos en la deshidratación osmótica de papas. Rumbos Tecnol. 2010, 2, 57–66. Available online: https://ri.conicet.gov.ar/handle/11336/135833 (accessed on 9 October 2022).

- Cerdán Guevara, K.; López Ninaquispe, C. Efecto de la Concentración del Soluto en la Deshidratación Osmótica del Aguaymanto (Physalis Peruvian)—Lambayeque 2014. Bachelor’s Thesis, Universidad Señor de Sipán, Chiclayo, Peru, 2016. Repositorio Institucional-USS. Available online: http://repositorio.uss.edu.pe//handle/20.500.12802/2301 (accessed on 9 October 2022).

- García, M.; Cortes, M.; Rodríguez, E. Evaluación del Secado de Perejil Aplicando Técnicas de Deshidratación Osmótica Como Pretratamiento. Rev. Fac. Nal. Agr. Medellín 2010, 63, 5693–5705. [Google Scholar]

- Martinez, D.; Feiden, A.; Bariccatti, R.; Zara, F. Ethanol Production from Waste of Cassava Processing. Appl. Sci. 2018, 8, 2158. [Google Scholar] [CrossRef] [Green Version]

- Travalini, A.; Lamsal, B.; Magalhães, W.; Demiate, I. Cassava starch films reinforced with lignocellulose nanofibers from cassava bagasse. Int. J. Biol. Macromol. 2019, 139, 1151–1161. [Google Scholar] [CrossRef]

- Polachini, T.; Betiol, L.; Lopes-Filho, J.; Telis-Romero, J. Water adsorption isotherms and thermodynamic properties of cassava bagasse. Thermochim. Acta 2016, 632, 79–85. [Google Scholar] [CrossRef] [Green Version]

- Bussolo de Souza, C.; Jonathan, M.; Isay Saad, S.; Schols, H.; Venema, K. Characterization and in vitro digestibility of by-products from Brazilian food industry: Cassava bagasse, orange bagasse and passion fruit peel. Bioact. Carbohydr. Diet. Fibre 2018, 16, 90–99. [Google Scholar] [CrossRef]

- Chen, J.; Liu, X.; Wei, D.; Chen, G. High yields of fatty acid and neutral lipid production from cassava bagasse hydrolysate (CBH) by heterotrophic Chlorella protothecoides. Bioresour. Technol. 2015, 191, 281–290. [Google Scholar] [CrossRef]

- Liu, L.; Chen, J.; Lim, P.; Wei, D. Enhanced single cell oil production by mixed culture of Chlorella pyrenoidosa and Rhodotorula glutinis using cassava bagasse hydrolysate as carbon source. Bioresour. Technol. 2018, 255, 140–148. [Google Scholar] [CrossRef]

- Corredor, Y.; Pérez, L. Aprovechamiento de residuos agroindustriales en el mejoramiento de la calidad del ambiente. Rev. Fac. De Cienc. Básicas 2018, 14, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Keller, M.; Ambrosio, E.; de Oliveira, V.M.; Góes, M.M.; de Carvalho, G.M.; Batistela, V.R.; Garcia, J.C. Polyurethane foams synthesis with cassava waste for biodiesel removal from water bodies. Bioresour. Technol. Rep. 2020, 10, 100396. [Google Scholar] [CrossRef]

- Alvarez, B.; Denise, C. Conservación y Transformación de Alimentos Autóctonos de la Región Cordobesa; project; Universidad de Córdoba: Córdoba, Colombia, 2016. [Google Scholar]

- Serpa Padilla, C.T.; Serpa Fajardo, J.G.; Hernández Ramos, E. Aprovechamiento biotecnológico del bagazo de yuca. Rev. EDIA 2022, 5, 21–23. Available online: https://revistas.sena.edu.co/index.php/edia/article/view/4835/5043 (accessed on 9 October 2022).

- Avilez, X.; Fajardo, J.; Ramos, E. Aprovechamiento del bagazo de yuca en la elaboración de biomateriales. Rev. EDIA 2020, 5, 24–26. Available online: https://revistas.sena.edu.co/index.php/edia/article/view/4836 (accessed on 9 October 2022).

- Zheng, J.; Huang, S.; Zhao, R.; Wang, N.; Kan, J.; Zhang, F. Effect of four viscous soluble dietary fibers on the physicochemical, structural properties, and in vitro digestibility of rice starch: A comparison study. Food Chem. 2021, 362, 130181. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.; Yu, X.; Yagoub, A.E.A.; Xu, B.; Wu, B.; Zhang, L.; Zhou, C. Vacuum pretreatment coupled to ultrasound assisted osmotic dehydration as a novel method for garlic slices dehydration. Ultrason. Sonochem. 2019, 50, 363–372. [Google Scholar] [CrossRef] [PubMed]

- Pérez-Won, M.; Lemus-Mondaca, R.; Tabilo-Munizaga, G.; Pizzaro, S.; Noma, S.; Igura, N.; Shimoda, M. Modelling of red abalone (Haliotis rufescens) slices drying process: Effect of osmotic dehydration under high pressure as a pretreatment. Innov. Food Sci. Emerg. Technol. 2016, 34, 127–134. [Google Scholar] [CrossRef]

- Romdhane, N.; Djendoubi, N.; Bonazzi, C.; Kechaou, N.; Mihoubi, N. Effect of combined air-drying-osmotic dehydration on kinetics of techno-functional properties, color and total phenol contents of lemon (Citrus limon. v. lunari) Peels. Int. J. Food Eng. 2016, 12, 515–525. [Google Scholar] [CrossRef]

- AOAC. Official Methods of the Association of Official Methods of Analysis, 16th ed.; AOAC International: Gaithersburg, MD, USA, 1997. [Google Scholar]

- Eyerson, K.; Ankrah, E. Composition of Foods Commonly Used in Ghana; Food Research Institute-Ghana: Accra, Ghana, 1975. [Google Scholar]

- Estrada, H.; Restrepo, C.; Saumett, H.; Pérez, L. Osmotic Dehydration and Hot Air Drying on Mango, Guava and Lemon to Obtain Functional Ingredients. Inf. Tecnológica 2018, 29, 197–204. [Google Scholar] [CrossRef]

- García, F.; Bejarano, D.; Paredes, L.; Vega, R.; Encinas, J. La deshidratación osmótica mejora la calidad de Ananas comosus deshidratada. Sci. Agropecu. 2018, 9, 349–357. [Google Scholar] [CrossRef] [Green Version]

- Sanez Falcón, L. Actividad de Agua de Arándanos Deshidratados por Método Combinado Osmosis—Aire Caliente; Repositorio Institucional-UNAC; Universidad Nacional del Callao: Bellavista, Peru, 2021; Available online: http://repositorio.unac.edu.pe/handle/20.500.12952/5646 (accessed on 9 October 2022).

- de Armas, R.R.; Acosta, E.A.; Muni, J.A. Afrecho de yuca como sustituto parcial del maíz en la alimentación de cerdos de engorde. La Técnica 2017, 2, 54–61. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=6230432&info=resumen&idioma=ENG (accessed on 10 October 2022). [CrossRef]

- Paternina Contreras, A.; Salcedo Mendoza, J.; Contreras Lozano, K.; García Paternina, M. Characterization and desorption isotherm modeling of cassava bagasse (Manihot esculenta Crantz). Starch-Stärke 2017, 69, 1600020. [Google Scholar] [CrossRef]

- Assis, F.; Morais, R.; Morais, A. Osmotic dehydration with sorbitol combined with hot air convective drying of apple cubes. J. Food Sci. Technol. 2017, 54, 3152–3160. [Google Scholar] [CrossRef]

- Guiamba, I.; Ahrné, L.; Khan, M.; Svanberg, U. Retention of β-carotene and vitamin C in dried mango osmotically pretreated with osmotic solutions containing calcium or ascorbic acid. Food Bioprod. Process. 2016, 98, 320–326. [Google Scholar] [CrossRef]

- Sharma, M.; Dash, K. Effect of ultrasonic vacuum pretreatment on mass transfer kinetics during osmotic dehydration of black jamun fruit. Ultrason. Sonochem. 2019, 58, 104693. [Google Scholar] [CrossRef]

- Geankoplis, C.J. Procesos de Transporte y Operaciones Unitarias; Compañía Editorial Continental (CECSA): Mexico City, Mexico, 1998; Available online: https://www.academia.edu/6627933/Procesos_de_transporte_y_operaciones_unitarias_Geankoplis (accessed on 10 October 2022).

- Navarrete Villanueva, S.L.H.E. Elaboración de Papaya (Carica papaya), por Deshidratación Osmótica. Specialization Thesis, Universidad Nacional Autónoma de Nicaragua, León, León, Nicaragua, 2003. [Google Scholar]

- Bambicha, R.; Agnelli, M.; Mascheroni, R. Optimizacion Del Proceso De Deshidratacion Osmotica De Calabacita En Soluciones Ternarias. Av. Cien. Ing. 2012, 3, 121–136. [Google Scholar]

- García-Paternina, M.; Alvis-Bermudez, A.; García-Mogollon, C. Evaluación de los pretratamientos de deshidratación osmótica y microondas en la obtención de hojuelas de mango (Tommy Atkins). Inf. Tecnol. 2015, 26, 63–70. [Google Scholar] [CrossRef]

- Benavides Chamorro, J.G. Efectos de la Deshidratación Osmótica y Secado Sobre las Características Físico Químicas y Sensoriales de Snack de Mashua tropaeolum tuberosum. Bachelor’s Thesis, Universidad Técnica del Norte, Ibarra, Ecuador, 2017. Available online: http://repositorio.utn.edu.ec/handle/123456789/6071 (accessed on 10 October 2022).

- Castro Cabascango, L. Deshidratación Osmótica y Secado del Arazá Eugenia stipitata Mc Vaugh para la Obtención de un Snack. Bachelor’s Thesis, Universidad Técnica del Norte, Ibarra, Ecuador, 2017. Available online: http://repositorio.utn.edu.ec/handle/123456789/6544 (accessed on 10 October 2022).

- López Valencia, Y. Estudio de la Cinetica de Deshidratación Osmótica para la Conservación de Lisa (Mugil cephalus); Universidad Nacional de San Agustín de Arequipa: Arequipa, Peru, 2017; Available online: http://repositorio.unsa.edu.pe/handle/UNSA/4262 (accessed on 10 October 2022).

- de Mendonça, K.; Corrêa, J.; Junqueira, J.; Cirillo, M.; Figueira, F.; Carvalho, E. Influences of convective and vacuum drying on the quality attributes of osmo-dried pequi (Caryocar brasiliense Camb.) slices. Food Chem. 2017, 224, 212–218. [Google Scholar] [CrossRef]

- Andreou, V.; Thanou, I.; Giannoglou, M.; Giannakourou, M.; Katsaros, G. Dried Figs Quality Improvement and Process Energy Savings by Combinatory Application of Osmotic Pretreatment and Conventional Air Drying. Foods 2021, 10, 1846. [Google Scholar] [CrossRef]

- Taşova, M.; Polatcı, H.; Gökdoğan, O. Effect of osmotic dehydration pre-treatments on physicochemical and energy parameters of Kosia (Nashi) pear slices dried in a convective oven. J. Food Process. Preserv. 2022, 46, e16945. [Google Scholar] [CrossRef]

- Kurozawa, L.; Hubinger, M.; Park, K. Glass transition phenomenon on shrinkage of papaya during convective drying. J. Food Eng. 2012, 108, 43–50. [Google Scholar] [CrossRef]

- Larrea Olivero, B.; Rivas Cajo, J. Estabilización de Suelos Arcillosos con Cloruro de Sodio y Cloruro de Calcio. Bachelor Thesis, Universidad Católica de Santiago de Guayaquil, Guayaquil, Ecuador, 2019. Available online: http://repositorio.ucsg.edu.ec/handle/3317/12607 (accessed on 5 October 2022).

- Hinrichsen Triviños, N.N. Estudio de Comportamiento de Suelo Estabilizado Con Sal: Frente A La Acción Del Agua, para Distintas Mezclas. Undergraduate, Universidad Austral de Chile, Valdivia, Chile, 2005. [Google Scholar]

- Rodríguez, R. Fundamentos de Química General, 1st ed.; UPSE: La Libertad, Ecuador, 2017. [Google Scholar]

| Components | Contents |

|---|---|

| Moisture (moist basis) | 87.877 ± 0.314% |

| Dry matter (moist basis) | 12.123 ± 0.315% |

| Ashes (dry basis) | 1.6310 ± 0.017% |

| Protein (dry basis) | 1.8840 ± 0.250% |

| Fat (dry basis) | 0.5120 ± 0.075% |

| Fiber (dry basis) | 24.692 ± 0.277% |

| Carbohydrates (dry basis) | 71.281 ± 0.468% |

| Concentration (%NaCl) | Ratio s:m (g sol/g m) | Time (h) | Moisture (%) |

|---|---|---|---|

| 30 | 3 | 1.5 | 71.794 |

| 60 | 3 | 1.5 | 37.616 |

| 30 | 5 | 1.5 | 69.832 |

| 60 | 5 | 1.5 | 28.449 |

| 30 | 3 | 4.5 | 70.435 |

| 60 | 3 | 4.5 | 37.911 |

| 30 | 5 | 4.5 | 70.019 |

| 60 | 5 | 4.5 | 29.429 |

| Source | Sum of Squares | DF | Mean Square | F-Ratio | p-Value |

|---|---|---|---|---|---|

| A: Concentration | 2763.01 | 1 | 2763.01 | 29851.85 | 0.0037 * |

| B: ratio s:m | 50.1326 | 1 | 50.1326 | 541.64 | 0.0273 * |

| C: Time | 0.00133903 | 1 | 0.00133903 | 0.01 | 0.9238 |

| Trial | Concentration (%NaCl) | Solution to Sample Ratio (g sln/g m) | Drying Conditions | Drying Time Up to 12% bh (min) | Final Moisture 2 (%) | Processing Time 3 (min) | Observations |

|---|---|---|---|---|---|---|---|

| 1 | 60 | 3:1 | 45 °C 1 m/s | Nf 1 | 34.55 ± 1.98 | 880 | Crust formation that prevents drop of Moisture. At 720 min required by the standard treatment to reach 12% Moisture, samples still show high Moisture values. |

| 2 | 60 | 5:1 | 45 °C 1 m/s | Nf | 32.28 ± 3.21 | 920 | |

| 3 | 30 | 3:1 | 45 °C 1 m/s | Nf | 27.73 ± 2.52 | 840 | |

| 4 | 30 | 5:1 | 45 °C 1 m/s | Nf | 28.52 ± 1.10 | 900 | |

| 5 | 60 | 3:1 | 40 °C 1.5 m/s | Nf | 30.29 ± 2.50 | 880 | |

| 6 | 60 | 5:1 | 40 °C 1.5 m/s | Nf | 26.44 ± 1.37 | 820 | |

| 7 | 30 | 3:1 | 40 °C 1.5 m/s | Nf | 25.29 ± 2.91 | 900 | |

| 8 | 30 | 5:1 | 40 °C 1.5 m/s | Nf | 25.83 ± 1.70 | 880 | |

| 9 | 60 | 3:1 | 35 °C 2 m/s | Nf | 48.84 ± 1.40 | 820 | Insufficient drying conditions |

| 10 | 60 | 5:1 | 35 °C 2 m/s | Nf | 47.96 ± 2.39 | 900 | |

| 11 | 30 | 3:1 | 35 °C 2 m/s | Nf | 42.44 ± 3.15 | 880 | |

| 12 | 30 | 5:1 | 35 °C 2 m/s | Nf | 43.86 ± 0.96 | 920 | |

| Additional tests, lowering the concentration of osmotic agent: | |||||||

| 13 | 25 | 3:1 | 40 °C 1.5 m/s | Nf | 27.47 ± 2.10 | 880 | No drop in Moisture |

| 14 | 20 | 3:1 | 40 °C 1.5 m/s | 440 ± 20.17 | 12.00 | 440 | Excellent Result |

| Pattern | - | 40 °C 1.5 m/s | 720 ± 15.28 | 12.00 | 720 | None | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serpa-Fajardo, J.; Narváez-Guerrero, D.; Serpa-Padilla, C.; Hernández-Ramos, E.; Fernández-Lambert, G. Assessment of Parameters to Apply Osmotic Dehydration as Pretreatment for Improving the Efficiency of Convective Drying of Cassava Bagasse. Appl. Sci. 2022, 12, 12101. https://doi.org/10.3390/app122312101

Serpa-Fajardo J, Narváez-Guerrero D, Serpa-Padilla C, Hernández-Ramos E, Fernández-Lambert G. Assessment of Parameters to Apply Osmotic Dehydration as Pretreatment for Improving the Efficiency of Convective Drying of Cassava Bagasse. Applied Sciences. 2022; 12(23):12101. https://doi.org/10.3390/app122312101

Chicago/Turabian StyleSerpa-Fajardo, José, Diego Narváez-Guerrero, Carolina Serpa-Padilla, Elvis Hernández-Ramos, and Gregorio Fernández-Lambert. 2022. "Assessment of Parameters to Apply Osmotic Dehydration as Pretreatment for Improving the Efficiency of Convective Drying of Cassava Bagasse" Applied Sciences 12, no. 23: 12101. https://doi.org/10.3390/app122312101