Investigation with Non-Destructive and Destructive Methods for Assessment of Concrete Compressive Strength

Abstract

:1. Introduction

2. Methods Used for Determining the Compressive Strength of Concrete

2.1. Visual Inspection

2.2. Non-Destructive Testing of Concrete

2.2.1. Elastic Rebound Method

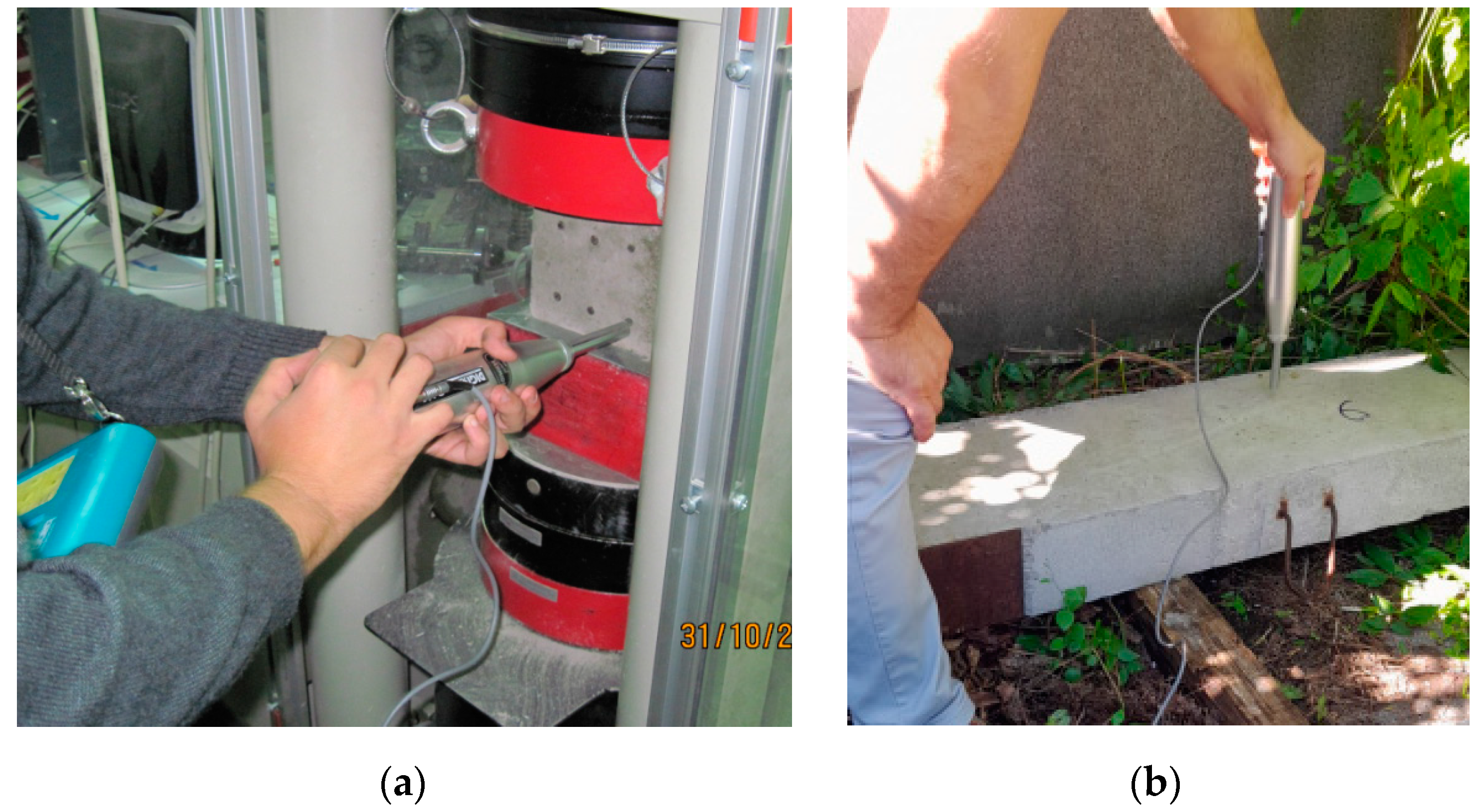

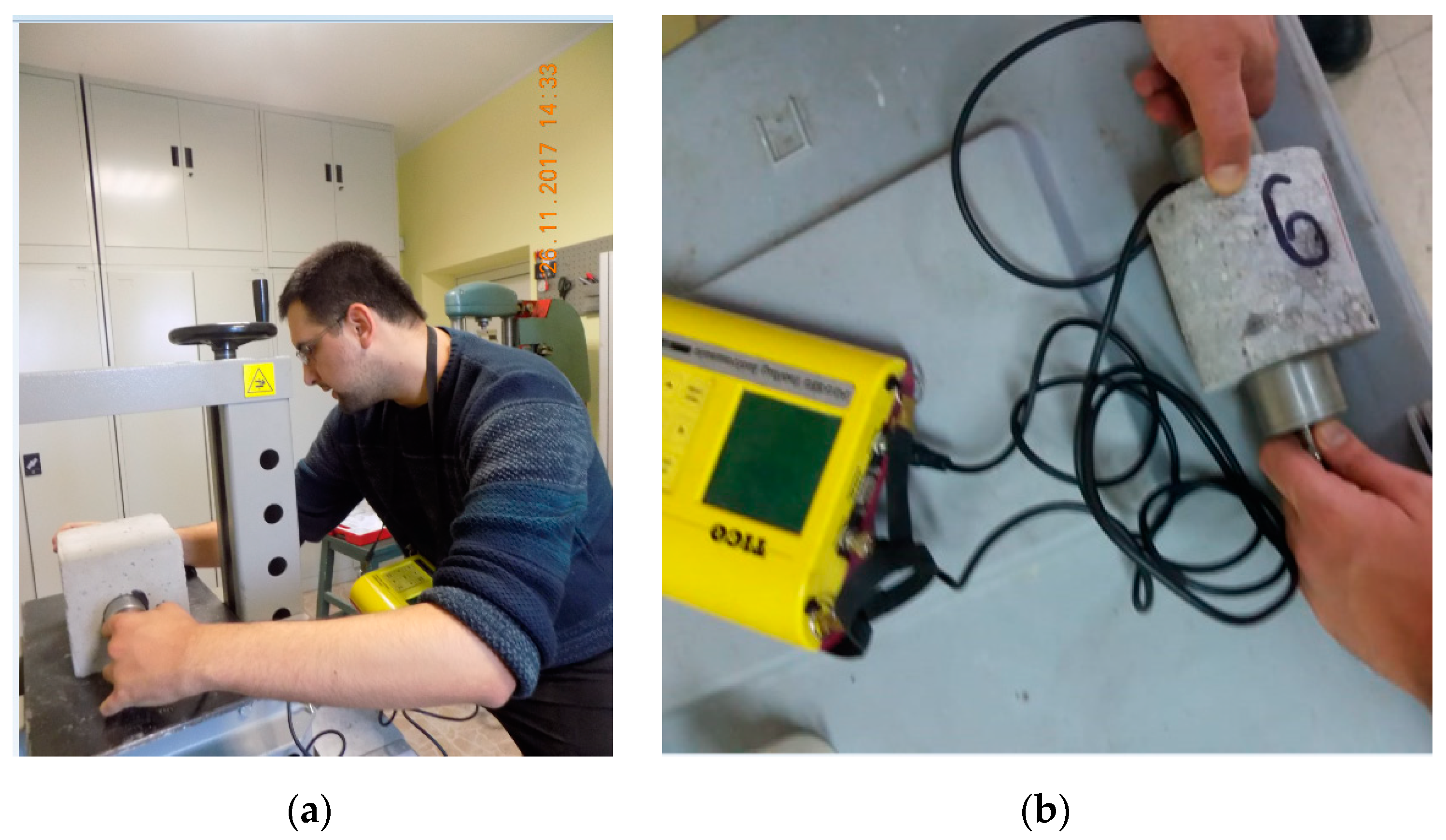

2.2.2. Non-Destructive Ultrasonic Pulse Velocity Method (UPVM)

- Approach 2: dependence of fc,UPV,app2 on the weight per unit volume and dynamic modulus of elasticity of concrete, which were determined based on the velocity of the ultrasonic signal.

2.3. Destructive Determination of Concrete Compressive Strength

2.4. SonReb Method

3. Experimental Setup

3.1. RC Beams

3.2. Test Specimens

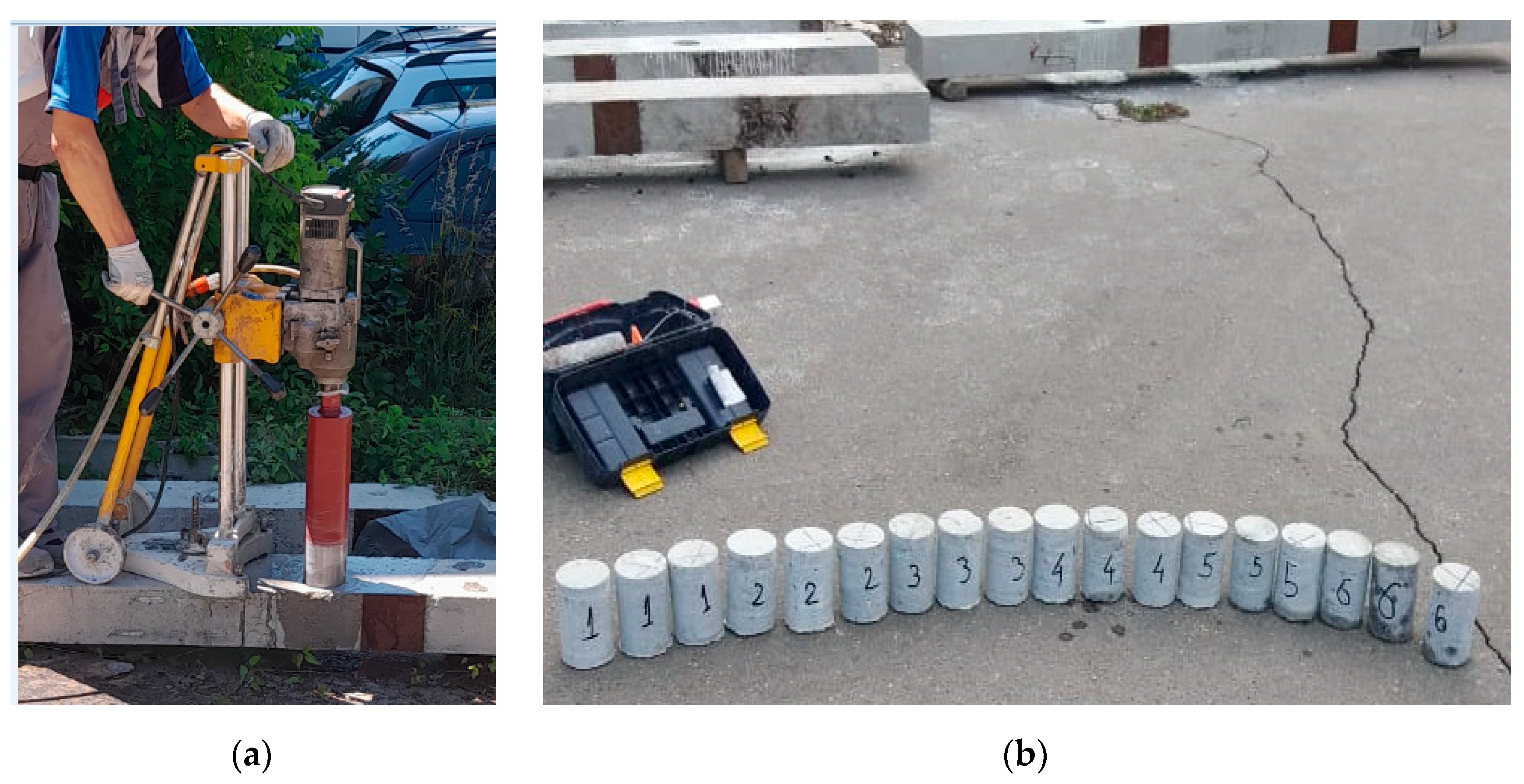

- Cored specimens. They were taken using a drilling machine according to EN 12504-1 [46] from the reinforced concrete beams at an age of 1926 days (Figure 3a). The machine platform had to be perpendicular to the surface from which the core was drilled in order to avoid obtaining a distorted specimen [8,42]. The diameter of the cores (Figure 3b) depended on the ratio of the diameter to the maximum size of the coarse aggregate [16,23,47], determined according to EN 12504-1 [46] and this was equal to 100 mm, i.e., the requirement that the ratio was not less than 3 was met.Eleven of the cored specimens without visible defects and the presence of reinforcement were prepared by cutting off their ends so that they become cylinders with a height and diameter equal to 100 mm. The main limitations in the number of cores taken under real conditions [1,18,19,47,48] were related to costs and the destructive effects on reinforced concrete structures.

4. Experimental Results

4.1. Visual Inspection

4.2. Compressive Strength of Concrete Determined by Its Surface Hardness (Figure 4)

4.3. Compressive Strength of Concrete Determined via UPVM

- Three cubes with dimensions of 150/150/150 mm for each day at 28, 244, 280, 293 and 342 days;

- Twelve cubes on the 1126th day;

- Eleven cored specimens with a height and diameter of 100 mm, taken from the reinforced concrete beams on the 1926th day.

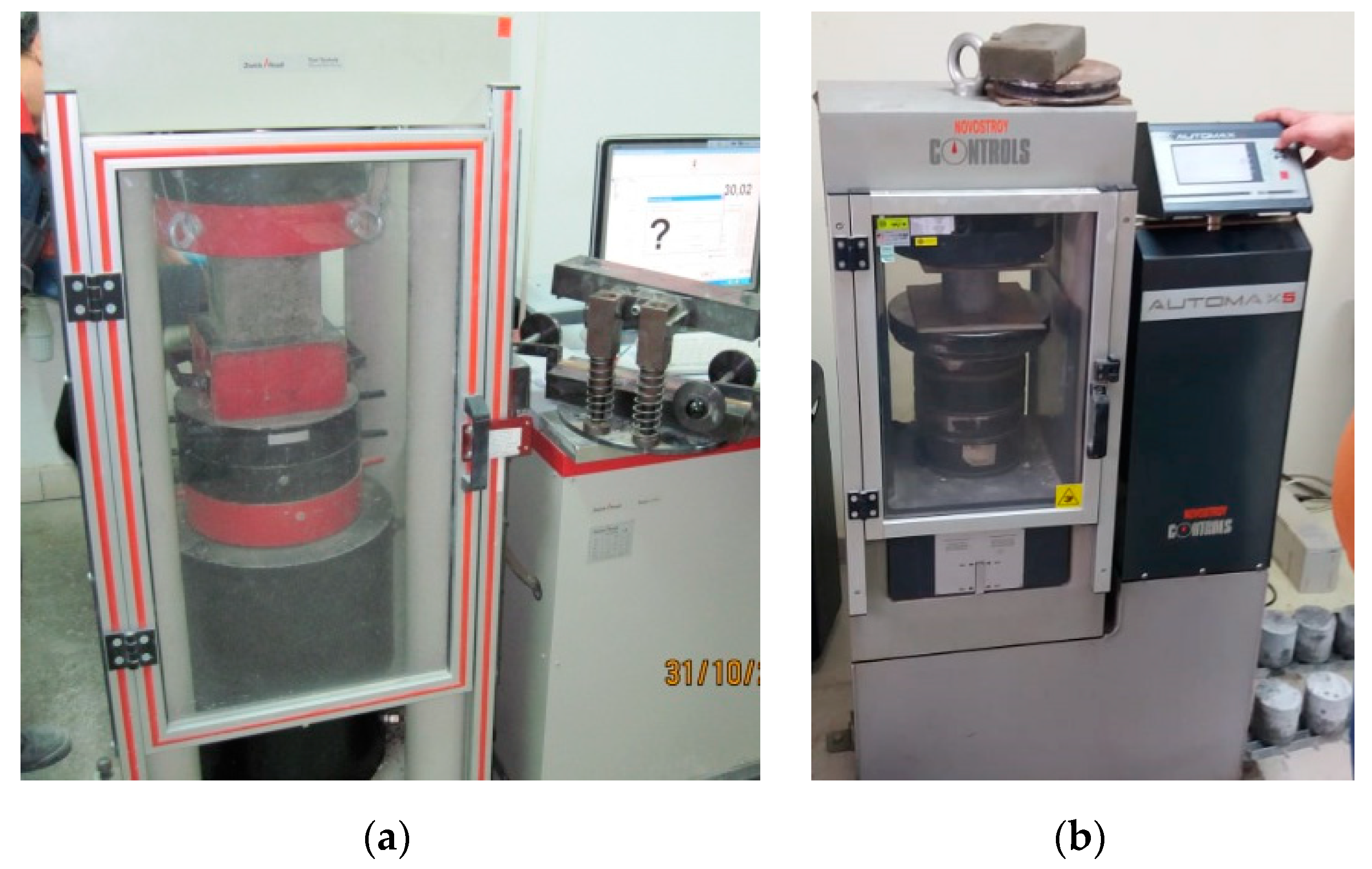

4.4. Compressive Strength of Concrete, Determined via Destructive Testing of Test Specimens—Cubes and Cores

- Three cubes with dimensions of 150/150/150 mm for each day at the ages of 28, 244, 280, 293 and 342 days;

- Twelve cubes with dimensions of 150/150/150 mm on the 1126th day; and

- Eleven cored specimens, taken from the reinforced concrete beams on the 1926th day. After cutting off their ends and preparing them for testing, the cores become cylinders of the same height and diameter, which were equal to 100 mm, i.e., according to EN 13791 [36]. The obtained compressive strength was equivalent to the compressive strength from the testing of 150/150/150 mm cubes.

4.5. Determination of the Compressive Strength of Concrete via the SonReb Method

5. Processing of the Results and Discussion

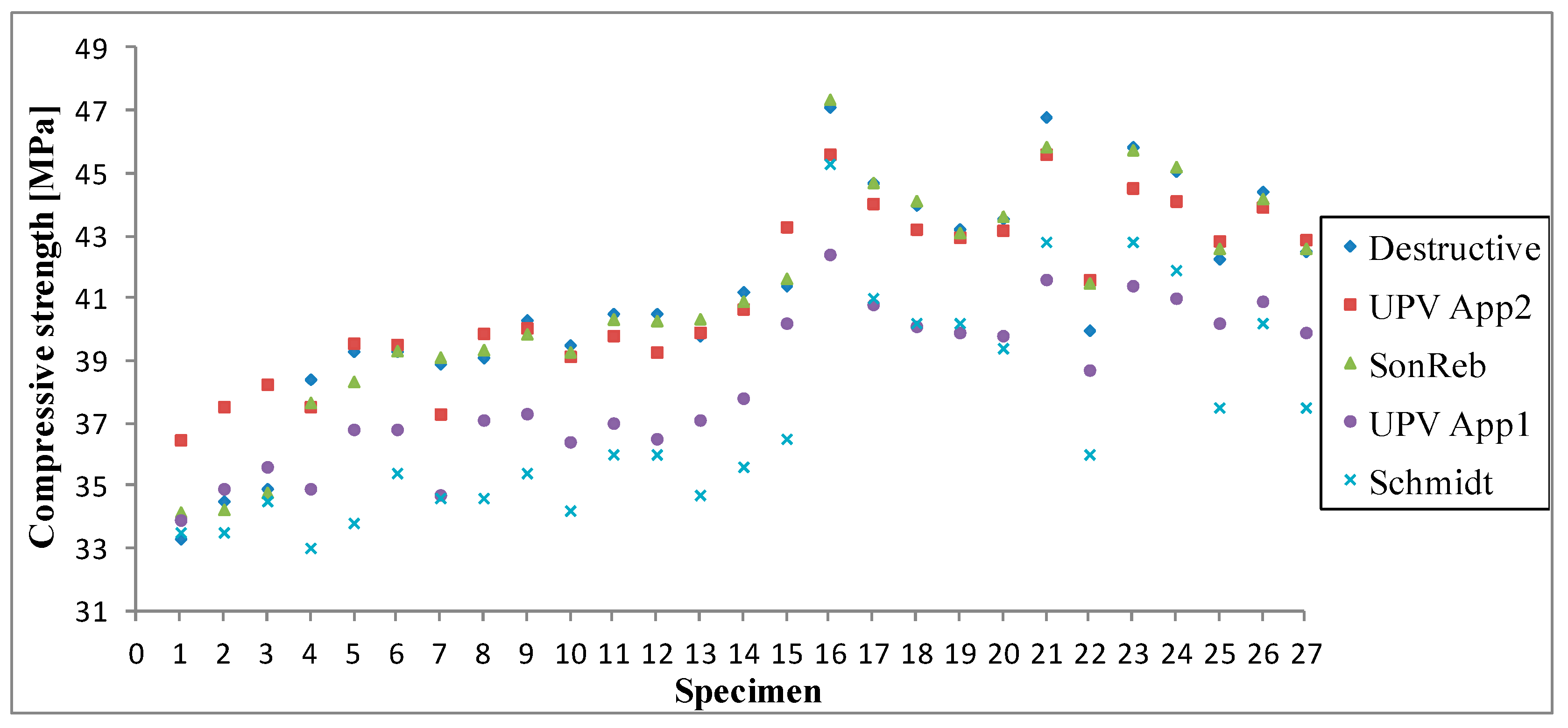

5.1. Compressive Strength for Different Ages of Concrete

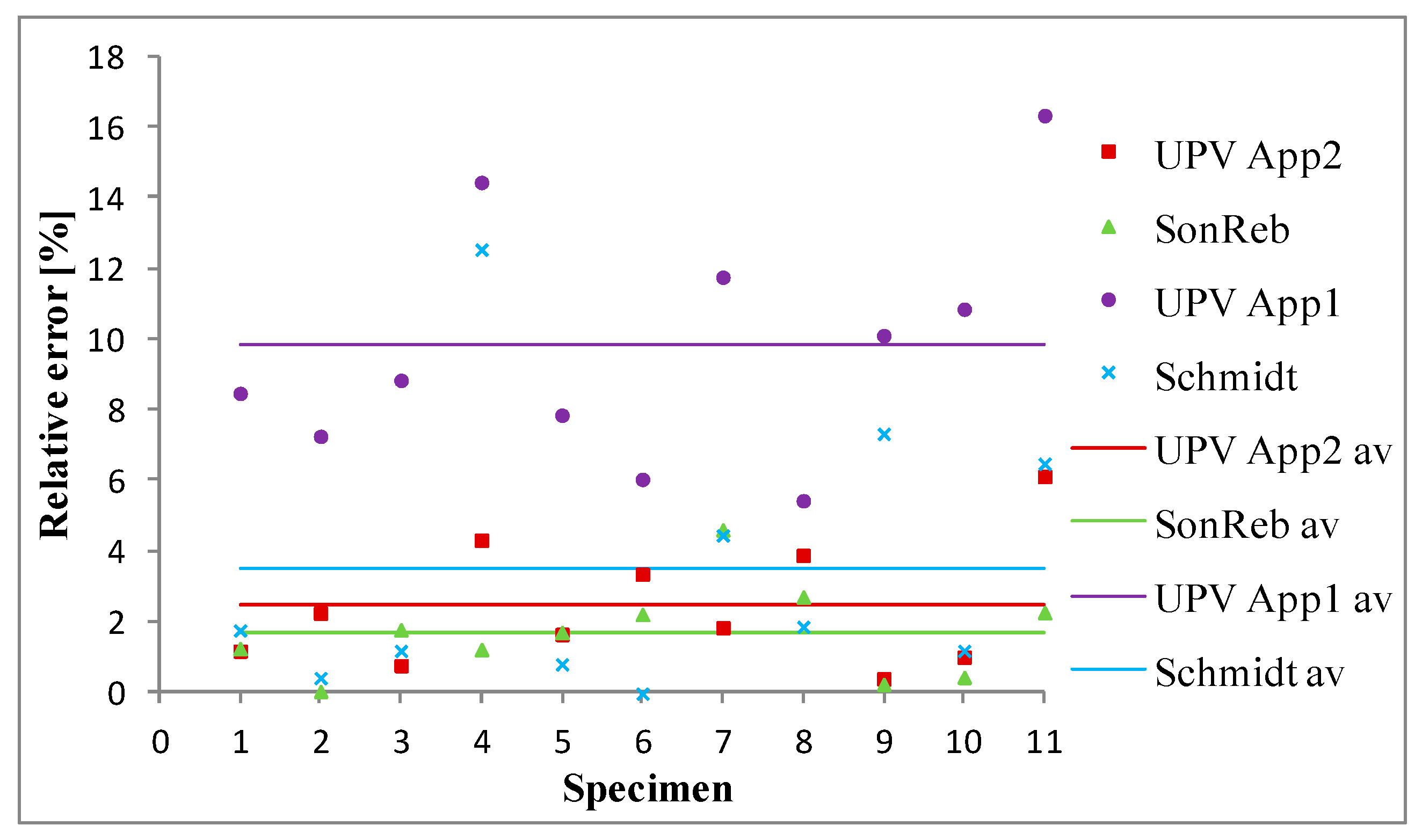

5.2. Relative Error in Determining Compressive Strength using Non-Destructive Methods

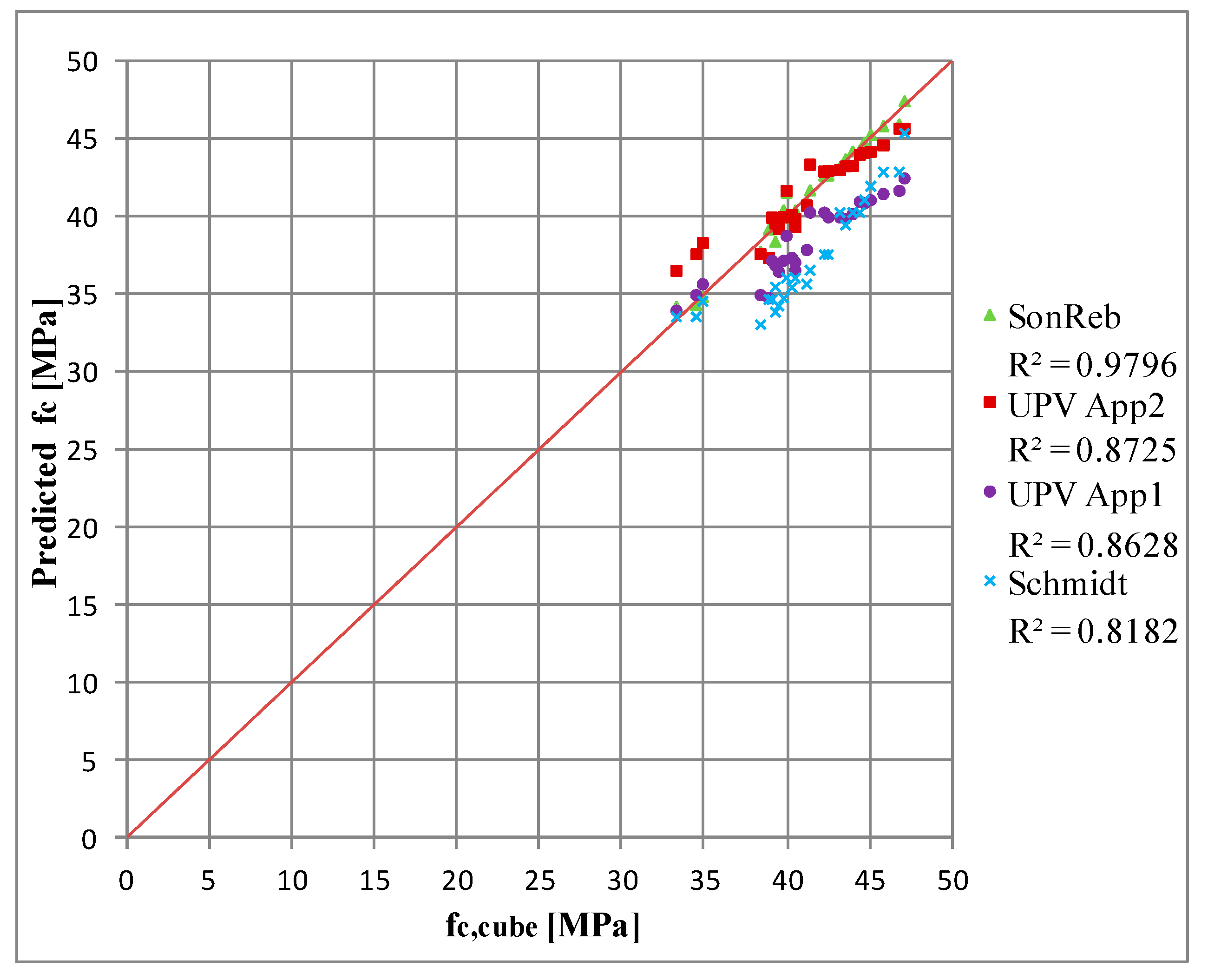

5.3. Correlation between the Reference Compressive Strength of Concrete and That Determined via Different Non-Destructive Methods

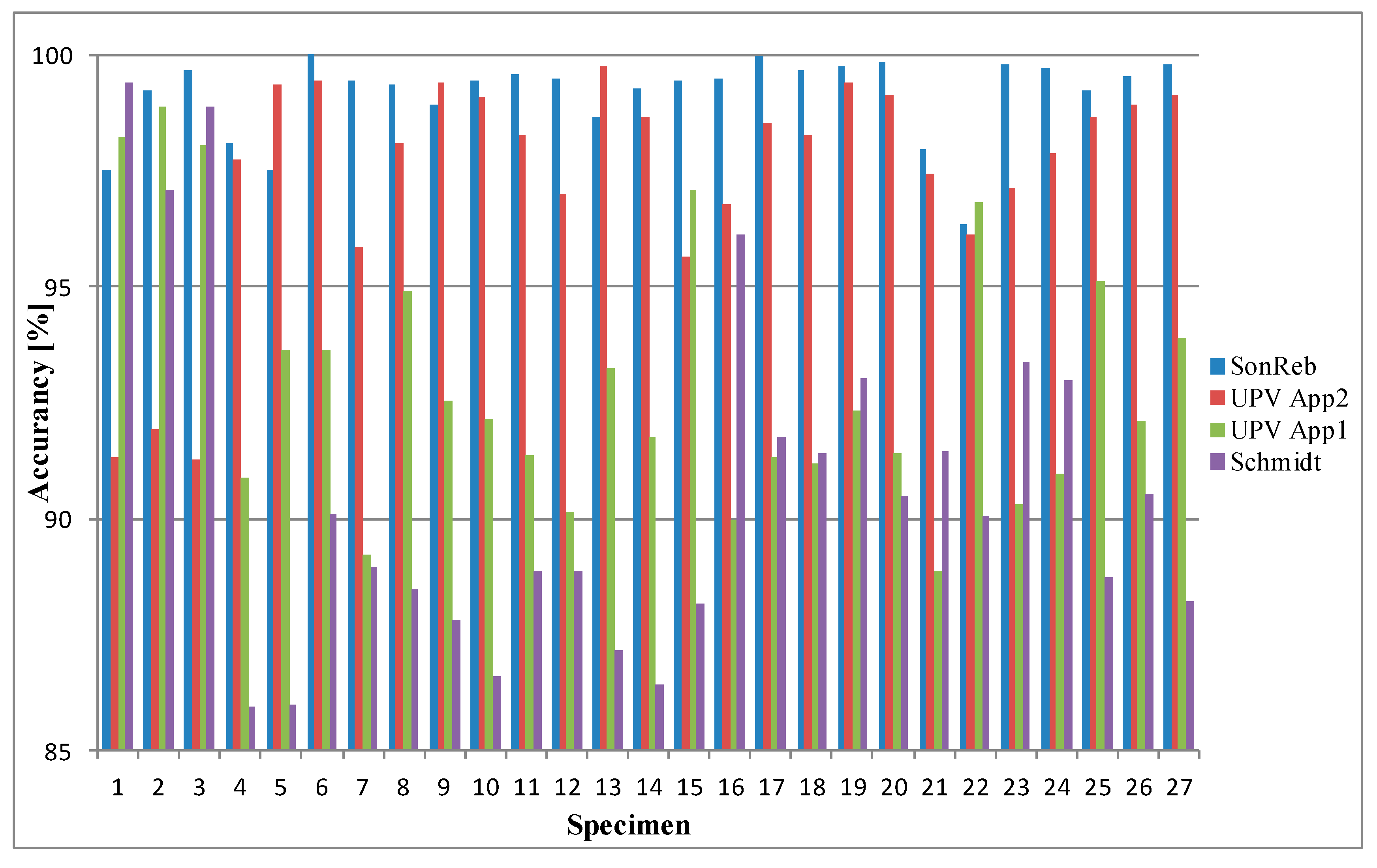

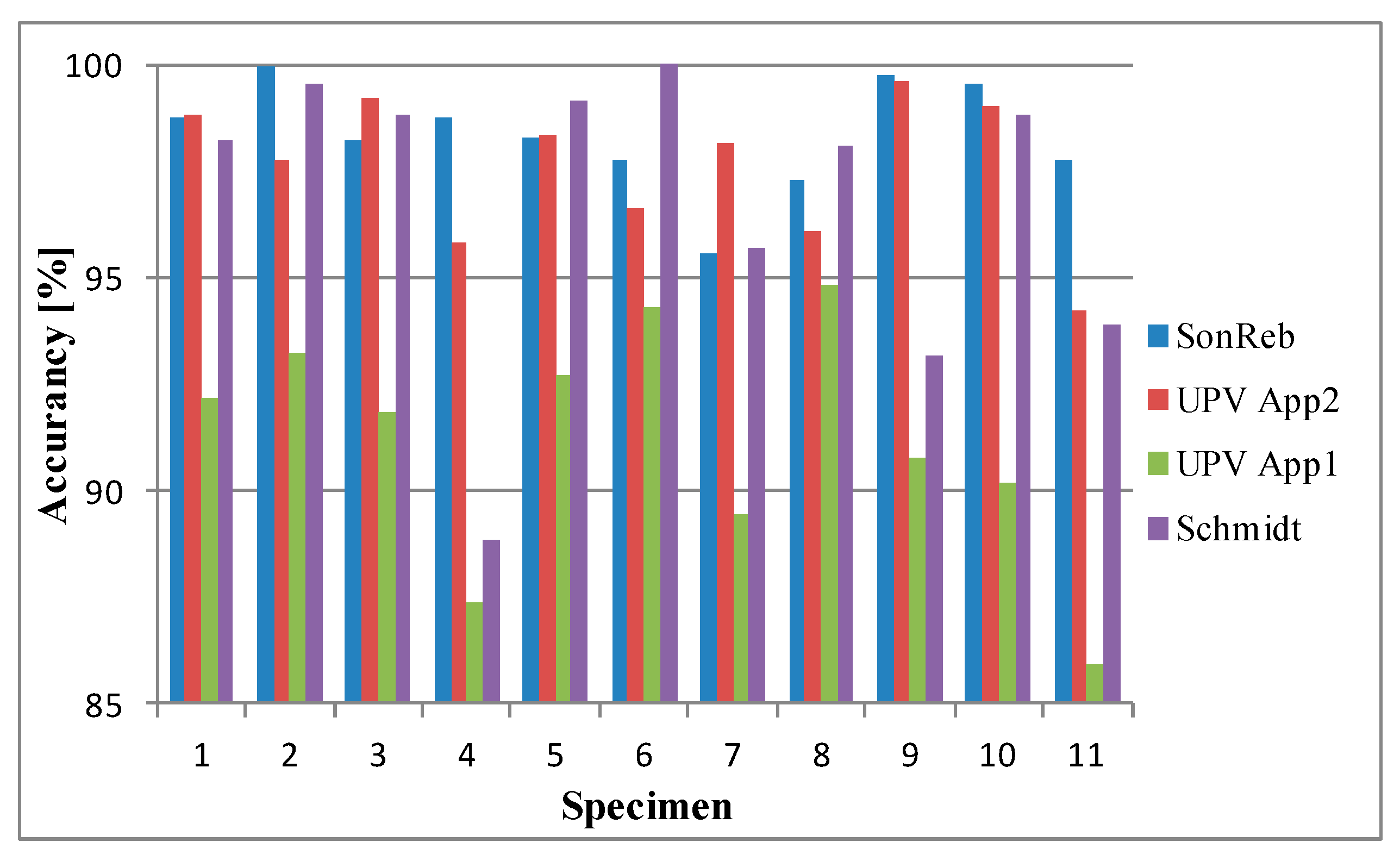

5.4. Evaluation the Accuracy of the Compressive Strength Determined Using Non-Destructive Methods Compared to Reference Values

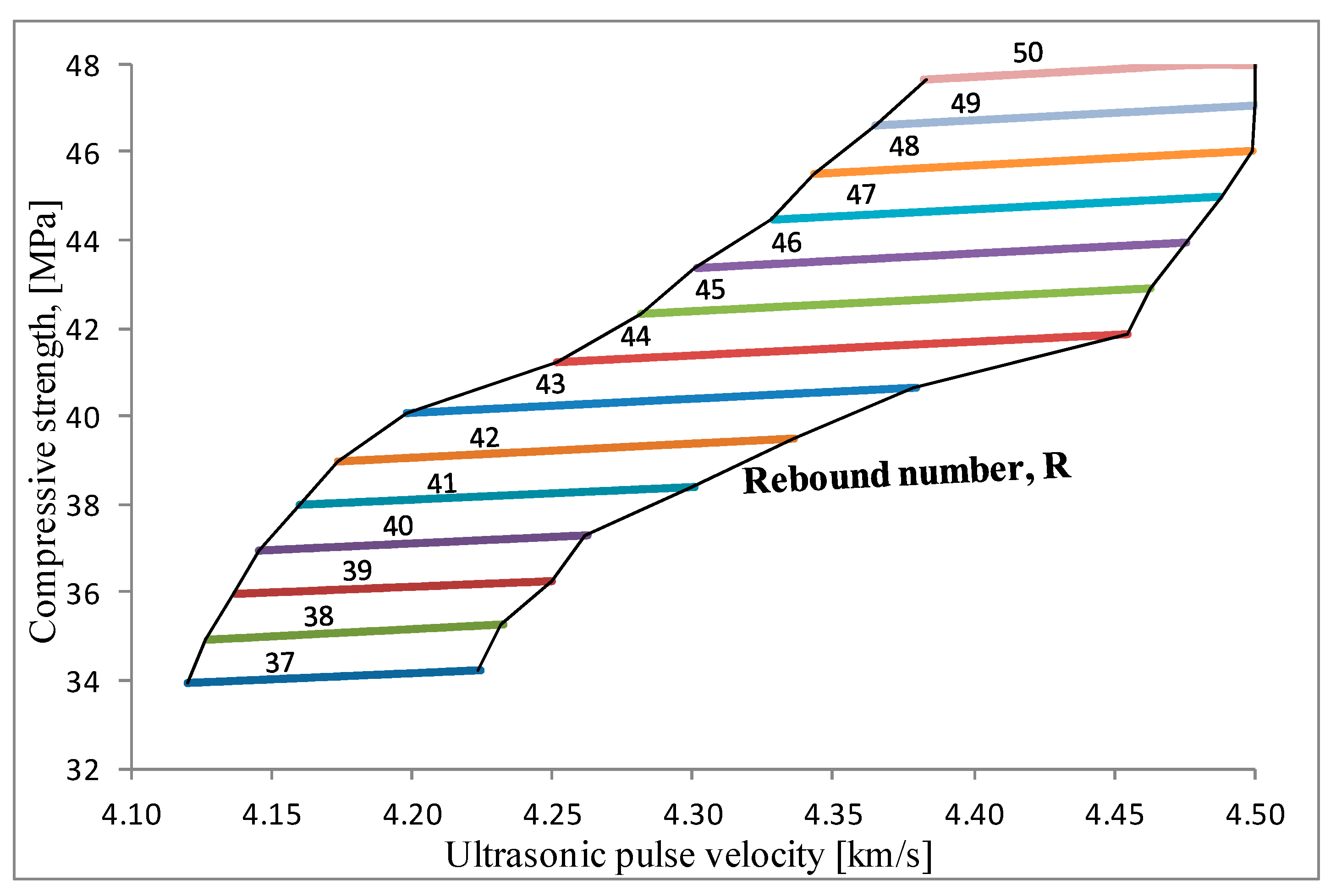

5.5. Typical Multiple-Correlation Relationship in the Form of a Nomogram for the Determination of Concrete Compressive Strength

6. Conclusions

- The results of the destructive tests were used as a reference and compared with those obtained using the elastic rebound method, UPVM (using two approaches) and the SonReb method. The compressive strength value observed in the destructive testing of test specimens ranged between and . In determining the number of tests and the number of methods used, the aim was to achieve the lowest price.

- The relative error when using the elastic rebound method was large and reached 14.1%. The accuracy was low compared to the other non-destructive methods used in the experiments. The results regarding the rebound number were used in obtaining correlation curves for the tested specimens. This method is suitable for the rapid investigation of a large number of concrete or reinforced concrete structural elements in laboratory and field tests. To reduce the influence of different factors, the test should be repeated at least 10 times within each test region.

- The relative error when using UPVM according to approach 2 was smaller (from 0.3% to 9.6%) compared to that observed using UPVM according to approach 1 (from 1.2% to 16.4%) and the elastic rebound method. Accuracy was greater when using approach 2 compared to approach 1 and the elastic rebound method. The results obtained regarding the ultrasonic signal velocity were used to develop correlation curves for the tested specimens. The method provided reliable results, the measurements were fast, the required equipment was relatively cheap.

- When using a combination of methods, as with the SonReb method, more reliable results were obtained, with values close to the reference values. The relative error in this method was the smallest and reached 4.6%. The accuracy of this method was the highest (from 96% to 100%) compared to that of the other non-destructive methods used. The regression analysis performed and the correlation curves obtained in this study can be used to determine the compressive strength of concrete at any point of the entire structure solely on the basis of non-destructive testing, provided that the concrete used is the same.

- The created nomograms could help to optimize the process of evaluating and tracking the compressive strength and behavior of concrete in the future monitoring and quality control of the investigated reinforced concrete elements. Only measurements of the rebound number with the elastic rebound method and the ultrasonic pulse velocity with UPVM are required to be made.

- The use of these nomograms for other reinforced concrete structures with similar or different concrete compressive strength values may lead to large errors and inaccuracies in the assessments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Alwash, M. Assessment of Concrete Strength in Existing Structures Using Nondestructive Tests and Cores: Analysis of Current Methodology and Recommendations for more Reliable Assessment. Ph.D. Thesis, University of Bordeaux, Bordeaux, France, 2017. [Google Scholar]

- Karaiskos, G.; Deraemaeker, A.; Aggelis, D.; Hemelrijck, D. Monitoring of Concrete Structures Using the Ultrasonic Pulse Velocity Method. Smart Mater. Struct. 2015, 24, 113001. [Google Scholar] [CrossRef] [Green Version]

- Dimov, D. Investigation and Testing of Structures and Bridges, 3rd ed.; DL & M: Sofia, Bulgaria, 2016. [Google Scholar]

- Khan, A.; Bin Ibrahim, A.N.; Bin Ismail, P.; Forde, M.; Gilmour, R.; Kato, K.; Ooka, N.; Siong, S.T.; Terada, K.; Wiggerhauser, H. Guidebook on Non-Destructive Testing of Concrete Structure TCS-17; International Atomic Energy Agency: Vienna, Austria, 2002. [Google Scholar]

- Castañeda, A.; Albear, J.J.H.; Corvo, F.; Marrero, R. Concrete Quality Assessment before Building Structures Submitting to Environmental Exposure Conditions. Rev. Constr. 2017, 16, 374–387. [Google Scholar] [CrossRef] [Green Version]

- Gupta, S. Comparison of Non-Destructive and Destructive Testing on Concrete: A Review. Trends Civ. Eng. Its Archit. 2018, 3, 351–357. [Google Scholar] [CrossRef] [Green Version]

- Hrischev, H.; Rostovsky, I.; Conev, I.; Nikolov, V. Investigation for Estimating of Concrete Strength by the Maturity Method and the Rebound Hammer. AIP Conf. Proc. 2022, 2557, 040001. [Google Scholar] [CrossRef]

- Minutolo, V.; Di Ronza, S.; Eramo, C.; Ferla, P.; Palladino, S.; Zona, R. The Use of Destructive and non Destructive Testing in Concrete Strength Assessment for a School Buildin. Int. J. Adv. Res. Eng. Technol. 2019, 10, 252–267. [Google Scholar] [CrossRef]

- Kaplan, G.; Yaprak, H.; Memis, S.; Alnkaa, A. Artificial Neural Network Estimation of the Effect of Varying Curing Conditions and Cement Type on Hardened Concrete Properties. Buildings 2019, 9, 10. [Google Scholar] [CrossRef] [Green Version]

- Nucera, F.; Pucinotti, R. Destructive and Non-Destructive Testing on Reinforced Concrete Structure: The Case Study of the Museum of Magna Graecia in Reggio Calabria, Mediterranean University of Reggio Calabria. In Proceedings of the 39th International Conference and Exhibition, Prague, Czech Republic, 4–6 November 2009. [Google Scholar]

- Hajjeh, H. Correlation Between Destructive and Non-Destructive Strengths of Concrete Cubes Using Regression Analysis. Contemp. Eng. Sci. 2012, 5, 493–509. [Google Scholar]

- Jedidi, M.; Kaouther, M. Destructive and Non-destructive Testing of Concrete Structures. Jordan J. Civ. Eng. 2014, 8, 432–441. [Google Scholar]

- Bhosale, N.; Salunkhe, P. To Establish Relation Between Destructive and Non-Destructive Tests on concrete. Int. J. Eng. Res. Gen. Sci. 2016, 4, 634–644. [Google Scholar]

- Abdulkadir, M.; Karim, A.; Abdullah, A. Destructive and Non Destructive Strength Evaluation of Concrete Exposed to Fire. Zankoy Sulaimani J. Zankoy Sulaimani Part A 2017, 19, 43–55. [Google Scholar] [CrossRef]

- Martínez-Molina, W.; Torres-Acosta, A.; Jáuregui, J.; Chávez-García, H.; Alonso-Guzmán, E.; Graff, M.; Arteaga-Arcos, J. Predicting Concrete Compressive Strength and Modulus of Rupture Using Different NDT Techniques. Adv. Mater. Sci. Eng. 2014, 2014, 742129. [Google Scholar] [CrossRef] [Green Version]

- Celik, A.; Kilinc, K.; Tuncan, M.; Tuncan, A. Distributions of Compressive Strength Obtained from Various Diameter Cores. ACI Mater. J. 2012, 109, 6. [Google Scholar]

- EN 12390-2:2009; Testing Hardened Concrete—Part 2: Making and Curing Specimens for Strength Tests. CEN: Brussels, Belgium, 2009.

- Masi, A.; Nigro, D.; Vona, M. Effect of Core Drilling and Subsequent Restoration on RC Column Strength. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisbon, Spain, 24–28 September 2012. [Google Scholar]

- Bungey, J.H.; Millard, S.G.; Grantham, M.G. Testing of Concrete in Structures; CRC Press: London, UK, 2014. [Google Scholar] [CrossRef]

- Breysse, D. Non-Destructive Assessment of Concrete Structures: Reliability and Limits of Single and Combined Techniques, State-of-the-Art Report of RILEM Technical Committee 207-INR; Springer: Berlin, Germany, 2012. [Google Scholar] [CrossRef]

- Bolborea, B.; Baera, C.; Dan, S.; Gruin, A.; Burduhos-Nergis, D.-D.; Vasile, V. Concrete Compressive Strength by Means of Ultrasonic Pulse Velocity and Moduli of Elasticity. Materials 2021, 14, 7018. [Google Scholar] [CrossRef] [PubMed]

- Malhotra, V.; Carino, N. Handbook on Nondestructive Testing of Concrete, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar] [CrossRef]

- Ju, M.; Park, K.; Oh, H. Estimation of Compressive Strength of High Strength Concrete Using Non-Destructive Technique and Concrete Core Strength. Appl. Sci. 2017, 7, 1249. [Google Scholar] [CrossRef] [Green Version]

- Kocáb, D.; Misák, P.; Cikrle, P. Characteristic Curve and Its Use in Determining the Compressive Strength of Concrete by the Rebound Hammer Test. Materials 2019, 12, 2705. [Google Scholar] [CrossRef] [Green Version]

- EN 12504-2:2012; Testing Concrete in Structures—Part 2: Non-Destructive Testing—Determination of Rebound Number. CEN: Brussels, Belgium, 2012.

- Hannachi, S.; Guetteche, M. Application of the Combined Method for Evaluating the Compressive Strength of Concrete on Site. Open J. Civ. Eng. 2012, 2, 16–21. [Google Scholar] [CrossRef] [Green Version]

- Poorarbabi, A.; Ghasemi, M.; Moghaddam, M.A. Concrete compressive strength prediction using non-destructive tests through response surface methodology. Ain Shams Eng. J. 2020, 11, 939–949. [Google Scholar] [CrossRef]

- Ahmad, N.; Rahim, R.; Rahim, H.; Rahiman, M. A Review of Ultrasonic Application on Non-destructive Testing Method for Concrete Structure. J. Teknol. 2014, 119–122. [Google Scholar] [CrossRef] [Green Version]

- Lorenzi, A.; Tisbierek, F.; Pinto, L. Ultrasonic Pulse Velocity Analysis in Concrete Specimens. In Proceedings of the 4th Conferencia Panamericana de END, Buenos Aires, Argentina, 22–26 October 2007. [Google Scholar]

- Naik, T.; Malhotra, V.; Popovics, J. The Ultrasonic Pulse Velocity Method, In Handbook on Nondestructive Testing of Concrete; CRC Press: Boca Raton, FL, USA, 2006. [Google Scholar]

- Panzera, T.; Christoforo, A.; Cota, F.; Borges, P.; Bowen, C. Ultrasonic Pulse Velocity Evaluation of Cementitious Materials. In Advances in Composite Materials—Analysis of Natural and Man-Made Materials; InTech: Rijeka, Croatia, 2011. [Google Scholar] [CrossRef] [Green Version]

- Hadianfard, M.; Jafari, S. Prediction of Lightweight Aggregate Concrete Compressive Strength Using Ultrasonic Pulse Velocity Test through Gene Expression Programming. Sci. Iran. 2016, 23, 2506–2513. [Google Scholar] [CrossRef] [Green Version]

- Savaliya, K.; Thaker, K.; Dave, U. Comparison between Different Methods of Ultrasonic Pulse Velocity Tests on Concrete. In Proceedings of the National Conference on Advances in Engineering and Technology, Ambala, India, 29 March 2014. [Google Scholar]

- EN 12390-3:2009; Testing Hardened Concrete—Part 3: Compressive Strength Of Test Specimens. CEN: Brussels, Belgium, 2009.

- EN 12390-4:2000; Testing Hardened Concrete—Part 4: Compressive Strength—Specification for Testing Machines. CEN: Brussels, Belgium, 2000.

- BDS EN 13791:2007/NA:2011; Assessment of In-Situ Compressive Strength in Structures and Precast Concrete Components. Bulgarian Institute for Standardization: Sofia, Bulgaria, 2011.

- Cristofaro, M.; D’Ambrisi, A.; Stefano, M.; Tanganelli, M.; Pucinotti, R. Mechanical Characterization of Concrete from Existing Buildings with SonReb Method. In Proceedings of the 15th World Conference on Earthquake Engineering, Lisboa, Portugal, 24–28 September 2012. [Google Scholar]

- Cristofaro, M.; Viti, S.; Tanganelli, M. New predictive models to evaluate concrete compressive strength using the SonReb method. J. Build. Eng. 2020, 27, 100962. [Google Scholar] [CrossRef]

- Jain, A.; Kathuria, A.; Kumar, A.; Verma, Y.; Murari, K. Combined Use of Non-Destructive Tests for Assessment of Strength of Concrete in Structure. Procedia Eng. 2013, 54, 241–251. [Google Scholar] [CrossRef] [Green Version]

- Chandak, N.; Kumavat, H. SonReb Method for Evaluation of Compressive Strength of Concrete. IOP Conf. Ser.: Mater. Sci. Eng. 2010, 810, 012071. [Google Scholar] [CrossRef]

- Pucinotti, R. The Use of Multiple Combined Non Destructive Testing in the Concrete Strenght Assessent: Applications on Laboratory Specimens. Electron. Resour. 2009, 13, 2. [Google Scholar]

- Dauji, S.; Bhalerao, S.; Srivastava, P.; Bhargava, K. Conservative Characteristic Strength of Concrete from Nondestructive and Partially Destructive Testing. J. Asian Concr. Fed. 2019, 5, 25–39. [Google Scholar] [CrossRef]

- Nikhil, M.; BalkiMinal, R.; Chhabria, S.; Ghare, D.; Tele, S.; Shweta, P. The use of Combined Non Destructive Testing in the Concrete Strength Assessment from Laboratory Specimens and Existing Buildings. Int. J. Curr. Eng. Sci. Res. 2015, 2, 55–59. [Google Scholar]

- EN 12390-1:2012; Testing Hardened Concrete—Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. CEN: Brussels, Belgium, 2012.

- EN 12350-1:2009; Testing Fresh Concrete—Part 1: Sampling and Common Apparatus. CEN: Brussels, Belgium, 2009.

- EN 12504-1:2009; Testing Concrete in Structures—Part 1: Cored Specimens—Taking, Examining and Testing in Compression. CEN: Brussels, Belgium, 2009.

- Brunarski, L.; Dohojda, M. An Approach to In-situ Compressive strength of Concrete. Bull. Pol. Acad. Sciences. Tech. Sci. 2016, 64, 687–695. [Google Scholar] [CrossRef] [Green Version]

- Marco, V. A Review of Experimental Results about in Situ Concrete Strength. Adv. Mater. Res. 2013, 773, 278–282. [Google Scholar] [CrossRef]

- EN 12504-4:2004; Testing Concrete in Structures—Part 4: Determination of Ultrasonic Pulse Velocity. CEN: Brussels, Belgium, 2004.

| Age (Days) | Test Specimen, № | Median R | Rs · (N/mm2) | fc,Schmidt (N/mm2) |

|---|---|---|---|---|

| 28th | Cube 1 | 37 | 33.5 | 33.5 |

| Cube 2 | 37 | 33.5 | 33.5 | |

| Cube 3 | 37.5 | 34.5 | 34.5 | |

| 244th | Cube 4 | 40.5 | 40.5 | 33.0 |

| Cube 5 | 41 | 41.5 | 33.8 | |

| Cube 6 | 42 | 43.5 | 35.4 | |

| 280th | Cube 7 | 42 | 43.5 | 34.6 |

| Cube 8 | 42 | 43.5 | 34.6 | |

| Cube 9 | 42.5 | 44.6 | 35.4 | |

| 293rd | Cube 10 | 42 | 43.5 | 34.2 |

| Cube 11 | 43 | 45.7 | 36.0 | |

| Cube 12 | 43 | 45.7 | 36.0 | |

| 342nd | Cube 13 | 43 | 45.7 | 34.7 |

| Cube 14 | 43.5 | 46.9 | 35.6 | |

| Cube 15 | 44 | 48.0 | 36.5 | |

| 1126th | Cube 16 | 49.5 | 60.4 | 45.3 |

| Cube 17 | 47 | 54.7 | 41.0 | |

| Cube 18 | 46.5 | 53.6 | 40.2 | |

| Cube 19 | 46.5 | 53.6 | 40.2 | |

| Cube 20 | 46 | 52.5 | 39.4 | |

| Cube 21 | 48 | 57.0 | 42.8 | |

| Cube 22 | 44 | 48.0 | 36.0 | |

| Cube 23 | 48 | 57.0 | 42.8 | |

| Cube 24 | 47.5 | 55.9 | 41.9 | |

| Cube 25 | 45 | 50.0 | 37.5 | |

| Cube 26 | 46.5 | 53.6 | 40.2 | |

| Cube 27 | 45 | 50.0 | 37.5 | |

| 1926th | Core 1 | 46 | 52.5 | 45.5 |

| Core 2 | 46 | 52.5 | 45.5 | |

| Core 3 | 48 | 56.6 | 49.0 | |

| Core 4 | 52 | 67.6 | 59.1 | |

| Core 5 | 47 | 54.7 | 47.8 | |

| Core 6 | 47 | 54.7 | 47.8 | |

| Core 7 | 45 | 50.7 | 44.3 | |

| Core 8 | 46.5 | 53.6 | 46.7 | |

| Core 9 | 50 | 61.8 | 54.0 | |

| Core 10 | 48.5 | 58.0 | 50.2 | |

| Core 11 | 50 | 61.8 | 54.0 |

| Age (Days) | Test Specimen, № | VUPV,mean (km/s) |

fc,UPV,app1 (N/mm2) |

fc,UPV,app2 (N/mm2) |

|---|---|---|---|---|

| 28th | Cube 1 | 4.187 | 33.9 | 36.5 |

| Cube 2 | 4.219 | 34.9 | 37.5 | |

| Cube 3 | 4.240 | 35.6 | 38.2 | |

| 244th | Cube 4 | 4.219 | 34.9 | 37.5 |

| Cube 5 | 4.278 | 36.8 | 39.6 | |

| Cube 6 | 4.277 | 36.8 | 39.5 | |

| 280th | Cube 7 | 4.212 | 34.7 | 37.3 |

| Cube 8 | 4.287 | 37.1 | 39.9 | |

| Cube 9 | 4.292 | 37.3 | 40.0 | |

| 293rd | Cube 10 | 4.266 | 36.4 | 39.1 |

| Cube 11 | 4.285 | 37.0 | 39.8 | |

| Cube 12 | 4.270 | 36.5 | 39.3 | |

| 342nd | Cube 13 | 4.288 | 37.1 | 39.9 |

| Cube 14 | 4.309 | 37.8 | 40.7 | |

| Cube 15 | 4.381 | 40.2 | 43.3 | |

| 1126th | Cube 16 | 4.442 | 42.4 | 45.6 |

| Cube 17 | 4.401 | 40.8 | 44.0 | |

| Cube 18 | 4.379 | 40.1 | 43.2 | |

| Cube 19 | 4.372 | 39.9 | 42.9 | |

| Cube 20 | 4.378 | 39.8 | 43.2 | |

| Cube 21 | 4.442 | 41.6 | 45.6 | |

| Cube 22 | 4.335 | 38.7 | 41.6 | |

| Cube 23 | 4.414 | 41.4 | 44.5 | |

| Cube 24 | 4.403 | 41.0 | 44.1 | |

| Cube 25 | 4.369 | 40.2 | 42.8 | |

| Cube 26 | 4.398 | 40.9 | 43.9 | |

| Cube 27 | 4.370 | 39.9 | 42.9 | |

| 1926th | Core 1 | 4.605 | 48.5 | 44.2 |

| Core 2 | 4.608 | 48.6 | 44.3 | |

| Core 3 | 4.739 | 54.0 | 49.2 | |

| Core 4 | 4.876 | 60.1 | 54.8 | |

| Core 5 | 4.692 | 52.0 | 47.4 | |

| Core 6 | 4.660 | 50.7 | 46.2 | |

| Core 7 | 4.578 | 47.4 | 43.2 | |

| Core 8 | 4.648 | 50.2 | 45.7 | |

| Core 9 | 4.772 | 55.4 | 50.5 | |

| Core 10 | 4.762 | 55.0 | 50.1 | |

| Core 11 | 4.853 | 59.0 | 53.8 |

| Age (Days) | Test Specimen, № | Cube Dimensions | Mass (kg) | F (kN) | Fc,cube (N/mm2) | ||

|---|---|---|---|---|---|---|---|

| a | b | h | |||||

| (mm) | (mm) | (mm) | |||||

| 28th | Cube 1 | 149.8 | 149.9 | 150.2 | 7.77 | 747.6 | 33.3 |

| Cube 2 | 149.9 | 149.9 | 150.3 | 7.78 | 776.3 | 34.5 | |

| Cube 3 | 149.9 | 150 | 150 | 7.78 | 785.1 | 34.9 | |

| 244th | Cube 4 | 150 | 149.9 | 150 | 7.76 | 863.1 | 38.4 |

| Cube 5 | 149 | 150.5 | 150.3 | 7.73 | 882.2 | 39.3 | |

| Cube 6 | 150.5 | 149.6 | 150 | 7.76 | 883.8 | 39.3 | |

| 280th | Cube 7 | 149.8 | 149.5 | 150 | 7.70 | 872.1 | 38.9 |

| Cube 8 | 150 | 149 | 150.2 | 7.73 | 875.0 | 39.1 | |

| Cube 9 | 149.7 | 149.9 | 150 | 7.72 | 903.8 | 40.3 | |

| 293rd | Cube 10 | 149.7 | 151 | 150 | 7.77 | 893.7 | 39.5 |

| Cube 11 | 149.6 | 150.3 | 150.2 | 7.75 | 910.7 | 40.5 | |

| Cube 12 | 149.6 | 149.4 | 150 | 7.69 | 904.3 | 40.5 | |

| 342nd | Cube 13 | 149.7 | 149.8 | 150 | 7.66 | 891.7 | 39.8 |

| Cube 14 | 149.3 | 149.7 | 149.5 | 7.66 | 920.3 | 41.2 | |

| Cube 15 | 149.5 | 149.7 | 150.3 | 7.76 | 926.9 | 41.4 | |

| 1126th | Cube 16 | 148.6 | 147.7 | 149.8 | 7.60 | 1034.1 | 47.1 |

| Cube 17 | 148.8 | 150.0 | 150 | 7.65 | 997.6 | 44.7 | |

| Cube 18 | 148.5 | 149.5 | 150 | 7.62 | 976.4 | 44.0 | |

| Cube 19 | 150.9 | 148.6 | 149.6 | 7.69 | 969.0 | 43.2 | |

| Cube 20 | 149 | 149.6 | 149.4 | 7.67 | 970.6 | 43.6 | |

| Cube 21 | 146.5 | 149.5 | 150 | 7.55 | 1025.0 | 46.8 | |

| Cube 22 | 150.5 | 149.7 | 149.4 | 7.69 | 900.6 | 40.0 | |

| Cube 23 | 147.2 | 149.5 | 149.7 | 7.56 | 1008.8 | 45.8 | |

| Cube 24 | 149.5 | 149.9 | 150.3 | 7.74 | 1009.9 | 45.1 | |

| Cube 25 | 151.2 | 149.4 | 149.8 | 7.73 | 954.7 | 42.3 | |

| Cube 26 | 148.1 | 149.5 | 149.9 | 7.61 | 983.3 | 44.4 | |

| Cube 27 | 150.6 | 149.5 | 149.8 | 7.66 | 956.9 | 42.5 | |

| 1926th | Cored specimen № | D (mm) | L (mm) | Mass(kg) | (kN) | (N/mm2) | |

| Core 1 | 99 | 99 | 1.792 | 298.9 | 44.7 | ||

| Core 2 | 99 | 99 | 1.796 | 303.3 | 45.3 | ||

| Core 3 | 99 | 94 | 1.746 | 331.9 | 49.6 | ||

| Core 4 | 99 | 100 | 1.867 | 351.5 | 52.5 | ||

| Core 5 | 99 | 100 | 1.890 | 322.3 | 48.2 | ||

| Core 6 | 99 | 98 | 1.818 | 319.9 | 47.8 | ||

| Core 7 | 99 | 99 | 1.835 | 283.9 | 42.4 | ||

| Core 8 | 99 | 96 | 1.764 | 318.4 | 47.6 | ||

| Core 9 | 99 | 100 | 1.838 | 336.4 | 50.3 | ||

| Core 10 | 99 | 103 | 1.890 | 332.3 | 49.6 | ||

| Core 11 | 99 | 99 | 1.822 | 339.7 | 50.7 | ||

| Age (Days) | Test Specimen, № | fc,SonReb (N/mm2) |

|---|---|---|

| 28th | Cube 1 | 34.1 |

| Cube 2 | 34.2 | |

| Cube 3 | 34.8 | |

| 244th | Cube 4 | 37.7 |

| Cube 5 | 38.3 | |

| Cube 6 | 39.3 | |

| 280th | Cube 7 | 39.1 |

| Cube 8 | 39.3 | |

| Cube 9 | 39.9 | |

| 293rd | Cube 10 | 39.3 |

| Cube 11 | 40.3 | |

| Cube 12 | 40.3 | |

| 342nd | Cube 13 | 40.3 |

| Cube 14 | 40.9 | |

| Cube 15 | 41.6 | |

| 1126th | Cube 16 | 47.4 |

| Cube 17 | 44.7 | |

| Cube 18 | 44.1 | |

| Cube 19 | 43.1 | |

| Cube 20 | 43.6 | |

| Cube 21 | 45.8 | |

| Cube 22 | 41.5 | |

| Cube 23 | 45.8 | |

| Cube 24 | 45.2 | |

| Cube 25 | 42.6 | |

| Cube 26 | 44.2 | |

| Cube 27 | 42.6 | |

| 1926th | Core 1 | 45.3 |

| Core 2 | 45.3 | |

| Core 3 | 48.7 | |

| Core 4 | 53.2 | |

| Core 5 | 47.4 | |

| Core 6 | 46.7 | |

| Core 7 | 44.4 | |

| Core 8 | 46.3 | |

| Core 9 | 50.2 | |

| Core 10 | 49.4 | |

| Core 11 | 51.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ivanchev, I. Investigation with Non-Destructive and Destructive Methods for Assessment of Concrete Compressive Strength. Appl. Sci. 2022, 12, 12172. https://doi.org/10.3390/app122312172

Ivanchev I. Investigation with Non-Destructive and Destructive Methods for Assessment of Concrete Compressive Strength. Applied Sciences. 2022; 12(23):12172. https://doi.org/10.3390/app122312172

Chicago/Turabian StyleIvanchev, Ivan. 2022. "Investigation with Non-Destructive and Destructive Methods for Assessment of Concrete Compressive Strength" Applied Sciences 12, no. 23: 12172. https://doi.org/10.3390/app122312172

APA StyleIvanchev, I. (2022). Investigation with Non-Destructive and Destructive Methods for Assessment of Concrete Compressive Strength. Applied Sciences, 12(23), 12172. https://doi.org/10.3390/app122312172