Experimental Study on Torsional Shear Testing of Asphalt Mixture

Abstract

:1. Introduction

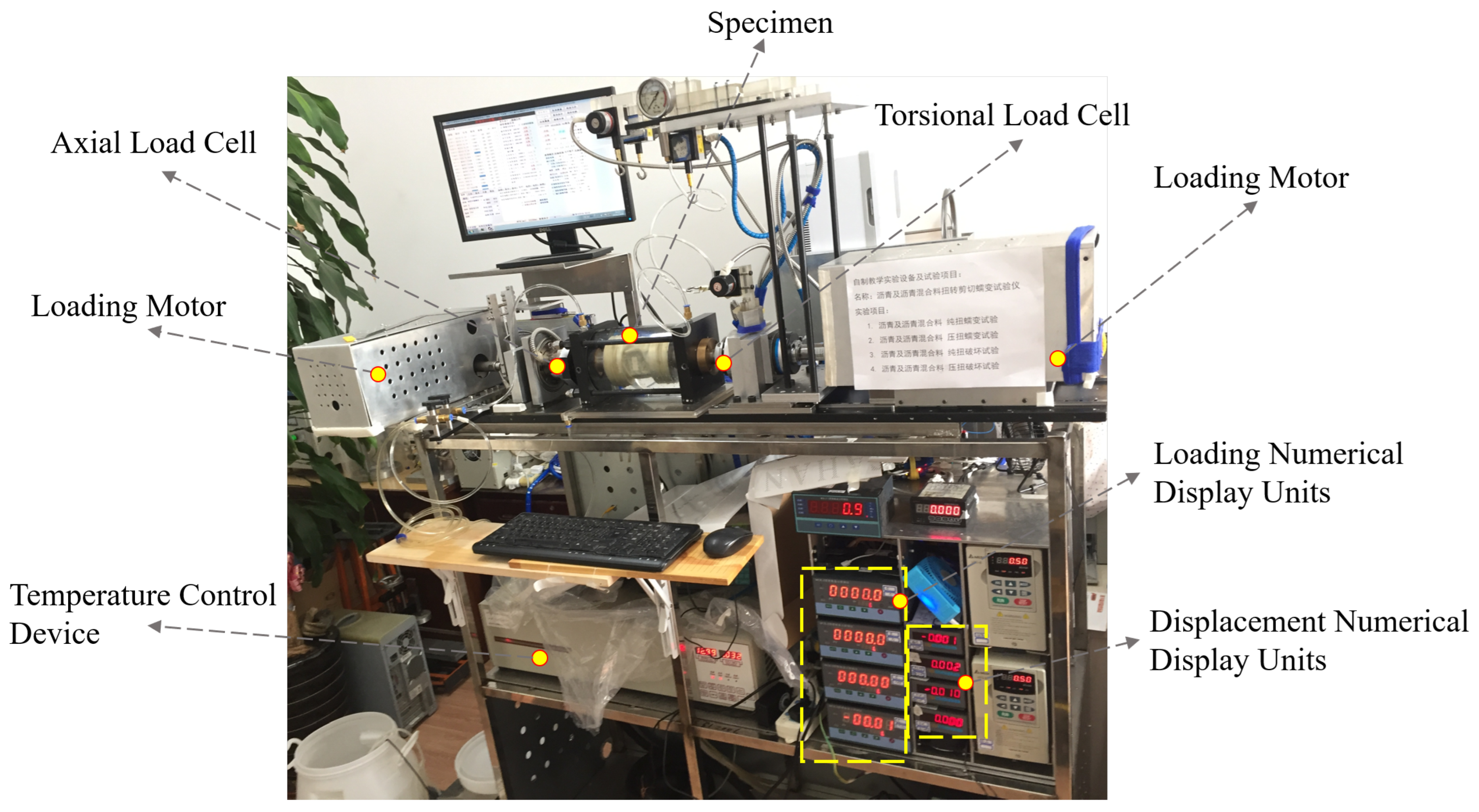

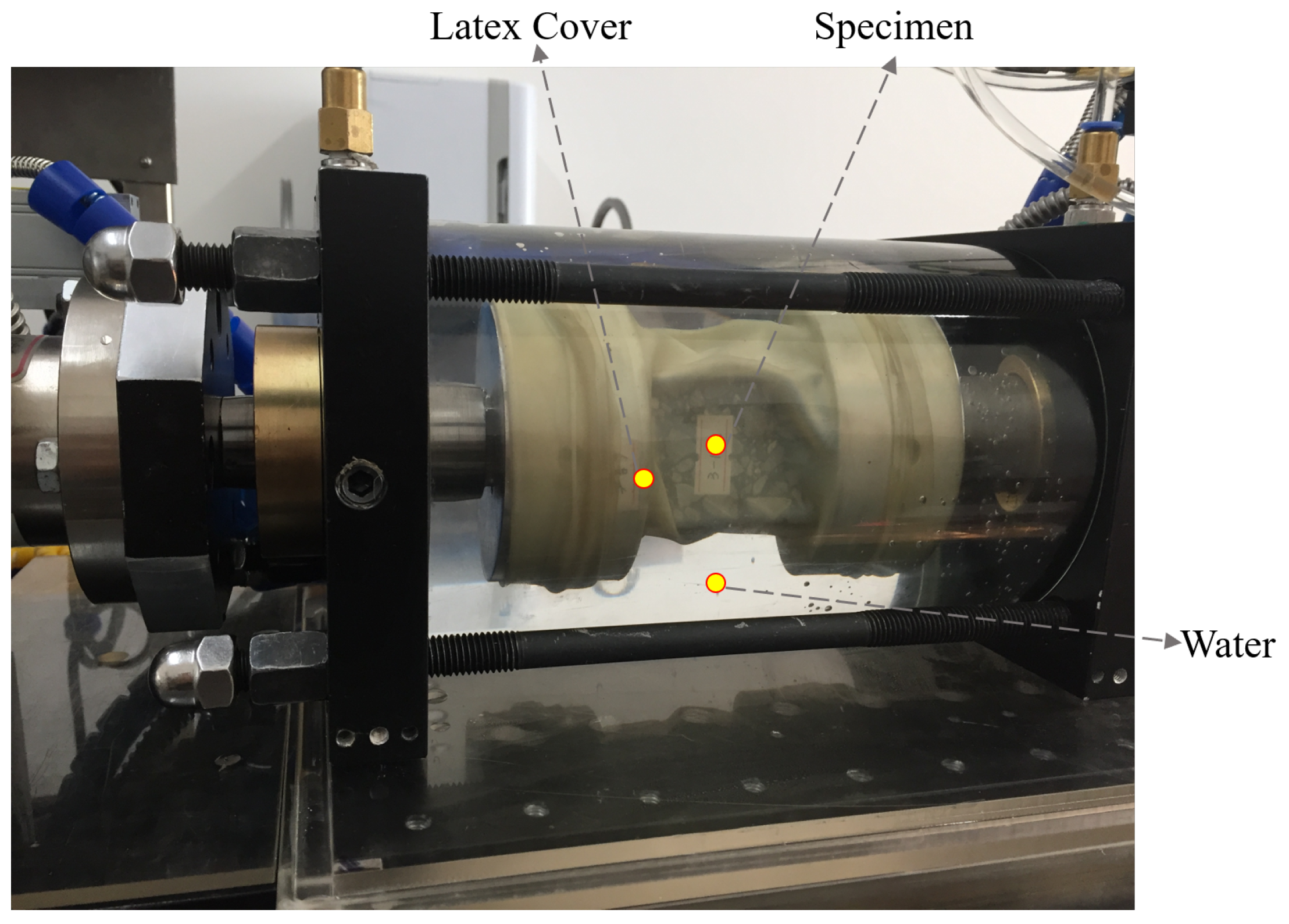

2. The Torsional Shear Testing Device and the Specimen Size

2.1. The Torsional Shear Testing Device

2.2. The Option of Specimen Size

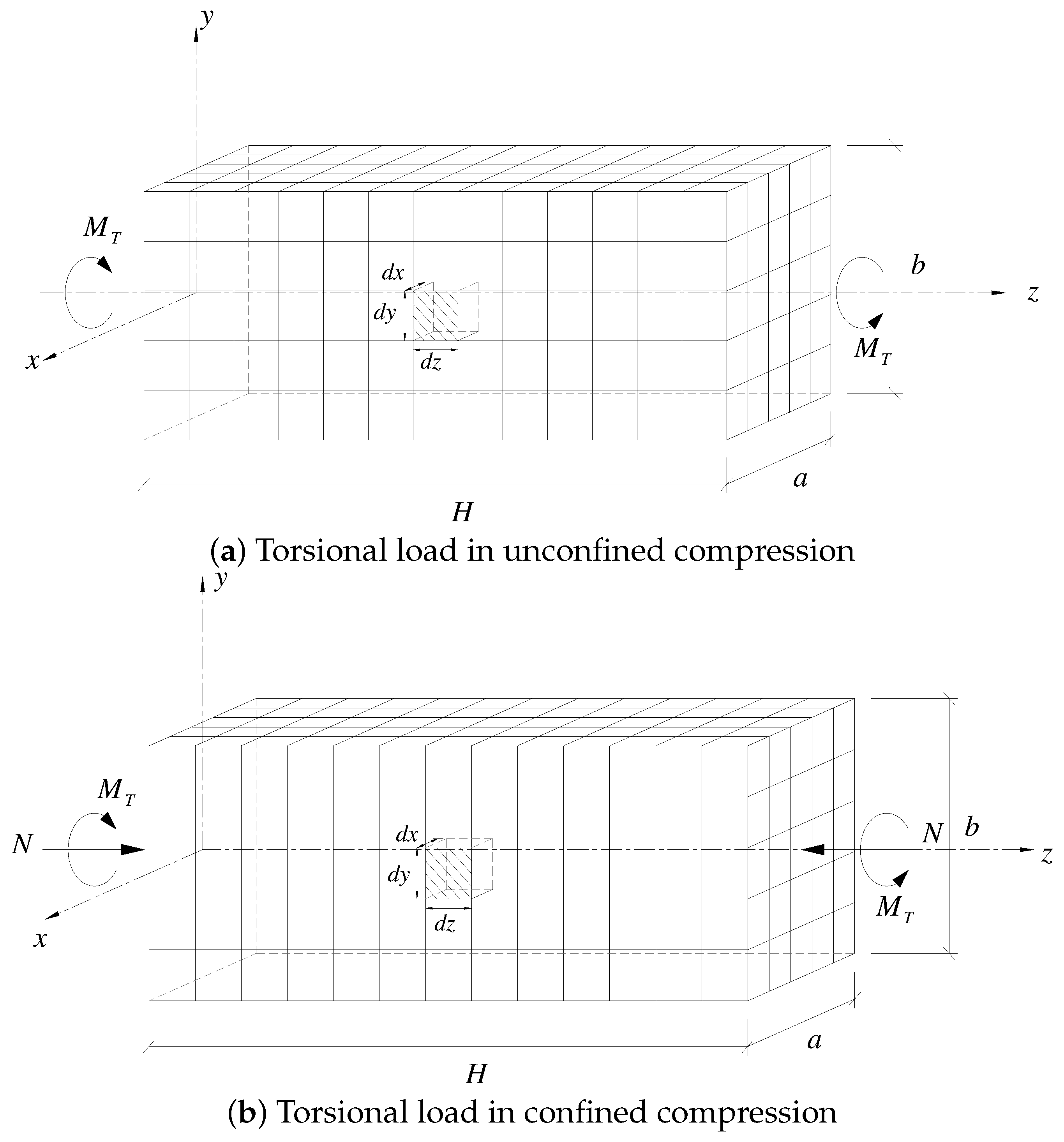

3. The Mechanical Theory of Torsional Shear Tests

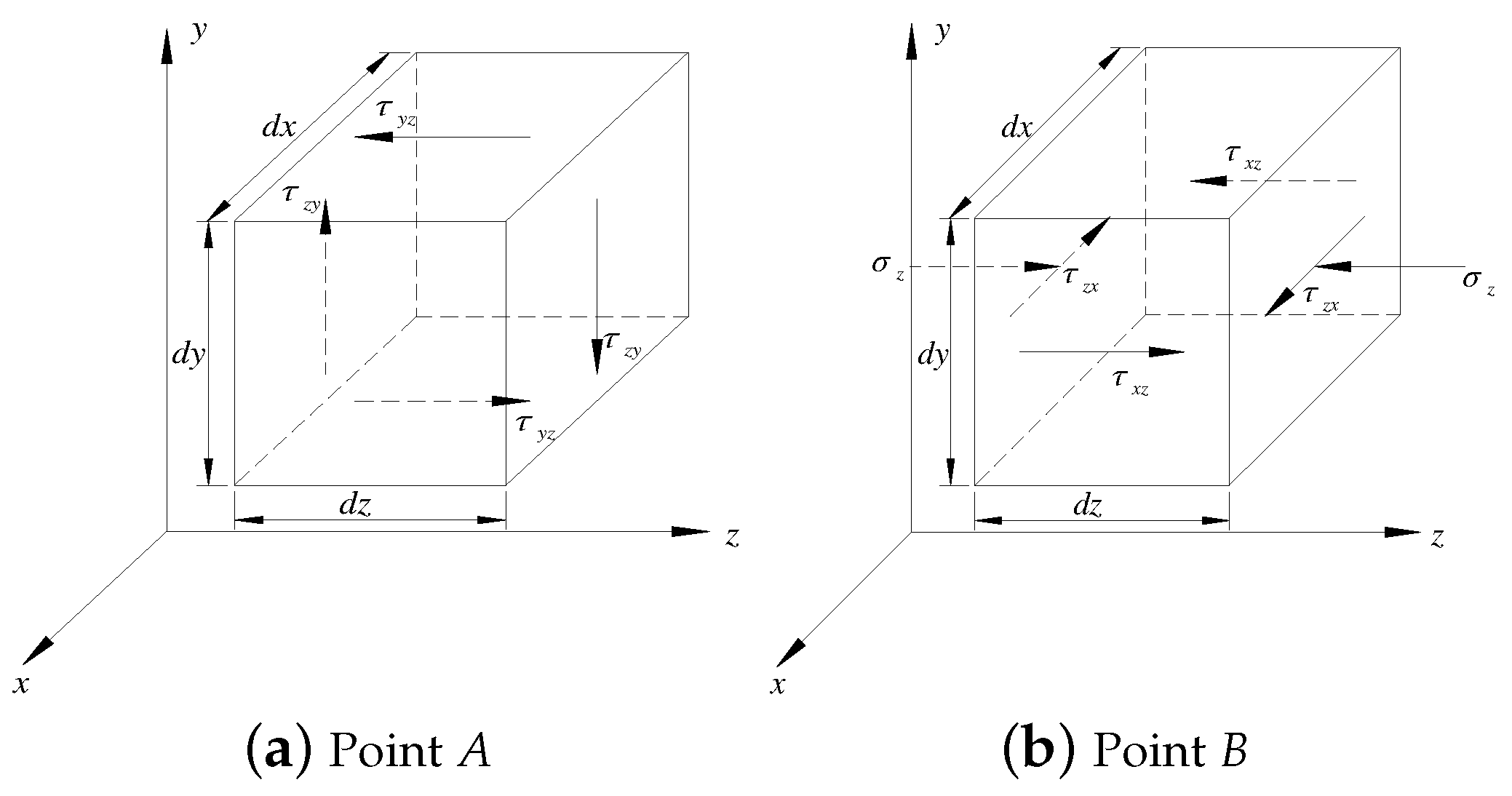

3.1. The Analysis of Torsional Stress for a Prism

3.1.1. Torque in Unconfined Compression

3.1.2. Torque in the Confined Compression

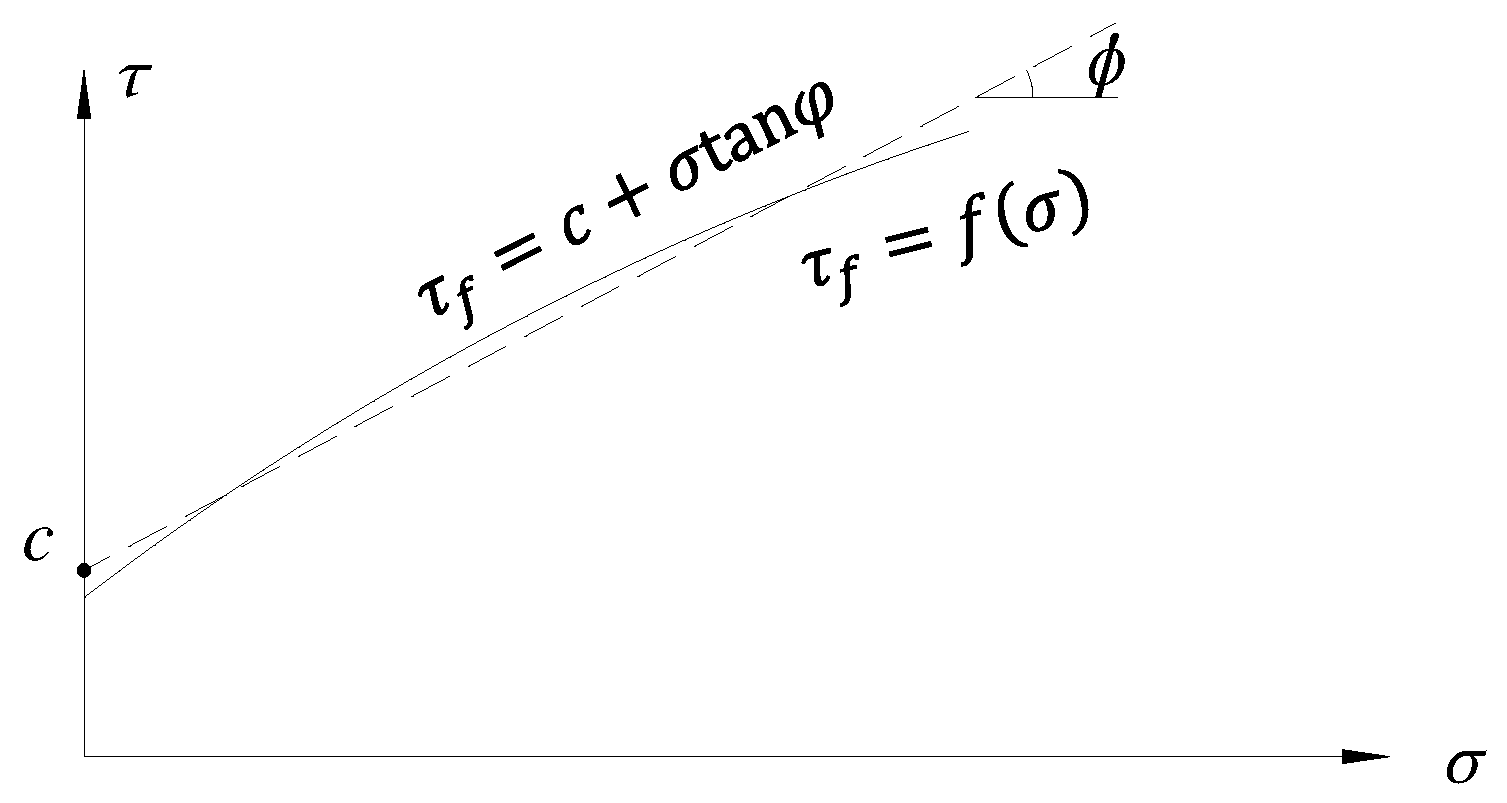

3.2. Failure Criteria of Asphalt Mixture

4. Materials and Specimen Preparation

4.1. Materials Preparation

4.1.1. Modified Asphalt Binder

4.1.2. Aggregate Gradation of Asphalt Mixtures

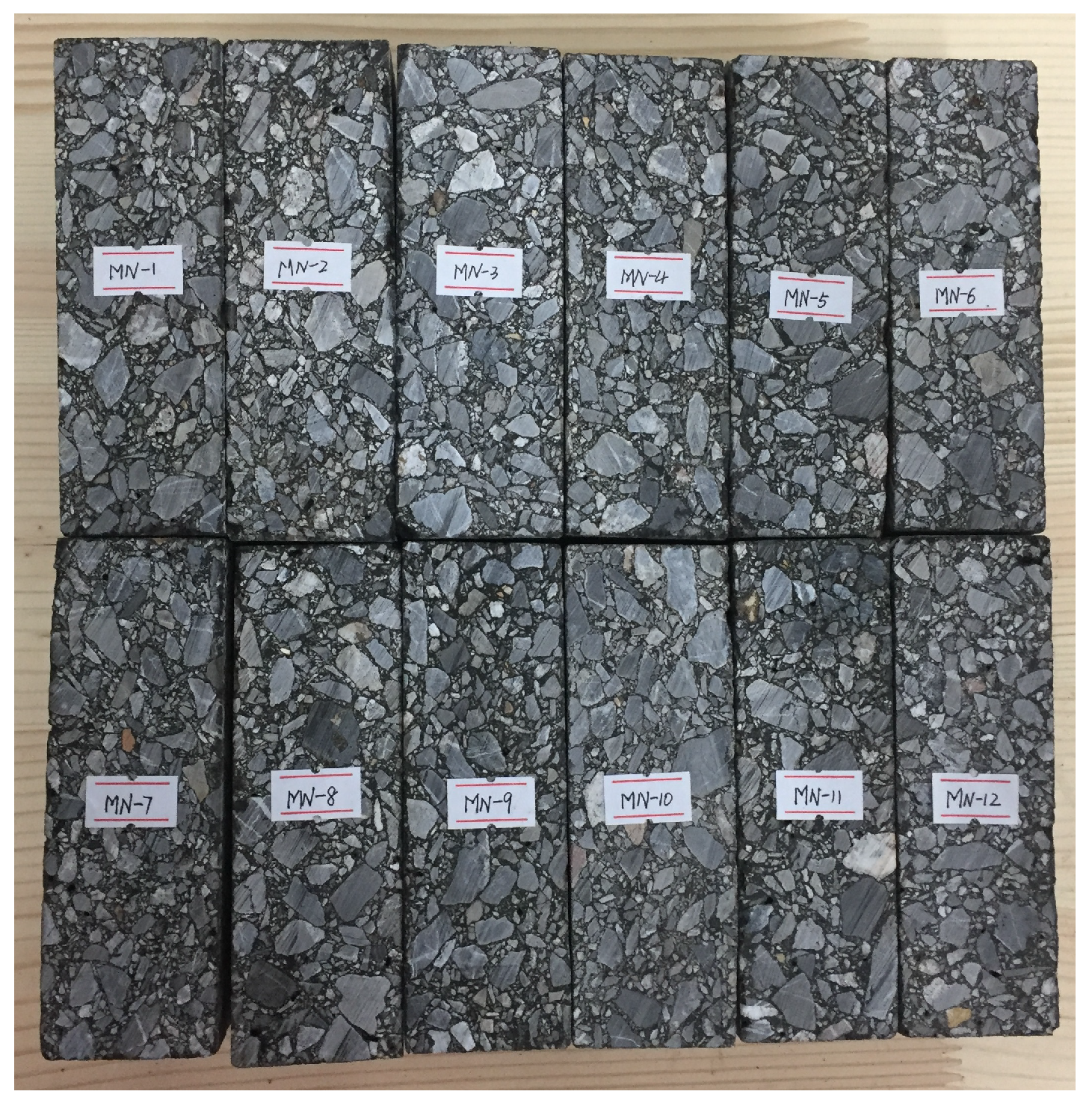

4.2. Specimen Preparation

5. Experimental Plans

6. Experimental Results

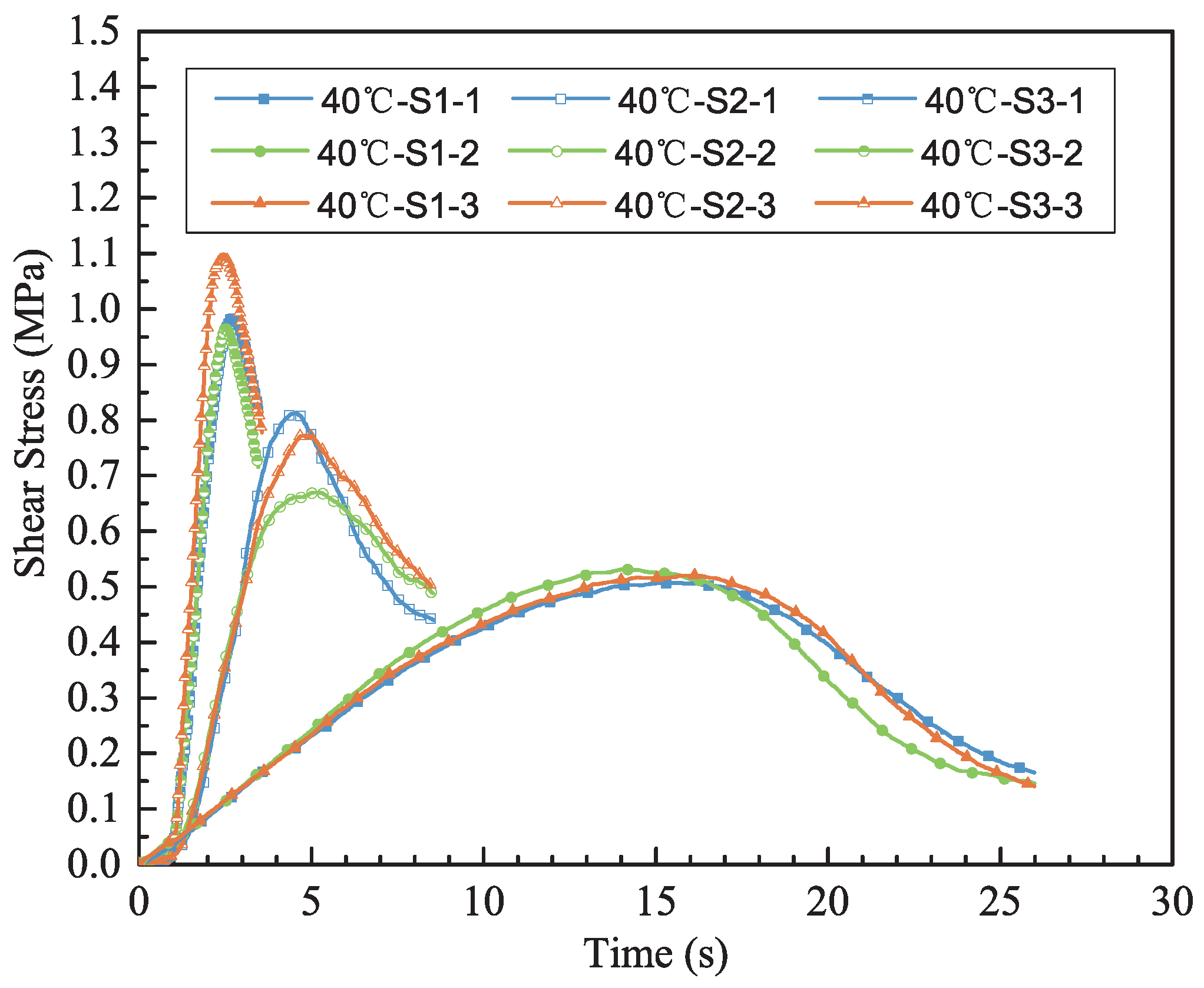

6.1. Results of the Torsional Shear Test in Unconfined Compression

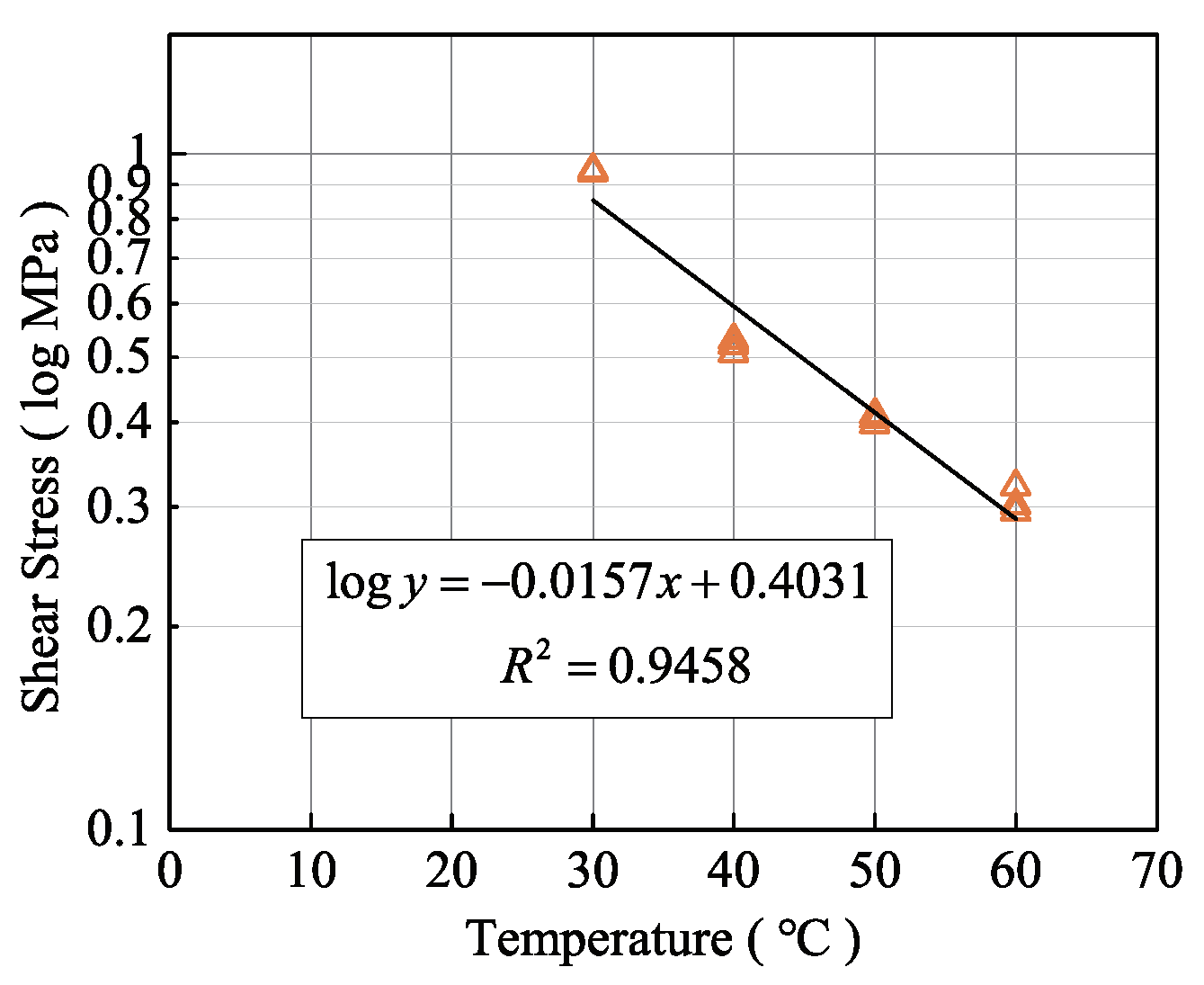

6.1.1. Effects of the Test Temperature

6.1.2. Effects of the Loading Speed

6.2. Results of the Torsional Shear Test in Confined Compression

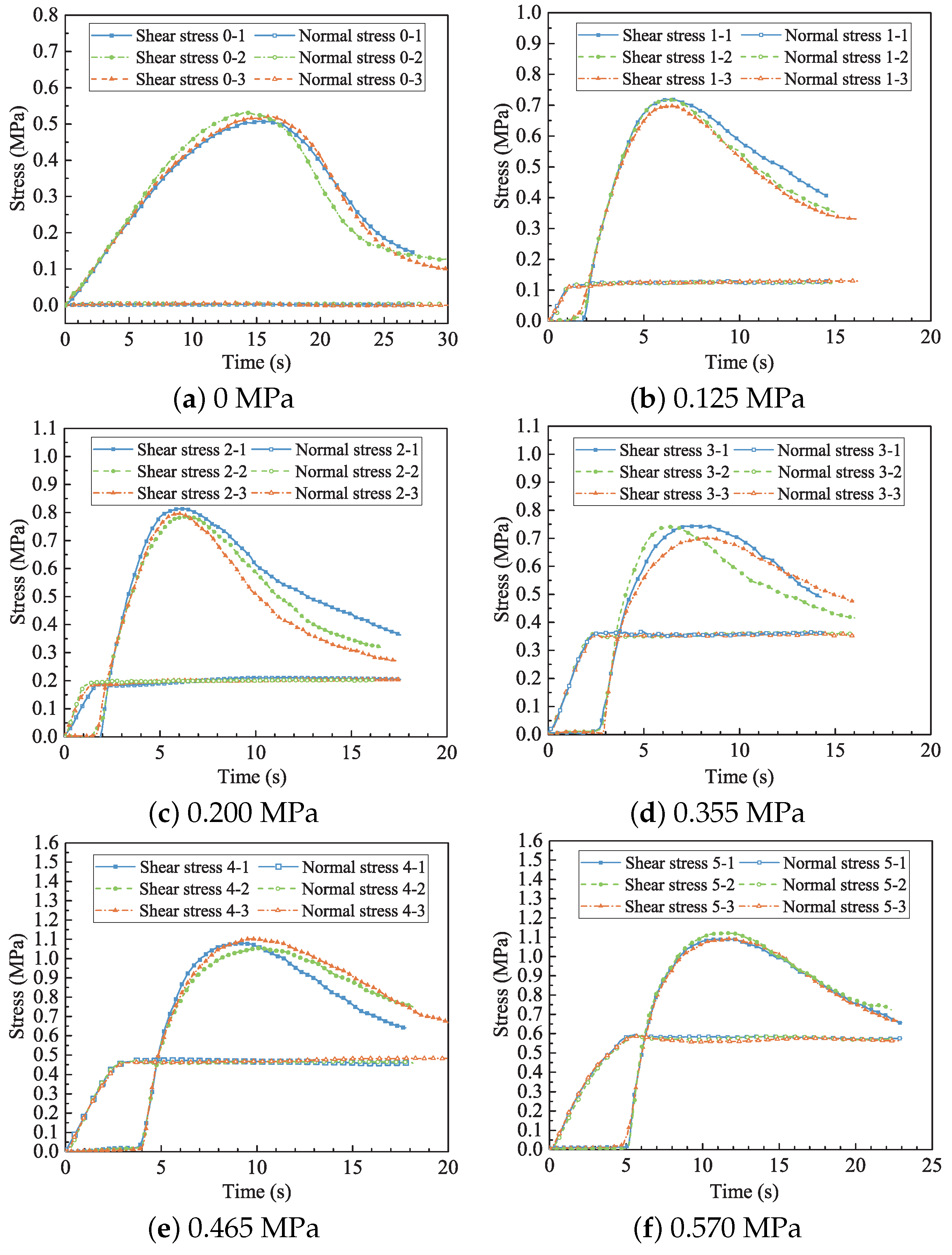

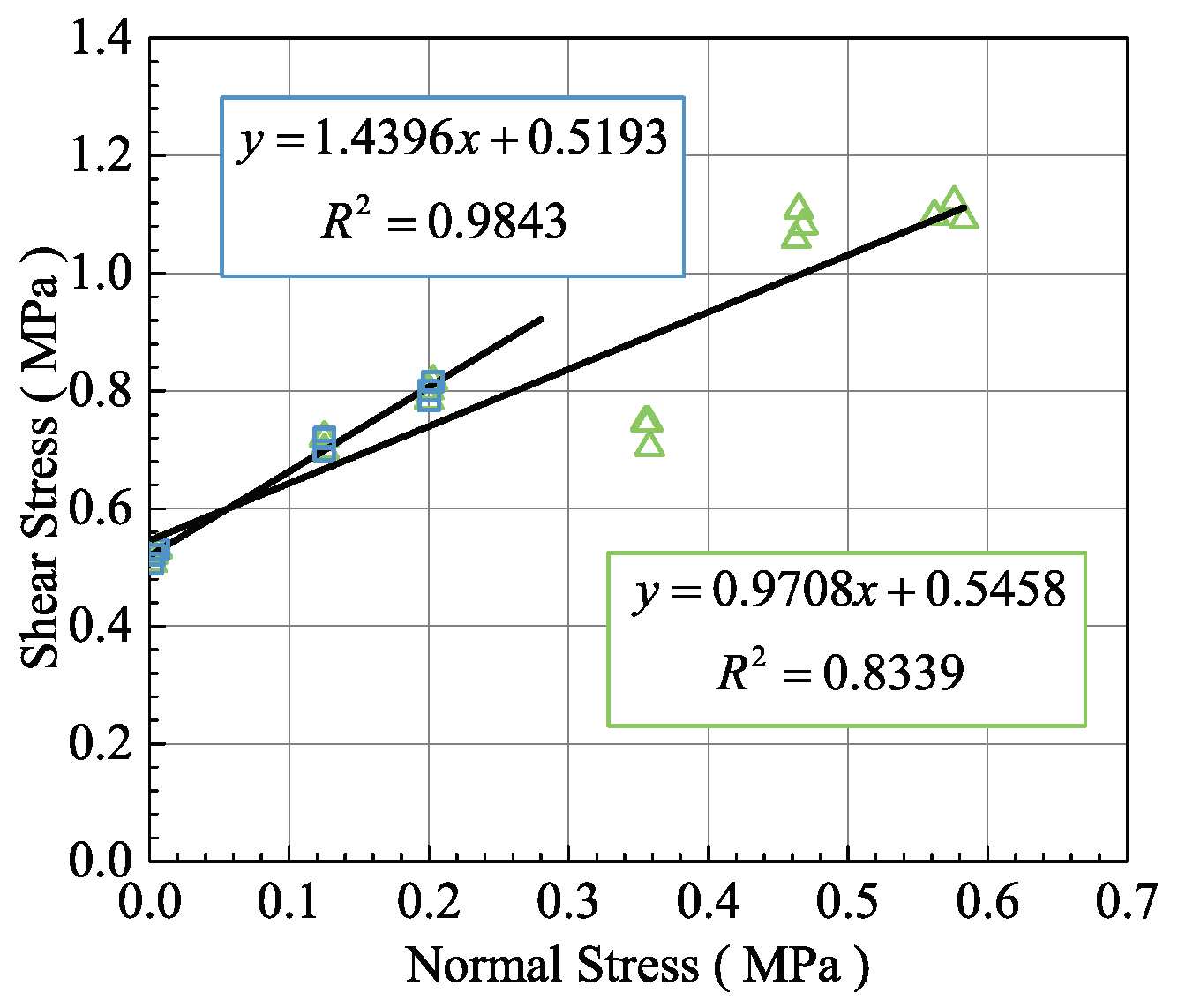

Effects of the Normal Stress

7. Analyses of the Torsional Shear Test

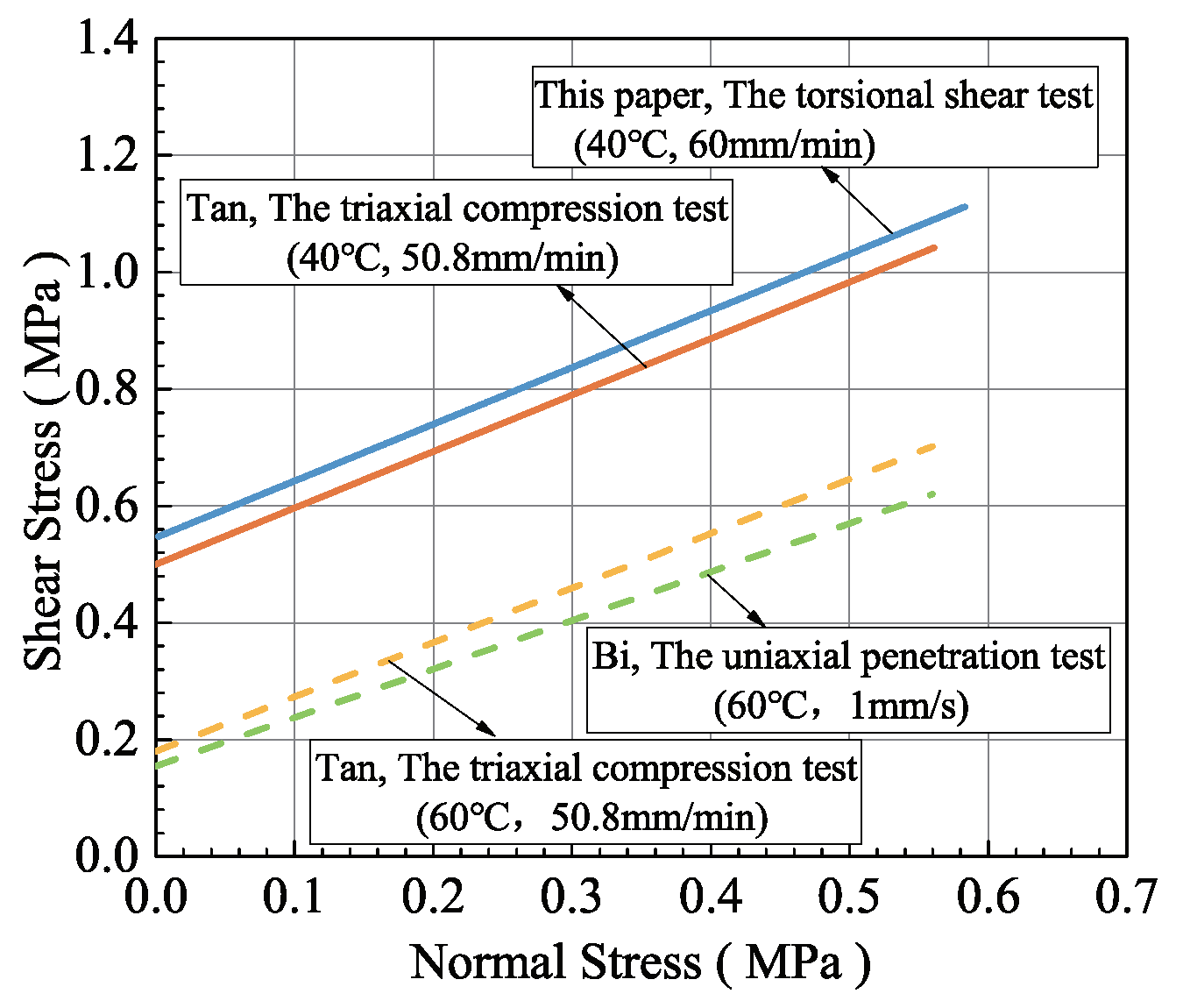

7.1. Cohesion

7.2. The Angle of Internal Friction

8. Conclusions

- Temperatures and loading speeds are the issue to consider on the torsional shear test in unconfined compression. The viscoplastic behavior of asphalt mixtures is considered to be of much importance.

- For the prismatic specimen in the torsional shear test in confined compression, the normal stress can be dynamically controlled to reach conditions of combined axial and torsional loads.

- The cohesion of experimental measurements was 9% smaller than the simulated one. The magnitude of the normal stress was significantly affected by the shear stress strength. The nonlinearity of Mohr’s failure envelope should be considered at a low normal stress level.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Novak, M.; Birgisson, B.; Roque, R.; Choubane, B. One-Way and Two-Way Directional Heavy-Vehicle Simulator Loading: Effects on Rutting in Hot-Mix Asphalt Pavements. Transp. Res. Rec. J. Transp. Res. Board 2004, 1896, 208–214. [Google Scholar] [CrossRef]

- Yoo, P.J.; Al-Qadi, I.L.; Elseifi, M.A.; Janajreh, I. Flexible pavement responses to different loading amplitudes considering layer interface condition and lateral shear forces. Int. J. Pavement Eng. 2006, 7, 73–86. [Google Scholar] [CrossRef]

- Ministry of Transport of the People’s Republic of China. Specifications for Design of Highway Asphalt Pavement: JTG D50-2017(EN); China Road and Bridge Corporation: Beijing, China, 2017.

- Zak, J.; Monismith, C.L.; Coleri, E.; Harvey, J. Uniaxial Shear Tester—New test method to determine shear properties of asphalt mixtures. Road Mater. Pavement Des. 2017, 18, 87–103. [Google Scholar] [CrossRef]

- Sousa, J.; Monismith, C.L. Dynamic Properties of Asphalt Concrete. J. Test. Eval. 1988, 16, 350–363. [Google Scholar]

- Zahw, M. Development of Testing Framework for Evaluation of Rutting Resistance of Asphalt Mixes. Ph.D. Thesis, Al-Azhar University, Cairo, Egypt, Carleton University, Ottawa, ON, Canada, 1995. [Google Scholar]

- Abd El Nabi, R. Influence of Highway Geometry on Distress of Asphalt Concrete Pavements. Ph.D. Thesis, Zagazig University, Zagazig, Egypt, Carleton University, Ottawa, ON, Canada, 1995. [Google Scholar]

- Goodman, S.N. Design, Development and Validation of the In-Situ Shear Stiffness Test (InSiSSTtm) Facility for Asphalt Concrete Pavements. Ph.D. Thesis, Carleton University, Ottawa, ON, Canada, 2000. [Google Scholar]

- ASTM. Standard Test Method for Determining the Complex Shear Modulus (G*) of Bituminous Mixtures Using Dynamic Shear Rheometer: D7552-09; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Li, Y.H. Study on Experimental Method and Rotational Shear Testing Apparatus of Asphalt and Asphalt Mixtures. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2013. (In Chinese). [Google Scholar]

- Ragni, D.; Takarli, M.; Petit, C.; Graziani, A.; Canestrari, F. Use of acoustic techniques to analyse interlayer shear-torque fatigue test in asphalt mixtures. Int. J. Fatigue 2020, 131, 105356. [Google Scholar] [CrossRef]

- Brown, S.F.; Brodrick, B.V.; Tekieli, K.; Collop, A.C. A torsional hollow cylinder research apparatus for studying the permanent deformation characteristics of asphalt. Road Mater. Pavement Des. 2013, 14, 65–85. [Google Scholar] [CrossRef]

- Saada, A.S.; Townsend, F.C. State of the art: Laboratory strength testing of soils. In Laboratory Shear Strength of Soil; Yong, R.N., Townsend, F.C., Eds.; ASTM: West Conshohocken, PA, USA, 1981; pp. 7–77. [Google Scholar]

- Kuwano, J.; Katagiri, M.; Kita, K.; Nakano, M.; Kuwano, R. A review of Japanese standards for laboratory shear tests. In Advanced Laboratory Stress-Strain Testing of Geomaterials; Tatsuoka, F., Shibuya, S., Kuwano, R., Eds.; Routledge: London, UK, 2001; pp. 53–64. [Google Scholar]

- Lade, P.V. Torsion shear apparatus for soil testing. In Laboratory Shear Strength of Soil; Yong, R.N., Townsend, F.C., Eds.; ASTM: Philadelphia, PA, USA, 1981; pp. 145–163. [Google Scholar]

- Ministry of Transport of the People’s Republic of China. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering: JTG E20-2011; China Communications Press: Beijing, China, 2011. (In Chinese)

- Benedetto, H.D.; Gabet, T.; Grenfell, J.; Perraton, D.; Sauzéat, C.; Bodin, D. Mechanical Testing of Bituminous Mixtures. In Advances in Interlaboratory Testing and Evaluation of Bituminous Materials; Partl, M.N., Bahia, H.U., Canestrari, F., De la Roche, C., Benedetto, H.D., Piber, H., Sybilski, D., Eds.; Springer: Dordrecht, The Netherlands; Heidelberg, Germany; New York, NY, USA; London, UK, 2012; pp. 143–256. [Google Scholar]

- Budhu, M. Soil Mechanics and Foundations, 3rd ed.; John Wiley & Sons Inc: Hoboken, NJ, USA, 2010. [Google Scholar]

- Tan, S.A.; Low, B.H.; Fwa, T.F. Behavior of asphalt concrete mixtures in triaxial compression. J. Test. Eval. 1994, 22, 195–203. [Google Scholar]

- Bi, Y.F.; Sun, L.J. Research on test method of asphalt mixture’s shearing properties. J. Tongji Univ. (Nat. Sci.) 2005, 33, 1036–1040. (In Chinese) [Google Scholar]

| Sieve size (mm) | 16.0 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 |

| Passing by weight (%) | 100 | 98.4 | 76.6 | 44.3 | 31.4 | 22.6 | 16.2 | 11.5 | 8.6 | 5.7 |

| Property | Value |

|---|---|

| Air void content, % | 4.4 |

| Marshall stability, kN | 9.96 |

| Marshall stability, mm | 3.0 |

| Voids in mineral aggregate (VMA), % | 15.6 |

| Voids filled with asphalt (VFA), % | 71.6 |

| Specimen | T | Specimen | T | ||

|---|---|---|---|---|---|

| No. | (C) | (MPa) | No. | (C) | (MPa) |

| 30 C-S1-1 | 30 | 0.941 | 40 C-S1-1 | 40 | 0.507 |

| 30 C-S1-2 | 30 | 0.946 | 40 C-S1-2 | 40 | 0.530 |

| 30 C-S1-3 | 30 | 0.938 | 40 C-S1-3 | 40 | 0.521 |

| 50 C-S1-1 | 50 | 0.405 | 60 C-S1-1 | 60 | 0.295 |

| 50 C-S1-2 | 50 | 0.398 | 60 C-S1-2 | 60 | 0.322 |

| 50 C-S1-3 | 50 | 0.411 | 60 C-S1-3 | 60 | 0.302 |

| Specimen | Loading Speed | Specimen | Loading Speed | ||

|---|---|---|---|---|---|

| No. | (rad/min) | (MPa) | No. | (rad/min) | (MPa) |

| 40 C-S2-1 | 3.98 | 0.842 | 40 C-S3-1 | 8.42 | 0.983 |

| 40 C-S2-2 | 3.65 | 0.668 | 40 C-S3-2 | 8.36 | 0.964 |

| 40 C-S2-3 | 3.67 | 0.786 | 40 C-S3-3 | 8.45 | 1.090 |

| Specimen | Specimen | Specimen | ||||||

|---|---|---|---|---|---|---|---|---|

| No. | (MPa) | (MPa) | No. | (MPa) | (MPa) | No. | (MPa) | (MPa) |

| 0-1 | 0.002 | 0.507 | 1-1 | 0.125 | 0.721 | 2-1 | 0.203 | 0.816 |

| 0-2 | 0.006 | 0.530 | 1-2 | 0.125 | 0.719 | 2-2 | 0.200 | 0.784 |

| 0-3 | 0.003 | 0.521 | 1-3 | 0.125 | 0.699 | 2-3 | 0.200 | 0.800 |

| 3-1 | 0.357 | 0.746 | 4-1 | 0.468 | 1.081 | 5-1 | 0.583 | 1.091 |

| 3-2 | 0.355 | 0.746 | 4-2 | 0.463 | 1.058 | 5-2 | 0.576 | 1.121 |

| 3-3 | 0.358 | 0.704 | 4-3 | 0.465 | 1.108 | 5-3 | 0.562 | 1.097 |

| Loading Condition | Linear Regression Function | Coefficient of Determination |

|---|---|---|

| = 2.4 rad/min | 0.9458 | |

| T = 40 C | 0.9093 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, G.; Li, Y.; Chen, J.; Sun, Y.; Wang, W.; Liu, Y. Experimental Study on Torsional Shear Testing of Asphalt Mixture. Appl. Sci. 2022, 12, 12242. https://doi.org/10.3390/app122312242

Wang G, Li Y, Chen J, Sun Y, Wang W, Liu Y. Experimental Study on Torsional Shear Testing of Asphalt Mixture. Applied Sciences. 2022; 12(23):12242. https://doi.org/10.3390/app122312242

Chicago/Turabian StyleWang, Guangyuan, Yuhua Li, Jingyun Chen, Yiren Sun, Weiying Wang, and Yongjun Liu. 2022. "Experimental Study on Torsional Shear Testing of Asphalt Mixture" Applied Sciences 12, no. 23: 12242. https://doi.org/10.3390/app122312242

APA StyleWang, G., Li, Y., Chen, J., Sun, Y., Wang, W., & Liu, Y. (2022). Experimental Study on Torsional Shear Testing of Asphalt Mixture. Applied Sciences, 12(23), 12242. https://doi.org/10.3390/app122312242