Numerical Optimization of the EGR Rate and Injection Timing with a Novel Cavitation Model in a Diesel Engine Fueled with PODE/Diesel Blends

Abstract

:1. Introduction

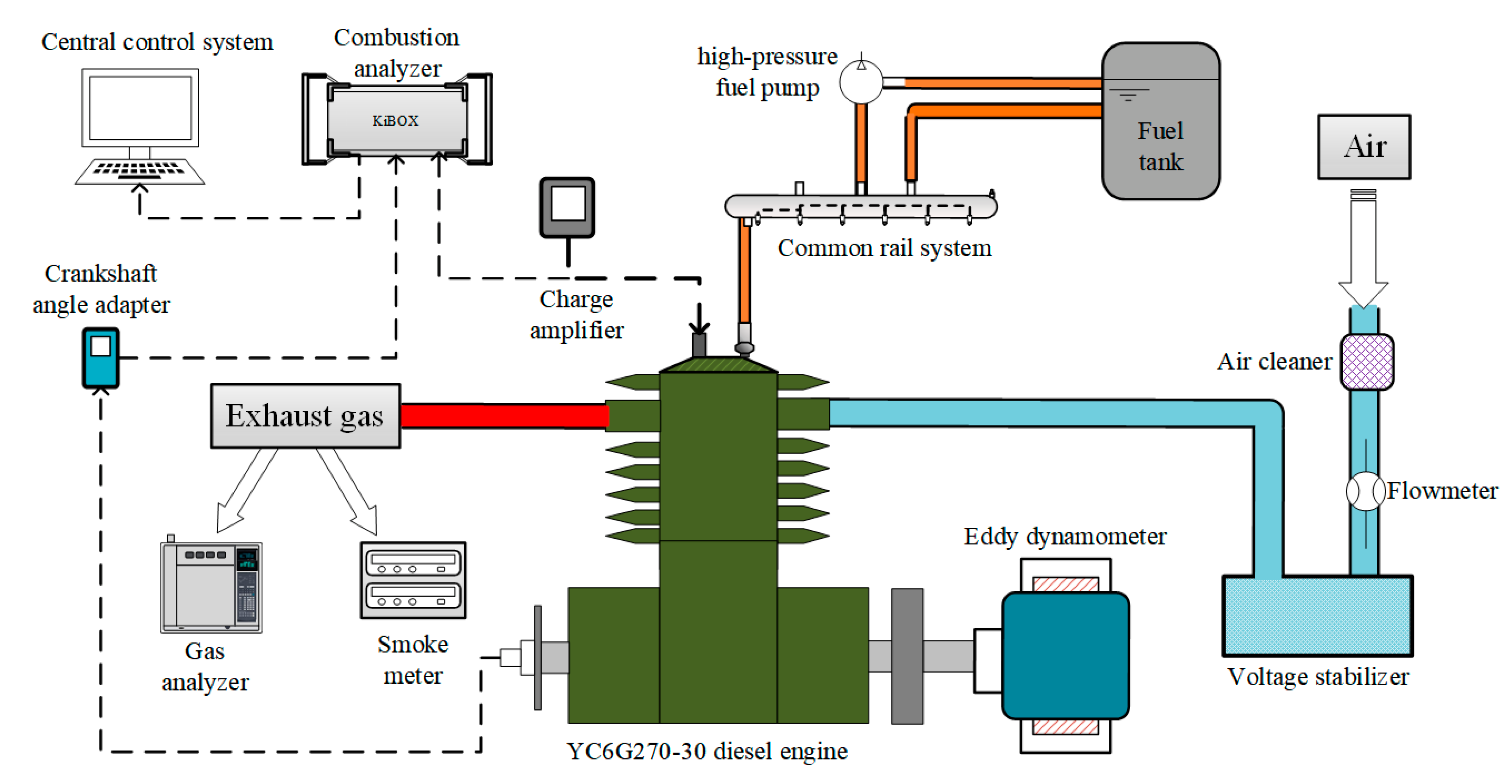

2. Experimental Setup and Methodology

3. Simulation Setup and Validation

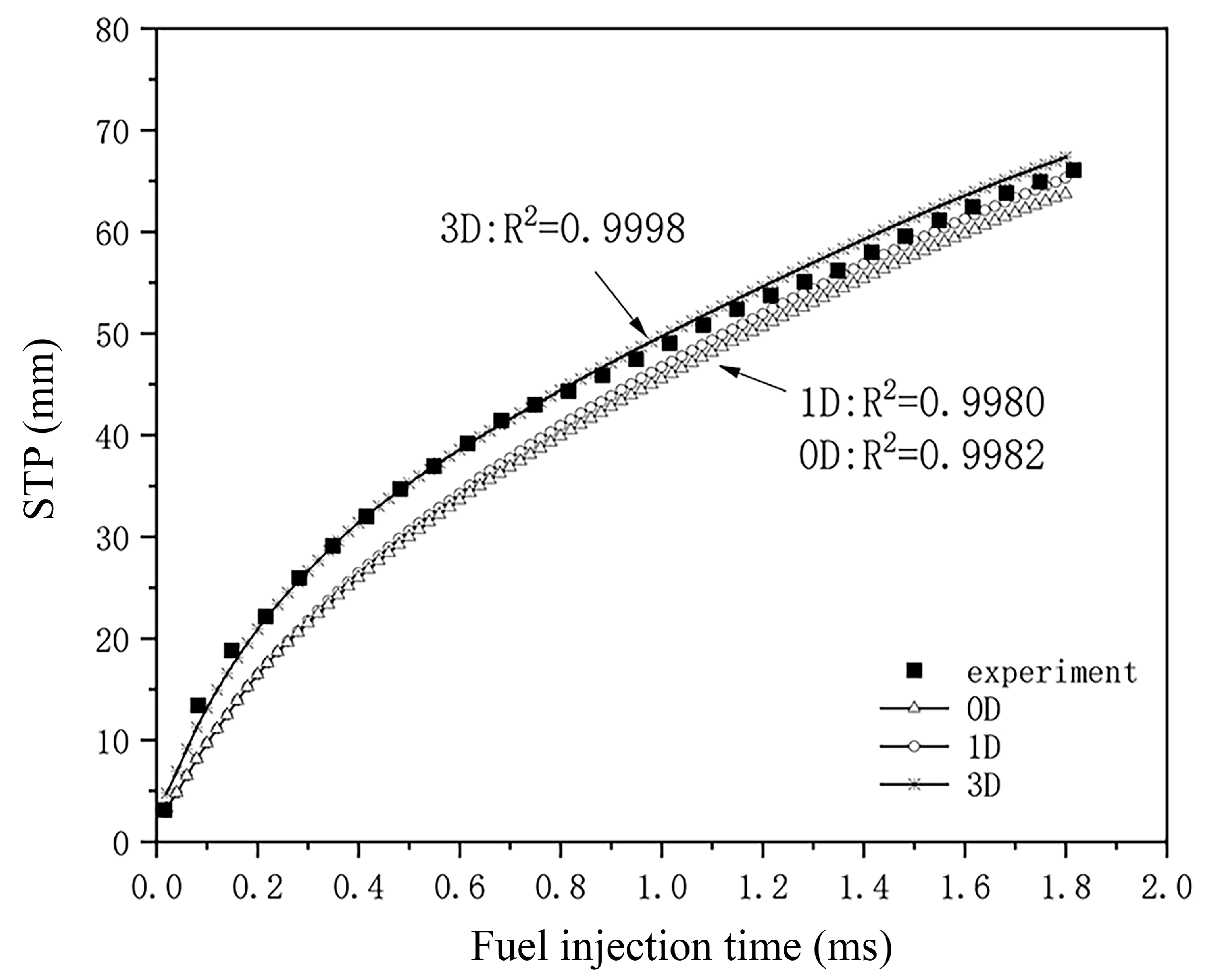

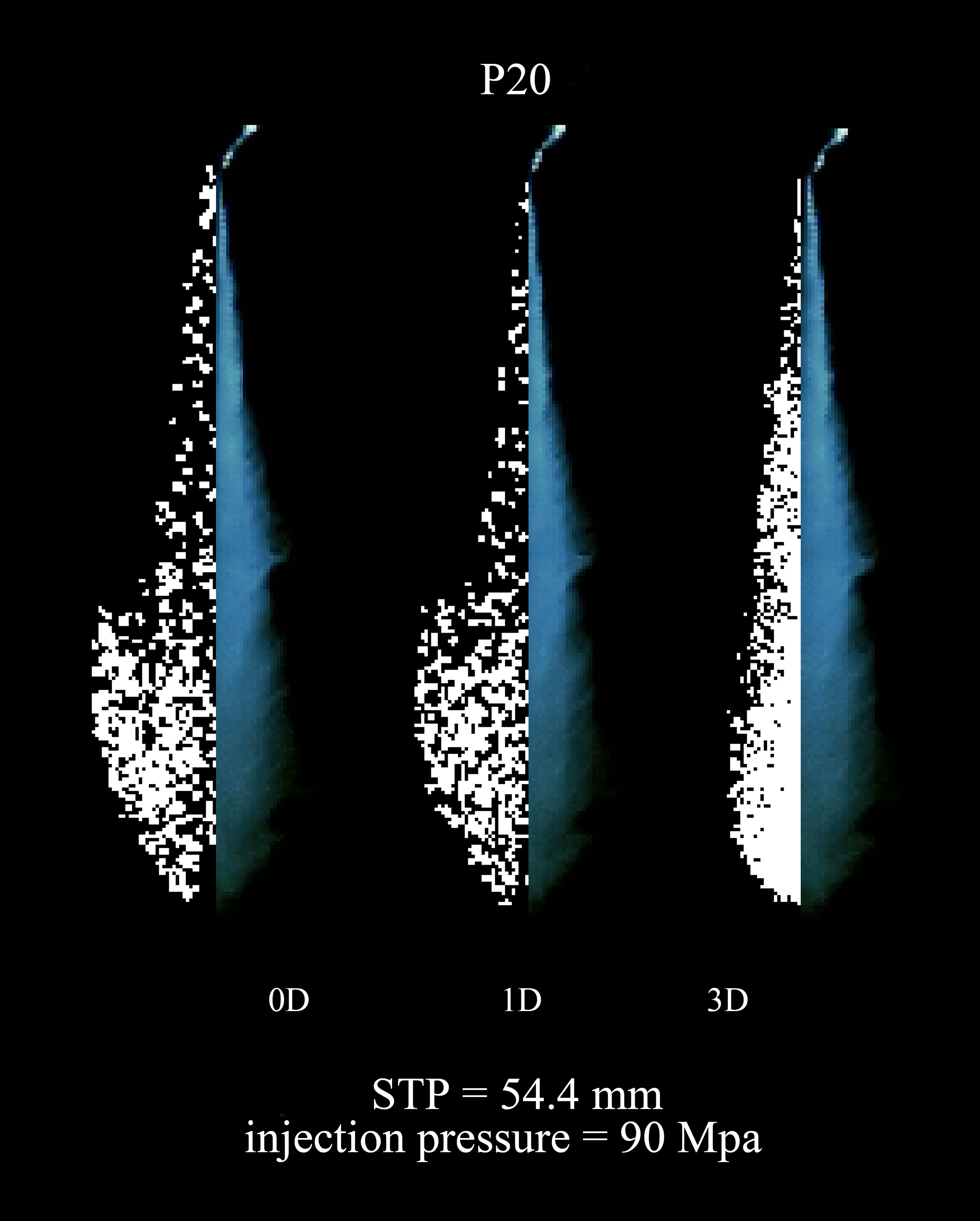

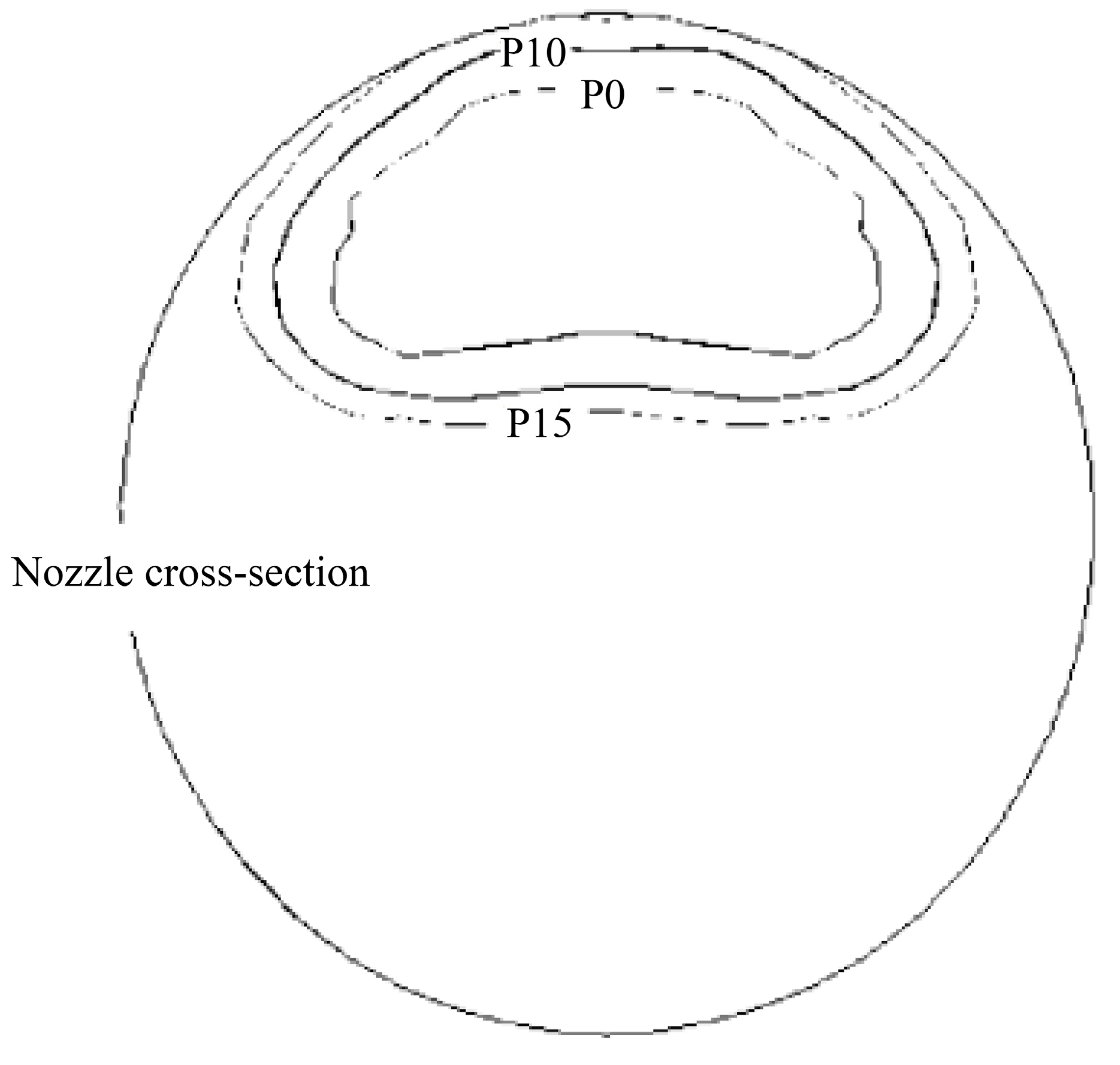

3.1. Spray Model

3.1.1. Cavitation Sub-Model

3.1.2. Spray Model Validation

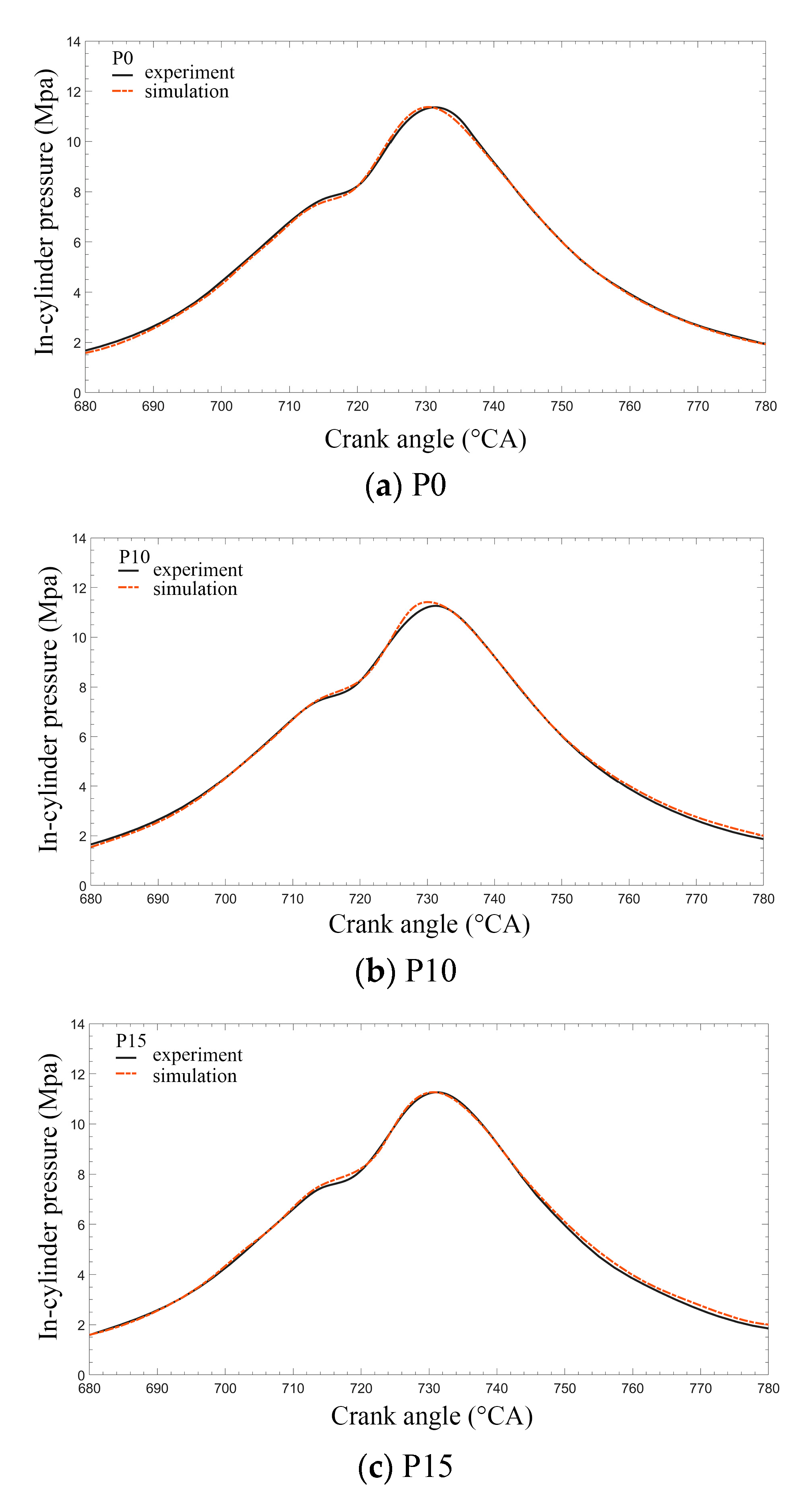

3.2. Numerical Engine Model

3.2.1. Model Summary and Simulation Procedure

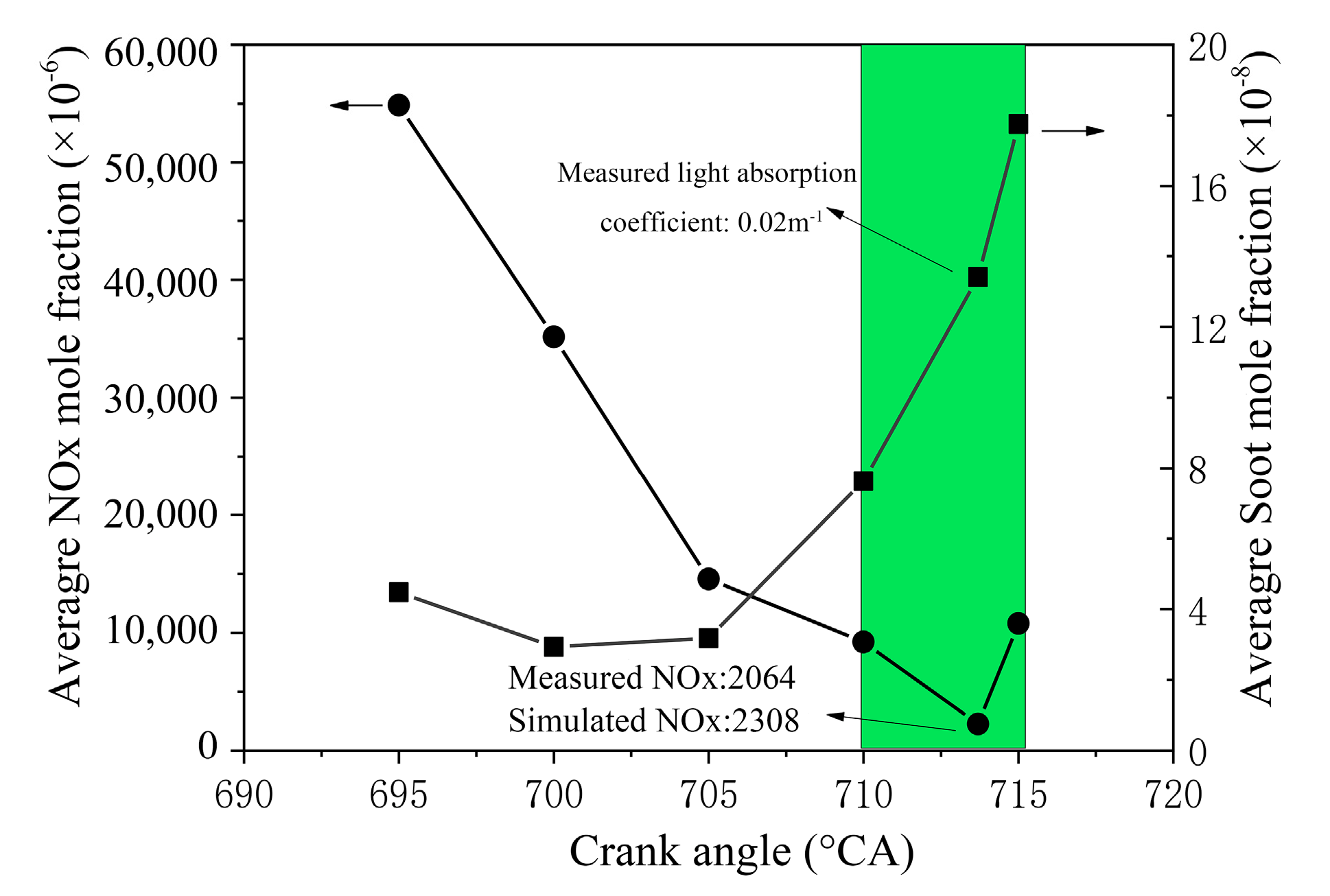

3.2.2. Model Validation

4. Results and Discussion

4.1. Effects of the Blending Ratios on Emissions

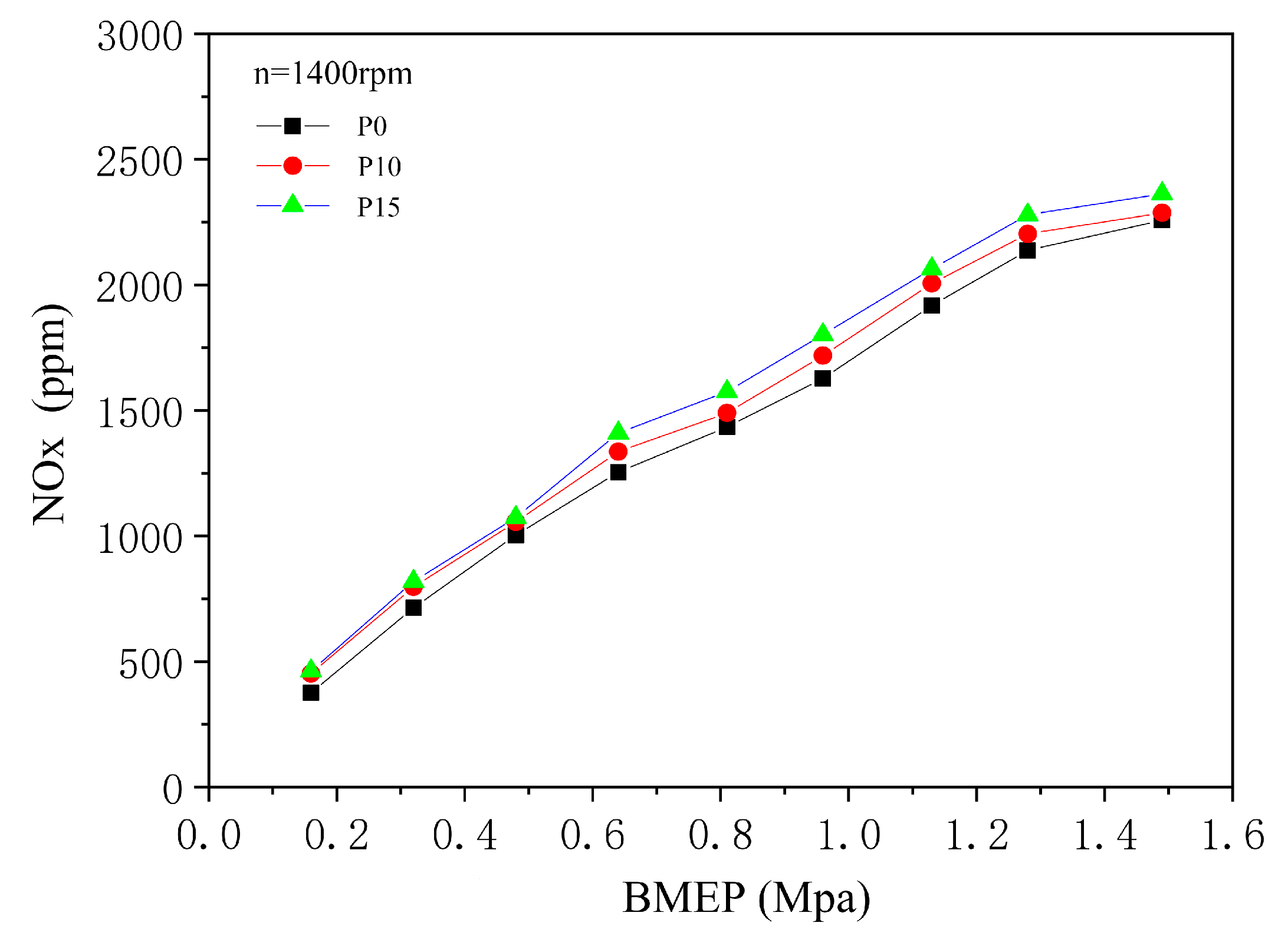

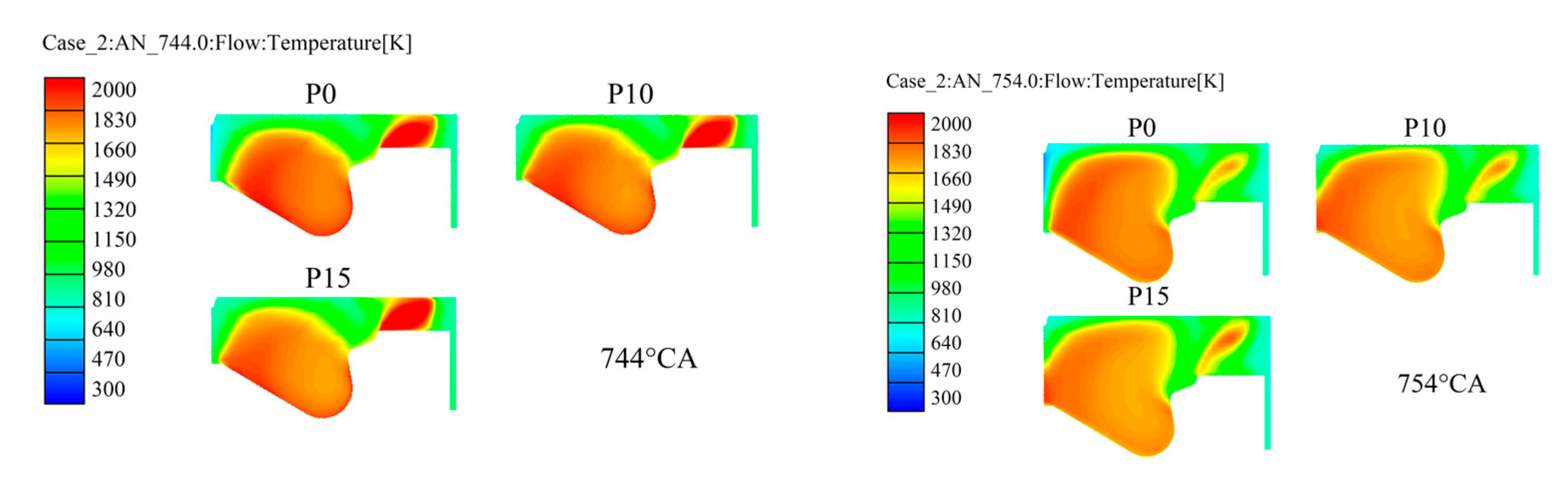

4.1.1. NOx Emission Characteristics

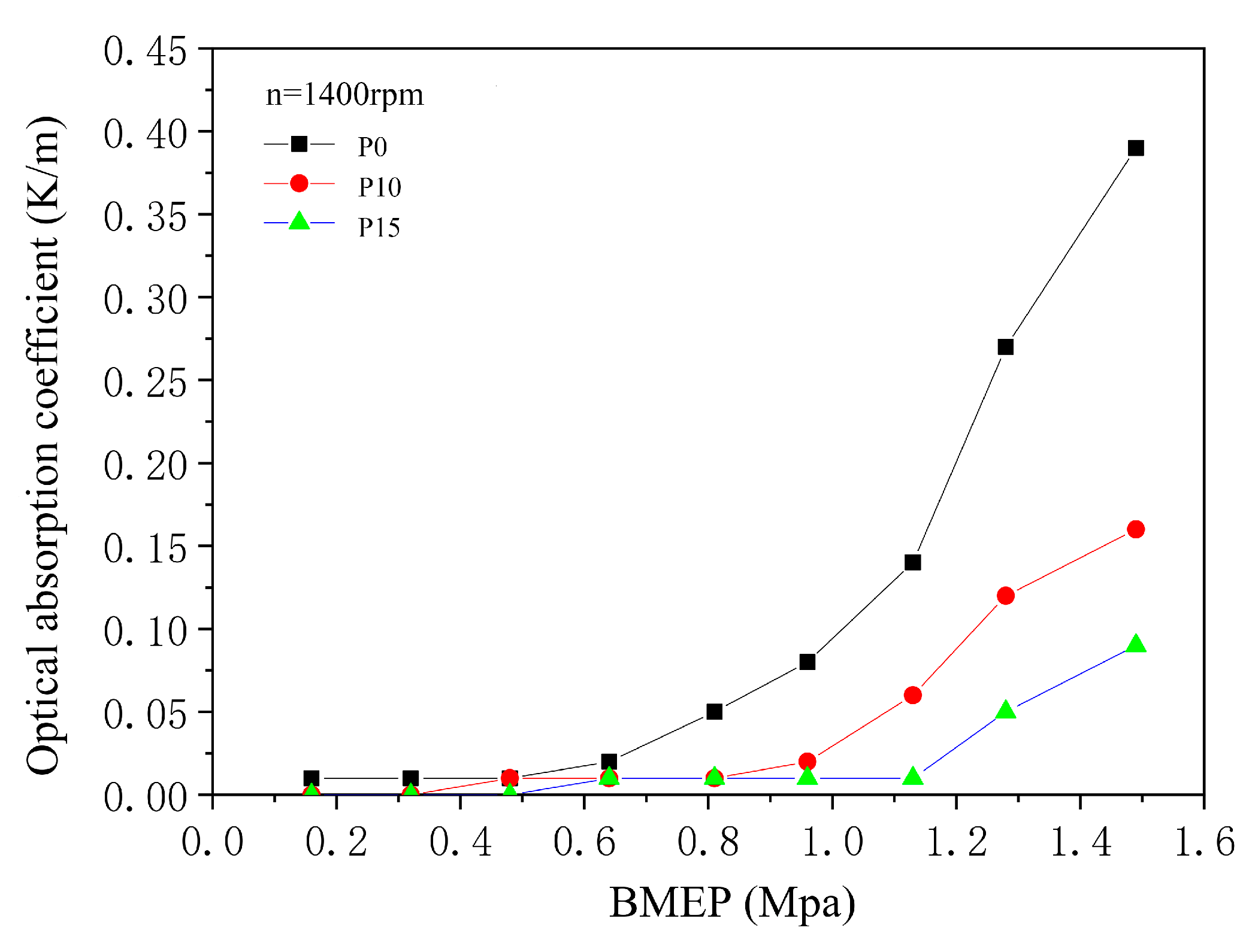

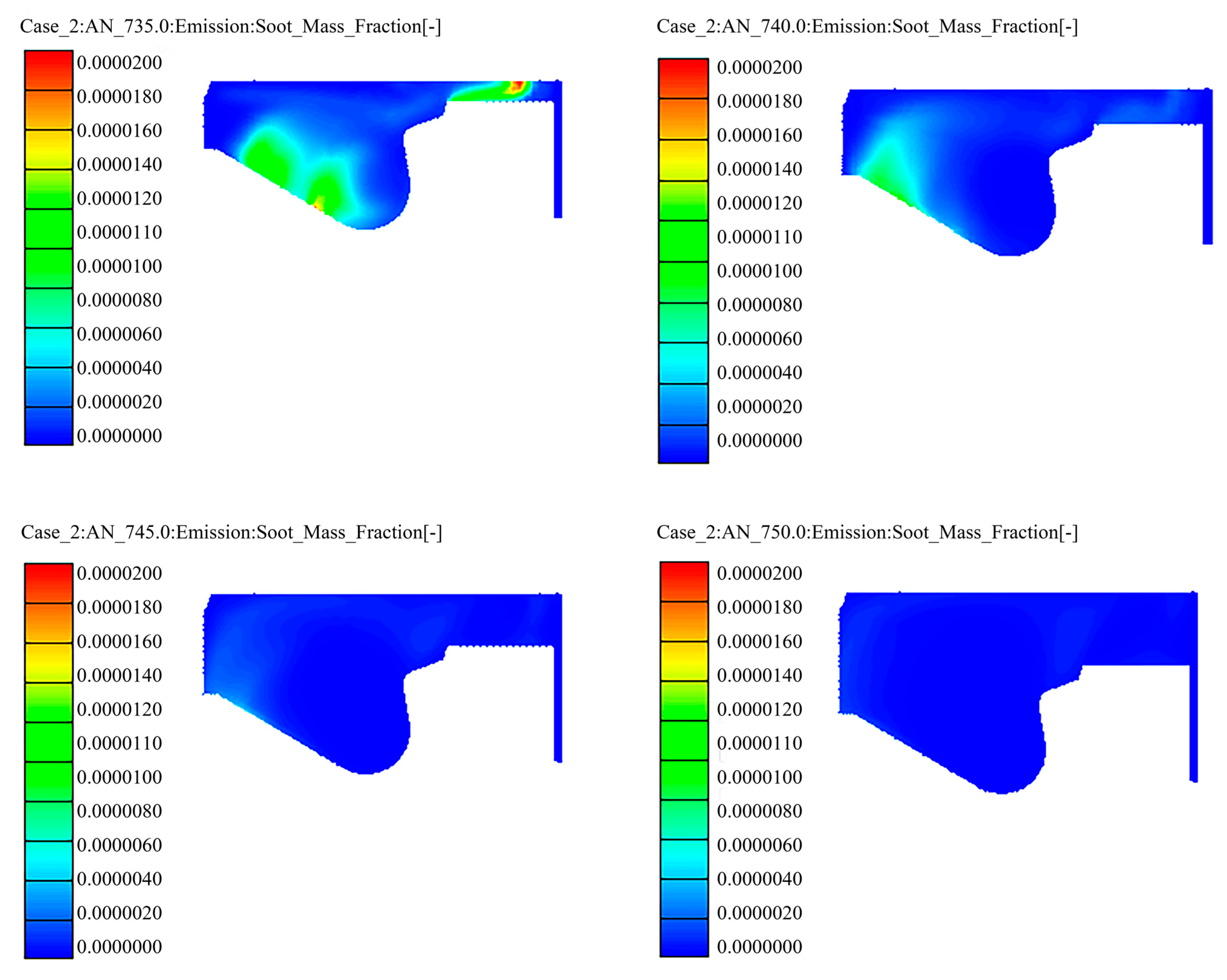

4.1.2. Soot Emission Characteristics

4.2. Effects of the Injection Timing on Engine Performance

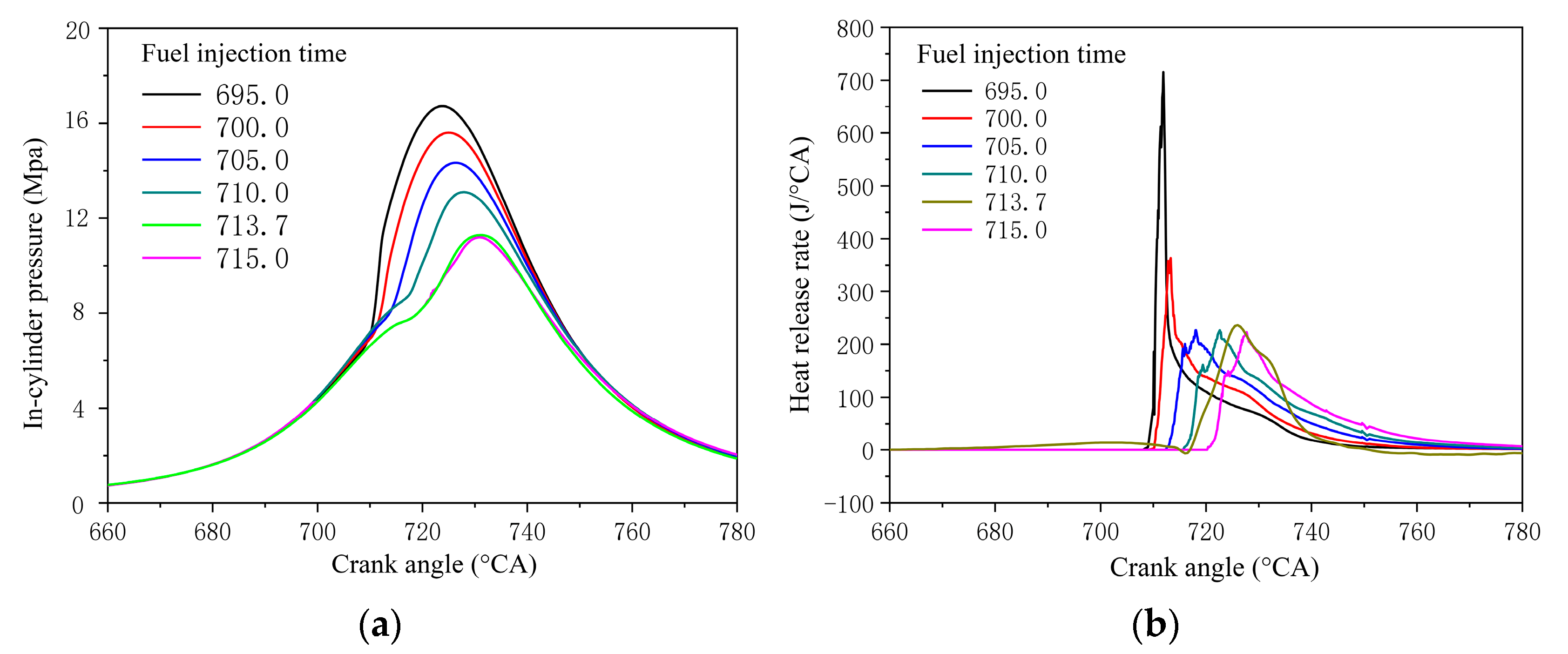

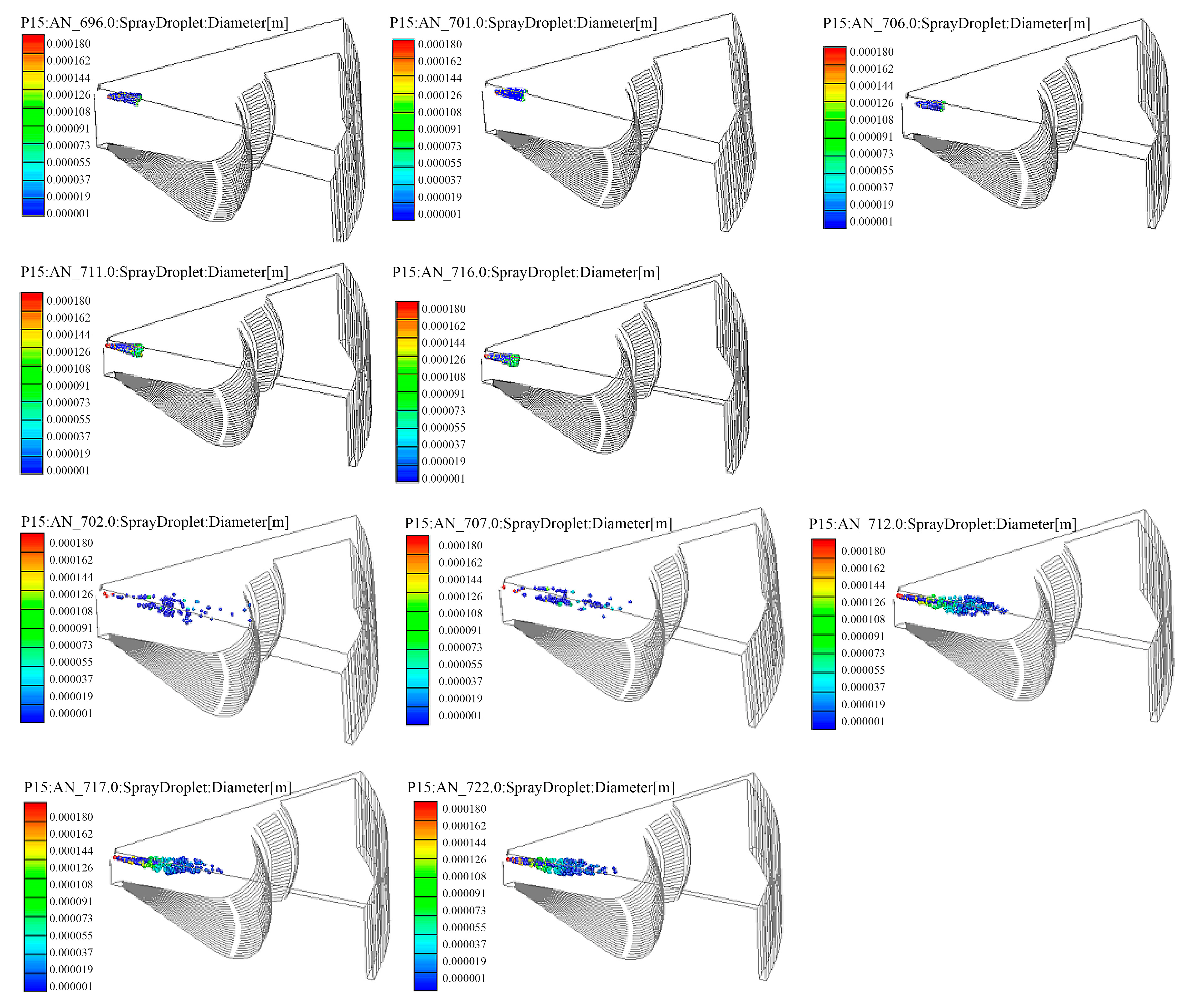

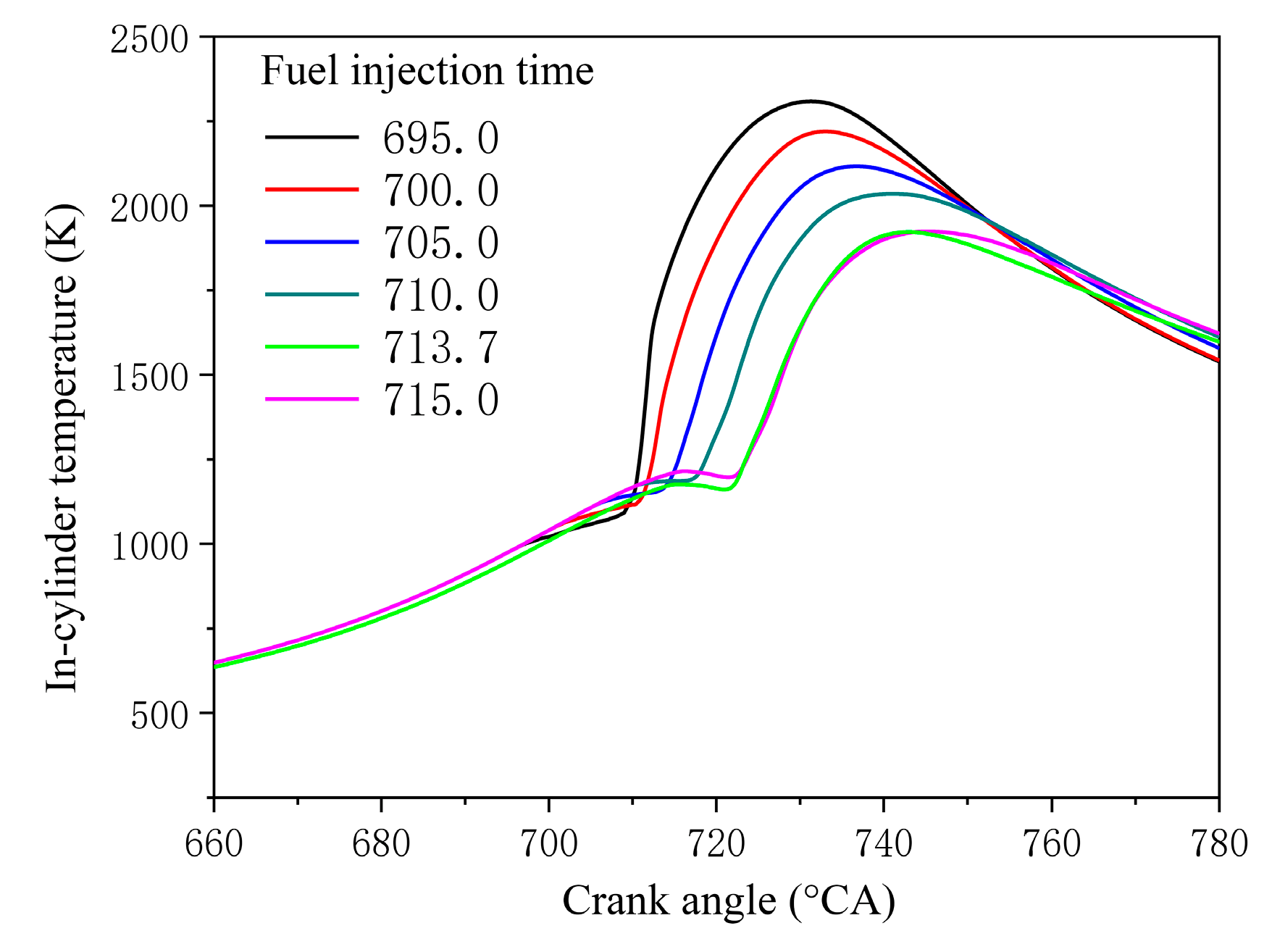

4.2.1. Combustion Characteristics

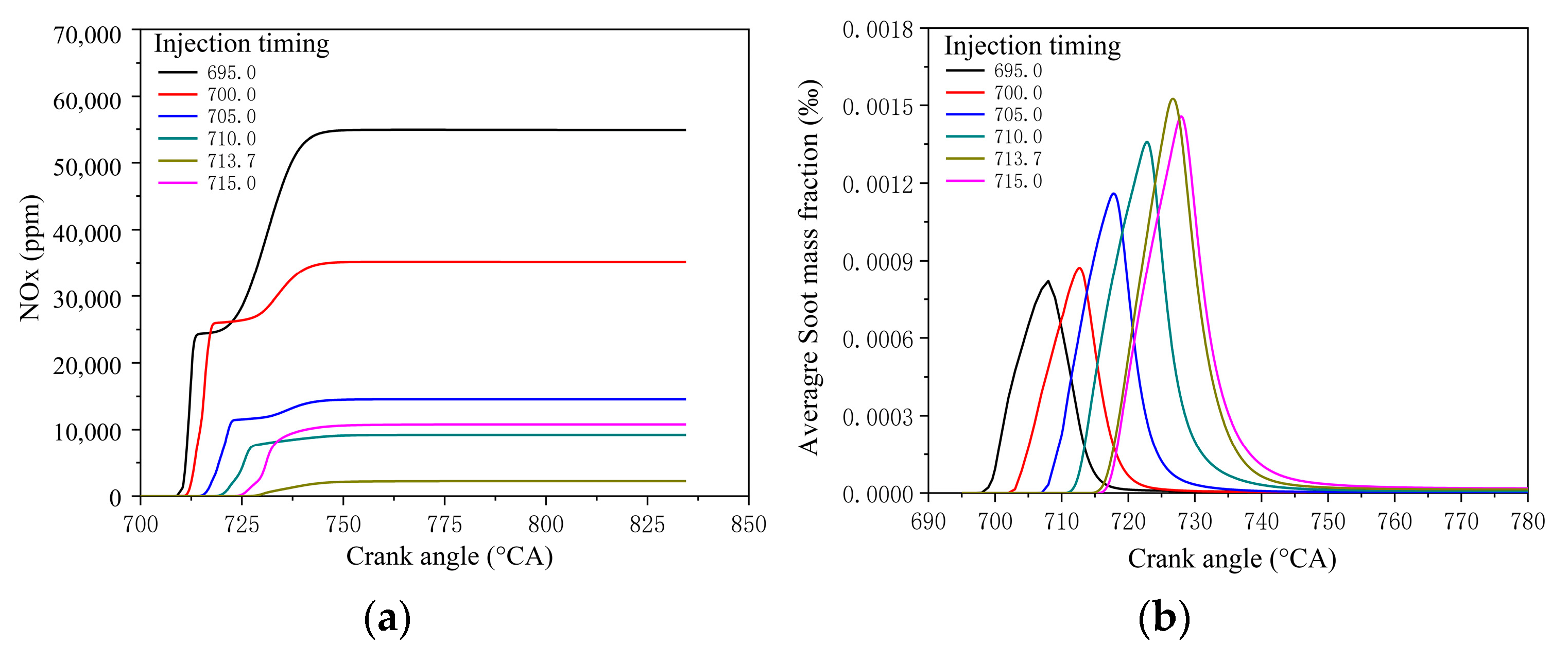

4.2.2. NOx and Soot Emission Characteristics

4.3. Effects of the EGR Rate on Engine Performance

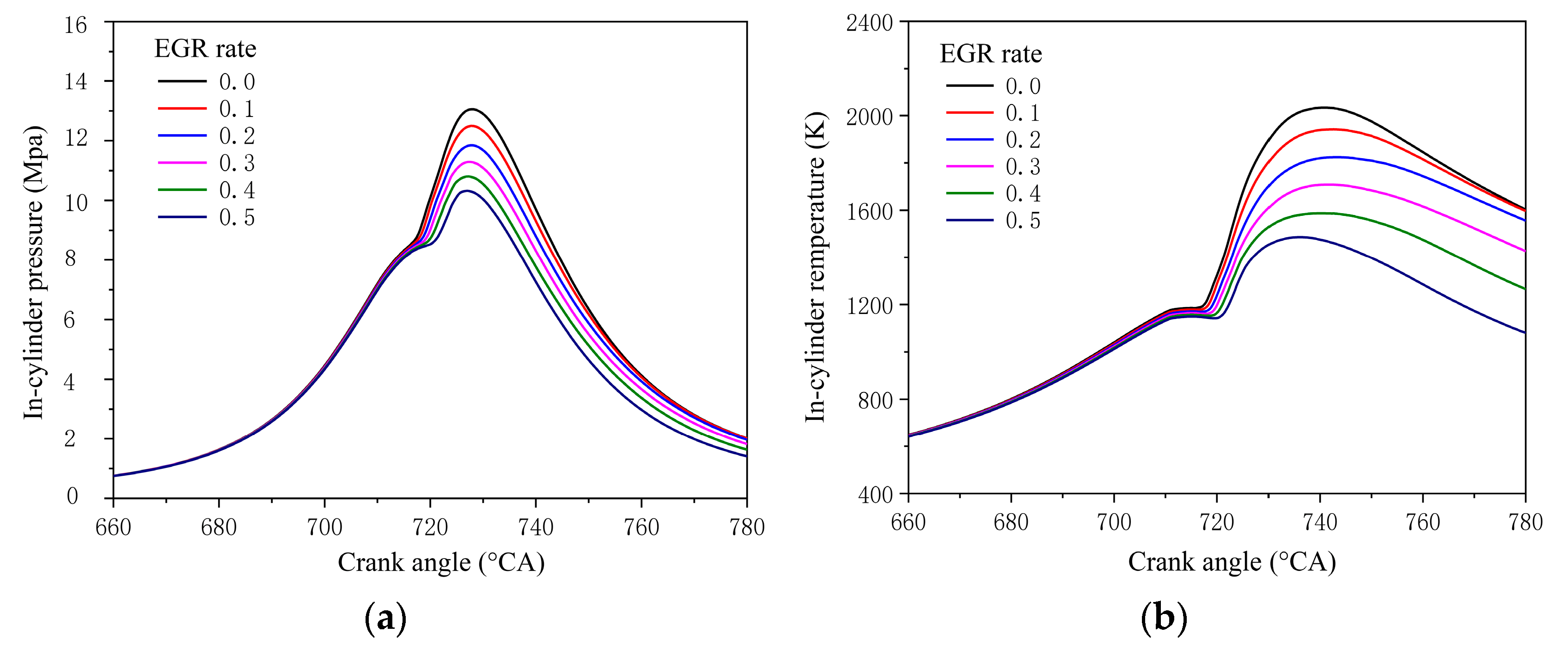

4.3.1. Combustion Characteristics

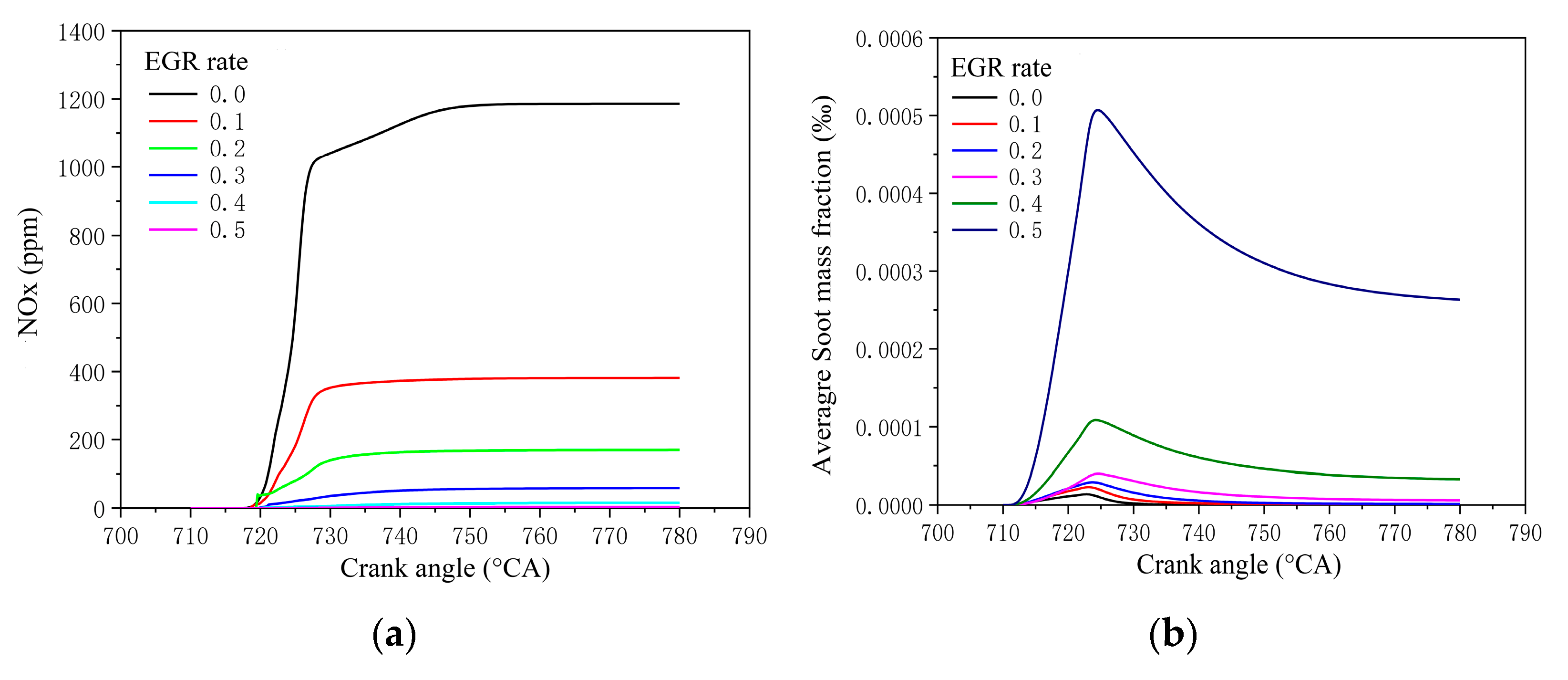

4.3.2. NOx and Soot Emission Characteristics

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kober, T.; Schiffer, H.W.; Densing, M.; Panos, E. Global energy perspectives to 2060—WEC’s World Energy Scenarios 2019. Energy Strategy Rev. 2020, 31, 100523. [Google Scholar] [CrossRef]

- Olabi, A.G.; Maizak, D.; Wilberforce, T. Review of the regulations and techniques to eliminate toxic emissions from diesel engine cars. Sci. Total. Environ. 2020, 748, 141249. [Google Scholar] [CrossRef]

- Barro, C.; Parravicini, M.; Boulouchos, K.; Liati, A. Neat polyoxymethylene dimethyl ether in a diesel engine; part 2: Exhaust emission analysis. Fuel 2018, 234, 1414–1421. [Google Scholar] [CrossRef]

- Arcoumanis, C.; Bae, C.; Crookes, R.; Kinoshita, E. The potential of di-methyl ether (DME) as an alternative fuel for compression-ignition engines: A review. Fuel 2008, 87, 1014–1030. [Google Scholar] [CrossRef]

- Duraisamy, G.; Rangasamy, M.; Govindan, N. A comparative study on methanol/diesel and methanol/PODE dual fuel RCCI combustion in an automotive diesel engine. Renew. Energy 2020, 145, 542–556. [Google Scholar] [CrossRef]

- Liu, H.; Ma, X.; Li, B.; Chen, L.; Wang, Z.; Wang, J. Combustion and emission characteristics of a direct injection diesel engine fueled with biodiesel and PODE/biodiesel fuel blends. Fuel 2017, 209, 62–68. [Google Scholar] [CrossRef]

- Liu, J.; Yang, J.; Sun, P.; Gao, W.; Yang, C.; Fang, J. Compound combustion and pollutant emissions characteristics of a common-rail engine with ethanol homogeneous charge and polyoxymethylene dimethyl ethers injection. Appl. Energy 2019, 239, 1154–1162. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Li, Y.; Zheng, Y.; He, T.; Wang, J. Recent progress in the application in compression ignition engines and the synthesis technologies of polyoxymethylene dimethyl ethers. Appl. Energy 2019, 233–234, 599–611. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Wang, P.; Sun, P.; Liu, H.; Meng, Z.; Zhang, L.; Ma, H. An overview of polyoxymethylene dimethyl ethers as alternative fuel for compression ignition engines. Fuel 2022, 318, 123582. [Google Scholar] [CrossRef]

- Baranowski, C.J.; Bahmanpour, A.M.; Kröcher, O. Catalytic synthesis of polyoxymethylene dimethyl ethers (OME): A review. Appl. Catal. B Environ. 2017, 217, 407–420. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Z.; Wang, J.; He, X.; Zheng, Y.; Tang, Q.; Wang, J. Performance, combustion and emission characteristics of a diesel engine fueled with polyoxymethylene dimethyl ethers (PODE3-4)/diesel blends. Energy 2015, 88, 793–800. [Google Scholar] [CrossRef]

- Liu, J.; Wang, H.; Li, Y.; Zheng, Z.; Xue, Z.; Shang, H.; Yao, M. Effects of diesel/PODE (polyoxymethylene dimethyl ethers) blends on combustion and emission characteristics in a heavy duty diesel engine. Fuel 2016, 177, 206–216. [Google Scholar] [CrossRef]

- Mario, M.; Renata, P.; Leonardo, P.; Salvatore, F. Emission Performance of Neat and Blended Polyoxymethylene Dimethyl Ethers in an Old Light-Duty Diesel Car; SAE International: Warrendale, PA, USA, 2013. [Google Scholar]

- Renata, P.; Nicola Del, G.; Mario, M.; Chiara, G.; Carlo, B.; Leonardo, P. Combustion Behaviour and Emission Performance of Neat and Blended Polyoxymethylene Dimethyl Ethers in a Light-Duty Diesel Engine; SAE International: Warrendale, PA, USA, 2012. [Google Scholar]

- Lumpp, B.; Rothe, D.; Pastötter, C.; Lämmermann, R.; Jacob, E. Oxymethylene ethers as diesel fuel additives of the future. MTZ Worldw. Emagazine 2011, 72, 34–38. [Google Scholar] [CrossRef]

- Chen, H.; Su, X.; Li, J.; Zhong, X. Effects of gasoline and polyoxymethylene dimethyl ethers blending in diesel on the combustion and emission of a common rail diesel engine. Energy 2019, 171, 981–999. [Google Scholar] [CrossRef]

- Liu, J.; Sun, P.; Huang, H.; Meng, J.; Yao, X. Experimental investigation on performance, combustion and emission characteristics of a common-rail diesel engine fueled with polyoxymethylene dimethyl ethers-diesel blends. Appl. Energy 2017, 202, 527–536. [Google Scholar] [CrossRef]

- Liu, H.; Wang, X.; Wu, Y.; Zhang, X.; Jin, C.; Zheng, Z. Effect of diesel/PODE/ethanol blends on combustion and emissions of a heavy duty diesel engine. Fuel 2019, 257, 116064. [Google Scholar] [CrossRef]

- Wang, T.; Liu, J.; Sun, P.; Ji, Q.; Gao, W.; Yang, C. Influence of injection parameters on combustion, gaseous emissions and particle size distribution of a CRDI diesel engine operating with PODE/diesel blends. Fuel 2020, 281, 118733. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, X.; Liu, H.; Wu, Y.; Zaman, M.; Geng, Z.; Jin, C.; Zheng, Z.; Yue, Z.; Yao, M. Effect of soybean oil/PODE/ethanol blends on combustion and emissions on a heavy-duty diesel engine. Fuel 2021, 288, 119625. [Google Scholar] [CrossRef]

- Barro, C.; Parravicini, M.; Boulouchos, K. Neat polyoxymethylene dimethyl ether in a diesel engine; part 1: Detailed combustion analysis. Fuel 2019, 256, 115892. [Google Scholar] [CrossRef]

- LeBlanc, S.; Sandhu, N.; Yu, X.; Han, X.; Wang, M.; Tjong, J.; Zheng, M. An Investigation Into OME3 on a High Compression Ratio Engine. In Proceedings of the Internal Combustion Engine Division Fall Technical Conference, American Society of Mechanical Engineers, Virtual, Online, 4–6 November 2020; Volume 84034. [Google Scholar]

- Li, D.; Liu, S.; Wei, Y.; Liang, R.; Tang, Y. Numerical investigation on transient internal cavitating flow and spray characteristics in a single-hole diesel injector nozzle: A 3D method for cavitation-induced primary break-up. Fuel 2018, 233, 778–795. [Google Scholar] [CrossRef]

- Lambert, J.H. Photometria Sive de Mensura et Gradibus Luminis. Sumptibus Vidvae; Nabu Press: Charleston, SC, USA, 1760. [Google Scholar]

- Li, D.; Gao, Y.; Liu, S.; Ma, Z.; Wei, Y. Effect of polyoxymethylene dimethyl ethers addition on spray and atomization characteristics using a common rail diesel injection system. Fuel 2016, 186, 235–247. [Google Scholar] [CrossRef]

- Launder, B.; Sharma, B.I. Application of the energy-dissipation model of flow near a spinning disc. Lett. Heat Mass Transfer 1974, 1, 131–138. [Google Scholar] [CrossRef]

- Liu, A.B.; Mather, D.; Reitz, R.D. Modeling the Effects of Drop Drag and Breakup on Fuel Sprays. SAE Trans. 1993, 102, 83–95. [Google Scholar]

- Naber, J.D.; Reitz, R.D. Modeling Engine Spray/Wall Impingement. SAE Trans. 1988, 97, 118–140. [Google Scholar]

- Pinchon, P. Three Dimensional Modelling of Combustion in a Prechamber Diesel Engine. SAE Trans. 1989, 98, 1202–1223. [Google Scholar]

- Colin, O.; Benkenida, A. The 3-Zones Extended Coherent Flame Model (Ecfm3z) for Computing Premixed/Diffusion Combustion. Oil Gas Sci. Technol. 2006, 59, 593–609. [Google Scholar] [CrossRef]

- Zeldvich, Y.B. The oxidation of nitrogen in combustion and explosions. J. Acta Physicochim. 1946, 21, 577. [Google Scholar]

- Tuovinen, H. Application of Flamelet Chemistry Model to Vitiated Methane-Air Diffusion Flames; Lund University: Lund, Sweden, 1992. [Google Scholar]

- Gao, W.; Liu, J.; Sun, P.; Wang, T.; Chen, L.; Wang, B.; Kang, T.; Liu, S.; Shi, K. Numerical simulation on NO and soot formation process of a diesel engine with polyoxymethylene dimethyl ethers-diesel blend fuel. Energy Sources Part A RecoveryUtil. Environ. Eff. 2020, 1–16. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Z.; Wang, L.; Wang, P.; Sun, P.; Ma, H.; Wu, P. Effects of PODE/diesel blends on particulate matter emission and particle oxidation characteristics of a common-rail diesel engine. Fuel Process. Technol. 2021, 212, 106634. [Google Scholar] [CrossRef]

- Tian, J.; Cai, Y.; Shi, Y.; Cui, Y.; Fan, R. Effect of Polyoxymethylene Dimethyl Ethers/Diesel Blends on Fuel Properties and Particulate Matter Oxidation Activity of A Light-Duty Diesel Engine. Int. J. Automot. Technol. 2019, 20, 277–288. [Google Scholar] [CrossRef]

| Component | Melting Point (°C) | Boiling Point (°C) | Cetane Number | Density (g/mL@25 °C) | Viscosity (MPa s@25 °C) | Low Calorific Value (MJ/kg) | Oxygen Content (wt%) |

|---|---|---|---|---|---|---|---|

| PODE1 | −105 | 42 | 30 | 0.86 | 0.58 | 22.4 | 42.1 |

| PODE2 | −69.7 | 105 | 63 | 0.98 | 0.64 | 20.6 | 45.3 |

| PODE3 | −42.5 | 156 | 67 | 1.03 | 1.05 | 19.4 | 47.1 |

| PODE4 | −9.8 | 202 | 76 | 107 | 1.75 | 18.7 | 48.2 |

| PODE5 | 18.3 | 242 | 90 | 1.11 | 2.24 | 18.1 | 48.5 |

| Items | Specification |

|---|---|

| Model | YC6G270-30 |

| Type | six-cylinder, w type |

| Bore × Stroke (mm × mm) | 112 × 132 |

| Compression ratio | 17.5 |

| Displacement (L) | 7.8 |

| Fuel injector model | CRIN-138 Eight-hole fuel injector |

| Connection Rod (mm) | 210.82 |

| IVO/IVC (℃A) | 13.5 BTDC/38.5 ABDC |

| EVO/EVC (℃A) | 56.5 BBDC/11.5 ATDC |

| Rated power/kW @ rpm | 199 @ 2200 |

| Maximum torque/Nm @ rpm | 1080 @ (1400–1600) |

| Fuel | P0 | P10 | P15 |

|---|---|---|---|

| Density @ 293 K (kg/m3) | 850 | 872 | 883 |

| Viscosity @ 293 K (MPa s) | 4.73 | 3.37 | 3.18 |

| Surface tension (MN/m) | 23.85 | 24.62 | 24.79 |

| Cetane number | 50.1 | 52.2 | 53.3 |

| Calorific value (kJ/kg) | 42,900 | 41,020 | 39,950 |

| Mathematical Physics Model | Type |

|---|---|

| Turbulence model | standard k-ε [26] |

| Atomization model | 3D Coupling method [23] |

| Secondary crushing model | Wave [27] |

| Bump wall model | Walljet0 [28] |

| Spontaneous combustion model | Auto-Ignition [29] |

| Combustion model | ECFM-3Z [30] |

| NOx emission model | Extended Zeldovich [31] |

| Soot emission model | Lund Flamelet Model [32] |

| Parameter | Value | ||

|---|---|---|---|

| Engine Speed (rpm) | 1400 | ||

| BMEP (MPa) | 1.1 | ||

| Fuel | P0 | P10 | P15 |

| Injection quantity (mg/cycle) | 492.62 | 512.79 | 525.57 |

| Injection start point (°CA) | 713.9 | 713.8 | 713.7 |

| Injection duration (°CA) | 11.6 | 11.9 | 12.4 |

| Single-hole injection quantity (mg/cycle) | 10.26 | 10.68 | 10.95 |

| NOx Emission Mole Fraction (×10−6) | P0 | P10 | P15 |

|---|---|---|---|

| Test results | 1918 | 2189 | 2200 |

| Simulation results | 1954 | 2270 | 2308 |

| Error value | 1.84% | 3.57% | 4.68% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wei, Y.; Zhang, C.; Zhu, Z.; Zhang, Y.; He, D.; Liu, S. Numerical Optimization of the EGR Rate and Injection Timing with a Novel Cavitation Model in a Diesel Engine Fueled with PODE/Diesel Blends. Appl. Sci. 2022, 12, 12556. https://doi.org/10.3390/app122412556

Wei Y, Zhang C, Zhu Z, Zhang Y, He D, Liu S. Numerical Optimization of the EGR Rate and Injection Timing with a Novel Cavitation Model in a Diesel Engine Fueled with PODE/Diesel Blends. Applied Sciences. 2022; 12(24):12556. https://doi.org/10.3390/app122412556

Chicago/Turabian StyleWei, Yanju, Chenyang Zhang, Zengqiang Zhu, Yajie Zhang, Dunqiang He, and Shenghua Liu. 2022. "Numerical Optimization of the EGR Rate and Injection Timing with a Novel Cavitation Model in a Diesel Engine Fueled with PODE/Diesel Blends" Applied Sciences 12, no. 24: 12556. https://doi.org/10.3390/app122412556

APA StyleWei, Y., Zhang, C., Zhu, Z., Zhang, Y., He, D., & Liu, S. (2022). Numerical Optimization of the EGR Rate and Injection Timing with a Novel Cavitation Model in a Diesel Engine Fueled with PODE/Diesel Blends. Applied Sciences, 12(24), 12556. https://doi.org/10.3390/app122412556