Abstract

Although the energy structure has been gradually enriched in recent years, China, as the world’s largest producer and consumer of coal, still accounts for more than 50% of resources. Therefore, in this paper, the high carbon fly ash raw ash (HCFARA) was mechanically activated, and the flotation was treated to obtain decarburized fly ash (DFA) with a loss on ignition of 1.18%, water demand ratio of 101% and strength activity coefficient of 74.5%. With the exception of for water demand ratio, the rest meet the national requirements for the use of Class I fly ash. The foam concrete was prepared by partially replacing cement with decarburized fly ash in different proportions and at different water-to-cement ratios (0.3, 0.4 and 0.5) in order to study its dry density, porosity, compressive strength and thermal conductivity. The results show that the porosity of foam concrete grows with the increase in water-to-cement ratio and fly ash replacement rate. In addition, the dry density and thermal conductivity of the prepared foam concrete can meet the requirements of A05 grade foam concrete (Density less than 500 kg/m3, thermal conductivity less than 0.12 W/(m·k)). The compressive strength can meet the requirements of C0.3 grade foam concrete (Minimum use standard).

1. Introduction

In the current global warming situation, countries have searched for methods and established systems in the fields of construction and industry to reduce CO2 emissions and achieve low-carbon sustainable development. China has also adopted policies such as the “Healthy Building Evaluation Criteria”. Improving the resource utilization rate of construction waste is one of the concerns in China. In response to the policy of low-carbon environmental protection and technological innovation, this study uses decarbonized fly ash to prepare foam concrete for the purpose of green recycling and other uses.

Foam concrete is a new type of thermal material, formed by mixing ng foam with cement and then cast-in-place after mixing with other mixes. The density of this concrete is between 100~2000 kg/m3 and the thermal conductivity is generally around 0.1 W/(m·k). Compared to ordinary concrete, it is lighter in weight with a better thermal insulation performance and is conducive to long-distance transportation. Its workability is related to the interaction between its blowing agent and cement [1]. F.K. [2] prepared foam concrete using cement, expanded vermiculite powder and silica powder and conducted a study on its dry and wet density, water absorption, ultrasonic, compressive strength and thermal conductivity. The results showed that the compressive strength of the foam concrete ranged between 0.4 and 3.7 MPa, the density ranged between 587 and 1040 kg/m3, and the thermal conductivity ranged between 0.059 and 0.237 W/(m·k). Li [3] prepared foam concrete by adding insulation and nanoporous aerogel to the foam concrete with a density of 198 kg/m3 and thermal conductivity of 0.049 W/(m·k) for a new aerogel foam concrete. It can be seen that foam concrete has excellent insulation properties. However, at the same time, the foam concrete itself also has certain problems: low strength, large shrinkage and easy to crack.

In the process of preparing foam concrete from decarbonized fly ash, the utilization of fly ash can also be a further concern. In terms of our environment-energy relationship, our electrical energy comes from coal combustion [4]. According to statistics, in 2020, China’s coal-fired power generation accounts for 50.2% of the global total, and fly ash emissions are also upwards of 50%, both of which rank first in the world. From the global utilization of fly ash, the utilization rate of fly ash is 25%. Among them, India is 38%, the United States is 65%, and China is 45%. It can be seen that an increasing number of researchers in China are gradually paying attention to the comprehensive utilization of fly ash, which has in turn been strongly supported by the state. At present, the utilization of fly ash in China is mainly used in the fields of construction materials, agriculture, roads and mine rehabilitation, etc., 1. In building materials: Jiang [5] found that the partial replacement of cement with fly ash is helpful for high-temperature construction in China. Konstantin [6] found that when the fly ash admixture is 15%, the 7d strength of concrete can reach 20 MPa and the 365d strength can reach 47.7 MPa. 2. In agriculture: It can improve the acidity and permeability of the soil, whilst reducing the swelling rate of the soil. It can also effectively consume the fly ash piled up and landfilled, alleviating the pressure on land and environment. 3. In the road: when the fly ash admixture is between 0% and 60%, its strength decreases with the increase in fly ash. However, when the fly ash admixture is within 40%, it can meet the compressive strength requirements of the road [7]. In addition, when the admixture is 15–30%, its 28 day compressive strength is 50.8 MPa, which can be used as asphalt pavement [8]. In addition to the three aspects described above, fly ash can also be used as an external admixture for special concrete to improve the performance of such concrete. Kudva [9] carried out the proportional design of self-compacting concrete and aggregate-free concrete with high admixture levels. The 28d compressive strength of both concretes reached 60 MPa when the fly ash admixture was 80%. Jung [10] used rice husk ash, silica fume and fly ash to partially replace cement. While exploring the microscopic aspects, it was also found that the prepared concrete could meet the requirements of the relevant codes for compressive strength and porosity. Fly ash concrete is also more widely used in practical engineering, and Hashmi et al. [11] examined its members such as beams and slabs and found that the deflection characteristics and cracking patterns of fly ash concrete are similar to those of ordinary concrete. It was also found that the addition of fly ash reduced the chloride ion attack on reinforced concrete [12]. In addition, other researchers have found that the effect of fly ash on concrete-related properties gradually decreases as the water-to-cement ratio increases [13]. In summary, it is clear that the research and utilization of fly ash should continue.

The cementitious material of foam concrete is usually cement, but to reduce cost and relieve environmental pressure while improving its performance in all aspects, fly ash can be considered to partially replace cement. Shang [14] coated the surface of sodium alginate beads with fly ash, thereby synthesizing a new type of inorganic bubbles and partially replacing them with fine aggregates to prepare foam concrete. This demonstrates that the compressive strength and thermal conductivity of the foam concrete prepared by using the new bubbles were 53.8% and 81.1% higher than those of ordinary concrete of the same density class. Chen [15] found that mixing with a certain amount of fly ash can significantly improve the compressive and flexural strength of aerated concrete. Drochytka [16] found, after two years of follow-up tests, that the addition of fly ash resulted in a decrease in concrete strength, but noted little change in thermal conductivity. Yuan [17] prepared a foam concrete mixed with large amounts of lime mud and fly ash. It was found that the addition of lime mud and fly ash reduced the mechanical properties and drying shrinkage of the concrete, and Krishna [18] came to a similar conclusion. Zhang [19] studied the effect law of hydrogen peroxide admixture on fly ash foam concrete using the chemical foaming method. It was found that the dry density, strength and thermal conductivity of the concrete decreased with the increase in the blowing agent admixture. It was also found that when the H2O2 admixture was in the range of between 5.5 and 7.5%, it caused a significant increase in the pore size. The above-mentioned utilization of fly ash is not well purified. Mao [20] found that the content of decarburized fly ash above 45 μm was greater than 12%, which could not meet the requirements for the use of Class I fly ash. In addition, polished fly ash can significantly improve the strength of fly ash concrete. In fly ash decarbonization technology, Tao [21] conducted a kinetic analysis of charged fly ash particles, which can effectively improve the efficiency of decarbonization.

In summary, there is still relatively little research on high carbon fly ash decarburization technology. In addition, in some areas, the fly ash with a high carbon content generated due to technical limitations cannot be effectively utilized. In contrast to previous studies, modified kitchen waste oil is used as a novel trapping agent in this paper. This can not only effectively improve the utilization rate of kitchen waste oil, but, additionally, its ability to change the hydrophobicity of mineral surface far exceeds that of traditional petrochemical-based trapping agents (kerosene). Thus, a decarburized fly ash with a comparable performance to Class I fly ash was obtained. In addition, the decarburized fly ash was combined with foam concrete to evaluate the relevant performance of foam concrete under different water-cement ratios and decarburized fly ash admixtures In order to provide a new idea for sustainable development.

2. Experimental Program

2.1. Materials

2.1.1. Cement

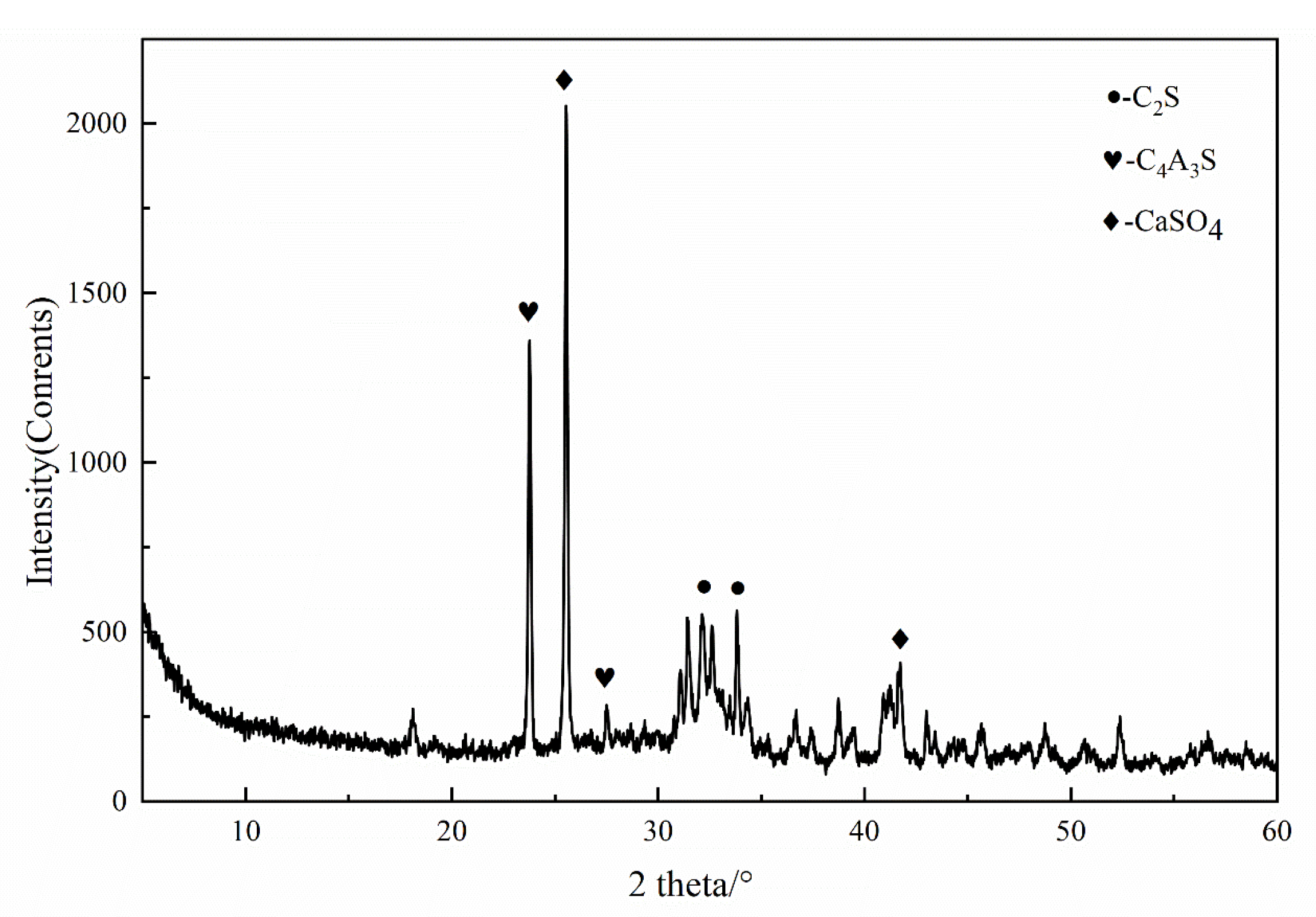

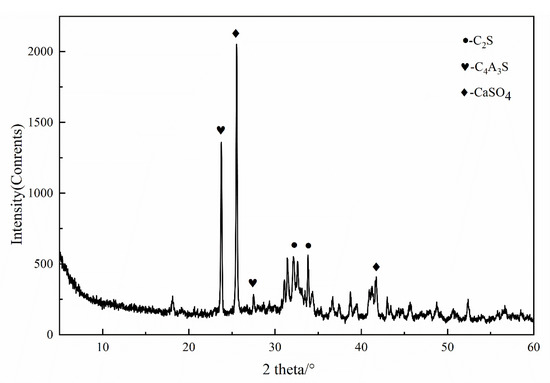

In this test, high-belite sulfoaluminate cement (HBSAC) was used as the cementitious material, purchased from Tangshan Polar Bear Cement Company Limited, Hebei Province, China, with a strength grade of 42.5. The chemical components and basic indexes are shown in Table 1 and Table 2. The XRD analysis results are shown in Figure 1.

Table 1.

The chemical component of HBSAC.

Table 2.

Physical and mechanical properties of HBSAC.

Figure 1.

The XRD analysis of HBSAC.

2.1.2. Relevant Reagents

Sec-Octanol (analytically pure), polycarboxylic acid high efficiency water reducing agent (liquid form, 30% water reduction rate) and modified kitchen waste oil were used. The cement foaming agent adopts plant protein type foaming agent, and its relevant indexes are shown in Table 3.

Table 3.

Foaming agent technical indexes.

According to the preliminary test [22], it can be found that the modified kitchen waste oil can change the hydrophobicity of mineral surface better than kerosene. The trapping performance is higher than that of kerosene. The process of producing the modified kitchen oil trap was as follows: the kitchen waste oil from the dining hall of Qingdao Agricultural University was mixed 1:1 with ethanol in a round-bottom flask through standing, precipitation, filtration and distillation. The reaction was carried out in a stirrer at a speed of 1000 r/min, an oil bath temperature of 80 °C and a catalyst of 2% concentrated sulfuric acid for 6 h. After the reaction was completed, ethyl acetate was mixed 1:1 with the reaction product. Finally, the reaction product was extracted with water, and the extracted product was treated in a rotary evaporator at 80 °C to obtain the kitchen waste oil trap. As shown in Figure 2.

Figure 2.

Modified kitchen waste oil trap.

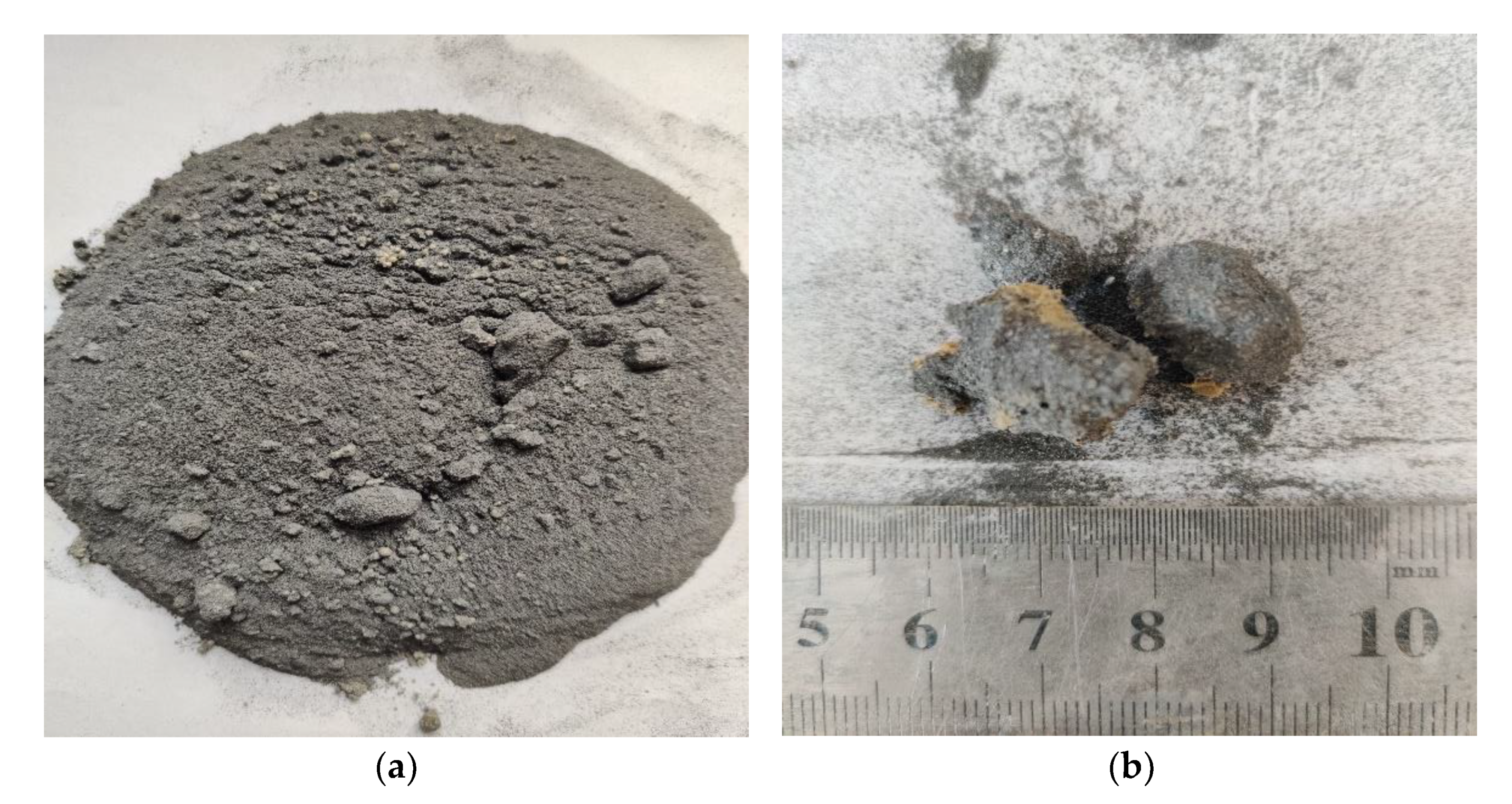

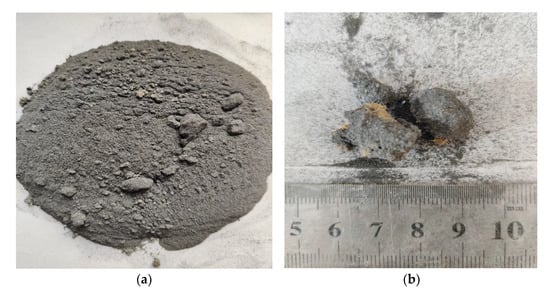

2.1.3. High Carbon Fly Ash Raw Ash

The high carbon fly ash raw ash (HCFARA) used in this experiment was provided by Shandong Junhong Environmental Protection Technology Co., Ltd. of China, as shown in Figure 3a. It was determined that the burning loss was 24.6%, which could not meet the maximum burn loss requirement of Class III fly ash, as stipulated by the relevant standards. In addition, its particle size distribution is not uniform as there are more sintered particles, as shown in Figure 3b. Therefore, it needs to be processed for mechanical grinding. The particle size distribution is shown in Table 4.

Figure 3.

(a) The appearance of HCFARA; (b) Sintered particles in the HCFARA.

Table 4.

The Particle size grade of high carbon fly ash raw ash.

2.1.4. Decarburized Fly Ash

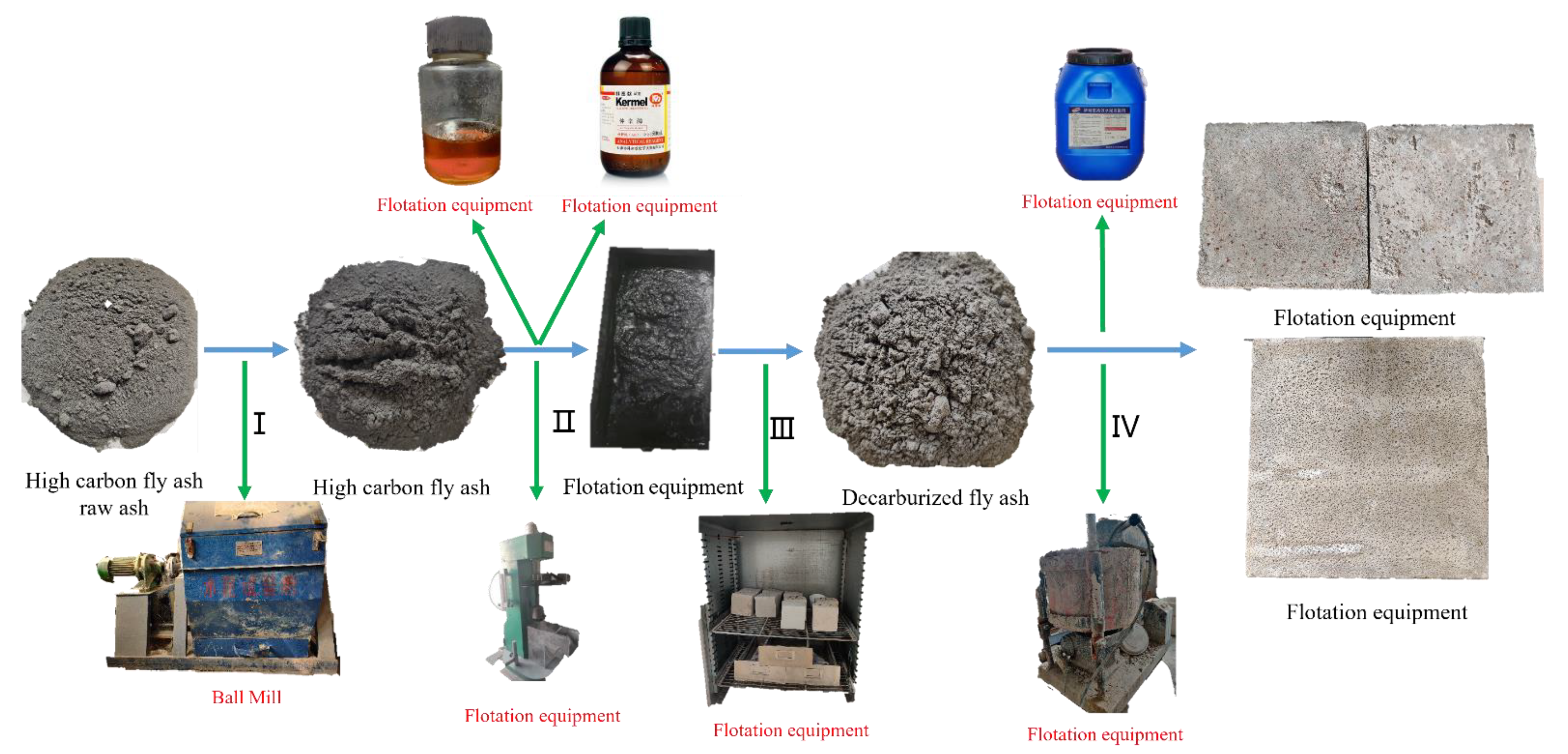

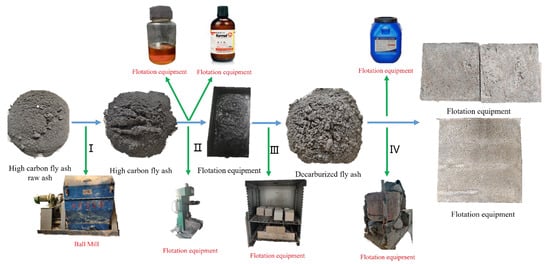

The purpose of this experiment is to prepare decarburized fly ash through the mechanical activation-froth flotation technique using high carbon fly ash raw ash. Through the preliminary experimental research, a flotation agent system with modified kitchen waste oil as the trapping agent and sec-octanol as the foaming agent was proposed. The relevant parameters in the flotation process were optimized by orthogonal experiments: Mechanical activation time 30 min, the impeller speed was 2000 r/min, the pulp concentration was 120 g/L, the bubble scraping time was 10 min, the aeration volume per unit area was 0.20 m³/(m2·min), and the flotation pulp temperature was 20 °C, the amount of kitchen waste oil collector was 5 kg/t, and the amount of sec-octanol was 4 kg/t. Under this condition, the efficiency of flotation and energy saving can be ensured at the same time. The final DFA, with a burn-off of 1.18%, a water demand ratio of 101% and a strength activity factor of 74.5%, was obtained, and the main performance indexes are shown in Table 5. It can be seen that, with the exception of the water demand ratio, all the requirements for Class I fly ash in GB/T 1596-2017 “Fly ash used for cement and concrete” are satisfied.

Table 5.

Main properties of decarburized fly ash.

2.2. Foam Concrete Matching Ratio and Preparation

A total of 18 groups of concrete were prepared in this experiment, and HBSAC and DFA were used as the composite cementitious materials. Based on the group’s previous research [23], the control of the water-reducing agents and foam dosing is 1.2% and 15% of the number of cementitious materials, respectively, and the water-to-cement ratio of 0.3, 0.4 and 0.5 was taken, respectively. The DFA substitution rate was 0–25% and the gradient was 5% to prepare the foam concrete. The specific matching ratio is shown in Table 6.

Table 6.

Foam concrete mix ratio design table.

The cement foaming agent foaming scheme is dilution ratio 1:20, air pressure foaming machine suction valve angle α 60°. In the foaming process, the pressure of the air compressor is constant at 0.5 MPa, and when the foam produced by the foaming machine is more uniform, the weight of the concrete is weighed for mixing. The foam performance is shown in Table 7.

Table 7.

Physical properties of foam.

The preparation process of the foam concrete is as follows: (1) Place the weighed cementitious material into the mixing pot and start stirring; (2) Mix the water and water-reducing agent well and put them into the stirring pot for 1 min; (3) Use the foaming machine to start foaming during the stirring process and weigh the foam mass of the foaming agent according to the matching ratio. After weighing, add the foam to the mixing pot immediately (this step takes less than 1 min); (4) Continue to mix for 2 min and then carry out the test mold pouring. The flow chart is shown in Figure 4.

Figure 4.

High carbon fly ash mechanical activation-flotation process and the preparation process of foam concrete.

2.3. Experimental Methods

2.3.1. The Basic Properties of Foam Concrete

The basic performance of the foam concrete prepared with DFA is carried out, concerning JG/T 266-2011 “Foam Concrete”, under the standard maintenance conditions (temperature 20 ± 3 °C, humidity 90% or more) to the corresponding age for performance testing. The foam concrete was cured to 28 d, and the porosity was measured by the drainage method. The setting time of the HBSAC composite cementitious material mixed with DFA is referred to as GB/T 1346-2011 “Test methods for water requirement of normal consistency, setting time and soundness of the portland cement”. There was no foam or water reduction during the test.

2.3.2. Compressive Strength of Foam Concrete

Eighteen sets of 100 mm × 100 mm × 100 mm cubic specimens were prepared according to the GB/T 50081-2019 “Standard for Test Methods of Physical and Mechanical Properties of Concrete”. After curing with the mold for 24 h, the mold was removed and put into the standard curing room. After curing to 3 d, 7 d and 28 d, respectively, the specimens were taken out and tested for compressive strength with a correction factor of 0.95.

2.3.3. Insulation Property of Foam Concrete

The thermal insulation property of the foam concrete is characterized according to its thermal conductivity. The thermal conductivity test is carried out concerning GB/T10294-2008 “Thermal insulation—Determination of steady-state thermal resistance and related properties—Guarded hot plate apparatus”. Specimens with dimensions of 300 mm × 300 mm × 35 mm were prepared. The specimens were maintained under standard conditions until 26 d. They were taken out and dried in an oven to a constant weight for thermal conductivity testing. The hot plate temperature was set to 35 °C and the cold plate temperature to 15 °C. The automatic detection time is 90 min, and the preliminary estimate is 60 min. The thermal conductivity is calculated according to Equation (1), and the average value of the group is taken as the final result.

where Kc is the thermal conductivity (W/m·k); Φ is the average thermal conductivity of the specimen after completion of the test (J/s); d is the specimen thickness (mm); S is the test area of the specimen (m2); ΔT is the temperature difference between the hot plate and cold plate (°C).

3. Results and Discussions

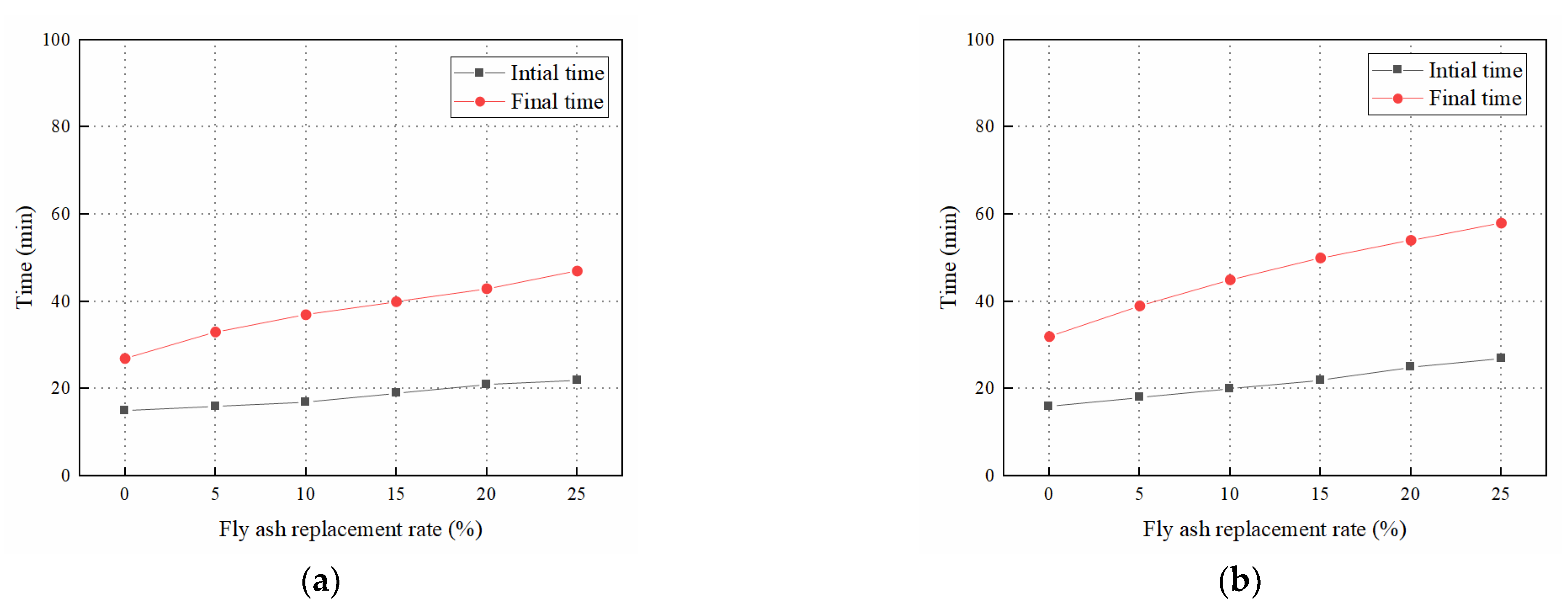

3.1. Setting Time of Composite Cementitious Materials

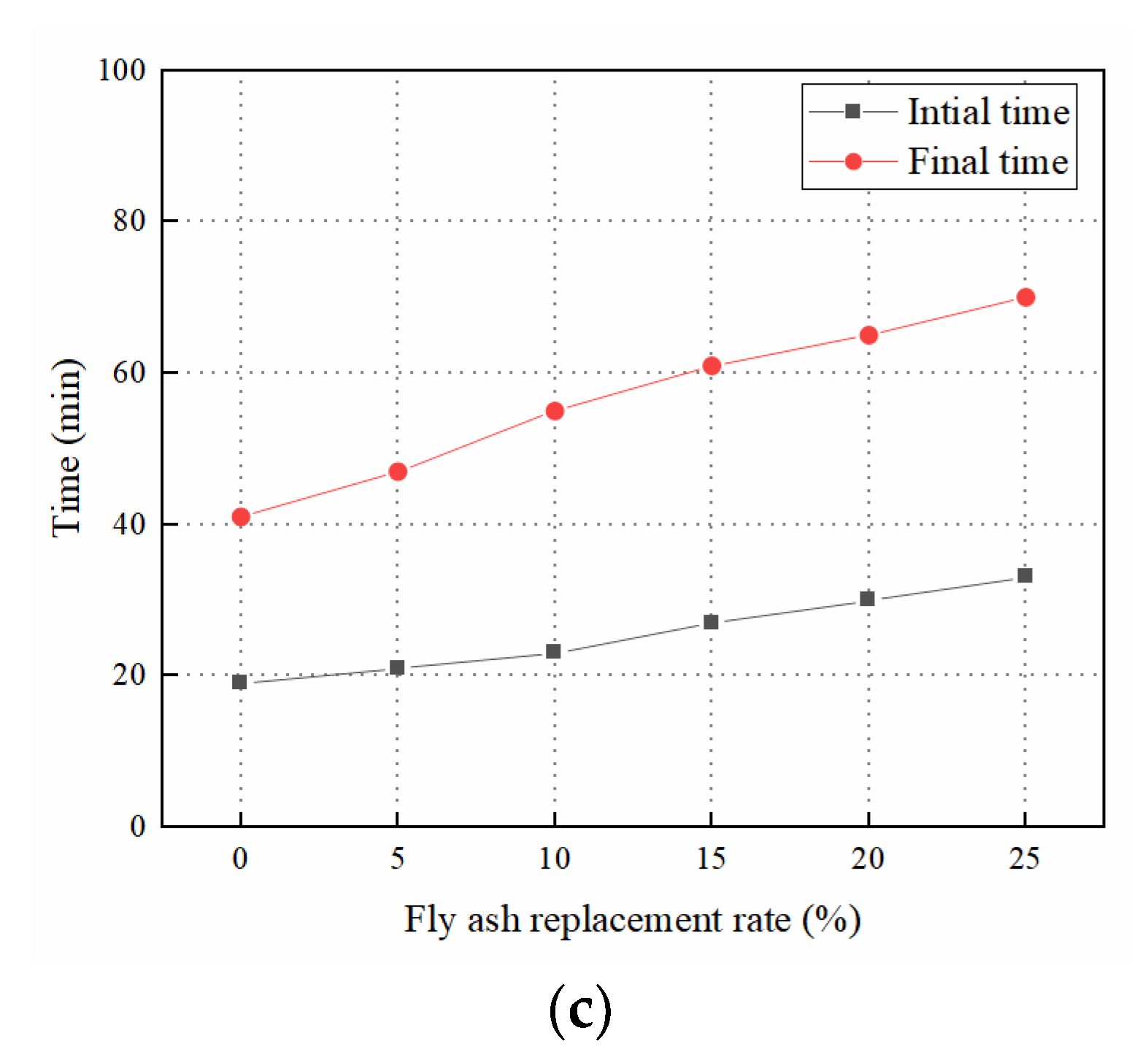

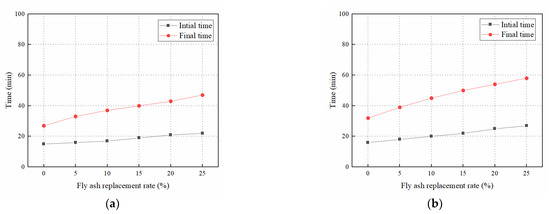

Figure 5a–c reflects the setting time of the composite cementitious materials at different DFA substitution rates. It can be seen from the figure that the initial and final setting times of the composite cementitious material increase with the increase in the DFA substitution rate, and the time difference between them also increases. Taking H3-1 and H3-6 as examples, the initial and final setting times of H3-1 were 19 min and 41 min, with a time difference of 22 min. The initial and final setting times of H3-6 were 33 min and 70 min, with a time difference of 37 min. The reason for this phenomenon may be that the increase in DFA doping reduces the content of anhydrous calcium sulfoaluminate used for the hydration reaction in the composite cementitious material system, which further affects the hydration rate. At the same time, fly ash in the hydration process is often combined with Ca(OH)2 to achieve the “secondary reaction” and cannot directly provide hydration products. This leads to an increase in the setting time of the composite cementitious material system.

Figure 5.

Setting time of composite cementitious materials with different DFA substitution rates (a) water to binder ratio 0.3 (b) water to binder ratio 0.4 (c) water to binder ratio 0.5.

It can also be noted that the increase in the water-to-cement ratio also prolongs the setting time of the composite cementitious material. Taking H1-4 and H3-4 as examples, the initial and final setting time of H1-4 is 19 min and 40 min, and the initial and final setting time of H3-4 is 27 min and 61 min. When the water-to-cement ratio was increased from 0.3 to 0.5, the initial and final setting times increased by 8 min and 21 min, respectively. This is primarily because the increase in water-collagen ratio, while increasing the water consumption, is equivalent to diluting the concentration of each ion in the slurry. This leads to a slowing down of the accumulation of hydration products, which is further manifested by an increase in the setting time.

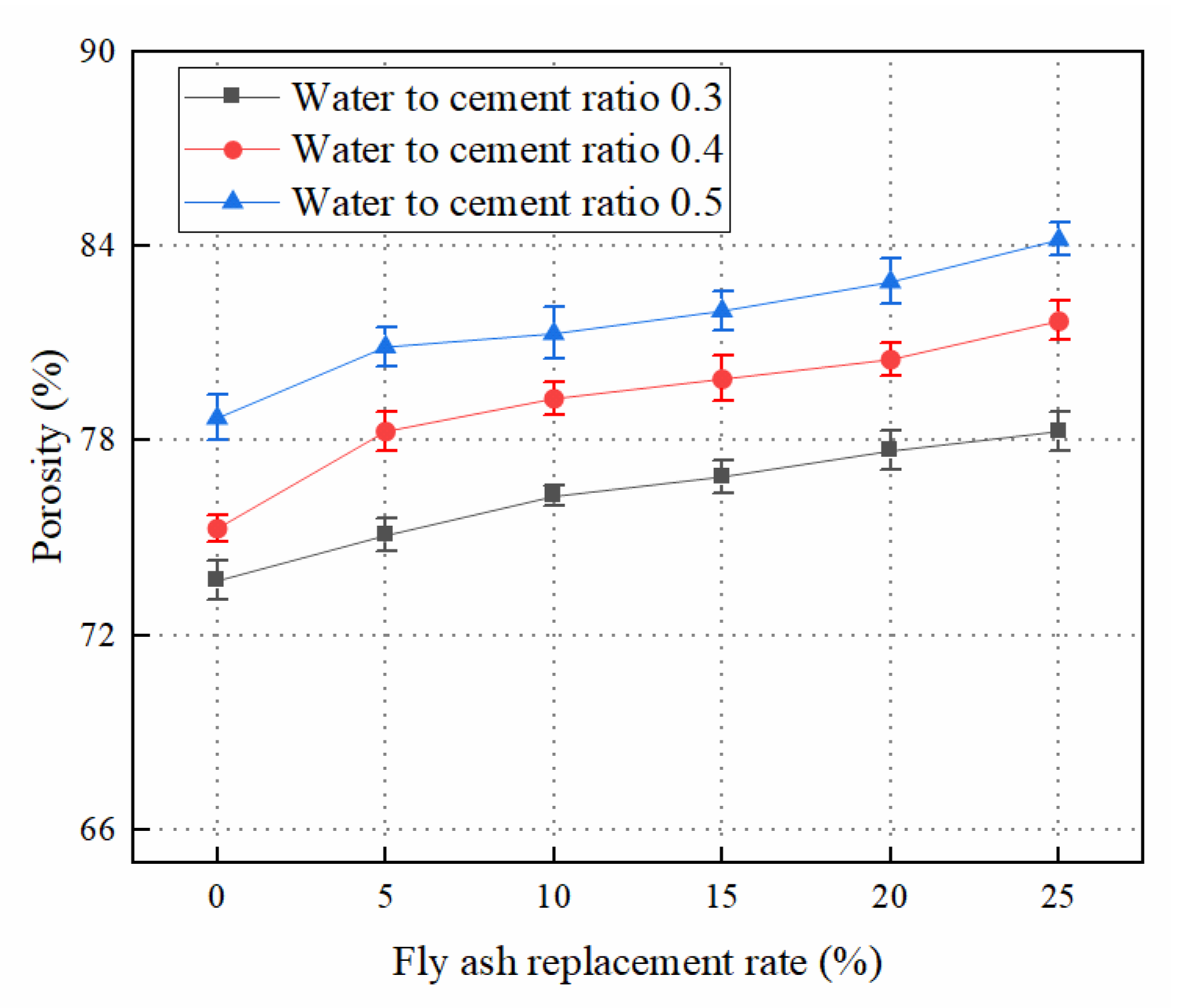

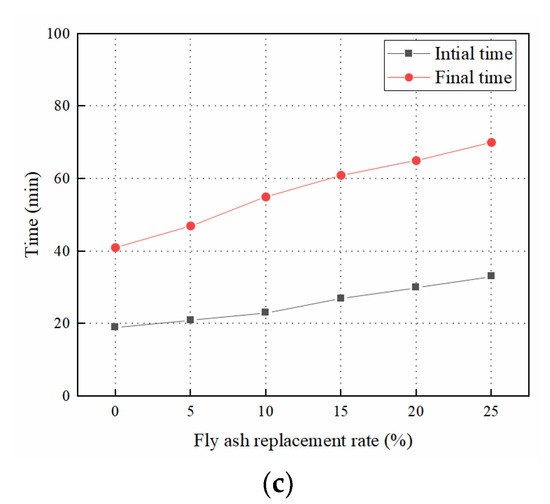

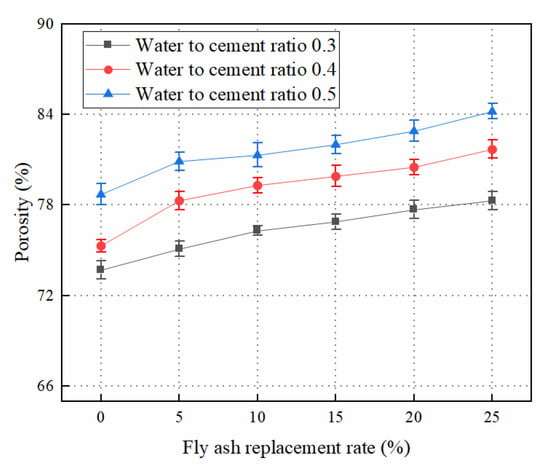

3.2. Porosity

Figure 6 shows the porosity of the foam concrete with different mix ratios. It can be seen from the figure that the porosity of the foam concrete continues increasing with the increase in the DFA substitution. Taking the water-to-cement ratio of 0.4 as an example, the porosity of the foam concrete increased from 75.3% to 81.7% when the substitution rate increased from 0% to 25%. This is mainly because, in the case of the constant water-to-cement ratio, the increase in DFA content will reduce the fluidity of concrete and prolong the setting time of concrete. This reduces the loss of foam during preparation and also gives a better environment for foam morphology to develop, thus increasing the porosity of the concrete. Secondly, the activity of the DFA is much lower than that of cement. In addition, the “secondary hydration reaction” of the DFA is extremely dependent on the hydration product of cement -Ca(OH)2. The increase in DFA doping reduced the production of Ca(OH)2. When the amount of DFA is too high and the Ca(OH)2 generated by hydration is not enough to react completely with the DFA, the unreacted DFA will also increase the porosity of the foam concrete.

Figure 6.

The porosity of foam concrete with different matching ratios.

Meanwhile, at the same DFA substitution rate, the porosity of the concrete continues to increase with the increase in the water-to-cement ratio. Taking the DFA substitution rate of 15% as an example, the porosity of the concrete increased from 76.9% to 82% when the water-to-cement ratio increased from 0.3 to 0.5. The reason for this phenomenon is the nature of DFA itself. When the water-to-cement ratio increases, it can increase the viscosity of the foam concrete, which reduces the loss of foam in the mixing process and facilitates the development of foam within the slurry. The final expression is the increase in porosity.

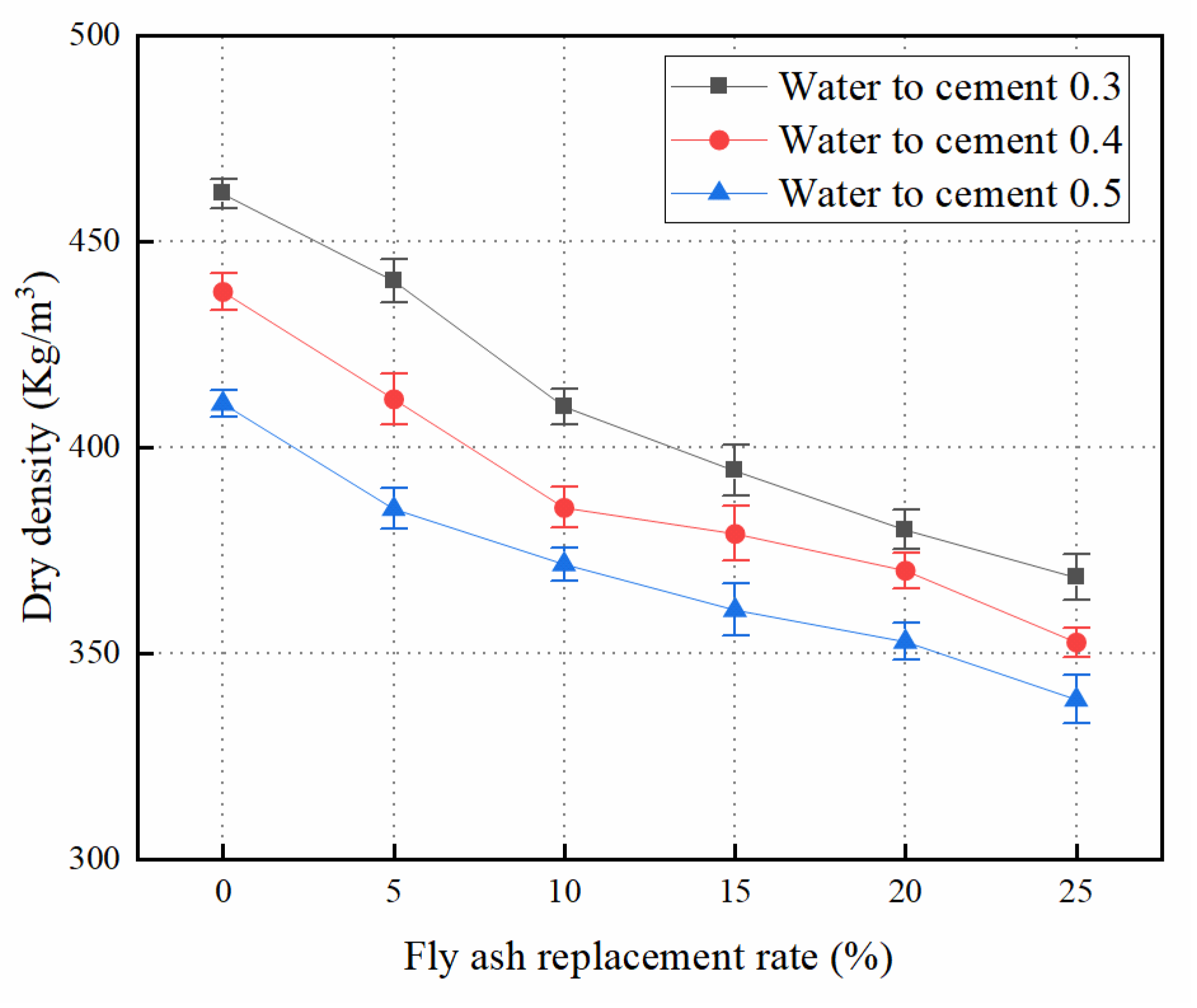

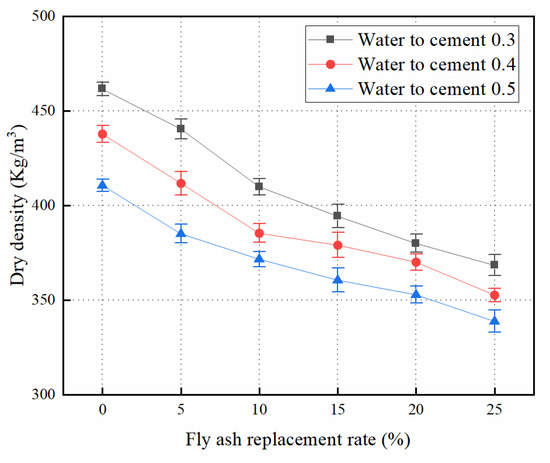

3.3. Dry Density

Figure 7 reflects the test results of the dry density of the foam concrete. The dry density of the foam concrete is between 338.89~461.51 kg/m3. It can be seen from the figure that the dry density gradually decreased with the increase in the DFA substitution rate and the increase in water-to-cement ratio, but it is not linearly correlated.

Figure 7.

The density of foam concrete with different matching ratios.

The reason for this phenomenon may be because DFA has a lower density compared to HBSAC. The increase in the DFA content reduces the density of the composite cementitious material. Secondly, the addition of DFA improves the foaming environment of the foaming agent and increases the foam content in the concrete, in disguise. At the same time, DFA also causes the development of an internal hole structure and prolonged annexation time. This phenomenon becomes increasingly obvious with the increase in the DFA admixture. In addition, according to the existing research surface [24], the size of the internal pores of concrete shows a negative correlation with dry density. In the mixing process of foam concrete, with the decrease in the viscosity and the increase in fluidity, it leads to the increase in air content in the mixing-molding process, which creates more bubbles inside the concrete. This further reduces the dry density of the foam concrete. Taking group H2 as an example, the dry density of the concrete decreased from 437.7 kg/m3 to 352.7 kg/m3 when the fly ash substitution rate increased from 0% to 25%.

In the process of preparing the foam concrete, the increase in the water-to-cement ratio causes an increase in the mixing water quantity. However, most of the water evaporates from the concrete interior as free water during the entire curing age and drying process. At the same time, we know that the water used for the hydration of concrete increases with the proportion of cementitious materials. As the water-to-cement ratio increases, the proportion of cementitious materials gradually decreases, which means that the water used for the hydration reaction is decreasing and the free water is increasing.

According to JG/T 266-2011 “Foam Concrete”, the dry density of all the 18 groups of foam concrete prepared in this test can meet the requirements of A0.5 grade.

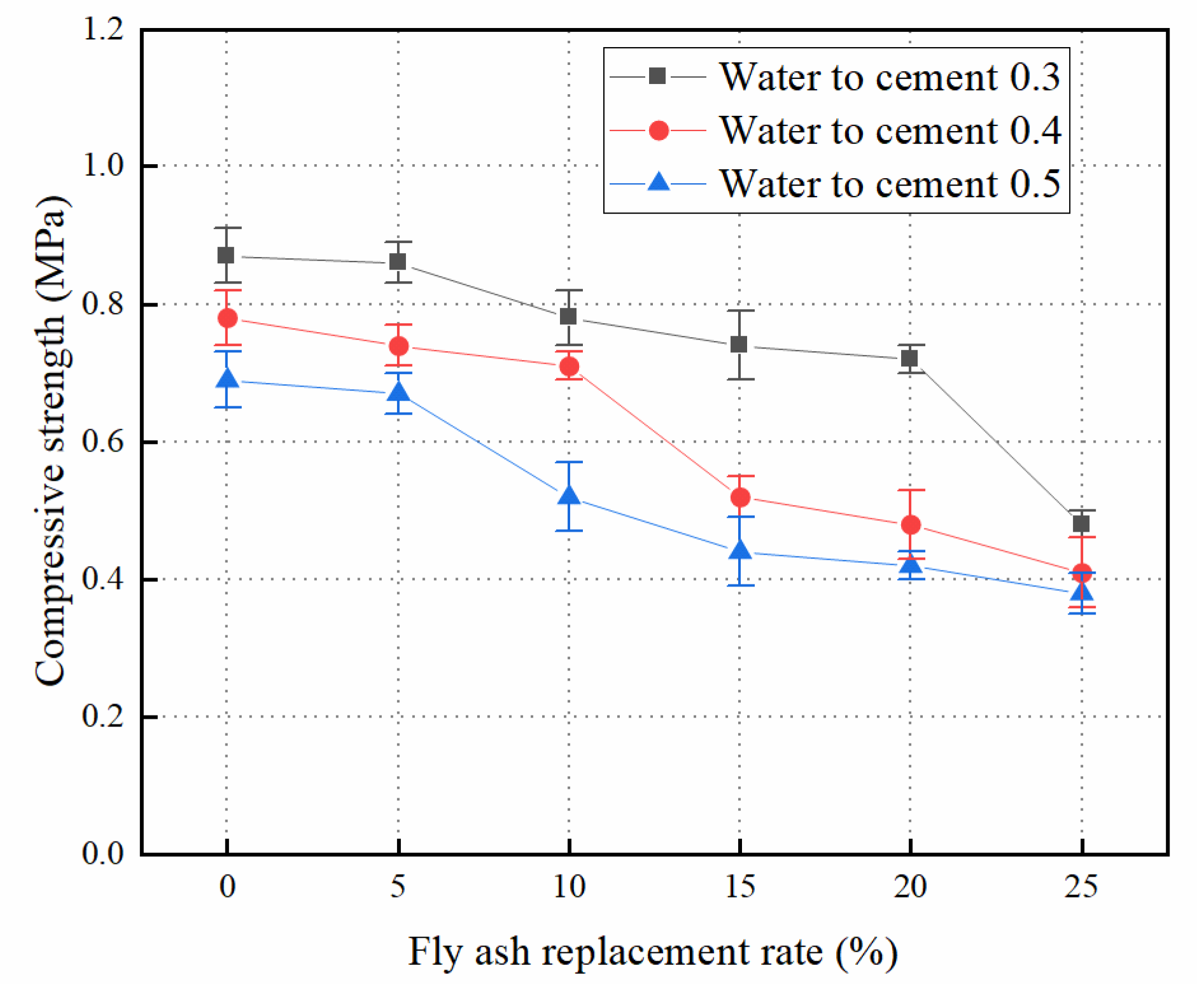

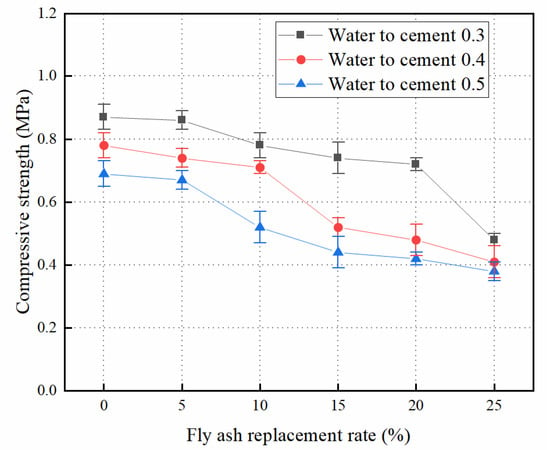

3.4. Compressive Strength

Figure 8 reflects the results of the compressive strength measurement of the foam concrete with different mix ratios. From the figure, it can be seen that the compressive strength of the concrete decreases continuously with the increase in the DFA admixture, while keeping the water-to-cement ratio constant. Meanwhile, the H1, H2 and H3 groups showed a sudden drop in DFA content up to 20%, 15% and 10%. The strengths were reduced from 0.72 MPa to 0.48 MPa, 0.71 MPa to 0.52 MPa, and 0.67 MPa to 0.52 MPa, respectively, with reductions of 33.3%, 26.7%, and 22.4%. This is caused by the mineral composition of the cementitious material. The mineral composition of HBSAC is mainly anhydrous calcium sulfoaluminate and dicalcium silicate. In the early stage of the hydration reaction, Aft is mainly formed by the hydration of anhydrous calcium sulfoaluminate to improve the strength, and in the later stage, dicalcium silicate is hydrated to form hydrated calcium silicate and Ca(OH)2 to provide strength [25]. Meanwhile, although the DFA with mechanical activation-flotation has higher activity, the hydration products of anhydrous calcium sulfoaluminate can further react with Ca(OH)2. This means a disguised weakening of the DFA activity. Secondly, due to the relatively slow hydration rate of dicalcium silicate, when the DFA content reaches a certain level, the Ca(OH)2 generated by hydration is inevitably unable to meet the amount required for the DFA to carry out the “secondary hydration reaction”. This also results in a lot of residual un-reacted DFA inside the concrete, which not only reduces the compactness of the concrete, but also reduces the compressive strength of the concrete.

Figure 8.

The 28d compressive strength of foam concrete with different matching ratios.

We can also learn from the figure that an increase in the water-to-cement ratio decreases the compressive strength of concrete at the same DFA substitution rate. Taking H1-4 and H3-4 as examples, the 28 d compressive strengths of both were 0.72 MPa and 0.44 MPa, with a decrease of 38.8%. This is because, although the amount of gelling material is the same for both, H3-4 will obtain more gelling material slurry as the water-to-cement ratio increases. When the water-to-cement ratio is larger, the content of HBSAC in the same volume of cementitious material slurry will be less. In addition, as the main strength contributor, the content reduction of HBSAC will inevitably reduce the strength of the foam concrete. Secondly, due to the same volume of the mold at the time of casting, less HBSAC hydration products distributed in the same volume of space will also make the foam concrete less compact and thus reduce the compressive strength.

According to JG/T 266-2011 “Foam Concrete”, all the 18 groups of foam concrete prepared in this test meet the requirements of C0.3 grade foam concrete.

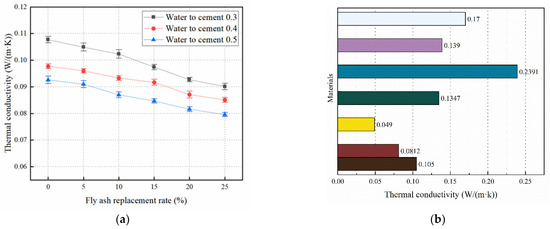

3.5. Thermal Insulation Performance

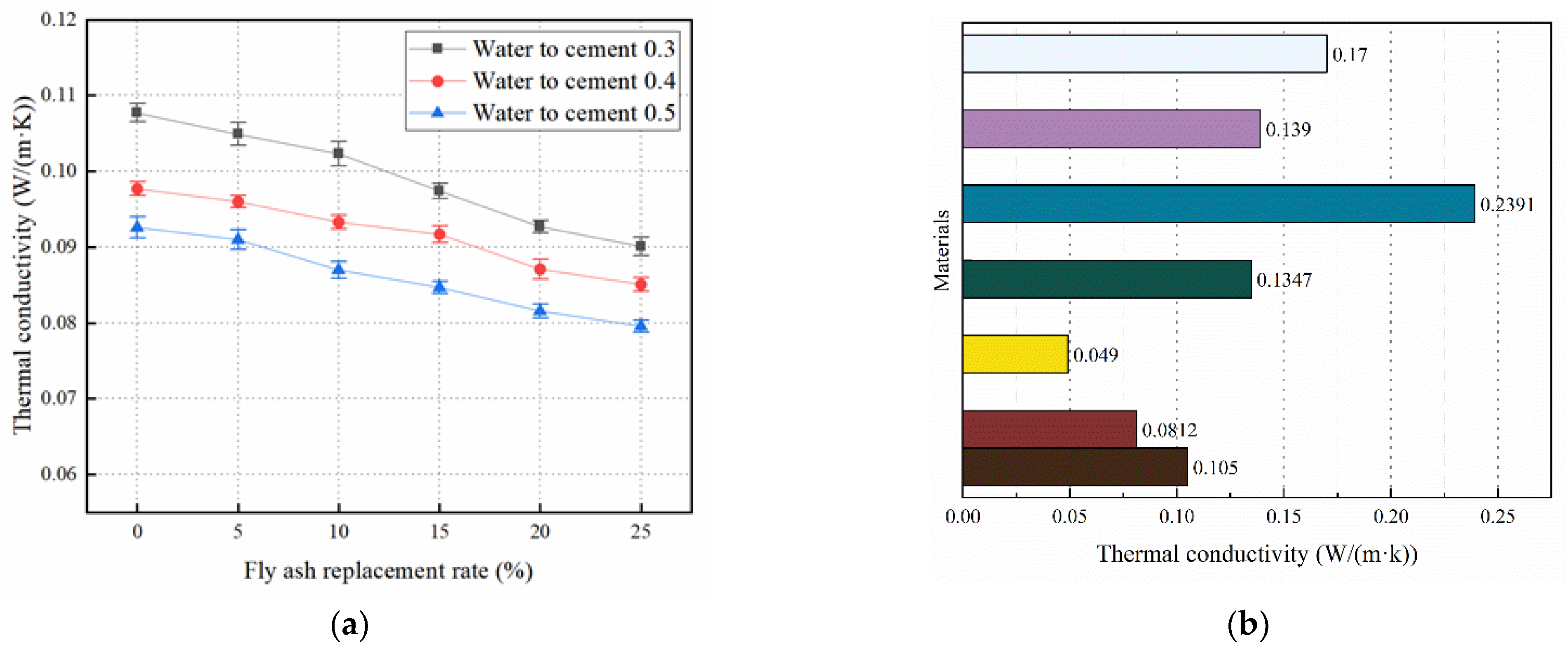

This test measures the thermal insulation performance of foam concrete by testing for thermal conductivity, and the measurement results are shown in Figure 9a. From the figure, it can be seen that with the increase in DFA admixture and water-to-cement ratio, the thermal conductivity of DFA decreases continuously and the thermal insulation performance improves gradually.

Figure 9.

(a) Thermal conductivity of foam concrete with different fitting ratios (b) Thermal conductivity of different types of foam concrete.

The main reason for such phenomena is the increase in porosity, which we usually consider as decreasing the thermal conductivity of concrete. This is because the thermal conductivity of air is much lower than that of cement paste, and the addition of DFA will increase the porosity and pore size inside the foam concrete. Taking group H2 as an example, the porosity of the foam concrete increased from 75.3% to 81.7% when the DFA admixture increased from 0% to 25%, while the thermal conductivity decreased from 0.0977 W/(m·k) to 0.0851 W/(m·k). With the same content of DFA, the increase in the water-to-cement ratio also leads to the formation of more pores inside the dried concrete, increasing the content of internal air. This eventually leads to a decrease in the thermal conductivity of the foam concrete.

Figure 9b collects the data from some researchers on the thermal conductivity of foam concrete [3,26,27,28,29] and makes a comparison with the foam concrete prepared in this test. It can be seen from the figure that the thermal conductivity of the foam concrete prepared in this test ranged between 0.0796 and0.1077 W/(m·k). With the exception of the foam concrete prepared using super-insulating nano-multi-air gel, the thermal conductivity of all other foam concretes was higher than that of the foam concrete prepared in this test. Meanwhile, according to JG/T 266-2011 “Foam Concrete”, all the 18 groups of foam concrete prepared in this test meet the requirements of A05 grade foam concrete.

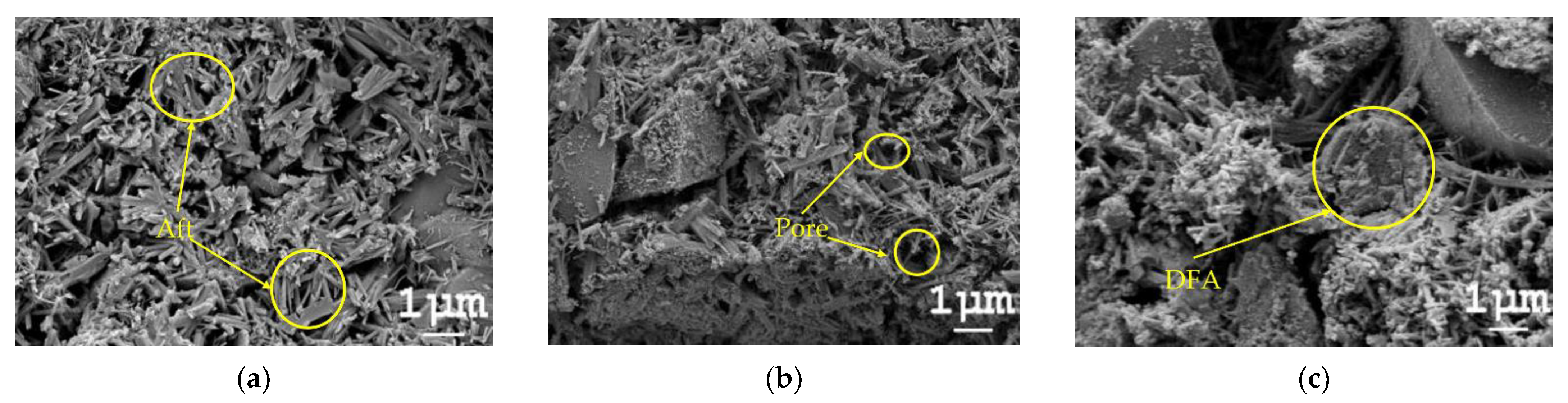

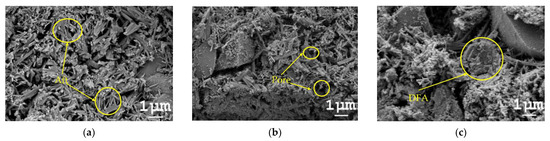

3.6. SEM Analysis of Foam Concrete

To further verify the above analysis, SEM microscopic analysis of H2-1, H2-3 and H2-6 was performed, as shown in Figure 10a–c. As can be seen from the figure, the 28 d hydration products of the three groups of foam concrete are mainly pin-stick-like Aft laps and are filled with partial gel. Meanwhile, in H2-3 and H2-6, the fly ash particles are filled between the hydration products and covered with the product of “secondary hydration reaction”, hydrated calcium silicate. In addition, the development of Aft was limited with the increase in the DFA substitution rate. The morphology gradually changed from rod-like to needle-like and the unreacted DFA particles gradually increased. This also verifies that the main cause of the change in the properties related to foam concrete are the deterioration of the Aft morphology, the reduction in the hydration products and the weakening of the DFA “secondary hydration reaction”.

Figure 10.

SEM analysis of H2 (a) H2-1 (b) H2-3 (c) H2-6.

4. Conclusions

The purpose of this paper is to prepare decarburized fly ash using high carbon fly ash raw ash and combine it with foam concrete. While improving the resource utilization rate of fly ash, the related properties of foam concrete are improved. Finally, the following conclusions are drawn:

- (1)

- The decarburized fly ash obtained from the grinding-flotation treatment of raw high carbon fly ash using mechanical activation and a kitchen waste oil trapping agent meets the requirements for the use of Class I fly ash, with the exception of the water demand ratio.

- (2)

- With the increase in the water-to-cement ratio and DFA substitution rate, the setting time of the composite cementitious materials and the porosity of the foam concrete showed an increasing trend.

- (3)

- With the increase in the water-to-cement ratio and DFA substitution rate, the dry density, compressive strength and thermal conductivity of the foam concrete all show a decreasing trend.

- (4)

- The dry density and thermal conductivity of the prepared foam concrete can meet the requirements of A05 grade foam concrete. The compressive strength can meet the requirements of C0.3 grade foam concrete.

- (5)

- SEM analysis verified that the deterioration of the foam concrete performance was caused by the deterioration of the Aft morphology, the reduction in hydration products and the weakening of the DFA “secondary hydration reaction”.

- (6)

- It can be seen from the SEM that the morphology of the decarburized fly ash is irregular, and there are a few round microbeads similar to those of fly ash. This is also reflected in the higher water demand ratio of decarburized fly ash than Class I fly ash. This leads to the poor workability of concrete prepared with decarburized fly ash compared to normal concrete. The decarburized fly ash will partially replace cement to prepare recycled concrete, study its mechanical properties, thermal insulation properties, durability performance, and make a comparison with Class I fly ash. This will be a key factor for whether decarburized fly ash can be widely used.

Author Contributions

Data curation, Y.G. and C.X.; formal analysis, Z.H. and L.W.; methodology, G.Y.; resources, S.Z. and P.W.; software, P.W.; writing—original draft, Y.G.; writing—review & editing, Q.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [National Natural Science Foundation of China] grant numbers [51878366, 51978353, and 52078261]. This research was funded by [Natural Science Foundation of Shandong Province] grant numbers [ZR2019PEE007 and ZR2020ME036]. This research was funded by [Major Science and Technology Innovation Project of Shandong Province] grant number [2021SFGC0201-04]. This research was funded by [Municipal School Enterprise Cooperation Project] grant numbers [2422243, 2421073, and 2419133]. This research was funded by [Qingdao Municipal Government Procurement Project] grant numbers [ZFCG2019000063 and ZFCG2022007092]. This research was funded by [Qingdao Science and Technology Demonstration and Guidance Project] grant number [20-3-4-10-nsh].

Institutional Review Board Statement

This statement is not required for my study.

Informed Consent Statement

Not applicable.

Data Availability Statement

The study did not report any data.

Conflicts of Interest

The authors declare no conflict of interest regarding the publication of this paper.

Abbreviations

The following abbreviations are used in this manuscript:

| HCFARA | High carbon fly ash raw ash |

| HBSAC | High-belite sulfoaluminate cement |

| DFA | Decarburized fly ash |

References

- Li, H.; Jun, L.; Zhongyuan, L.; Yunhui, N. Influence of foaming agent on cement and foam concrete. Constr. Build. Mater. 2021, 280, 122399. [Google Scholar]

- Koksal, F.; Sahin, Y.; Gencel, O. Influence of expanded vermiculite powder and silica fume on properties of foam concretes. Constr. Build. Mater. 2020, 257, 119547. [Google Scholar] [CrossRef]

- Li, P.; Wu, H.; Liu, Y.; Yang, J.; Fang, Z.; Lin, B. Preparation and optimization of ultra-light and thermal insulative aerogel foam concrete. Constr. Build. Mater. 2019, 205, 529–542. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Ma, S.; Zheng, S.; Zhang, Y.; Chu, P.K. Utilization of coal fly ash in China: A mini-review on challenges and future directions. Environ. Sci. Pollut. Res. Int. 2020, 28, 18727–18740. [Google Scholar] [CrossRef]

- Nguyen, T.T.N.; Nguyen, A.T.; Vu, Q.V.; Ngo, V.T.; Lam, T.Q.K. The strength of fly ash concrete of experimental design. Mag. Civil Eng. 2022, 109, 10911. [Google Scholar] [CrossRef]

- Konstantin, S.; Mohamadreza, M.; Habib, T.; Hani, T. Class F Fly Ash Assessment for Use in Concrete Pavements; Technical Report; Center for By-Product Utilization (CBU) at UW-Milwaukee: Milwaukee, WI, USA, 2017; p. 1. [Google Scholar]

- Reddy, M.I.; Selvam, R.; Govindaraj, V.; Murugan, M. Performance and life-cycle assessment of high-volume fly ash concrete mixes containing steel slag sand. Constr. Build. Mater. 2022, 341, 127814. [Google Scholar]

- Zhai, H.-X.; Tang, Y.-Z.; Chen, S.-H.; Chen, H.-H.; Cheng, B.-Q.; Cai, X.; Wei, Y.-H. Experimental Research on Durability of Fly Ash Pavement Concrete and Mix Proportion Optimization. Adv. Mater. Sci. Eng. 2021, 2021, 864706. [Google Scholar] [CrossRef]

- Kudva, P.L.; Nayak, G.; Shetty, K.K.; Sugandhini, H. A sustainable approach to designing high volume fly ash concretes. Mater. Today Proc. 2022, 65, 1138–1145. [Google Scholar] [CrossRef]

- Jung, S.-H.; Saraswathy, V.; Karthick, S.; Kathirvel, P.; Kwon, S.-J. Microstructure Characteristics of Fly Ash Concrete with Rice Husk Ash and Lime Stone Powder. Int. J. Concr. Struct. Mater. 2018, 12, 17. [Google Scholar] [CrossRef]

- Hashmi, A.F.; Shariq, M.; Baqi, A. Flexural performance of high volume fly ash reinforced concrete beams and slabs. Structures 2020, 25, 868–880. [Google Scholar] [CrossRef]

- Sanjeev, N.; Kumar, K.H.; Sanjeev, K. Harish Kumar, Mechanical and Durability Properties of Concrete Incorporating Flyash. Int. J. Innov. Technol. Explor. Eng. 2019, 8. [Google Scholar]

- Sheng, L.; Hongbo, L.; Changyu, Y.; Yongfa, D.; Xuanshuo, Z.; Jing, Z. Investigating the Mechanical and Durability Characteristics of Fly Ash Foam Concrete. Materials 2022, 15, 6077. [Google Scholar]

- Shang, X.; Qu, N.; Li, J. Development and functional characteristics of novel foam concrete. Constr. Build. Mater. 2022, 324, 126666. [Google Scholar] [CrossRef]

- Chen, Y.-F.; Yang, D.-S.; Xie, L.-L.; Yang, X.-S.; Wu, Y.-R.; Huang, Y.-J. Activity of sedimentary-fly-ash-aerated concrete. Emerg. Mater. Res. 2018, 7, 242–248. [Google Scholar] [CrossRef]

- Drochytka, R.; Helanová, E. Development of Microstructure of the Fly Ash Aerated Concrete in time. Procedia Eng. 2015, 108, 624–631. [Google Scholar] [CrossRef]

- Huaqiang, Y.; Zhi, G.; Renjuan, S.; Xixi, X.; Yu, L.; Yifeng, L.; Hongzhi, Z. Drying shrinkage, durability and micro-structure of foamed concrete containing high volume lime mud-fly ash. Constr. Build. Mater. 2022, 327, 126990. [Google Scholar]

- Ai Krishna, A.; Siempu, R.; Sandeep Kumar, G.A.V.S. Study on the fresh and hardened properties of foam concrete in-corporating fly ash. Mater. Today: Proc. 2021, 46, 8639–8644. [Google Scholar]

- Zhang, D.; Ding, S.; Ma, Y.; Yang, Q. Preparation and Properties of Foam Concrete Incorporating Fly Ash. Materials 2022, 15, 6287. [Google Scholar] [CrossRef]

- Zhang, Q.; Mao, S.; Jiang, M.; Chen, X.D.; Cheng, W. Experiment on Decarburization of High Carbon Fly Ash and Preparation of Concrete. Adv. Mater. Res. 2014, 881–883, 1250–1254. [Google Scholar] [CrossRef]

- Tao, Y.; Zhang, L.; Tao, D.; Xian, Y.; Sun, Q. Effects of key factors of rotary triboelectrostatic separator on efficiency of fly ash decarbonization. Int. J. Min. Sci. Technol. 2017, 27, 1037–1042. [Google Scholar] [CrossRef]

- Hu, Z.W.; Li, Q.Y.; Lin, X.L.; Guo, Y.X. Flotation of high carbon fly ash with kitchen waste oil trap. China Environ. Sci. 2021, 41, 5210–5216. (In Chinese) [Google Scholar]

- Liu, C.; Luo, J.; Li, Q.; Gao, S.; Su, D.; Zhang, J.; Chen, S. Calcination of green high-belite sulphoaluminate cement (GHSC) and performance optimizations of GHSC-based foamed concrete. Mater. Des. 2019, 182, 107986. [Google Scholar] [CrossRef]

- Khan, Q.S.; Sheikh, M.N.; McCarthy, T.; Robati, M.; Allen, M. Experimental investigation on foam concrete without and with recycled glass powder: A sustainable solution for future construction. Constr. Build. Mater. 2019, 201, 369–379. [Google Scholar] [CrossRef]

- Hou, L.; Li, J.; Lu, Z.; Niu, Y.; Jiang, J.; Li, T. Effect of nanoparticles on foaming agent and the foamed concrete. Constr. Build. Mater. 2019, 227, 116698. [Google Scholar] [CrossRef]

- Song, Q.; Bao, J.; Xue, S.; Zhang, P.; Mu, S. Collaborative disposal of multisource solid waste: Influence of an admixture on the properties, pore structure and durability of foam concrete. J. Mater. Res. Technol. 2021, 14, 1778–1790. [Google Scholar] [CrossRef]

- Gökçe, H.S.; Hatungimana, D.; Ramyar, K. Effect of fly ash and silica fume on hardened properties of foam concrete. Constr. Build. Mater. 2018, 194, 1–11. [Google Scholar] [CrossRef]

- Samson, G.; Cyr, M.; Gao, X.X. Thermomechanical performance of blended metakaolin-GGBS alkali-activated foam concrete. Constr. Build. Mater. 2017, 157, 982–993. [Google Scholar] [CrossRef]

- Markin, V.; Krause, M.; Otto, J.; Schröfl, C.; Mechtcherine, V. 3D-printing with foam concrete: From material design and testing to application and sustainability. J. Build. Eng. 2021, 43, 102870. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).