Linear Active Disturbance Rejection Control-Based Diagonal Recurrent Neural Network for Radar Position Servo Systems with Dead Zone and Friction

Abstract

:1. Introduction

- A.

- Literature Review

- B.

- Contributions Statement

- C.

- Paper Organization

2. Radar Position Servo System Modeling

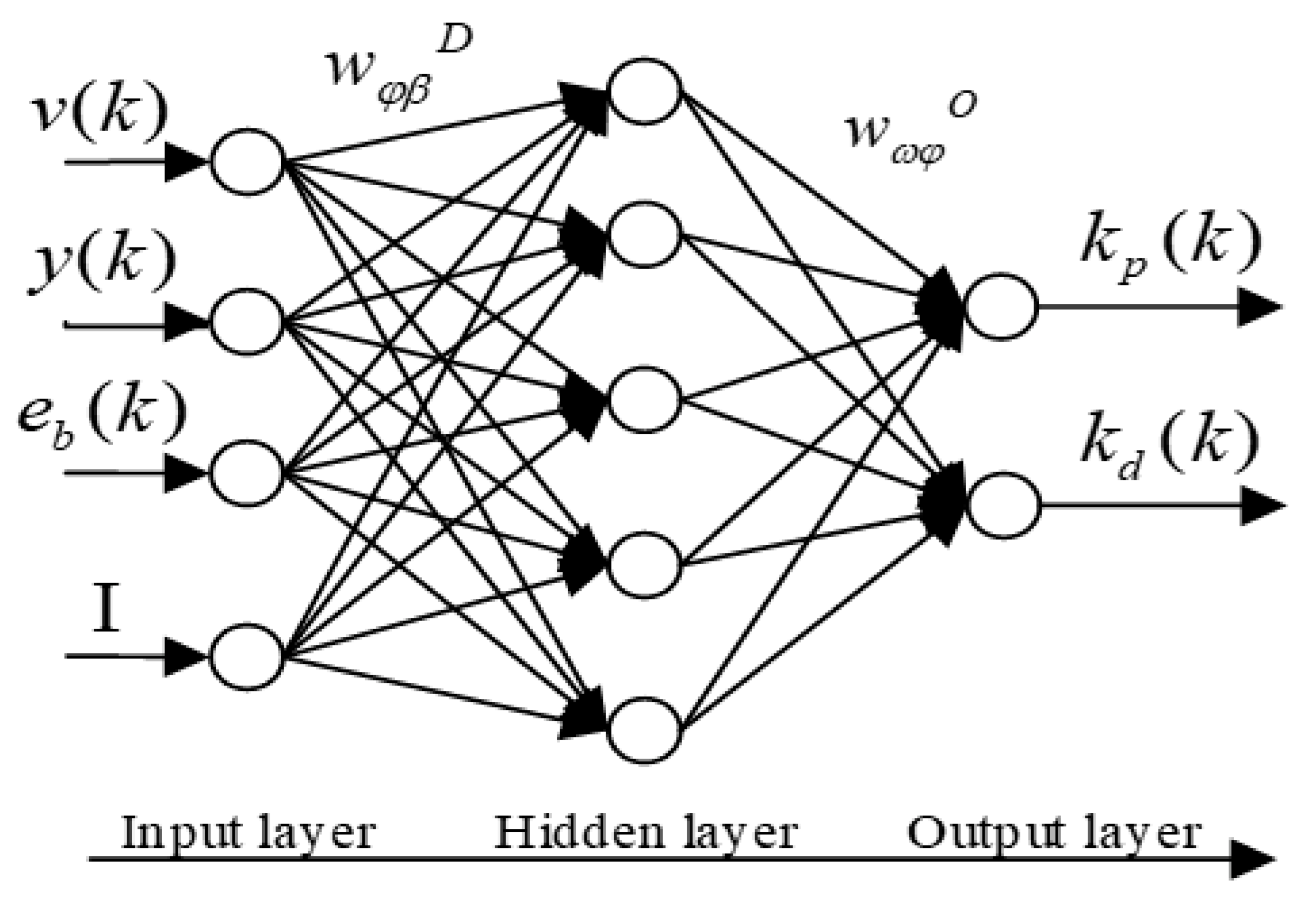

3. Compound Controller DRNN-LADRC Design

3.1. Preliminary to LADRC

3.2. Proposed Adaptive Tracking Differentiator Design

3.3. Proposed Improved LADRC Design

4. Case Study

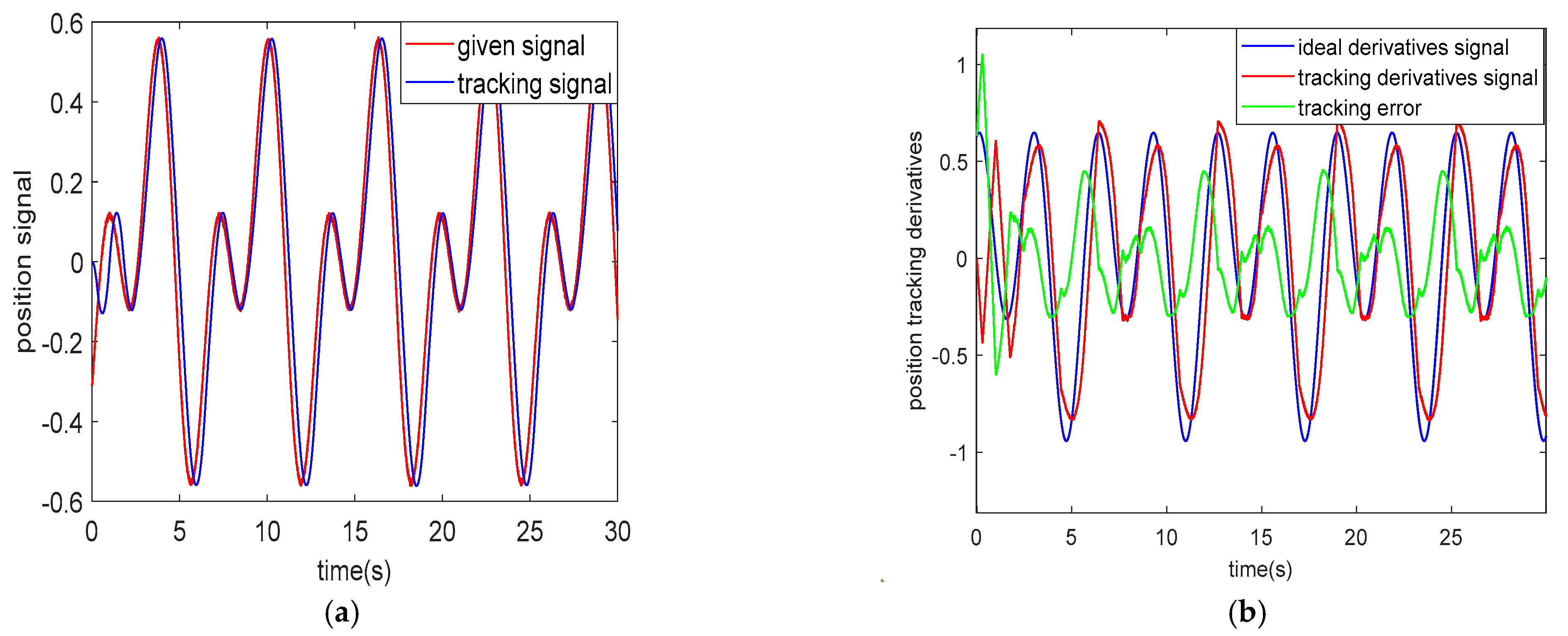

4.1. Case Study 1: Performance Comparison between ATD and TD

4.2. Case Study 2: Regular Controller Performances

4.3. Case Study 3: Performance Comparison between DRNN-LADRC and BPNN-LADRC

4.4. Case Study 4: Robust Performance Verification

4.5. Case Study 5: Step Response via the LADRC by Introducing ATD

4.6. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Y.; Zhang, Q.P.; Zhang, Y.C.; Pei, J.F.; Huang, Y.L.; Yang, J.Y. Fast Split Bregman Based Deconvolution Algorithm for Airborne Radar Imaging. Remote Sens. 2020, 12, 1747. [Google Scholar] [CrossRef]

- Cui, X.-D.; Yao, Z.-G.; Zhao, Z.-L.; Wang, M.-W.; Fan, C.-H.; Su, T. Comparison of Liquid Water Content Retrievals for Airborne Millimeter-Wave Radar with Different Particle Parameter Schemes. J. Trop. Meteorol. 2020, 6, 188–198. [Google Scholar]

- Yang, Z.W.; Xu, H.J.; Huang, P.H.; Liu, A.F.; Tian, M. Preliminary Results of Multichannel SAR-GMTI Experiments for Airborne Quad-Pol Radar System. IEEE Trans. Geosci. Remote Sens. 2020, 58, 3822–3840. [Google Scholar] [CrossRef]

- Zhou, Q.S.; Li, Z.H.; Shi, J.P.; Mao, Y.X. Robust cognitive transmit waveform and receive filter design for airborne MIMO radar in signal-dependent clutter environment. Digit. Signal Process. 2020, 101, 102709. [Google Scholar] [CrossRef]

- Mei, D.; Yu, Z.Q. Active disturbance rejection control strategy for airborne radar stabilization platform based on cascade extended state observer. Assem. Autom. 2020, 40, 613–624. [Google Scholar] [CrossRef]

- Ji, H.Y.; Li, Z.J.; Pan, K.D.; Zhang, Z.J. Shipborne Radar Servo Control based on Neural Sliding Mode Variable Structure. In Proceedings of the 2018 IEEE 3rd Advanced Information Technology, Electronic and Automation Control Conference (IAEAC), Chongqing, China, 12–14 October 2018; pp. 231–235. [Google Scholar]

- Li, B.A.; Tan, Y.H.; Zhou, L.; Dong, R.L. Robust-nonsmooth Kalman Filtering for Stochastic Sandwich Systems with Dead-zone. Int. J. Control Autom. Syst. 2020, 19, 101–111. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhao, S.Y.; Li, H.Y.; Lu, R.Q.; Wu, C.W. Adaptive Neural Network Tracking Control for Robotic Manipulators With Dead Zone. IEEE Trans. Neural Netw. Learn. Syst. 2018, 30, 1–10. [Google Scholar] [CrossRef]

- Sun, P. Adaptive Robust Motion Control of an Ironless Permanent Magnet Linear Synchronous Motor with Dead-zone Compensation. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–5. [Google Scholar]

- Lu, K.X.; Liu, Z.; Lai, G.Y.; Zhang, Y.; Chen, C.L.P. Adaptive Fuzzy Tracking Control of Uncertain Nonlinear Systems Subject to Actuator Dead Zone with Piecewise Time-varying Parameters. IEEE Trans. Fuzzy Syst. 2018, 27, 1493–1505. [Google Scholar] [CrossRef]

- Ren, J.B.; Wang, B.F.; Cai, M.J.; Yu, J.P. Adaptive Fast Finite-Time Consensus for Second-Order Uncertain Nonlinear Multi-Agent Systems with Unknown Dead-Zone. IEEE Access 2020, 8, 25557–25569. [Google Scholar] [CrossRef]

- Xing, M.M.; Zhou, L.L.; Zhang, C.M.; Xue, K.F.; Zhang, Z.Y. Simulation Analysis of nonlinear friction of rod string in Sucker Rod Pumping System. J. Comput. Nonlinear Dyn. 2019, 14, 091008. [Google Scholar] [CrossRef]

- Stribeck, R. Die wesentlichen Eigenschaften der Gleitund Rollenlager–The key qualities of sliding and roller bearings. Z. Des Ver. Dtsch. Ing. 1902, 46, 1342–1348. [Google Scholar]

- Wan, L.L.; Zhang, C.; Chen, Y. Adaptive steering control system of the USV with friction compensation. In Proceedings of the 2018 Chinese Automation Congress (CAC), Xi’an, China, 30 November–2 December 2018; pp. 1831–1834. [Google Scholar]

- Yang, H.J.; Sun, J.H.; Xia, Y.Q.; Zhao, L. Position Control for Magnetic Rodless Cylinders with Strong Static Friction. IEEE Trans. Ind. Electron. 2018, 65, 5806–5815. [Google Scholar] [CrossRef]

- Han, J.Q. From PID to Active Disturbance Rejection Control. IEEE Trans. Ind. Electron. 2009, 56, 900–906. [Google Scholar] [CrossRef]

- Gao, Z.Q. Scaling and bandwidth-parameterization based controller tuning. In Proceedings of the 2003 American Control Conference, Denver, CO, USA, 4–6 June 2003; Volume 6, pp. 4989–4996. [Google Scholar]

- Gao, Z.Q. On the centrality of disturbance rejection in automatic control. ISA Trans. 2014, 53, 850–857. [Google Scholar] [CrossRef] [Green Version]

- Zhang, M.; Zhuang, K.; Zhao, T.; Chen, X.; Xue, J.; Qiao, Z.; Cui, S.; Gao, Y. Bus Voltage Control of Photovoltaic Grid Connected Inverter Based on Adaptive Linear Active Disturbance Rejection. Energies 2022, 15, 5556. [Google Scholar] [CrossRef]

- Zhao, F.Z.; Wang, X.; Zhu, T. Low-Frequency Passivity-Based Analysis and Damping of Power-Synchronization Controlled Grid-Forming Inverter. IEEE J. Emerg. Sel. Top. Power Electron. 2022. [Google Scholar] [CrossRef]

- Chi, W.C.; Ma, S.J.; Sun, J.Q. A hybrid multi-degree-of-freedom vibration isolation platform for spacecrafts by the linear active disturbance rejection control. Appl. Math. Mech. 2020, 41, 805–818. [Google Scholar] [CrossRef]

- Ma, Y.J.; Yang, L.Y.; Zhou, X.S.; Yang, X.; Zhou, Y.L.; Zhang, B. Linear Active Disturbance Rejection Control for DC Bus Voltage Under Low-Voltage Ride-Through at the Grid-Side of Energy Storage System. Energies 2020, 13, 1207. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.Y.; Liu, J.Z.; Zhou, S.L. Linear active disturbance rejection control for pressurized water reactor power based on partial feedback linearization. Ann. Nucl. Energy 2019, 137, 107088. [Google Scholar] [CrossRef]

- Li, H.; Liu, X.X.; Lu, J.W. Research on Linear Active Disturbance Rejection Control in DC/DC Boost Converter. Electronics 2019, 8, 1249. [Google Scholar] [CrossRef] [Green Version]

- Elkenawy, A.; El-Nagar, A.M.; El-Bardini, M.; El-Rabaie, N.M. Diagonal recurrent neuron network observer-based adaptive control for unknown nonlinear systems. Trans. Inst. Meas. Control 2020, 42, 2833–2856. [Google Scholar] [CrossRef]

- Liu, T.; Liang, S.; Xiong, Q.Y.; Wang, K. Adaptive Critic based Optimal Neurocontrol of a Distributed Microwave Heating System using Diagonal Recurrent Network. IEEE Access 2018, 6, 68839–68849. [Google Scholar] [CrossRef]

- Kumar, R.; Srivastava, S.; Gupta, J.R.P. Diagonal recurrent neural network based adaptive control of nonlinear dynamical systems using lyapunov stability criterion. ISA Trans. 2017, 67, 407–427. [Google Scholar] [CrossRef] [PubMed]

- Kumar, R.; Srivastava, S.; Gupta, J.R.P.; Mohindru, A. Diagonal recurrent neural network based identification of nonlinear dynamical systems with Lyapunov stability based adaptive learning rates. Neurocomputing 2018, 287, 102–117. [Google Scholar] [CrossRef]

- Zhang, Q.; Guan, L.W.; Xu, D.X. Odometer Velocity and Acceleration Estimation Based on Tracking Differentiator Filter for 3D-Reduced Inertial Sensor System. Sensors 2019, 19, 4501. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, R.H.; Liu, C.; Ning, Y.H.; Xie, Y. Improved auto-disturbance rejection controller of radar servo-system with high tracking accuracy. J. Electr. Mach. Control 2019, 23, 102–109. [Google Scholar]

- Wang, R.L.; Lu, B.C.; Hou, Y.L.; Gao, Q. Passivity-Based Control for Rocket Launcher Position Servo System Based on ADRC Optimized by IPSO-BP Algorithm. Shock. Vib. 2018, 2018, 5801573. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Q.; Goforth, F.J. A disturbance rejection based control approach for hysteretic systems. In Proceedings of the 49th IEEE Conference on Decision and Control (CDC), Atlanta, GA, USA, 15–17 December 2010; pp. 3748–3753. [Google Scholar]

- Gao, Z.Q.; Huang, Y.; Han, J.Q. An alternative paradigm for control system design. In Proceedings of the 40th IEEE Conference on Decision and Control, Orlando, FL, USA, 4–7 December 2001; pp. 4578–4585. [Google Scholar]

- Dinkar, S.K.; Deep, K. Opposition-based antlion optimizer using Cauchy distribution and its application to data clustering problem. Neural Comput. Appl. 2019, 32, 6967–6995. [Google Scholar] [CrossRef]

- Liu, W.C.; Cheng, L.; Hou, Z.G.; Tan, M. An active disturbance rejection controller with hysteresis compensation for piezoelectric actuators. In Proceedings of the 2016 12th World Congress on Intelligent Control and Automation (WCICA), Guilin, China, 12–15 June 2016; pp. 2148–2153. [Google Scholar]

- Ku, C.C.; Lee, K.Y. System Identification and Control Using Diagonal Recurrent Neural networks. In Proceedings of the 1992 American Control Conference, Chicago, IL, USA, 24–26 June 1992; pp. 545–549. [Google Scholar]

- Liu, T.; Liang, S.; Xiong, Q.Y.; Wang, K. Two-Stage Method for Diagonal Recurrent Neural Network Identification of a High-Power Continuous Microwave Heating System. Neural Process. Lett. 2019, 50, 2161–2182. [Google Scholar] [CrossRef]

- Yuan, R.F.; Wu, G.Q. Mechanism analysis of vehicle start-up judder based on gradient characteristic of Stribeck effect. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2019, 234, 505–521. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, S.; Zhu, G.; Zhao, T. Linear Active Disturbance Rejection Control-Based Diagonal Recurrent Neural Network for Radar Position Servo Systems with Dead Zone and Friction. Appl. Sci. 2022, 12, 12839. https://doi.org/10.3390/app122412839

Cui S, Zhu G, Zhao T. Linear Active Disturbance Rejection Control-Based Diagonal Recurrent Neural Network for Radar Position Servo Systems with Dead Zone and Friction. Applied Sciences. 2022; 12(24):12839. https://doi.org/10.3390/app122412839

Chicago/Turabian StyleCui, Shuai, Guixin Zhu, and Tong Zhao. 2022. "Linear Active Disturbance Rejection Control-Based Diagonal Recurrent Neural Network for Radar Position Servo Systems with Dead Zone and Friction" Applied Sciences 12, no. 24: 12839. https://doi.org/10.3390/app122412839