Progressive Failure Analysis for 5MW-Class Wind Turbine Composite Blades with Debonding Damage based on CZM Method

Abstract

1. Introduction

2. Experimental and Numerical Failure Analysis of Adhesive Joints

2.1. Theoretical Background

2.2. Specimen Preparation

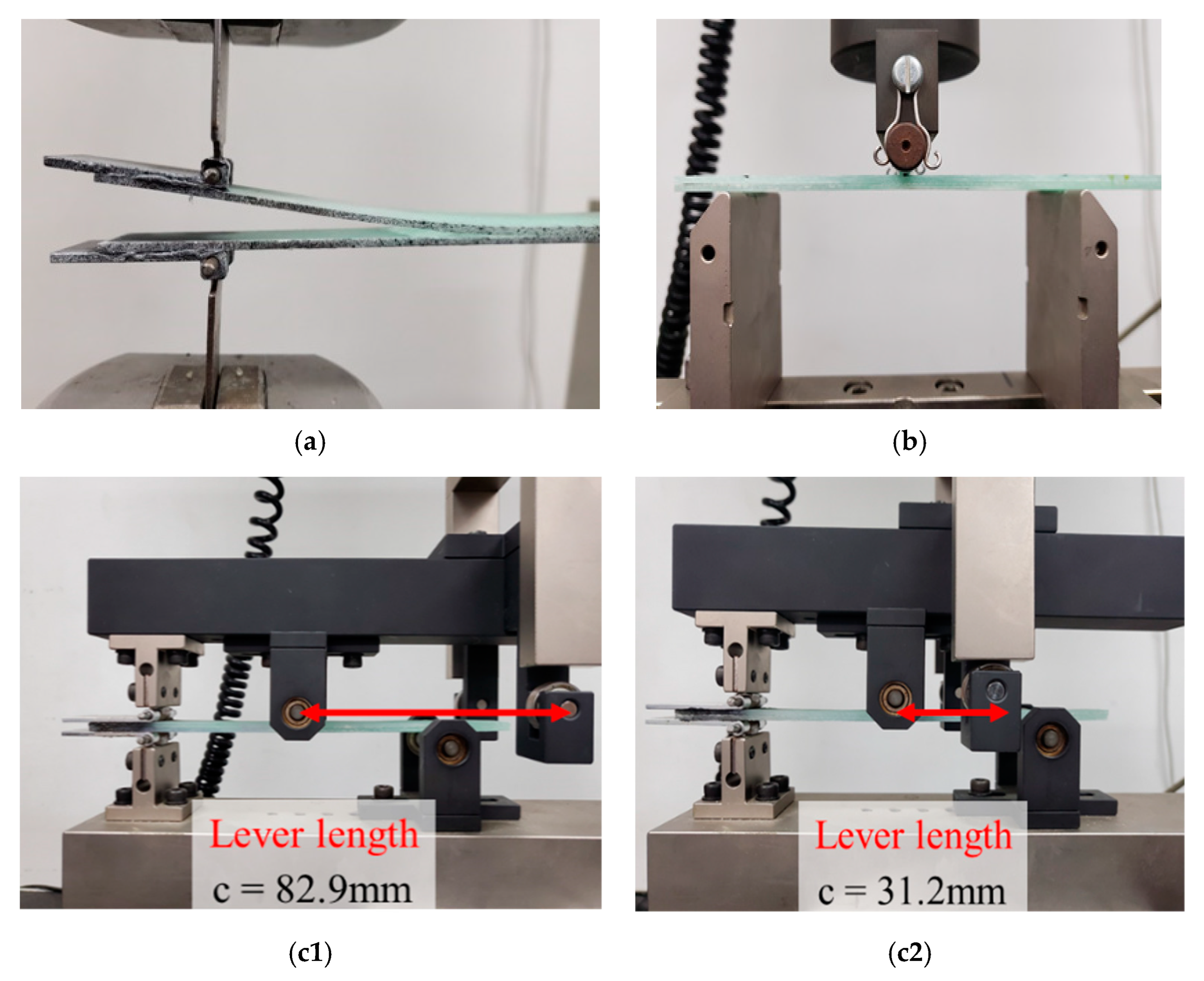

2.3. Experimental Test Procedure

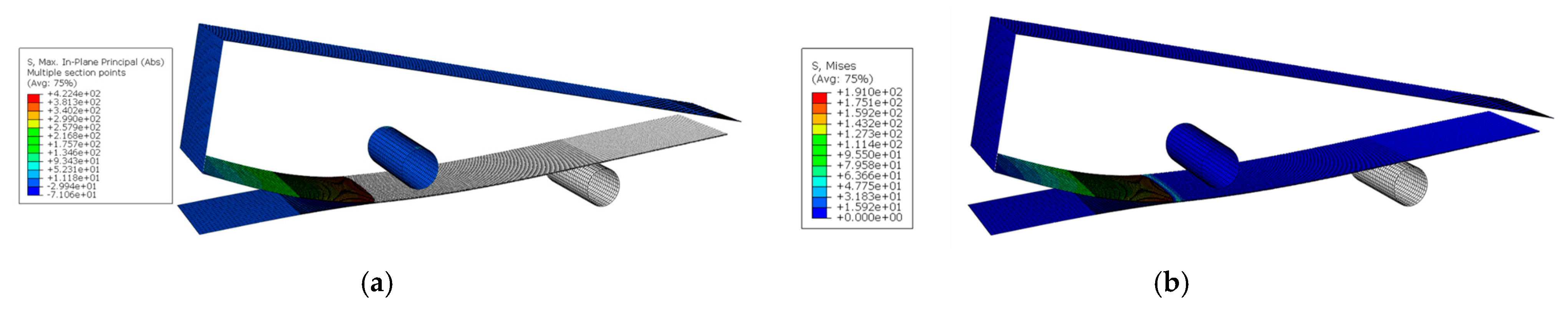

2.4. FE Analysis—Numerical Modeling Method for Test Specimen-Level

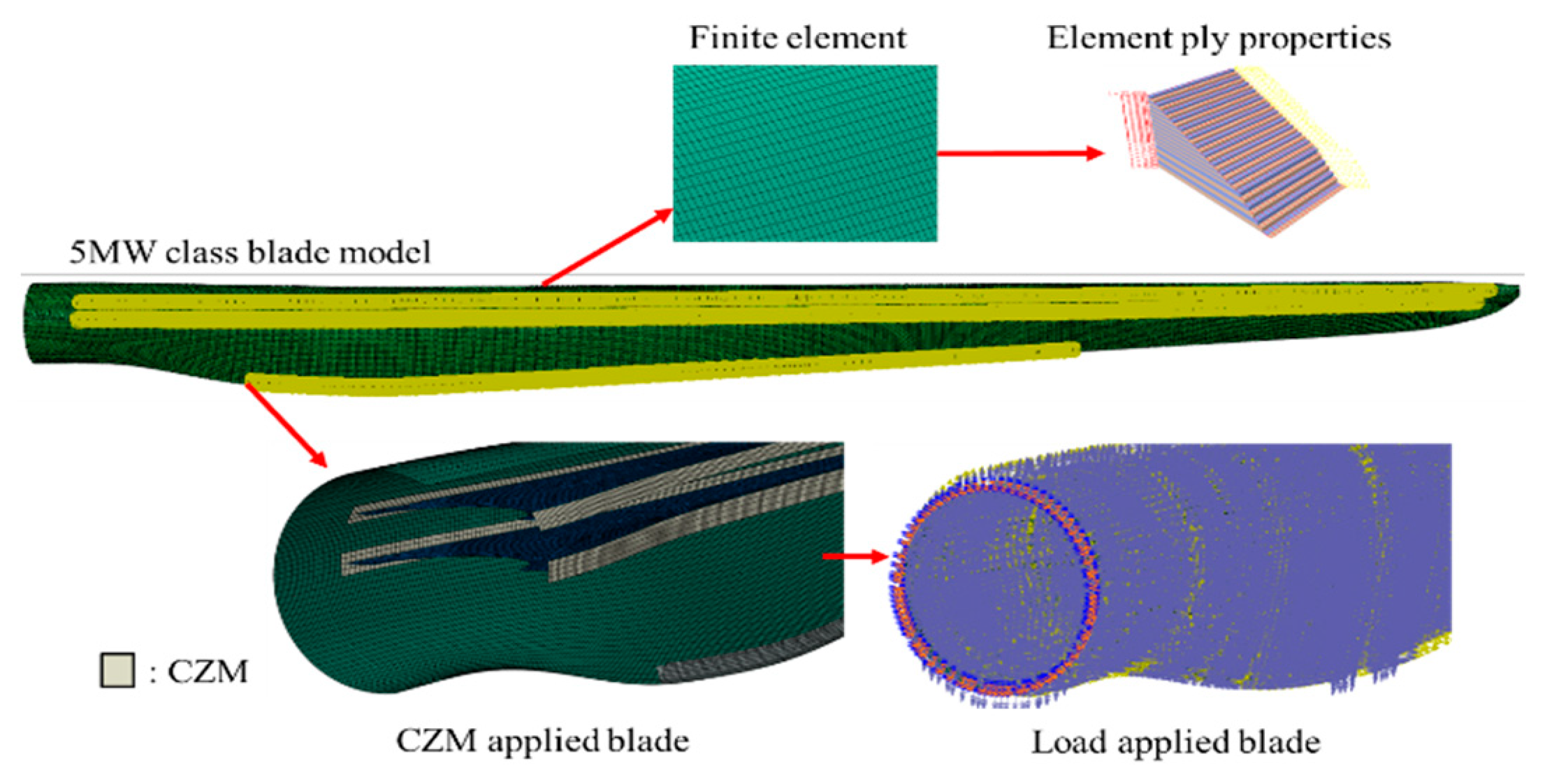

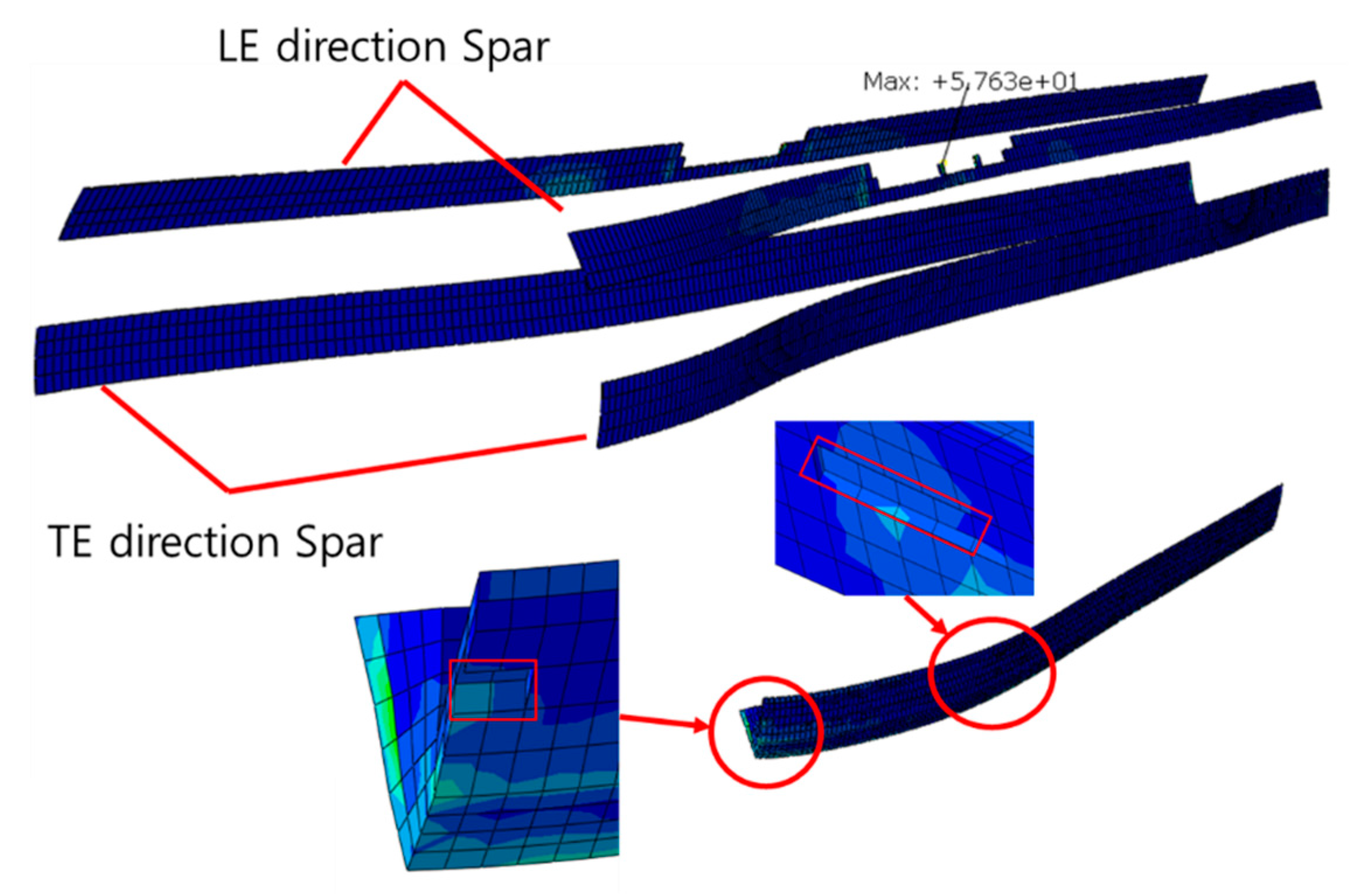

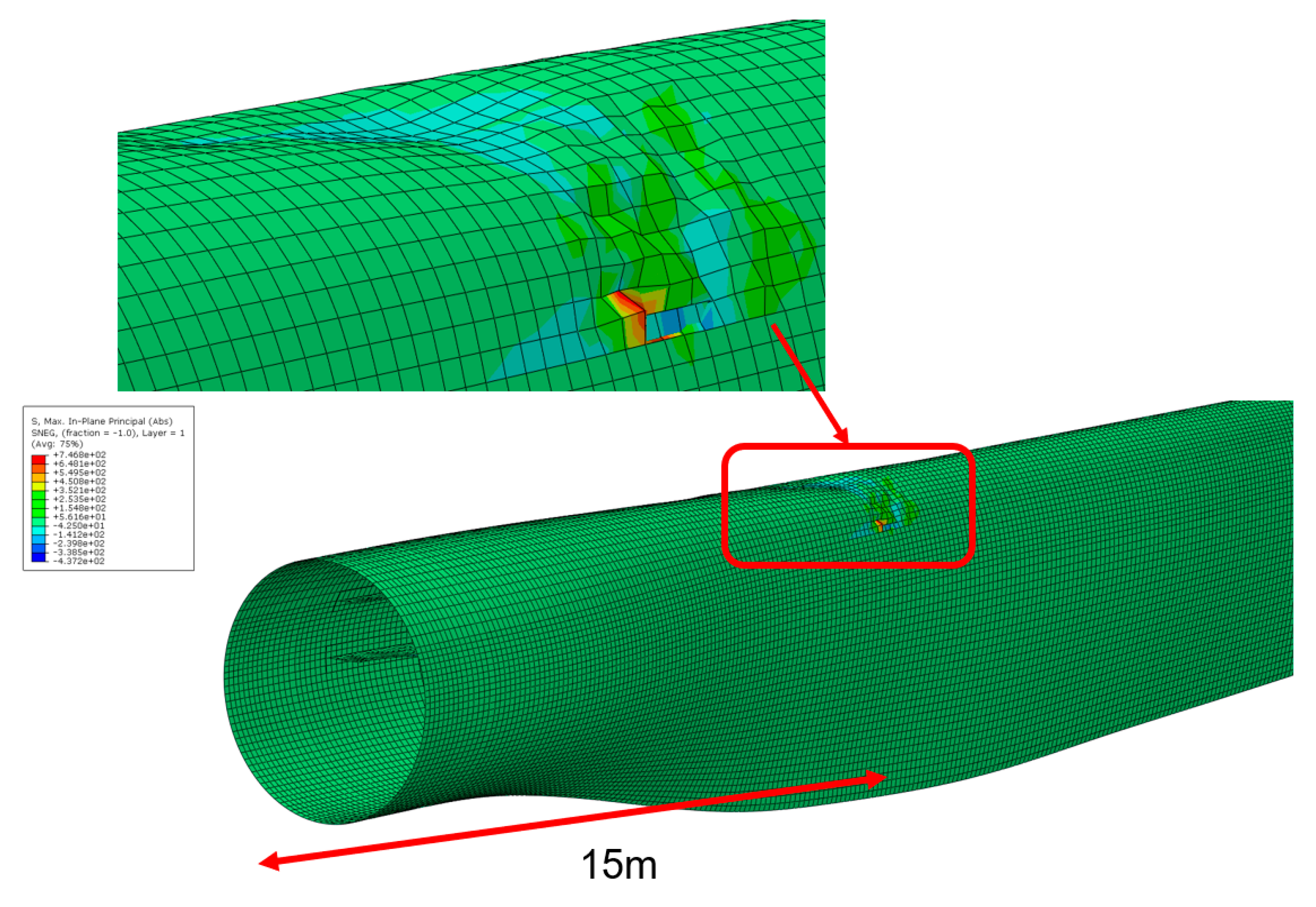

2.5. Composite Blade Numerical Modeling Method

3. Results

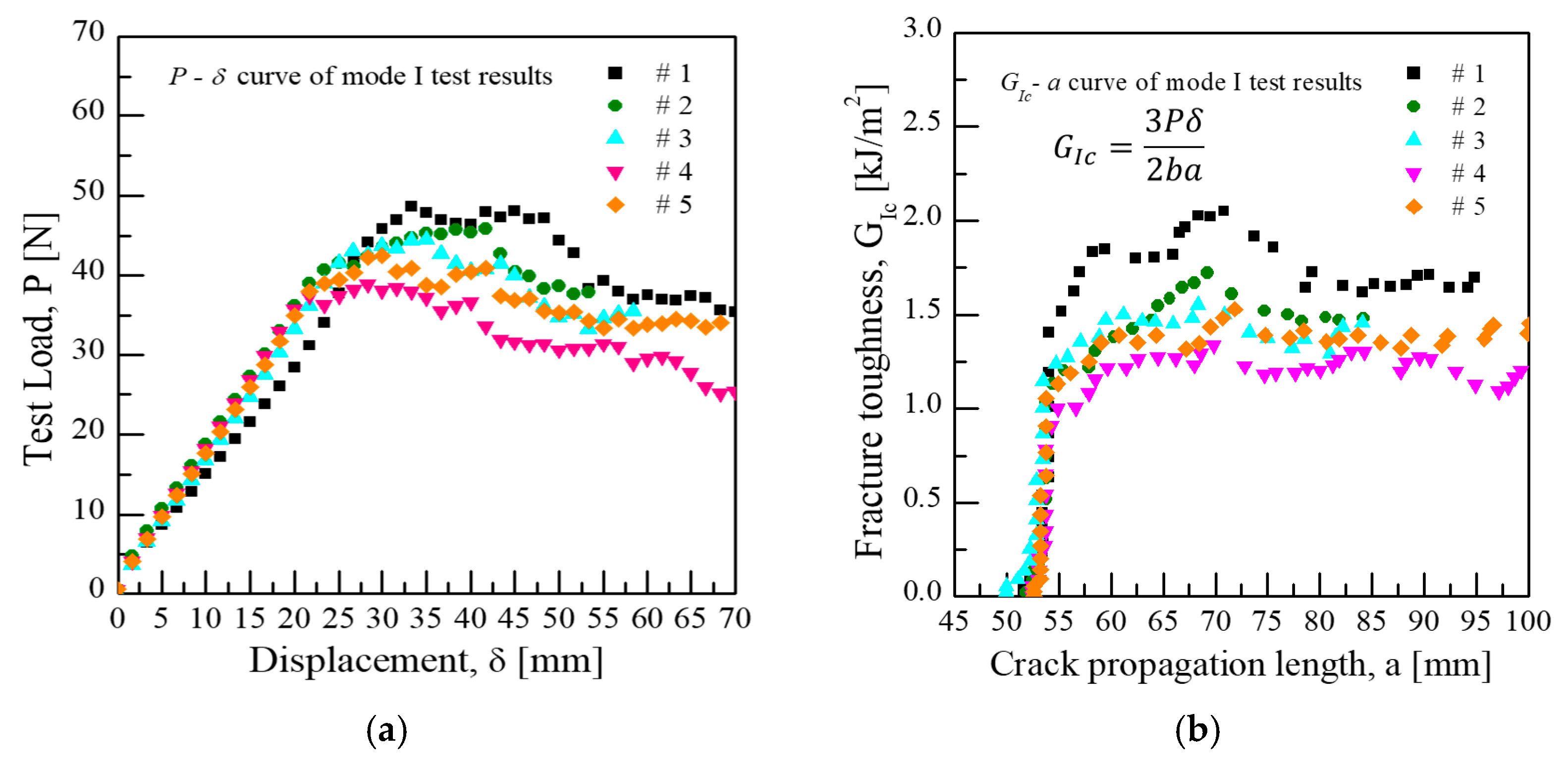

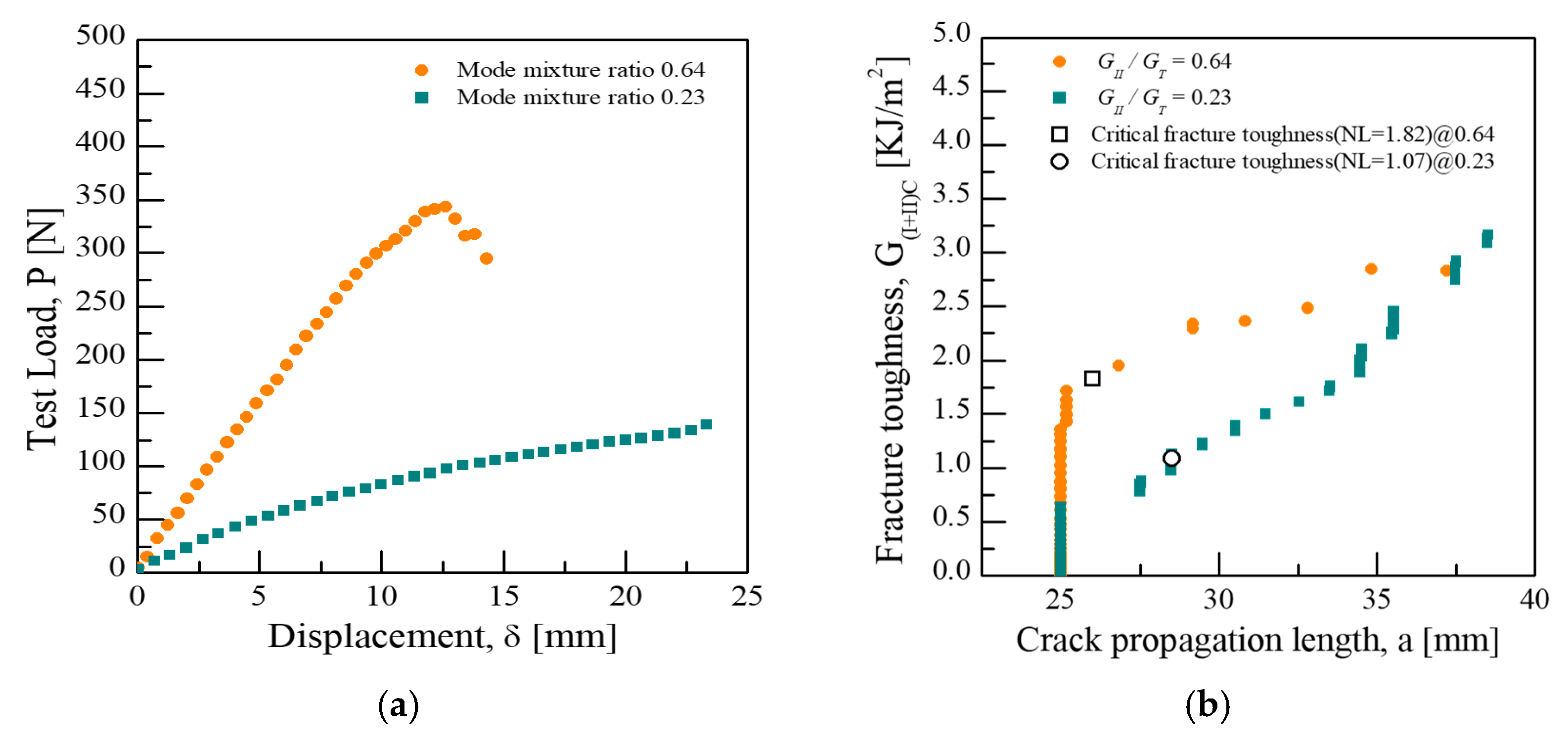

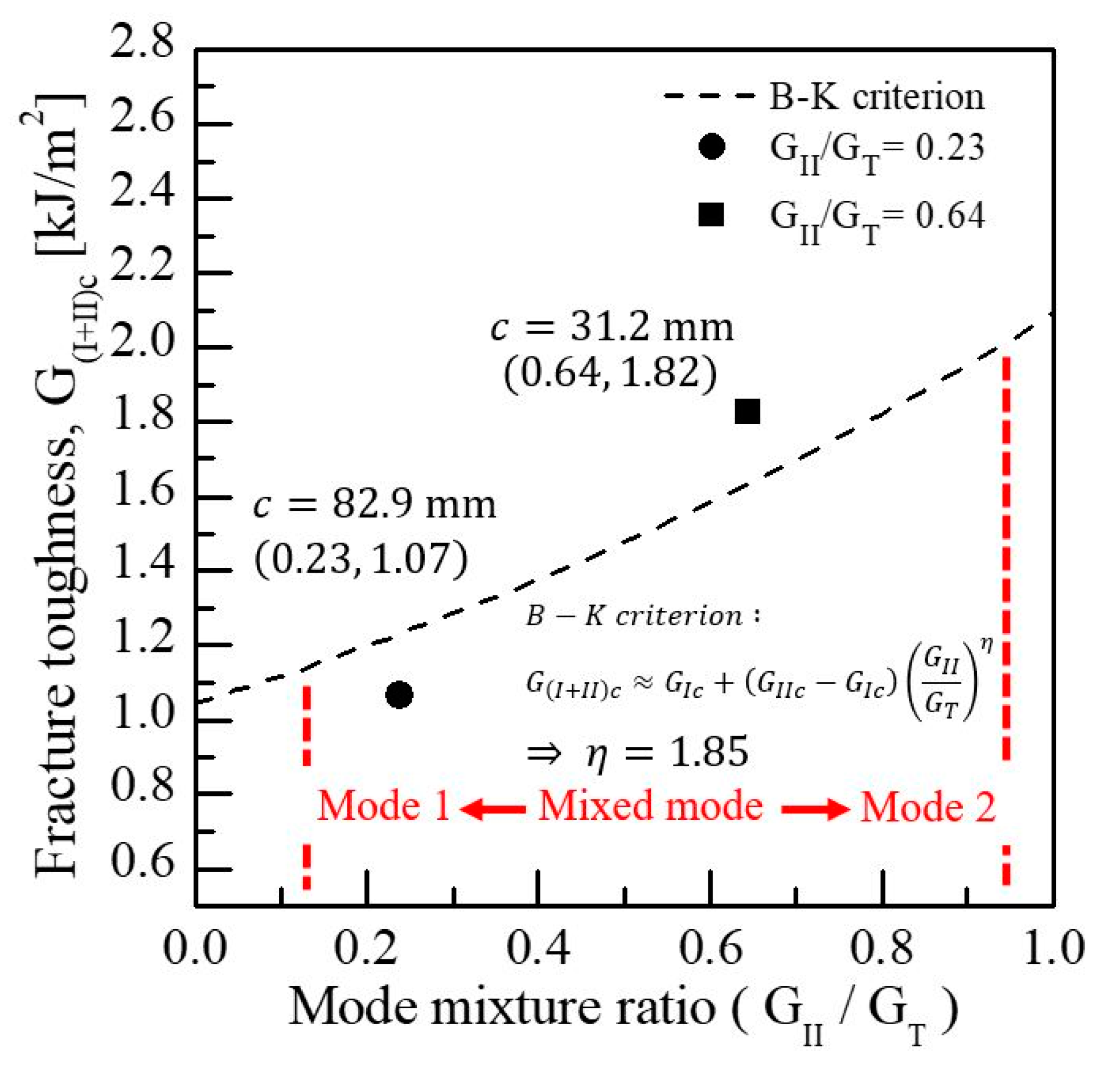

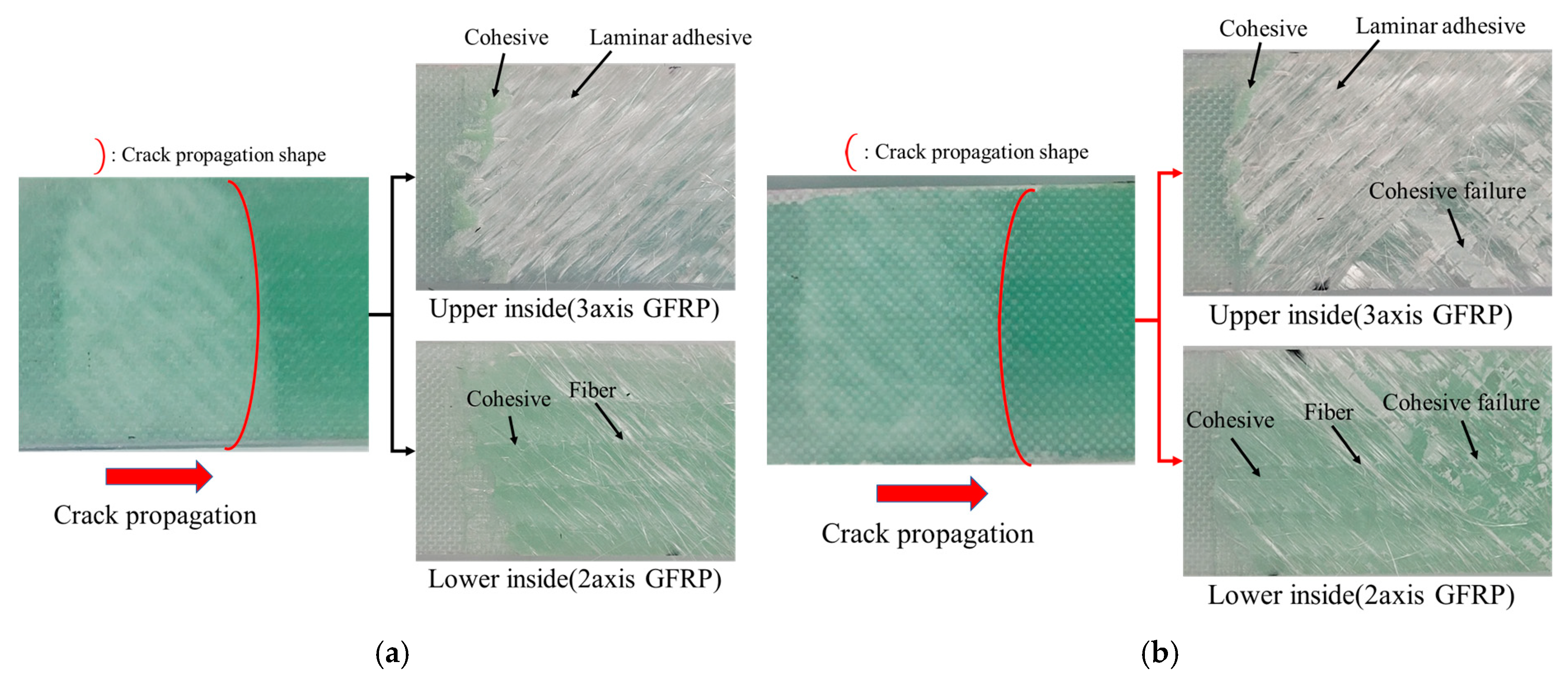

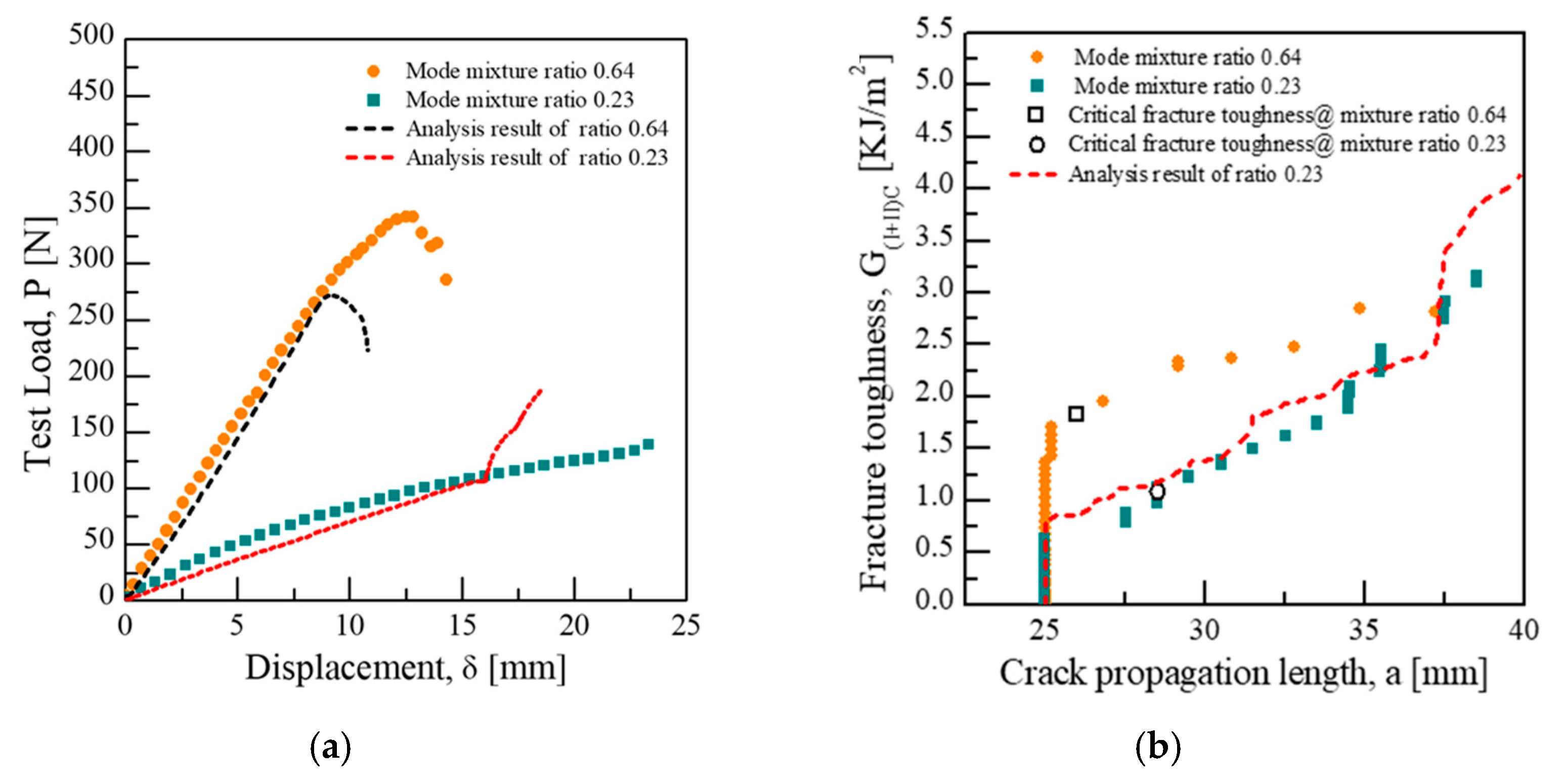

3.1. Fracture Toughness for Mode I, Mode II, and Mixed-Mode Tests

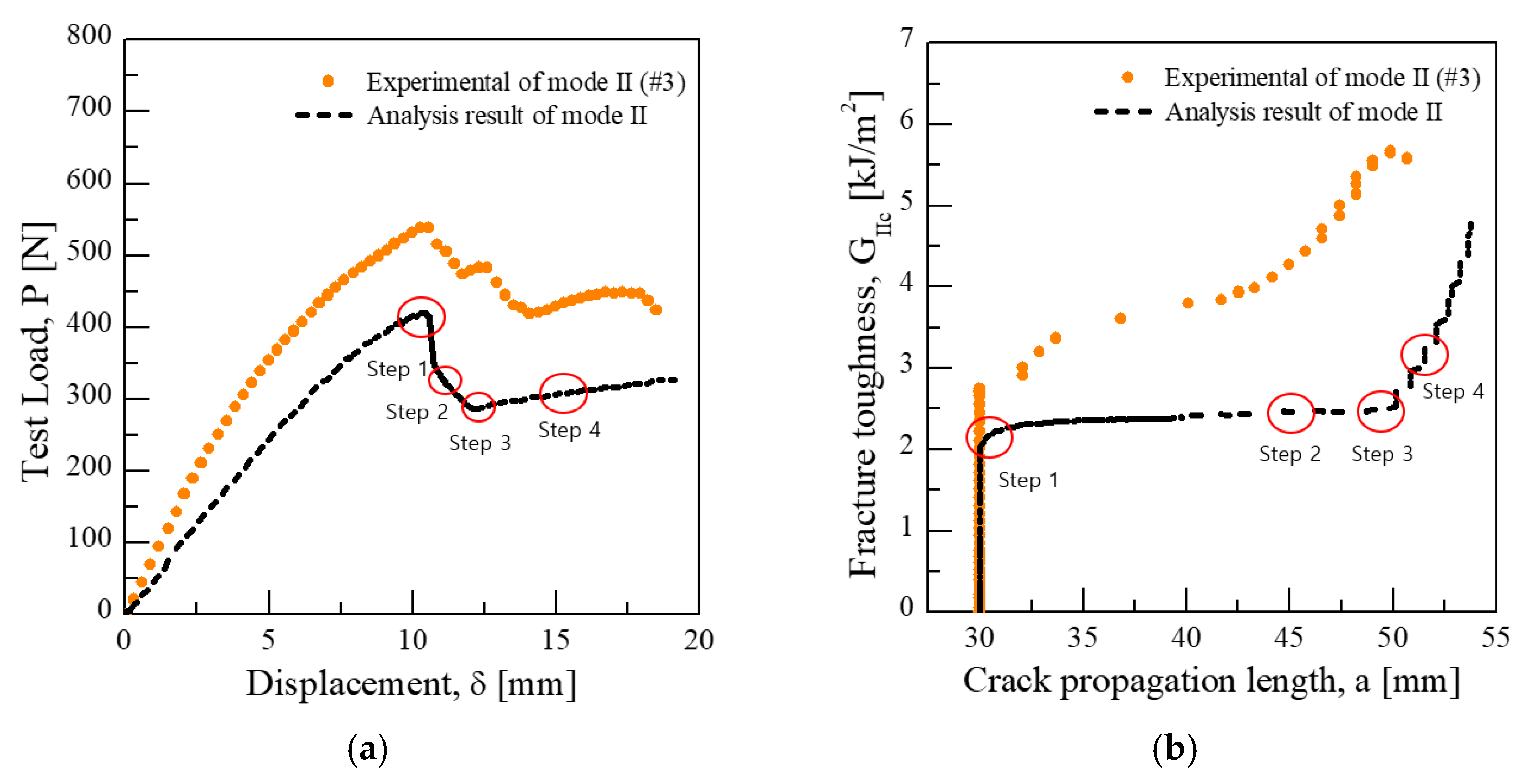

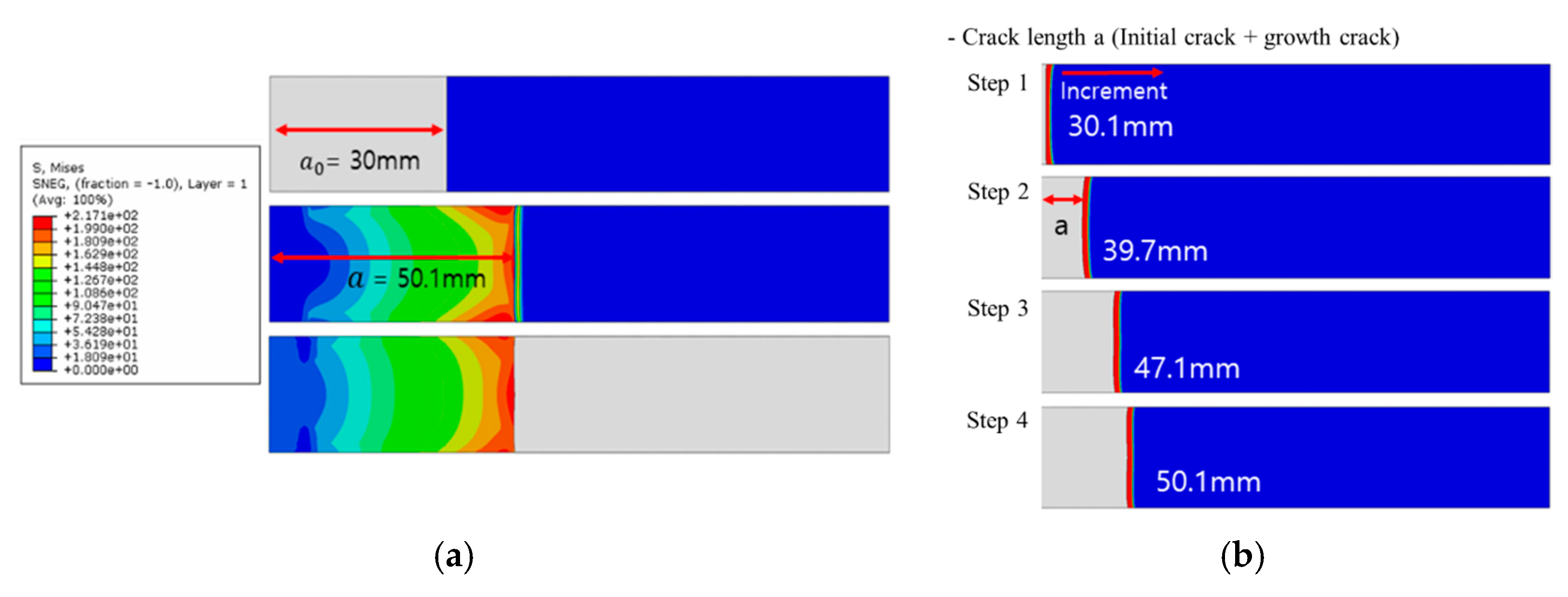

3.2. FE Analysis for Mode I, Mode II, and Mixed-Mode Tests

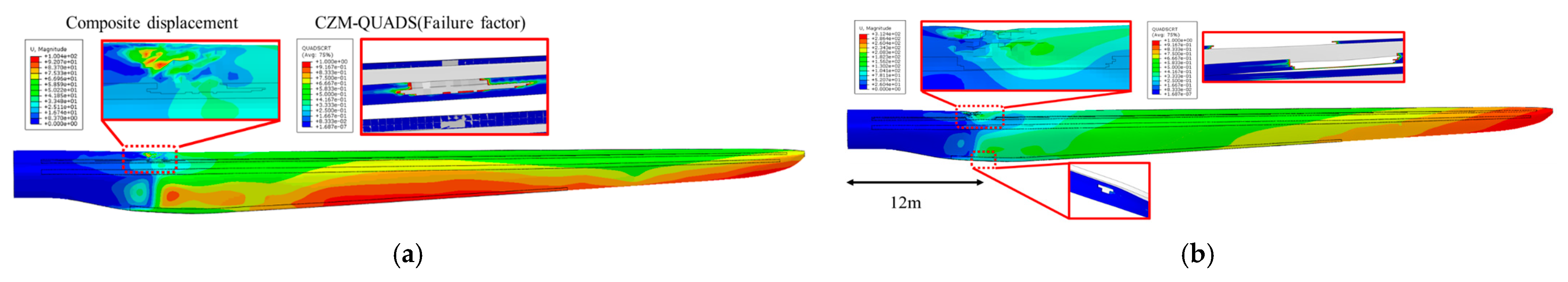

3.3. Progressive Failure Analysis for Full-Scale Composite Blade

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Eder, M.A.; Bitsche, R.D. Fracture analysis of adhesive joints in wind turbine blades. Wind Energy 2015, 18, 1007–1022. [Google Scholar] [CrossRef]

- Kretsis, G. A Review of the tensile, compressive, flexural and shear properties of hybrid fibre-reinforced plastic. Composites 1989, 18, 13–23. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part A 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Chen, X.; Zhao, W.; Zhao, X.L.; Xu, J.Z. Failure test and finite element simulation of a large wind turbine composite blade under static loading. Energies 2014, 7, 2274–2297. [Google Scholar] [CrossRef]

- Sang, S.M.; Kwak, J.H.; Kwon, O.H. The study on the interlaminar fracture toughness of the laminated UHMWPE/CFRP composite. Master’s Thesis, Pukyoung National University, Busan, Republic of Korea, 2020. [Google Scholar]

- Al-Khudairi, O.; Hadavinia, H.; Little, C.; Gillmore, G.; Greaves, P.; Dyer, K. Full-scale fatigue testing of a wind turbine blade in flapwise direction and examining the effect of crack propagation on the blade performance. Materials 2017, 10, 1152. [Google Scholar] [CrossRef] [PubMed]

- Robert, W.M.; Alessandro, S.; Andrew, S.; Robert, H.G.; Christopher, N. Comparison of nondestructive testing techniques for the inspection of wind turbine blades spar caps. Wind Energy 2018, 21, 980–996. [Google Scholar]

- Gulasik, H.; Coker, D. Delamination-debond behaviour of composite T-joints in wind turbine blades. J. Phys. Conf. Ser. 2014, 524, 1–11. [Google Scholar] [CrossRef]

- Ji, Y.M.; Han, K.S. Fracture mechanics approach for failure of adhesive joints in wind turbine blades. Renew. Energy 2013, 65, 23–28. [Google Scholar] [CrossRef]

- Philipp, U.H.; Kim, B. Effect of trailing edge damage on full-scale wind turbine blade failure. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Roham, R.; Mohammad, R.H.-T. Failure analysis of a composite wind turbine at the adhesive Joint of the trailing edge. Eng. Fail. Anal. 2021, 121, 105148. [Google Scholar]

- Lahuertam, F.; de Ruiter, M.J.; Espinosa, L.; Smissaert, D. Assessment of wind turbine blade trailing edge failure with sub-component tests. In Proceedings of the 21st International Conference on Composite Materials, Xi’an, China, 20–25 August 2017. [Google Scholar]

- Philipp, U.H. An advanced structural trailing edge modelling method for wind turbine blades. Compos. Struct. 2017, 180, 521–530. [Google Scholar]

- Jang, Y.J.; Jin, J.W.; Lee, J.H.; Kang, K.W. Long-term durability of offshore wind turbine composite blades based on nonlinear load behavior due to pitch movement. J. Mech. Sci. Technol. 2020, 34, 2347–2355. [Google Scholar] [CrossRef]

- ASTM D6671/D6671M-06; Standard Test Method for Mixed Mode I—Mode II Interlaminar Fracture Toughness of Unidirectional Fiber Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2013. [CrossRef]

- ASTM D5528-01; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2017. [CrossRef]

- ASTM D7905/D7905M-19e1; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Kunigal, N.S.; Raghu, P.; John, S.; Sandi, M. Assessment of mode-II fracture tests for unidirectional fiber reinforced composite laminates. J. Reinf. Plast. Compos. 2015, 34, 1905–1925. [Google Scholar]

- Kim, H.G.; Jang, Y.J.; Kang, K.W. Evaluation of interlayer fracture toughness of laminated biaxial/triaxial hybrid composite for wind turbine blade. J. Wind Energy 2021, 12, 68–79. [Google Scholar]

- Brian, R.R. Definition of a 5MW/61.5MW wind turbine blade reference model. Sandia National Laboratories: Albuquerque, NM, USA, 2013; SAND2013-2569:463454. [Google Scholar]

- Cui, W.C.; Wisnom, M.R.; Jones, M. A comparison of failure criteria to predict delamination of unidirectional glass/epoxy specimens waisted through the thickness. Composites 1992, 23, 158–166. [Google Scholar] [CrossRef]

- Benzeggagh, M.L.; Kenane, M. Measurement of mixed-mode delamination fracture toughness of unidirectional glass/epoxy composites with mixed-mode bending apparatus. Compos. Sci. Technol. 1996, 56, 439–449. [Google Scholar] [CrossRef]

- Camanho, P.P.; Davila, C.G. Mixed-Mode Decohesion Finite Elements for the Simulation of Delamination in Composite Materials; NASA/TM-2002-211737; NASA Technical Reports Server: Washington, DC, USA, 2002. [Google Scholar]

- Camanho, P.P.; Davila, C.G.; de Moura, M.F. Numerical simulation of mixed-mode progressive delamination in composite materials. J. Compos. Mater. 2003, 37, 1415–1438. [Google Scholar] [CrossRef]

- SOBRIETY Corp. MercuryRT Rear-time tracking system. Available online: http://www.dynrot.eu/t_optical_systems_en.htm (accessed on 9 December 2022).

- ABAQUS 2021 User’s Manual; Dssault System’s Simulia Corp.: Providence, RI, USA, 2021.

- Kim, D.W.; Jeong, G.; Lim, J.H.; Yu, B.M.; Lee, K.S. A lightweight design of the spar cap of wind turbine blades with carbon fiber composite and ply reduction ratio. J. Aerosp. Syst. Eng. 2018, 12, 66–75. [Google Scholar]

- Frantisek, S.; Tomas, K.; Karel, R. Determination of mode II interlaminar fracture toughness of CFRP composites using numerical simulations. Key Eng. Mater. 2019, 801, 71–76. [Google Scholar]

| Stiffness [MPa] | KI | 4500 |

| KII | 4270 | |

| KIII | 4270 | |

| Strength [MPa] | SI | 64.92 |

| SII | 113 | |

| SIII | 113 |

| 3axis GFRP | 2axis GFRP | |

|---|---|---|

| E11 [MPa] | 26,700 | 10,900 |

| E22 [MPa] | 13,300 | 10,900 |

| G13 [MPa] | 74,600 | 11,600 |

| ν | 0.513 | 0.646 |

| ρ [kg/m3] | 2267 | 2243 |

| Rated power (MW) | 5 | Blade set angle (°) | 0 |

| Class | IIA | Rotor shaft tilt angle (°) | 5 |

| No. of blades | 3 | Maximum chord length (m) | 4.1 |

| Blade length (m) | 61.5 | Rotor overhang (m) | 5 |

| Hub height (m) | 90.55 | Rotor position | Upwind |

| Tower height (m) | 88.15 | Transmission | Gearbox |

| Cut-in wind speed (m/s) | 3 | Power control | Pitch |

| Rated wind speed (m/s) | 11.4 | Fixed/Variable | Variable |

| Cut-out wind speed (m/s) | 25 | Gear Ratio | 97 |

| Rated rotational speed (rpm) | 12.1 | Substructure type | Jacket |

| Load Case | Fx [kN] | Fy [kN] | Fz [kN] | Mx [kNm] | My [kNm] | Mz [kNm] | ||

|---|---|---|---|---|---|---|---|---|

| Fx | Max | dlc1.2k4 | 542.2 | −154.0 | 857.0 | 13,664 | 2784.7 | −385.1 |

| Min | dlc6.4b1 | −345.5 | −51.5 | −125.8 | −7659.2 | 1339.5 | 127.3 | |

| Fy | Max | dlc1.2k5 | 138.0 | 346.1 | 894.8 | 4482.3 | −8479.7 | −200.6 |

| Min | dlc1.2k5 | 193.6 | −270.5 | 826.3 | 1962.2 | 7784.2 | −147.6 | |

| Fz | Max | dlc1.2k5 | 112.6 | 64.5 | 1207.9 | 1622.7 | −1579.8 | −193.3 |

| Min | dlc6.4b3 | −137.7 | −6.10 | −236.5 | −4069.6 | 684.0 | 80.0 | |

| Mx | Max | dlc1.2f4 | 499.9 | −46.6 | 614.9 | 18,051 | 635.5 | −414.9 |

| Min | dlc6.4b3 | −297.5 | −59.2 | −203.7 | −8005.4 | 2009.3 | 151.5 | |

| My | Max | dlc1.2k5 | 193.6 | −270.5 | 826.3 | 1962.2 | 7784.2 | −147.6 |

| Min | dlc1.2k5 | 138.0 | 346.1 | 894.8 | 4482.3 | −8479.7 | −200.6 | |

| Mz | Max | dlc6.4b5 | −211.7 | −39.5 | −233.5 | −6822.9 | 2050.6 | 193.1 |

| Min | dlc1.2f3 | 535.6 | −204.3 | 838.8 | 17440 | 4034.7 | −472.5 | |

| Mode Mixture Ratio | 23% | 64% |

|---|---|---|

| c [mm] | 82.9 | 31.2 |

| P [N] | 107.2 | 340.2 |

| 1.07 | 1.82 |

| Fracture toughness | 1.12 | |

| 2.02 | ||

| 2.02 | ||

| Material constant | B–K criterion [Mixed-mode], | 1.85 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jang, Y.; Kim, H.; Kang, K. Progressive Failure Analysis for 5MW-Class Wind Turbine Composite Blades with Debonding Damage based on CZM Method. Appl. Sci. 2022, 12, 12973. https://doi.org/10.3390/app122412973

Jang Y, Kim H, Kang K. Progressive Failure Analysis for 5MW-Class Wind Turbine Composite Blades with Debonding Damage based on CZM Method. Applied Sciences. 2022; 12(24):12973. https://doi.org/10.3390/app122412973

Chicago/Turabian StyleJang, Yunjung, Hakgeun Kim, and Kiweon Kang. 2022. "Progressive Failure Analysis for 5MW-Class Wind Turbine Composite Blades with Debonding Damage based on CZM Method" Applied Sciences 12, no. 24: 12973. https://doi.org/10.3390/app122412973

APA StyleJang, Y., Kim, H., & Kang, K. (2022). Progressive Failure Analysis for 5MW-Class Wind Turbine Composite Blades with Debonding Damage based on CZM Method. Applied Sciences, 12(24), 12973. https://doi.org/10.3390/app122412973