A Numerical Study on Blade Design and Optimization of a Helium Expander for a Hydrogen Liquefaction Plant

Abstract

:1. Introduction

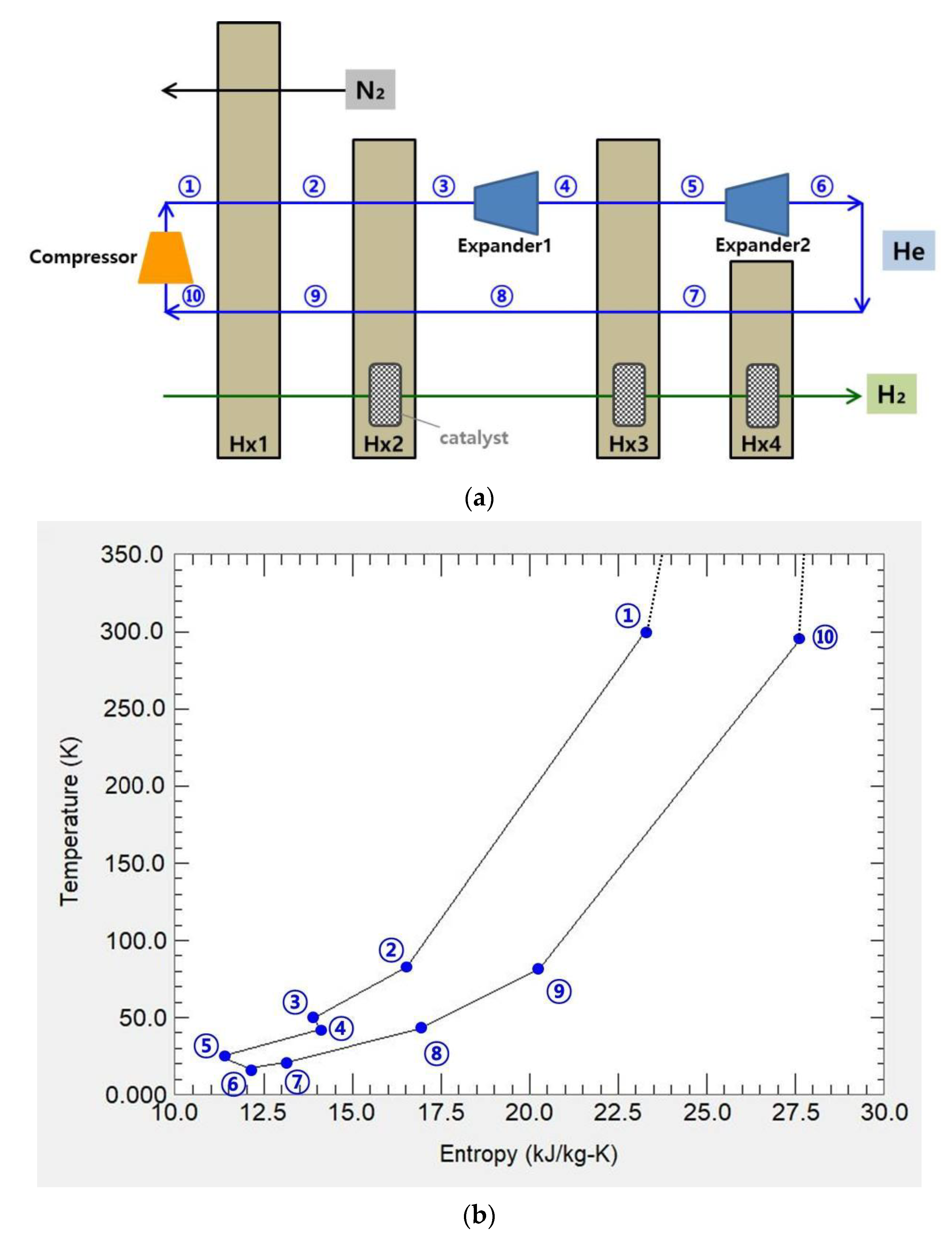

2. Operation Conditions

3. Expander Design

3.1. Preliminary Design

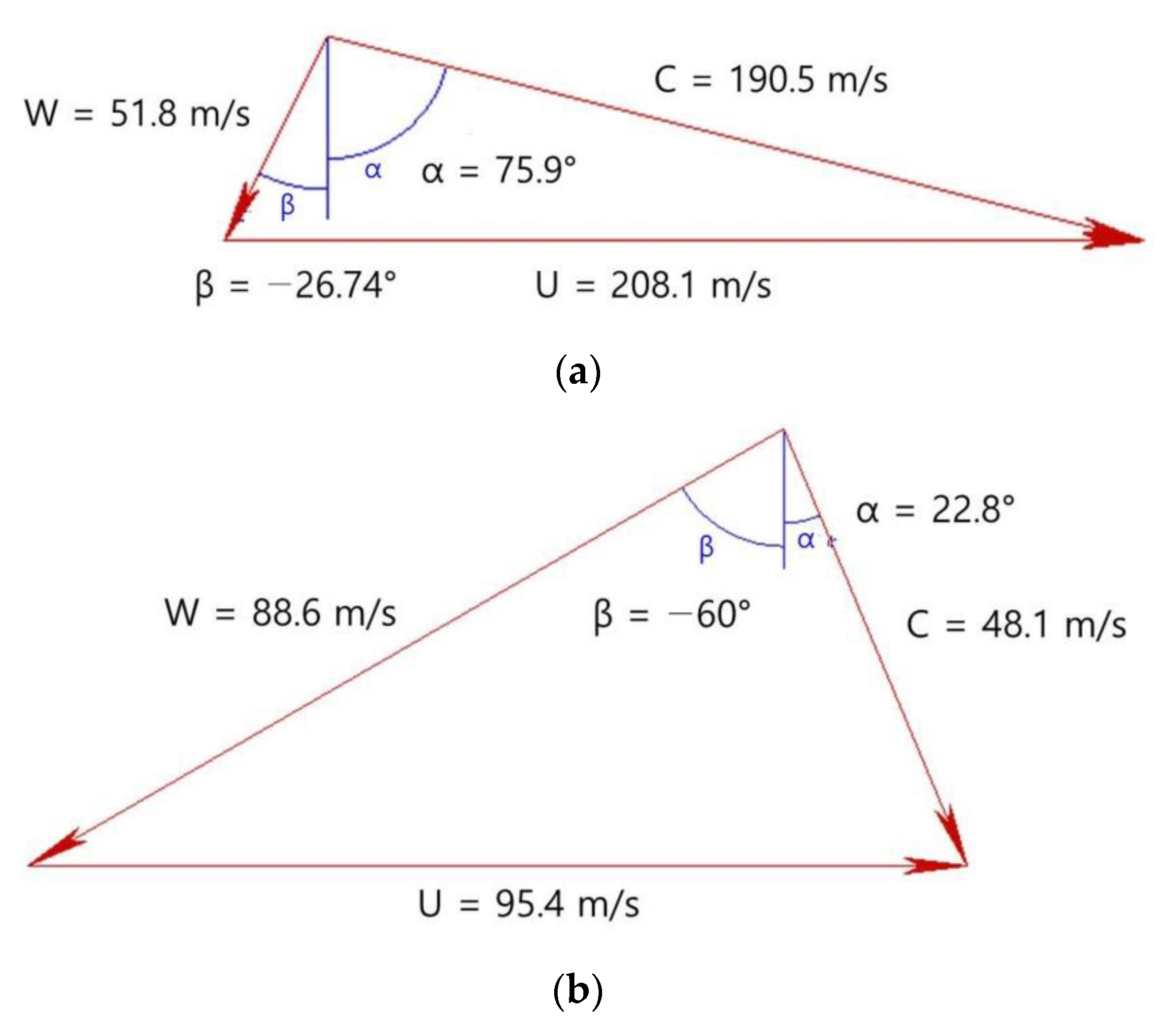

3.2. Meanline Design

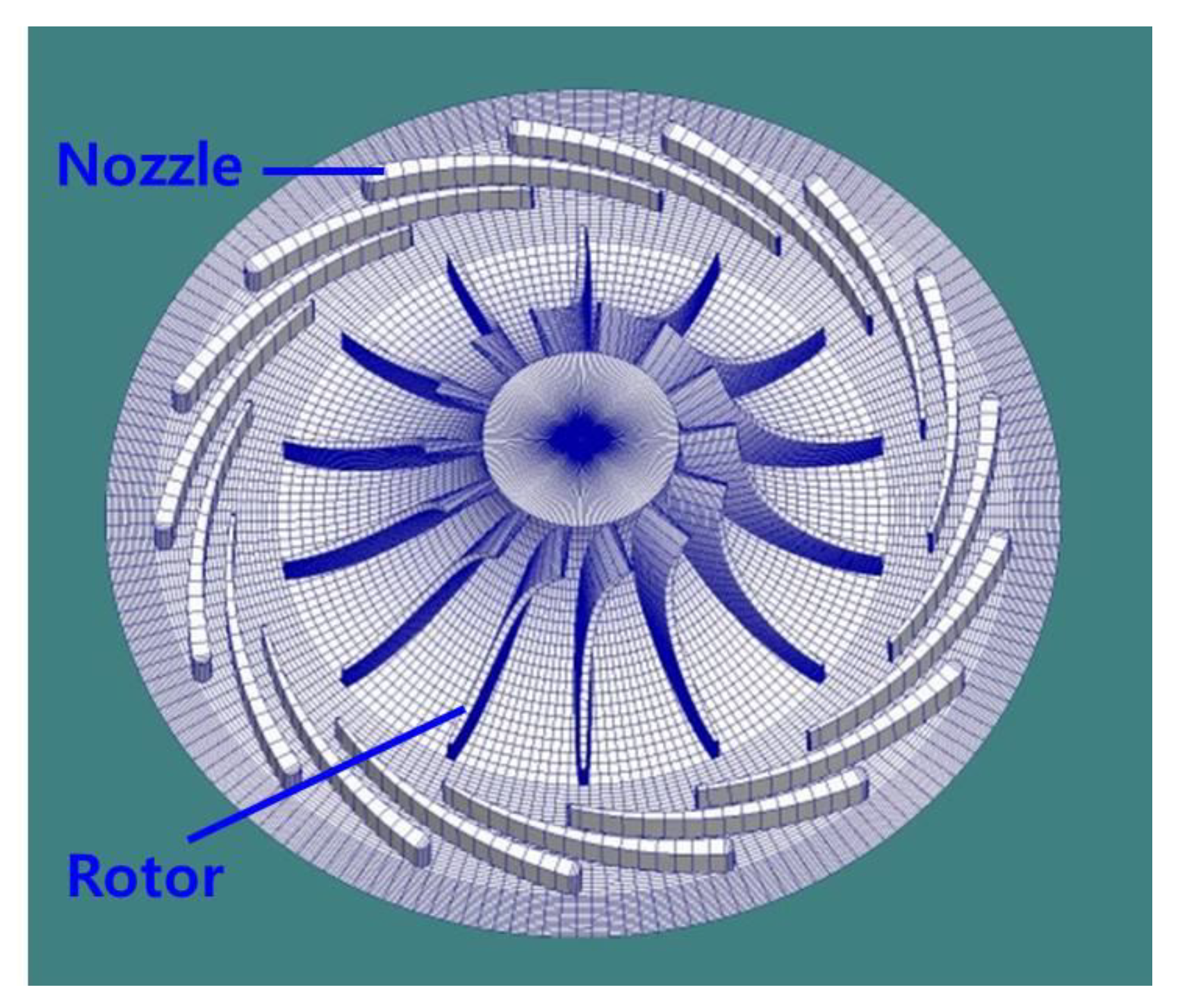

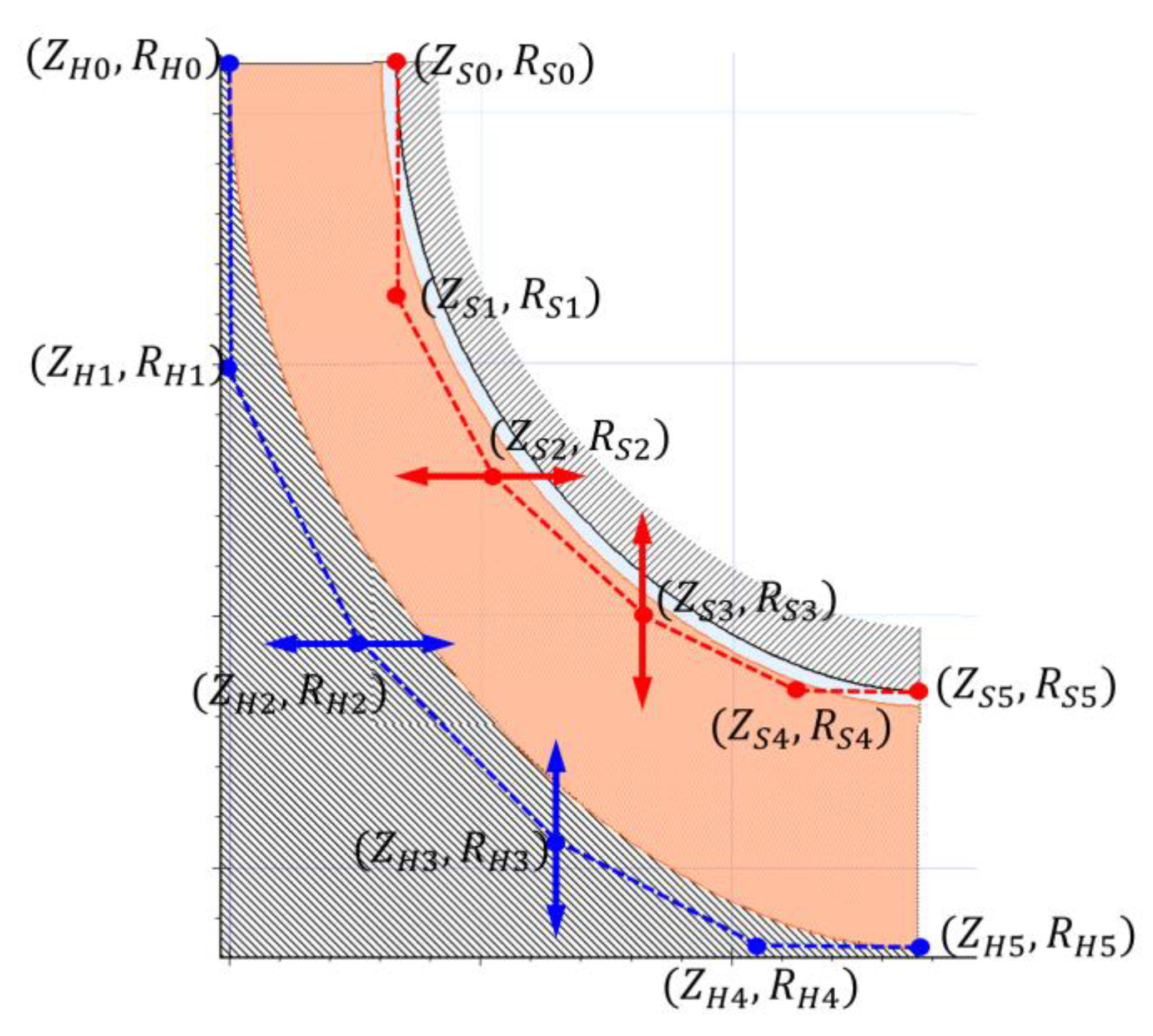

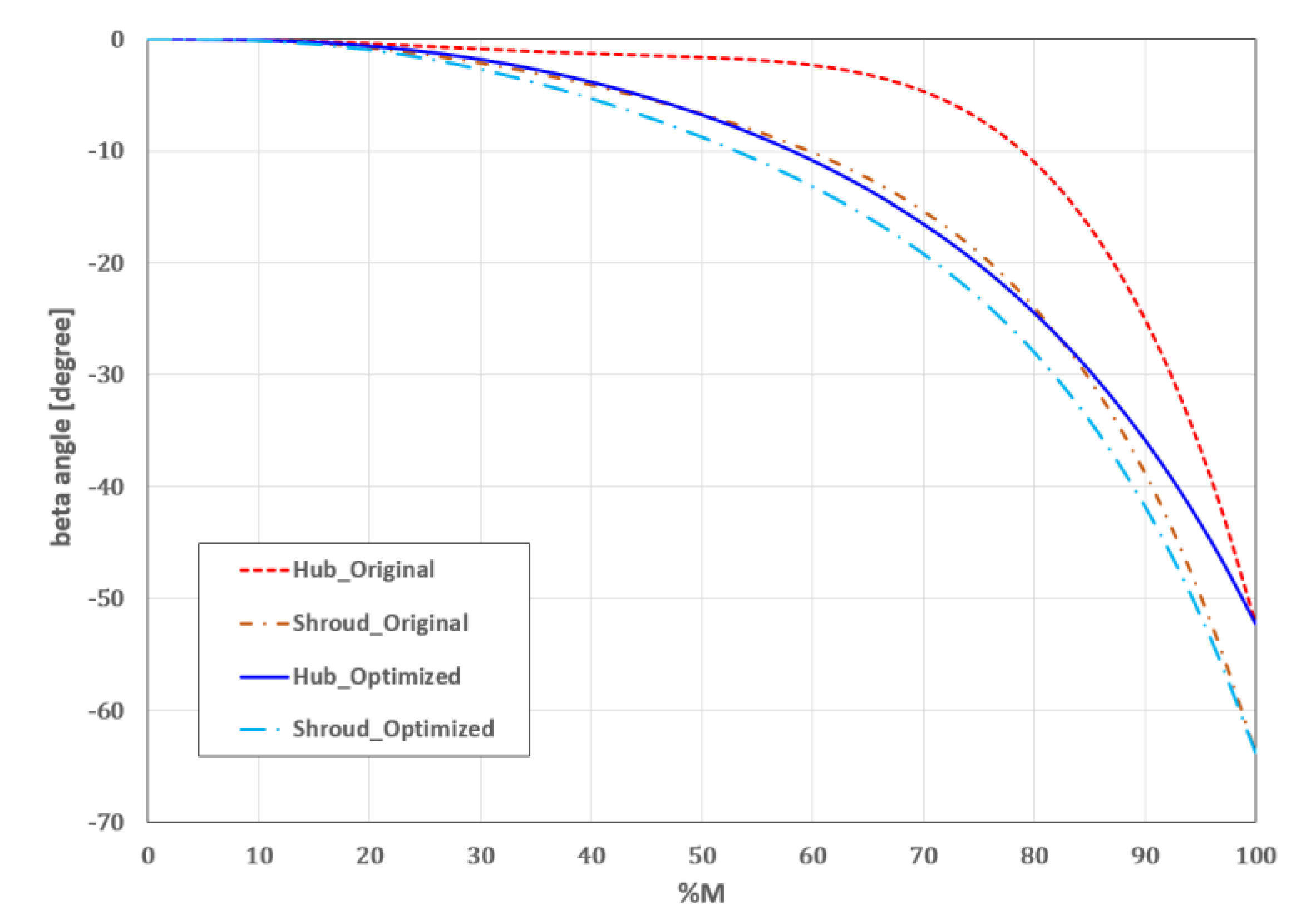

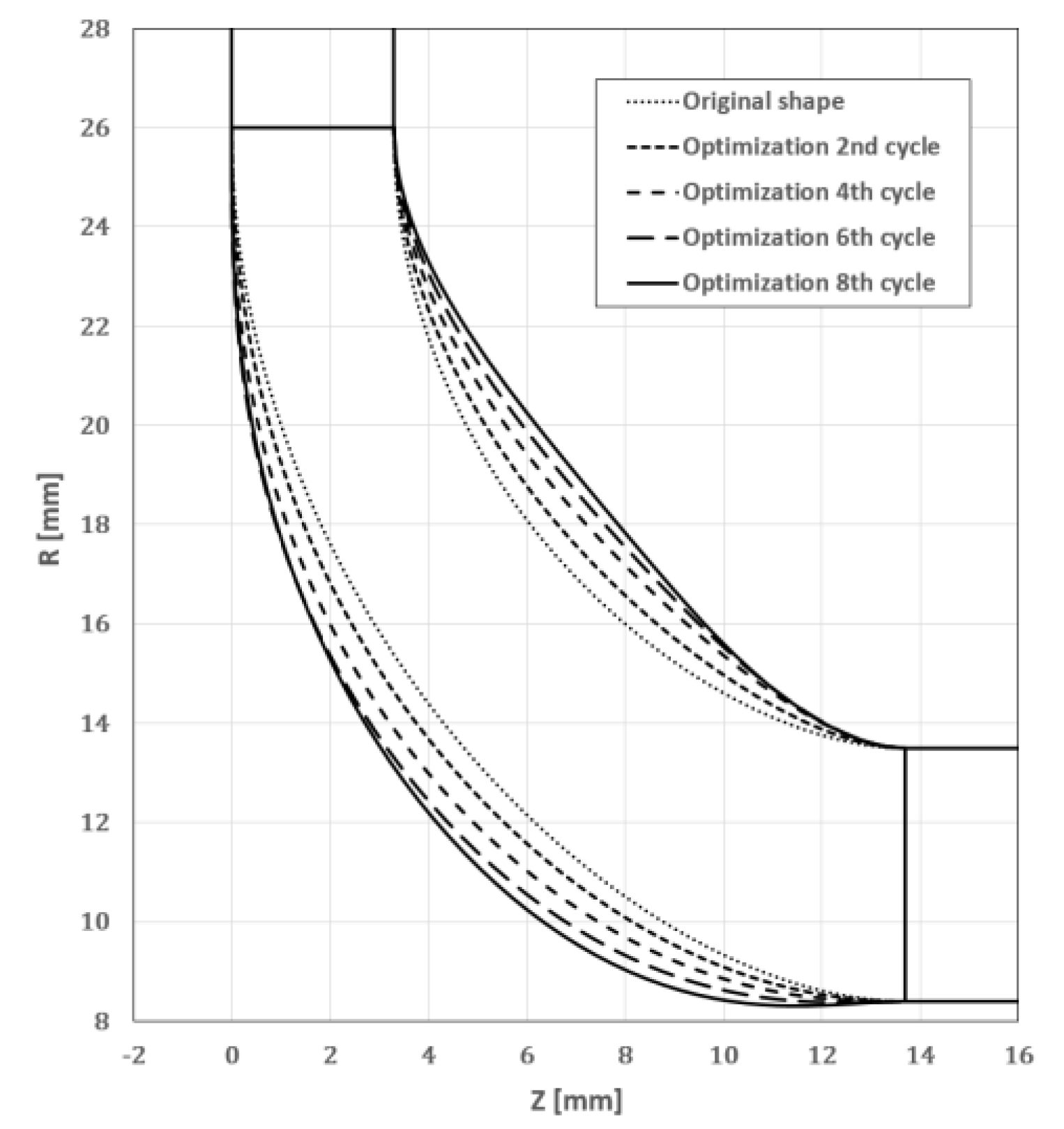

3.3. 3D Shape Generation

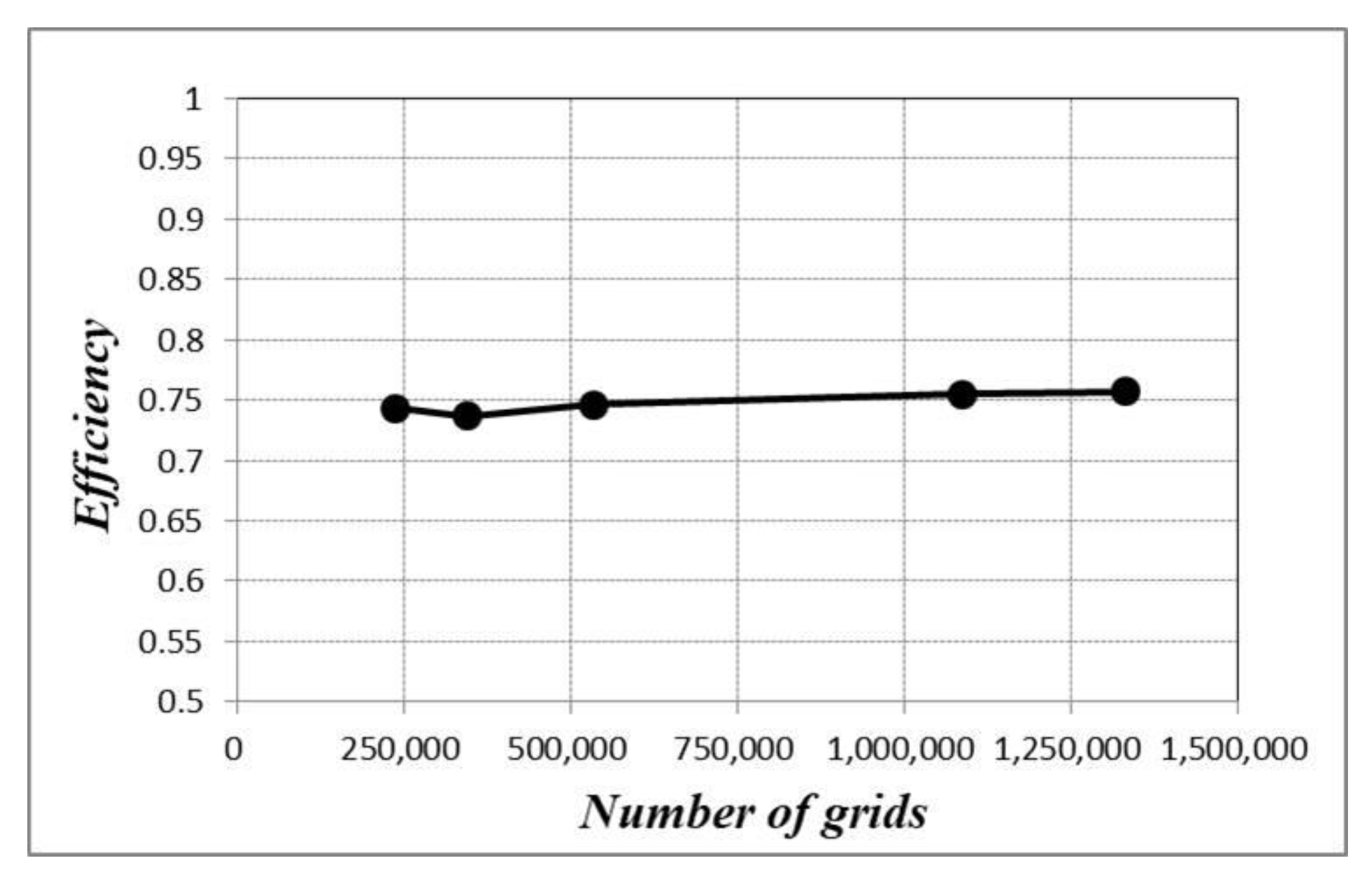

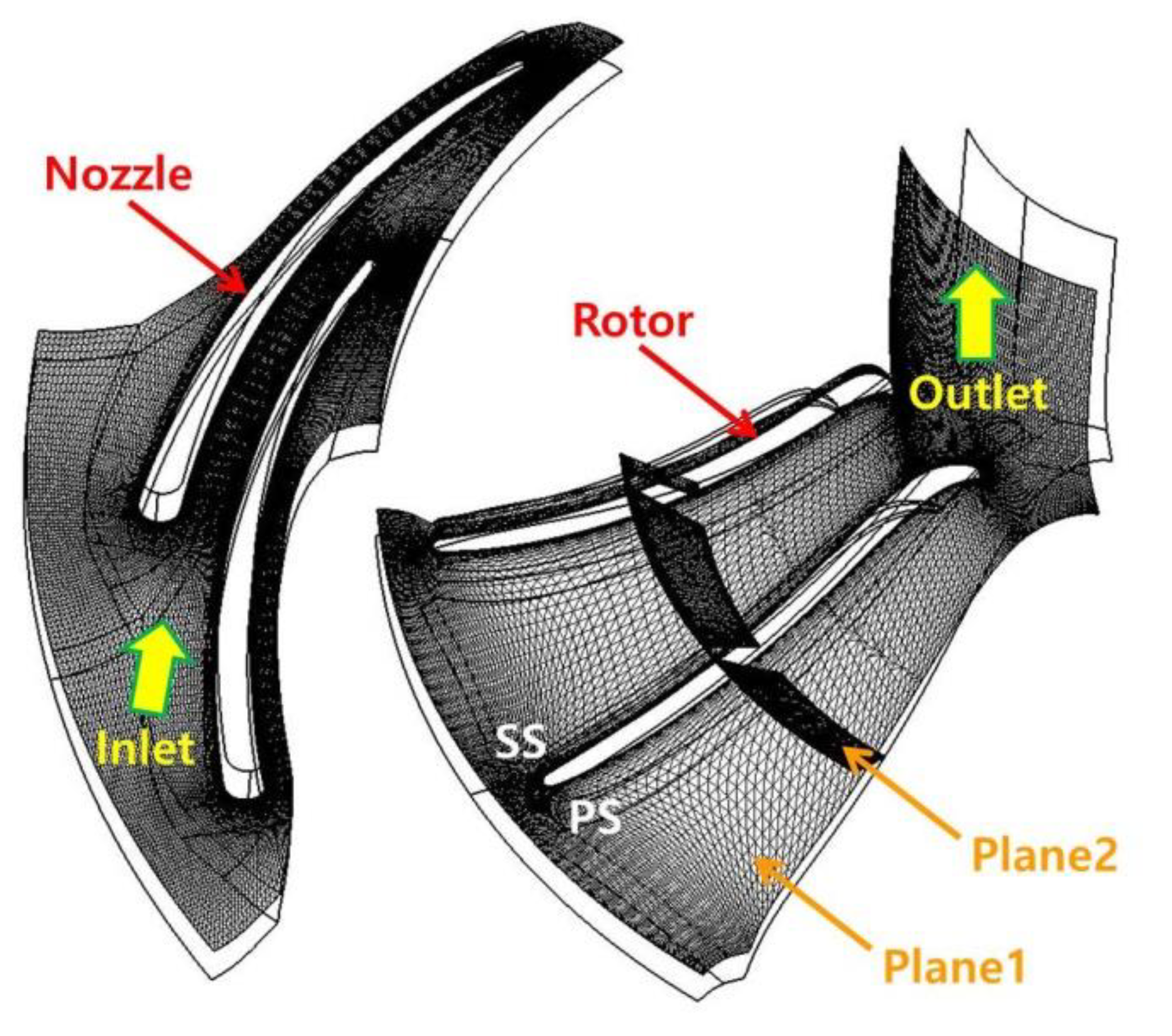

3.4. Numerical Analysis

4. Optimization

4.1. Optimization Methodology

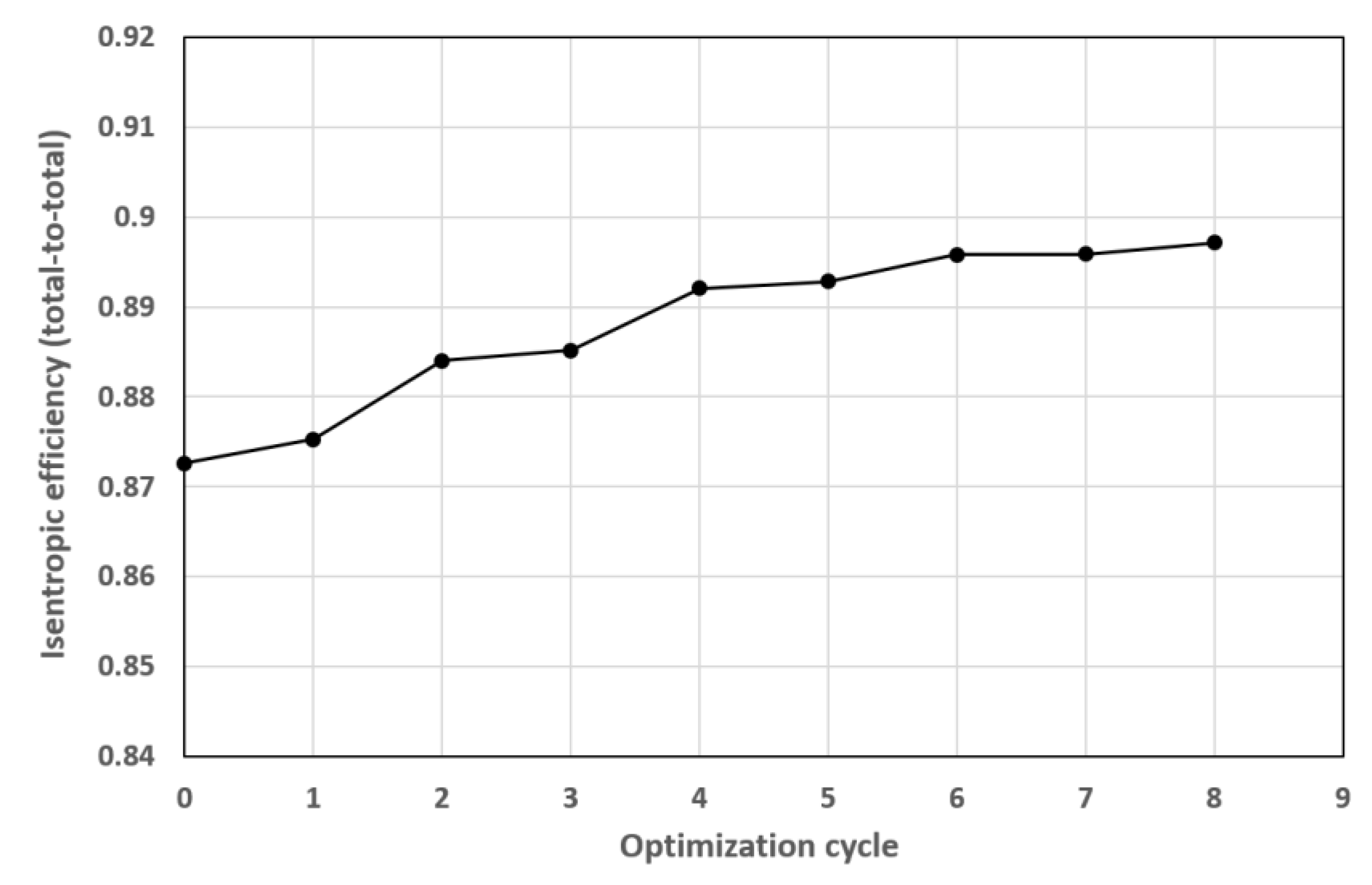

4.2. Optimization of the Expander

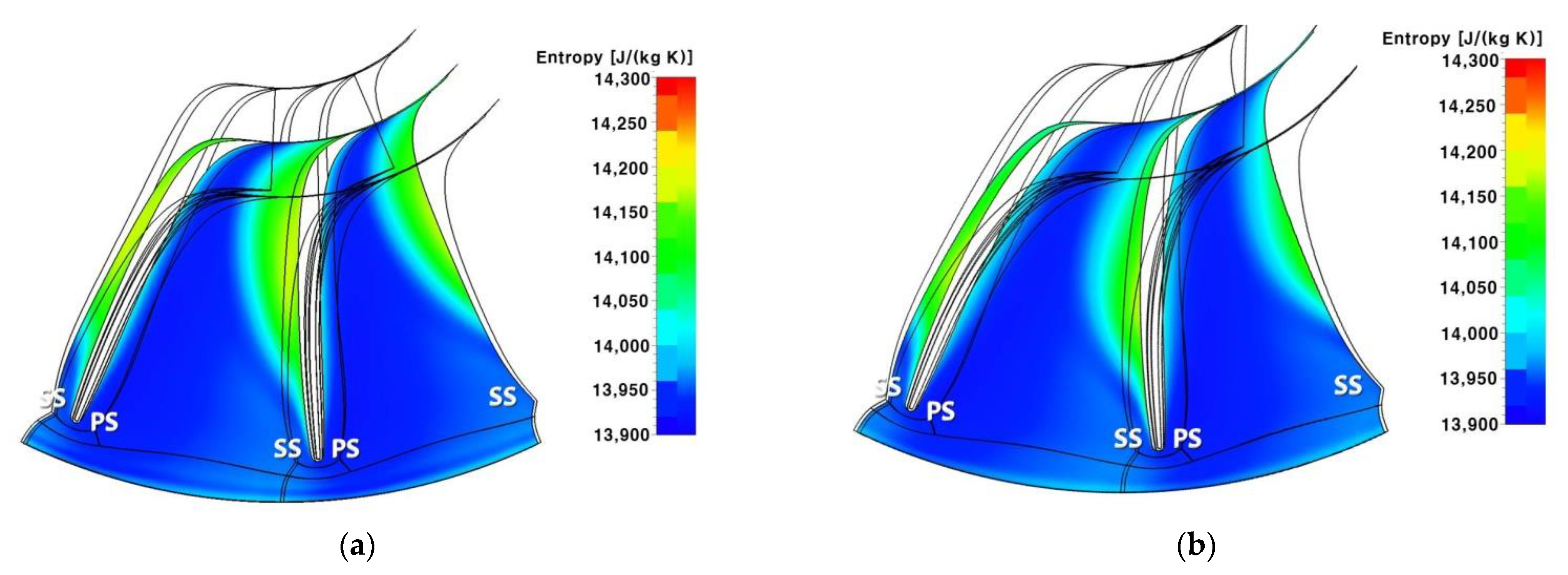

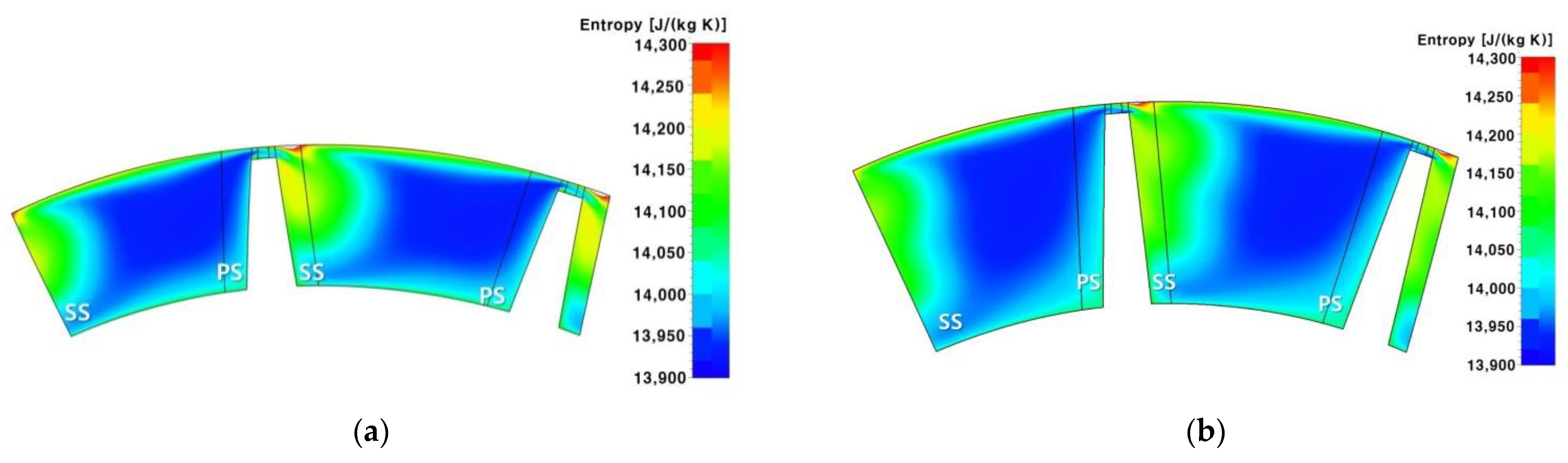

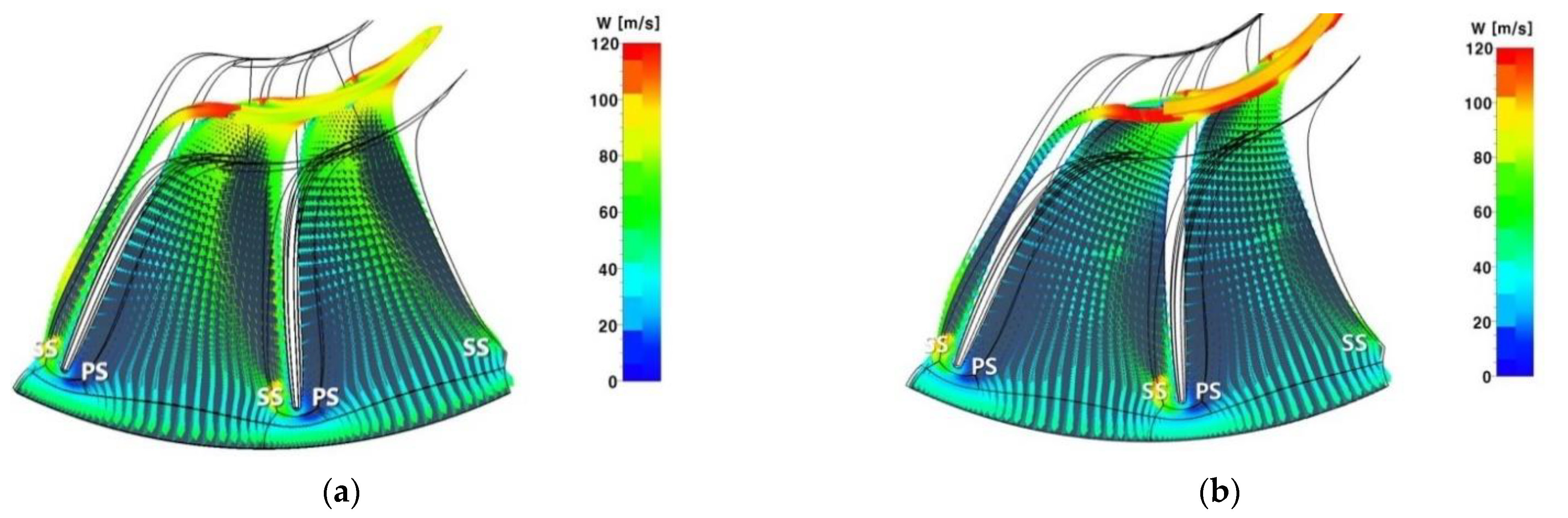

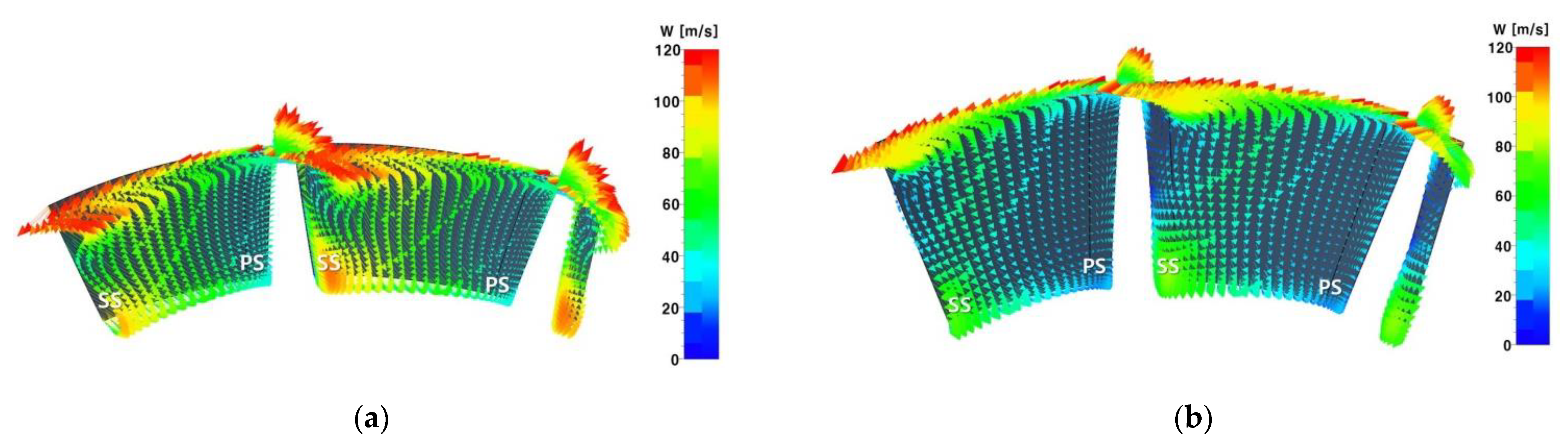

4.3. Optimization Results at Design Point

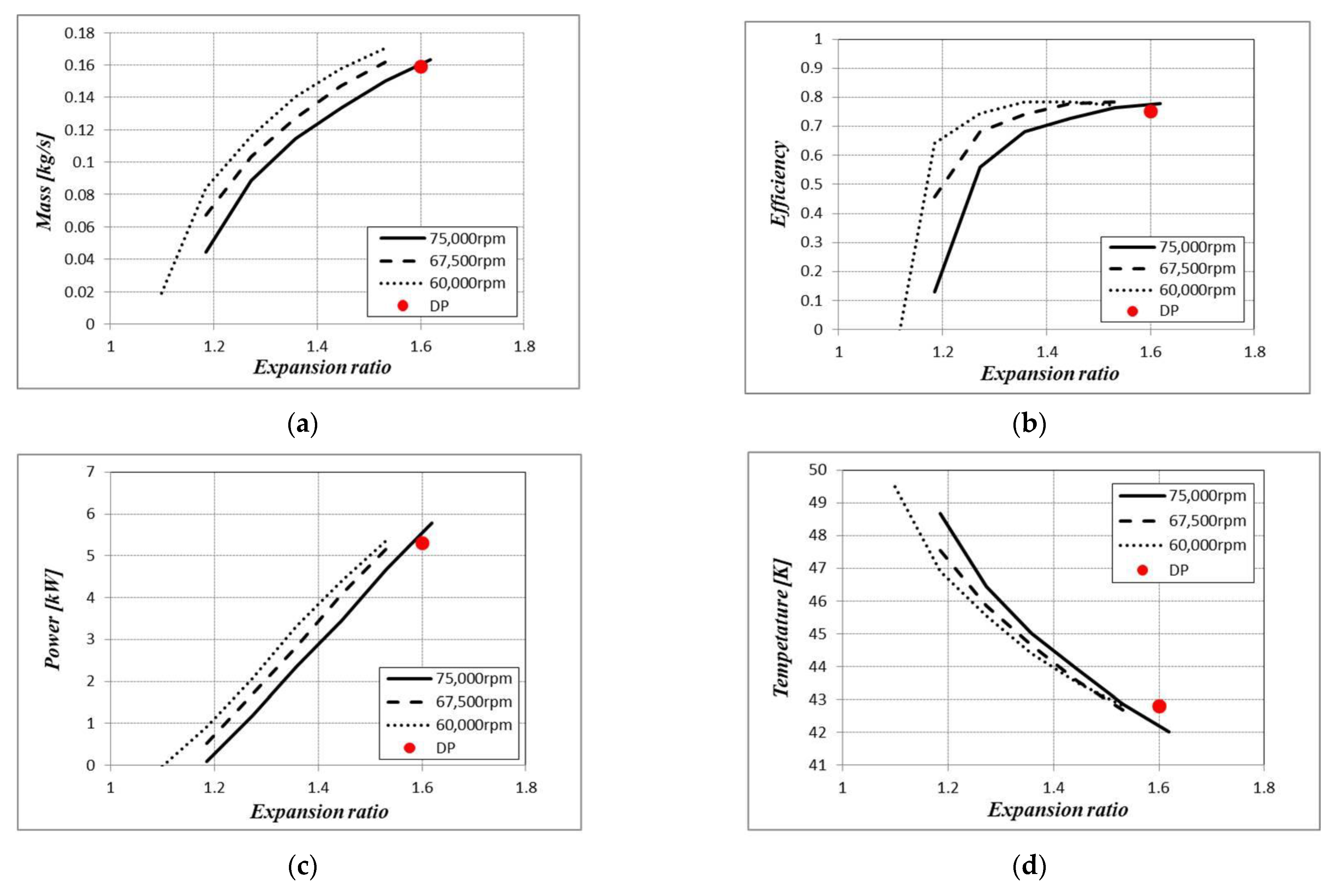

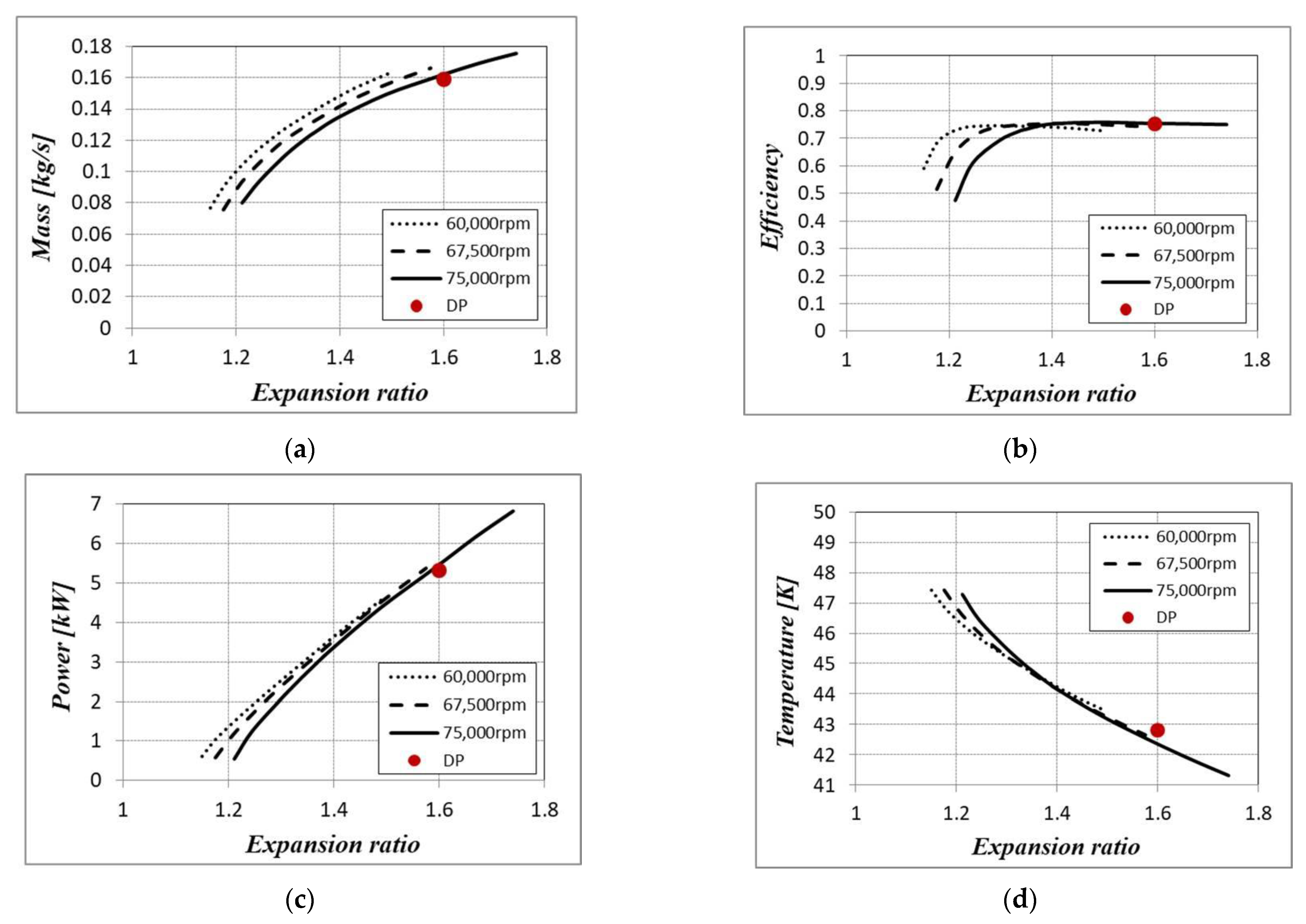

4.4. Comparison of Performance Curve

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| DOE | Design of experiments |

| DP | Design point |

| PS | Pressure side |

| RSM | Response surface method |

| RPM | Revolutions per minute |

| SS | Suction side |

| TPD | Tons per day |

| Nomenclature | |

| α | Absolute flow angle [°] |

| β | Blade beta angle, relative flow angle [°] |

| C | Absolute flow velocity [m/s] |

| d | Rotor diameter [mm] |

| D_tip | Rotor tip diameter [mm] |

| Ds | Specific diameter |

| Δ | Difference |

| η | Efficiency |

| h | Enthalpy [J/kg] |

| Hx | Heat exchanger |

| In | Inlet |

| Ns | Specific speed |

| Out | Outlet |

| Ω | Revolution speed [rad/sec] |

| Pr | Pressure ratio |

| Q | Flow rate [㎥/sec] |

| R | Radial |

| S | Entropy [J/kg-K] |

| T | Temperature [K] |

| U | Rotor tip velocity [m/s] |

| W | Relative velocity [m/s] |

| Z | Axial |

| Subscript | |

| 0 | Volute |

| 1 | Nozzle inlet |

| 2 | Nozzle throat |

| 3 | Nozzle outlet |

| 4 | Rotor inlet |

| 5 | Rotor throat |

| 6 | Rotor outlet |

| Isen | Isentropic |

| T | Total |

| TT | Total to total |

References

- Simms, J. Fundamentals of Turboexpanders “Basic Theory and Design”; SIMMS Machinery International, Inc.: Santa Maria, CA, USA, 2009. [Google Scholar]

- Jumonville, J. Tutorial on cryogenic turboexpanders. In Proceedings of the Thirty-Ninth Turbomachinery Symposium; Texas A&M University, Turbomachinery Laboratories: College Station, TX, USA, 2010; pp. 147–154. [Google Scholar]

- Yoshida, S.; Kamioka, Y. Development of a neon cryogenic turboexpander with magnetic bearings. AIP Conf. Proc. 2010, 1218, 895–902. [Google Scholar]

- Hirai, H.; Hirokawa, M.; Yoshida, S.; Sano, T.; Ozaki, S. Development of a turbine-compressor for 10 kW class neon turbo-Brayton refrigerator. AIP Conf. Proc. 2014, 1573, 1236–1241. [Google Scholar]

- Li, J.; Xiong, L.Y.; Peng, N.; Dong, B.; Wang, P.; Liu, L.Q. Measurement and control system for cryogenic helium gas bearing turbo-expander experimental platform based on Siemens PLC S7-300. AIP Conf. Proc. 2014, 1573, 1743–1749. [Google Scholar]

- Ghosh, S.K.; Seshaiah, N.; Sahoo, R.K.; Sarangi, S.K. Design of turboexpander for cryogenic application. Indian J. Cryog. 2015, 2. [Google Scholar]

- Ghosh, S.K. Experimental and Computational Studies on Cryogenic Turboexpander. Ph.D. Thesis, National Institute of Technology, Rourkela, India, 29 July 2008. [Google Scholar]

- Choudhury, B.K. Design and Construction of Turboexpander Based Nitrogen Liquefier. Ph.D. Thesis, National Institute of Technology, Rourkela, India, 24 December 2013. [Google Scholar]

- Song, P.; Sun, J.; Wang, K. Swirling and cavitating flow suppression in a cryogenic liquid turbine expander through geometric optimization. J. Power Energy 2015, 229, 628–646. [Google Scholar] [CrossRef]

- Huang, N.; Li, Z.; Zhu, B. Cavitating flow suppression in the draft tube of a cryogenic turbine expander through runner optimization. Processes 2020, 8, 270. [Google Scholar] [CrossRef] [Green Version]

- Moustapha, H.; Zelesky, M.F.; Baines, N.C.; Japikse, D. Axial and Radial Turbines; Concepts ETI, Inc.: White River Junction, VT, USA, 2003. [Google Scholar]

- Cho, S.-Y.; Choi, B.-S.; Lim, H.-S. Study of pressure loss according to the cross-sectional shapes of volute on radial turbine. J. Korean Soc. Power Syst. Eng. 2019, 23, 55–64. [Google Scholar] [CrossRef]

- Barton, R.R. Tutorial: Simulation Metamodeling. In Proceedings of the 2015 Winter Simulation Conference, IEEE, Huntington Beach, CA, USA, 6–9 December 2015; pp. 1765–1779. [Google Scholar]

- Karmoker, J.R.; Hasan, I.; Ahmed, N.; Saifuddin, M.; Reza, M.S. Development and Optimization of Acyclovir Loaded Mucoadhesive Microspheres by Box -Behnken Design. Dhaka Univ. J. Pharm. Sci. 2019, 18, 1–12. [Google Scholar] [CrossRef]

- Greenfield, T.; Metcalfe, A.V. Design and Analysis Your Experiment with MINITAB; John Wiley & Sons Ltd.: West Sussex, UK, 2010. [Google Scholar]

- Montgomery, D.C. Introduction to Statistical Quality Control; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2005. [Google Scholar]

| Process @ T–s Diagram | Component |

|---|---|

| ①-② | Heat exchanger 1 |

| ②-③ | Heat exchanger 2 |

| ③-④ | Expander 1 |

| ④-⑤ | Heat exchanger 3 |

| ⑤-⑥ | Expander 2 |

| ⑥-⑦ | Heat exchanger 4 |

| ⑦-⑧ | Heat exchanger 3 |

| ⑧-⑨ | Heat exchanger 2 |

| ⑨-⑩ | Heat exchanger 1 |

| ⑩-① | Compressor with cooler |

| Parameter | Unit | Expander 1 (③–④) | Expander 2 (⑤–⑥) |

|---|---|---|---|

| Pt_in | bar | 9.76 | 5.98 |

| Tt_in | K | 49.1 | 24.8 |

| Pt_out | bar | 6.1 | 1.62 |

| Tt_out | K | 42.8 | 17 |

| Pr | - | 1.6 | 3.69 |

| Efficiency | % | 74.7 | 76.3 |

| Power | kW | 5.32 | 6.2 |

| Ns | Unit | 0.2 | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | 0.392 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Efficiency | - | 0.76 | 0.81 | 0.85 | 0.87 | 0.87 | 0.84 | 0.8 | 0.72 | 0.61 | 0.85 |

| RPM | - | 38,191 | 57,286 | 76,382 | 95,477 | 114,573 | 133,668 | 152,764 | 171,859 | 190,955 | 75,000 |

| Power | kW | 5.4 | 5.7 | 6.0 | 6.1 | 6.1 | 6.0 | 5.6 | 5.1 | 4.3 | 6.0 |

| Ds | - | 10.0 | 6.67 | 5.0 | 4.0 | 3.33 | 2.86 | 2.5 | 2.22 | 2.0 | 5.09 |

| D_tip | mm | 105.59 | 70.39 | 52.8 | 42.24 | 35.2 | 30.17 | 26.4 | 23.46 | 21.12 | 53.77 |

| U_tip | m/s | 211.15 | 211.15 | 211.15 | 211.15 | 211.15 | 211.15 | 211.15 | 211.15 | 211.15 | 211.15 |

| Parameter | Unit | Dimension |

|---|---|---|

| RPM | - | 75,000 |

| Number of nozzles | - | 17 |

| Nozzle inlet radius (N1) | mm | 36.5 |

| Nozzle outlet radius (N2) | mm | 29.5 |

| Nozzle height | mm | 3.3 |

| Nozzle outlet blade angle | ° | 76.21 |

| Number of rotors | - | 14 |

| Rotor inlet radius (R1) | mm | 26 |

| Rotor outlet shroud radius (R2) | mm | 13.2 + 0.3 |

| Rotor outlet hub radius (R3) | mm | 8.4 |

| Rotor outlet blade angle | ° | −60 |

| Cycle | Design Parameters | Metamodel |

|---|---|---|

| 1 | blade angle | |

| 2 | meridional contours | |

| 3 | blade angle | |

| 4 | meridional contours | |

| 5 | blade angle | |

| 6 | meridional contours | |

| 7 | blade angle | |

| 8 | meridional contours |

| Expansion Ratio | Efficiency | ΔEfficiency [%] * | Outlet Temperature [K] | ΔTemperature [%] * | ||

|---|---|---|---|---|---|---|

| Original | Optimized | Original | Optimized | |||

| 1.74 | 0.750 | 0.764 | 1.9 | 41.306 | 41.167 | 0.34 |

| 1.67 | 0.752 | 0.767 | 1.94 | 41.813 | 41.674 | 0.33 |

| 1.59 (DP) | 0.754 | 0.769 | 1.98 | 42.415 | 42.281 | 0.32 |

| 1.49 | 0.758 | 0.768 | 1.32 | 43.252 | 43.161 | 0.21 |

| 1.40 | 0.752 | 0.752 | 0.08 | 44.164 | 44.144 | 0.05 |

| 1.35 | 0.733 | 0.734 | 0.1 | 44.73 | 44.718 | 0.03 |

| 1.34 | 0.723 | 0.725 | 0.15 | 44.973 | 44.948 | 0.06 |

| 1.30 | 0.690 | 0.685 | −0.73 | 45.528 | 45.526 | 0.00 |

| 1.24 | 0.586 | 0.555 | −5.21 | 46.564 | 46.66 | −0.21 |

| 1.21 | 0.466 | 0.419 | −10.07 | 47.319 | 47.488 | −0.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, H.; Seo, J.; Park, M.; Choi, B.; Park, J.; Bang, J.; Lee, D.; Kim, B.; Kim, S.; Lim, Y.; et al. A Numerical Study on Blade Design and Optimization of a Helium Expander for a Hydrogen Liquefaction Plant. Appl. Sci. 2022, 12, 1411. https://doi.org/10.3390/app12031411

Lim H, Seo J, Park M, Choi B, Park J, Bang J, Lee D, Kim B, Kim S, Lim Y, et al. A Numerical Study on Blade Design and Optimization of a Helium Expander for a Hydrogen Liquefaction Plant. Applied Sciences. 2022; 12(3):1411. https://doi.org/10.3390/app12031411

Chicago/Turabian StyleLim, Hyungsoo, Jeongmin Seo, Mooryong Park, Bumseog Choi, Junyoung Park, Jesung Bang, Donghyun Lee, Byungock Kim, Soowon Kim, Youngchul Lim, and et al. 2022. "A Numerical Study on Blade Design and Optimization of a Helium Expander for a Hydrogen Liquefaction Plant" Applied Sciences 12, no. 3: 1411. https://doi.org/10.3390/app12031411

APA StyleLim, H., Seo, J., Park, M., Choi, B., Park, J., Bang, J., Lee, D., Kim, B., Kim, S., Lim, Y., & Alford, A. (2022). A Numerical Study on Blade Design and Optimization of a Helium Expander for a Hydrogen Liquefaction Plant. Applied Sciences, 12(3), 1411. https://doi.org/10.3390/app12031411