Effect of Femtosecond Laser Polarization on the Damage Threshold of Ta2O5/SiO2 Film

Abstract

:1. Introduction

2. Experiment

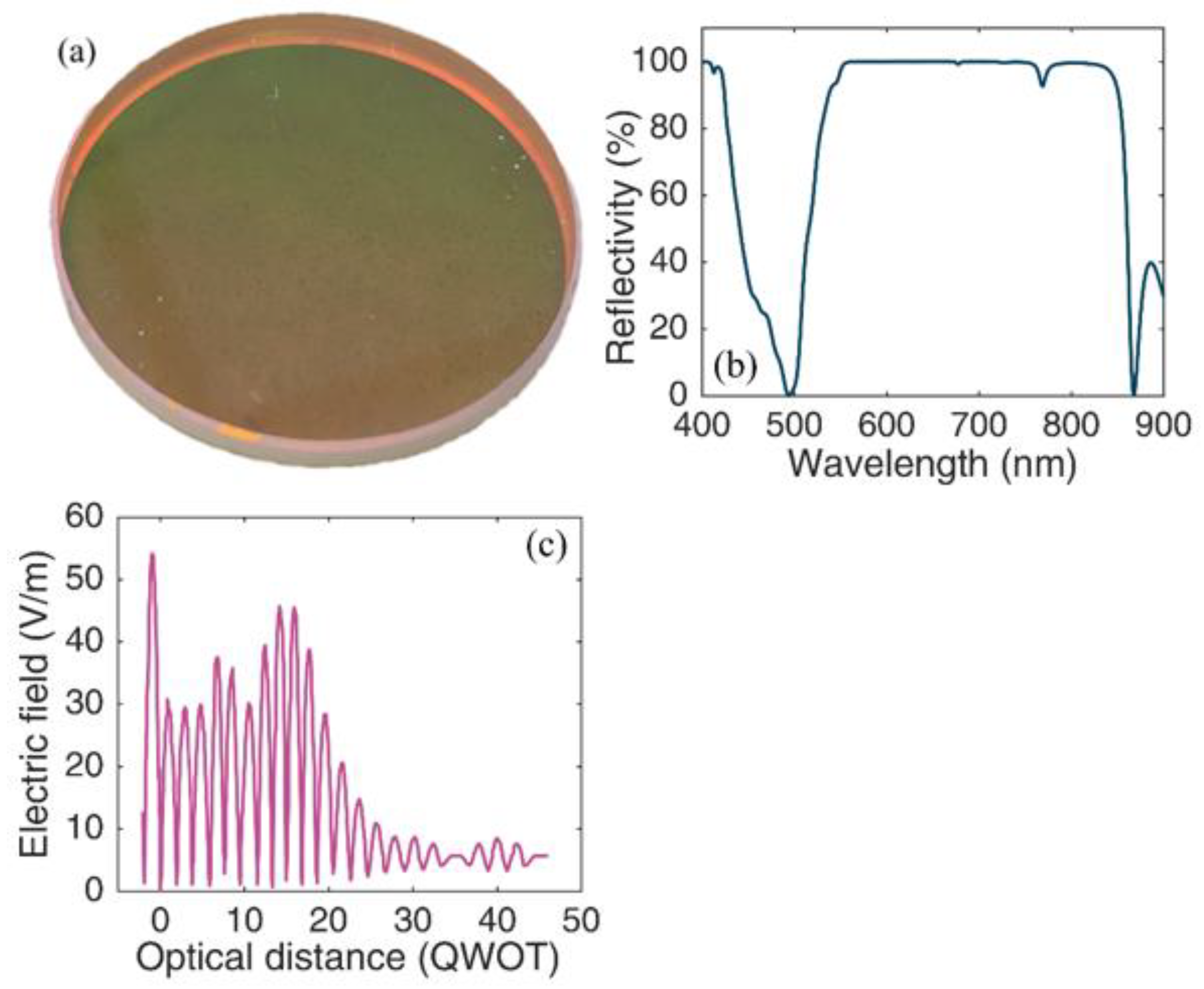

2.1. Sample Preparation

2.2. Experimental Setup

2.3. Experimental Process

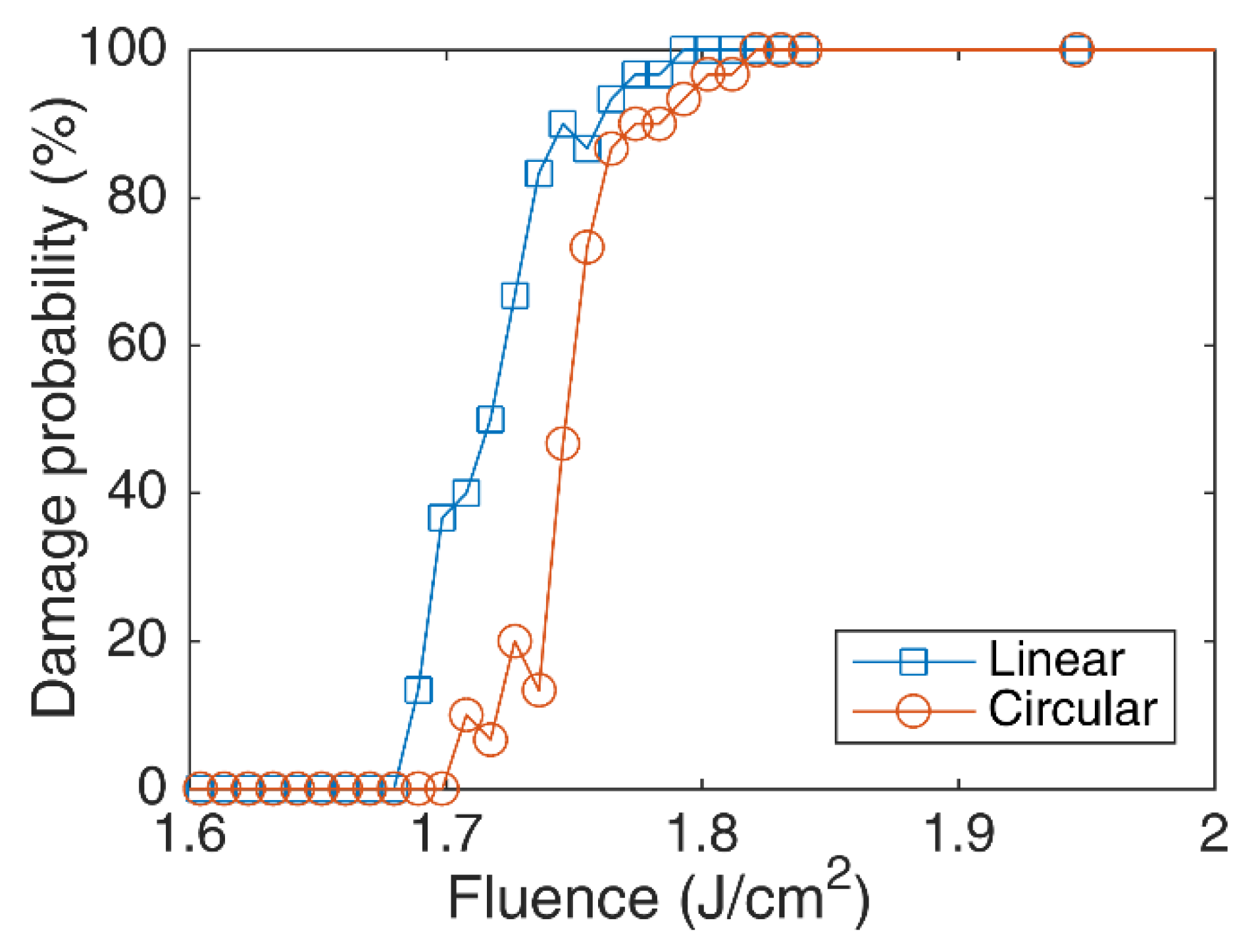

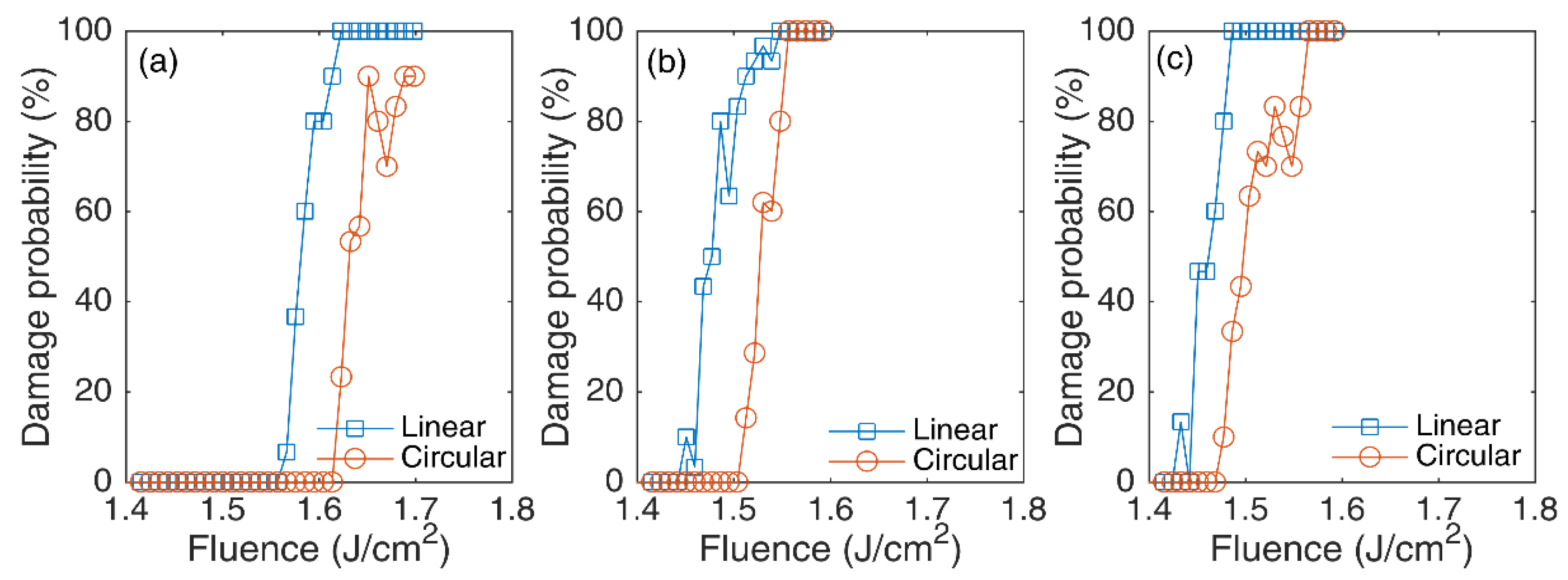

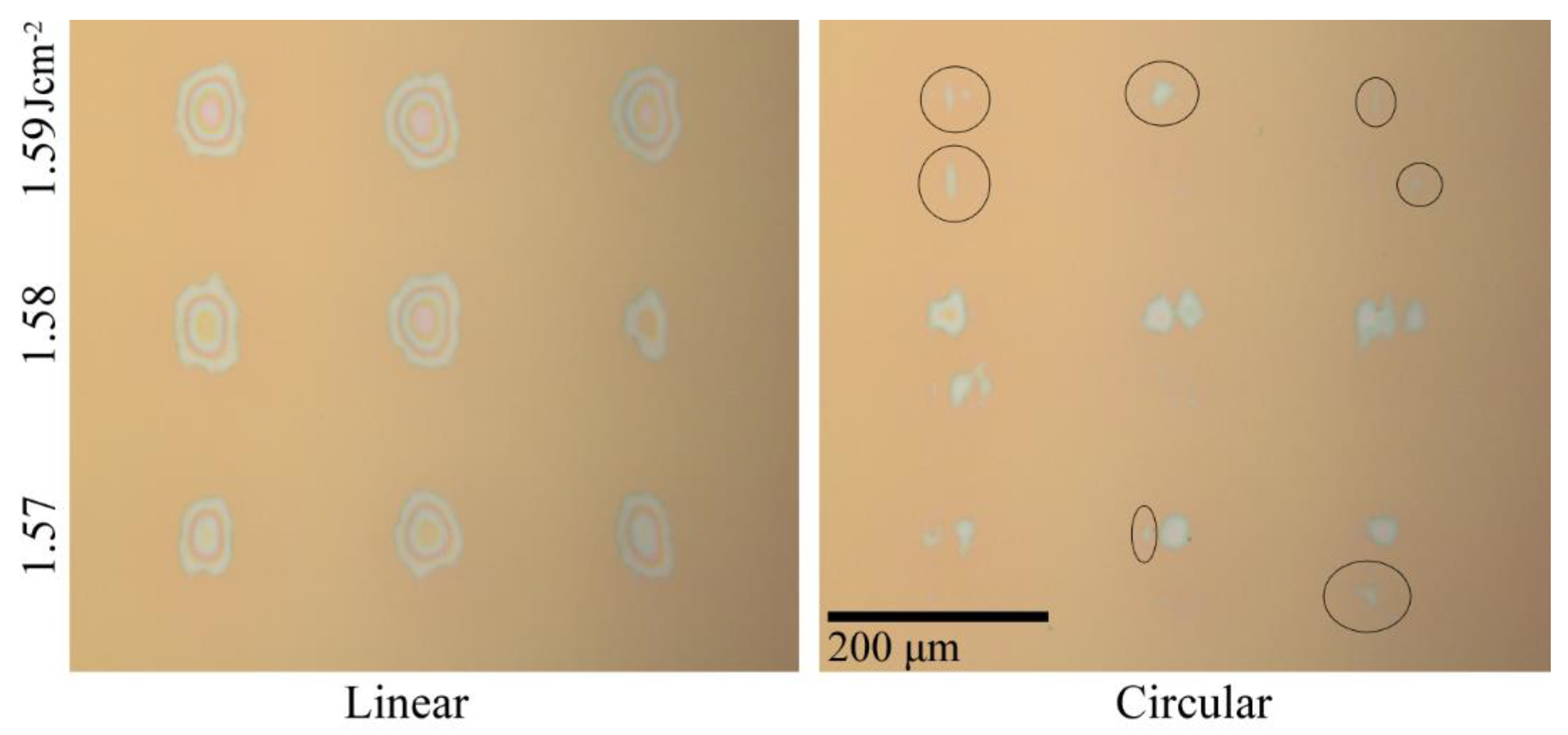

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kumar, S.; Shankar, A.; Kishore, N.; Mukherjee, C.; Kamparath, R.; Thakur, S. Laser induced damage threshold of Ta2O5 and Ta2O5/SiO2 films at 532 and 1064 nm. Optik 2019, 176, 438–447. [Google Scholar] [CrossRef]

- Gallais, L.; Douti, D.-B.; Commandré, M.; Batavičiūtė, G.; Pupka, E.; Ščiuka, M.; Smalakys, L.; Sirutkaitis, V.; Melninkaitis, A. Wavelength dependence of femtosecond laser-induced damage threshold of optical materials. J. Appl. Phys. 2015, 117, 223103. [Google Scholar] [CrossRef] [Green Version]

- Zhu, M.; Yi, K.; Li, D.; Liu, X.; Qi, H.; Shao, J. Influence of SiO2 overcoat layer and electric field distribution on laser damage threshold and damage morphology of transport mirror coatings. Opt. Commun. 2014, 319, 75–79. [Google Scholar] [CrossRef]

- Wang, T.; Yang, L.H. Research on SiO2 film laser damage threshold. In Proceedings of the 6th International Symposium on Advanced Optical Manufacturing and Testing Technologies (AOMATT)—Advanced Optical Manufacturing Technologies, Xiamen, China, 26–29 April 2012. [Google Scholar]

- Bonse, J.; Solis, J.; Urech, L.; Lippert, T.; Wokaun, A. Femtosecond and nanosecond laser damage thresholds of doped and undoped triazenepolymer thin films. Appl. Surf. Sci. 2007, 253, 7787–7791. [Google Scholar] [CrossRef]

- Muller, M.; Barkusky, F.; Feigl, T.; Mann, K. Euv damage threshold measurements of mo/si multilayer mirrors. Appl. Phys. A Mater. Sci. Process. 2012, 108, 263–267. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Bi, J. Study on melting and thermal-stress damage thresholds of silicon induced by long pulsed laser at 0.532, 1.064 and 10.6 μm. Optik 2017, 131, 917–924. [Google Scholar] [CrossRef]

- Schaffer, C.B.; Brodeur, A.; Mazur, E. Laser-induced breakdown and damage in bulk transparent materials induced by tightly focused femtosecond laser pulses. Meas. Sci. Technol. 2001, 12, 1784–1794. [Google Scholar] [CrossRef]

- Bonod, N.; Néauport, J. Optical performance and laser induced damage threshold improvement of diffraction gratings used as compressors in ultra high intensity lasers. Opt. Commun. 2006, 260, 649–655. [Google Scholar] [CrossRef] [Green Version]

- Uteza, O.; Bussière, B.; Canova, F.; Chambaret, J.P.; Delaporte, P.; Itina, T.; Sentis, M. Laser-induced damage threshold of sapphire in nanosecond, picosecond and femtosecond regimes. Appl. Surf. Sci. 2007, 254, 799–803. [Google Scholar] [CrossRef]

- Stevanovic, I.; Balogh-Michels, Z.; Bächli, A.; Wittwer, V.J.; Südmeyer, T.; Stuck, A.; Gischkat, T. Influence of the secondary ion beam source on the laser damage mechanism and stress evolution of IBS Hafnia layers. Appl. Sci. 2021, 11, 189. [Google Scholar] [CrossRef]

- Wu, X.; Yin, H.; Li, Q. Ablation and patterning of carbon nanotube film by femtosecond laser irradiation. Appl. Sci. 2019, 9, 3045. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Liu, L.; Tang, W.; Shao, J.; Li, X.; Sun, J.; Shao, M.; Cheng, X. Experimental study on the damage of optical materials by out of band composite laser. Appl. Sci. 2020, 10, 3578. [Google Scholar]

- Jin-Young, K.; Garg, A.; Rymaszewski, E.J.; Toh-Ming, L. High frequency response of amorphous tantalum oxide thin films. IEEE Trans. Compon. Packag. Technol. 2001, 24, 526–533. [Google Scholar] [CrossRef]

- Pecovska-Gjorgjevich, M.; Novkovski, N.; Atanassova, E. Electrical properties of thin rf sputtered Ta2O5 films after constant current stress. Microelectron. Reliab. 2003, 43, 235–241. [Google Scholar] [CrossRef]

- Dimitrova, T.; Arshak, K.; Atanassova, E. Crystallization effects in oxygen annealed Ta2O5 thin films on si. Thin Solid Films 2001, 381, 31–38. [Google Scholar] [CrossRef]

- Shibata, S. Dielectric constants of Ta2O5 thin films deposited by r.F. Sputtering. Thin Solid Films 1996, 277, 1–4. [Google Scholar] [CrossRef]

- Becker, J.; Bernhardt, A. ISO 11254: An International Standard for the Determination of the Laser-Induced Damage Threshold. In Laser-Induced Damage in Optical Materials; International Society for Optics and Photonics: Belligham, WA, USA, 1994; Volume 2114, pp. 703–713. [Google Scholar]

- Wu, S.J.; Shi, W.; Su, J.H. Using an external electric field to reduce laser damage of dlc films. Int. J. Mater. Prod. Technol. 2013, 45, 74–82. [Google Scholar] [CrossRef]

- Delone, N.; Krainov, V. Multiphoton Processes in Atoms; Springer: Berlin/Heidelberg, Germany, 2000. [Google Scholar]

- Keldysh, L.V. Ionization in field of a strong electromagnetic wave. J. Exp. Phys. 1964, 47, 1945–1957. [Google Scholar]

- Chin, S.L.; Yergeau, F.; Lavigne, P. Tunnel ionisation of Xe in an ultra-intense CO2 laser field (1014 w cm−2) with multiple charge creation. J. Phys. B At. Mol. Phys. 1985, 18, L213–L215. [Google Scholar] [CrossRef]

- Mlejnek, M.; Wright, E.M.; Moloney, J.V. Femtosecond pulse propagation in argon: A pressure dependence study. Phys. Rev. E 1998, 58, 4903–4910. [Google Scholar] [CrossRef]

- Ladouceur, H.D.; Baronavski, A.P.; Lohrmann, D.; Grounds, P.W.; Girardi, P.G. Electrical conductivity of a femtosecond laser generated plasma channel in air. Opt. Commun. 2001, 189, 107–111. [Google Scholar] [CrossRef]

- Temnov, V.V.; Sokolowski-Tinten, K.; Zhou, P.; El-Khamhawy, A.; von der Linde, D. Multiphoton ionization in dielectrics: Comparison of circular and linear polarization. Phys. Rev. Lett. 2006, 97, 237403. [Google Scholar] [CrossRef] [PubMed]

- Jing, X.; Shao, J.; Zhang, J.; Jin, Y.; He, H.; Fan, Z. Calculation of femtosecond pulse laser induced damage threshold for broadband antireflective microstructure arrays. Opt. Express 2009, 17, 24137–24152. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhao, Y.; Shao, J.; Fan, Z. Effect of native defects and laser-induced defects on multi-shot laser-induced damage in multilayer mirrors. Chin. Opt. Lett. 2011, 9, 093102. [Google Scholar] [CrossRef]

- Natoli, J.Y.; Bertussi, B.; Commandré, M. Effect of multiple laser irradiations on silica at 1064 and 355 μm. Opt. Lett. 2005, 30, 1315–1317. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Jia, X.; Wang, Y.; Zhang, Y.; Chen, A.; Shao, J.; Zheng, C. Effect of Femtosecond Laser Polarization on the Damage Threshold of Ta2O5/SiO2 Film. Appl. Sci. 2022, 12, 1494. https://doi.org/10.3390/app12031494

Zhang L, Jia X, Wang Y, Zhang Y, Chen A, Shao J, Zheng C. Effect of Femtosecond Laser Polarization on the Damage Threshold of Ta2O5/SiO2 Film. Applied Sciences. 2022; 12(3):1494. https://doi.org/10.3390/app12031494

Chicago/Turabian StyleZhang, Luwei, Xiaodong Jia, Yunzhe Wang, Yin Zhang, Anmin Chen, Junfeng Shao, and Changbin Zheng. 2022. "Effect of Femtosecond Laser Polarization on the Damage Threshold of Ta2O5/SiO2 Film" Applied Sciences 12, no. 3: 1494. https://doi.org/10.3390/app12031494