Modeling the Life Cycle Inventory of a Centralized Composting Facility in Greece

Abstract

:Featured Application

Abstract

1. Introduction

2. Methodology

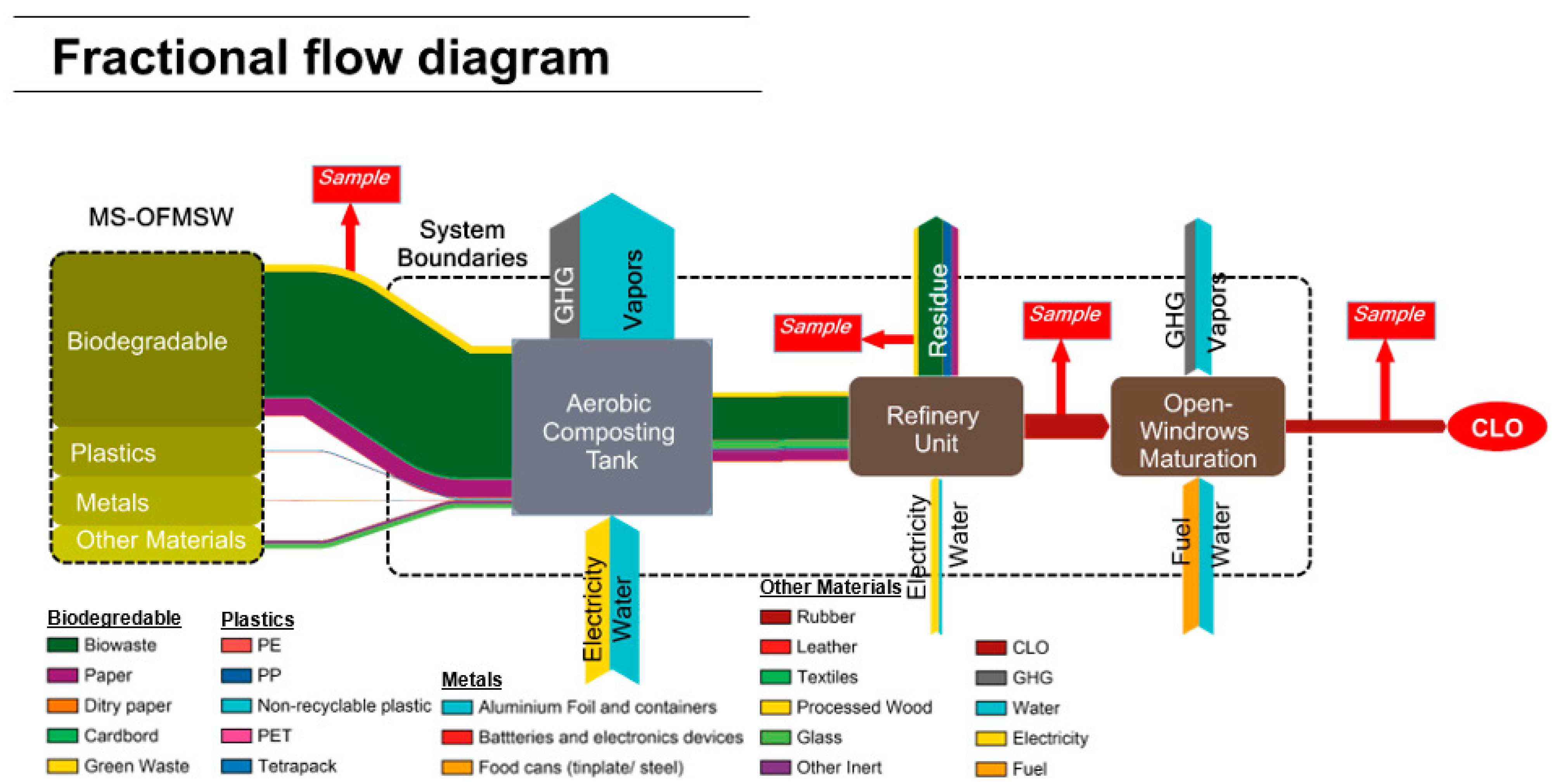

2.1. Composting Units

2.2. Sample Collection and Characterization

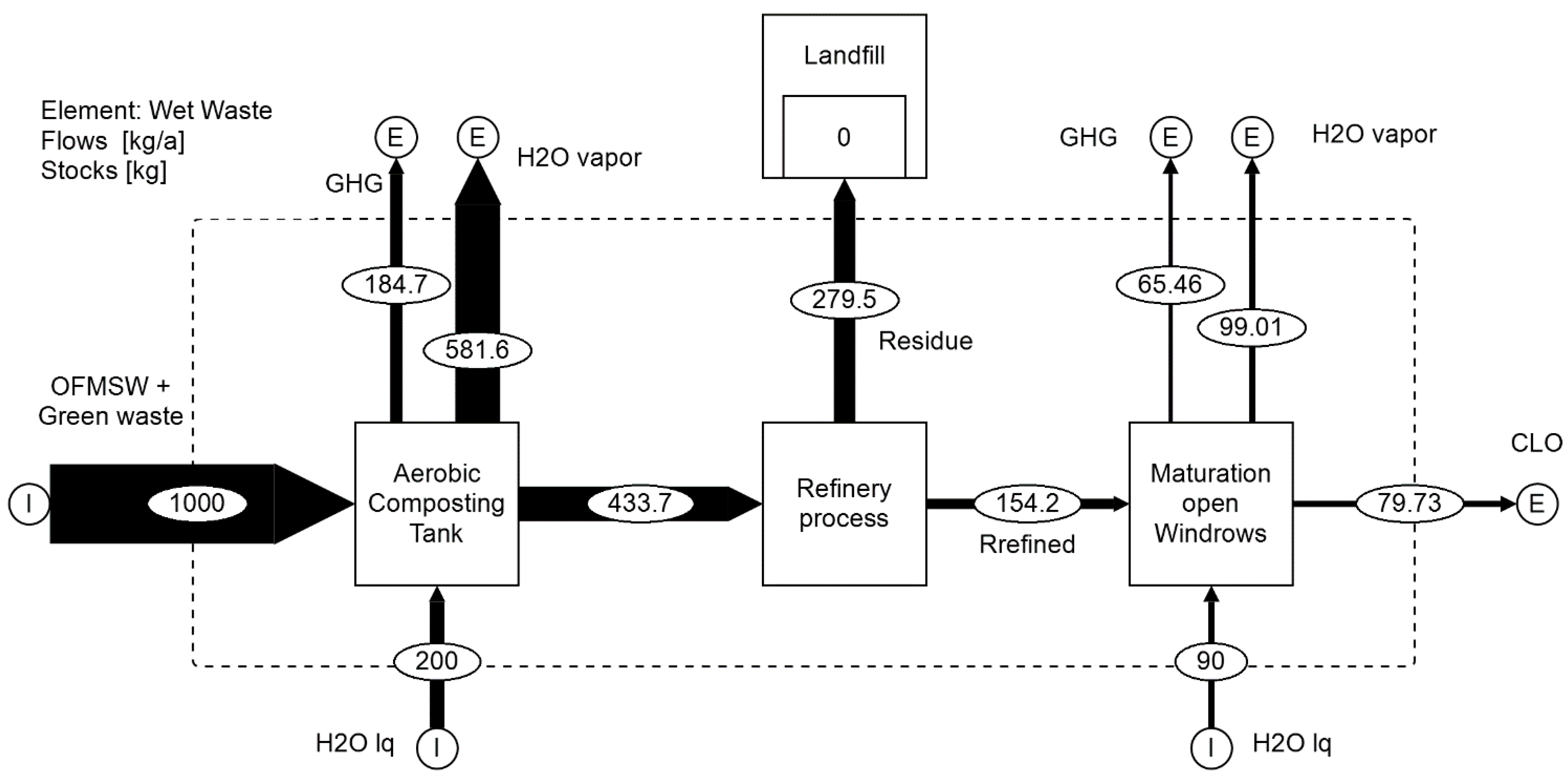

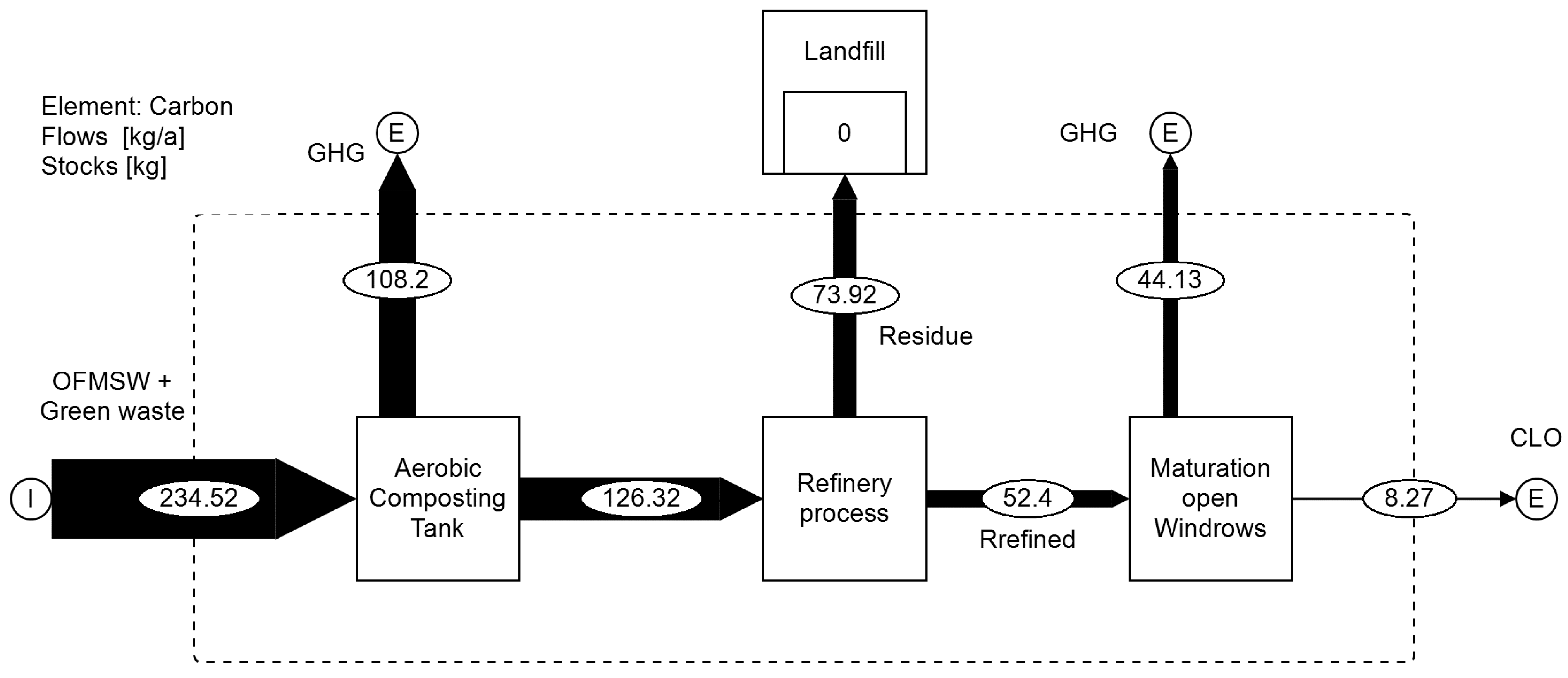

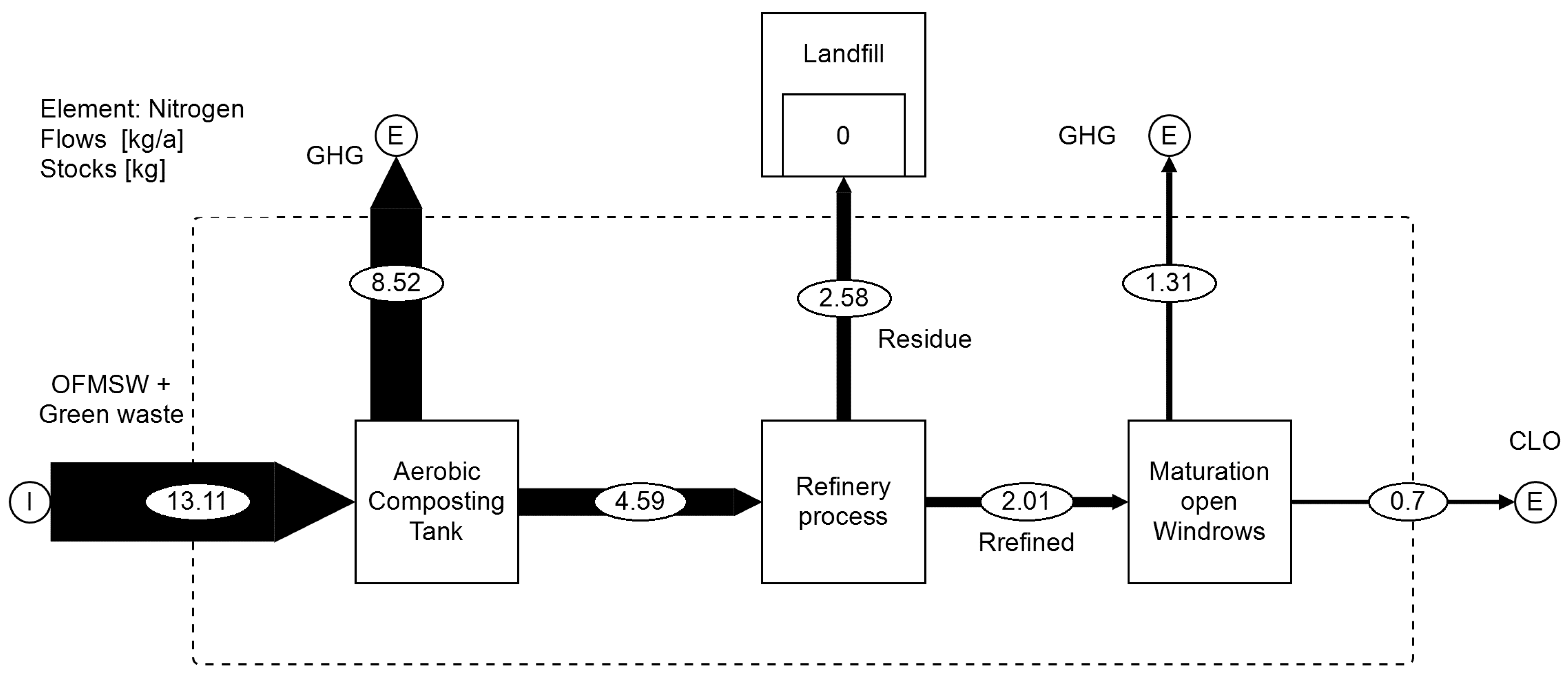

2.3. Life Cycle Inventory (LCI) Modeling

2.4. GHG Emissions

2.5. Site-Specific Data

2.6. Life Cycle Inventory Boundaries

2.7. Sensitivity Analysis

3. Results

3.1. Waste Composition

3.2. Material Flow Analysis

3.3. Mass Balance

3.4. Estimation of Resources Consumed

3.4.1. Electricity

3.4.2. Fuel

3.4.3. Water

3.5. Sensitivity Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Malamis, D.; Bourka, A.; Stamatopoulou, Ε.; Moustakas, K.; Skiadi, O.; Loizidou, M. Study and assessment of segregated biowaste composting: The case study of Attica municipalities. J. Environ. Manag. 2017, 203, 664–669. [Google Scholar] [CrossRef]

- Bartocci, P.; Zampilli, M.; Liberti, F.; Pistolesi, V.; Massoli, S.; Bidini, G.; Fantozzi, F. LCA analysis of food waste co-digestion. Sci. Total Environ. 2020, 709, 136187. [Google Scholar] [CrossRef]

- Ardolino, F.; Colaleo, G.; Arena, U. The cleaner option for energy production from a municipal solid biowaste. J. Clean. Prod. 2020, 266, 121908. [Google Scholar] [CrossRef]

- Zeller, V.; Lavigne, C.; D’Ans, P.; Towa, E.; Achten, W.M.J. Assessing the environmental performance for more local and more circular biowaste management options at city-region level. Sci. Total Environ. 2020, 745, 140690. [Google Scholar] [CrossRef]

- EEA. Bio-Waste in Europe—Turning Challenges into Opportunities; Europian Environment Agency: Luxemburg, 2020. [Google Scholar]

- Council of the European Communities Council Directive 1999/31/EC on the landfill. Off. J. Eur. Communities 1999, L182/1. [CrossRef]

- Van Fan, Y.; Tin, C.; Perry, S. Anaerobic digestion of municipal solid waste: Energy and carbon emission footprint. J. Environ. Manag. 2018, 223, 888–897. [Google Scholar] [CrossRef]

- Wi, M.; Kulig, A.; Lelici, K. Applied sciences Odour Emissions of Municipal Waste Biogas Plants—Impact of Technological Factors, Air Temperature and Humidity. Appl. Sci. 2020, 10, 1093. [Google Scholar]

- Graça, J.; Murphy, B.; Pentlavalli, P.; Allen, C.C.R.; Bird, E.; Gaffney, M.; Duggan, T.; Kelleher, B. Bacterium consortium drives compost stability and degradation of organic contaminants in in-vessel composting process of the mechanically separated organic fraction of municipal solid waste (MS-OFMSW). Bioresour. Technol. Rep. 2021, 13, 100621. [Google Scholar] [CrossRef]

- Wei, Y.; Li, J.; Shi, D.; Liu, G.; Zhao, Y.; Shimaoka, T. Environmental challenges impeding the composting of biodegradable municipal solid waste: A critical review. Resour. Conserv. Recycl. 2017, 122, 51–65. [Google Scholar] [CrossRef] [Green Version]

- Díaz, M.J.; Ruiz-Montoya, M.; Palma, A.; de-Paz, M.V. Thermogravimetry applicability in compost and composting research: A review. Appl. Sci. 2021, 11, 1692. [Google Scholar] [CrossRef]

- Boldrin, A.; Andersen, J.K.; Møller, J.; Christensen, T.H.; Favoino, E. Composting and compost utilization: Accounting of greenhouse gases and global warming contributions. Waste Manag. Res. J. Sustain. Circ. Econ. 2009, 27, 800–812. [Google Scholar] [CrossRef] [Green Version]

- Carabassa, V.; Domene, X.; Alcañiz, J.M. Soil restoration using compost-like-outputs and digestates from non-source-separated urban waste as organic amendments: Limitations and opportunities. J. Environ. Manag. 2020, 255, 109909. [Google Scholar] [CrossRef]

- Vasileiadou, A.; Zoras, S.; Iordanidis, A. Biofuel potential of compost-like output from municipal solid waste: Multiple analyses of its seasonal variation and blends with lignite. Energy 2021, 236, 121457. [Google Scholar] [CrossRef]

- Bhattacharyya, P.; Chakrabarti, K.; Chakraborty, A. Effect of MSW Compost on Microbiological and Biochemical Soil Quality Indicators. Compost Sci. Util. 2003, 11, 220–227. [Google Scholar] [CrossRef]

- Baiano, S.; Fabiani, A.; Fornasier, F.; Ferrarini, A.; Innangi, M.; Mocali, S.; Morra, L. Biowaste compost amendment modifies soil biogeochemical cycles and microbial community according to aggregate classes. Appl. Soil Ecol. 2021, 168, 104132. [Google Scholar] [CrossRef]

- Palansooriya, K.N.; Shaheen, S.M.; Chen, S.S.; Tsang, D.C.W.; Hashimoto, Y.; Hou, D.; Bolan, N.S.; Rinklebe, J.; Ok, Y.S. Soil amendments for immobilization of potentially toxic elements in contaminated soils: A critical review. Environ. Int. 2020, 134, 105046. [Google Scholar] [CrossRef]

- BSI 14040; Environmental Management–Life Cycle Assessment—Principles and Framework. International Standard Organization: London, UK, 2006.

- Christensen, T.H.H.; Damgaard, A.; Levis, J.; Zhao, Y.; Björklund, A.; Arena, U.; Barlaz, M.A.A.; Starostina, V.; Boldrin, A.; Astrup, T.F.F.; et al. Application of LCA modelling in integrated waste management. Waste Manag. 2020, 118, 313–322. [Google Scholar] [CrossRef]

- Ripa, M.; Fiorentino, G.; Vacca, V.; Ulgiati, S. The relevance of site-specific data in Life Cycle Assessment (LCA). The case of the municipal solid waste management in the metropolitan city of Naples (Italy). J. Clean. Prod. 2017, 142, 445–460. [Google Scholar] [CrossRef]

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA studies of solid waste management systems—Part I: Lessons learned and perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef]

- Pini, M.; Neri, P.; Ferrari, A.M. Environmental Performance of Waste Management in an Italian Region: How LCI Modelling Framework could Influence the Results. Procedia CIRP 2018, 69, 956–961. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, Y.; Damgaard, A.; Wang, Q.; Lu, W.; Wang, H.; Christensen, T.H. Material flow analysis of alternative biorefinery systems for managing Chinese food waste. Resour. Conserv. Recycl. 2019, 149, 197–209. [Google Scholar] [CrossRef]

- Mironov, V.; Vanteeva, A.; Sokolova, D.; Merkel, A.; Nikolaev, Y. Microbiota dynamics of mechanically separated organic fraction of municipal solid waste during composting. Microorganisms 2021, 9, 1877. [Google Scholar] [CrossRef]

- EL.STAT. Revision of the Results of the 2011 Population and Housing Census for the Resident, De Jure (Registered) and De Facto Population of Greece; Hellenic Statistical Authority: Pireas, Greece, 2014. [Google Scholar]

- Prefecture of Crete. Integration of the Local Waste Plans of the Municipalities of the Region. of Crete in the Regional Waste Management Planning (PESDAK) (Report in Greek Language); Prefecture of Crete Authority: Crete, Greece, 2016.

- Cecchi, F.; Traverso, P.; Pavan, P.; Bolzonella, D.; Innocenti, L. Characteristics of the OFMSW and Behavior of the Anaerobic Digestion Process. ChemInform 2003, 34, 141. [Google Scholar] [CrossRef]

- Edjabou, M.E.; Jensen, M.B.; Götze, R.; Pivnenko, K.; Petersen, C.; Scheutz, C.; Astrup, T.F. Municipal solid waste composition: Sampling methodology, statistical analyses, and case study evaluation. Waste Manag. 2015, 36, 12–23. [Google Scholar] [CrossRef] [Green Version]

- Cencic, O.; Rechberger, H. Material Flow Analysis with Software STAN. EnviroInfo 2008—Environ. Inform. Ind. Ecol. 2008, 2008, 440–447. [Google Scholar]

- Sevigné-Itoiz, E.; Gasol, C.M.; Rieradevall, J.; Gabarrell, X. Methodology of supporting decision-making of waste management with material flow analysis (MFA) and consequential life cycle assessment (CLCA): Case study of waste paper recycling. J. Clean. Prod. 2015, 105, 253–262. [Google Scholar] [CrossRef]

- Henriksen, T.; Levis, J.W.; Barlaz, M.A.; Damgaard, A. Approaches to fill data gaps and evaluate process completeness in LCA—perspectives from solid waste management systems. Int. J. Life Cycle Assess. 2019, 24, 1587–1601. [Google Scholar] [CrossRef] [Green Version]

- Clavreul, J.; Baumeister, H.; Christensen, T.H.; Damgaard, A. An environmental assessment system for environmental technologies. Environ. Model. Softw. 2014, 60, 18–30. [Google Scholar] [CrossRef] [Green Version]

- Favoino, E.; Hogg, D. The potential role of compost in reducing greenhouse gases. Waste Manag. Res. 2008, 26, 61–69. [Google Scholar] [CrossRef]

- Fruergaard, T.; Astrup, T.; Ekvall, T. Energy use and recovery in waste management and implications for accounting of greenhouse gases and global warming contributions. Waste Manag. Res. J. Sustain. Circ. Econ. 2009, 27, 724–737. [Google Scholar] [CrossRef]

- Koffi, B.; Cerutti, A.; Duerr, M.; Iancu, A.; Kona, A.; Janssens-Maenhout, G. CoM Default Emission Factors for the Member States of the European Union Dataset-Version 2017; European Commission—Joint Research Centre (JRC): Ispra, Italy, 2017. [Google Scholar]

- Djuric Ilic, D.; Eriksson, O.; Ödlund, L.; Åberg, M. No zero burden assumption in a circular economy. J. Clean. Prod. 2018, 182, 352–362. [Google Scholar] [CrossRef]

- Nakatani, J. Life cycle inventory analysis of recycling: Mathematical and graphical frameworks. Sustainability 2014, 6, 6158–6169. [Google Scholar] [CrossRef] [Green Version]

- Clavreul, J.; Guyonnet, D.; Christensen, T.H. Quantifying uncertainty in LCA-modelling of waste management systems. Waste Manag. 2012, 32, 2482–2495. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Andreasi Bassi, S.; Christensen, T.H.; Damgaard, A. Environmental performance of household waste management in Europe—An example of 7 countries. Waste Manag. 2017, 69, 545–557. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hung, M.L.; Ma, H.W. Quantifying system uncertainty of life cycle assessment based on Monte Carlo simulation. Int. J. Life Cycle Assess. 2009, 14, 19–27. [Google Scholar] [CrossRef]

- Burnley, S.J. A review of municipal solid waste composition in the United Kingdom. Waste Manag. 2007, 27, 1274–1285. [Google Scholar] [CrossRef]

- Riber, C.; Rodushkin, I.; Spliid, H.; Christensen, T.H. Method for fractional solid-waste sampling and chemical analysis. Int. J. Environ. Anal. Chem. 2007, 87, 321–335. [Google Scholar] [CrossRef]

- Alvarez, J.V.V.L.L.; Larrucea, M.A.; Bermúdez, P.A.; Chicote, B.L. Biodegradation of paper waste under controlled composting conditions. Waste Manag. 2009, 29, 1514–1519. [Google Scholar] [CrossRef]

- Riber, C.; Petersen, C.; Christensen, T.H. Chemical composition of material fractions in Danish household waste. Waste Manag. 2009, 29, 1251–1257. [Google Scholar] [CrossRef]

- Eggleston, S.; Buendia, L.; Miwa, K.; Ngara, T.; Tanabe, K. 2006 IPCC Guidelines for National Greenhouse Gas. Inventories, Prepared by the National Greenhouse Gas Inventories Programme; Institute for Global Environmental Strategies: Kanagawa, Japan, 2006. [Google Scholar]

- Christensen, T.H.; Gentil, E.; Boldrin, A.; Larsen, A.W.; Weidema, B.P.; Hauschild, M. C balance, carbon dioxide emissions and global warming potentials in LCA-modelling of waste management systems. Waste Manag. Res. J. Sustain. Circ. Econ. 2009, 27, 707–715. [Google Scholar] [CrossRef]

- Saer, A.; Lansing, S.; Davitt, N.H.; Graves, R.E. Life cycle assessment of a food waste composting system: Environmental impact hotspots. J. Clean. Prod. 2013, 52, 234–244. [Google Scholar] [CrossRef]

- López, M.; Soliva, M.; Martínez-Farré, F.X.; Fernández, M.; Huerta-Pujol, O. Evaluation of MSW organic fraction for composting: Separate collection or mechanical sorting. Resour. Conserv. Recycl. 2010, 54, 222–228. [Google Scholar] [CrossRef]

- Campuzano, R.; González-Martínez, S. Characteristics of the organic fraction of municipal solid waste and methane production: A review. Waste Manag. 2016, 54, 3–12. [Google Scholar] [CrossRef]

- Gutiérrez, M.C.; Martín, M.A.; Serrano, A.; Chica, A.F. Monitoring of pile composting process of OFMSW at full scale and evaluation of odour emission impact. J. Environ. Manag. 2015, 151, 531–539. [Google Scholar] [CrossRef] [PubMed]

- Sailer, G.; Eichermüller, J.; Poetsch, J.; Paczkowski, S.; Pelz, S.; Oechsner, H.; Müller, J. Characterization of the separately collected organic fraction of municipal solid waste (OFMSW) from rural and urban districts for a one-year period in Germany. Waste Manag. 2021, 131, 471–482. [Google Scholar] [CrossRef] [PubMed]

- Tuomela, M.; Vikman, M.; Hatakka, A.; Itävaara, M.; It, M. Biodegradation of lignin in a compost environment: A review. Bioresour. Technol. 2000, 72, 169–183. [Google Scholar] [CrossRef]

- Yuan, J.; Zhang, D.; Li, Y.; Chadwick, D.; Li, G.; Li, Y.; Du, L. Effects of adding bulking agents on biostabilization and drying of municipal solid waste. Waste Manag. 2017, 62, 52–60. [Google Scholar] [CrossRef]

- Cerda, A.; Artola, A.; Font, X.; Barrena, R.; Gea, T.; Sánchez, A. Composting of food wastes: Status and challenges. Bioresour. Technol. 2018, 248, 57–67. [Google Scholar] [CrossRef] [Green Version]

- Davis, G.U. Open windrow composting of polymers: An investigation into the operational issues of composting polyethylene (PE). Waste Manag. 2005, 25, 401–407. [Google Scholar] [CrossRef]

- Komilis, D.P.; Ham, R.K. Carbon dioxide and ammonia emissions during composting of mixed paper, yard waste and food waste. Waste Manag. 2006, 26, 62–70. [Google Scholar] [CrossRef]

- Gui, J.; Sun, Y.; Wang, J.; Chen, X.; Zhang, S.; Wu, D. Microplastics in composting of rural domestic waste: Abundance, characteristics, and release from the surface of macroplastics. Environ. Pollut. 2021, 274, 116553. [Google Scholar] [CrossRef] [PubMed]

- Vithanage, M.; Ramanayaka, S.; Hasinthara, S.; Navaratne, A. Compost as a carrier for microplastics and plastic-bound toxic metals into agroecosystems. Curr. Opin. Environ. Sci. Health 2021, 24, 100297. [Google Scholar] [CrossRef]

- Narancic, T.; Verstichel, S.; Reddy Chaganti, S.; Morales-Gamez, L.; Kenny, S.T.; De Wilde, B.; Babu Padamati, R.; O’Connor, K.E. Biodegradable Plastic Blends Create New Possibilities for End-of-Life Management of Plastics but They Are Not a Panacea for Plastic Pollution. Environ. Sci. Technol. 2018, 52, 10441–10452. [Google Scholar] [CrossRef] [PubMed]

- Hellmann, B.; Zelles, L.; Palojärvi, A.; Bai, Q. Emission of climate-relevant trace gases and succession of microbial communities during open-windrow composting. Appl. Environ. Microbiol. 1997, 63, 1011–1018. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hargreaves, J.C.; Adl, M.S.; Warman, P.R. A review of the use of composted municipal solid waste in agriculture. Agric. Ecosyst. Environ. 2008, 123, 1–14. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, M.P. GHG emission and carbon sequestration potential from MSW of Indian metro cities. Urban. Clim. 2014, 8, 30–41. [Google Scholar] [CrossRef]

- Staley, B.F.; Barlaz, M.A. Composition of Municipal Solid Waste in the United States and Implications for Carbon Sequestration and Methane Yield. J. Environ. Eng. 2009, 135, 901–909. [Google Scholar] [CrossRef]

- Andersen, J.K.; Boldrin, A.; Christensen, T.H.; Scheutz, C. Mass balances and life cycle inventory of home composting of organic waste. Waste Manag. 2011, 31, 1934–1942. [Google Scholar] [CrossRef] [Green Version]

- Amlinger, F.; Peyr, S.; Cuhls, C. Green house gas emissions from composting and mechanical biological treatment. Waste Manag. Res. J. Sustain. Circ. Econ. 2008, 26, 47–60. [Google Scholar] [CrossRef]

- Clemens, J.; Cuhls, C. Greenhouse gas emissions from mechanical and biological waste treatment of municipal waste. Environ. Technol. 2003, 24, 745–754. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, X.; Wang, F.; Bai, Z.; Chadwick, D.; Misselbrook, T.; Ma, L. The progress of composting technologies from static heap to intelligent reactor: Benefits and limitations. J. Clean. Prod. 2020, 270, 122328. [Google Scholar] [CrossRef]

- Themelis, N.J.; Kim, Y.H. Material and energy balances in a large-scale aerobic bioconversion cell. Waste Manag. Res. J. Sustain. Circ. Econ. 2002, 20, 234–242. [Google Scholar] [CrossRef] [PubMed]

- Groen, E.A.; Heijungs, R.; Bokkers, E.A.M.; de Boer, I.J.M. Methods for uncertainty propagation in life cycle assessment. Environ. Model. Softw. 2014, 62, 316–325. [Google Scholar] [CrossRef]

- Helton, J.C.; Johnson, J.D.; Sallaberry, C.J.; Storlie, C.B. Survey of sampling-based methods for uncertainty and sensitivity analysis. Reliab. Eng. Syst. Saf. 2006, 91, 1175–1209. [Google Scholar] [CrossRef] [Green Version]

- Groen, E.A.; Bokkers, E.A.M.; Heijungs, R.; de Boer, I.J.M. Methods for global sensitivity analysis in life cycle assessment. Int. J. Life Cycle Assess. 2017, 22, 1125–1137. [Google Scholar] [CrossRef] [Green Version]

- Laurent, A.; Clavreul, J.; Bernstad, A.; Bakas, I.; Niero, M.; Gentil, E.; Christensen, T.H.; Hauschild, M.Z. Review of LCA studies of solid waste management systems—Part II: Methodological guidance for a better practice. Waste Manag. 2014, 34, 589–606. [Google Scholar] [CrossRef]

- EU 2018/851; Directive 2018/851 Amending Directive 2008/98/EC on Waste Framework. Official Journal of the European Union: Luxembourg, 2018; p. L-150/109.

- Doing, M. The Market. for Mechanical Biological Waste Treatment in Europe—Locations, Plants, Backgrounds and Market Estimations; Ecoprog GmbH: Köln, Germany, 2017. [Google Scholar]

- Environmental Protection Agency. National Plan for Waste Management—Including Hazardous Waste (Legislation in Greek Language); Environmental Protection Agency: Athens, Greece, 2020; p. 729.

- Abeliotis, K.; Kalogeropoulos, A.; Lasaridi, K. Life Cycle Assessment of the MBT plant in Ano Liossia, Athens, Greece. Waste Manag. 2012, 32, 213–219. [Google Scholar] [CrossRef]

| Composting Conditions | Value—Factor | |

| Mixing ratio by volume (OFMSW:GW) | 1:4 | |

| Retention time in the composting tank | 4 weeks | |

| Refinery unit | Yes | |

| Residue after treatment | Used for landfill cover | |

| Maturation time | 6–9 months | |

| Personel | Number of People | Involvement |

| Operation manager (senior engineer) | 1 | Full-time |

| Front line stuff (workers) | 2 | Full-time |

| Heavy machinery operator | 1 | Full-time |

| Mentainence mechanic | 1 | Part-time |

| Mentainence electrician | 1 | Part-time |

| Truck driver | 1 | Part-time |

| Type of Process/Emission | Emission Factor | Reference |

|---|---|---|

| Provision of diesel oil | 0.306 kg CO2-eq/L diesel | [33] |

| Combustion of diesel oil | 2.7 kg CO2-eq/L diesel | [32] |

| Provision of electricity | 0.810 kg CO2-eq/kWh | [33] |

| Fraction | OFMWS Composition (%) | OFMSW Water Content (%) | TS (%) | VS (%) | Ash (%) | C Bio (%) | C Fossil (%) | N(%) |

|---|---|---|---|---|---|---|---|---|

| Biodegradable | ||||||||

| Biowaste | 76.49 ± 10.55 | 56.04 | 37.40 | 90.00 | 10.00 | 54.60 | 0.60 | 3.72 |

| Paper | 11.40 ± 10.91 | 33.29 | 87.00 | 72.30 | 27.70 | 37.60 | 0.20 | 0.18 |

| Dirty paper | 0.29 ± 0.63 | 53.30 | 75.50 | 91.10 | 8.90 | 44.60 | 0.91 | 0.30 |

| Cardboard | 1.24 ± 17.06 | 39.33 | 89.50 | 84.90 | 15.10 | 41.10 | 0.30 | 0.24 |

| Green waste | 4.64 ± 1.62 | 47.00 | 53.00 | 93.00 | 7.00 | 43.02 | 0.00 | 0.15 |

| Plastics * | ||||||||

| Soft plastic (PE) | 0.30 ± 2.90 | 28.25 | 85.89 | 95.60 | 4.40 | 0.41 | 81.60 | 0.20 |

| Hard plastic (PP) | 0.29 ± 2.05 | 22.83 | 96.80 | 97.80 | 2.20 | 0.40 | 79.50 | 5.50 |

| Non-recyclable plastic | 0.30 ± 3.90 | 0.00 | 92.90 | 94.50 | 5.50 | 0.36 | 70.60 | 0.50 |

| Metals | ||||||||

| Aluminum foil and containers | 0.14 ± 0.47 | 24.95 | 81.20 | 23.90 | 76.10 | 13.70 | 1.52 | 0.40 |

| Batteries and electronic devices | 0.14 ± 0.93 | 9.72 | 91.10 | 14.20 | 85.80 | 4.35 | 4.35 | 0.10 |

| Food cans (tinplate/steel) | 0.15 ± 1.57 | 7.03 | 86.82 | 0.00 | 100.00 | 0.00 | 0.00 | 0.00 |

| Other materials | ||||||||

| Rubber | 0.11 ± 3.58 | 34.42 | 92.30 | 90.30 | 9.70 | 52.30 | 13.10 | 0.60 |

| Leather | 0.11 ± 3.58 | 34.42 | 93.30 | 87.40 | 12.60 | 30.70 | 30.70 | 0.30 |

| Textile | 0.11 ± 3.58 | 34.42 | 94.00 | 96.40 | 3.60 | 39.10 | 13.00 | 3.20 |

| Processed wood | 0.11 ± 3.58 | 34.42 | 84.60 | 96.30 | 3.70 | 49.40 | 0.00 | 0.00 |

| Glass | 3.17 ± 2.05 | 2.23 | 99.70 | 1.20 | 98.80 | 0.00 | 0.00 | 0.10 |

| Other Inert | 1.81 ± 2.87 | 34.71 | 63.40 | 2.30 | 97.70 | 0.65 | 0.65 | 0.00 |

| Fraction | Degradation Factor (%) |

|---|---|

| Biowaste | 48 |

| Paper | 61 |

| Dirty paper | 43.3 |

| Cardboard | 51 |

| Green waste | 15 |

| Soft plastic (PE) | 10 |

| Other inert | 5 |

| Other materials | 0 |

| Fraction | Transfer Coefficients (%) |

|---|---|

| Biowaste | 45 |

| Paper | 60 |

| Cardboard | 100 |

| Green waste | 5 |

| Soft plastic (PE) | 2 |

| Hard plastic (PP) | 1 |

| Non-recyclable plastic | 1 |

| Other materials | 0 |

| Row Labels | Process Attributed | Unit/Mg of Material Treated in the Corresponding Process Material | |

|---|---|---|---|

| Backhoe loader (L of diesel) | MIDI wheel loader (L/Mg) | Maturation | 2.201 |

| Wheel loader (L of diesel) | Wheel loader (L/Mg) | Maturation | 1.096 |

| Other tractor (L of diesel) | Hook lift (L/Mg) | Maturation | 0.311 |

| Other drivable machines (L of diesel) | Compost turner (L/Mg) | Maturation | 0.098 |

| Marginal Electricity Consumption (kWh) | Electricity (kWh/Mg) | Aerobic composting Tank and Refinery | 34.56 |

| Water consumption for composting process in aerobic composting tank | L/Mg entering main composting | Aerobic composting Tank and Refinery | 200.0 |

| Water consumption for maturation state in open windrows | L/Mg material in windrows | Maturation | 583.7 |

| Refinery Output | Rejects Output | Final CLO | |

|---|---|---|---|

| Degradation Factor | |||

| Aerobic composting tank | |||

| Biowaste | 0.8 | 0.9 | 0.2 |

| Paper | 0.2 | 0.1 | 0.1 |

| Dirty paper | 0.0 | 0.0 | 0.0 |

| Cardboard | 0.0 | 0.0 | 0.0 |

| Green waste | 0.0 | 0.0 | 0.0 |

| Soft plastic (PE) | 0.0 | 0.0 | 0.0 |

| Other Inert | 0.0 | 0.0 | 0.0 |

| Transfer coefficient | |||

| Refinery process | |||

| Biowaste | 0.0 | 0.0 | 0.0 |

| Paper | 1.0 | 1.0 | 0.5 |

| Dirty paper | 0.3 | 0.3 | 0.2 |

| Cardboard | 0.0 | 0.0 | 0.0 |

| Green waste | 0.0 | 0.0 | 0.0 |

| Soft plastic (PE) | 0.0 | 0.0 | 0.0 |

| Degradation Factor | |||

| Open windrows | |||

| Degradation Factor | - | - | 1.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chazirakis, P.; Giannis, A.; Gidarakos, E. Modeling the Life Cycle Inventory of a Centralized Composting Facility in Greece. Appl. Sci. 2022, 12, 2047. https://doi.org/10.3390/app12042047

Chazirakis P, Giannis A, Gidarakos E. Modeling the Life Cycle Inventory of a Centralized Composting Facility in Greece. Applied Sciences. 2022; 12(4):2047. https://doi.org/10.3390/app12042047

Chicago/Turabian StyleChazirakis, Panagiotis, Apostolos Giannis, and Evangelos Gidarakos. 2022. "Modeling the Life Cycle Inventory of a Centralized Composting Facility in Greece" Applied Sciences 12, no. 4: 2047. https://doi.org/10.3390/app12042047

APA StyleChazirakis, P., Giannis, A., & Gidarakos, E. (2022). Modeling the Life Cycle Inventory of a Centralized Composting Facility in Greece. Applied Sciences, 12(4), 2047. https://doi.org/10.3390/app12042047