Concrete Blocks Reinforced with Arundo donax Natural Fibers with Different Aspect Ratios for Application in Bioarchitecture

Abstract

:1. Introduction

Significance of Current Work

2. Materials and Methods

2.1. Arundo donax Fibers

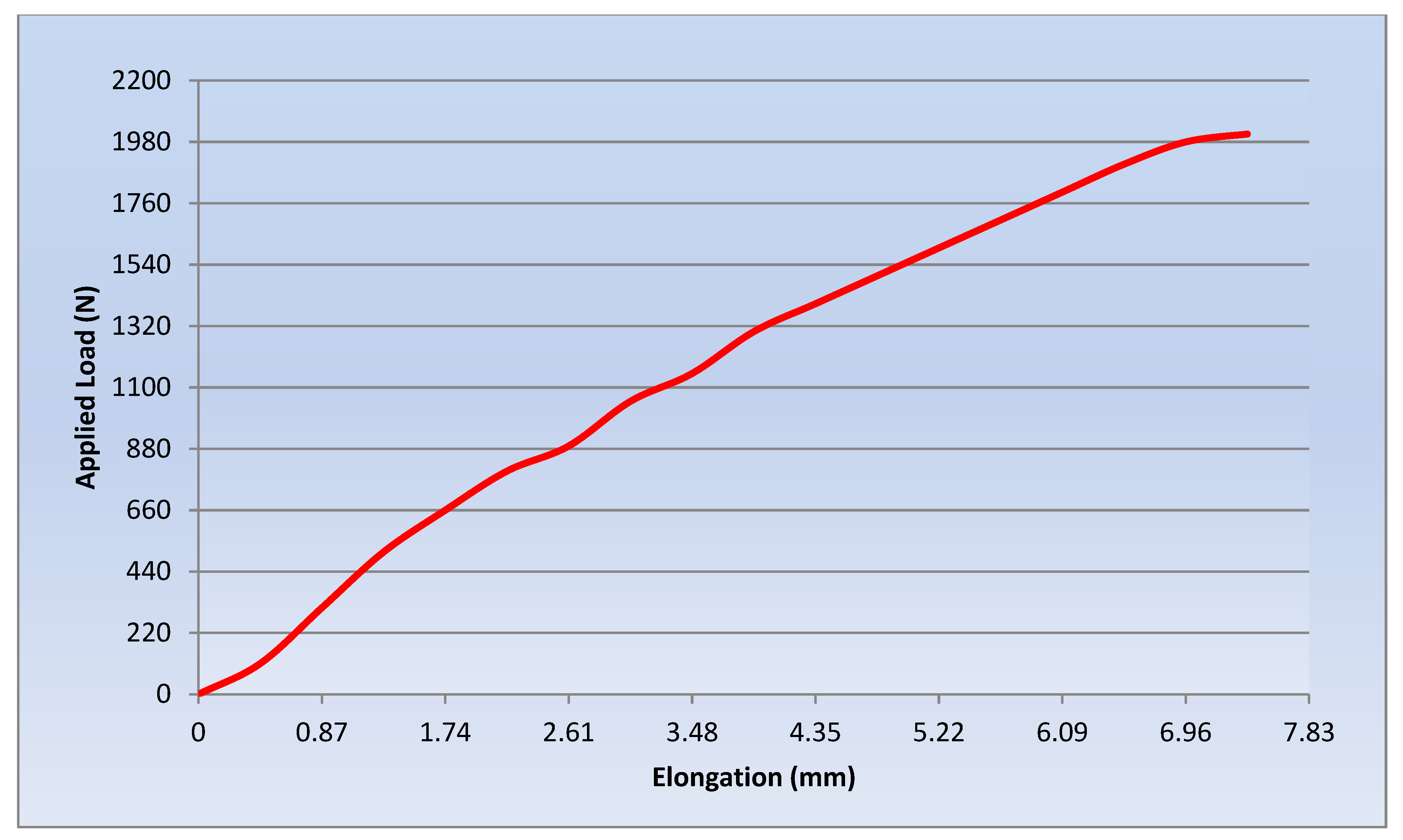

2.2. Tensile Test on Arundo donax Fibers

2.3. Cylindrical Concrete Samples

- 4 samples were reinforced with natural fiber having AR = 30: length equal to 90 mm and transversal equivalent diameter equal to 3 mm;

- 4 samples were reinforced with natural fiber having AR = 50: length equal to 150 mm and transversal equivalent diameter equal to 3 mm;

- 4 samples were reinforced with natural fiber having AR = 70: length equal to 210 mm and transversal equivalent diameter equal to 3 mm.

- Pozzolanic cement “CEM IV 325”, according to UNI EN 197-1:2011 [86], in a percentage of 20% of the total volume, that constitutes the active component of concrete. Compared to Portland cement, it has a slower hardening process, thus improving workability and durability [87]. Today, industrial cement manufacturers are increasingly using materials such as pozzolan, fly ash, and volcanic ash, to replace part of Portland cement, in order to reduce CO2 emissions and the relative cost, and to improve the resistance to chemical attack by sulphates and sea water.

- sand particles, consisting of loose sedimentary rock with a grain size measuring less than 1.5 mm and a humidity content below 10%, in a percentage of 30% of the total volume;

- quarry gravel, crushed and rounded rock with granule size less than 30 mm, in a percentage of 40% of the total volume;

- water, which has the fundamental function of hydrating the cement and whose quantity greatly influences the strength characteristics of the hardened concrete, in a percentage of 10% of the total volume.

2.4. Splitting Tensile Strength Test on Cylindrical Samples (Brazilian Test)

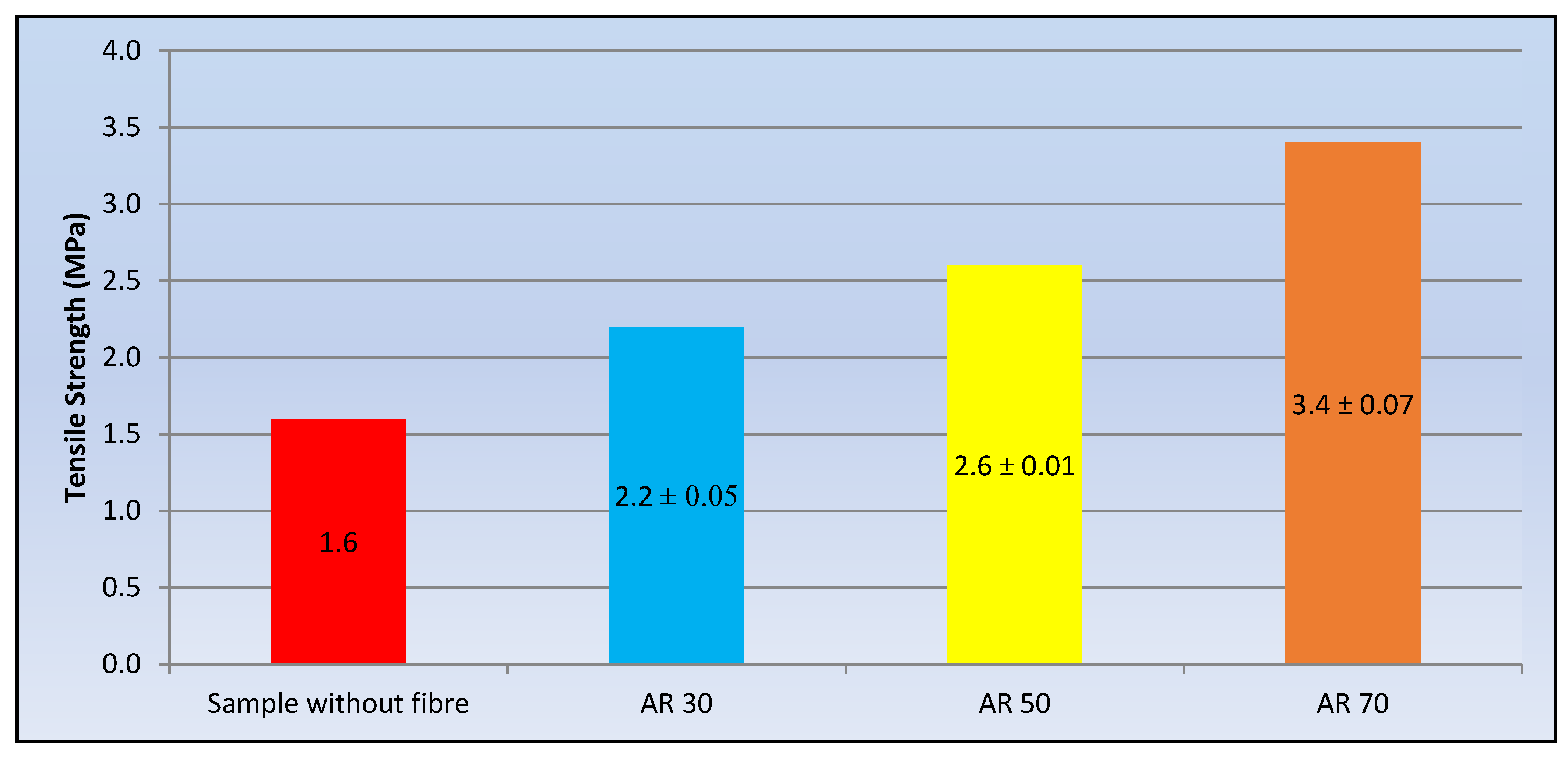

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statuto, D.; Picuno, P. Valorisation of vernacular farm buildings for the sustainable development of rural tourism in mountain areas of the Adriatic-Ionian macro-region. J. Agric. Eng. 2017, 48, 21–26. [Google Scholar] [CrossRef]

- Picuno, C.A.; Laković, I.; Roubis, D.; Picuno, P.; Kapetanović, A. Analysis of the characteristics of traditional rural constructions for animal corrals in the Adriatic-Ionian area. Sustainability 2017, 9, 1441. [Google Scholar] [CrossRef] [Green Version]

- Yoo, D.Y.; Kim, S.; Park, G.J.; Park, J.J.; Kim, S.W. Effect of fiber shape, aspect ratio, and volume fraction on flexural behavior of ultra-high performance fiber-reinforced cement composites. Compos. Struct. 2017, 174, 375–388. [Google Scholar] [CrossRef]

- Xiao, J.; Qiang, C.; Nanni, A.; Zhang, K. Use of sea-sand and seawater in concrete construction: Current status and future opportunities. Constr. Build. Mater. 2017, 155, 1101–1111. [Google Scholar] [CrossRef]

- Biswas, R.K.; Iwanami, M.; Chijiwa, N.; Nakayama, K. Numerical evaluation on the effect of steel bar corrosion on the cyclic behaviour of RC bridge piers. Mater. Today Proc. 2021, 44, 2393–2398. [Google Scholar] [CrossRef]

- Li, Z. Advanced Concrete Technology, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Picuno, C.; Godosi, Z.; Kuchta, K.; Picuno, P. Agrochemical plastic packaging waste decontamination for recycling: Pilot tests in Italy. J. Agric. Eng. 2019, 50, 99–104. [Google Scholar] [CrossRef]

- Manniello, C.; Statuto, D.; Di Pasquale, A.; Picuno, P. Planning the flows of residual biomass produced by wineries for their valorisation in the framework of a circular bioeconomy. In Lecture Notes in Civil Engineering; Springer: Cham, Switzerland, 2020; Volume 67, pp. 295–303. [Google Scholar]

- Statuto, D.; Tortora, A.; Picuno, P. A GIS approach for the quantification of forest and agricultural biomass in the Basilicata region. J. Agric. Eng. 2013, 44, 627–631. [Google Scholar] [CrossRef]

- Statuto, D.; Frederiksen, P.; Picuno, P. Valorization of Agricultural by-products within the “Energyscapes”: Renewable energy as driving force in modeling rural landscape. Nat. Resour. Res. 2019, 28, 111–124. [Google Scholar] [CrossRef]

- Manniello, C.; Statuto, D.; Di Pasquale, A.; Cillis, G.; Picuno, P. The impact of soil fertility on the characteristics of the rural landscape for its protection. In Proceedings of the Public Recreation and Landscape Protection—With Sense Hand in hand? Křtiny, Czech Republic, 13–15 May 2019; pp. 484–488. [Google Scholar]

- Manniello, C.; Statuto, D.; Di Pasquale, A.; Giuratrabocchetti, G.; Picuno, P. Planning the flows of residual biomass produced by wineries for the preservation of the rural landscape. Sustainability 2020, 12, 847. [Google Scholar] [CrossRef] [Green Version]

- Coutts, R.S.P. Flax fibres as a reinforcement in cement mortars. Int. J. Cem. Compos. Lightweight Concr. 1983, 5, 257–262. [Google Scholar] [CrossRef]

- Boghossian, E.; Wegner, L.D. Use of flax fibres to reduce plastic shrinkage cracking in concrete. Cem. Concr. Compos. 2008, 30, 929–937. [Google Scholar] [CrossRef]

- Yaremko, C. Durability of Flax Fibre Reinforced Concrete. Master’s thesis, Department of Civil Engineering, University of Saskatchewan, Saskatoon, SK, Canada, 2012; p. 129. [Google Scholar]

- Fic, S.; Brzyski, P.; Szelag, M. Composite based on foam lime mortar with flax fibres for use in the building industry. Proc. ECOPole 2015, 9, 25–31. [Google Scholar] [CrossRef]

- Snoeck, D.; De Belie, N. Mechanical and self-healing properties of cementitious composites reinforced with flax and cottonised flax, and compared with polyvinyl alcohol fibres. Biosyst. Eng. 2012, 111, 325–335. [Google Scholar] [CrossRef]

- Baley, C. Analysis of the flax fibres tensile behaviour and analysis of the tensile stiffness increase. Compos. Part A Appl. Sci. Manuf. 2002, 33, 939–948. [Google Scholar] [CrossRef]

- Kizilkanat, A.B.; Kabay, N.; Akyuncu, V.; Chowdhury, S.; Akca, A.H. Mechanical properties and fracture behavior of basalt and glass fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2015, 100, 218–224. [Google Scholar] [CrossRef]

- Murthy, Y.I.; Sharda, A.; Jain, G. Performance of Glass Fiber Reinforced Concrete. Int. J. Eng. 2012, 1, 2008–2010. [Google Scholar]

- Yost, J.R.; Gross, S.P.; Dinehart, D.W. Effective Moment of Inertia for Glass Fiber Reinforced Polymer Reinforced Concrete Beams. Struct. J. 2003, 100, 732–739. [Google Scholar]

- Sen, T.; Jagannatha, R.H. Various industrial applications of hemp, kinaf, flax and ramie natural fibres. Int. J. Innov. Manag. Technol. 2011, 2, 192–198. [Google Scholar]

- Murphy, F.; Pavia, S.; Walker, R. An assessment of the physical properties of lime-hemp concrete. In Proceedings of BRI/CRI; Ní Nualláin, N.A., Walsh, D., West, R., Cannon, E., Caprani, C., McCabe, B., Eds.; University College Cork: Cork, Ireland, 2010; pp. 431–439. [Google Scholar]

- Li, Z.; Wnag, X.; Wang, L. Properties of hemp fibre reinforced concrete composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 497–505. [Google Scholar] [CrossRef] [Green Version]

- Awwad, E.; Mabsout, M.; Hamad, B.; Talal Farran, M.; Khatib, H. Studies on fibre-reinforced concrete using industrial hemp fibres. Constr. Build. Mater. 2012, 35, 710–717. [Google Scholar] [CrossRef]

- Awwad, E.; Chouetier, D.; Khatib, H. Concrete masonry blocks reinforced with local industrial hemp fibres and hurds. In Proceedings of the 3rd International Conference on Sustainable Construction Materials and Technology, Kyoto, Japan, 18–21 August 2013; p. 11. [Google Scholar]

- Awwad, E.; Hamad, B.; Mabsout, M.; Khatib, H. Structural behaviour of simply supported beams cast with hemp-reinforced concrete. ACI Struct. J. 2014, 111, 1307–1316. [Google Scholar] [CrossRef]

- Sedan, D.; Pagnounx, C.; Smith, A.; Chotard, T. Mechanical properties of hemp fibre reinforced cement: Influence of the fibre/matrix interaction. J. Eur. Ceram. Soc. 2008, 28, 183–192. [Google Scholar] [CrossRef]

- Rohit, K.; Dixit, S. A Review-Future Aspect of Natural Fiber Reinforced Composite. Polym. Renew. Resour. 2016, 7, 43–59. [Google Scholar] [CrossRef]

- Staiger, M.P.; Tucker, N. Natural-fiber composites in structural applications. In Properties and Performance of Naturalfibre Composites; Pickering, K., Ed.; Woodhead Publishing: Cambridge, UK, 2008. [Google Scholar]

- Mansur, M.A.; Aziz, M.A. A study of jute fibre reinforced cement composites. Int. J. Cem. Compos. Lightweight Concr. 1982, 4, 75–82. [Google Scholar] [CrossRef]

- Kharagpur, I.T. Development of Jute Fibre Reinforced Cement Concrete Composites; National Jute Board, Ministry of Textile, Govt. of India: Kolkata, India, 2011. [Google Scholar]

- Sen, T.; Jagannatha, R.H. Strengthening of RC beams in flexure using natural jute fibre textile reinforced composite system and its comparative study with CFRP and GFRP strengthening systems. Int. J. Sustain. Built. Environ. 2013, 2, 41–55. [Google Scholar] [CrossRef] [Green Version]

- Faruk, O.; Sain, M. Biofibre Reinforcement in Composite Materials; Woodhead Publishing: Sawston, UK, 2015; p. 772. ISBN 9781782421221. [Google Scholar]

- Lobovikov, M.; Shyam, P.; Piazza, M.; Ren, H.; Wu, J. Non Wood Forest Products 18 World Bamboo Resources. A Thematic Study Prepared in the Framework of the Global Forest Resources Assessment; Food and Agriculture Organization of the United Nations: Rome, Itaty, 2007. [Google Scholar]

- Balaji, A.; Karthikeyan, B.; Sundar Raj, C. Bagasse Fiber—The Future Biocomposite Material: A Review. Int. J. Chemtech Res. 2014, 7, 223–233. [Google Scholar]

- Akil, H.M.; Omar, M.F.; Mazuki, A.A.M.; Safiee, S.; Ishak, Z.A.M.; Abu Bakar, A. Kenaf fibre reinforced composites. A review. Mater. Design 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Awang, H.; Ahmad, M.H.; Al-Mulali, M.Z. Influence of kenaf and polypropylene fibres on mechanical and durability properties of fibre reinforced lightweight foamed concrete. J. Eng. Sci. Technol. 2015, 10, 496–508. [Google Scholar]

- Elsaid, A.; Dawood, M.; Seracino, R.; Bobko, C. Mechanical properties of kenaf fiber reinforced concrete. Constr. Build. Mater. 2011, 25, 1991–2001. [Google Scholar] [CrossRef]

- Arshad, S.; Sharif, M.B.; Hassan, M.I.; Khan, M. Efficiency of Supplementary Cementitious materials and Natural Fiber on Mechanical Performance of Concrete. Arab. J. Sci. Eng. 2020, 45, 8577–8589. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, J. Impact of partial replacement of cement with rice husk ash and proportionate addition of coconut fibre on concrete. Int. J. Mech. Eng. Technol. 2017, 8, 1806–1813. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Natural Fibers, Biopolymers and Biocomposites; Taylor & Francis: Boca Raton, FL, USA, 2005. [Google Scholar]

- Ahmad, W.; Farooq, S.H.; Usman, M.; Khan, M.; Ahmad, A.; Aslam, F.; Al Yousef, R.; Al Abduljabbar, H.; Sufian, N. Effect of Coconut Fiber Length and Content on Properties of High Strength Concrete. Materials 2020, 13, 1075. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sanjuàn, M.A.; Toledo Filho, R.D. Effectiveness of crack control at early age on the corrosion of steel bars in low modulus sisal and coconut fibre reinforced mortars. Cem. Concr. Res. 1998, 28, 555–565. [Google Scholar] [CrossRef]

- Tolêdo Filho, R.D.; Scrivener, K.; England, G.L.; Ghavami, K. Durability of alkali-sensitive sisal and coconut fibres in cement mortar composites. Cem. Concr. Compos. 2000, 22, 127–143. [Google Scholar] [CrossRef]

- John, V.M.; Cincotto, M.A.; Sjöström, C.; Agopyan, V.; Oliveira, C.T.A. Durability of slag mortar reinforced with coconut fibre. Cem. Concr. Compos. 2005, 27, 565–574. [Google Scholar] [CrossRef]

- Almeida, E.F.S.; Tonoli, G.H.D.; Santos, S.F.; Savastano, H. Improved durability of vegetable fibre reinforced cement composite subject to accelerated carbonation at early age. Cem. Concr. Compos. 2013, 42, 49–58. [Google Scholar] [CrossRef]

- Ali, M.; Liu, A.; Sou, H.; Chouw, N. Mechanical and dynamic properties of coconut fibre reinforced concrete. Constr. Build. Mater. 2012, 30, 814–825. [Google Scholar] [CrossRef]

- Al-Masoodi, A.H.H.; Kawan, A.; Kasmuri, M.; Hamid, R.; Khan, M.N.N. Static and dynamic properties of concrete with different types and shapes of fibrous reinforcement. Constr. Build. Mater. 2016, 104, 247–262. [Google Scholar] [CrossRef]

- Alavez-Ramirez, R.; Chiñas-Castillo, F.; Morales-Dominguez, V. Effect of wheat straw ash on mechanical properties of autoclaved mortar. Cem. Concr. Res. 2014, 32, 859–863. [Google Scholar]

- Khedari, J.; Watsanasathaporn, P.; Hirunlabh, J. Development of fibre-based soil–cement block with low thermal conductivity. Cem. Concr. Compos. 2005, 27, 111–116. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Suntijitto, A. Properties of natural fibre cement materials containing coconut coir and oil palm fibres for residential building applications. Constr. Build. Mater. 2015, 94, 664–669. [Google Scholar] [CrossRef]

- Ali, M. Seismic performance of coconut-fibre-reinforced-concrete columns with different reinforcement configurations of coconut-fibre ropes. Constr. Build. Mater. 2014, 70, 226–230. [Google Scholar] [CrossRef]

- Statuto, D.; Bochicchio, M.; Sica, C.; Picuno, P. Experimental development of clay bricks reinforced with agricultural by-products. In Proceedings of the 46th Symposium “Actual Tasks on Agricultural Engineering”, Opatija, Croatia, 27 February–1 March 2018. [Google Scholar]

- Parlato, M.; Porto, S.M.C.; Cascone, G. Raw earth-based building materials: An investigation on mechanical properties of Floridia soil-based adobes. J. Agric. Eng. 2021, 52, 1154. [Google Scholar] [CrossRef]

- Fiore, V.; Valenza, A.; Di Bella, G. Artichoke (Cynara cardunculus L.) fibres as potential reinforcement of composite structures. Compos. Sci. Technol. 2011, 71, 1138–1144. [Google Scholar] [CrossRef]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, K.U.; Joseph, R. Isora fiber: Morphology, chemical composition, surface modification, physical, mechanical and thermal properties—A potential natural reinforcement. J. Nat. Fibers 2006, 3, 13–27. [Google Scholar] [CrossRef]

- Seki, Y.; Sarikanat, M.; Sever, K.; Durmuşkahya, C. & Durmus¸ kahya, C. Extraction and properties of Ferula communis (chakshir) fibers as novel reinforcement for composites materials. Compos. Part B Eng. 2013, 44, 517–523. [Google Scholar]

- Sarikanat, M.; Seki, Y.; Sever, K.; Durmuşkahya, C. Determination of properties of Althaea officinalis L. (Marshmallow) fibres as a potential plant fibre in polymeric composite materials. Compos. Part B Eng. 2014, 57, 180–186. [Google Scholar] [CrossRef]

- D’Almeida, J.R.M.; Aquino, R.C.M.P.; Monteiro, S.N. Tensile mechanical properties, morphological aspects and chemical characterization of piassava (Attalea funifera) fibers. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1473–1479. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Navaneethakrishnan, P.; Shankar, S.; Rajasekar, R. Characterization of new cellulose sansevieria ehrenbergii fibers for polymer composites. Compos. Interfaces 2013, 20, 575–593. [Google Scholar] [CrossRef]

- Da Silva Santos, R.; De Souza, A.A.; DePaoli, M.A.; De Souza, C.M.L. Cardanolformaldehyde thermoset composites reinforced with buriti fibers: Preparation and characterization. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1123–1129. [Google Scholar] [CrossRef]

- Danso, H.; Brett Martinson, D.; Ali, M.; Williams, J. Effect of fibre aspect ratio on mechanical properties of soil building blocks. Constr. Build. Mater. 2015, 83, 314–319. [Google Scholar] [CrossRef] [Green Version]

- Bouhicha, M.; Aouissi, F.; Kenai, S. Performance of composite soil reinforced with barley straw. Cem. Concr. Compos. 2005, 27, 617–621. [Google Scholar] [CrossRef]

- Juárez, C.; Guevara, B.; Valdez, P.; Durán-Herrera, A. Mechanical properties of natural fibers reinforced sustainable masonry. Constr. Build. Mater. 2010, 24, 1536–1541. [Google Scholar] [CrossRef]

- Aymerich, F.; Fenu, L.; Meloni, P. Effect of reinforcing wool fibres on fracture and energy absorption properties of an earthen material. Constr. Build. Mater. 2012, 27, 66–72. [Google Scholar] [CrossRef]

- Gaw, B.; Zamora, S. Soil Reinforcement with Natural Fibers for Low-Income Housing Communities; Worcester Polytechnic Institute: Worcester, MA, USA, 2011. [Google Scholar]

- Pari, L.; Suardi, A.; Giannini, E.; Civitarese, V. Strategie per meccanizzare la raccolta di canna comune. Suppl. All'informatore Agrar. 2009, 29, 22–25. [Google Scholar]

- Ververis, C.; Georghiou, K.; Christodoulakis, N.; Santas, P.; Santas, R. Fiber dimensions, lignin and cellulose content of various plant materials and their suitability for paper production. Ind. Crops Prod. 2014, 19, 245–254. [Google Scholar] [CrossRef]

- Flores, J.A.; Pastor, J.J.; Martinez-Gabaroon, A.; Gimeno-Blanes, F.J.; Rodriguez-Guisado, I. Arundo donax chipboard based on urea-formaldehyde resin using under 4mm particles size meets the standard criteria for indoor use. Ind. Crops Prod. 2011, 34, 1538–1542. [Google Scholar] [CrossRef]

- Ferrandez-Garcia, M.T.; Ferrandez-Garcia, C.E.; Garcia-Ortuño, T.; Ferrandez-Garcia, A.; Ferrandez-Villena, M. Experimental evaluation of a new giant reed (Arundo donax L.) composite using citric acid as a natural binder. Agronomy 2019, 9, 882. [Google Scholar] [CrossRef] [Green Version]

- Barreca, F. The natural material in bioconstruction between tradition and innovation: The use of giant reed Arundo donax L. in the rural constructions. In Proceedings of the CIGR XVIIth World Congress, Québec City, QC, Canada, 13–17 June 2010. [Google Scholar]

- Ferrandez-Garcia, C.E.; Andreu Rodriguez, J.; Ferrandez-Garcia, M.T.; Ferrandez-Villena, M.; Garcia-Ortuño, T. Panels made with giant reed bonded with nonmodified starches. Bioresources 2012, 7, 5904–5916. [Google Scholar] [CrossRef] [Green Version]

- Spatz, H.-C.; Beismann, H.; Brüchert, F.; Emanns, A.; Speck, T. Biomechanics of Giant Reed Arundo Donax. Philos. Trans. R. Soc. Lond. Ser. B Biol. Sci. 1997, 352, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Conte, P.; Fiore, V.; Valenza, A. Structural and Mechanical Modification Induced by Water Content in Giant Wild Reed (A. donax L.). ACS Omega 2018, 3, 18510–18517. [Google Scholar] [CrossRef] [Green Version]

- Molari, L.; Coppolino, F.S.; Garcia, J.J. Arundo donax: A widespread plant with great potential as sustainable structure material. Constr. Build. Mater. 2021, 268, 121143. [Google Scholar] [CrossRef]

- Ortuno, T.G.; Andreu, J.; Fernandez Garcia, M.T.; Fernandez Villena, M. Study of the Mechanical Properties of Giant Reed as a Green Building Material. In Proceedings of the Second International Conference on Advances in Civil, Structural and Environmental Engineering—ACSEE, Zurich, Switzerland, 25–26 October 2014; The IRED: New York, NY, USA, 2014. [Google Scholar]

- Fiore, V.; Scalici, T.; Valenza, A. Characterisation of a new natural fiber Arundo donax L. as potential reinforcement of polymer composites. Carbohydr. Polym. 2014, 106, 77–83. [Google Scholar] [CrossRef] [PubMed]

- Manniello, C.; Cillis, G.; Statuto, D.; Di Pasquale, A.; Picuno, P. Experimental analysis on concrete blocks reinforced with Arundo donax fibers. J. Agric. Eng. 2021, 12, 88. (in press). [Google Scholar] [CrossRef]

- Picuno, P. Use of traditional material in farm buildings for a sustainable rural environment. Int. J. Sustain. Built Environ. 2016, 5, 451–460. [Google Scholar] [CrossRef] [Green Version]

- Coppolino, C.; Molari, L.; Maraldi, M.; Greco, S. Prove di Caratterizzazione Meccanica della Canna Comune (Arundo Donax) in Prospettiva di un uso Strutturale Sostenibile; Dipartimento di Ingegneria Civile, Chimica, Ambientale e dei Materiali, Alma Mater Studiorum, Università di Bologna: Bologna, Italy, 2018. [Google Scholar]

- Hardion, L.; Verlaque, R.; Saltonstall, K.; Leriche, A.; Vila, B. Origin of the Invasive Arundo donax (Poaceae): A Trans-Asian Expedition in Herbaria. Ann. Bot. 2014, 114, 455–462. [Google Scholar] [CrossRef] [Green Version]

- Bucci, A.; Barone, C.F.; Pilu, R. La Canna Comune (Arundo donax L.)—Aspetti Storici, Scientifici e Tecnologici; ARACNE Editrice S.r.l.: Rome, Italy, 2012. [Google Scholar]

- GBIF. Free and Open Access to Biodiversity Data—Arundo donax L. 2021. Available online: https://www.gbif.org/species/2703041 (accessed on 19 November 2021).

- UNI EN 197-1; Italian Standard: Composition, Specifications and Conformity Criteria for Common Cements. UNI-Ente italiano di normazione: Italy, 2011.

- Gamage, N.; Setunge, S.; Liyanage, K. An Investigation of Usability of Brown Coal Fly Ash for Building Materials. Appl. Mech. Mater. 2013, 30–35, 438–439. [Google Scholar] [CrossRef]

- UNI EN 12390-6; Italian Standard: Testing of Hardened Concrete—Part 6: Indirect Tensile Strength of Samples. UNI-Ente italiano di normazione: Italy, 2019.

- ISO 22157; Italian Standard: Bamboo Structures—Determination of Physical and Mechanical Properties of Bamboo Culms—Test Methods. International Organization for Standardization: Italy, 2019.

- Sharma, V.; Vinayak, H.K.; Marwaha, B.M. Enhancing sustainability of rural adobe houses of hills by addition of vernacular fiber reinforcement. Int. J. Sustain. Built Environ. 2015, 4, 348–358. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, S.R.; Pepe, M.; Martinelli, E.; De Andrade Silva, F.; Toledo Filho, R.D. Bond-Slip laws for Natural Fibers in High Performance Cementitious Matrices. In Proceedings of the New Boundaries of Structural Concrete, Villa Orlandi, Capri Island, Italy, 29 September–1 October 2016. [Google Scholar]

- Cao, M.; Li, L.; Khan, M. Effect of hybrid fibers, calcium carbonate whisker and coarse sand on mechanical properties of cement-based composites. Mater. Costr. 2018, 68, e156. [Google Scholar] [CrossRef] [Green Version]

- Cao, M.; Xie, C.; Li, L.; Khan, M. The relationship between reinforcing index and flexural parameters of new hybrid fiber reinforced slab. Comput. Concr. 2018, 22, 481–492. [Google Scholar] [CrossRef]

| Maximum Tensile Strength [MPa] | Elongation at Yield Point [mm] | Yield Point [MPa] | Young Modules [GPa] |

|---|---|---|---|

| 133.9 ± 0.33 | 7.9 ± 0.045 | 131.8 ± 0.45 | 2.5 ± 0.0072 |

| Comparison Sample without Fiber | Maximum Applied Load (N) | Deformation (mm) | Tensile Strength (MPa) | Tensile Strength by Law (MPa) |

|---|---|---|---|---|

| 37,100 | 0.71 | 1.6 | 1.58 | |

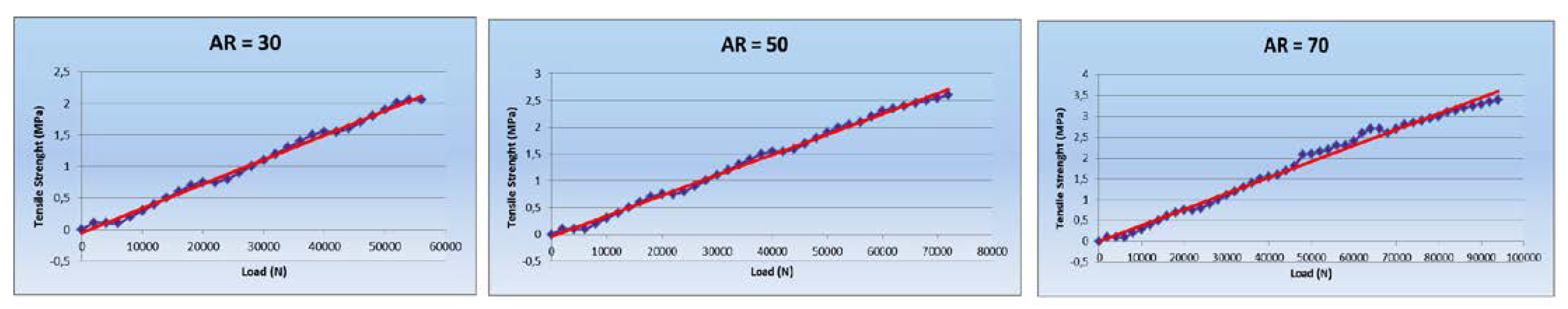

| AR | Average Value (N) | Average Value (mm) | Average Value (MPa) | Average Value (MPa) |

| 30 | 54,525 | 1.3 ± 0.01 | 2.2 ± 0.005 | 2.3 ± 0.01 |

| 50 | 72,700 | 1.6 ± 0.013 | 2.6 ± 0.01 | 3.1 ± 0.01 |

| 70 | 95,800 | 2.4 ± 0.006 | 3.4 ± 0.007 | 4.1 ± 0.005 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manniello, C.; Cillis, G.; Statuto, D.; Di Pasquale, A.; Picuno, P. Concrete Blocks Reinforced with Arundo donax Natural Fibers with Different Aspect Ratios for Application in Bioarchitecture. Appl. Sci. 2022, 12, 2167. https://doi.org/10.3390/app12042167

Manniello C, Cillis G, Statuto D, Di Pasquale A, Picuno P. Concrete Blocks Reinforced with Arundo donax Natural Fibers with Different Aspect Ratios for Application in Bioarchitecture. Applied Sciences. 2022; 12(4):2167. https://doi.org/10.3390/app12042167

Chicago/Turabian StyleManniello, Canio, Giuseppe Cillis, Dina Statuto, Andrea Di Pasquale, and Pietro Picuno. 2022. "Concrete Blocks Reinforced with Arundo donax Natural Fibers with Different Aspect Ratios for Application in Bioarchitecture" Applied Sciences 12, no. 4: 2167. https://doi.org/10.3390/app12042167