1. Introduction

Concentrated solar thermal systems are among the most cost-effective ways to replace fossil fuel. The parabolic solar dish system is a highly valued concentrated solar thermal system because of its high concentration ratio and efficiency at high temperatures [

1]. Both the thermal and the optical efficiency of parabolic dish collectors are the highest among all concentrators [

2]. They use parabolic mirrors to concentrate solar rays on the focal point where their energy can be converted and transported by a receiver [

3]. The mirror can be one large, smooth mirror or be made of a number of smaller mirrors.

The manufacture of a large-area monolithic parabolic mirror requires a high level of technology and cost. Therefore, a combination of small mirrors is generally used, which means that a number of small mirrors are fixed on the structure to let their center form a large paraboloid.

Using spherical mirrors instead of parabolic mirrors can keep performance and greatly reduce the processing difficulty, and it is a common manufacturing method for a combined dish system. In 1988, Hedgepeth and Miller [

4] proposed an outer space solar dish concentrator system in the NASA report, composed of hexagonal and square spherical mirrors. In 1993, an 87.7 m

2 combined square mirror dish concentrating system was developed with an output power of 90 kW and optical efficiency of about 88% [

5]. The Australian National University (ANU) designed and produced a 400 m

2 combined dish system named ‘SG3′ in 2003 that consists of identical multi-triangle spherical mirror to reduce the cost of production [

6]. A similar system was subsequently constructed at the Ben Gurion University in Israel [

7]. Later, in 2011, ANU designed and built a 500 m

2 multi-mirror combined system [

2]. It contained 380 identical 1.17 m × 1.17 m spherical mirrors with a focal length of 13.4 m. In the same year, Li [

8] proposed a multi-mirror combined technology that uses multiple flat mirrors to form a dish shape. In 2012, Liu [

9] designed an 8.15 kW combined dish system consisting of 164 flat mirrors, and analyzed the effects of the mirror size and position on optical performance.

There are three types of method for the optical performance simulation of solar dish concentrators in the literature. The first method is the ray tracing method which is a microscopic method and can be applied in most cases, where it can provide an enormous amount of numerical information. It is easy to code and has been developed by many researchers [

10,

11,

12], but it obscures functional relationships and is time-consuming, as pointed out by Bendt and Rabl [

13].

The second method is to first calculate the solar energy flux at the receiver surface, and then the total intercepted energy is obtained through integration; many functions have been proposed to predict the flux at the receiver. The first function for calculating the radiation flux of the solar dish receiver was proposed by Hukuo and Mii [

14], which is based on the assumption that the solar radiation source is a uniform disc. Later, some similar distribution equations were proposed by Hiester [

15], O’Neill, and Hudson [

16] with the same assumption. In fact, it is different from a real solar disc because of the effect of solar limb darkening [

17]. Trombe [

18] considered the brightness distribution of the solar disc, but ignored the solar halo and the optical error of the concentrator. Biggs and Vittltoe [

19] considered the elliptical distribution of the optical error to propose a general function for a solar concentrator which was applied in the Helios program. It was further developed in the CIRCE program [

20] for performance analysis of various solar dish concentrating collectors. However, both of these functions for calculation of the radiation flux at the receiver surface are too complicated to integrate analytically; thus, a numerical method is often preferred. On the basis of the Gaussian brightness distribution approximation, Bendt and Rabl [

13] presented an angular acceptance function for both flat and sphere receivers to calculate the optical efficiency. Stine and Harrigan [

21] reported a different equation which was also based on the Gauss approximation.

The third method is to directly calculate the optical efficiency of a paraboloid dish solar concentrator with a cavity [

22] or sphere [

23] receiver solar dish system, which is fast while ensuring accuracy. The optical performance of a solar dish system is affected by many factors, such as geometric concentration ratio, rim angle, focal length, and optical error of mirrors [

22]. Hafez and Soliman [

24] introduced that the optimization of system performance is closely related to the rim angle of the system, receiver size, and concentration ratio. There have been many studies on the performance analysis and optimization of solar parabolic dish concentrators for typical single-mirror systems, but there is little research on combined dish systems except for the solar trace.

In the performance analysis of multi-mirror combined solar dish systems, Johnston et al. [

25] applied a ray tracing method to predict the flux density distribution of a 400 m

2 solar combined dish system. Using this method, the optical performance of 54 triangular spherical mirrors in the system was further analyzed in 2003 [

6]. Lovegrove et al. [

2] applied the ray tracing method to evaluate the optical performance of a 500 m

2 square spherical multi-mirror combined dish concentrating system and preliminarily demonstrated that the optimized combined dish system can achieve a geometric concentration ratio of more than 2000. Huang [

26] developed a design and optimization analysis of a combined dish system containing 16 mirrors. They calculated the flux density distribution of the receiver under different optical errors and focal plane radii using the Monte Carlo ray tracing method. A similar analysis was also performed for this combined system [

27]. Wang et al. [

28] conducted a study on a combined dish system consisting of 450 square mirrors of 0.1 m × 0.1 m, and used TracePro software to analyze the flux density distribution of two concentrator surfaces.

Currently, ray tracing is the main method to study the optical performance of a combined dish system. However, this method requires tracking a large number of rays to obtain high accuracy, which is very time-consuming and difficult to use for system optimization; accordingly, only some specific designs have been studied.

In this work, using the previously developed method of directly calculating the optical efficiency of concentrators [

29], a new model for the optical efficiency calculation of a combined dish system is first proposed, and the accuracy of this method is validated by the SolTrace code. Then, the optical performance of a combined solar dish system composed of 249 spherical mirrors is studied using the method. The effects of the receiver radius, system focal length, optical error, and mirror focal length on the optical performance of the combined disc system are analyzed. Lastly, in order to maximize the annual average net thermal efficiency, an optimization model is developed, and the optimal design parameters of the combined dish system are calculated.

2. Method: The Optical Efficiency Calculation Model and Optimization Method for Combined Dish System

2.1. Combined Spherical Mirrors Dish System Design

Small-sized square spherical mirrors were installed on the frame structure of the solar dish system. The size of each mirror was 0.5 m × 0.5 m, and the total mirror area of the system was 62.25 m

2. The system had nine layers in both vertical and horizontal directions, with a total of 249 mirrors. An octagonal solar dish system centered on the bottom mirror is shown in

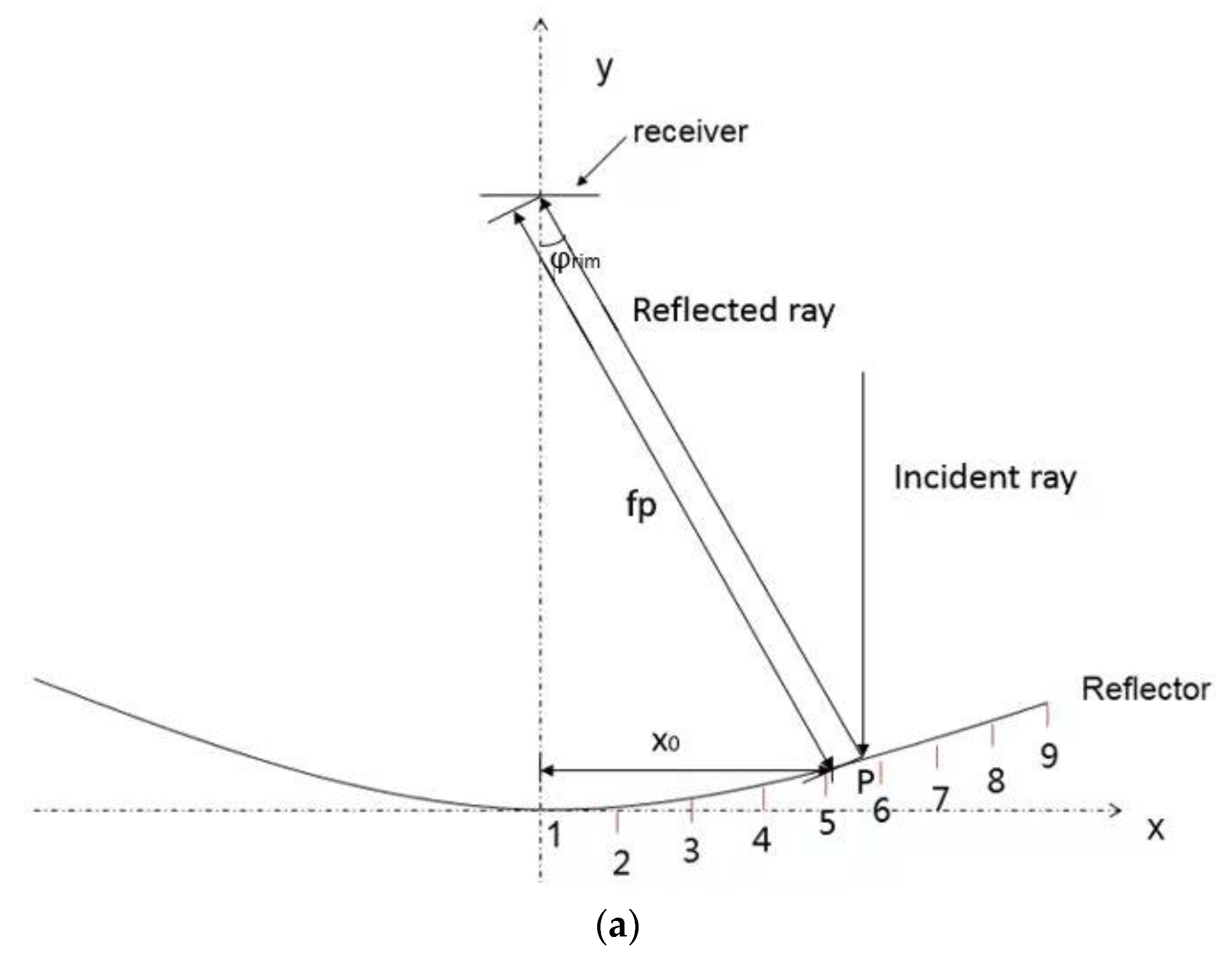

Figure 1.

The distance from the reflection point P to the center of the receiver is

where

f0 is the system focal length, and

φrim is the rim angle of the mirror.

where

x0 is the vertical distance from the reflection point p to the principal axis.

Therefore, it can be obtained from Equations (1) and (2) that

2.2. Optical Efficiency Calculation Model for Combined Dish System

We previously proposed a method to calculate the optical efficiency of a rectangular spherical mirror with a rectangular receiver [

29]. The model developed in this work converts the square receiver to a circular receiver. The calculation principle is similar, as briefly introduced below.

For a reflection point P of the dish system, the reflected light intensity distribution is

Beff (

θ). As shown in

Figure 2, the central solar ray from the sun is reflected at point P to intersect with the receiver at point O. The center solar ray OP is set as the

z-axis. When the light cone reaches the reference plane U which is perpendicular to the

z-axis and passes point O, a circular light spot is formed. If the angle between the light ray and the central solar ray is

θ, the radiation energy reflected from point P absorbed by the receiver can be expressed as follows [

30]:

where

fat is the reflectivity of the mirror, and

frec is the absorptivity of the receiver. D is the integral range which is determined by the range of the receiver projection on the reference plane. The distribution of the reflected solar intensity is obtained by the convolution of the actual solar intensity distribution and Gaussian distribution of the optical error.

If

B (

θ) is the normalized reflected radiation distribution, then

where

ηp is the optical efficiency at point P of the heliostats, which is defined as the ratio of the energy absorbed by the receiver to the energy reflected from the point P.

θp is the maximum angle of

θ where the ray at the circle can be partly intercepted by the receiver.

As shown in

Figure 3,

θp = arctan (OE/OP), where O is the intersection point of the reflected central solar ray on the receiver plane, and OE and OP are the distances between the points O and E, and P, respectively.

Here, the ray tracing method was applied to calculate the value of g (θ). It represents the percentage of light intercepted by the receiver. When the radial angle of the reflected light is θ and the azimuth angle is φ, the vector coordinate of the light in the coordinate axis is (sinθcosφ, sinθsinφ, cosθ). Therefore, whether the reflected light is received by the receiver can be estimated, and the intersection of the reflected light ray on the receiver plane can be calculated.

As shown in

Figure 3, there are two cases of O inside and outside the receiver. The first case is that the point O is in the area of the receiver, as shown in

Figure 3 (left); thus,

θT is determined by the minimum distance to the center of the receiver, and θT = arctan(OT/OP), where OT is the distance between the point O and T. If θ is less than or equal to θT, all reflected rays are intercepted, i.e., g (θ) = 1.

If point O is outside of area S, as shown in

Figure 3 (right), then

If θ is less than or equal to θT, it means that no reflected light is intercepted; thus, g (θ) = 0.

The convolution of the actual solar intensity distribution and the optical error Gaussian distribution is used to obtain the distribution of reflected light intensity [

30]. Here, a polynomial fitting method is used to approximate the actual solar intensity distribution data [

31], and the Buie exponential decreasing model [

32] is applied to simulate the halo distribution [

30].

Therefore, the calculation formulas of the average optical efficiency

η and the interception rate

γ of a single mirror are

where

S represents the projected area of the mirror under direct sunlight. The Gauss–Legendre integration method is used to solve them. Here, the space between adjacent mirrors is big enough in the combined dish system; thus, the shadowing and blocking of heliostats is small enough to be neglected.

Therefore, in the case of a fixed system focal length, the interception rate of a single mirror at different locations can be calculated. Finally, the interception rate of all mirrors is averaged to be the interception rate of the entire dish system.

Compared to other models, the proposed model is more precise because of the complex model, as it only approximates the elliptic Gaussian distribution to a circular Gaussian distribution which is a general assumption. The model considers the optical error, the actual solar intensity distribution including the halo distribution and circumsolar ratio, and system design parameters such as mirror size, specular focal length, and receiver size. This model can be used to calculate mirrors with various shapes although only the spherical mirror is analyzed as an example.

2.3. Optimization Method for Combined Dish System

The net thermal energy is equal to the absorbed optical energy minus heat loss of the receiver. The heat loss rate depends on the receiver structure, operation temperature, thermal properties of the material used, and so on. If the operation temperature is fixed, the heat loss rate per unit glass or open window surface area can be considered as a constant. The optimization process is described below.

The annual input of solar energy to a paraboloid dish is

The annual net thermal energy to a paraboloid dish is

where

ηopt is the optical efficiency of solar system, and

n (

t) is correlated with local weather, i.e.,

n (

t) = 0 when it is cloudy or rainy, and

n (

t) = 1 when it is sunny.

DNI (

t) refers to the direct normal incident solar radiation,

q is the heat loss rate,

r is the radius of the receiver, and

g (

t) represents the operating condition function; it is assumed that the radiation is strong enough when the solar elevation is equal to or more than 15°.

According to Equations (12) and (13), the annual net heat efficiency of the system is calculated as follows:

Considering the heat loss of the receiver, Equation (14) can be simplified as

where DNI is the average direct normal irradiation on a sunny day, and q/DNI is defined as the heat loss coefficient ξ, which represents the ratio of the heat loss rate of the receiver to the annual average solar radiation when the system works. ξ is about 18.177 and 168.25 for 1.67 × 10

3 W/m

2 and 1.63 × 10

4 W/m

2 heat loss rates of the two typical receivers with or without glass windows, respectively [

22], as shown in

Table 1.

Although some optimization algorithms can be applied including genetic, pattern search, and quasi-Newton algorithms, the annual average efficiency of the combined solar dish system under various designs is calculated to reduce the error of the optimized results.

4. Discussion

In this work, a model for the direct calculation of optical efficiency for the optical performance of a combined dish concentrated solar system with a cavity receiver was first proposed and then validated with SolTrace. In this method, the optical efficiency of each reflection point on the mirror is first calculated, and then the total optical efficiency is obtained by integrating the whole mirror. Spherical mirrors, as well as flat mirrors or other curved mirrors, in a combined dish system can be analyzed using the proposed method, but the spherical mirror combined dish system was analyzed as an example in this work. Each mirror is regarded as a heliostat; therefore, the present method for the combined solar dish system is rather similar to that of the solar tower system, but the receiver is a cavity with a circular opening, unlike the rectangular opening of the solar tower system. This leads to more computation than the solar tower system because numerical integration is needed for integration to the azimuth angle, which is analytically solved in the heliostat of the solar tower system. However, it still needs only 3% of the time of the SolTrace code. The average and maximum relative difference between the present integration method and the SolTrace code is only 0.51% and 1.14%, respectively. The present results indicates that the present integration methods for calculating the optical performance of the combined solar dish system have good precision and higher computation speed than that of the SolTrace method.

The optical performance of a combined solar dish system composed of 249 spherical mirrors was studied using this model. The effects of receiver radius, system focal length, optical error, and mirror focal length on the optical performance of the combined disc system were analyzed. Previously, the flux distribution at the receiver surface was studied under different designs for the combined solar dish system using the solar trace method. Johnston et al. [

6] studied the combined dish system with a triangle spherical mirror, whereas Huang et al. [

26] studied the combined dish system with a circular parabolic mirror. However, they gave little information on the intercept factor. The optical performance of a combined dish system is seldom studied. The present study provides rather complete information on the optical performance of a combined dish system. Johnston et al. [

6] showed that the radius of the receiver for 90% interception of the solar power increases if the optical error of the mirror increases. The present paper indicates that the intercept factor of the system increases if the radius increases or if the optical error of the mirror decreases. Hence, the present results are rather consistent with those of the Johnston, but give more complete information.

The present optical performance study indicates that the optical efficiency of the combined solar dish system with less than 4 mrad optical error will have a higher intercept factor than that of a paraboloidal dish system with 5 mrad optical error under the same design. This agrees with Johnston’s results. As the processing of the paraboloidal mirror is more complicated than that of the spherical mirror, the optical error of the spherical mirror is often less than that of the paraboloidal mirror; for example, the optical error of a spherical mirror for solar energy application is about 1–2 mrad [

35], but that for a parabolic mirror is about 3–4 mrad [

36]. The present study indicates that the performance of a combined solar system with a spherical mirror is better than that of a paraboloidal solar dish system if the same processing is applied or the same cost of manufacturing is applied.

The main virtue of the present method is the high computation speed, enabling the development of an optimization method. For simplicity, the net thermal efficiency optimization model of the system assumes that the operating temperature of the receiver is fixed; at this point, the heat loss rate per unit area of glass or window area can be regarded as a constant. In this paper, q/DNI is the energy loss coefficient of the system, i.e., the ratio of the heat loss of the receiver to the direct solar energy received by the system. When q/DNI is 18.177 and 168.25, it represents energy loss rates of 1.67 × 103 W /m2 and 1.63 × 104 W /m2, respectively, produced by two typical receivers under the conditions with and without a glass window. This may be the first available method for optimization of a combined solar dish system.

The present method cannot calculate the solar flux of the receiver surface. As the geometrical ratio of the solar dish system is often over 1000, the maximum power of the receiver surface is often very high, and it is easy to exceed the limit of the receiver. Therefore, the calculation of the solar flux of the receiver surface is a necessary step of the design, and the present method cannot replace the ray tracing method for flux calculation.

5. Conclusions

This work presented a new optical model that can be used to analyze and optimize the optical performance of a combined solar dish system. Using the calculation method for direct efficiency of a reflecting point we previously proposed [

28], the optical efficiency of a single mirror in the combined dish system is first calculated, and then the optical performance of the entire dish system is obtained through integrating the whole mirror. It is the first model to directly calculate the optical efficiency and the first optimizing method of a combined solar dish system.

Compared with the results calculated by SolTrace, the proposed method showed good consistency. Moreover, using the Intel i7-6700 CPU 3.40 GHz computer as an example, only one single processor was used to calculate the intercept factor of a 3 m × 3 m combined dish system when the receiver radius was 0.1 m. The proposed method took 4.3 s, whereas SolTrace needed 142.1 s. Therefore, this indicates that the results calculated using the proposed method are reliable, and the calculation speed is faster. In addition, optimization design requires simultaneously considering multiple impact factors; thus, using the proposed method is more computationally advantageous. Therefore, the optical model proposed in this paper is effective to study the optical performance of a combined dish system.

Taking a combined solar dish system of 62.25 m2 as an example, using this method, the optical performance of a multi-mirror combined solar dish system was analyzed with the change in system focal length, receiver radius, and optical error. The results can be summarized as follows:

The intercept factor of the combined dish system decreased with the increase in optical error. Comparing to a typical single parabolic dish system, a lower optical error of the combined dish system with a spherical mirror can be achieved at the same cost, and its performance is better than the ordinary solar dish as the spherical mirror is more easily manufactured than the parabolic mirror under the ordinary manufacture process.

A better performance system can be achieved when each spherical mirror focal length is equal to the distance from the mirror center to the receiver center. However, considering the cost, a uniform focal length may be applied for the entire mirror system. The optimal results show that their performance difference is very small.

The system intercept factor increased first with increasing system focal length and then decreased. The optimal system focal length can be calculated for the optimized design. A larger optical error results in the intercept factor of the system being more significantly affected by the changes in system focal length.

The intercept factor gradually increased as the radius of the receiver increased. When the receiver radius was greater than 0.1 m, the intercept factor was close to 100%. However, a larger receiver will lose more heat, thereby decreasing the net efficiency of the system; hence, an optimized receiver is recommended.

Using the proposed method, the system design parameters including receiver radius and system focal length were optimized to obtain the optimal net thermal efficiency of the combined dish system. Without considering the cost, the focal length of each mirror at different positions was further optimized. When the optical error was 2 mrad, the net thermal efficiency of the system reached a maximum of 86.05% when the radius of the receiver was 0.1 m and the focal length of the system was 7 m. At this time, the optimal system intercept factor was 98.81%. If the mirrors used had the same focal length, thereby reducing the cost, the optimal fixed mirror focal length was 8 m, and the net thermal efficiency could reach 85.87%. The optimal design parameters under different optical error conditions were calculated, which has a certain significance for the establishment of a combined solar dish system in the future.