Abstract

Flexible pavement deterioration due to moisture intrusion and aging is the key concern worldwide for highway engineers. However, this damage has not been properly investigated in detail due to lack of appropriate experimental and modeling techniques. Such lacking hinders the design of long-lasting pavements, as the effects of environmental damages are unknown, especially for modified asphalt. Therefore, the current study aims at determining a better approach for modeling asphalt adhesion damage using Artificial Neural Networks (ANNs). The Atomic Force Microscopy (AFM) test was deployed to determine the adhesion and cohesion forces of asphalt samples with varying contents of polymer and Antistripping Agents (ASAs). Two types of ANN models, namely multilayer perceptions (MLPs) and radial basis function neural network (RBFNN), were used in this effort. Two popular modifications, namely ensemble learning and hierarchical modeling, were also engaged to achieve convenient and accurate damage models. The analysis found that RBFNN was better suited for hierarchical models than MLP. RBFNN is preferred for aged and moisture-damaged samples which have less variation in their datasets. Hierarchical models are convenient to apply as they can be applied to any type of asphalt sample. However, they produced a small reduction in accuracy (less than 10%) as compared to other models. The accuracy of the hierarchical model was found to be satisfactory. The ensemble learning approach showed slight improvement in accuracy for all models ranging between 1–3%, i.e., 6–8 nN. This study recommends the use of hierarchical models, developed with ensemble learning, for prediction of asphalt damage. The results of the study will be helpful for researchers and practitioners working on pavement materials for developing prediction models to prepare a better mix design of polymer modified asphalt.

1. Introduction

The harmful effects of the presence of moisture on the extent and severity of most road surface damage in the world are beyond doubt [1]. In the UK alone, billions of Euros are spent annually to overhaul the damage to the roads and paving, which is partly caused by the effects of the existing moisture on asphalt mixes [2]. Similar consequences have also been reported for other parts of the world as well [3]. Due to the moisture intrusion in the asphalt pavements, it loses the adhesion between the aggregate and bitumen as well as cohesion strength between the bitumen and/or bitumen-filler mastic [4,5,6]. Due to such losses, the bond between the aggregate and asphalt breaks off by stripping action. It was discovered by Lottman [7] that the key drawback of asphalt pavements occurs due to stripping, which is experienced by at least 50 state highway agencies in the USA. In addition, it reduces the stiffness and strength of the asphalt in the practical fields as well [8].

However, the realistic reason for moisture causing damage is not yet construed and developed. It is suspected to be ruled in part by the physio-chemical relations between mastic and aggregates in the existence of moisture/water. According to Nguyen et al. [9], a major cause of adhesion loss is due to build-up of an intermediate moisture layer which affects several mono layer thicknesses (35–45 nm) at the aggregate–asphalt interface. In addition, the chemical and mineralogical composition of aggregate particles may have a more fundamental role in the creation of moisture damage than asphalt properties such as penetration grade, molecular size distribution, acid types and percentages [5].

Chemical additives such as Antistripping Agents (ASAs) are used to chemically improve the adhesion force between the asphalt and the aggregate particles to resist the water-stripping action [10]. Currently, almost all the State Departments of Transportation (DOTs) in the USA use a nominal percentage of Antistripping Agents in asphalt. Laboratory tests have been performed to assess the effect of ASAs on the adhesion and cohesion bonds of asphalt [11,12,13,14]. A nano level experiment was performed in the laboratory with Atomic Force Microscopy (AFM) to determine the effects of ASAs in terms of adhesive and cohesive forces [15,16]. The study simulated adhesion and cohesion of asphalt by using functionalized tips to probe the asphalt sample. The test data suggested that the existing relationship between the test variables is very complicated and to some extent beyond explanation. Another study showed that the performance of ASAs is complex and non-linear in nature because of the various mix properties of asphalt [17], type and dose of ASA, and moisture condition of asphalt [12]. Hence, it is difficult to assess and predict the enhancement of resistivity of moisture damage by laboratory tests, which opens the arena for determining the best modeling technique for predicting asphalt adhesion under various conditions.

Machine learning (ML) is a field of modeling which has become popular due to its adaptability and robustness. Techniques which come under the discipline of ML deal with the modeling of different aspects of given datasets without assuming any prior information about them [18]. ML techniques have been adopted in various fields due to their ability to capture complex non-linear structures and relationships [19]. Artificial Neural Networks (ANNs) are one of the ML techniques which have been preferred for prediction problems due to the fact that they provide a convenient method to map the relationship between input and output parameters. Researchers have used them as a standalone method, as well as with integration with other ML techniques, such as fuzzy logic [20].

Artificial Neural Networks (ANNs) have lately become important and alternative analytic tools to conventional methods for modeling complex and non-linear relationships [21] and can be used as an instrument for the development of models to predict the effect of ASAs. The ANN tools and approaches have been used with great success to model structural damage detection [22], material behavior modeling [23], and structural optimization [24]. Mohammadhassani [25] used an ANN to predict deflections of a deep beam at mid span with high level of confidence as compared to other available methods. This approach has also been used to model the nitrogen dioxide dispersion from vehicular types of exhaust emissions [26], and to simulate pollutant dispersion [27].

In the context of predicting characteristics of asphalt, few studies have been found in which ANNs have been used for this purpose, including Shafabakhsh [28] and Hu and Qian [29]. However, these studies do not cover predicting the adhesion force of asphalt modified with Carbon Nanotubes (CNT). Moreover, modeling adhesion force obtained from Atomic Force Microscopy (AFM) has also not been carried out in the current literature. With this motivation, this paper attempts to evaluate the performance of the two most popular types of ANNs. Another novelty of the current research is the attempt to increase the practical convenience and accuracy of the models by employing hierarchical modeling and ensemble learning approaches on the ANNs. AFM laboratory test data were used to assess and predict the performance of different ASAs on adhesion and cohesion behavior for varying properties and moisture condition of asphalt. The literature does not agree on the use of any particular type of ANN for prediction problems. Hence, two common types of ANNs were used for the development of models in this study and their prediction performance was compared to investigate their suitability for the available dataset. This was necessary since there are no studies found on the use of ANNs for predicting adhesion of modified asphalt samples.

The specific objective of this study includes developing and comparing hierarchical ANN models for prediction of the adhesion force of modified asphalt, with different polymer and ASA contents, under moisture-damaged and aged conditions. Moreover, performance of single models is also compared with ensembles which are developed using simple average methods. Materials used and modeling approach applied in this study are described in Section 2. Results are discussed in Section 3. Section 4 concludes the paper.

2. Materials and Methods

In this study, Styrene-Butadiene (SB) and Styrene-Butadiene-Styrene (SBS) types of polymers were utilized in order to modify the base binder. A total of two different percentages (4% and 5% by weight) of polymers were used. The polymer modified binders were further modified with single wall and double wall Carbon Nanotubes (CNT) (0.5%, 1.0% and 1.5% by weight). CNTs are nanometric scale forms with high strength and rigidity [30]. AASHTO T-283 method was used to simulate moisture damage effect in laboratory. The aging simulation was performed in the laboratory with the draft oven. The samples were placed inside the convection oven for continuous seven (7) days with an elevated temperature to accelerate the field aging. Thus, the derived samples are called aged samples in this study. In these experiments, a total of 290 AFM laboratory tests were accomplished. A detailed description of the whole testing and procedures can be found in Tarefder et al. [15].

2.1. Statistical Analysis and Selection of Modeling Approach

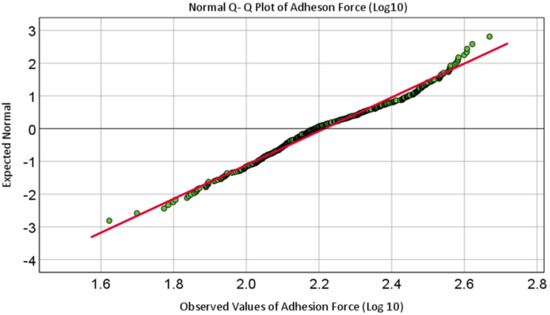

One-way ANOVA tests were performed to check statistical significance of the variables listed in the Table 1. In order to perform one-way ANOVA, it was necessary to confirm the normality assumption of the observed data for adhesion forces. The observed data were transformed using 10 base logarithm and plotted as shown in Figure 1. It was found that the observed data transformed well, as the R2 value was found as 0.988. Then, the one-way ANOVA test was performed and shown in Table 2.

Table 1.

Details of variables.

Figure 1.

Normal Q-Q plot confirming normality of adhesion forces (R2 = 0.989).

Table 2.

Results of One-Way ANOVA tests.

The one-way ANOVA test showed that there was no significant effect in the adhesion forces in using (i) different percentage of CNT, (ii) different percentage of SBs and SBSs, and (iii) SWNT and MWNT since the p-values are more than 0.05. However, some significant results were found for the different sample status, i.e., fresh, aged and moisture-damaged samples and different chemical compositions, namely Silicon Nitrate (Si3N4), Ammonia (NH3), Hydroxide (OH), Carboxylic (COOH) and Methyl (CH3). Nonetheless, such statistical analysis does not yet confirm and reveal inherent relations among variables with the adhesion forces which can predict the adhesion forces with satisfactory accuracy. Thus, it was necessary to devise a different approach for modeling adhesion forces. Hence, Artificial Neural Network technique was deployed with two widely used modifications namely ensemble learning and hierarchical modeling.

2.2. AFM Test Results for ANN Feed

In this study the laboratory generated AFM data for different conditioned (fresh, moisture damaged and aged) asphalt samples were obtained using tips made up of five different compounds. The results were then used to develop the prediction models. The details of the variables used in modeling are given in Table 1.

ANNs were used to develop hierarchical models as well as models for specific sample types (moisture damaged and aged) in this study. Hierarchical models were developed to predict the asphalt adhesion force for all types of data samples by introducing a classifying variable, for denoting the type of sample, in the model. Hence, the same model could be applied to fresh or damaged samples. Further details about ANN models used in this study can be found in the proceeding section.

2.3. Artificial Neural Networks

ANN can be defined as a computer-based program which uses special tools for simulation tasks. A very widespread and popular type of ANN is known as multilayer perceptions (MLPs), which satisfactorily received a good reputation and acceptance in major engineering investigations and development areas such as: petroleum engineering, classification and speech recognition, pattern recognition and identification, control systems as well as computer vision applications.

These networks utilize input layer with an output layer. Moreover, for processing units, it uses one or more layers, known as hidden layers. These networks can be trained into carrying a precise type of work by re-adjusting the ideal forms of the nodal connections among several parts. The MLPs are trained in a professional manner such that any kind of individual input parameter leads to a target/result value. For this kind of model, all the nodal connections (weights) are changed uninterruptedly for accomplishing the targeted value. Normally, several trials are required for training of network before reaching an acceptable difference (error) between actual and target value.

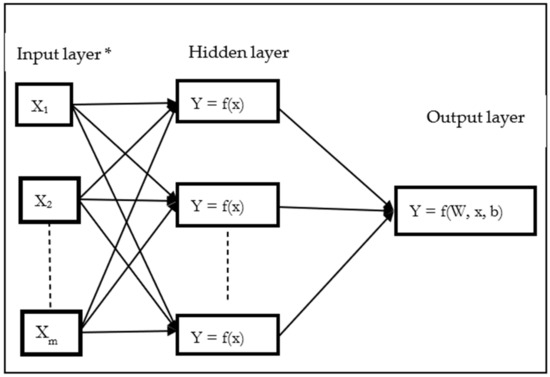

In addition to MLPs, radial basis function neural networks (RBFNNs) were also used in this study. Both these types have been frequently used in prediction problems in various studies including the following: Karlik and Olgac [31], Yilmaz and Kaynar [32], and Zare et al. [33]. Some of these studies also presented a comparison between the performances of these models. Yilmaz and Kaynar [32] showed higher performance of RBFNN, while it was the opposite for Zare et al. [33]. However, it was observed that the difference in performance of these models was not substantial in both cases for validation of the dataset. The basic structure of ANN and the difference in the processing units of both types of ANNs were given by Yilmaz and Kaynar [32] as shown in Figure 2 along with Equations (1) and (2).

where:

Figure 2.

ANN Model. * Refer to Table 2 for details of variables in input layer.

- X = Input vector;

- W = Weight vector;

- b = Biasness factor;

- μ = Center of neuron.

A Gaussian function is applied to the processing unit for RBFNN, while MLP adopts a generalized regression function. Hence, the applicability of each type of model depends upon the nature of problem to be addressed and it cannot be generalized for all cases. Hence, comparison of these types for prediction of modified asphalt adhesion force is justified.

Three performance measures were used in this study to evaluate the accuracy of ANN models, namely root mean square error (RMSE), mean absolute percentage error (MAPE), and correlation coefficient (CC). These measures focus on different aspects of accuracy. RMSE has a squaring mechanism to magnify large errors while suppressing smaller errors, MAPE relates the magnitude of error to the magnitude of the observed value, and lastly, CC evaluates the closeness of predicted values’ trend to that of the observed ones. These measures have been used in different studies to evaluate accuracy of ANN models [15,32,34]. They were calculated as per Equations (3)–(5).

where:

- P = Predicted values;

- n = Number of samples;

- o = Observed values.

It is also important to use appropriate sampling technique for training and validation dataset to avoid bias in accuracy because of specific data samples. This issue was addressed by using the bootstrap sampling in this study. This sampling technique adopts replacing the samples with the appropriate values based upon functional distribution for parameters, consequently removing outliers [35,36].

ANNs have been reported to have problem of convergence on local minima. Ensemble learning approach has been adopted in this study to address this issue, in which ANNs of slightly inferior performance can be combined synergistically to achieve better performance [37]. In this study, the ensembles were developed using the averages of outputs from MLP and RBFNN models.

3. Results

All networks were tried with a different number of neurons until the optimum values were reached. For each trial with a different number of neurons, the performance measures of RMSE, MAPE and CC were observed for the test set. The number of neurons with the best values of above-mentioned performance measures was selected for further comparisons. Table 3 shows the number of neurons for each case with different types of ANNs. The number for neurons for RBFNN is generally higher than that for MLP. This trend could be attributed to the algorithms of these types, wherein RBFNN applies a more complicated approach of calculating the center of each neuron and applying a Gaussian function to it. On the other hand, MLP applies a relatively simplistic function to each neuron resembling to generalized regression. The combined dataset was used for the development of a hierarchical model. It was found that less than 5 neurons were sufficient for MLP, while more than 10 neurons were required for RBFNN in all cases. The calculated number of neurons in the input layer is exactly equivalent to the number of input variables (or independent), whereas the output layer containing one neuron as a single output is desired from the model.

Table 3.

Type of ANNs and number of neurons.

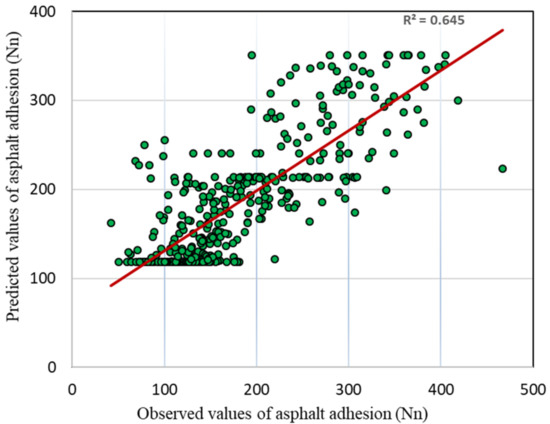

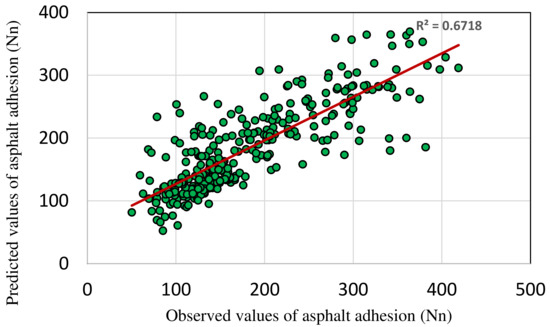

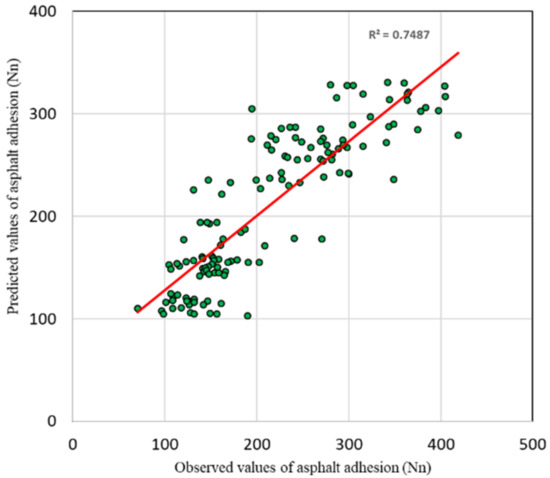

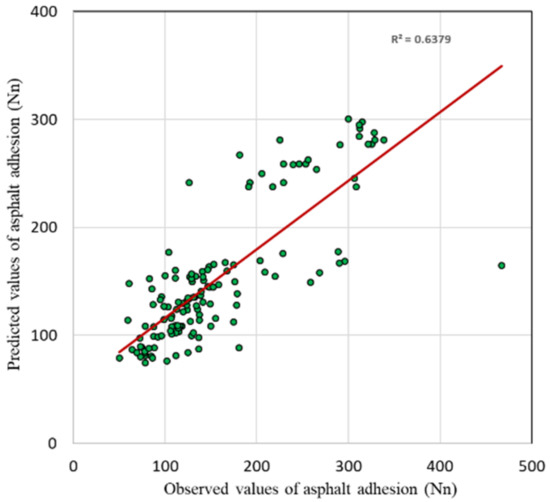

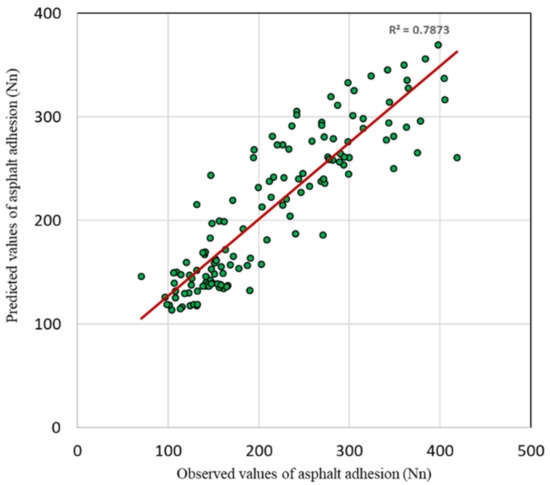

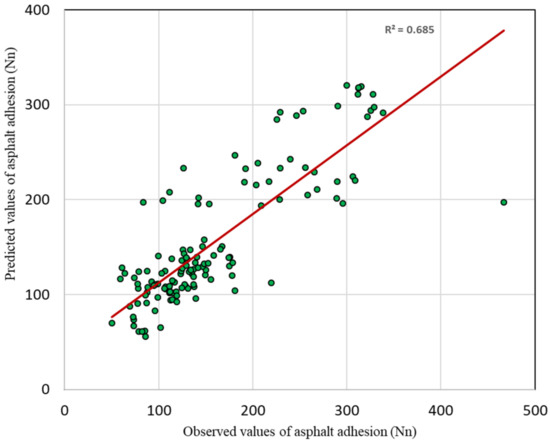

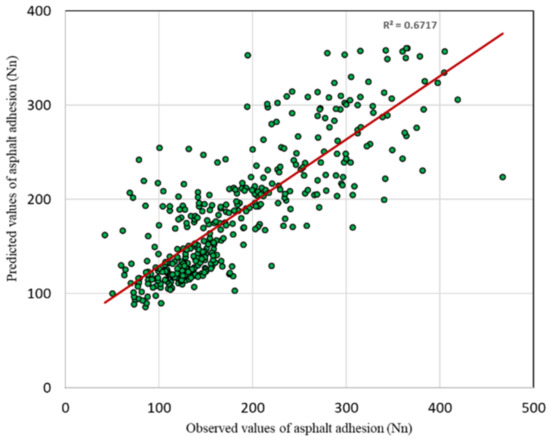

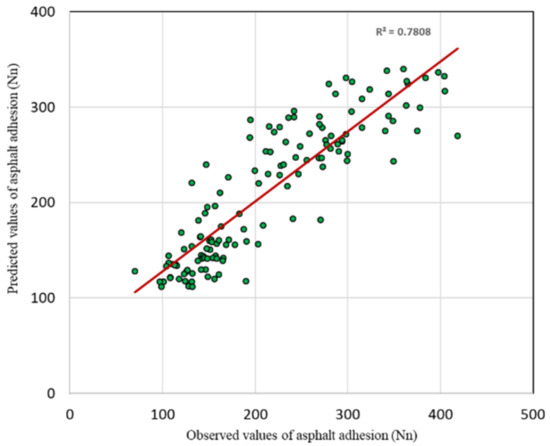

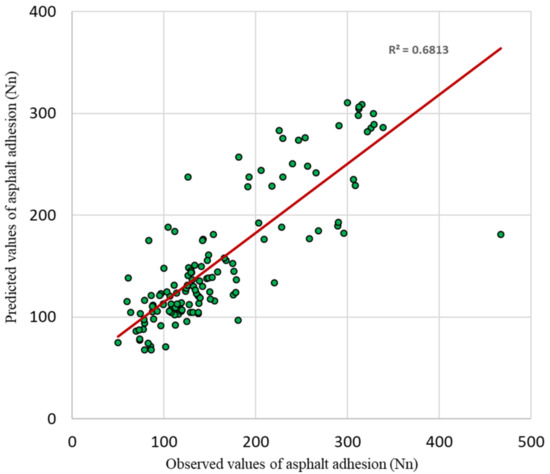

Data presented in Table 4, Table 5 and Table 6 depict the comparison of performance measures for MLP and RBFNN models for different types of samples. Models were calculated only for moisture damaged and aged samples since they are more critical as compared to fresh samples for pavement design. The scatterplots for all these models are shown in Figure 3, Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8.

Table 4.

Performance measures for hierarchical ANNs of combined samples.

Table 5.

Performance measures for ANNs of moisture-damaged samples.

Table 6.

Performance measures for ANNs of aged samples.

Figure 3.

Scatterplot for hierarchical MLP.

Figure 4.

Scatterplot for hierarchical RBFNN.

Figure 5.

Scatterplot for MLP of moisture-damaged samples.

Figure 6.

Scatterplot for RBFNN of moisture-damaged samples.

Figure 7.

Scatterplot for MLP of aged samples.

Figure 8.

Scatterplot for RBFNN of aged samples.

It can be observed that RBFNN performs better than MLP for the hierarchical model, while MLP had better accuracy for moisture-damaged and aged sample models. Hence, it can be said that the use of RBFNN is more suitable for relatively complex problems while MLP should be preferred for simpler problems. The results of this study also point to the fact that complex models may not always provide better models, and rather they should be selected based upon the nature of problem. This in conformance with the results from Stein and Looby [38] in their study related to Quantitative Systems Pharmacology (QSP) models.

The superior performance of RBFNN and MLP in different cases can be attributed to their processing mechanisms, as shown in Figure 2. MLP uses a non-linear regression-like approach for calculating weights, which is useful for data items with less variability. On the other hand, RBFNN calculates the centroid for each node and takes the difference from the input parameters, in which case each node can act as a classifier, where the centroid is calculated to be closer to a specific class of dataset. Therefore, RBFNN becomes more suitable for a hierarchical model.

The accuracy of the hierarchical model was found to be less than the models for moisture-damaged and aged samples. This is understandable because the samples for the hierarchical model contain a lot more variation than the other models. However, the accuracy of the hierarchical (RBFNN) model was not totally unacceptable, as the CC value was found to be 0.8 or more and the MAPE values were close to 20%. Considering the convenience offered by using the hierarchical model, these accuracy levels can be considered sufficient, and its use can be recommended. Further improvements can be made in this model with a larger dataset.

The performance for ensembles for each case is shown in Table 7, Table 8 and Table 9, while their scatterplots are shown in Figure 9, Figure 10 and Figure 11. Their accuracy was compared with individual models with the best accuracy in each case, which were RBFNN for the hierarchical model compared with MLP for moisture-damaged and aged samples. It can be observed that ensemble learning resulted in a small improvement in the accuracy, compared to the respective best ANN model, in all the cases.

Table 7.

Performance measures for ensemble and RBFNN for hierarchical models.

Table 8.

Performance measures for ensembles and MLP for models of moisture-damaged samples.

Table 9.

Performance measures for ensembles and MLP for models of aged samples.

Figure 9.

Scatterplot of hierarchical ensemble.

Figure 10.

Scatterplot for ensemble of moisture-damaged samples.

Figure 11.

Scatterplot for ensemble of aged samples.

The test accuracies of this study were compared with another similar study carried out by Hassan et al. [39]. In doing so, it was found that the accuracies of this study’s models on test datasets for aged and moisture-damaged samples were slightly better. CC values obtained in the above study were 0.8 or less while in this study they are well above this value for the respective cases. Moreover, the MAPE for said study went as high as 26% in some cases, while it does not go above 22.52% in this study for aged or moisture-damaged samples. Hierarchical modeling was applied for the first time in this study, hence it could not be compared with any previous study.

4. Conclusions

The prediction of adhesive forces in asphalt, modified with Antistripping Agents (ASAs) and polymers, was studied in this research work. The fresh asphalt samples were mixed with polymers and Antistripping Agents to investigate the moisture damage and aging perspectives. The test results obtained from Atomic Force Microscopy (AFM) laboratory testing were used to model ANN to predict the adhesive forces. Two types of ANN models, namely multilayer perceptions (MLPs) and radial basis function neural network (RBFNN), were used. The conclusions drawn from the current study are summarized as follows.

Hierarchical modeling proved to be a convenient approach for predicting asphalt adhesion force, although it was found to be less accurate, as the CC and MAPE values were close to those of MLP models for moisture-damaged and aged samples. This could be attributed to the lower complexity of samples in the moisture-damaged and aged datasets.

Compared to MLP, RBFNN was found to be more suitable for developing hierarchical models, with a decrease in error of 8% for the test dataset.

However, MLP was found generally more suitable than RBFNN for the prediction of adhesion force in moisture-damaged and aged asphalt samples. In particular, for the test dataset of aged asphalt samples, the MLP model showed an increase of 0.26 in CC, a decrease in MAPE by 3%, and a decrease in RMSE by 7 nN, as compared to the RBFNN model.

The application of ensemble learning, using the simple average of both ANN models, was found to be useful in improving prediction accuracy. The ensemble showed an approximate increase in CC value of 0.03, a decrease in MAPE by approximately 1%, and a decrease in RMSE by 8 nN for the test dataset of the hierarchical model. It improved the prediction accuracy of the moisture-damaged and aged samples model by reducing MAPE approximately 3% and RMSE approximately 6 nN in the test dataset.

On the basis of the findings of this study, it is recommended to use the ensemble hierarchical model to design longer-lasting pavements with modified asphalt.

Author Contributions

Conceptualization, U.G., M.S.A., M.A., M.K.I. and F.I.S.; methodology and software, U.G. and M.S.A.; validation, M.K.I. and F.I.S.; formal analysis, U.G.; resources and data curation, M.A.; writing—original draft preparation, review and editing, M.K.I. and U.G.; supervision, F.I.S.; project administration, M.K.I.; funding acquisition, M.K.I. All authors have read and agreed to the published version of the manuscript.

Funding

This work was financially supported by the Deanship of Scientific Research (Nasher Track) in the King Faisal University, Saudi Arabia, grant number: NA000172. And the APC also funded by the same grant.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author, Md. Arifuzzaman, upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Miller, J.; Bellinger, W. Distress Identification Manual for the Long-Term Pavement Performance Program, 4th ed.; Federal Highway Administration Report: FHWA-RD-03-031; Transportation Research Board: Washington, DC, USA, 2003. [Google Scholar]

- Asphalt Industry Alliance (AIA). Annual Local Authority Road Maintenance (ALARM) Survey; HHMPE: London, UK, 2009. [Google Scholar]

- Athigakunagorn, N. Determining the effectiveness of asphalt concrete overlays on rigid pavement using discrete-event simulation. Eng. J. 2017, 21, 171–182. [Google Scholar] [CrossRef][Green Version]

- Airey, G.; Choi, Y. State of the art report on moisture sensitivity test methods for bituminous pavement materials. Road Mater. Pavement Des. 2002, 3, 355–372. [Google Scholar] [CrossRef]

- Airey, G.; Masad, E.; Bhasin, A.; Caro, S.; Little, D. Asphalt mixture moisture damage assessment combined with surface energy characterization. In Advanced Characterization of Pavement and Soil Engineering Materials; Taylor & Frances Group: Abingdon, UK, 2007; pp. 739–748. [Google Scholar]

- Apeagyei, A.K.; Grenfell, J.R.A.; Airey, G. Moisture-induced strength degradation of aggregate–asphalt mastic bonds. Road Mater. Pavement Des. 2014, 15, 239–262. [Google Scholar] [CrossRef]

- Lottman, R. Predicting Moisture-Induced Damage to Asphalt Concrete; NCHRP Report 192; TRB—National Research Council: Washington, DC, USA, 1978. [Google Scholar]

- Hamedi, G.H.; Tahami, S.A. The effect of using anti-stripping additives on moisture damage of hot mix asphalt. Int. J. Adhes. Adhes. 2018, 81, 90–97. [Google Scholar] [CrossRef]

- Nguyen, T.; Byrd, E.; Alsheh, D.; Bentz, D. Relation between adhesion loss and water at the polymer/substrate interface. In Proceedings of the Adhesion Society Meeting, Hilton Head Island, SC, USA, 19–22 February 1995. [Google Scholar]

- Huang, Y. Pavement Analysis and Design, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1993. [Google Scholar]

- Anderson, D.; Dukatz, E.; Petersen, J. The effect of antistrip additives on the properties of asphalt cement. Asph. Paving Technol. 1982, 51, 298–317. [Google Scholar]

- Kanitpong, K.; Bahia, H. Relating adhesion and cohesion of asphalts to the effect of moisture on laboratory performance of asphalt mixtures. Transp. Res. Rec. 2005, 1901, 33–43. [Google Scholar] [CrossRef]

- Gandhi, S.; Copeland, K.; Putman, B.; Amirkhanian, S. Laboratory evaluation of long term effectiveness of liquid antistripping agents. In Proceedings of the TRB Annual Meeting, Washington, DC, USA, 21–25 January 2007. [Google Scholar]

- Amirkhanian, S.N.; Xiao, F.; Corley, M. Laboratory Performance of Liquid Anti-Stripping Agents in Asphalt Mixtures Used in South Carolina; No. Report No. FHWA-SC-18-01; South Carolina Department of Transportation: Columbia, SC, USA, 2018. [Google Scholar]

- Tarefder, R.A.; Ahsan, S. Arifuzzaman using a neural network model to assess the effect of antistripping agents on the performance of moisture-conditioned asphalt. J. Mater. Civ. Eng. 2017, 29, 04016250. [Google Scholar] [CrossRef]

- Arifuzzaman, M.; Islam, M.S.; Hossain, M.I. Moisture damage evaluation in SBS and lime modified asphalt using AFM and artificial intelligence. Neural Comput. Appl. 2017, 28, 125–134. [Google Scholar] [CrossRef]

- Curtis, C.W. A Literature Review of Liquid Antistripping and Tests for Measuring Stripping; A/UIR-90-016; Strategic Highway Research Program: Washington, DC, USA, 1990. [Google Scholar]

- Mahesh, B. Machine learning algorithms—A review. Int. J. Sci. Res. (IJSR) 2020, 9, 381–386. [Google Scholar]

- Niaghi, A.R.; Hassanijalilian, O.; Shiri, J. Estimation of reference evapotranspiration using spatial and temporal machine learning approaches. Hydrology 2021, 8, 25. [Google Scholar]

- Alizamir, M.; Kisi, O.; Adnan, R.M.; Kuriqi, A. Modelling reference evapotranspiration by combining neuro-fuzzy and evolutionary strategies. Acta Geophys. 2020, 68, 1113–1126. [Google Scholar] [CrossRef]

- Rao, P.; Rao, P.; Deepak, B. GRNN-immune based strategy for estimating and optimizing the vibratory assisted welding parameters to produce quality welded joints. Eng. J. 2017, 21, 252–267. [Google Scholar]

- Wu, X.; Ghaboussi, J.H., Jr.; Garrett, J. Use of neural networks in detection of structural damage. Comput. Struct. 1992, 42, 649–659. [Google Scholar] [CrossRef]

- Nehdi, M.; Djebbar, Y.; Khan, A. Neural network model for preformed-foam cellular concrete. ACI Mater. J. 2001, 98, 402–409. [Google Scholar]

- Hossain, K.M.; Lachemi, M.; Easa, S.M. Artificial neural network model for the strength prediction of fully restrained RC slabs subjected to membrane action. Comput. Concr. 2006, 3, 439–454. [Google Scholar] [CrossRef]

- Mohammadhassani, M.; Nezamabadi-Pour, H.; Jumaat, M.Z.; Jameel, M.; Arumugam, A.M. Application of artificial neural networks (ANNs) and linear regressions (LR) to predict the deflection of concrete deep beams. Comput. Concr. 2013, 11, 237–252. [Google Scholar] [CrossRef]

- Nagendra, S.S.; Khare, M. Artificial neural network approach for modelling nitrogen dioxide dispersion from vehicular exhaust emissions. Ecol. Model. 2006, 190, 99–115. [Google Scholar] [CrossRef]

- Hossain, K.M.A. Predictive ability of improved neural network models to simulate pollutant dispersion. Int. J. Atmos. Sci. 2014, 2014, 141923. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Ani, O.J.; Talebsafa, M. Artificial neural network modeling (ANN) for predicting rutting performance of nano-modified hot-mix asphalt mixtures containing steel slag aggregates. Constr. Build. Mater. 2015, 85, 136–143. [Google Scholar] [CrossRef]

- Hu, J.; Qian, Z. The prediction of adhesive failure between aggregates and asphalt mastic based on aggregate features. Constr. Build. Mater. 2018, 183, 22–31. [Google Scholar] [CrossRef]

- Vivanco-Benavides, L.E.; Martínez-González, C.L.; Mercado-Zúñiga, C.; Torres-Torres, C. Machine learning and materials informatics approaches in the analysis of physical properties of carbon nanotubes: A review. Comput. Mater. Sci. 2021, 201, 110939. [Google Scholar] [CrossRef]

- Karlik, B.; Olgac, A. Performance analysis of various activation functions in generalized MLP architectures of neural networks. Int. J. Artif. Intell. Expert Syst. 2011, 1, 111–122. [Google Scholar]

- Yilmaz, I.; Kaynar, O. Multiple regression, ANN (RBF, MLP) and ANFIS models for prediction of swell potential of clayey soils. Expert Syst. Appl. 2011, 38, 5958–5966. [Google Scholar] [CrossRef]

- Zare, M.; Pourghasemi, H.R.; Vafakhah, M.; Pradhan, B. Landslide susceptibility mapping at Vaz Watershed (Iran) using an artificial neural network model: A comparison between multilayer perceptron (MLP) and radial basic function (RBF) algorithms. Arab. J. Geosci. 2013, 6, 2873–2888. [Google Scholar] [CrossRef]

- Kashaninejad, M.; Dehghani, A.A.; Kashiri, M. Modeling of wheat soaking using two artificial neural networks (MLP and RBF). J. Food Eng. 2008, 91, 602–607. [Google Scholar] [CrossRef]

- Efron, B. Bootstrap methods: Another look at the jackknife. In Breakthroughs in Statistics; Springer: New York, NY, USA, 1992; pp. 569–593. [Google Scholar]

- Kohavi, R. A study of cross-validation and bootstrap for accuracy estimation and model selection. Int. Jt. Conf. Artif. Intell. (IJCAI) 1995, 14, 1137–1145. [Google Scholar]

- Hansen, L.; PSalamon, P. Neural network ensembles. IEEE Trans. Pattern Anal. Mach. Intell. 1990, 12, 993–1001. [Google Scholar] [CrossRef]

- Stein, A.M.; Looby, M. Benchmarking QSP models against simple models: A path to improved comprehension and predictive performance. CPT Pharmacomet. Syst. Pharmacol. 2018, 7, 487–489. [Google Scholar] [CrossRef]

- Hassan, M.R.; Mamun, A.A.; Hossain, M.I.; Arifuzzaman, M. Moisture damage modeling in lime and chemically modified asphalt at nanolevel using ensemble computational intelligence. Comput. Intell. Neurosci. 2018, 2018, 7525789. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).