Simulation of Track-Soft Soil Interactions Using a Discrete Element Method

Abstract

:1. Introduction

2. Material and Methods

2.1. Parameters Calibration of Scaled-Up Particles

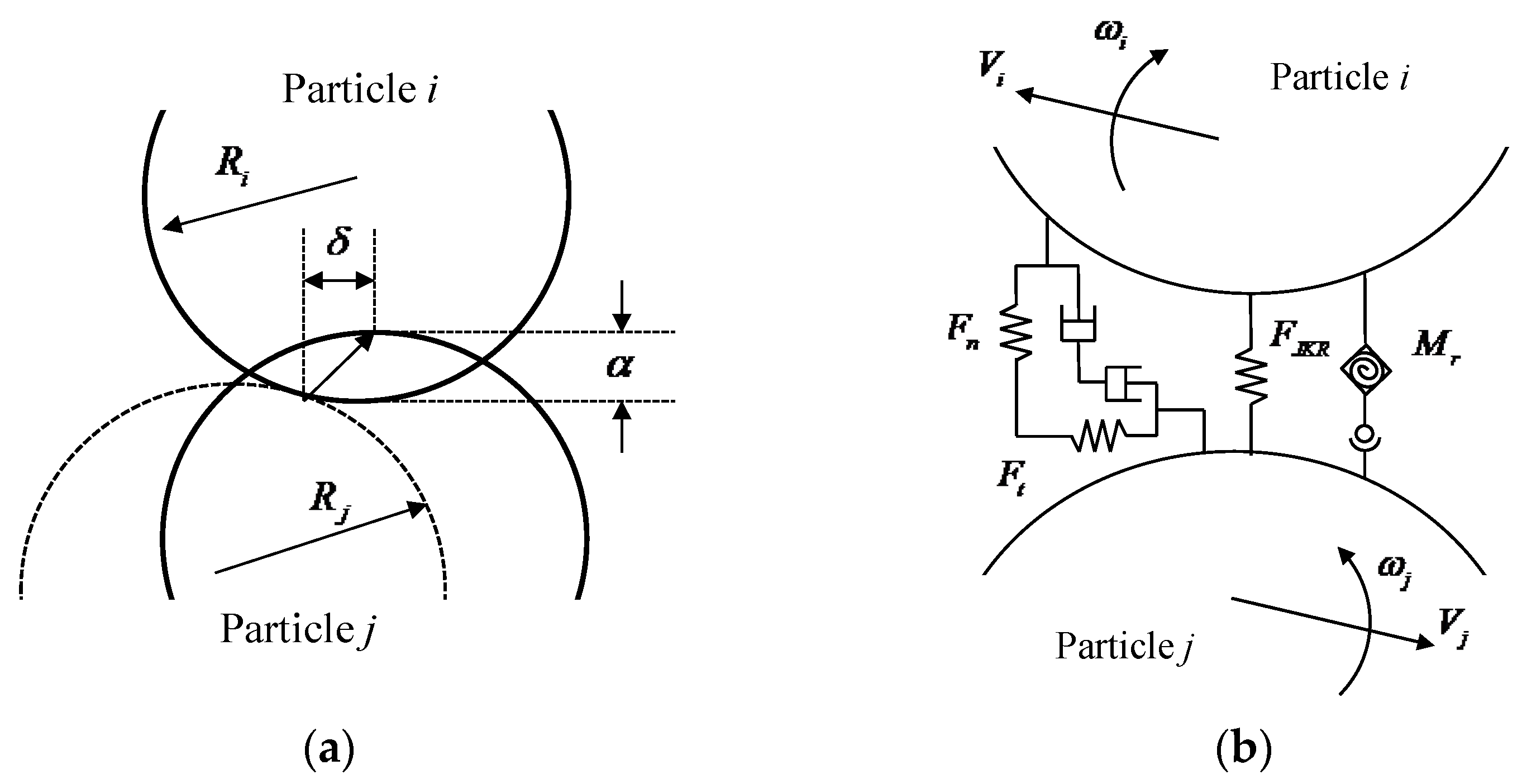

2.1.1. JKR Model in the DEM

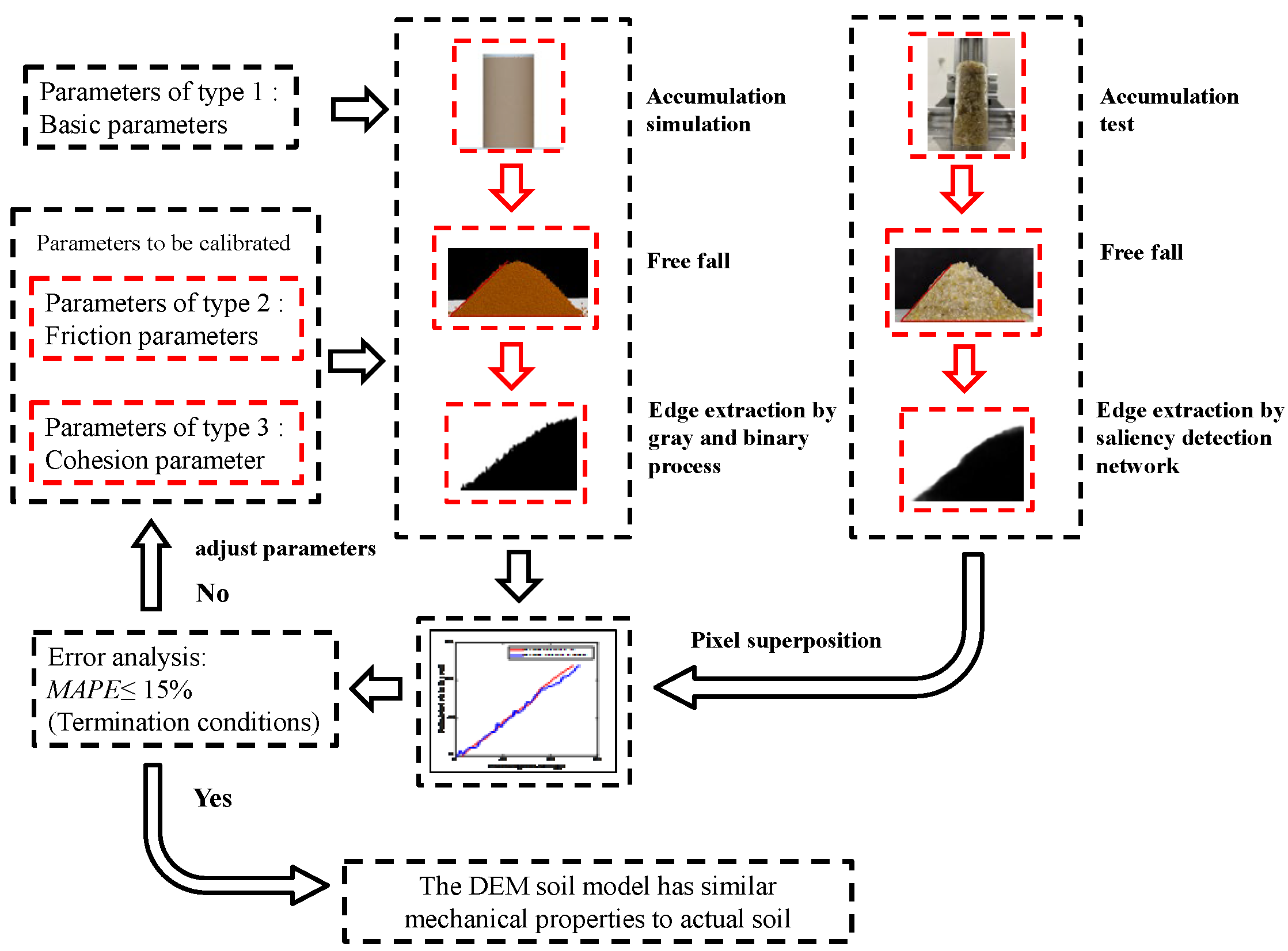

2.1.2. Calibration of the JKR Model Parameters

- (1)

- The intrinsic parameters of particles, including wet density, Poisson ratio, shear modulus and particle size, are basic parameters and can be measured by the test. The parameters are shown in Table 2;

- (2)

- The contact parameters of particles, including the static friction coefficient and rolling friction coefficient, are friction characteristic parameters and can be measured by tests or calibrated by simulations. The friction between particles is calculated according to the friction characteristic parameters, and the specific calculation method refers to the Hertz–Mindlin model [20,21];

- (3)

- The JKR models specific particle parameters, i.e., surface energy, which is a cohesive characteristic parameter and is difficult to measure. However, it can be calibrated by DEM simulation. The cohesive force between particles is calculated according to the cohesive characteristic parameters, as shown in Equation (1).

| Property | Value | Source |

|---|---|---|

| Shear modulus of clay (MPa) | 2.85 × 104 | Ucgul [27] |

| Poisson’s ratio of clay | 0.3 | Asaf [28] |

| Coefficient of restitution of clay–clay | 0.4 | Wang [29] |

| Coefficient of restitution of clay–PVC | 0.4 | Wang [29] |

| Shear modulus of sand (MPa) | 4.3 × 104 | Asaf [28] |

| Poisson’s ratio of sand | 0.3 | Asaf [28] |

| Coefficient of restitution of sand–sand | 0.6 | Das [30] |

| Restitution coefficient of sand–PVC | 0.6 | Das [30] |

| Density of PVC (g cm−3) | 1.3 | Suggested by EDEM [31] |

| Elastic modulus of PVC (MPa) | 2.41 × 103 | Suggested by EDEM [31] |

| Poisson’s ratio of PVC | 0.383 | Suggested by EDEM [31] |

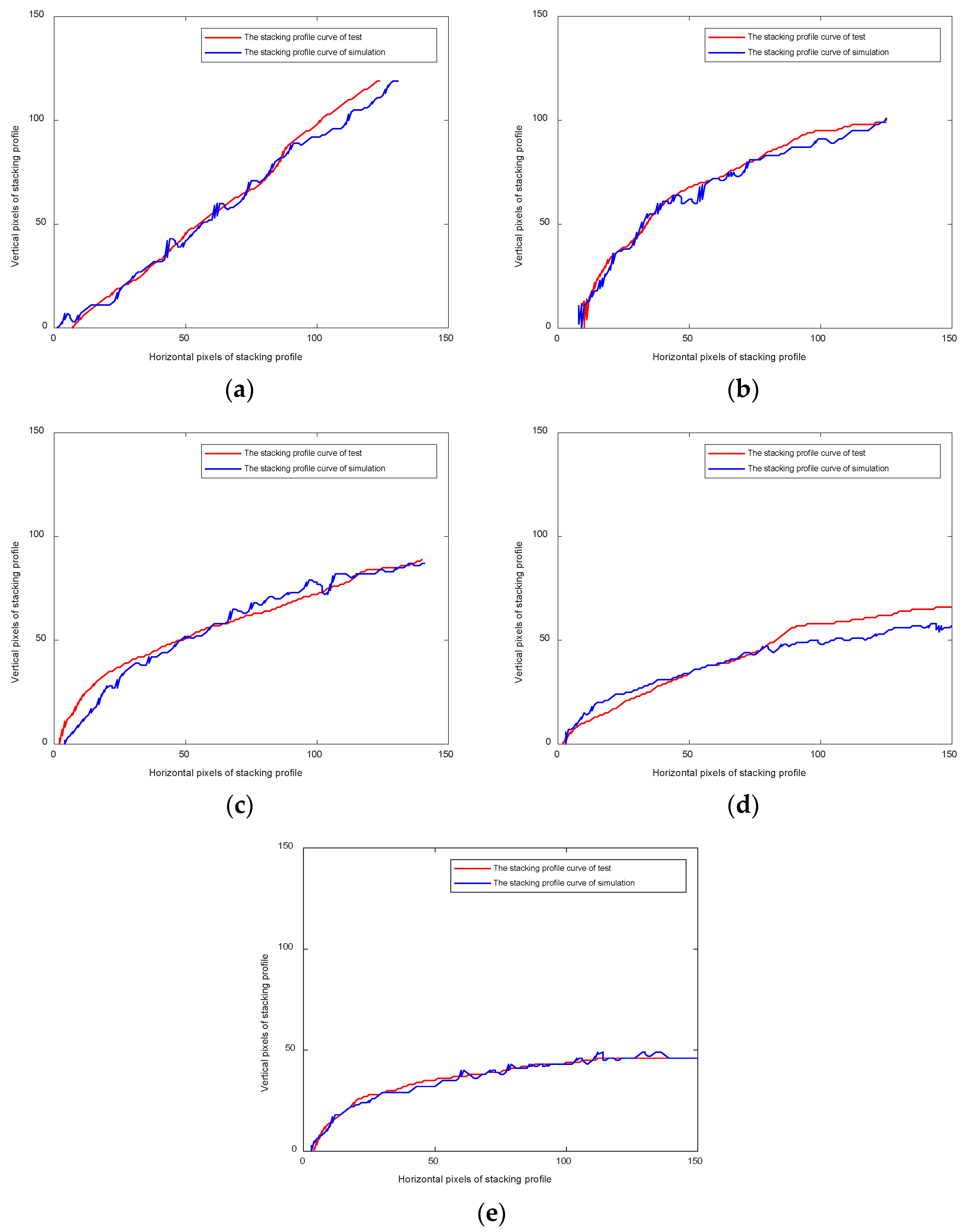

2.1.3. Parameter Calibration by the Accumulation Test

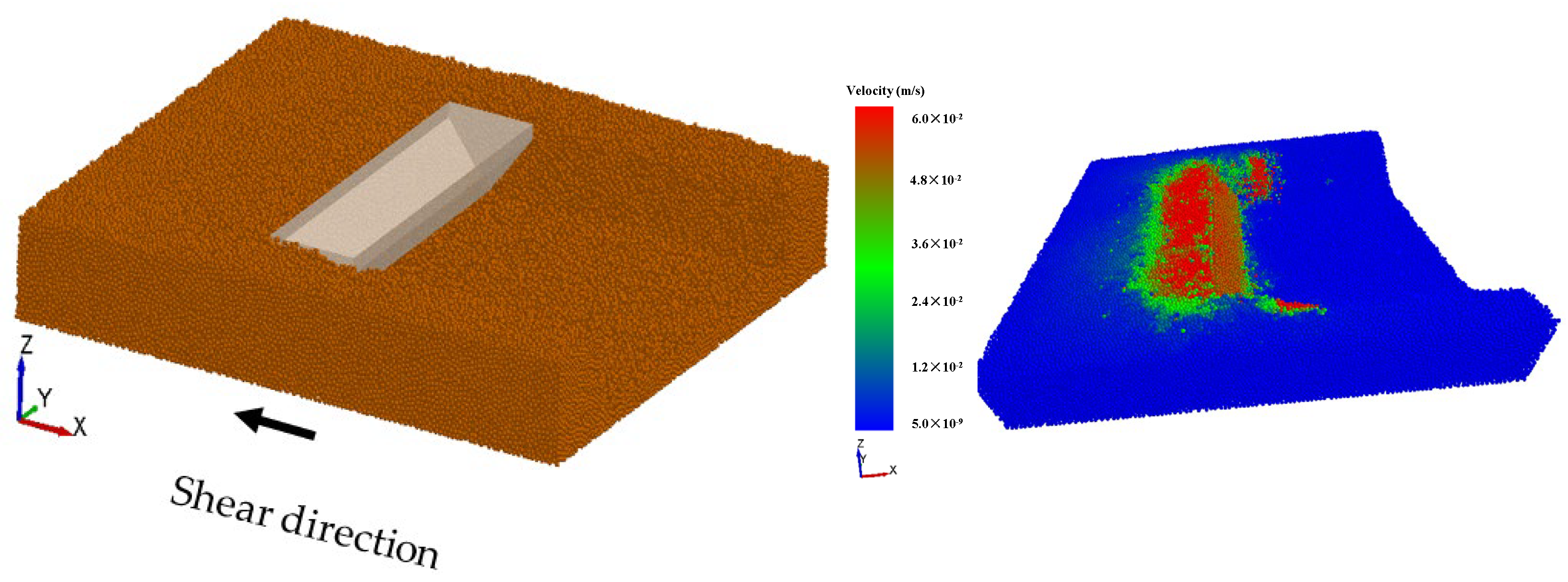

2.2. Interaction between Soil and Track

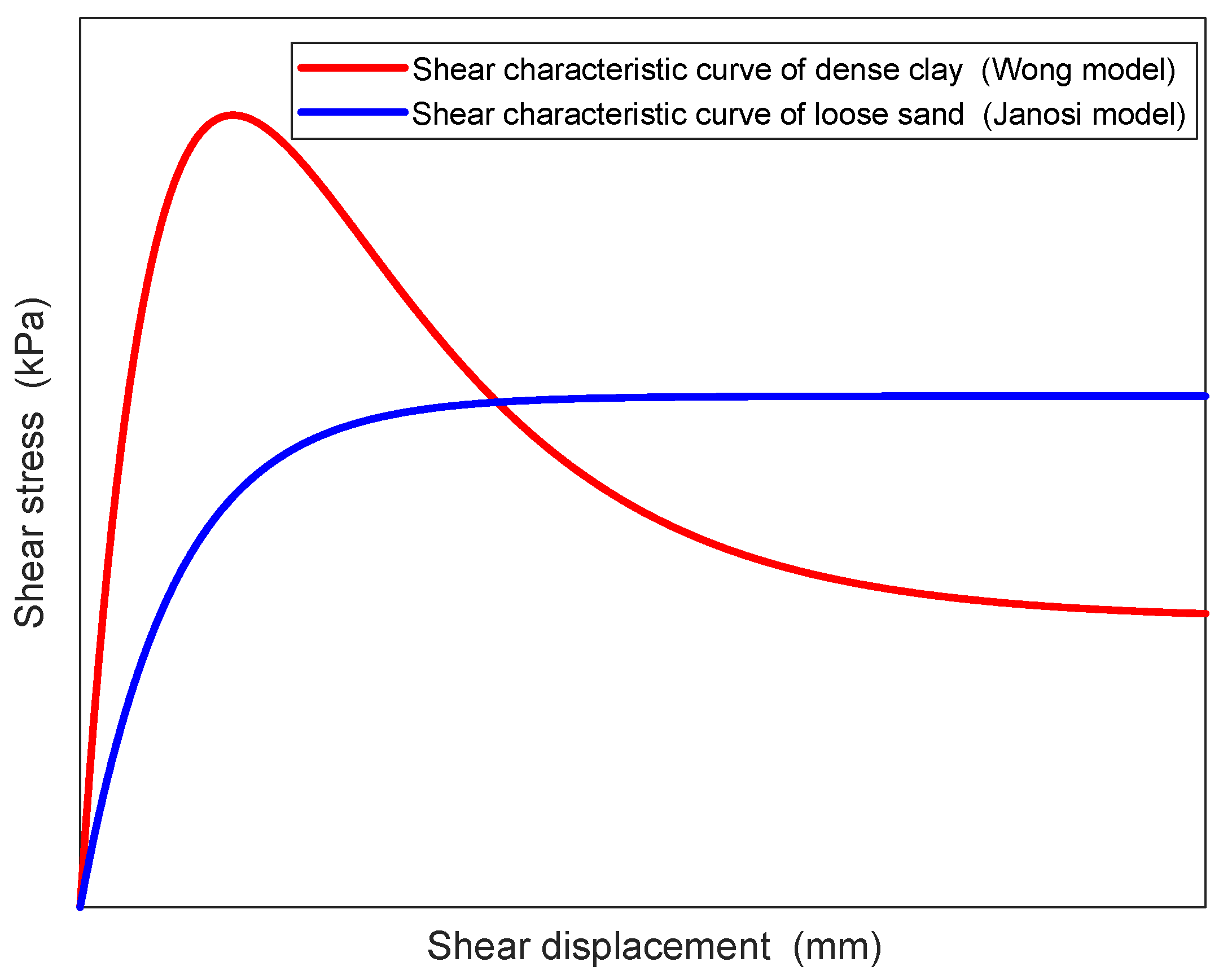

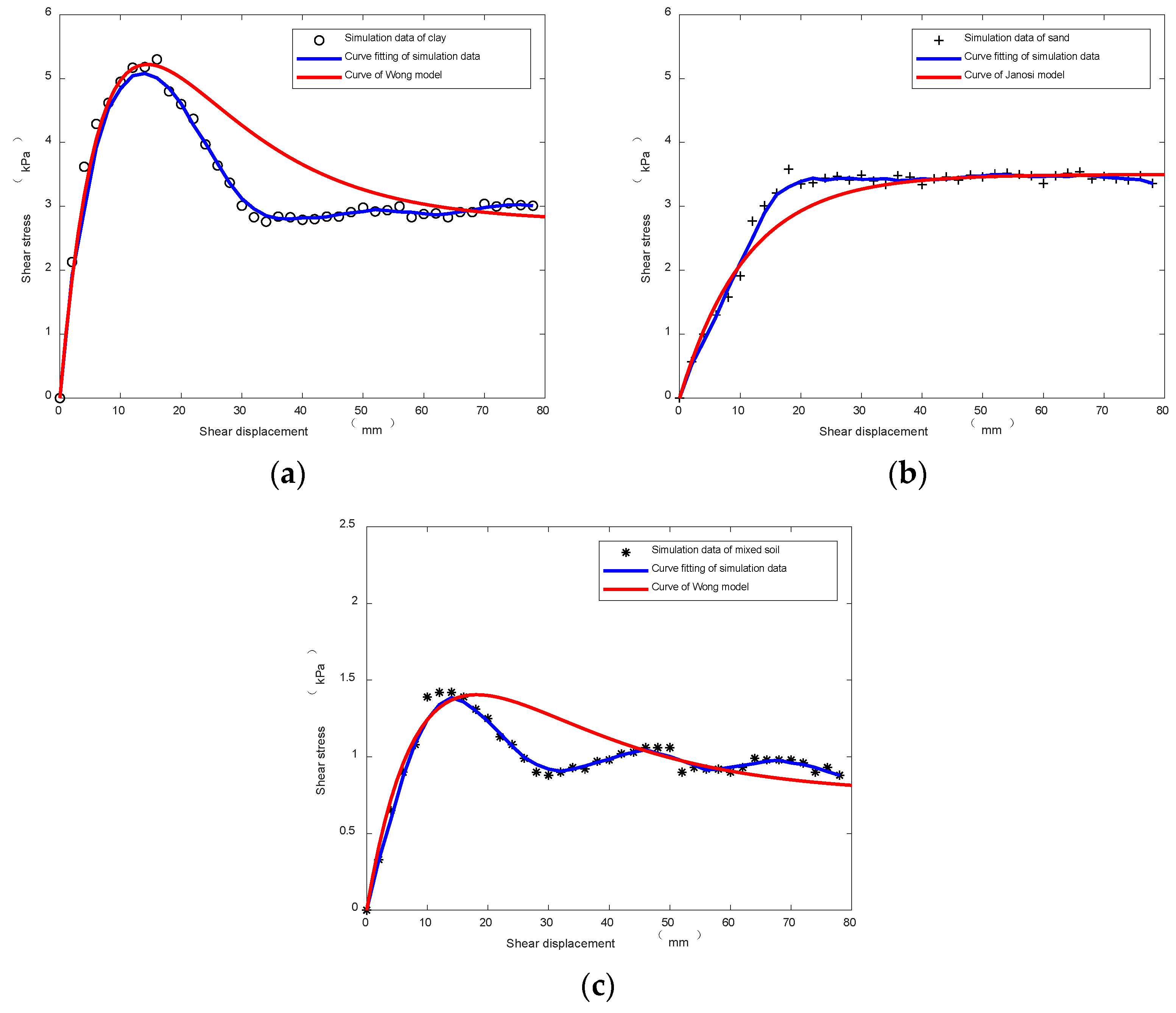

2.2.1. Shear Stress–Displacement Model

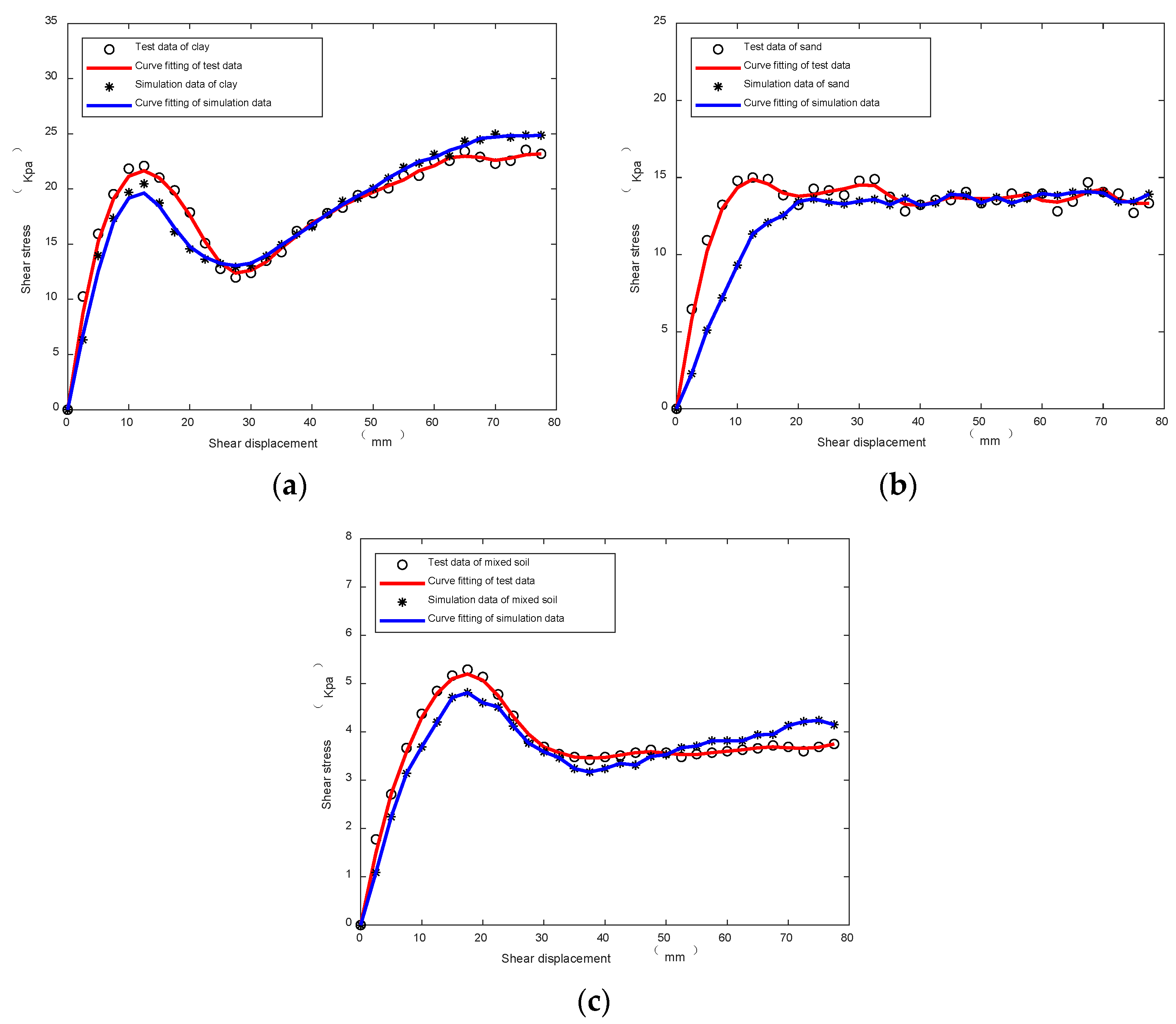

2.2.2. Shear Stress–Displacement Test

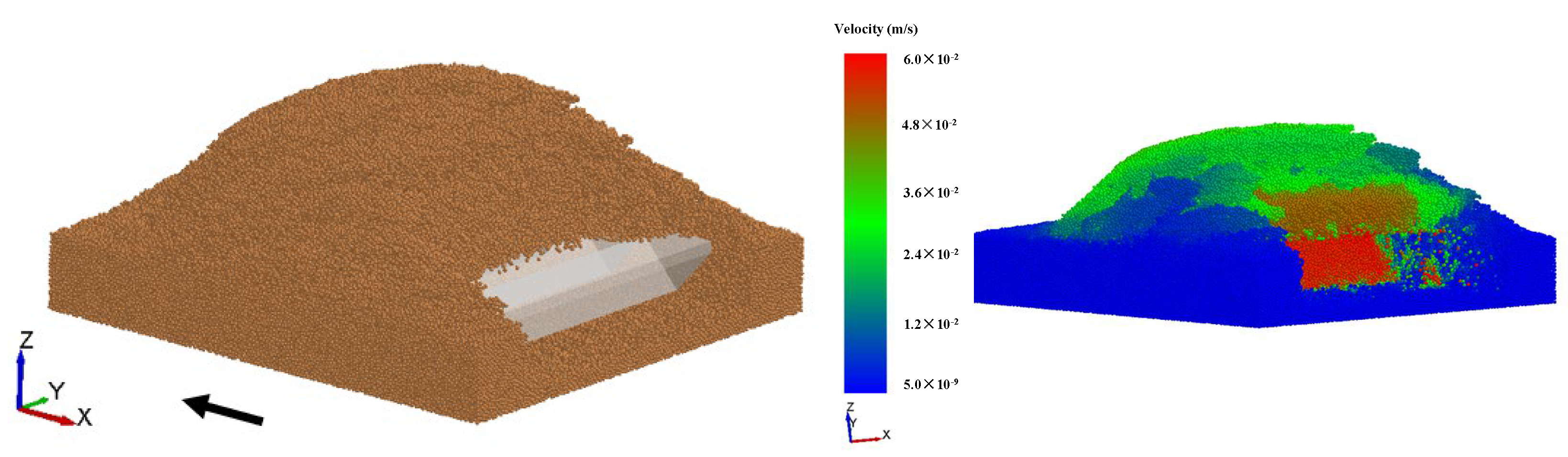

2.2.3. Shear Stress–Displacement DEM Simulation and Modification Process

2.3. Verification of Traction Performance of Soft Soil

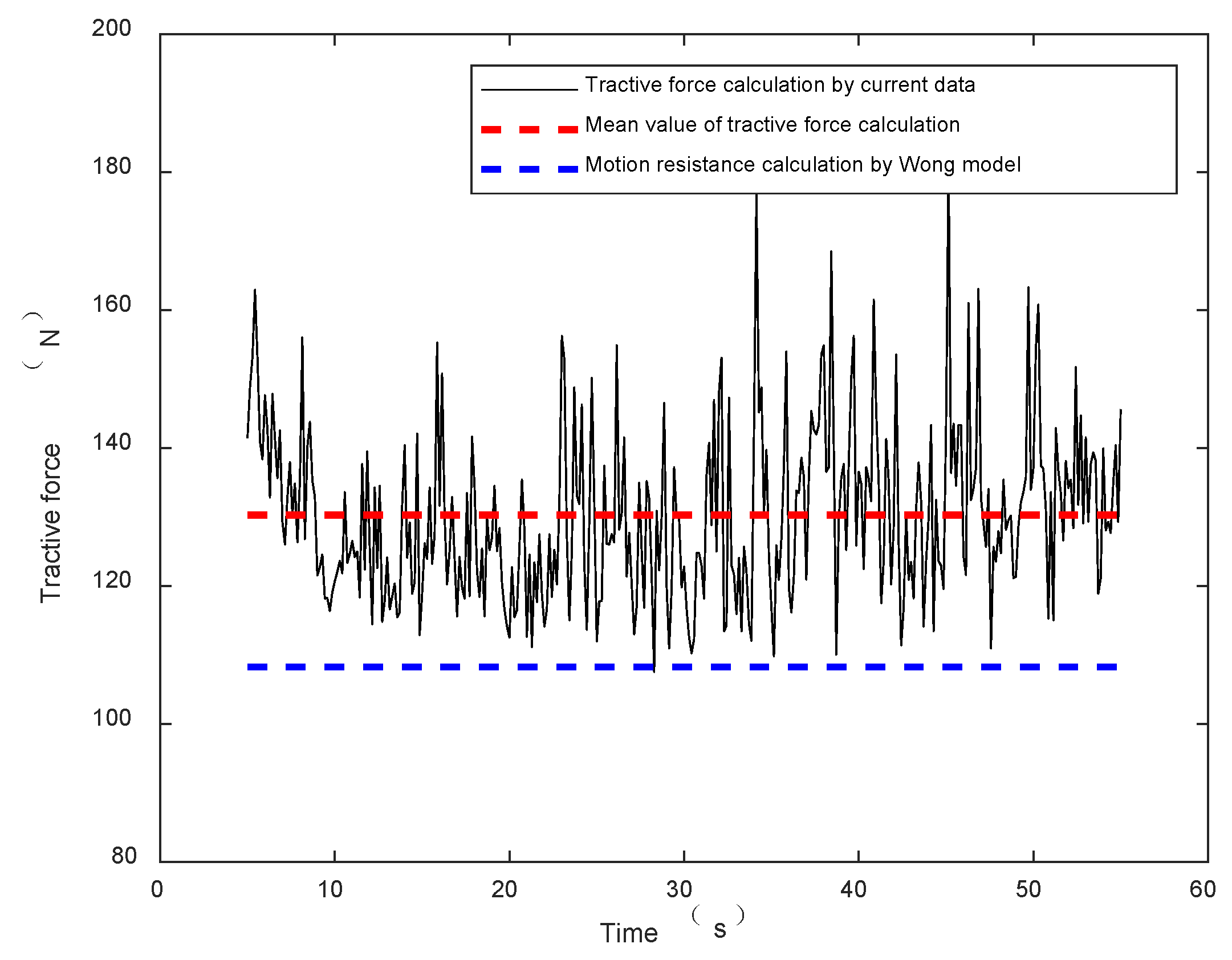

2.3.1. Traction Calculation and Travel Test of Tracked Vehicle

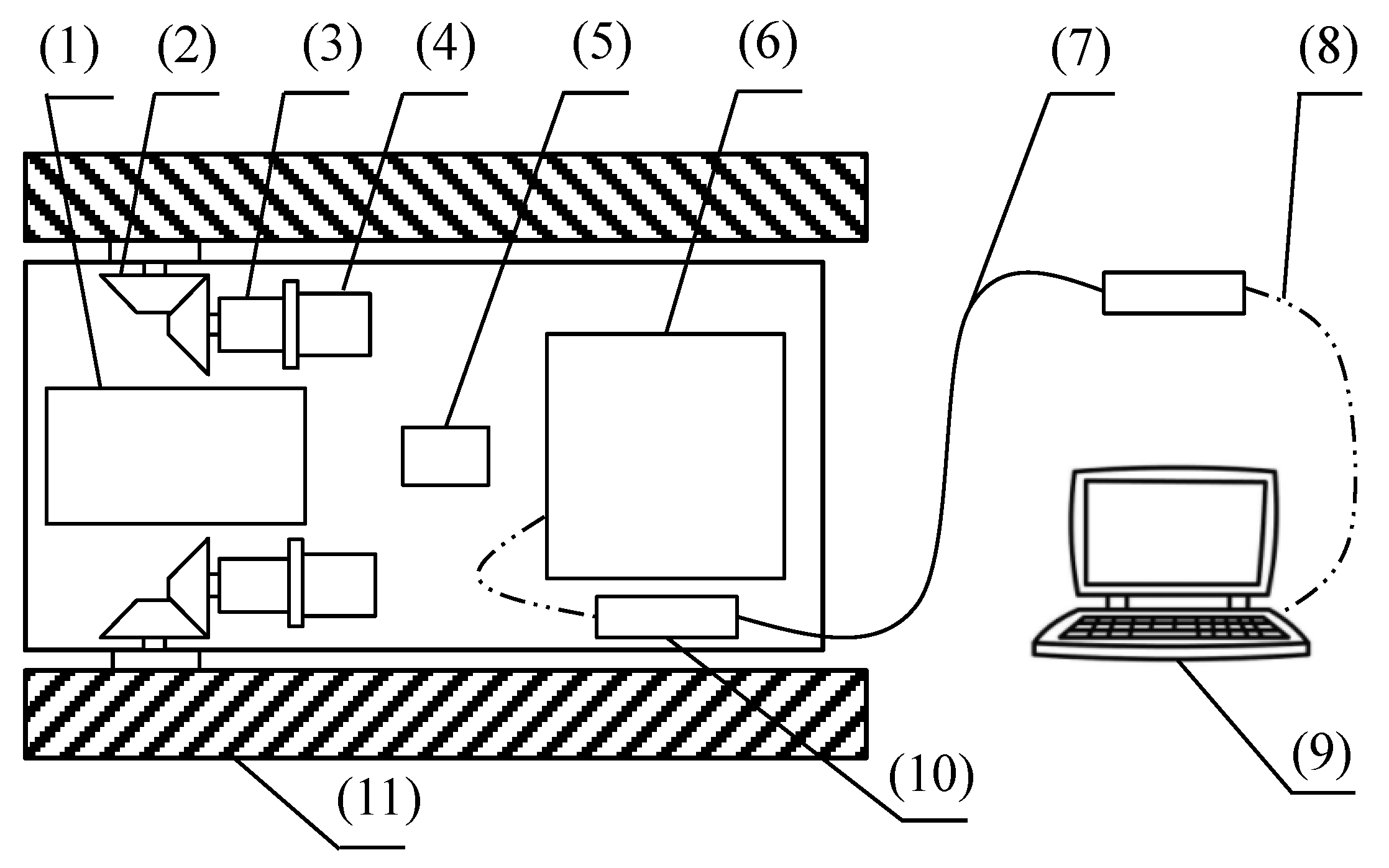

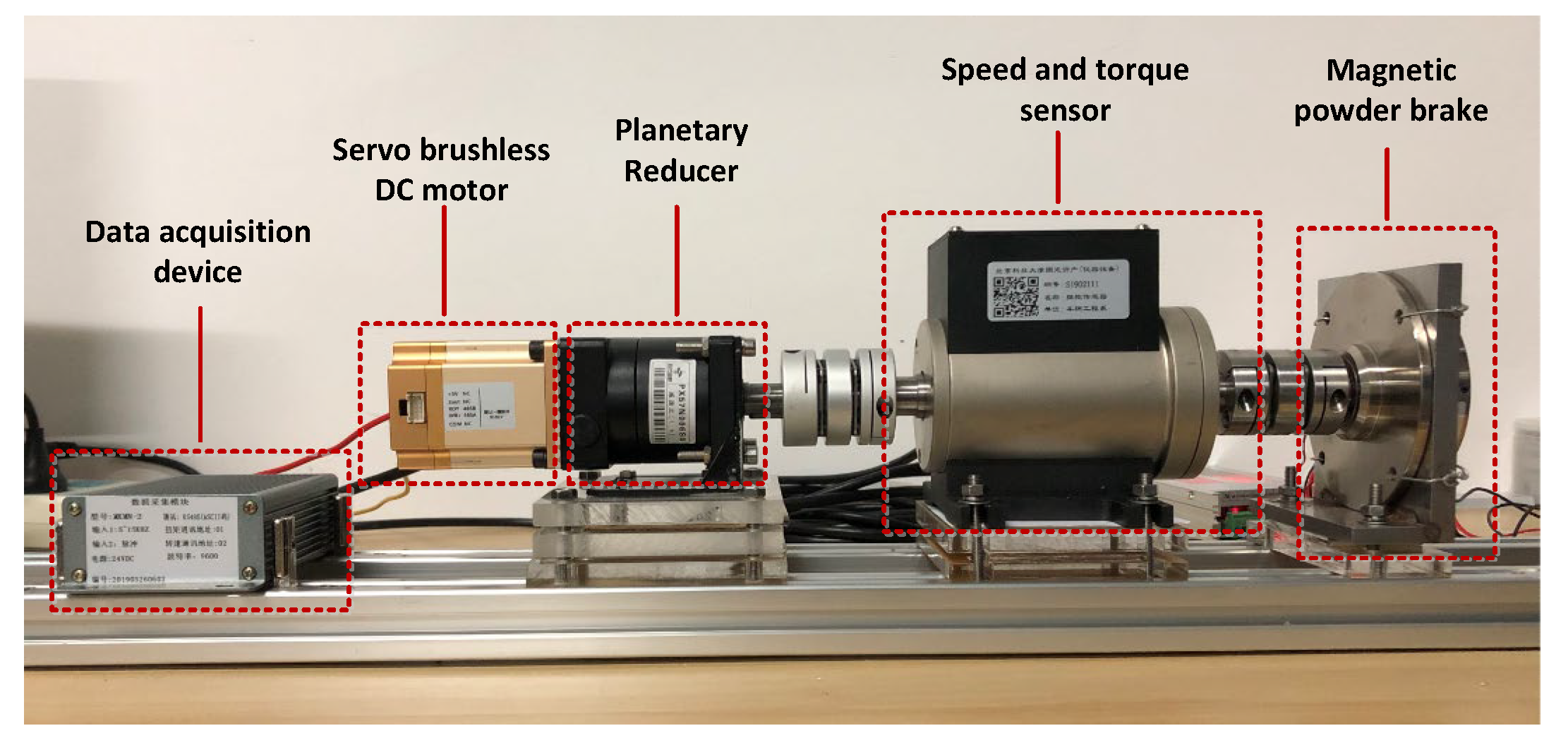

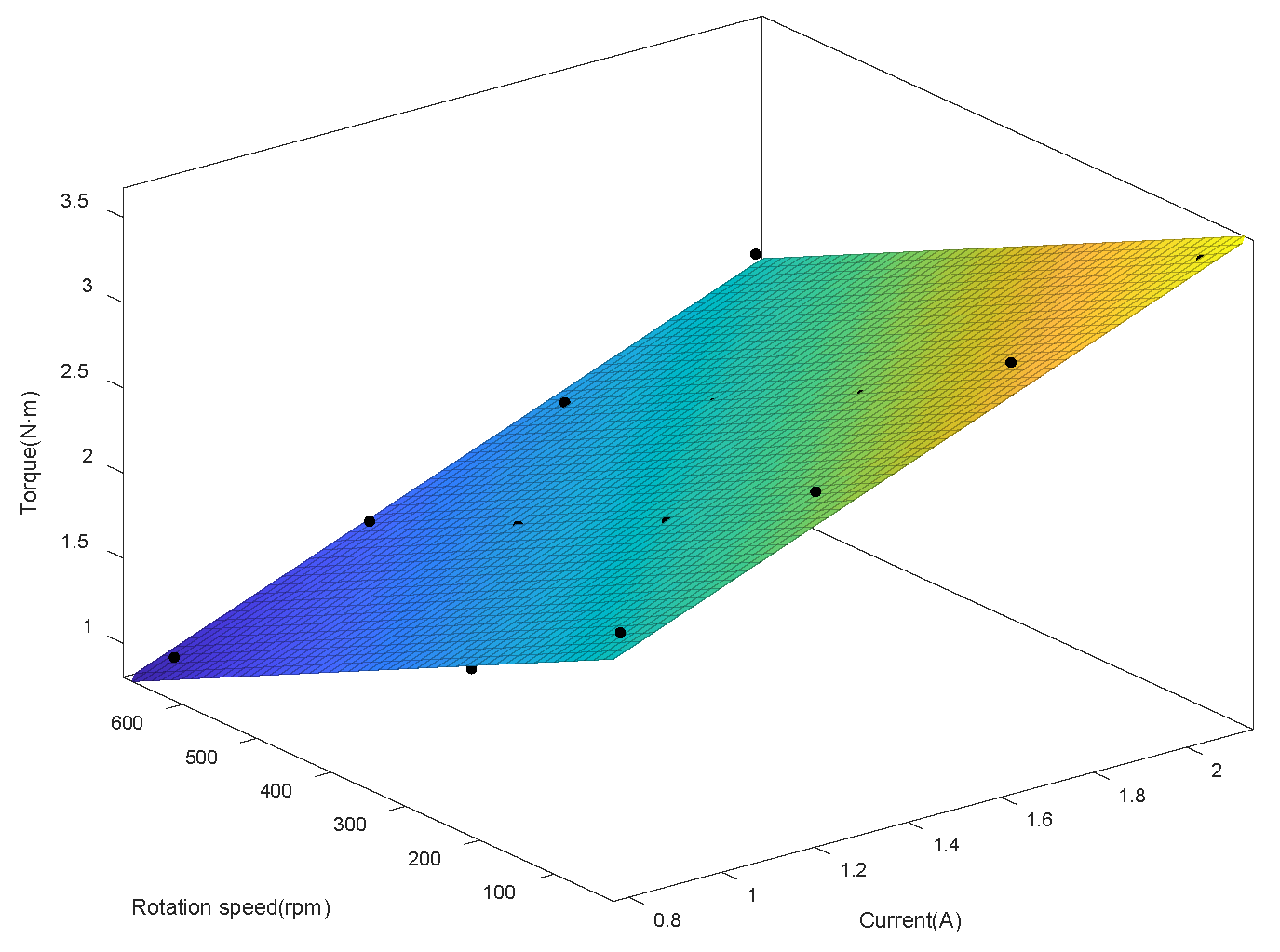

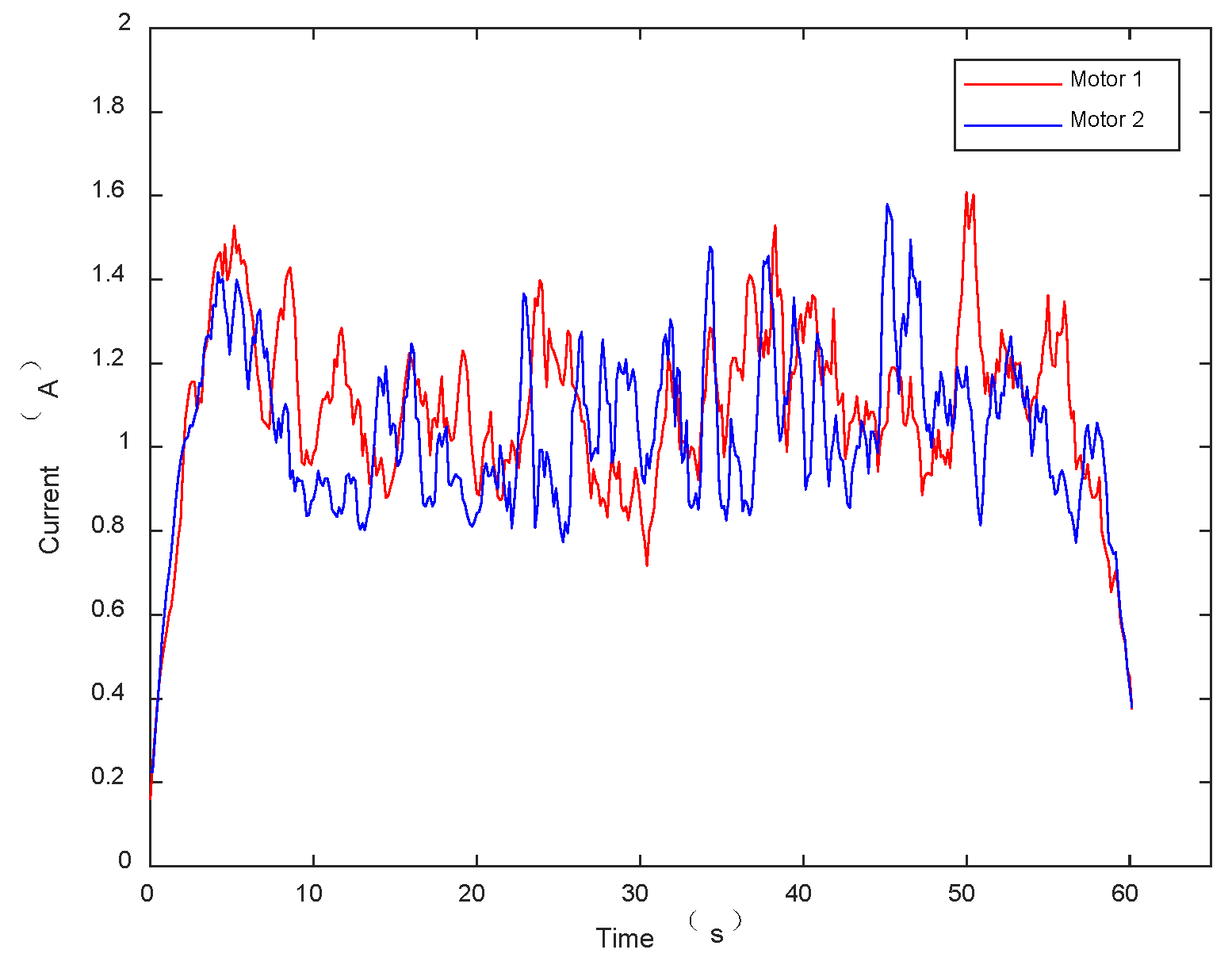

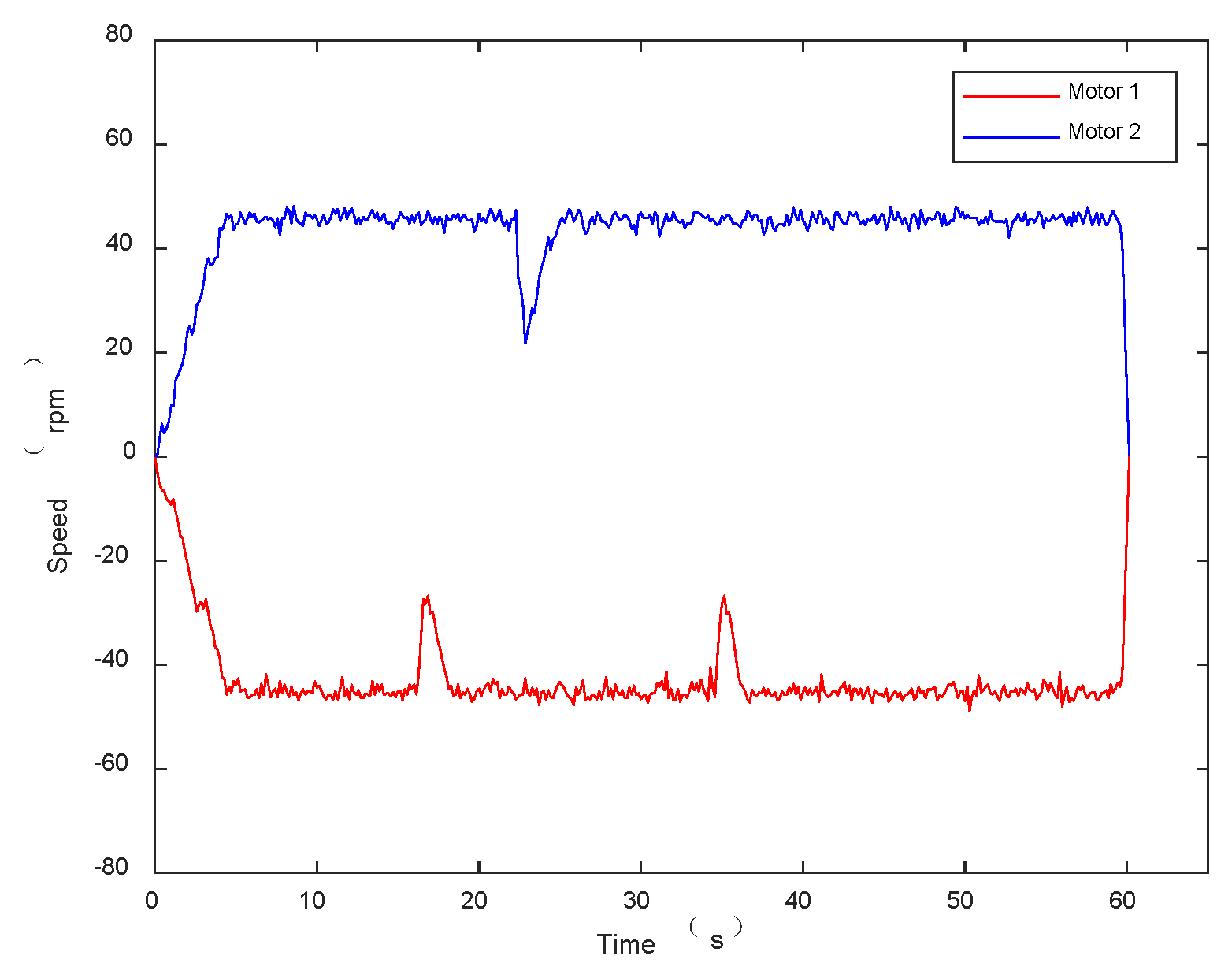

2.3.2. Drive Motor Characteristic Tests

3. Results and Discussion

3.1. Mechanical Property Verification of Scaled-Up Particles

3.2. Soil Shear Characteristic Verification of Track Segment

3.2.1. Comparative Analysis of the Results of the Soil Shear Test and DEM Simulation

3.2.2. Modified DEM Simulation of Track Segment Shear Process

3.3. Soft Soil Traction Verification

4. Conclusions

- (1)

- According to the actual particle size of clay and sand, the particles were scaled up to 1 mm for DEM simulations. Based on the scaled-up particle size, the cohesion and friction characteristic parameters were calibrated. Appropriate DEM input parameters of the scaled-up DEM particle could reproduce the soft soil accumulation shape with acceptable error.

- (2)

- Calibrated scaled-up DEM particles were used in the soil shear stress–displacement simulation. The shear stress–displacement DEM simulation results were in accordance with the mechanical response and trends in the soil shear stress–displacement tests.

- (3)

- The revised shear stress–displacement DEM simulation results were applied to the soil traction performance model calculation of the tracked vehicle. The relative error between the traction performance calculation result and the tracked vehicle travel test result was 16.8%, which proved that it is feasible to perform soft soil DEM simulations with the scaled-up particle method.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AOR | Angle of repose | |

| CPU | Central processing unit | |

| MAPE | Mean absolute percentage error | |

| PVC | Polyvinyl chloride | |

| DC | Direct current | |

| F.S | Full scale | |

| wt | Weight | |

| Nomenclature | ||

| Equivalent Young’s modulus | Pa | |

| Equivalent radius | m | |

| Surface energy | J m−2 | |

| Interaction parameter | ||

| , | Velocity of particle i and j | m s−1 |

| , | Angular velocity of particle i and j | rad s−1 |

| Normal contact force | N | |

| Tangential contact force | N | |

| Equivalent JKR normal elastic force | N | |

| Rolling friction moment | N m | |

| , | Elastic modulus of particle i and j | Pa |

| , | Poisson ratio of particle i and j | |

| , | Radius of particle i and j | m |

| Maximum shear stress | Pa | |

| , | Shear displacement where the maximum shear stress occurs | m |

| Ratio of residual shear stress to maximum shear stress | ||

| Number of samples | ||

| Test value of samples | ||

| Simulation value of samples | ||

| Traction force of soil | N | |

| Contact area between track and soil | m2 | |

| Width of track | m | |

| Contact length between track and soil | m | |

| Grouser height | m | |

| Gravity of tracked vehicle | N | |

| Slip ratio of tracked vehicle | ||

| Load torque of the motor | N m | |

| Current of the motor | A | |

| Rotary speed of the motor | rpm |

References

- Hata, S.; Hosoi, T. On the effects of lug pitch upon the tractive effort about track-laying vehicles. Proc. Int. Conf. ISTVS 1981, 1, 255–262. [Google Scholar]

- Muro, T.; Omoto, K.; Futamura, M. Traffic Performance of a bulldozer running on a weak terrain vehicle model test. Doboku Gakkai Ronbunshu 1988, 397, 151–157. [Google Scholar] [CrossRef] [Green Version]

- Oida, A.; Ohkubo, S. Effect of tire lug cross section on tire performance simulated by distinct element method. In Proceedings of the 13th International Conference of ISTVS, Munich, Germany, 14–17 September 1999; pp. 345–352. [Google Scholar]

- Nakashima, H.; Yoshida, T.; Wang, X.L.; Shimizu, H.; Miyasaka, J.; Ohdoi, K. Comparison of gross tractive effort of a single grouser in two-dimensional DEM and experiment. J. Terramech. 2015, 62, 41–50. [Google Scholar] [CrossRef]

- Du, Y.; Gao, J.; Jiang, L.; Zhang, Y. Numerical analysis on tractive performance of off-road wheel steering on sand using discrete element method. J. Terramech. 2017, 71, 25–43. [Google Scholar] [CrossRef]

- Peters, J.; Vahedifard, F.; Jelinek, B.; Mason, G.; Priddy, J. The discrete element method for vehicle-terrain analysis. In Proceedings of the 15th European-African Regional Conference of the International Society for Terrain-Vehicle Systems, Prague, Czech Republic, 9–11 September 2019. [Google Scholar]

- Zhou, L.; Gao, J.; Hu, C.; Li, Q. Numerical simulation and testing verification of the interaction between track and sandy ground based on discrete element method. J. Terramech. 2021, 95, 73–88. [Google Scholar] [CrossRef]

- Thakur, S.C.; Ooi, J.Y.; Ahmadian, H. Scaling of discrete element model parameters for cohesionless and cohesive solid. Powder Technol. 2016, 293, 130–137. [Google Scholar] [CrossRef] [Green Version]

- Lommen, S.; Mohajeri, M.; Lodewijks, G.; Schott, D. DEM particle upscaling for large-scale bulk handling equipment and material interaction. Powder Technol. 2019, 352, 273–282. [Google Scholar] [CrossRef]

- Mohajeri, M.J.; van Rhee, C.; Schott, D.L. Replicating cohesive and stress-history-dependent behavior of bulk solids: Feasibility and definiteness in DEM calibration procedure. Adv. Powder Technol. 2021, 32, 1532–1548. [Google Scholar] [CrossRef]

- Pöschel, T.; Saluena, C.; Schwager, T. Scaling properties of granular materials. In Continuous and Discontinuous Modelling of Cohesive-Frictional Materials; Springer: Berlin/Heidelberg, Germany, 2001; pp. 173–184. [Google Scholar]

- Deng, J.Y.; Hu, J.; Li, Q.D.; Li, H.L.; Yu, T.C. Simulation and experimental study on the subsoiler based on EDEM discrete element method. J. Chin. Agric. Mech. 2016, 37, 14–18. [Google Scholar]

- Huang, Y.; Hang, C.; Yuan, M.; Wang, B.; Zhu, R. Discrete element simulation and experiment on disturbance behavior of sub soiling. Trans. Chin. Soc. Agric. Mach. 2016, 47, 80–88. [Google Scholar]

- Xia, R.; Li, B.; Wang, X.; Li, T.; Yang, Z. Measurement and calibration of the discrete element parameters of wet bulk coal. Measurement 2019, 142, 84–95. [Google Scholar] [CrossRef]

- Bahrami, M.; Naderi-Boldaji, M.; Ghanbarian, D.; Ucgul, M.; Keller, T. DEM simulation of plate sinkage in soil: Calibration and experimental validation. Soil Tillage Res. 2020, 203, 104700. [Google Scholar] [CrossRef]

- Li, P.; Ucgul, M.; Lee, S.H.; Saunders, C. A new approach for the automatic measurement of the angle of repose of granular materials with maximal least square using digital image processing. Comput. Electron. Agric. 2020, 172, 105356. [Google Scholar] [CrossRef]

- Roessler, T.; Richter, C.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials–part I: Solving the problem of ambiguous parameter combinations. Powder Technol. 2019, 343, 803–812. [Google Scholar] [CrossRef]

- Richter, C.; Roessler, T.; Kunze, G.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials–Part II: Efficient optimization-based calibration. Powder Technol. 2020, 360, 967–976. [Google Scholar] [CrossRef]

- Orefice, L.; Khinast, J.G. A novel framework for a rational, fully-automatised calibration routine for DEM models of cohesive powders. Powder Technol. 2020, 361, 687–703. [Google Scholar] [CrossRef]

- Hertz, H. Ueber die Berührung fester elastischer Körper. J. Die Reine Angew. Math. 1882, 92, 156–171. [Google Scholar]

- Mindlin, R.D.; Deresiewicz, H. Elastic spheres in contact under varying oblique forces. J. Applied Mech. 1953, 20, 327–344. [Google Scholar] [CrossRef]

- Tsuji, Y.; Tanaka, T.; Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 1992, 71, 239–250. [Google Scholar] [CrossRef]

- Sakaguchi, H.; Ozaki, E.; Igarashi, T. Plugging of the flow of granular materials during the discharge from a silo. Int. J. Mod. Phys. B 1993, 7, 1949–1963. [Google Scholar] [CrossRef]

- Johnson, K.L.; Kendall, K.; Roberts, A. Surface energy and the contact of elastic solids. Proc. R. Soc. Lond. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Tekeste, M.Z.; Way, T.R.; Syed, Z.; Schaferb, R.L. Modeling soil-bulldozer blade interaction using the discrete element method (DEM). J. Terramech. 2020, 88, 41–52. [Google Scholar] [CrossRef]

- Tsuji, T.; Nakagawa, Y.; Matsumoto, N.; Kadono, Y.; Takayama, T.; Tanaka, T. 3-D DEM simulation of cohesive soil-pushing behavior by bulldozer blade. J. Terramech. 2012, 49, 37–47. [Google Scholar] [CrossRef]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Three-dimensional discrete element modelling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil. Biosyst. Eng. 2014, 121, 105–117. [Google Scholar] [CrossRef]

- Asaf, Z.; Rubinstein, D.; Shmulevich, I. Determination of discrete element model parameters required for soil tillage. Soil Tillage Res. 2007, 92, 227–242. [Google Scholar] [CrossRef]

- Wang, D.; Wang, Y.; Yang, B.; Zhang, W.; Lancaster, N. Statistical analysis of sand grain/bed collision process recorded by high-speed digital camera. Sedimentolog 2008, 55, 461–470. [Google Scholar] [CrossRef]

- Das, B.M.; Khing, K.H. Cyclic Load-Induced Settlement of Shallow Foundations on Geogrid-Reinforced Layered Soil. In Proceedings of the Seventh International Offshore and Polar Engineering Conference, International Society of Offshore and Polar Engineers, Honolulu, HI, USA, 25–30 May 1997. [Google Scholar]

- EDEM. EDEM Theory Reference Guide; EDEM Solutions: Edinburgh, UK, 2011. [Google Scholar]

- Wong, J.; Thomas, J. On the characterization of the shear stress-displacement relationship of terrain. J. Terramech. 1983, 19, 225–234. [Google Scholar] [CrossRef]

- Wong, J.Y. Theory of Ground Vehicles, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2001; pp. 133–159. [Google Scholar]

- Janosi, Z. The analytical determination of drawbar pull as a function of slip for tracked vehicles in defarmable soils. In Proceedings of the 1st ISTVS International Conference, Turin, Italy, 24–27 September 1961. [Google Scholar]

| Property | Clay | Sand |

|---|---|---|

| Particle size (mm) | 0.05–0.075 | 0.5–1 |

| Wet density (g cm−3) | 1.45 | 1.97 |

| Dry density (g cm−3) | 0.67 | 1.63 |

| Moisture content (%) | 91 | 21 |

| Parameter | Track Segment |

|---|---|

| Material | PVC Rigid |

| Length (mm) | 80 |

| Width (mm) | 60 |

| Grouser height (mm) | 12 |

| Parameter | Value |

|---|---|

| Length, width and height of tracked vehicle (m) | |

| Weight of tracked vehicle (kg) | 24 |

| Interface length of track (m) | 0.32 |

| Servo brushless DC motor | Power up to 100 W; Rotational speed up to 1000 rad min−1; Torque up to 0.96 Nm Min resolution 1 mA |

| Planetary reducer | Reduction ratio 1:6 |

| Speed and torque sensor | Measuring range 0–100 Nm Measurement accuracy < 0.1% F.S Min resolution 0.01 Nm |

| Magnetic powder brake | Resistance force moment up to 6 Nm |

| Parameter | Clay | Mixed Soil 2# | Sand |

|---|---|---|---|

| (kPa) | 5.28 | 1.65 | 3.5 |

| 0.53 | 0.52 | – | |

| , (m) | 0.013 | 0.016 | 0.02 |

| Parameter | Motor 1 | Motor 2 |

|---|---|---|

| Average speed by measured (rpm) | 45.6 | 46.2 |

| Average current by measured (A) | 1.12 | 1.08 |

| Average torque by calculated (Nm) | 2.25 | 2.18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, J.; Shen, Y.; Yang, S.; Feng, Z. Simulation of Track-Soft Soil Interactions Using a Discrete Element Method. Appl. Sci. 2022, 12, 2524. https://doi.org/10.3390/app12052524

Wu J, Shen Y, Yang S, Feng Z. Simulation of Track-Soft Soil Interactions Using a Discrete Element Method. Applied Sciences. 2022; 12(5):2524. https://doi.org/10.3390/app12052524

Chicago/Turabian StyleWu, Jiaxiong, Yanhua Shen, Shudi Yang, and Zhipeng Feng. 2022. "Simulation of Track-Soft Soil Interactions Using a Discrete Element Method" Applied Sciences 12, no. 5: 2524. https://doi.org/10.3390/app12052524