1. Introduction

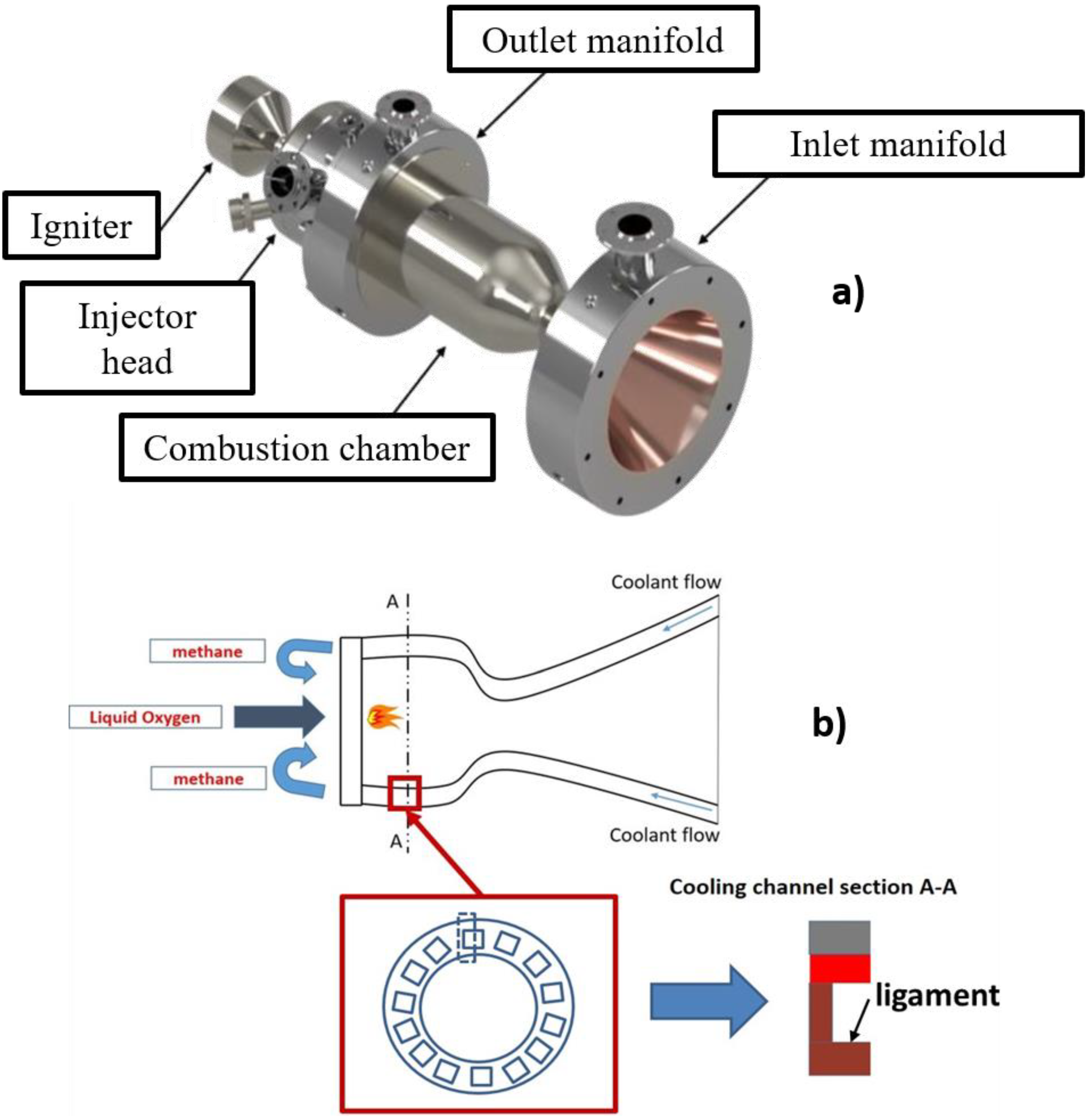

The aim of the HYPROB Program is to design, manufacture, and test a ground demonstrator of a liquid rocket engine employing liquid methane and liquid oxygen. Such a propulsion technology may cover a wide range of aerospace propulsion systems, from launcher main stages up to small thrusters. When the requested levels of thrust are relatively high, heavy heat fluxes and high chamber pressures are expected in the combustion chamber. Therefore, active cooling techniques can be used to keep the selected materials at acceptably low temperature values. The thrust chamber considered in the current investigation comprised an inner structure made of a CuCrZr alloy, and an external cold structure made of electrodeposited nickel. Methane, before being injected as fuel into the combustion chamber, also acts as a coolant fluid flowing through axial cooling channels, so as to partially remove heat from the inner structures, see

Figure 1. Even though temperature levels are lowered with such a cooling process, very high thermal gradients occur within the structure, separating the hot gas from the cooling channels, where the fuel temperature is considerably lower.

Several works can be found in the literature regarding the thermal–mechanical behavior of liquid rocket engines thrust chambers under cyclic loading conditions. These have demonstrated that plasticity effects should be modeled by means of both isotropic and kinematic hardening models. Additionally, a nonlinear kinematic hardening model should be adopted to simulate shakedown and ratcheting phenomena [

1,

2,

3]. In particular, when employing the Chaboche kinematic hardening model [

4], at least three nonlinear hardening models should be considered to simulate ratcheting behavior properly, i.e., the progressive plastic strain accumulation during cycling [

5]. Other researchers also demonstrated that low-cycle fatigue (LCF) and creep can be the main possible causes of failure, in turn, highlighting the need to accurately investigate these phenomena [

6,

7,

8]. Creep effects can be dominant when temperatures and stresses reach significantly high values [

9,

10,

11,

12]. Even if Norton secondary creep law [

13] has been usually considered for these applications in literature, the authors have chosen to adopt a more complete creep model taking account of both primary and secondary creep effects through combined time hardening rules. With regard to the LCF phenomenon, uniaxial fatigue criteria are usually adopted for these kind of applications, since circumferential plastic strains are the dominant contributors with respect to the radial and axial ones. However, authors have adopted a critical plane approach, namely, the Wang-Brown criterion [

14], to consider the effects of the multi-axiality of the stress-strain fields and non-proportionality of the loading conditions, because the influence of multiaxial and non-proportional loading effects is not negligible when evaluating the service life of these kind of structures. The latest advances of numerical methods, such as the finite element method (FEM), allowed us to study these complex structures and loading conditions, reducing the burden of expensive experimental tests.

The aim of the present work was to conduct a numerical investigation on the 3D thermal–mechanical behavior of a cooling channel of the thrust chamber by employing state-of-the-art numerical FEM models. This allowed us to take account of plasticity, creep, and LCF phenomena simultaneously. These analyses were conducted by means of the FEM code ANSYS. A preliminary work involving the same case study and concerning the adoption of global/local approaches can be found in [

15]. As a continuation of [

15], in the present work, plasticity effects were studied adopting the von Mises yield criterion, Prandtl-Reuss flow rule, and both isotropic and non-linear Chaboche kinematic hardening models. Multiaxial LCF evaluations were carried out by employing experimental fatigue test data available in literature [

16]. Finally, the combined time hardening creep model was adopted to simulate primary and secondary creep stages [

17]. A cumulative damage model, considering the effects of plastic instability (thermal ratcheting), creep, and fatigue, was employed so as to evaluate the number of cycles up to failure.

The rest of this document can be summarized as follows.

Section 2 describes the adopted mathematical models with the related governing equations.

Section 3 describes the numerical FEM models.

Section 4 describes the thermal–mechanical loading conditions, whereas

Section 5 presents the life prediction models adopted here. Finally, results are presented and discussed in

Section 6, whilst the concluding remarks are reported in

Section 7.

3. Numerical Model Description

Since the maximum heat flux values from the combustion chamber are expected in the throat, a local model of the throat region of the thrust chamber was examined in order to save the computation time required to investigate the whole chamber, see

Figure 4 and

Figure 5.

Only a half-cooling channel was modeled, thus taking advantage of the symmetry. Cyclic symmetry boundary conditions were enforced at the two cut surfaces, so as to simulate the whole 360° of the chamber.

Figure 6 shows a section of the cooling channel.

Figure 5 shows the position of the throat region, where heat transfer coefficients of coolant and hot gases reach their maximum values. The region of interest was chosen as being sufficiently far from the end sections of the models in order to reduce the impact of the approximations caused by pre-defined boundary conditions (not obtained by a rigorous submodeling approach) on the cut surfaces (see

Figure 5); here, the aim was to prove the effectiveness of the procedure, rather than strictly forecasting the working conditions.

The combustion chamber comprises three materials, as shown in

Figure 6:

CuCrZr alloy, in the region in contact with the coolant and the hot gases;

a thin layer of electrodeposited oxygen-free, high-thermal conductivity copper (OFHC);

a layer of electrodeposited nickel to provide adequate stiffness to the chamber.

Table 2,

Table 3,

Table 4,

Table 5,

Table 6 and

Table 7 summarize the physical and mechanical properties of the copper alloy (CuCrZr), the electrodeposited oxygen-free, high-thermal conductivity copper (OFHC), and nickel [

15].

Pressures of the coolant and hot gases were considered as being uniform and equal to 12 and 5 MPa, respectively. A constraint in one node in the axial direction was applied to prevent rigid body motion. The thermal and structural boundary conditions are reported in

Figure 7. Combustion gases, coolant bulk temperatures, and their respective heat transfer coefficients varied along the chamber axis, and their values were obtained by computational fluid dynamics (CFD) analyses [

25]. In particular, as reported by Ricci et al. [

29], two separate CFD simulations were conducted:

A convergence analysis on the FEM mesh was carried out in order to identify the best suited numerical grid to be considered in the analyses, see

Figure 9. In particular, in order to illustrate that grid convergence is reached, a node on the internal surface of the cooling channel, where maximum temperatures and plastic strains are envisaged, was selected (see

Figure 7).

Plastic strains, creep strains, and temperature values were compared for three grid configurations characterized by four, six and eight elements in the ligament thickness (

Figure 9 shows the “eight elements” configuration). In

Table 8, the results obtained at the end of the “hot phase” are summarized. The same considerations could be done for other nodes, but for the sake of simplicity, no other results are shown. The computation time needed to perform a thermo-structural analysis with 35 loading cycles is 70 h, adopting a two-core processor.

5. Life Prediction Models

5.1. Ratcheting

With regard to ratcheting, the accumulation of plastic strain

was evaluated by summing up the increment of plastic strain, cycle after cycle:

where the subscript

refers to the

ith cycle. The increment in the

ith cycle was evaluated by means of the following relationship:

where

are evaluated as follows:

with

and

representing the plastic strain at the end and at the beginning of the

ith cycle (

j = x,

y,

z;

k = x,

y,

z), respectively.

A significant number of thermal–mechanical cycles was simulated so as to be as accurate as possible in simulating the ratcheting phenomenon and evaluating whether it occurs in the ligament of the thrust chamber. If ratcheting stopped, no contribution of the plastic instability would be considered when evaluating the total usage factor, which sums the effects of creep, fatigue, and ratcheting. On the other hand, if ratcheting increased, with a continuous increment of plastic strains after a significant number of cycles, the service life of the cooling channel associated with plastic instability was evaluated by means of an extrapolation of the obtained plastic strain curve, up to reaching the elongation at break .

5.2. Creep

The number of cycles to failure

, as coming from the creep phenomenon, was evaluated by the following relationship:

where

is the temperature-dependant rupture time for a steady stress state

and

is the time interval during which the creep phenomenon occurs, see

Figure 10 where the experimental curves refer to one-dimensional creep tests at several temperature values [

16].

When the pressure in the cooling channel is low, the tangential compressive stresses arising during the hot phase remain compressive up to the end of the creep period; on the contrary, if the pressure in the cooling channel is high, the compressive stresses rapidly relax and become tensile before the end of the hot phase. In the former case, creep is not a potential failure mode, while in the latter, creep rupture damage could occur.

An analytical relationship between the equivalent stress and the number of cycles to failure was used by adopting a multiple linear regression model to fit the CuCrZr experimental creep tests.

The following relationship between steady state stress

and

was derived:

where

,

, and

are constants equal to 596.87 MPa, 799.87 MPa s

0.28, and −0.72 MPa/K, respectively. The corresponding coefficient of determination,

, is equal to 0.95.

In the next section it will be shown that, in the present test case, compressive stresses do not reverse to tensile ones, making, in such a way, the creep rupture damage not relevant.

5.3. Multiaxial LCF—Non Proportional Loading

Many structural components, such as thrust chambers, experience complex mechanical and thermal loads during their normal working conditions. Such loads can generate multi-axial stress–strain histories and also changes in the principal stress directions. Therefore, fatigue criteria, taking into account both multi-axiality and non-proportional loading, have to be adopted in these cases [

18,

19,

30,

31]. Most of the fatigue criteria propose to estimate the value of a uniaxial equivalent strain, which can be considered as being equivalent to the multiaxial strain field. The relationship between this uniaxial equivalent strain and the number of cycles to failure can be obtained through the Basquin–Manson–Coffin relationship [

30], represented through the following equation:

where the fatigue strength coefficient

and exponent

are parameters of Basquin law, whereas fatigue ductility coefficient

and exponent

are parameters of Coffin–Manson curve,

represents the mean stress normal to the maximum shear plane, and

2Nf is the number of reversals to failure.

The Wang-Brown criterion is based on a critical plane approach. As demonstrated through numerous experiments [

14], fatigue life is usually dominated by crack–growth along either shear planes or tensile planes. This criterion is then based on the idea that shear strains help to nucleate cracks, while normal strain contributes to their growth. The amplitude of the equivalent strain is evaluated according to the following equation:

where

is the maximum shear strain amplitude on the critical plane,

is the normal strain excursion, and

is the effective Poisson’s ratio. The experimental data regarding fatigue tests on CuCrZr coupons are reported in

Figure 11 [

16]. An analytical relationship between the equivalent strain amplitude and the number of cycles to failure was evaluated by adopting a multiple linear regression model to fit the CuCrZr experimental fatigue tests. Then, the equivalent strain amplitude

, estimated according to the Wang-Brown method, was used to estimate the fatigue life according to the following relationship:

where

,

and

are constants set as equal to 0.1684, 0.4580, and −0.5987, respectively. The corresponding coefficient of determination,

, is equal to 0.96.

Finally, a usage factor

was defined in order to sum the effects of all the described thermal–mechanical phenomena:

whereas the total number of cycles prior to failure

was evaluated as:

where

,

, and

are, respectively, the usage factors associated with plastic instability, creep, and low-cycle fatigue.

6. Results and Discussions

The main results of the thermal–mechanical analyses performed on the throat regions are described in this paragraph.

Figure 12 shows the temperature and the von Mises stress contour plots for the CuCrZr liner at the end of the purging phase, 0.3 s after starting the ignition phase, and at the end of it. The maximum temperature value of 545 K was still too small for the creep failure occurrence. Indeed, as shown in

Figure 12, the lowest temperature value considered in the creep tests is about 100 K greater than the maximum temperature value obtained in the thermal analysis. Furthermore, the ligament compressive stresses in the tangential direction detected in the hot phase remain compressive up to the end of the creep period. Therefore, no creep failure evaluations were needed for the life assessment. On the other hand, creep failure can become dominant when higher thrust levels are required; in fact, higher pressure values are expected in the thrust chamber in this case. However, it is clear that creep relaxation strongly influences the stress–strain response of the structure, leading to an asymmetrical hysteresis curve, which is the cause of an accumulation of tensile plastic strains in the ligament (see

Figure 13). Creep effects produce an upward trend of the stress–strain curve, leading to yielding in tension during the following purging phase.

On the other hand, when creep is not modeled, the ligament tensile yielding could not occur and, in turn, a stabilization of the stress–strain curve could be envisaged after a few cycles, leading to a non-conservative estimation of the thrust chamber service life. Therefore, the creep modeling is crucial when studying the ratcheting behavior of the cooling channel. Particularly, primary creep effects, i.e., when creep deformation rate is not constant, are dominant with respect to secondary creep ones, especially in the first ten loading cycles.

With regard to purging and ignition phases, a significant number of time steps were considered (see

Table 9). This was due to their very small duration and because very high thermal gradients stresses could be reached especially in initial time intervals. Consequently, a coarse time discretization of these phases could lead to inaccurate results in terms of accumulated plastic strains.

Plastic strains at the end of the ignition phase were reported in

Figure 14. It was clear that the tangential strains were dominant with respect to other directions. However, the axial strains were non-negligible, since their maximum value was about one third of the maximum plastic strain in the tangential direction. This demonstrated the need to adopt a multiaxial fatigue criteria.

Figure 15 and

Figure 16 show that the equivalent plastic strain increased cycle after cycle as a consequence of thermal ratcheting occurring in the ligament. The chosen kinematic hardening model with the three back stresses was capable of simulating ratcheting phenomena even after ten thermal–mechanical cycles. This result is in accordance with the results obtained in [

3], showing that at least three Frederick–Armstrong kinematic hardening models should be considered when employing the Chaboche model, in order to properly allow for ratcheting. In fact, if just two hardening models were considered, the shakedown effect would anyway occur after very few cycles. A trendline was extrapolated from the FEM results and a stabilization of the equivalent plastic strains is expected to happen within 30–35 cycles, see

Figure 16. As illustrated in

Figure 15,

Figure 16 and

Figure 17, the increment of plastic strain decreased cycle after cycle. Therefore, it is very likely that a stabilization of the stress–strain curve could occur, even though there is no assurance that it will happen. In this case, LCF could then become the only type of possible failure for the cooling channel. Non-proportional loading effects should be considered; as a matter of fact, the plot of tangential stress vs. tangential strain for a node on the internal surface of the chamber does not depict a straight line passing through the origin of the axes, see

Figure 18.

Finally, fatigue evaluations were carried out adopting the Wang-Brown criterion.

Figure 19 shows the service life contour plot obtained employing the abovementioned criterion, highlighting the minimum value of 4776 cycles.

7. Conclusions

A numerical investigation was conducted with the aim of predicting the service life of a liquid rocket engine thrust chamber. The throat region of the chamber was examined, since the maximum heat fluxes coming from the combustion chamber were expected to occur in this area. A damage model accounting for creep, plastic instability, and multiaxial low-cycle fatigue was adopted to estimate the service life of the chamber.

Results demonstrated that the influence of creep on the thrust chamber failure is negligible with the current geometry, whereas ratcheting is expected to stop after about 30–35 thermal–mechanical loading cycles. Low-cycle fatigue might therefore be the primary cause of failure and, adopting the Wang-Brown multi-axial fatigue criterion, the cooling channel in the throat region was calculated to withstand more than 4000 cycles. This result was consistent with those achieved with similar geometries and loading conditions.

In general, the present work allows us to understand the main factors the designer should consider when sizing a thrust chamber. As an example, the cooling efficiency should be as high as possible in order to reduce temperatures, thermal gradients, and stresses in the throat area, where creep could become a major factor, limiting the service life of the chamber significantly. Furthermore, creep should always be modeled with high fidelity numerical models because it can deeply affect the stress–strain behavior of the component.

As a future activity, submodeling approaches will be adopted in order to obtain more realistic boundary conditions in the cut sections of the local model. A damage model will be also implemented so as to predict the local damage initiation and its further evolution through the material.