Overall High-Performance Near-Infrared Photodetector Based on CVD-Grown MoTe2 and Graphene Vertical vdWs Heterostructure

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

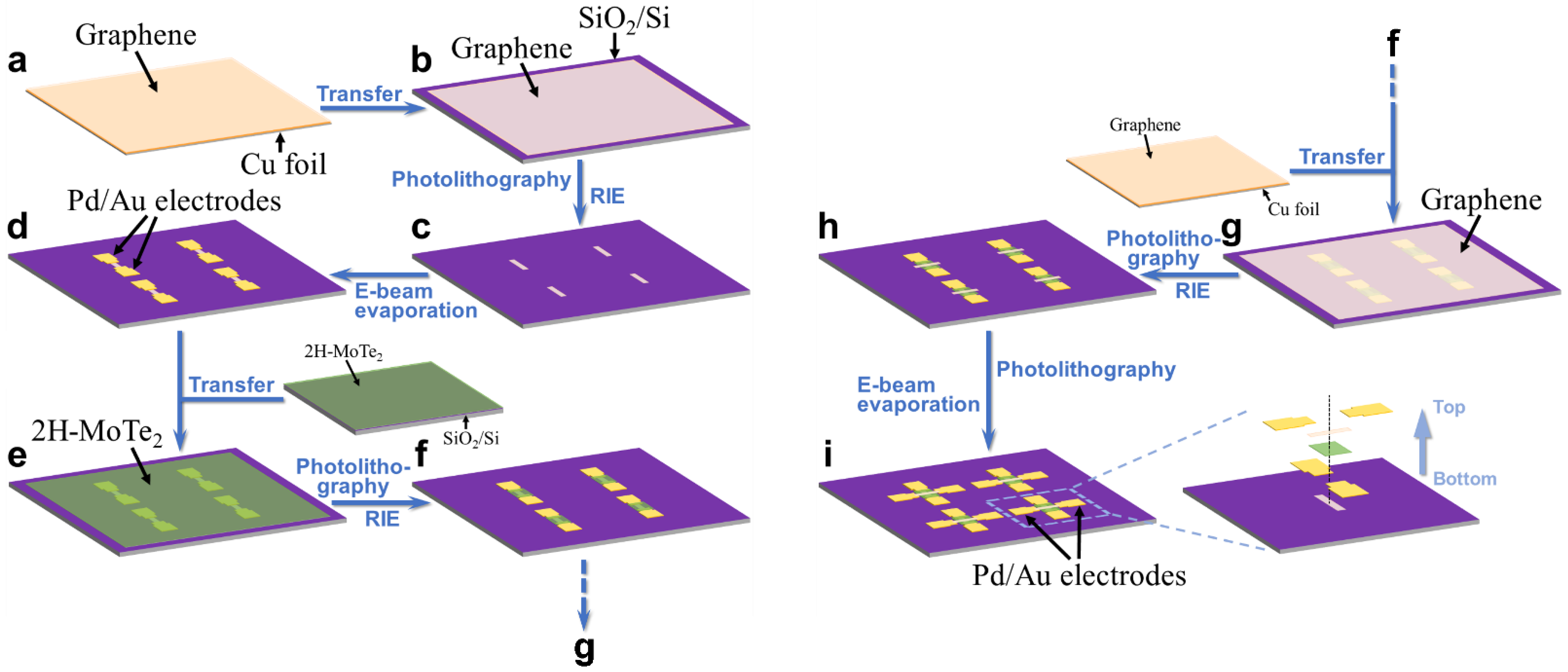

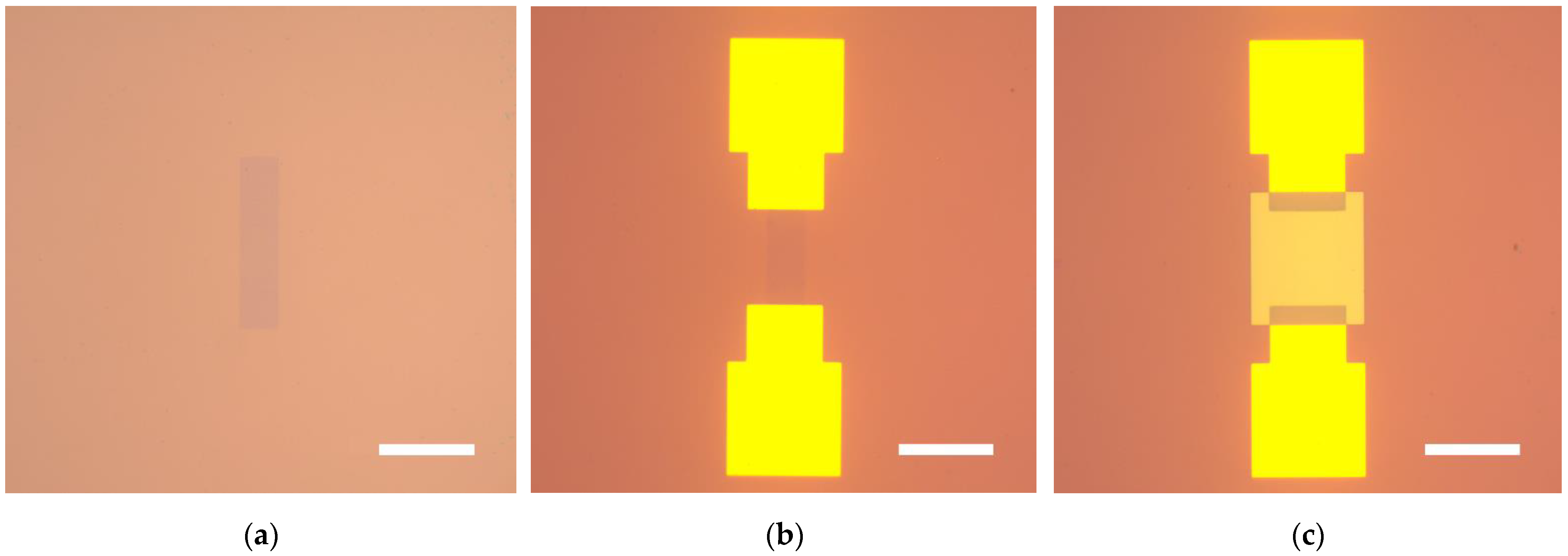

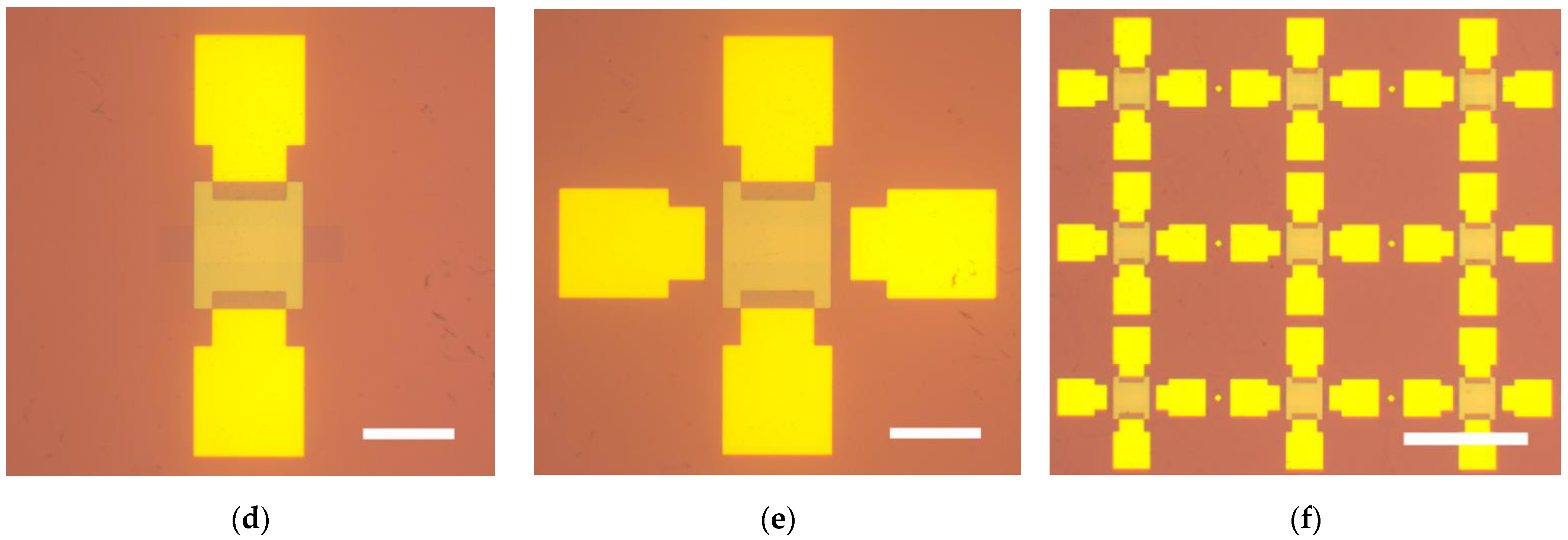

2.1. Fabrication of the Vertical vdWs Heterostructures

2.2. Atomic Layer Deposition (ALD) of Al2O3

2.3. Characterizations

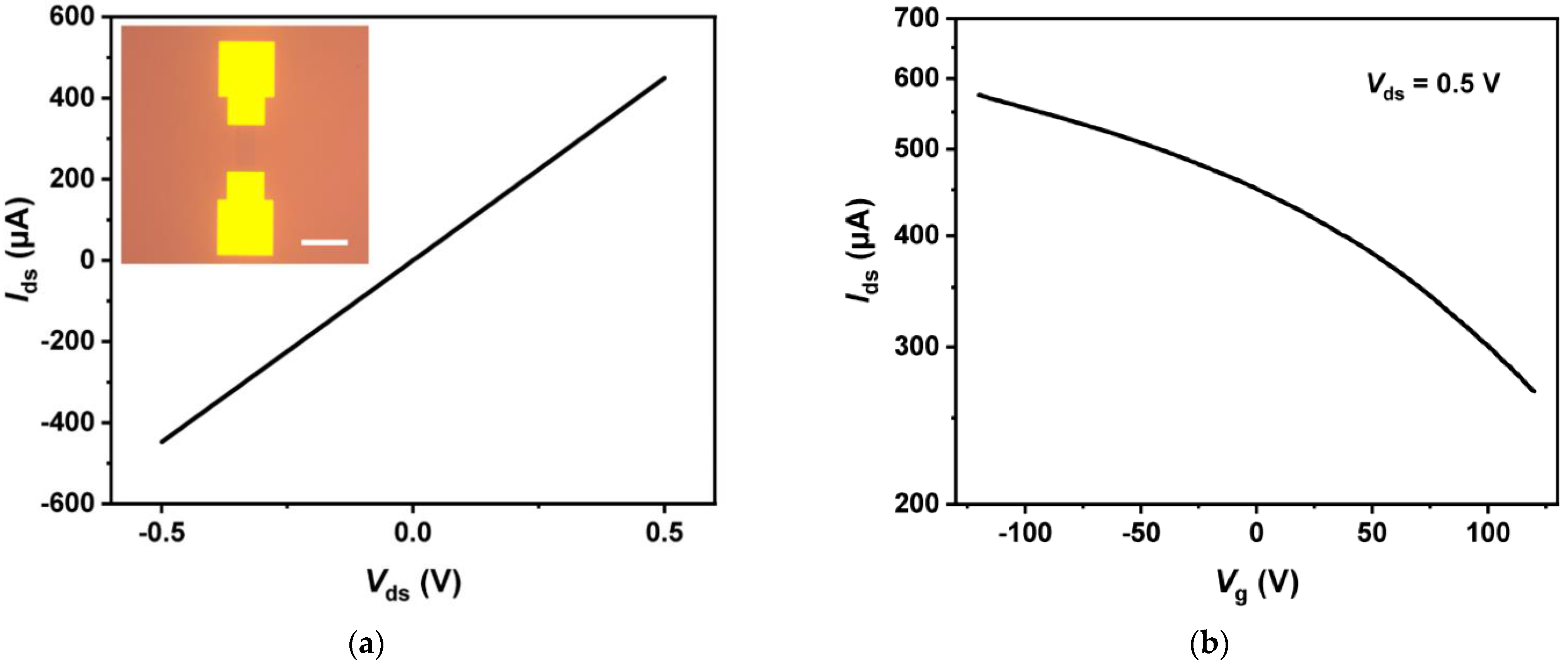

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Flory, N.; Ma, P.; Salamin, Y.; Emboras, A.; Taniguchi, T.; Watanabe, K.; Leuthold, J.; Novotny, L. Waveguide-integrated van der Waals heterostructure photodetector at telecom wavelengths with high speed and high responsivity. Nat. Nanotechnol. 2020, 15, 118–124. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Yan, F.; Lv, Q.; Zhu, W.; Hu, C.; Patane, A.; Wang, K. Enhanced Photoresponse in MoTe2 Photodetectors with Asymmetric Graphene Contacts. Adv. Opt. Mater. 2019, 7, 8. [Google Scholar] [CrossRef] [Green Version]

- Yu, W.; Li, S.; Zhang, Y.; Ma, W.; Sun, T.; Yuan, J.; Fu, K.; Bao, Q. Near-Infrared Photodetectors Based on MoTe2/Graphene Heterostructure with High Responsivity and Flexibility. Small 2017, 13, 8. [Google Scholar] [CrossRef] [PubMed]

- Huang, H.; Wang, J.; Hu, W.; Liao, L.; Wang, P.; Wang, X.; Gong, F.; Chen, Y.; Wu, G.; Luo, W.; et al. Highly sensitive visible to infrared MoTe2 photodetectors enhanced by the photogating effect. Nanotechnology 2016, 27, 445201. [Google Scholar] [CrossRef]

- Xu, Y.; Liu, C.; Guo, C.; Yu, Q.; Guo, W.; Lu, W.; Chen, X.; Wang, L.; Zhang, K. High performance near infrared photodetector based on in-plane black phosphorus p-n homojunction. Nano Energy 2020, 70, 104518. [Google Scholar] [CrossRef]

- Li, Q.; Guo, Y.; Liu, Y. Exploration of Near-Infrared Organic Photodetectors. Chem. Mater. 2019, 31, 6359–6379. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Y.; Gao, Y.; Luo, P.; Su, J.; Han, W.; Liu, K.; Li, H.; Zhai, T. 2D Metal Chalcogenides for IR Photodetection. Small 2019, 15, e1901347. [Google Scholar] [CrossRef]

- Zhang, K.; Fang, X.; Wang, Y.; Wan, Y.; Song, Q.; Zhai, W.; Li, Y.; Ran, G.; Ye, Y.; Dai, L. Ultrasensitive Near-Infrared Photodetectors Based on a Graphene-MoTe2-Graphene Vertical van der Waals Heterostructure. ACS Appl. Mater. Interfaces 2017, 9, 5392–5398. [Google Scholar] [CrossRef]

- Kim, H.J.; Lee, K.J.; Park, J.; Shin, G.H.; Park, H.; Yu, K.; Choi, S.-Y. Photoconductivity Switching in MoTe2/Graphene Heterostructure by Trap-Assisted Photogating. ACS Appl. Mater. Interfaces 2020, 12, 38563–38569. [Google Scholar] [CrossRef]

- Hu, R.-X.; Ma, X.-L.; An, C.-H.; Liu, J. Visible-to-near-infrared photodetector based on graphene-MoTe2-graphere heterostructure. Chin. Phys. B 2019, 28, 117802. [Google Scholar] [CrossRef]

- Xu, X.; Zhang, Z.; Qiu, L.; Zhuang, J.; Zhang, L.; Wang, H.; Liao, C.; Song, H.; Qiao, R.; Gao, P.; et al. Ultrafast growth of single-crystal graphene assisted by a continuous oxygen supply. Nat. Nanotechnol. 2016, 11, 930–935. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Jia, X.; Cheng, Z.; Xu, W.; Li, Y.; Dai, L. Low-power-consumption CMOS inverter array based on CVD-grown p-MoTe2 and n-MoS2. iScience 2021, 24, 103491. [Google Scholar] [CrossRef] [PubMed]

- Xu, X.; Liu, S.; Han, B.; Han, Y.; Yuan, K.; Xu, W.; Yao, X.; Li, P.; Yang, S.; Gong, W.; et al. Scaling-up Atomically Thin Coplanar Semiconductor-Metal Circuitry via Phase Engineered Chemical Assembly. Nano Lett. 2019, 19, 6845–6852. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Xu, X.; Chen, S.; Liu, S.; Cheng, X.; Xu, W.; Li, P.; Wan, Y.; Yang, S.; Gong, W.; Yuan, K.; et al. Millimeter-Scale Single-Crystalline Semiconducting MoTe2 via Solid-to-Solid Phase Transformation. J. Am. Chem. Soc. 2019, 141, 2128–2134. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Cheng, X.; Wang, Z.; Xia, C.; Cao, D.; Shen, L.; Wang, Q.; Yu, Y.; Shen, D. Reversible n-Type Doping of Graphene by H2O-Based Atomic-Layer Deposition and Its Doping Mechanism. J. Phys. Chem. C 2015, 119, 5995–6000. [Google Scholar] [CrossRef]

- Buscema, M.; Groenendijk, D.J.; Blanter, S.I.; Steele, G.A.; van der Zant, H.S.J.; Castellanos-Gomez, A. Fast and Broadband Photoresponse of Few-Layer Black Phosphorus Field-Effect Transistors. Nano Lett. 2014, 14, 3347–3352. [Google Scholar] [CrossRef] [Green Version]

- Ghatak, S.; Pal, A.N.; Ghosh, A. Nature of Electronic States in Atomically Thin MoS2 Field-Effect Transistors. ACS Nano 2011, 5, 7707–7712. [Google Scholar] [CrossRef] [Green Version]

- Lopez-Sanchez, O.; Lembke, D.; Kayci, M.; Radenovic, A.; Kis, A. Ultrasensitive photodetectors based on monolayer MoS2. Nat. Nanotechnol. 2013, 8, 497–501. [Google Scholar] [CrossRef]

- Island, J.; Blanter, S.I.; Buscema, M.; Van Der Zant, H.S.J.; Castellanos-Gomez, A. Gate Controlled Photocurrent Generation Mechanisms in High-Gain In2Se3 Phototransistors. Nano Lett. 2015, 15, 7853–7858. [Google Scholar] [CrossRef] [Green Version]

- Jin, W.; Gao, Z.; Zhou, Y.; Yu, B.; Zhang, H.; Peng, H.; Liu, Z.; Dai, L. Novel graphene-oxide-semiconductor nanowire phototransistors. J. Mater. Chem. C 2014, 2, 1592–1596. [Google Scholar] [CrossRef]

- Hu, P.; Wang, L.; Yoon, M.; Zhang, J.; Feng, W.; Wang, X.; Wen, Z.; Idrobo, J.C.; Miyamoto, Y.; Geohegan, D.B.; et al. Highly Responsive Ultrathin GaS Nanosheet Photodetectors on Rigid and Flexible Substrates. Nano Lett. 2013, 13, 1649–1654. [Google Scholar] [CrossRef] [PubMed]

- Ji, H.; Joo, M.-K.; Yun, Y.; Park, J.-H.; Lee, G.M.; Moon, B.H.; Yi, H.; Suh, D.; Lim, S.C. Suppression of Interfacial Current Fluctuation in MoTe2 Transistors with Different Dielectrics. ACS Appl. Mater. Interfaces 2016, 8, 19092–19099. [Google Scholar] [CrossRef] [PubMed]

- Wei, Y.; Ren, Z.; Zhang, A.; Mao, P.; Li, H.; Zhong, X.; Li, W.; Yang, S.; Wang, J. Hybrid Organic/PbS Quantum Dot Bilayer Photodetector with Low Dark Current and High Detectivity. Adv. Funct. Mater. 2018, 28, 28. [Google Scholar] [CrossRef]

- Khan, A.A.; Azam, M.; Eric, D.; Liang, G.-X.; Yu, Z.-N. Triple cation perovskite doped with the small molecule F4TCNQ for highly efficient stable photodetectors. J. Mater. Chem. C 2020, 8, 2880–2887. [Google Scholar] [CrossRef]

- Liang, Y.; Liang, H.; Xiao, X.; Hark, S. The epitaxial growth of ZnS nanowire arrays and their applications in UV-light detection. J. Mater. Chem. 2012, 22, 1199–1205. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, W.; Jie, J.S.; Meng, X.M.; Fan, X.; Lee, S.-T. Photoresponse Properties of CdSe Single-Nanoribbon Photodetectors. Adv. Funct. Mater. 2007, 17, 1795–1800. [Google Scholar] [CrossRef]

- Zou, X.; Xu, J.; Huang, H.; Zhu, Z.; Wang, H.; Li, B.; Liao, L.; Fang, G.; Zhu, Z. A comparative study on top-gated and bottom-gated multilayer MoS2 transistors with gate stacked dielectric of Al2O3/HfO2. Nanotechnology 2018, 29, 245201. [Google Scholar] [CrossRef]

- Bolshakov, P.; Zhao, P.; Azcatl, A.; Hurley, P.K.; Wallace, R.M.; Young, C.D. Improvement in top-gate MoS2 transistor performance due to high quality backside Al2O3 layer. Appl. Phys. Lett. 2017, 111, 032110. [Google Scholar] [CrossRef] [Green Version]

- Kung, S.-C.; van der Veer, W.E.; Yang, F.; Donavan, K.C.; Penner, R.M. 20 μs Photocurrent Response from Lithographically Patterned Nanocrystalline Cadmium Selenide Nanowires. Nano Lett. 2010, 10, 1481–1485. [Google Scholar] [CrossRef]

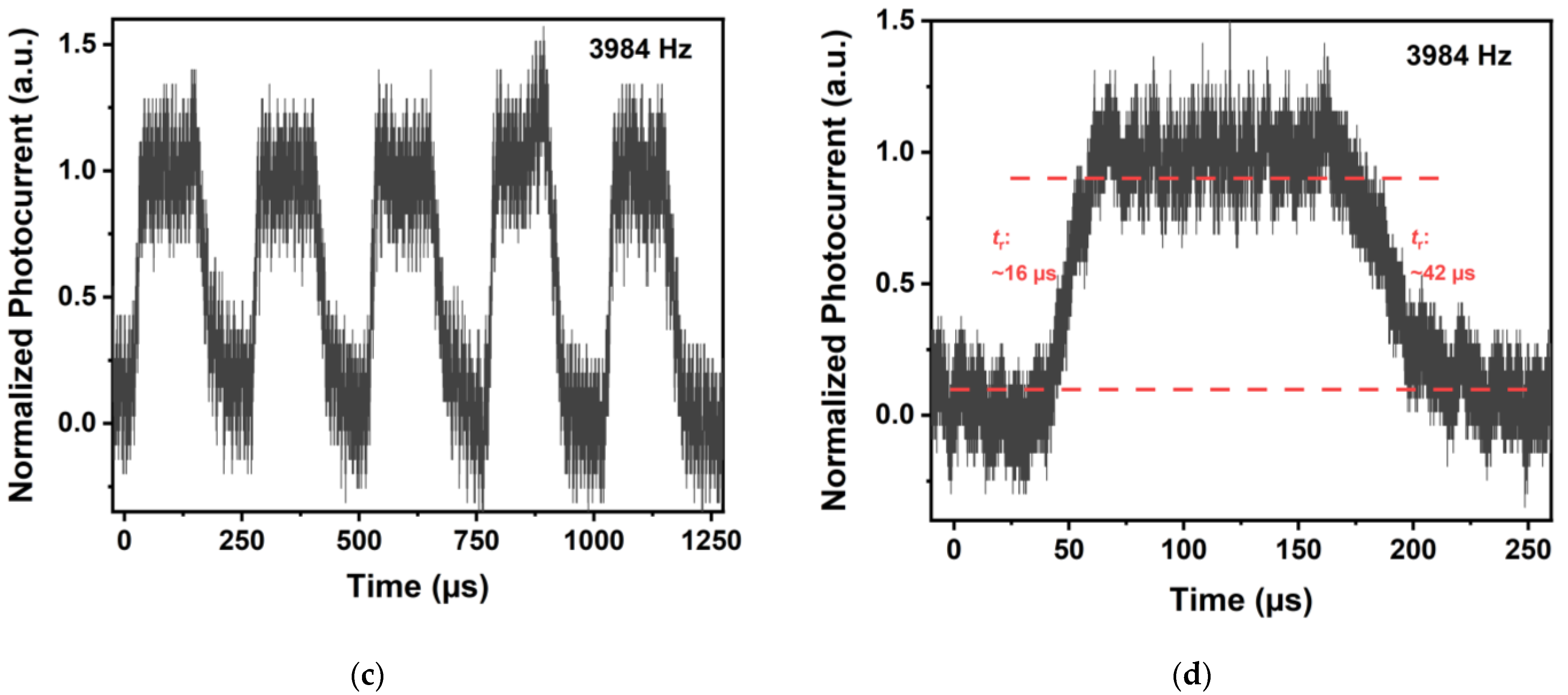

| Materials | Responsivity (mA/W) | Response Time (μs) | Wavelength (nm) | References |

|---|---|---|---|---|

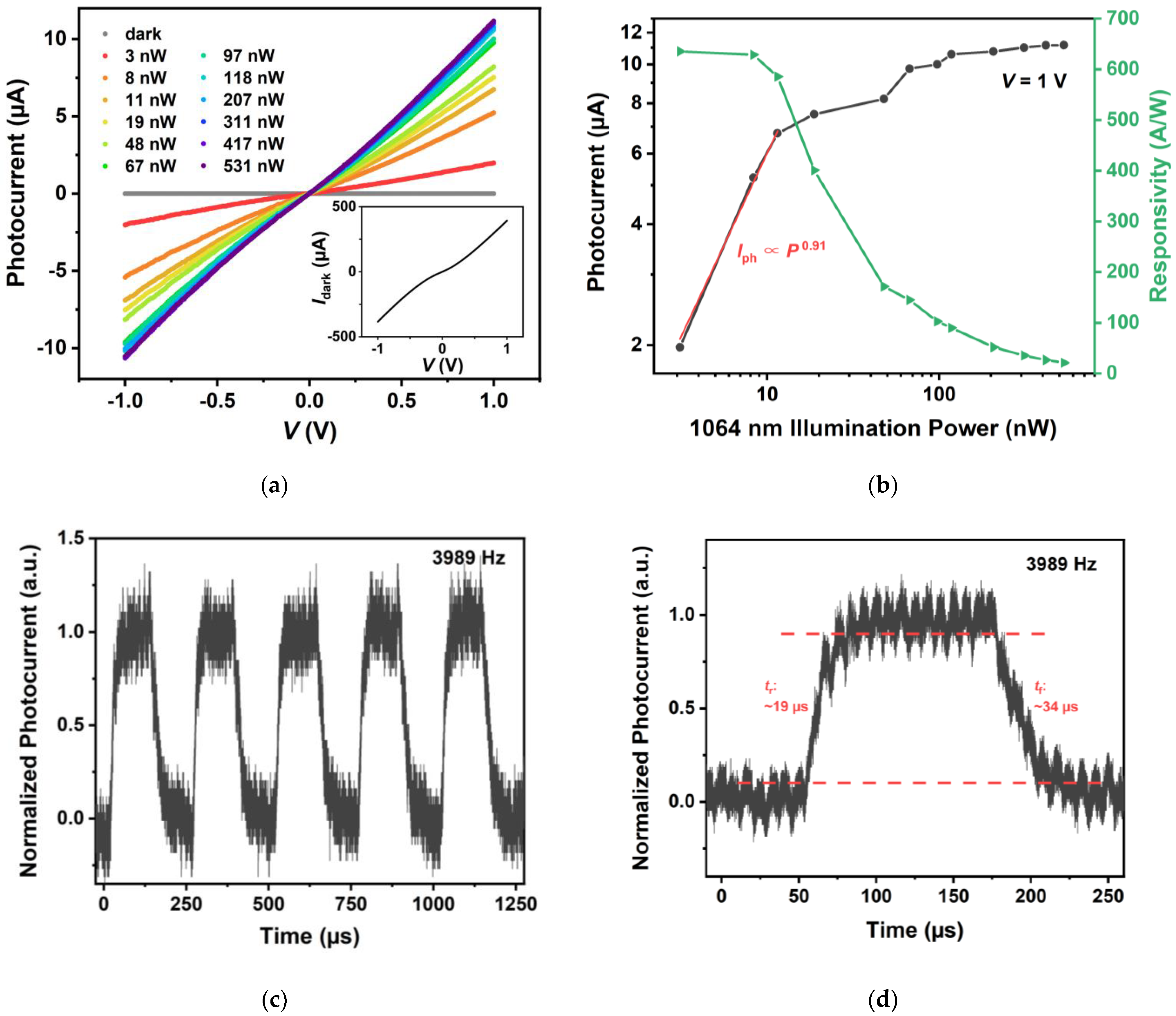

| MoTe2 with symmetric graphene contacts | 6.35 × 105 | 19 | 1064 | This work |

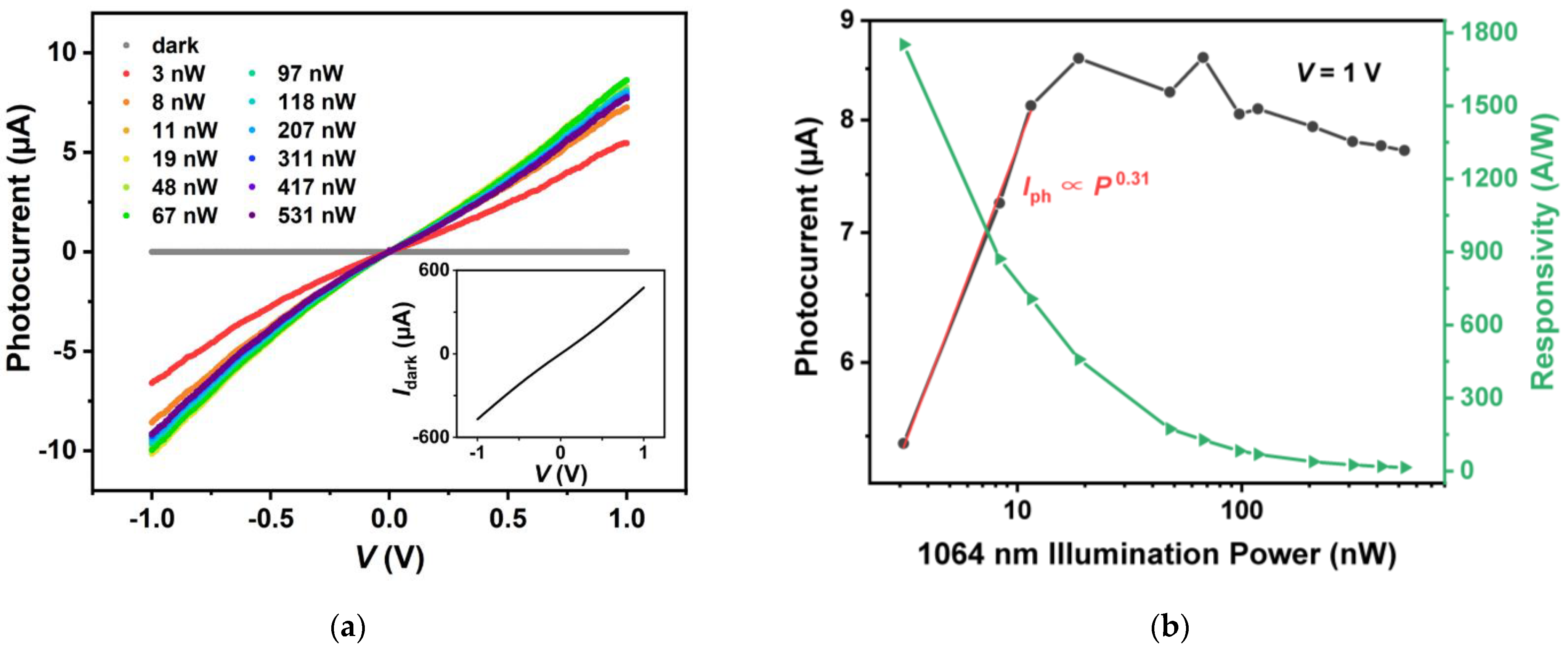

| MoTe2 with symmetric graphene contacts (Al2O3-encapsulated) | 1.75 × 106 | 16 | 1064 | |

| MoTe2 with symmetric graphene contacts | 154 | 1100 | [10] | |

| MoTe2 with asymmetric graphene contacts | 66 | 6.15 | 1064 | [2] |

| MoTe2 with asymmetric graphene contacts | 110 | 24 | 1064 | [8] |

| MoTe2/Graphene | 9.7082 × 105 | 7.8 × 104 | 1064 | [3] |

| MoTe2/Graphene | 2 × 104 | 975 | [9] | |

| MoTe2 with Cr/Au contacts | 24 | 1060 | [4] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, W.; Cheng, X.; Zhang, Z.; Cheng, Z.; Xu, X.; Xu, W.; Li, Y.; Liu, K.; Dai, L. Overall High-Performance Near-Infrared Photodetector Based on CVD-Grown MoTe2 and Graphene Vertical vdWs Heterostructure. Appl. Sci. 2022, 12, 3622. https://doi.org/10.3390/app12073622

Du W, Cheng X, Zhang Z, Cheng Z, Xu X, Xu W, Li Y, Liu K, Dai L. Overall High-Performance Near-Infrared Photodetector Based on CVD-Grown MoTe2 and Graphene Vertical vdWs Heterostructure. Applied Sciences. 2022; 12(7):3622. https://doi.org/10.3390/app12073622

Chicago/Turabian StyleDu, Wanying, Xing Cheng, Zhihong Zhang, Zhixuan Cheng, Xiaolong Xu, Wanjing Xu, Yanping Li, Kaihui Liu, and Lun Dai. 2022. "Overall High-Performance Near-Infrared Photodetector Based on CVD-Grown MoTe2 and Graphene Vertical vdWs Heterostructure" Applied Sciences 12, no. 7: 3622. https://doi.org/10.3390/app12073622

APA StyleDu, W., Cheng, X., Zhang, Z., Cheng, Z., Xu, X., Xu, W., Li, Y., Liu, K., & Dai, L. (2022). Overall High-Performance Near-Infrared Photodetector Based on CVD-Grown MoTe2 and Graphene Vertical vdWs Heterostructure. Applied Sciences, 12(7), 3622. https://doi.org/10.3390/app12073622