Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete

Abstract

:1. Introduction

2. Experimental Program of CFRC

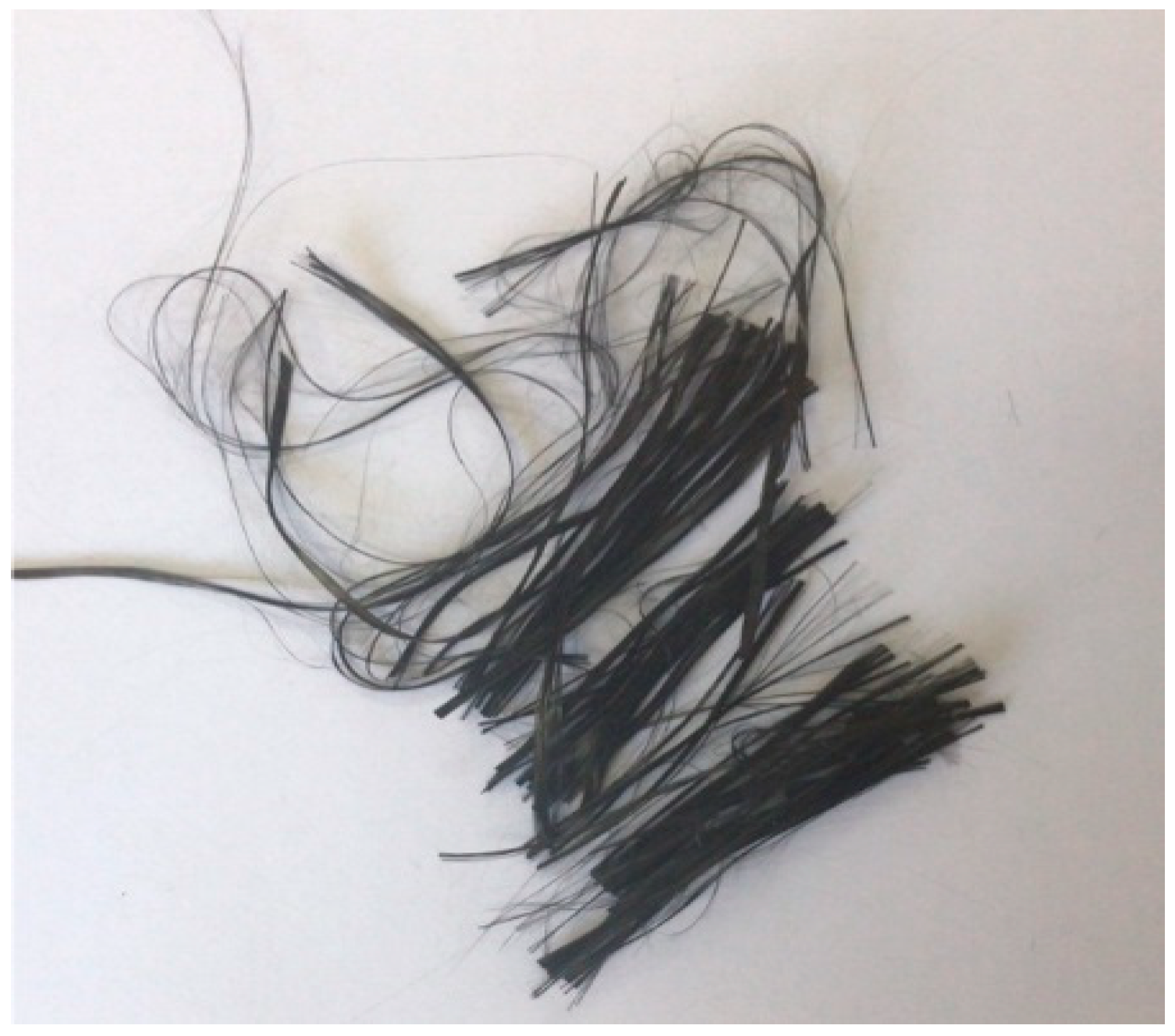

2.1. Materials

2.2. Mix Proportion

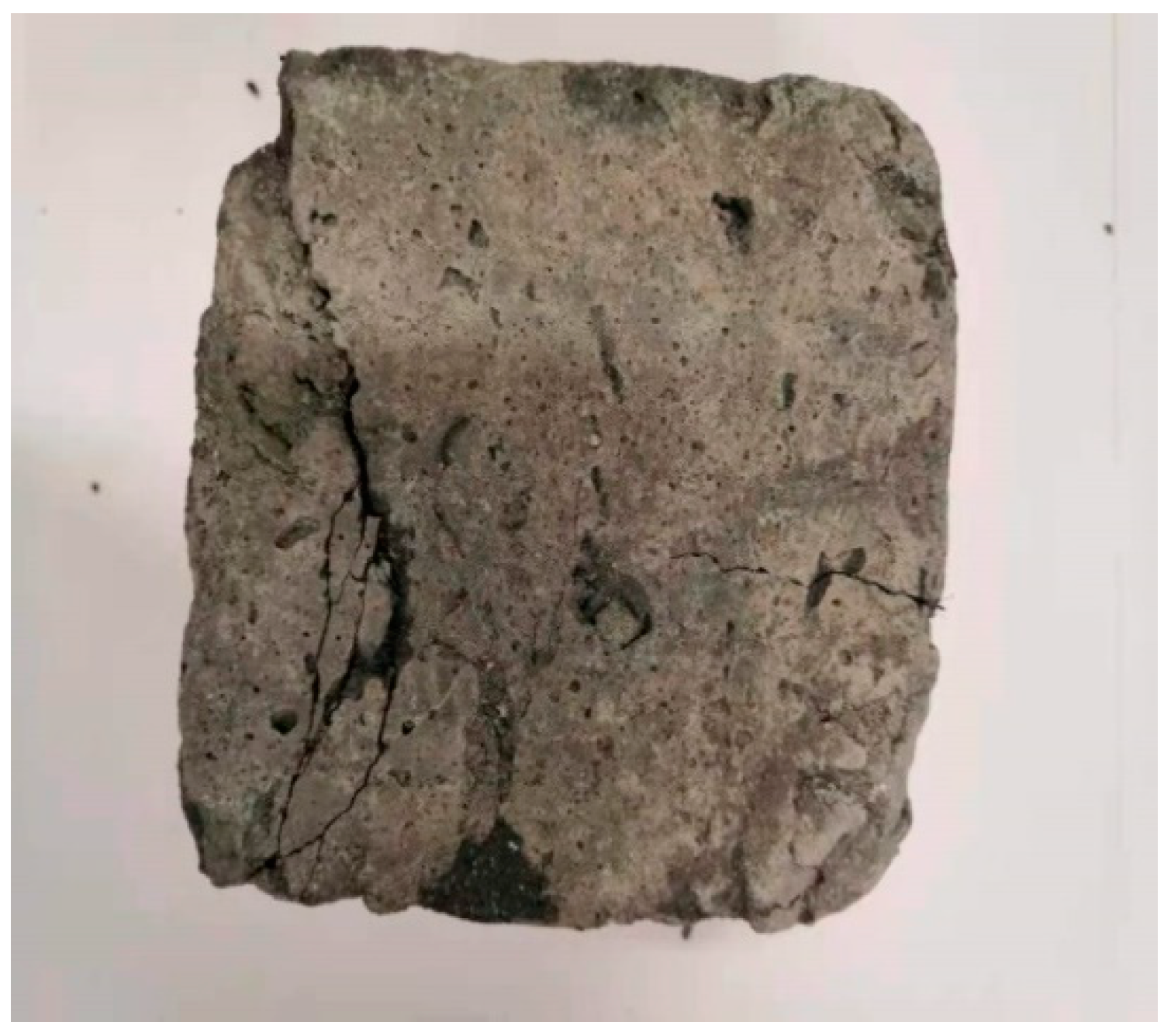

2.3. Preparation of Specimens

2.4. Test Procedure

3. Results and Discussion

3.1. Physical Properties of Fresh Concrete

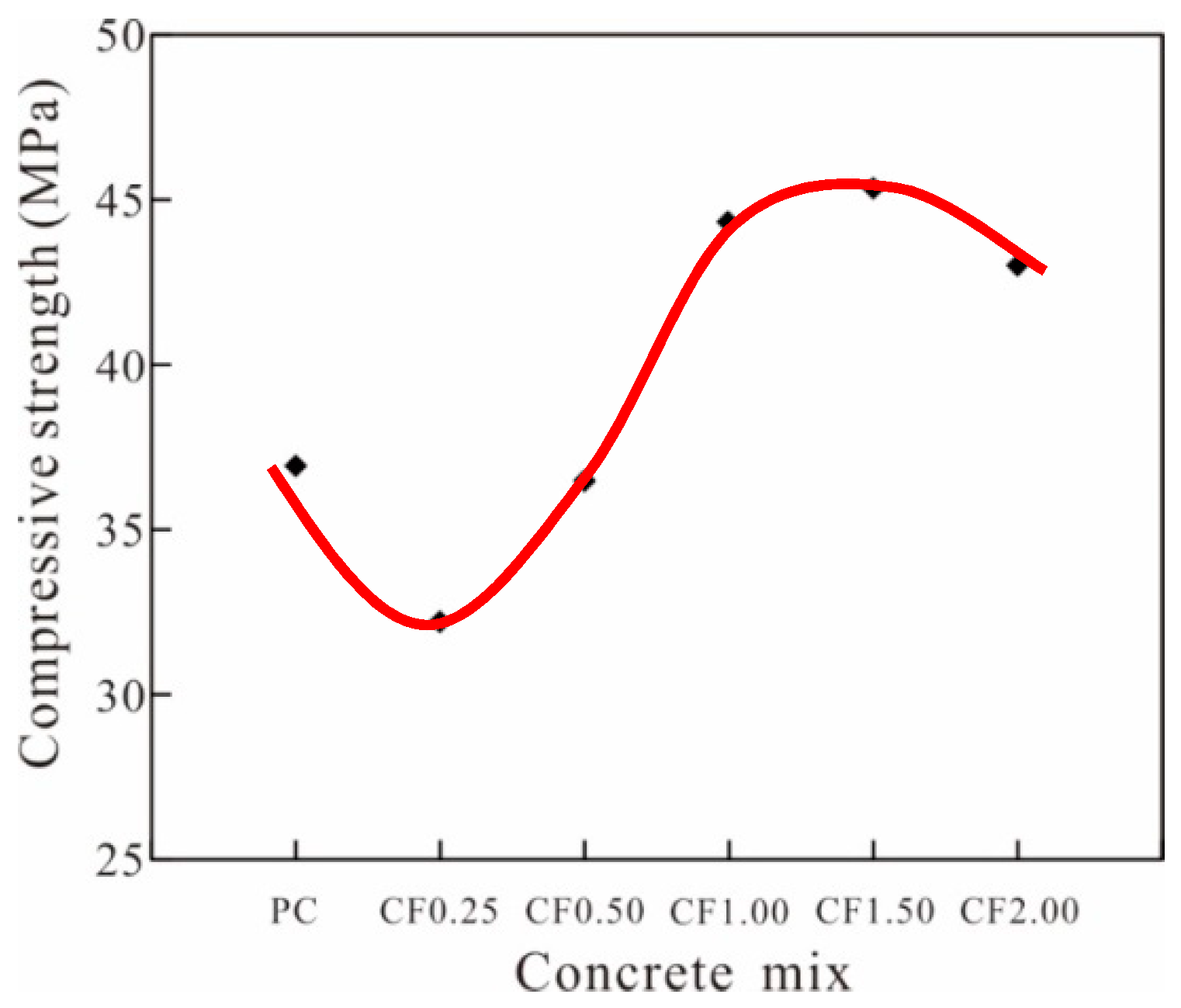

3.2. Effect of Carbon Fiber Content on Compressive Strength

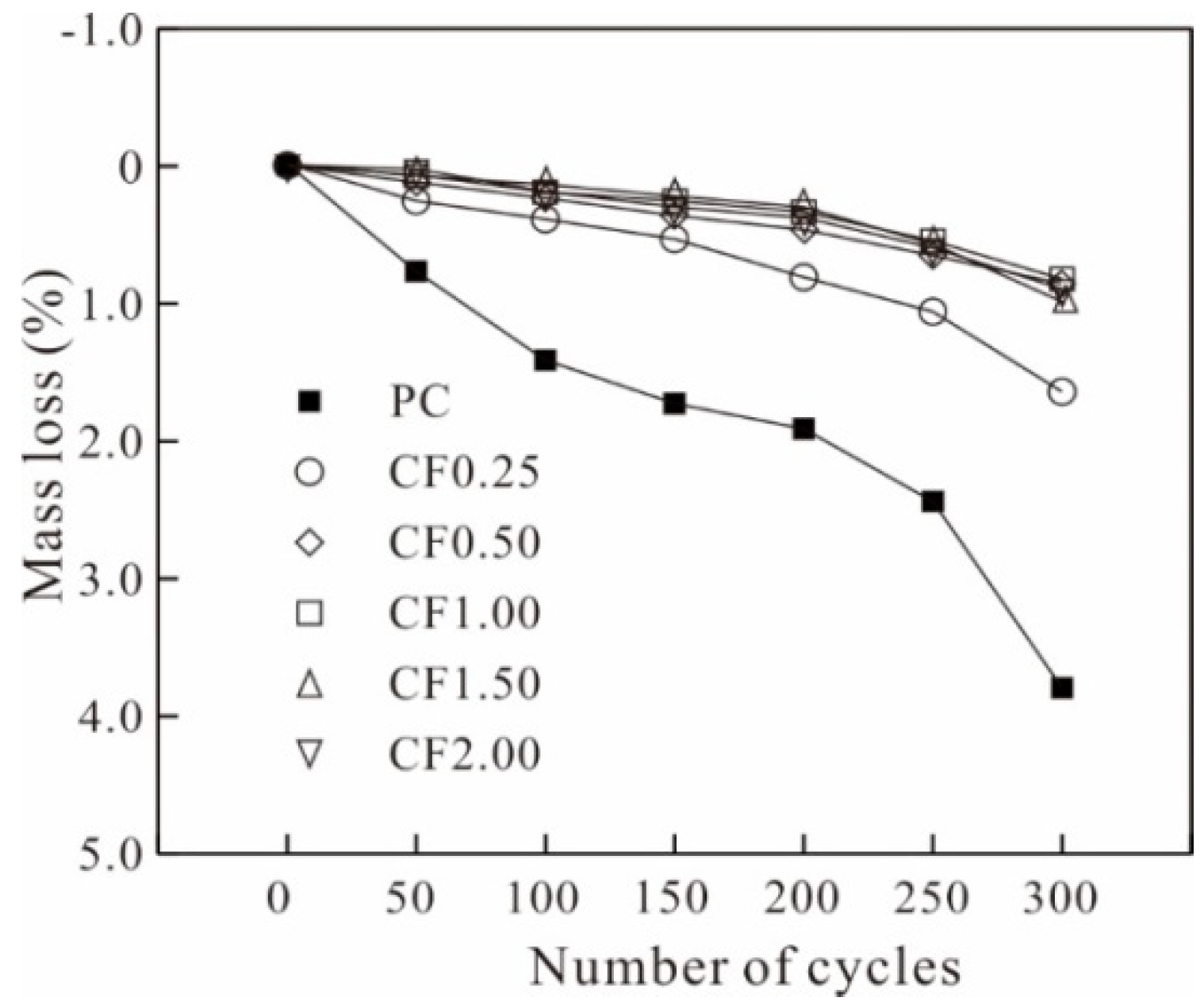

3.3. Frost Resistance of CFRC

4. Conclusions

- The slump of the concrete decreased from 188 to 140 mm with increasing carbon fiber content from 0 to 2.00 wt.‰, showing a decreased trend of workability.

- The addition of carbon fiber into concrete could decrease the compressive strength first and then cause it to increase, yielding the highest compressive strength of 40.1 MPa with a carbon fiber content of 1.50 wt.‰, which was 1.11 times that of the PC.

- The addition of carbon fibers could decrease the mass loss of the CFRC significantly. The frost-resistance mark of the CFRC could reach 250 freeze–thaw cycles for carbon fiber contents of 1.50 and 2.00 wt.‰, with corresponding strength losses of 20.2% and 22.8% after 250 cycles, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Flores Medina, N.; Barbero-Barrera, M.M. Mechanical and physical enhancement of gypsum composites through a synergic work of polypropylene fiber and recycled isostatic graphite filler. Constr. Build. Mater. 2017, 131, 165–177. [Google Scholar] [CrossRef]

- Cao, Q.; Gao, Q.; Gao, R.; Jia, J. Chloride penetration resistance and frost resistance of fiber reinforced expansive self-consolidating concrete. Constr. Build. Mater. 2018, 158, 719–727. [Google Scholar] [CrossRef]

- Karahan, O.; Atis, C.D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Yu, H.F.; Sun, W.; Zhang, Y.S.; Huang, D.S. Effect of expansive agent, fiber or their combination on freezing-thawing durability of high performance concrete. Nanjing Univ. Aeronaut. Astronaut. 2006, 38, 245–250. (In Chinese) [Google Scholar]

- Rai, A.; Joshi, Y.P. Applications and properties of fibre reinforced concrete. Int. J. Eng. Res. Ind. Appl. 2014, 4, 123–131. [Google Scholar]

- Al-lami, K.A. Experimental Investigation of Fiber Reinforced Concrete Beams. Master’s Thesis, Portland State University, Portland, OR, USA, 2015. [Google Scholar]

- Horňáková, M.; Lehner, P. Analysis of Measured Parameters in Relation to the Amount of Fibre in Lightweight Red CeramicWaste Aggregate Concrete. Mathematics 2022, 10, 229. [Google Scholar] [CrossRef]

- Zaid, O.; Mukhtar, F.M.; M-García, R.; Sherbiny, M.G.E.; Mohamed, A.M. Characteristics of high-performance steel fiber reinforced recycled aggregate concrete utilizing mineral filler. Case Stud. Constr. Mater. 2022, 16, 1–19. [Google Scholar] [CrossRef]

- Xiong, B.; Wang, Z.; Wang, C.; Xiong, Y.; Cai, C. Effects of short carbon fiber content on microstructure and mechanical property of short carbon fiber reinforced Nb/Nb5Si3 composites. Intermetallics 2019, 106, 59–64. [Google Scholar] [CrossRef]

- Hannant, P.J. Fibre Cements and Fibre Concretes; Wiley: New York, NY, USA, 1978. [Google Scholar]

- Mastali, M.; Dalvand, A.; Sattarifard, A. The impact resistance and mechanical properties of the reinforced self-compacting concrete incorporating recycled CFRP fiber with different lengths and dosages. Compos. B Eng. 2017, 112, 74–92. [Google Scholar] [CrossRef]

- Deng, Z. The fracture and fatigue performance in flexure of carbon fiber reinforced concrete. Cem. Concr. Compos. 2005, 27, 131–140. [Google Scholar] [CrossRef]

- Guo, Z.; Zhuang, C.; Li, Z.; Chen, Y. Mechanical properties of carbon fiber reinforced concrete (CFRC) after exposure to high temperatures. Compos. Struct. 2021, 256, 113072. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Chinese Planning Press: Beijing, China, 2009.

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Chinese Planning Press: Beijing, China, 2019.

- Iyer, P.; Kenno, S.Y.; Das, S. Mechanical properties of fiber-reinforced concrete made with basalt filament fibers. J. Mater. Civ. Eng. 2015, 27, 04015015. [Google Scholar] [CrossRef]

- GB/T50080-2016; Standard for Evaluation of Concrete Compressive Strength. Chinese Planning Press: Beijing, China, 2016.

- Powers, T.C. Physical properties of cement paste. In Chemistry of Cement: Proceedings of the Fourth International Symposium; U.S. Department of Commerce, National Bureau of Standards: Washington, DC, USA, 1960; pp. 577–613. [Google Scholar]

- Qian, C.; Stroeven, P. Fracture properties of concrete reinforced with steel–polypropylene hybrid fibres. Cem. Concr. Compos. 2000, 22, 343–351. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; He, W. Comparative study on flexural properties of ultra-high performance concrete with supplementary cementitious materials under different curing regimes. Constr. Build. Mater. 2017, 136, 307–313. [Google Scholar] [CrossRef] [Green Version]

- Abid, M.; Hou, X.; Zheng, W.; Waqar, G.Q. Mechanical properties of steel fiber-reinforced reactive powder concrete at high temperature and after cooling. Procedia Eng. 2017, 210, 597–604. [Google Scholar] [CrossRef]

- Bencardino, F.; Rizzuti, L.; Spadea, G.; Swamy, R.N. Experimental evaluation of fiber reinforced concrete fracture properties. Compos. B Eng. 2010, 41, 17–24. [Google Scholar] [CrossRef]

- Visalvanich, K.; Naaman, A.E. Fracture model for fiber reinforced concrete. J. Am. Concr. Inst. 1983, 80, 128–138. [Google Scholar] [CrossRef]

- Wecharatana, M.; Shah, S.P. A model for predicting fracture resistance of fiber reinforced concrete. Cem. Concr. Res. 1983, 13, 819–829. [Google Scholar] [CrossRef]

- Tjiptobroto, P.; Hansen, W. Tensile strain hardening and multiple cracking in high-performance cement-based composites containing discontinuous fibers. ACI Mater. J. 1993, 90, 16–25. [Google Scholar]

- Stähli, P.; Van Mier, J.G.M. Three-fibre-type hybrid fibre concrete. In Proceedings of the Fifth International Conference on Fracture Mechanics of Concrete and Concrete Structures, Vail, CO, USA, 12–16 April 2004; IA-FraMCoS. pp. 1105–1112. [Google Scholar]

- Sadrmomtazi, A.; Fasihi, A. Influence of polypropylene fibers on the performance of nano-SiO2-incorporated mortar. Iran. J. Sci. Technol. Tran. B Eng. 2010, 34, 385–395. [Google Scholar]

- Sakulich, A.R.; Li, V.C. Nanoscale characterization of engineered cementitious composites (ECC). Cem. Concr. Res. 2011, 41, 169–175. [Google Scholar] [CrossRef]

- Kang, S.H.; Kim, J.J.; Kim, D.J.; Chung, Y.-S. Effect of sand grain size and sand-to-cement ratio on the interfacial bond strength of steel fibers embedded in mortars. Constr. Build. Mater. 2013, 47, 1421–1430. [Google Scholar] [CrossRef]

- Lee, S.F.; Jacobsen, S. Study of interfacial microstructure, fracture energy, compressive energy and debonding load of steel fiber-reinforced mortar. Mater. Struct. 2011, 44, 1451–1465. [Google Scholar] [CrossRef] [Green Version]

- Sovják, R.; Máca, P.; Imlauf, T. Effect of fibre aspect ratio and fibre volume fraction on the effective fracture energy of ultra-high-performance fibre-reinforced concrete. Acta Polytech. 2016, 56, 319–327. [Google Scholar] [CrossRef]

- Sovják, R.; Máca, P.; Imlauf, T. Effect of fibre length on the fracture energy of UHPFRC. Procedia Eng. 2017, 193, 74–79. [Google Scholar] [CrossRef]

- Kim, K.-C.; Yang, I.-H.; Joh, C. Effects of single and hybrid steel fiber lengths and fiber contents on the mechanical properties of high-strength fiber-reinforced concrete. Adv. Civ. Eng. 2018, 2018, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Kang, S.-T.; Kim, J.-K. Investigation on the flexural behavior of UHPCC considering the effect of fiber orientation distribution. Constr. Build. Mater. 2012, 28, 57–65. [Google Scholar] [CrossRef]

- Au, C.; Buyukozturk, O. Effect of fiber orientation and ply mix on fiber reinforced polymer-confined concrete. J. Compos. Constr. 2005, 9, 397–407. [Google Scholar] [CrossRef] [Green Version]

- Vincent, T.; Ozbakkaloglu, T. Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete. Constr. Build. Mater. 2013, 47, 814–826. [Google Scholar] [CrossRef]

| Length (mm) | Diameter (mm) | Aspect Ratio | Volume Density (g/cm3) | Tensile Strength (MPa) | Elongation (%) | Tensile Modulus (GPa) | Carbon Content (%) |

|---|---|---|---|---|---|---|---|

| 6 | 0.007 | 857 | 1.80 | 4900 | 2.1 | 230 | >95 |

| Mix No. | Material Dosage (kg/m3) | |||||||

|---|---|---|---|---|---|---|---|---|

| Cement | FA | CA | Water | Carbon Fiber | D | HRWR | DA | |

| PC | 360 | 530 | 1366 | 144 | 0 | 2.88 | 1.44 | 0.72 |

| CF0.25 | 360 | 530 | 1366 | 144 | 0.6 | 2.88 | 1.44 | 0.72 |

| CF0.50 | 360 | 530 | 1366 | 144 | 1.2 | 2.88 | 1.44 | 0.72 |

| CF1.00 | 360 | 530 | 1366 | 144 | 2.4 | 2.88 | 1.44 | 0.72 |

| CF1.50 | 360 | 530 | 1366 | 144 | 3.6 | 2.88 | 1.44 | 0.72 |

| CF2.00 | 360 | 530 | 1366 | 144 | 4.8 | 2.88 | 1.44 | 0.72 |

| Specimen | PC | CF0.25 | CF0.50 | CF1.00 | CF1.50 | CF2.00 |

|---|---|---|---|---|---|---|

| Slump (mm) | 188 | 190 | 168 | 148 | 155 | 140 |

| Specimen | Compressive Strength (MPa) | ||||

|---|---|---|---|---|---|

| NO. 1 | NO. 2 | NO. 3 | Mean | Range | |

| PC | 37.4 | 35.8 | 37.6 | 36.9 | 1.8 |

| CF0.25 | 32.7 | 31.8 | 33.1 | 32.5 | 1.3 |

| CF0.50 | 35.9 | 34.5 | 36.1 | 35.5 | 1.5 |

| CF1.00 | 36.9 | 38.1 | 38.7 | 37.9 | 1.8 |

| CF1.50 | 40.3 | 40.6 | 42.0 | 41.0 | 1.7 |

| CF2.00 | 37.7 | 40.4 | 39.1 | 39.1 | 2.7 |

| Mass Loss Ratio (%) | ||||||

|---|---|---|---|---|---|---|

| F-T Cycles | 50 | 100 | 150 | 200 | 250 | 300 |

| PC | 0.76 | 1.41 | 1.72 | 1.91 | 2.44 | 3.79 |

| CF0.25 | 0.25 | 0.38 | 0.53 | 0.81 | 1.06 | 1.64 |

| CF0.50 | 0.08 | 0.15 | 0.20 | 0.26 | 0.57 | 0.98 |

| CF1.00 | 0.05 | 0.21 | 0.26 | 0.33 | 0.54 | 0.82 |

| CF1.50 | 0.11 | 0.22 | 0.36 | 0.46 | 0.63 | 0.86 |

| CF2.00 | 0.05 | 0.19 | 0.33 | 0.41 | 0.62 | 0.93 |

| Relative Compressive Strength (%) | ||||||

|---|---|---|---|---|---|---|

| F-T Cycles | 50 | 100 | 150 | 200 | 250 | 300 |

| PC | 0.91 | 0.79 | 0.63 | |||

| CF0.25 | 0.96 | 0.91 | 0.74 | |||

| CF0.50 | 0.99 | 0.94 | 0.88 | 0.71 | ||

| CF1.00 | 0.99 | 0.98 | 0.92 | 0.85 | 0.73 | |

| CF1.50 | 0.97 | 0.96 | 0.93 | 0.88 | 0.80 | |

| CF2.00 | 1.00 | 0.99 | 0.96 | 0.89 | 0.77 | 0.66 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kan, W.; Yang, Z.; Yu, L. Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete. Appl. Sci. 2022, 12, 3823. https://doi.org/10.3390/app12083823

Kan W, Yang Z, Yu L. Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete. Applied Sciences. 2022; 12(8):3823. https://doi.org/10.3390/app12083823

Chicago/Turabian StyleKan, Wenguang, Zailin Yang, and Liangliang Yu. 2022. "Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete" Applied Sciences 12, no. 8: 3823. https://doi.org/10.3390/app12083823

APA StyleKan, W., Yang, Z., & Yu, L. (2022). Study on Frost Resistance of the Carbon-Fiber-Reinforced Concrete. Applied Sciences, 12(8), 3823. https://doi.org/10.3390/app12083823