Recovery of Cork Manufacturing Waste within Mortar and Polyurethane: Feasibility of Use and Physical, Mechanical, Thermal Insulating Properties of the Final Green Composite Construction Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cork Waste

2.2. Mortars

2.3. Polyurethanes

3. Results and Discussion

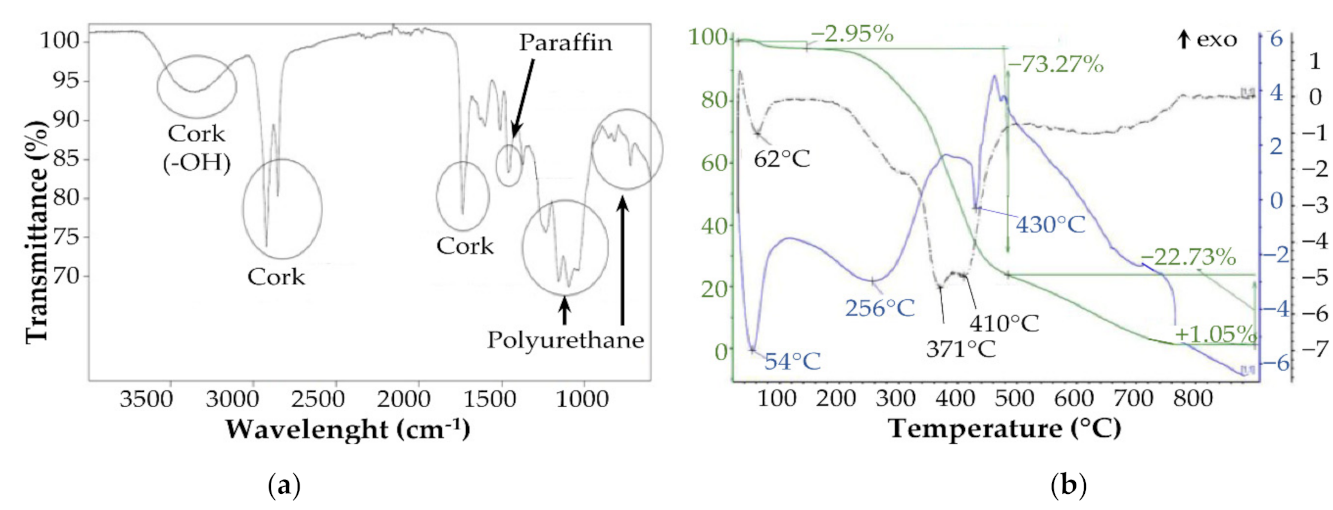

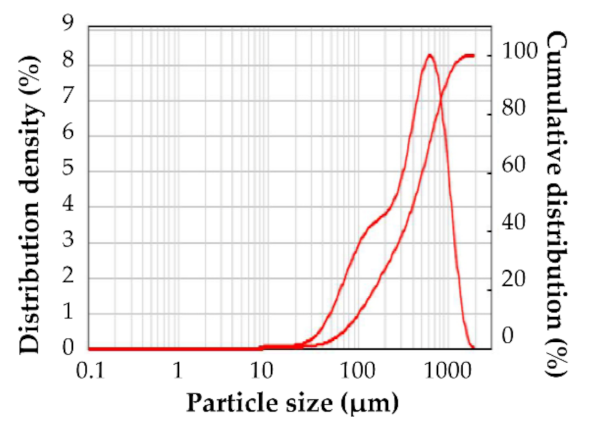

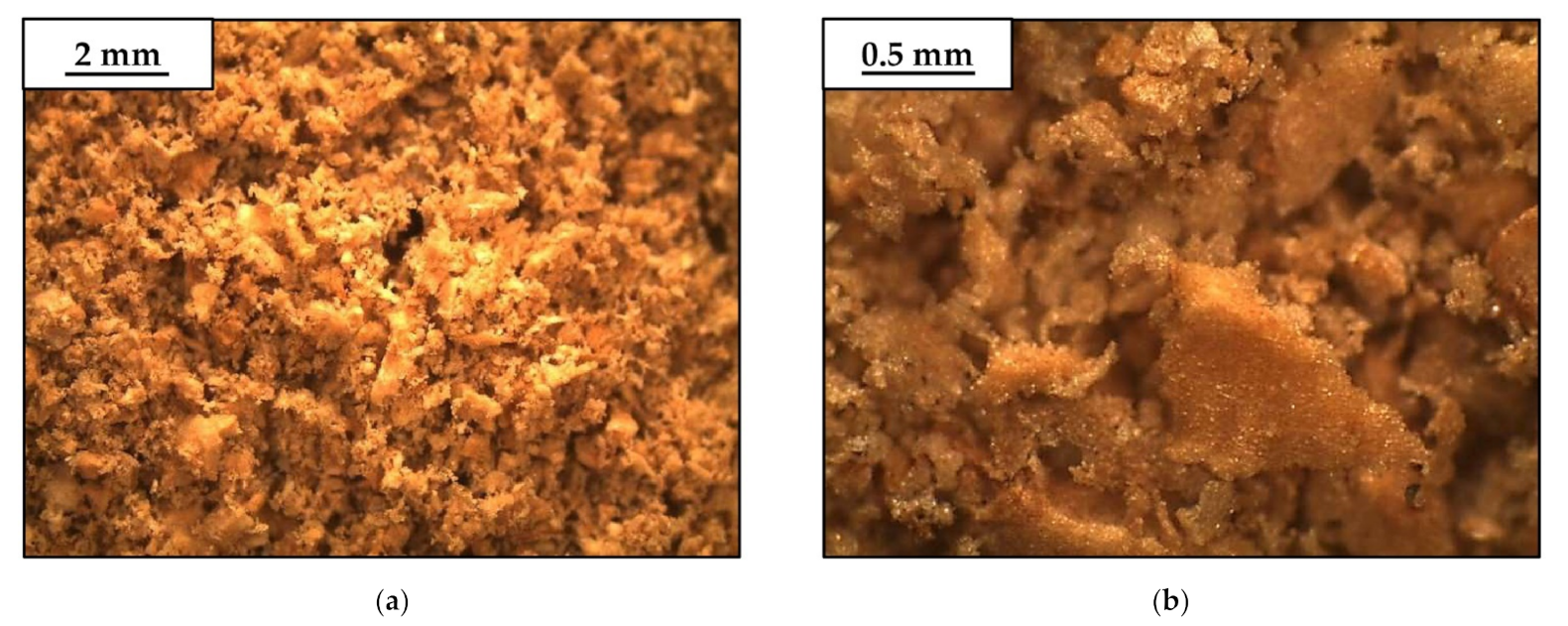

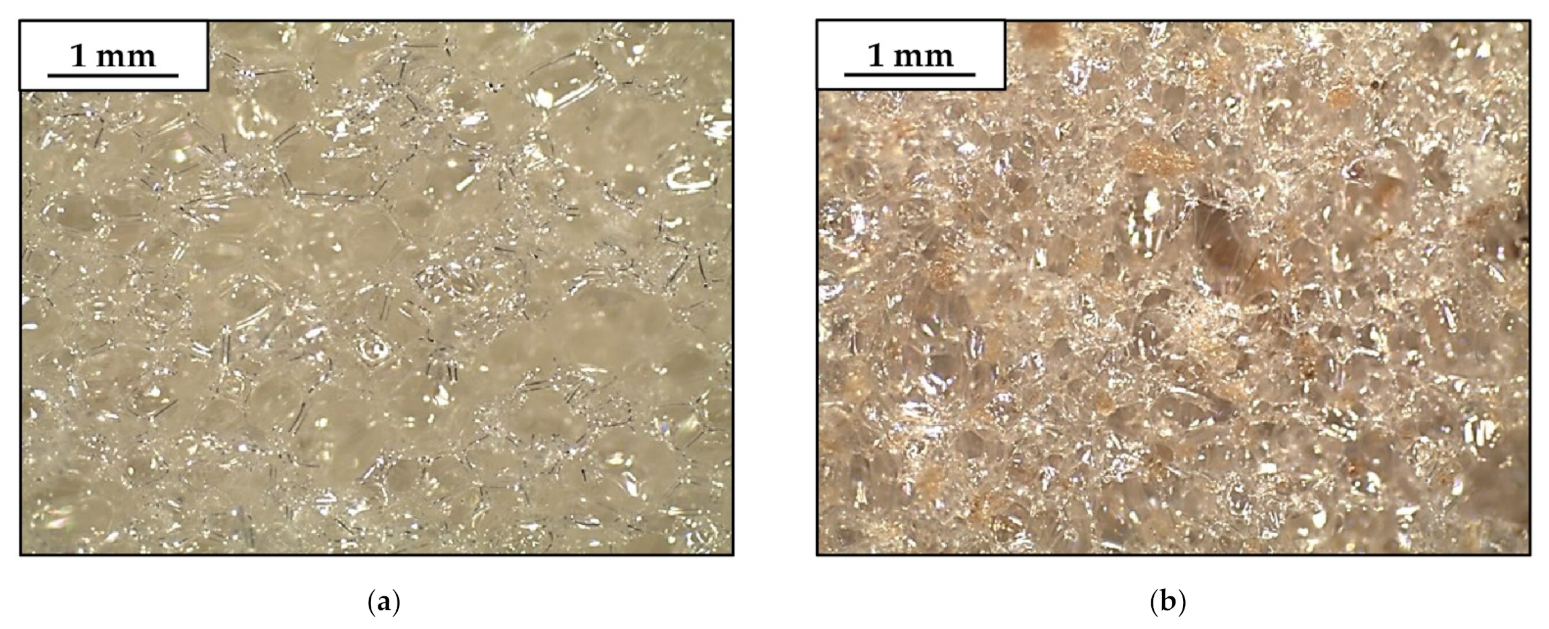

3.1. Characterization of Cork Waste

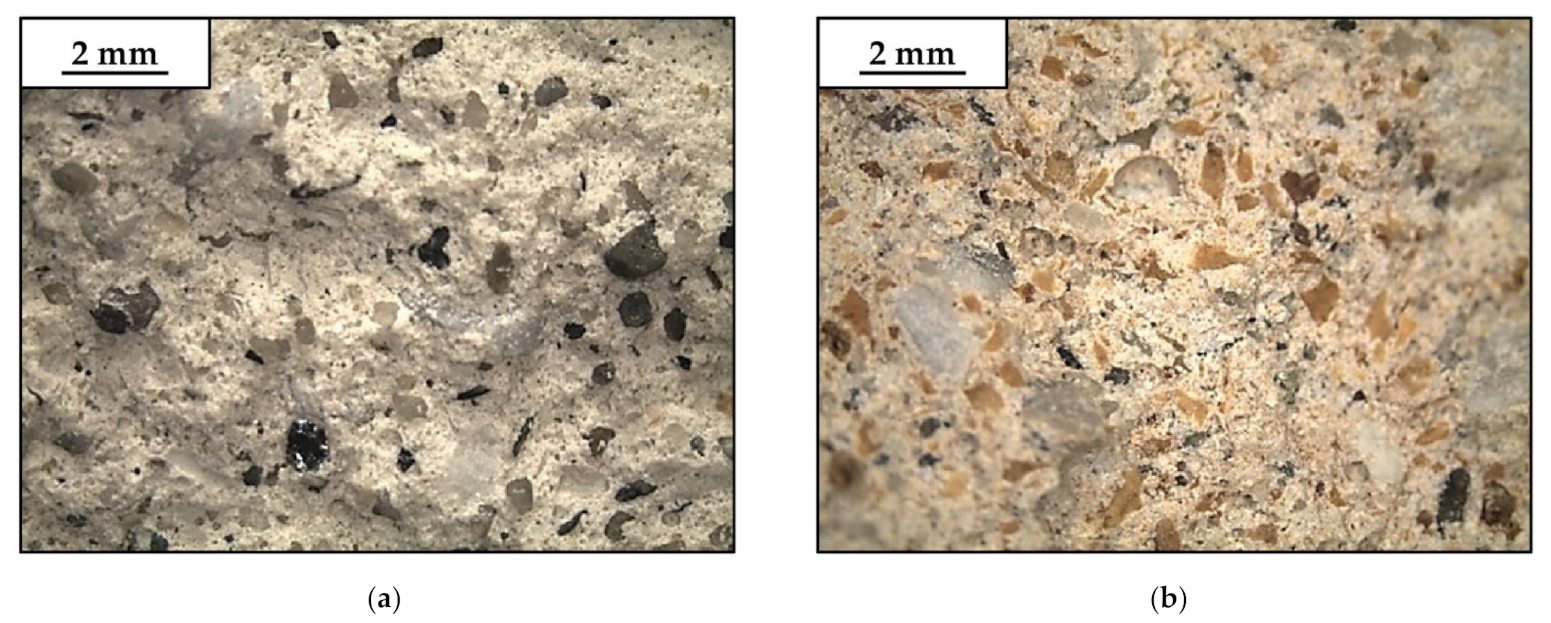

3.2. Characterization of Mortars Containing Cork Waste

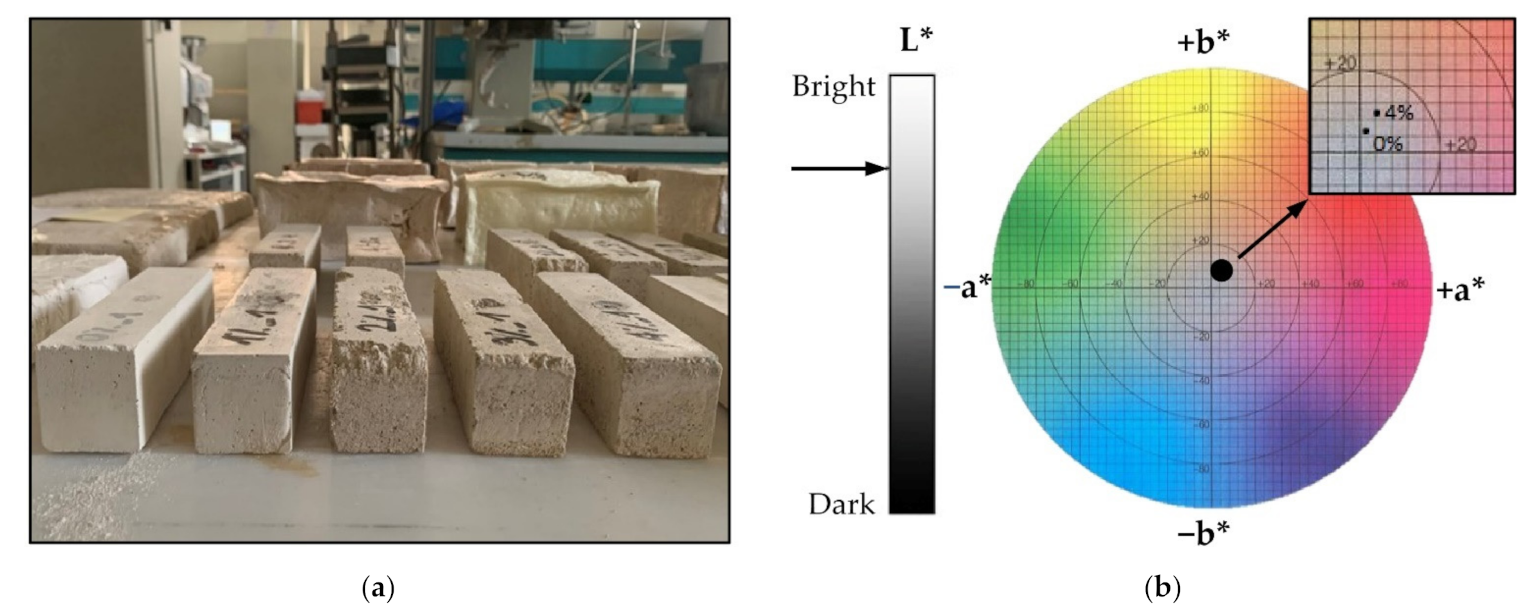

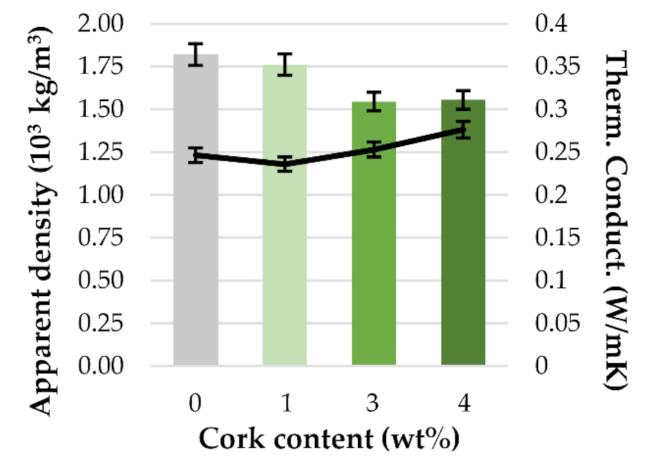

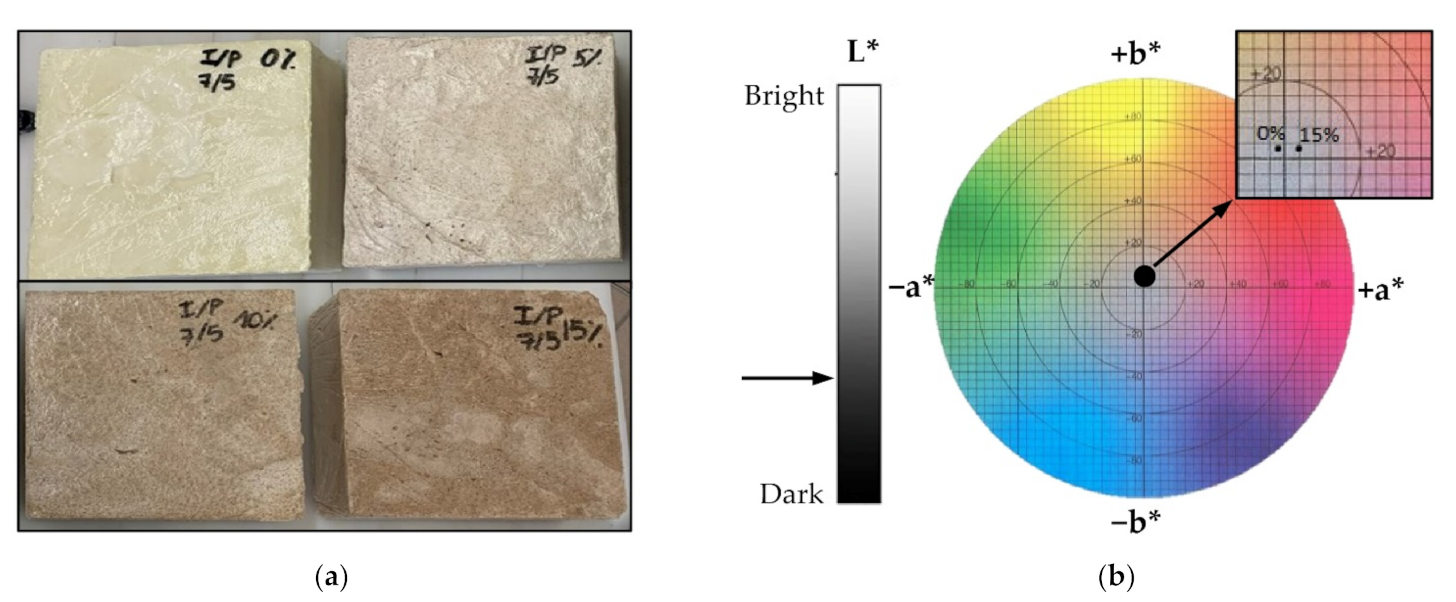

- a* > 0 predominance of red; a* < 0 predominance of green,

- b* > 0 predominance of yellow; b* < 0 predominance of blue,

- L*: 0 = dark, 100 = bright [31].

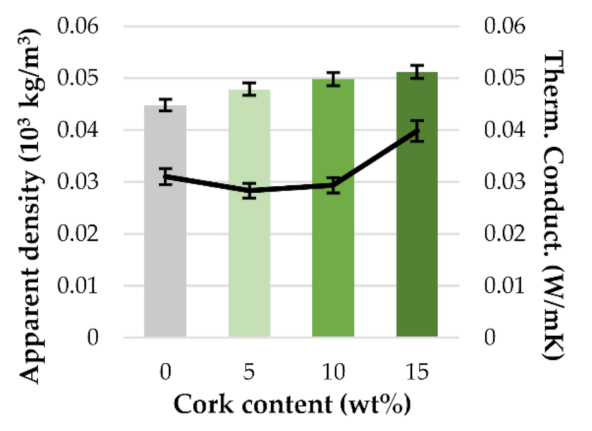

3.3. Characterization of Polyurethanes Containing Cork Waste

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Laurent, A.; Bakas, I.; Clavreul, J.; Bernstad, A.; Niero, M.; Gentil, E.; Hauschild, M.Z.; Christensen, T.H. Review of LCA studies of solid waste management systems–Part I: Lessons learned and perspectives. Waste Manag. 2014, 34, 573–588. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P. A scientometric review of waste material utilization in concrete for sustainable construction. Case Stud. Constr. Mater. 2021, 15, e00683. [Google Scholar] [CrossRef]

- Gomes, S.D.C.; Zhou, J.L.; Li, W.; Long, G. Progress in manufacture and properties of construction materials incorporating water treatment sludge: A review. Resour. Conserv. Recycl. 2019, 145, 148–159. [Google Scholar] [CrossRef]

- Li, X.; Qin, D.; Hu, Y.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P. A systematic review of waste materials in cement-based composites for construction applications. J. Build. Eng. 2021, 45, 103447. [Google Scholar] [CrossRef]

- Guo, P.; Meng, W.; Nassif, H.; Gou, H.; Bao, Y. New perspectives on recycling waste glass in manufacturing concrete for sustainable civil infrastructure. Constr. Build. Mater. 2020, 257, 119579. [Google Scholar] [CrossRef]

- Mohan, H.T.; Jayanarayanan, K.; Mini, K. Recent trends in utilization of plastics waste composites as construction materials. Constr. Build. Mater. 2021, 271, 121520. [Google Scholar] [CrossRef]

- Asim, M.; Uddin, G.M.; Jamshaid, H.; Raza, A.; Tahir, Z.U.R.; Hussain, U.; Satti, A.N.; Hayat, N.; Arafat, S.M. Comparative experimental investigation of natural fibers reinforced light weight concrete as thermally efficient building materials. J. Build. Eng. 2020, 31, 101411. [Google Scholar] [CrossRef]

- Belakroum, R.; Gherfi, A.; Kadja, M.; Maalouf, C.; Lachi, M.; El Wakil, N.; Mai, T. Design and properties of a new sustainable construction material based on date palm fibers and lime. Constr. Build. Mater. 2018, 184, 330–343. [Google Scholar] [CrossRef]

- Kang, S.; Zhao, Y.; Wang, W.; Zhang, T.; Chen, T.; Yi, H.; Rao, F.; Song, S. Removal of methylene blue from water with montmorillonite nanosheets/chitosan hydrogels as adsorbent. Appl. Surf. Sci. 2018, 448, 203–211. [Google Scholar] [CrossRef]

- Dawood, A.O.; Al-Khazraji, H.; Falih, R.S. Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Merlo, A.; Lavagna, L.; Suarez-Riera, D.; Pavese, M. Mechanical properties of mortar containing waste plastic (PVC) as aggregate partial replacement. Case Stud. Constr. Mater. 2020, 13, e00467. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R.; Liguori, B.; Iucolano, F. Recycled polyolefins waste as aggregates for lightweight concrete. Compos. Part B Eng. 2016, 106, 234–241. [Google Scholar] [CrossRef]

- Rashad, A.M. Recycled waste glass as fine aggregate replacement in cementitious materials based on Portland cement. Constr. Build. Mater. 2014, 72, 340–357. [Google Scholar] [CrossRef]

- Awolusi, T.F.; Sojobi, A.O.; Afolayan, J.O. SDA and laterite applications in concrete: Prospects and effects of elevated temperature. Cogent Eng. 2017, 4, 1387954. [Google Scholar] [CrossRef]

- Jerónimo, A.; Soares, C.; Aguiar, B.; Lima, N. Hydraulic lime mortars incorporating micro cork granules with antifungal properties. Constr. Build. Mater. 2020, 255, 119368. [Google Scholar] [CrossRef]

- Merabti, S.; Kenai, S.; Belarbi, R.; Khatib, J. Thermo-mechanical and physical properties of waste granular cork composite with slag cement. Constr. Build. Mater. 2021, 272, 121923. [Google Scholar] [CrossRef]

- El Wardi, F.Z.; Cherki, A.-B.; Mounir, S.; Khabbazi, A.; Maaloufa, Y. Thermal characterization of a new multilayer building material based on clay, cork and cement mortar. Energy Procedia 2019, 157, 480–491. [Google Scholar] [CrossRef]

- Członka, S.; Strąkowska, A.; Kairytė, A. Effect of walnut shells and silanized walnut shells on the mechanical and thermal properties of rigid polyurethane foams. Polym. Test. 2020, 87, 106534. [Google Scholar] [CrossRef]

- Otto, G.P.; Moisés, M.P.; Carvalho, G.; Rinaldi, A.W.; Garcia, J.C.; Radovanovic, E.; Fávaro, S.L. Mechanical properties of a polyurethane hybrid composite with natural lignocellulosic fibers. Compos. Part B Eng. 2017, 110, 459–465. [Google Scholar] [CrossRef]

- Santiago-Calvo, M.; Tirado-Mediavilla, J.; Rauhe, J.C.; Jensen, L.R.; Ruiz-Herrero, J.L.; Villafañe, F.; Rodríguez-Pérez, M. Ángel Evaluation of the thermal conductivity and mechanical properties of water blown polyurethane rigid foams reinforced with carbon nanofibers. Eur. Polym. J. 2018, 108, 98–106. [Google Scholar] [CrossRef]

- Antunes, M.; Velasco, J.I. Multifunctional polymer foams with carbon nanoparticles. Prog. Polym. Sci. 2014, 39, 486–509. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Correlo, V.M.; Chagas, J.A.; Mano, J.F.; Reis, R.L. Cork based composites using polyolefin’s as matrix: Morphology and mechanical performance. Compos. Sci. Technol. 2010, 70, 2310–2318. [Google Scholar] [CrossRef]

- Bruno, S. Manuale di Bioarchitettura—Bioedilizia e Fonti Alternative di Energia Rinnovabile; Dario Flaccovio Editore: Palermo, Italy, 2009. [Google Scholar]

- Riboulet, J.-M.; Alegoet, C. Aspetti Tecnici Della Tappatura Dei Vini; Oenoplurimedia: Chaintre, France, 1986. [Google Scholar]

- Kalidasan, B.; Pandey, A.; Shahabuddin, S.; George, M.; Sharma, K.; Samykano, M.; Tyagi, V.; Saidur, R. Synthesis and characterization of conducting Polyaniline@cobalt-Paraffin wax nanocomposite as nano-phase change material: Enhanced thermophysical properties. Renew. Energy 2021, 173, 1057–1069. [Google Scholar] [CrossRef]

- Van Oosten, T. PUR Facts: Conservation of Polyurethane Foam in Art and Design; Amsterdam University Press: Amsterdam, The Netherlands, 2011. [Google Scholar]

- Da Silva, S.M.; Oliveira, J. Cork powders wettability by the Washburn capillary rise method. Powder Technol. 2021, 387, 16–21. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Aroso, I.M.; Mano, J.F.; Covas, J.A.; Reis, R.L. Functionalized cork-polymer composites (CPC) by reactive extrusion using suberin and lignin from cork as coupling agents. Compos. Part B Eng. 2014, 67, 371–380. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Zang, C.; Ju, Z.; Hu, D.; Zhang, Y.; Jiang, J.; Liu, C. Consistent preparation, chemical stability and thermal properties of a shape-stabilized porous carbon/paraffin phase change materials. J. Clean. Prod. 2020, 247, 119565. [Google Scholar] [CrossRef]

- Vilela, C.; Sousa, A.F.; Freire, C.S.; Silvestre, A.J.; Neto, C.P. Novel sustainable composites prepared from cork residues and biopolymers. Biomass Bioenergy 2013, 55, 148–155. [Google Scholar] [CrossRef]

- Sato, T.; Ishida, F.; Tanioka, S.; Miura, Y.; Tanaka, K.; Suzuki, H. Colorimetry for Wall Appearance Study of Cerebral Aneurysms. Brain Hemorrhages, 2021; in press. [Google Scholar] [CrossRef]

- Jiang, C.; Jin, C.; Wang, Y.; Yan, S.; Chen, D. Effect of heat curing treatment on the drying shrinkage behavior and microstructure characteristics of mortar incorporating different content ground granulated blast-furnace slag. Constr. Build. Mater. 2018, 186, 379–387. [Google Scholar] [CrossRef]

| Cork (wt%) | Cork (vol%) | Cork (g) | Mortar 1 (g) | Effective Water 2 (g) | Extra Water 3 (g) | Superplast. (g) |

|---|---|---|---|---|---|---|

| 0 | 0.00 | 0.00 | 8041.04 | 1604.40 | 0.00 | 0.00 |

| 1 | 16.15 | 69.31 | 6931.04 | 1413.93 | 122.88 | 29.6 |

| 3 | 48.49 | 162.04 | 5431.49 | 1108.02 | 288.88 | 49.84 |

| 4 | 64.66 | 196.05 | 4901.29 | 999.86 | 347.58 | 44.96 |

| Cork (wt%) | Cork (vol%) | Cork (g) | Isocyanate (g) | Polyol (g) |

|---|---|---|---|---|

| 0 | 0.00 | 0.00 | 94.99 | 67.85 |

| 5 | 34.99 | 8.14 | 94.99 | 67.85 |

| 10 | 51.84 | 16.28 | 94.99 | 67.85 |

| 15 | 61.75 | 24.43 | 94.99 | 67.85 |

| Cork Content (wt%) | a* | b* | L* |

|---|---|---|---|

| 0 | 1.86 | 6.79 | 83.22 |

| 1 | 2.16 | 6.90 | 82.26 |

| 3 | 2.87 | 11.17 | 74.52 |

| 4 | 3.09 | 11.29 | 74.35 |

| Cork (wt%) | a* | b* | L* |

|---|---|---|---|

| 0 | −0.44 | 3.86 | 32.04 |

| 5 | 2.58 | 4.11 | 33.85 |

| 10 | 4.20 | 4.45 | 30.47 |

| 15 | 3.66 | 3.81 | 30.62 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malchiodi, B.; Marchetti, R.; Barbieri, L.; Pozzi, P. Recovery of Cork Manufacturing Waste within Mortar and Polyurethane: Feasibility of Use and Physical, Mechanical, Thermal Insulating Properties of the Final Green Composite Construction Materials. Appl. Sci. 2022, 12, 3844. https://doi.org/10.3390/app12083844

Malchiodi B, Marchetti R, Barbieri L, Pozzi P. Recovery of Cork Manufacturing Waste within Mortar and Polyurethane: Feasibility of Use and Physical, Mechanical, Thermal Insulating Properties of the Final Green Composite Construction Materials. Applied Sciences. 2022; 12(8):3844. https://doi.org/10.3390/app12083844

Chicago/Turabian StyleMalchiodi, Beatrice, Roberta Marchetti, Luisa Barbieri, and Paolo Pozzi. 2022. "Recovery of Cork Manufacturing Waste within Mortar and Polyurethane: Feasibility of Use and Physical, Mechanical, Thermal Insulating Properties of the Final Green Composite Construction Materials" Applied Sciences 12, no. 8: 3844. https://doi.org/10.3390/app12083844

APA StyleMalchiodi, B., Marchetti, R., Barbieri, L., & Pozzi, P. (2022). Recovery of Cork Manufacturing Waste within Mortar and Polyurethane: Feasibility of Use and Physical, Mechanical, Thermal Insulating Properties of the Final Green Composite Construction Materials. Applied Sciences, 12(8), 3844. https://doi.org/10.3390/app12083844