Dose-Area Product Determination and Beam Monitor Calibration for the Fixed Beam of the Shanghai Advanced Proton Therapy Facility

Abstract

:1. Introduction

2. Materials and Methods

2.1. SAPT and Beam Monitor System

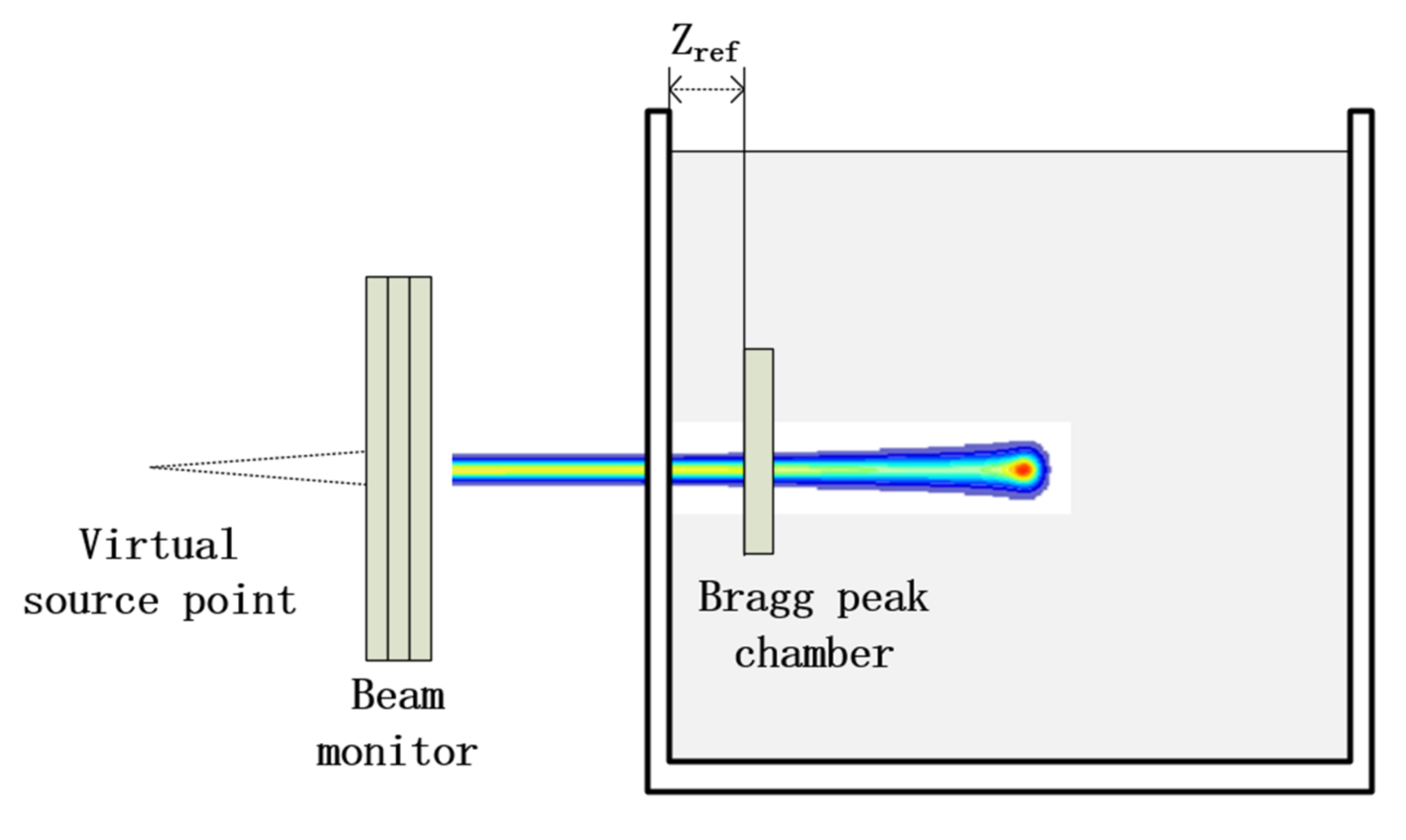

2.2. DAP Measurement with Single-Layer Method

2.3. DAP Measurement with Single-Spot Method

2.4. Nozzle Monte Carlo Modelling of SAPT

2.5. Log File Based Dose Reconstruction to Inspect the Iniformity

3. Results

3.1. Single-Energy Dose Distribution

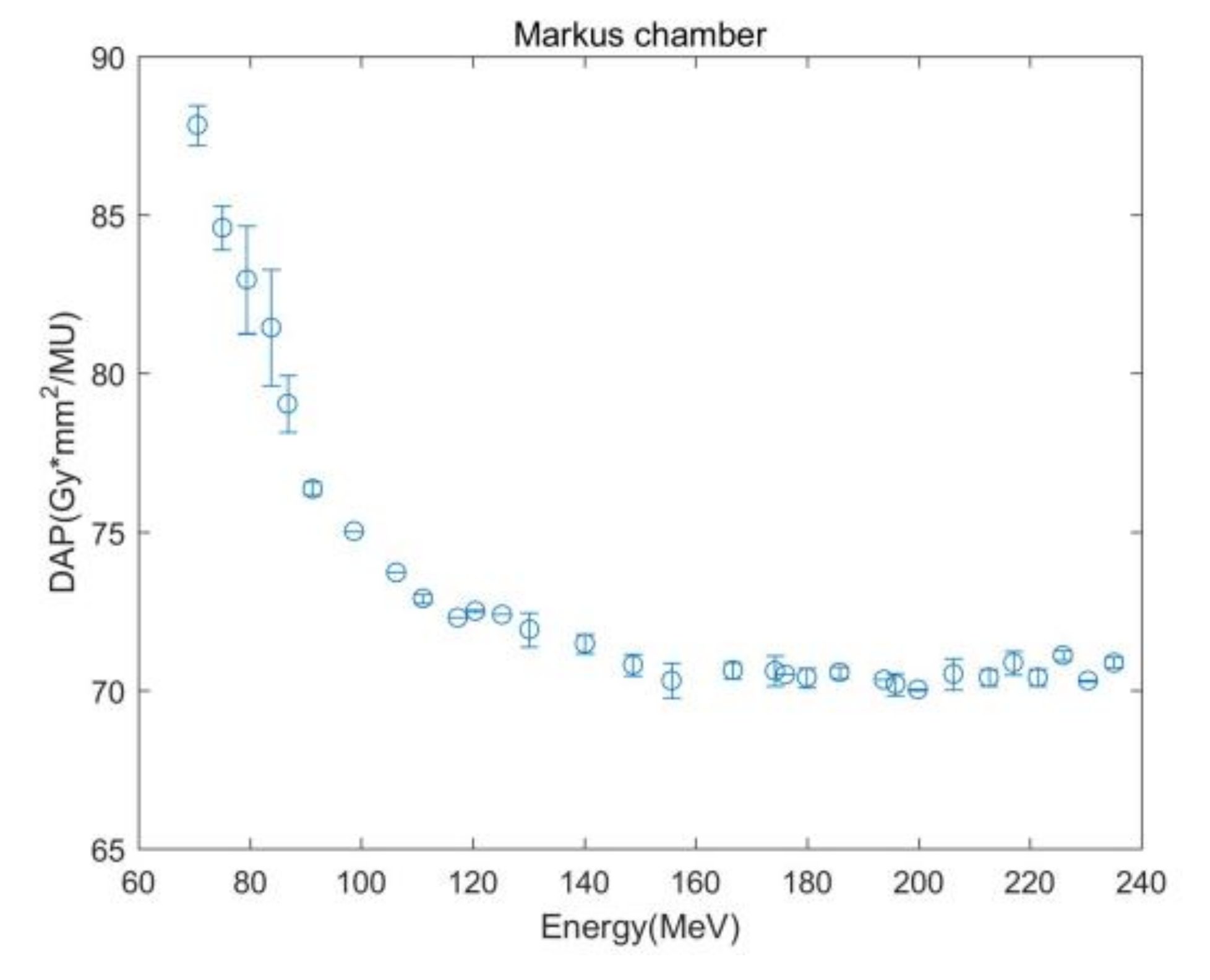

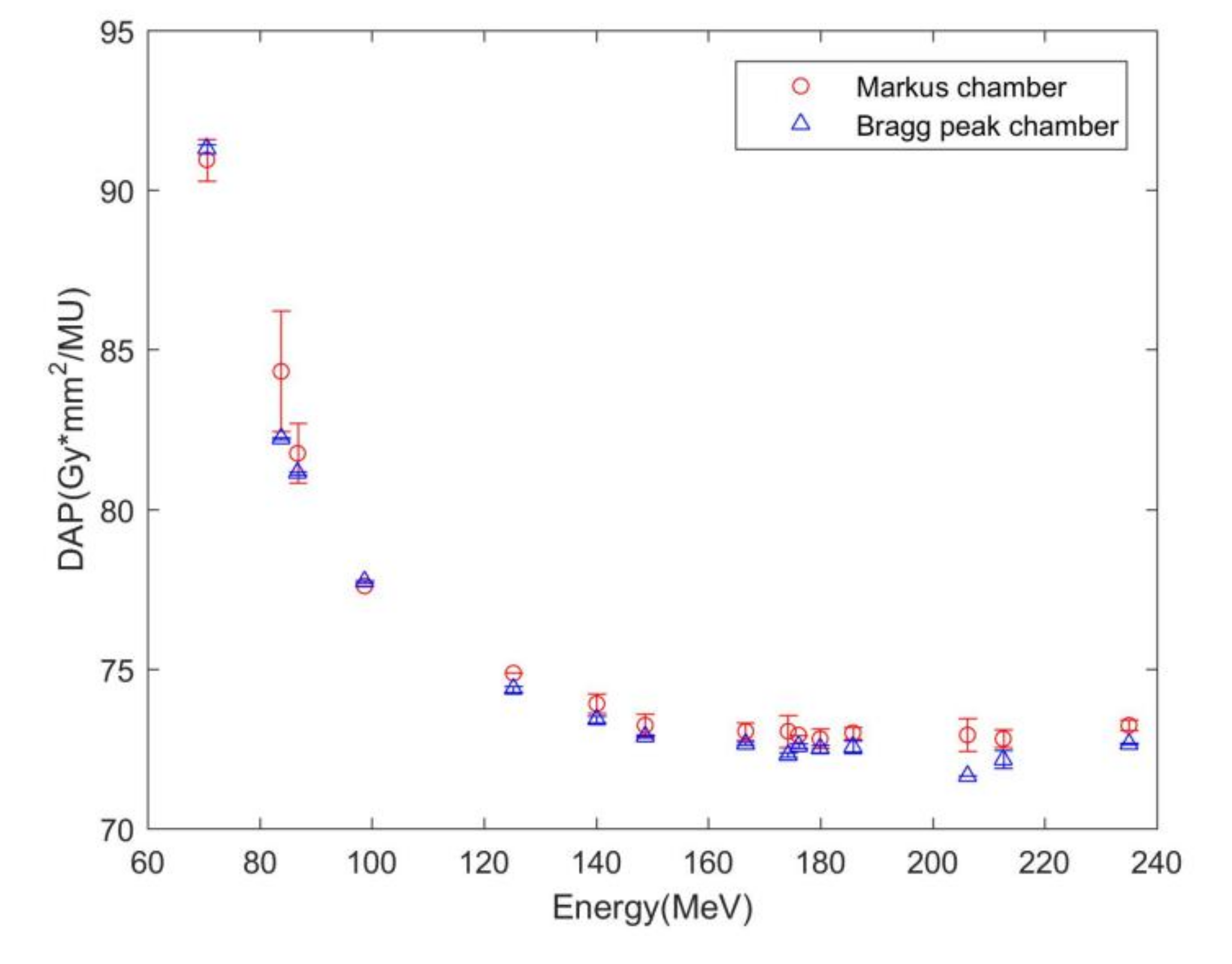

3.2. DAP Measurement

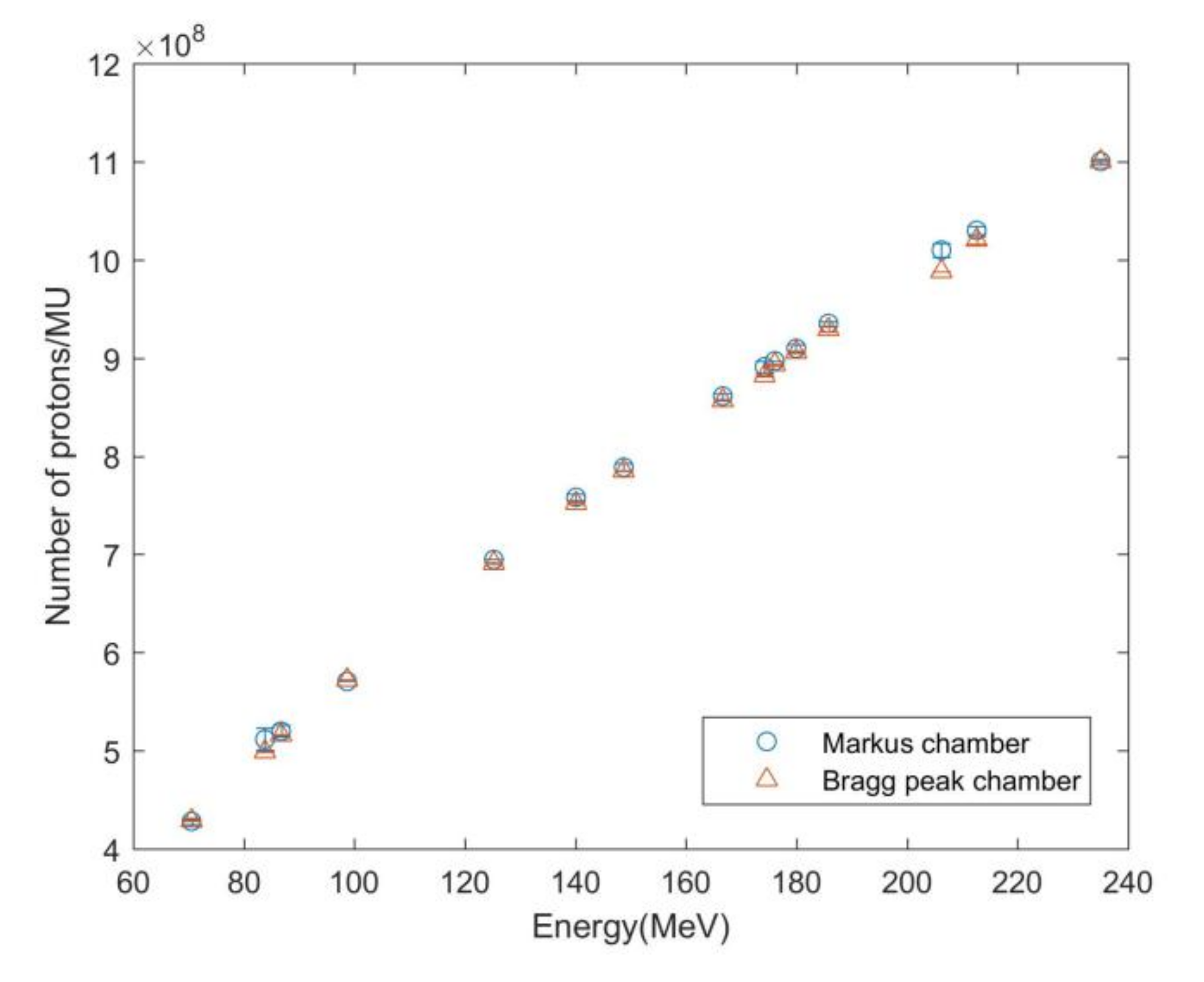

3.3. Number of Protons per MU

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goma, C.; Safai, S.; Voros, S. Reference dosimetry of proton pencil beams based on dose-area product: A proof of concept. Phys. Med. Biol. 2017, 62, 4991–5005. [Google Scholar] [CrossRef] [PubMed]

- Andreo, P.; Burns, D.T.; Hohlfeld, K.; Huq, M.S. Absorbed Dose Determination in External Beam Radiotherapy. IAEA TRS 398 an International Code of Practice for Dosimetry Based on Standards of Absorbed Dose to Water; International Atomic Energy Agency: Vienna, Austria, 2000. [Google Scholar]

- Jäkel, O.; Hartmann, G.H.; Karger, C.P.; Heeg, P. A calibration procedure for beam monitors in a scanned beam of heavy charged particles. Med. Phys. 2004, 31, 1009–1013. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.J.; Ding, X.N.; Hu, Y.L.; Kang, Y.X.; Liu, W.; Deng, W.; Bues, M. Technical Note: Comprehensive evaluation and implementation of two independent methods for beam monitor calibration for proton scanning beam. Med. Phys. 2019, 46, 5867–5875. [Google Scholar] [CrossRef] [PubMed]

- Farr, J.B.; Moyers, M.F.; Allgower, C.E.; Bues, M.; Hsi, W.-C.; Jin, H. Clinical commissioning of intensity-modulated proton therapy systems: Report of AAPM Task Group 185. Med. Phys. 2021, 48, e1–e30. [Google Scholar] [CrossRef] [PubMed]

- Kuess, P.; Bohlen, T.T.; Lechner, W.; Elia, A.; Georg, D.; Palmans, H. Lateral response heterogeneity of Bragg peak ionization chambers for narrow-beam photon and proton dosimetry. Phys. Med. Biol. 2017, 62, 9189–9206. [Google Scholar] [CrossRef] [PubMed]

- Gillin, M.T.; Sahoo, N.; Bues, M.; Ciangaru, G.; Sawakuchi, G.; Poenisch, F.; Arjomandy, B.; Martin, C.; Titt, U.; Suzuki, K.; et al. Commissioning of the discrete spot scanning proton beam delivery system at the University of Texas M.D. Anderson Cancer Centre, Proton Therapy Centre, Houston. Med. Phys. 2010, 37, 154–163. [Google Scholar] [CrossRef] [PubMed]

- Osorio, J.; Dreindl, R.; Grevillot, L.; Letellier, V.; Kuess, P.; Carlino, A.; Elia, A.; Stock, M.; Vatnitsky, S.; Palmans, H. Beam monitor calibration of a synchrotron-based scanned light-ion beam delivery system. Z. Med. Phys. 2021, 31, 154–165. [Google Scholar] [CrossRef] [PubMed]

- Rath, A.K.; Sahoo, N. (Eds.) Particle Raiotherapy. In Emerging Technology for Treatment of Cancer; Springer: New Delhi, India, 2016; pp. 1–194. [Google Scholar]

- Goma, C.; Lorentini, S.; Meer, D.; Safai, S. Proton beam monitor chamber calibration. Phys. Med. Biol. 2014, 59, 4961–4971. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Ho, M.W.; Park, J.; Hsi, W.C.; Liang, X.; Li, Z.; Song, Y.; Feng, H.; Zhang, Y. Fast MCsquare-Based Independent Dose Verification Platform for Pencil Beam Scanning Proton Therapy. Technol. Cancer Res. Treat. 2021, 20, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.; Kang, M.; Souris, K.; Ainsley, C.; Solberg, T.D.; McDonough, J.E.; Simone, C.B., 2nd; Lin, L. Validation and clinical implementation of an accurate Monte Carlo code for pencil beam scanning proton therapy. J. Appl. Clin. Med. Phys. 2018, 19, 558–572. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Palmans, H.; Vatnitsky, S.M. Beam monitor calibration in scanned light-ion beams. Med. Phys. 2016, 43, 5835–5847. [Google Scholar] [CrossRef] [PubMed]

- Grevillot, L.; Osorio Moreno, J.; Letellier, V.; Dreindl, R.; Elia, A.; Fuchs, H.; Carlino, A.; Kragl, G.; Palmans, H.; Vatnitsky, S.; et al. Clinical implementation and commissioning of the MedAustron Particle Therapy Accelerator for non-isocentric scanned proton beam treatments. Med. Phys. 2020, 47, 380–392. [Google Scholar] [CrossRef] [PubMed]

- Lorin, S.; Grusell, E.; Tilly, N.; Medin, J.; Kimstrand, P.; Glimelius, B. Reference dosimetry in a scanned pulsed proton beam using ionisation chambers and a Faraday cup. Phys. Med. Biol. 2008, 53, 3519–3529. [Google Scholar] [CrossRef] [PubMed]

- Shu, H.; Yin, C.; Zhang, H.; Liu, M.; Zhang, M.; Zhao, L.; Chu, K.; Dai, X.; Moyers, M.F. Scanned Proton Beam Performance and Calibration of the Shanghai Advanced Proton Therapy Facility. MethodsX 2019, 6, 1933–1943. [Google Scholar] [CrossRef] [PubMed]

- Perl, J.; Shin, J.; Schumann, J.; Faddegon, B.; Paganetti, H. TOPAS: An innovative proton Monte Carlo platform for research and clinical applications. Med. Phys. 2012, 39, 6818–6837. [Google Scholar] [CrossRef] [PubMed]

- International Commission on Radiation Units and Measurements (ICRU). Stopping of Ions Heavier Than Helium, ICRU Report 73; Oxford University Press: Oxford, UK, 2005. [Google Scholar]

- Elia, A.; Resch, A.F.; Carlino, A.; Böhlen, T.T.; Fuchs, H.; Palmans, H.; Letellier, V.; Dreindl, R.; Osorio, J.; Stock, M.; et al. A GATE/Geant4 beam model for the MedAustron non-isocentric proton treatment plans quality assurance. Phys. Med. 2020, 71, 115–123. [Google Scholar] [CrossRef] [PubMed]

- Wieser, H.-P.; Cisternas, E.; Wahl, N.; Ulrich, S. Development of the open-source dose calculation and optimization toolkit matRad. Med. Phys. 2017, 44, 2556–2568. [Google Scholar] [CrossRef] [PubMed]

- Arjomandy, B.; Taylor, P.; Ainsley, C.; Safai, S.; Sahoo, N.; Pankuch, M.; Farr, J.B.; Park, S.Y.; Klein, E.; Flanz, J.; et al. AAPM task group 224: Comprehensive proton therapy machine quality assurance. Med. Phys. 2019, 46, e678–e705. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Energy (MeV) | DAP (Gy*mm2/MU) | Standard Deviation (Gy*mm2/MU) | Percent Difference | |||

|---|---|---|---|---|---|---|

| MC | BPC | Mean Value | MC | BPC | ||

| 235 | 73.24 | 72.66 | 72.95 | 0.17 | 0.03 | −0.79% |

| 212.6 | 72.82 | 72.17 | 72.49 | 0.28 | 0.27 | −0.89% |

| 185.8 | 72.99 | 72.55 | 72.77 | 0.18 | 0.20 | −0.60% |

| 179.9 | 72.82 | 72.50 | 72.66 | 0.31 | 0.11 | −0.44% |

| 174.2 | 73.04 | 72.31 | 72.67 | 0.50 | 0.06 | −1.00% |

| 166.6 | 73.05 | 72.66 | 72.86 | 0.27 | 0.04 | −0.53% |

| 148.7 | 73.24 | 72.89 | 73.07 | 0.35 | 0.04 | −0.48% |

| 140.1 | 73.92 | 73.42 | 73.67 | 0.31 | 0.11 | −0.68% |

| 86.8 | 81.76 | 81.14 | 81.45 | 0.93 | 0.05 | −0.76% |

| 83.8 | 84.33 | 82.22 | 83.28 | 1.89 | 0.03 | −2.50% |

| 70.6 | 90.94 | 91.29 | 91.11 | 0.66 | 0.15 | 0.38% |

| Energy (MeV) | Number of Protons per MU | Standard Deviation | Percent Difference | |||

|---|---|---|---|---|---|---|

| MC | BPC | Mean Value | MC | BPC | ||

| 235 | 1.10 × 109 | 1.10 × 109 | 1.10 × 109 | 2.59 × 106 | 4.24 × 105 | −0.73% |

| 212.6 | 1.03 × 109 | 1.02 × 109 | 1.02 × 109 | 3.96 × 106 | 3.77 × 106 | −0.98% |

| 185.8 | 9.35 × 108 | 9.29 × 108 | 9.32 × 108 | 2.30 × 106 | 2.52 × 106 | −0.65% |

| 179.9 | 9.10 × 108 | 9.06 × 108 | 9.08 × 108 | 3.90 × 106 | 1.35 × 106 | −0.44% |

| 174.2 | 8.91 × 108 | 8.82 × 108 | 8.87 × 108 | 6.09 × 106 | 7.85 × 105 | −1.02% |

| 166.6 | 8.61 × 108 | 8.57 × 108 | 8.59 × 108 | 3.22 × 106 | 4.38 × 105 | −0.47% |

| 148.7 | 7.89 × 108 | 7.85 × 108 | 7.87 × 108 | 3.78 × 106 | 4.00 × 105 | −0.51% |

| 140.1 | 7.58 × 108 | 7.52 × 108 | 7.55 × 108 | 3.20 × 106 | 1.08 × 106 | −0.80% |

| 86.8 | 5.20 × 108 | 5.16 × 108 | 5.18 × 108 | 5.93 × 106 | 3.48 × 105 | −0.78% |

| 83.8 | 5.12 × 108 | 4.99 × 108 | 5.05 × 108 | 1.15 × 107 | 1.73 × 105 | −2.61% |

| 70.6 | 4.28 × 108 | 4.29 × 108 | 4.28 × 108 | 3.12 × 106 | 7.21 × 105 | 0.23% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, L.; Zhang, M.; Xiang, X.; Wang, X. Dose-Area Product Determination and Beam Monitor Calibration for the Fixed Beam of the Shanghai Advanced Proton Therapy Facility. Appl. Sci. 2022, 12, 4111. https://doi.org/10.3390/app12094111

Zhu L, Zhang M, Xiang X, Wang X. Dose-Area Product Determination and Beam Monitor Calibration for the Fixed Beam of the Shanghai Advanced Proton Therapy Facility. Applied Sciences. 2022; 12(9):4111. https://doi.org/10.3390/app12094111

Chicago/Turabian StyleZhu, Libing, Manzhou Zhang, Xincheng Xiang, and Xiangang Wang. 2022. "Dose-Area Product Determination and Beam Monitor Calibration for the Fixed Beam of the Shanghai Advanced Proton Therapy Facility" Applied Sciences 12, no. 9: 4111. https://doi.org/10.3390/app12094111

APA StyleZhu, L., Zhang, M., Xiang, X., & Wang, X. (2022). Dose-Area Product Determination and Beam Monitor Calibration for the Fixed Beam of the Shanghai Advanced Proton Therapy Facility. Applied Sciences, 12(9), 4111. https://doi.org/10.3390/app12094111