1. Introduction

The development of nuclear fission waste reduction and management strategies has been of interest for several decades. The first strong development push was affected by two important international projects on partitioning and transmutation (P&T) of transuranium isotopes active in the late 1980s and early 1990s: the OMEGA (Options for Making Extra Gains from Actinides and fission products) programme in Japan and the CAPRA/CADRA programme in France. The former [

1], the first major P&T project, arose from the Japan Atomic Energy Commission’s October 1988 report entitled “Long-Term Program for Research and Development on Nuclide Partitioning and Transmutation (P&T)”, which considered the conversion of High-Level Waste (HLW) into useful resources and the improvement of HLW disposal efficiency. As well as the OMEGA programme, this report plotted a course for technological development up to the year 2000. The French CAPRA/CADRA projects (CAPRA stands for Combustion Améliorée du Plutonium dans les Réacteurs Avancés or increased plutonium consumption in advanced reactors, whilst CADRA stands for Consommation d’Actinides et de Déchets dans les Réacteurs Avancés or consumption of actinides and waste in advanced reactors) were then established in 1991 by French law; this mandated a combined 15-year research programme to investigate the technical options available to the nuclear fuel cycle in France [

2] with the intention of investigating future options to apply fast reactors, originally foreseen for power production, to the burnup of excess plutonium, actinides and waste. Therefore, while the OMEGA project focused on partitioning, as well as on transmutation, the CAPRA/CADRA project was originally only dedicated to transmutation, with a major focus of this and related reactor studies being the reuse and incineration of Plutonium in the Superphénix prototype fast breeder reactor. Different aspects of the potential of fast reactor systems to be used for the burning of plutonium and minor actinides (MAs) (Np, Am, Cm) were considered in CAPRA and CADRA projects, with CAPRA mainly dealing with managing the plutonium stockpile and CADRA considering the burning (transmutation) of MAs and long-lived fission products [

3]. As a consequence, waste management through P&T has mainly since been seen as a distinct task requiring a separate/special type of reactor system. More recently the potential for bringing fast reactors into operation both for widespread power production and waste management has been explored. This has very often used a so-called double strata approach [

4,

5,

6] with sodium cooled fast reactors being proposed as the stratum (or tier) 1 system to produce energy from Plutonium and with a specific stratum/tier 2 system, e.g., an accelerator driven system (ADS) or critical solid fuelled fast reactor [

5], used to efficiently burn the remaining waste (low quality plutonium and minor actinides) [

6]. Now, this same approach is being followed in the recently established Russian P&T programme, but in contrast to the European programmes the Russian effort plans to use a molten salt fast reactor as its tier 2 burner system [

7,

8]. More generally, a question can now be posed: is it really necessary to have a two separated tiers approach, or would it not be possible and more conveniently go to a novel breakthrough technology, where both tiers are merged together which would in turn generate a market opportunity to deliver energy production and waste management in one integrated reactor system?

Given today’s vastly different energy landscape, compared to the 1990s when P&T was emerging, future energy technologies have to address the urgent challenges of net zero and sustainable energy research and development, the energy trilemma and the meeting of the UN sustainable development goals (SDGs). The trilemma is characterised (e.g., by the world energy council [

9] a UN-accredited body) by the three key interlinked challenges of reducing emissions, enhancing the security of supply, and reducing the overall cost of energy production. The challenges of this trilemma are also reflected in the UN SDG 7: “Ensure access to affordable, reliable, sustainable and modern energy for all as one piece of sustainable development of the future world” [

10]. The challenge is that waste management through P&T can only deliver on a subset of these new requirements, while overarching objectives, such as enhanced/sustainable resource utilization and energy security can only be met by closed fuel cycle operation with integrated P&T.

To meet these challenges in an integrated approach, we have proposed the iMAGINE concept, which aims at using molten salt fast reactors with integrated salt clean-up. This has the aim of operating on spent nuclear fuel and has the potential to deliver waste management [

11] and power production [

12] in one process. This new, integrated approach offers the prospect of a single holistic solution delivering not only an innovative system for energy production but also a highly sustainable process, e.g., through the integration of the separation and transmutation processes [

13,

14]. This offers the prospect of using only one reactor system and the avoidance of the extensive fuel cycle required in the previously described double strata approach. However, the key to the success of the envisaged technology is avoiding the constraints of the existing paradigms of reprocessing technologies, which focus on rigorous, complete and highly selective separation of fissile materials, and taking a strictly demand driven approach for long term reactor operation. Up until now, most of the salt clean-up, polishing, or other related processes are still based on separating fissile materials, e.g., the processes used at MSRE [

15], some newer proposals [

16,

17] and the processes proposed for EVOL [

18,

19]. The process aimed for here is completely different and could be called “reverse” reprocessing, in that the aim is to leave all fissile materials and all actinides, in the salt, while separating those selected elements which prevent the reactor from long term operation. This avoids proliferation issues as well as the formation of the so-called reprocessing “soup” containing a wide variety of different fission products which are hard to separate further or condition, each with very different chemical behavior.

Although we propose this completely different approach it should be recognised that those separation approaches which exist and are relevant, e.g., those which exploit the nature of the hot molten salt medium to generate, release and separate gaseous and volatile fission products can be utilised in this approach [

20] or other approaches [

21]. To be able to develop the required processes, it is first essential to identify the relevant elements which cause the largest effect in decreasing criticality after a certain time of operation. In addition, it is of high importance to know the concentrations of these elements and the separation efficiency required to overcome this decrease, since this will set the challenge for the separation processes to be developed. In this work, we now address each of these challenges to identify the development pathway for the proposed iMAGINE system. This considers a fuel composition relevant to the application of fuel waste burning, identifies the boundary conditions required for the “reverse” reprocessing approach and for salt clean-up and considers the potential consequences of the reactor chemistry.

2. The iMAGINE System and Its Optimization

In the IMAGINE system, the approach to sustainable and efficient operation is to concentrate on separating out the elements which prevent the reactor system from long term operation instead of reprocessing the entire fuel. This avoids the separation of fissile and fertile material, such as uranium, plutonium and the minor actinides with the consequent demand for fresh fuel production and the arising proliferation concerns. The new approach of cleaning the fuel in operation creates two further positive outcomes. First, by avoiding the proliferation issues of established reprocessing methods through avoiding the separation of fissile material, it also removes the potential opportunity for misuse and theft and the consequent requirement for a massive and expensive safeguarding activity. Secondly, it has the potential to remove one of the most challenging requirements of waste management; the demand when reprocessing and partitioning an extremely high separation rate of the actinides from the waste stream to avoid the loss of TRU material and its carry over into future final disposal. This problem is further aggravated in the current approach by the accumulation of fissile material in the waste stream when recycling multiple times (multi-recycling) in closed fuel cycle operations and P&T [

22]. To underline the serious consequences of the resulting radiotoxicity from such carryover, the influence of the separation efficiency of the TRU elements on the waste stream and the time scale of its radiotoxicity is given in

Figure 1. This observation makes it obvious that the losses result in an incomplete/insufficient result of the P&T process, not leading to the promised sharp decrease in the radiotoxicity but leading to a time delay of up to more than 1000 years before crossing the radiotoxicity line of the inserted fuel.

The development of the new, innovative iMAGINE approach to the separation of fission product elements will not only enable radically different thinking in transmutation but also in nuclear and separation chemistry with the demand to deliver breakthroughs not only in molten salt reactor design and operation but also in the development of salt clean-up processes; the iMAGINE approach will require developments in partitioning to deliver an integrated closed fuel cycle solution.

In particular, the use of liquid fuelled systems, such as molten salt reactors, offers the opportunity to reshape the reprocessing process completely [

24] by concentrating on those elements which have the largest impact on maintaining criticality during reactor operation. This breakthrough approach would concentrate on those elemental species which through neutron absorption have the strongest effect in reducing criticality, and therefore, reducing reactor fuel usage efficiency. This avoids the established approach of the complete removal/separation of fission products to regenerate the new, rigorously clean fuel required for solid fuel reactors. This new approach and these new processes offer significant optimization potential [

24] around such key factors as, the throughput of salt through the chemical cleaning process, the selection of elements/species for separation, and the required process efficiencies of these specific separation processes. In addition, there is the potential for the significant reduction or removal of the pre- and post-processing steps required for a solid fuel-based fuel cycle, such as the storage and transport of the spent fuel, its cooling and dissolution, the precipitation of select materials after separation as well as the subsequent solid fuel production. Some of these steps are very costly (both economically and in terms of resources) whilst others are very time consuming and can lead potentially to significant radiation exposure for workers [

7]. However, it is worth noting that these steps cannot be fully avoided in all fuel cycles, particularly those which rely on solid fuels and on aqueous reprocessing. In addition, there would be a further significant advantage of a process based on a fully integrated fuel cleaning system for a molten salt reactor overusing established reprocessing methods, with their demand for very high separation factors and costly fuel production. As it would only require separation of selected fission products, the actinides would stay in the fuel system, thus potentially reducing the need for such high separation factors to achieve P&T goals as well as avoiding the potential proliferation risk of the separated species, which is often cited as one of the highest risks of closed fuel cycle operation and P&T.

In order to implement this attractive approach, it is important first to establish which elements have to be separated from the fuel to design a demand driven separation process for salt clean-up. There has already been a first attempt published [

24], looking into reactor physics and identifying the elements which have the strongest influence on the system criticality, but this was based on the start-up configuration of a molten salt reactor operating on the spent nuclear fuel from light water reactors [

24]. This work now delivers an additional molten salt reactor priority list, created through the modelling of the operation of a chlorine molten salt fast reactor started with enriched Uranium. The calculations for this feasibility study model use a target burnup of 100 GWd/tHM.

3. Simulation Codes and Methods and Salt Data

The simulations for this feasibility study were performed using fast running unstructured mesh 2D deterministic simulations based on the SCALE/POLARIS neutron transport solver. POLARIS is a module of the SCALE code system [

25] for 2D deterministic transport simulation, mainly developed for cross section preparation for core simulators. POLARIS is a new module of SCALE 6.2 that provides a 2D lattice physics analysis capability, using a multigroup self-shielding method called the Embedded Self Shielding Method (ESSM) and a transport solver based on the Method of Characteristics (MoC). In general, POLARIS and its cross section library have been developed and validated for light water reactors; thus, we have provided in a recent publication [

26] the first verification against the Monte-Carlo code SERPENT [

27] and some new, extensive follow up verifications, by comparison with different deterministic and statistic solvers of the SCALE package including some continuous energy Monte-Carlo comparisons [

28].

The salt data for the applied fuel composition were based on two advanced Russian publications by Katyshev and Teslyuk [

29] and by Desyatnik and Katyshev [

30]. The base configuration is NaCl-UCl

3-UCl

4 with the eutectic composition of 45% (molar) NaCl–38.5% (molar) UCl

4–16.5% (molar) UCl

3. It is worthy of further detailed investigation due to its relatively high loading of fertile heavy metal material at the eutectic point, which makes it a very promising composition for achieving the required breeding efficiency essential for future self-sustained breeding [

31]. Thus, it is an ideal candidate to be used for a first investigation of the fission product accumulation and its effect on criticality when reaching a significant burnup to identify elements for a potential future element-based clean-up system. However, in the longer term, this composition will require a large upgrading of the thermo-physical dataset to a much wider temperature range as input for any kind of future modelling and simulation studies of a potential reactor. At the mentioned eutectic point, the NaCl-UCl

3-UCl

4 salt has a melting point of 338 °C [

29] and a density of 3.232 g/cm

3 at 980 K.

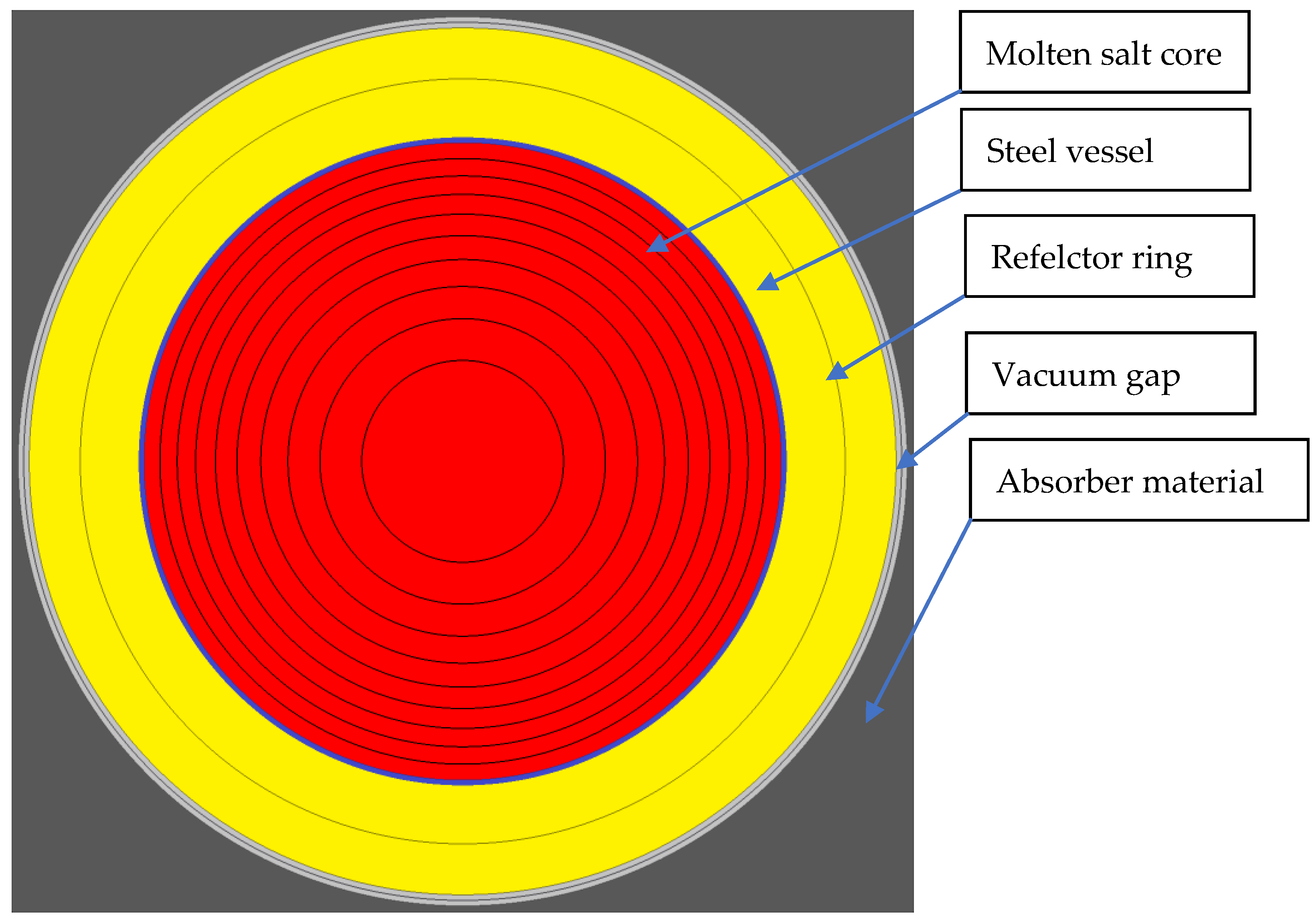

The model for this investigation, see

Figure 2, is based on and developed from two recent publications [

26,

31]. It has been developed for the evaluation of the burnup and breeding performance in a molten salt reactor as well as for the study of potential reactor control through temperature feedback. To allow for this, this very specific 2-D model has been built to take care of the very important effect of neutron leakage from a molten salt reactor core. The ring type model (thin black rings indicate the grid) consists of the reactor core of variable size (red), surrounded by a stainless-steel vessel of 20 mm thickness (blue) and a sodium reflector of 50 cm thickness (yellow). The arrangement is surrounded by a thin vacuum gap (light grey rings) and the rest of the unit cell is filled with a strong absorber (dark grey) to avoid the reflection of leaking neutrons from the core/reflector system through the reflective boundary conditions of the code originally developed to represent a unit cell in an infinite repetition of a fuel assembly.

The simplified modeling approach here is to; calculate the fuel composition data accumulated to a chosen burnup (here 100 GWd/tHM) using a conventional reactor approach without feeding and cleaning so as to have a sufficient amount of fission products accumulated to be able to study concentrations and criticality effect of each element to a reasonable accuracy. This is a simplified model as the final system will require an online clean-up system as well as an online feeding system, and therefore, will not involve batch reprocessing at fixed burnup, but the nature and degree of separation will be correlated in these cases. There are more comprehensive, newly developed codes for molten salt reactor modelling including salt clean-up models available [

32,

33]. However, the plan for this analysis is to create an understanding of the effect of each element in singular and to obtain an indication of the concentration of each of these elements at a certain point of operation to judge if these concentrations justify starting a separation process and to understand which sensitivity the new processes will require. For this analysis, the chosen approach seems to be absolutely appropriate and optimised.

4. Modelling and Simulation Results

The first step was to define a reasonable base case close to the eutectic composition 45%NaCl–38.5%UCl

4–16.5%UCl

3 which achieves a significant burnup and results in a sufficient amount of fission products to create a sufficient effect on criticality by each fission product. As well as being important to obtain a reliable estimation of the effect each fission product element has on criticality, it is also required to obtain insight into the likely concentrations of fission products as a basis for the design of a future separation (clean-up) system. The analysis is based on the standard case of [

26] at the lowest planned temperature level of 930 K, with a system radius of 213 cm, a target burnup of 100 GWd/tHM, an initial U-235 enrichment of 11.78 at% which has been found in an iterative approach to create a critical system at this temperature. The system size was iterated in a multi-stage approach. The first iteration is used to determine an enrichment which delivers an initial criticality for each size within an accuracy of <10 pcm, while in the second stage a burnup case was run to determine the maximum criticality achieved through the burnup with the aim of determining the radius that delivers a maximum

keff of 1.006 at the point of highest criticality, see

Figure 3.

The used model shows a typical burnup behaviour of a breeder system (see

Figure 3, or [

26]) which is characterised by a profile starting with growth in criticality until a single, central peak followed by a continuous decrease, cause dby the fission product accumulation and the effect of removing all fission products, see

Figure 4. The curve starts at criticality (iteration condition) with the degree of criticality rising initially caused by the breeding of new fissile material from the fertile U-238, see

Figure 5. In general, the breeding and burnup behaviour of a reactor core is characterised by a competition between different processes: (a) the formation of new fissile material, (b) the consumption of fissile and fertile material, and (c) the progressive build-up of fission products which has an increasingly strong and long term effect. Thus, the first part of the curve is dominated by breeding, which delivers an increase in criticality, whilst the second part is dominated by fission product accumulation, see

Figure 6 (and the slow decrease in the amount of fertile U-238 which slightly slows the breeding) which delivers a progressive decrease in criticality.

An extended burnup curve at the standard evaluation temperature of the study, 980 K, is given in

Figure 4. The curve using the higher temperature is used to create a balance between the over and under critical areas of the curve to obtain the best possible representation of breeding with the least influence of the

keff normalization on breeding. The reference (base) case radius of 213 cm is again showing the initial increase in criticality caused by breeding and the longer-term reduction of the criticality due primarily to fission product accumulation as given in the black curve of

Figure 3 (observe in addition to the slight reduction in the initial criticality due to the fuel temperature change from

Figure 3 to

Figure 4). To identify the potential maximal effect of a clean-up system that would remove all fission products, the criticality development of a theoretical system without fission product accumulation is then given for comparison. This result demonstrates both the large breeding which takes place in this system (see the Pu accumulation in

Figure 5) and the tremendous effect of the fission product accumulation on system criticality (see

Figure 6). The general form of the breeding curve is comparable to results for other breeding based systems, such as sodium cooled fast reactors [

34], while the detailed result is dominated by the core size/leakage and the correlation between fertile and fissile load in the system.

The detailed Pu breeding (

Figure 5) shows the growth of the plutonium content from zero in the initial composition to almost 10,000 ppm at the final burnup composition. Long term all Pu isotopes show an asymptotic approach to a steady-state value characterised by the specific balance between the breeding and the fission processes. The plutonium vector is mainly dominated by Pu-239. The higher Pu isotopes take longer to form but long-term, Pu-240 shows an increased steady-state amount due to its lower fission cross section, whilst Pu-241, with its significantly higher fission cross section, has a lower steady-state amount.

The fission product accumulation,

Figure 6 is seen to be almost linear with burnup for 5 leading fission product elements. In general, it is not surprising that the amount of fission products formed is directly proportional to the number of fission events that have taken place and thus to the amount of energy produced in the system (the burnup). Thinking a bit further into the future, this behaviour would change to asymptotic behaviour, with element concentration plateauing at a steady state value, if some constant share of the specific fission product element could be removed by a salt clean-up system.

For the full investigation of fission product accumulation, the 142 isotopes of the highest concentration were evaluated from the POLARIS calculation as tested in [

26]. The accumulation of these isotopes was analysed in detail and the leading isotopes of up to 37 elements have been considered.

The criticality effect of each of the different elements was determined through the use of a very specific procedure that has been developed and tested recently in [

24]. At the target burnup of 100 GWd/tHM, the detailed composition was reproduced as a new starting input for a follow up calculation. This base case including all fission products indicated a criticality value of

kref = 0.99224, used as the reference value. Based on this input a series of steady state calculations were then initiated to study the effect of the removal of the different fission product elements. Each time an element x was removed and the calculation was repeated, based on the new criticality value,

kx, Δ

keff in pcm was generated using Equation (1).

All major elements which result in a more than 50 pcm criticality effect (change in

keff), are given in

Table 1. The comprehensiveness of the chosen isotope and element set can be observed in the last two lines of the table. The line sum indicates the summed values of all considered isotopes in the table while the line whole indicates the effects when the whole isotope set of the POLARIS code is used. Thus, the considered isotope and element set given in the table considered 93% of the overall fission product concentration and 95% of the criticality reduction due to the fission product accumulation. The concentrations of these leading elements, in terms of their poisoning effect, can be seen to vary from Zirconium (at almost 4500 ppm) to Europium (~50 ppm) which reflects the widely differing neutron capture cross sections of these isotopes. One approach, in terms of developing potential separation methods, could be to only consider those elements with a significant concentration (say more than 500 ppm). This reduces the number of elements from 20 to 16. However, the ultimate decision criterion as which to elements should be separated should be those with the highest effect on criticality (combined through the content and the neutron capture cross section), which is readily assessed through Δ

keff. This indicates Ruthenium and Molybdenum as elements with the highest influence on criticality with more than 700 pcm effects after 100 GWd/tHM of burnup at reasonably high concentrations of 2500 to almost 4000 ppm. The next elements are Caesium, Neodymium, and Palladium with a criticality effect between 500 and 600 pcm, with both Nd and Cs each having a reasonable concentration of more than 3000 ppm, while the concentration of Palladium is only about 1000 ppm. The next level would be Technetium and Samarium with a criticality effect of slightly below 500 pcm, but both elements have relatively low concentrations below 1000 ppm. The strong relative effect of the Europium is highlighted. This element has by far the strongest effect on criticality per unit mass, as a result of the high capture cross section. However, the challenge of separating Europium would be high due to its relatively low concentration.

The overall criticality effect of all evaluated elements accounts for 6478 pcm in criticality loss, which correlates well with the result obtained without considering the fission products, see

Figure 4, which gives a criticality difference of 6448 pcm. Thus, both approaches deliver results that agree with the calculation accuracy expectations. In addition, it has to be mentioned that in the current criticality loss calculations all gaseous fission products are still considered dissolved, thus the real criticality loss of a molten salt reactor would be lower due to the release of at least a part of the gaseous fission products (e.g., Xe) and fission products (like I

2) with low melting points which will volatilise.

The results given in

Table 1 now form a basis for discussion of the interplay between reactor physics and chemistry. It should be noted that to date simulation results have been delivered through the use of a lattice code that is optimised solely for the determination of criticality, and which results in the highlighting of those major isotopes with the most effect on criticality through Δ

keff. However, this only returns those elements whose removal has the largest effect on criticality, without consideration of the ease of their separation chemistry. Building this in requires additional consideration of their chemical properties in terms of the range of oxidation state(s) possible in the molten salt (

Table 1), the resulting speciation (their chemical environment, which may be burnup dependent) and the process(es) by which they may then be separated. Building in such considerations in a more holistic judgment of physics and separation chemistry is likely to require a wider set of fission products to be considered, more than the criticality relevant fission products which are typically followed in a lattice code. Therefore, as a next step for this wider consideration, it is advisable to recheck this given list with an inventory code, such as ORIGEN of the SCALE package [

25] or FISPIN [

35], to ensure that a complete set of fission products is considered. This would then lead to more comprehensive studies which aim to model, understand then confirm experimentally this chemical speciation, any chemical reactions and the resulting chemical and physical properties. Using an inventory code will then inform the best possible approaches for future salt clean-up based on the chemical nature and environments of the different elements. One simple example would be Iodine, for which its formation in the −1 oxidation state should result in retention in the molten salt and potential complex formation, whilst its formation in the zero oxidation state as I

2 should result in ready volatilisation without the need for chemical separation. Going further, it must be recognised that identifying the evolution of elemental oxidation states and chemical speciation is only the important first step in then proposing and developing suitable reprocessing approaches for the identified fission product poisons and that the feasibility of such approaches may well in turn inform the final choice of neutron poisons to reprocess. Whilst not the subject of this paper, we acknowledge this to be a major challenge to be addressed in future publications, informed by this work.

Therefore, although initial inspection of

Table 1 suggests the development of separation technologies for Ruthenium and Molybdenum should be prioritised for salt clean-up, due to their preferential formation during burnup and their highest adverse effect on criticality; practical considerations, such as feasibility, economics, viability at scale and the separation rates of separation technologies also need to be considered. Ultimately, the final decision of which elements to separate from the fuel salt can only be made after evaluation of the possible separation technologies available for the elements present in their oxidation state(s). This is challenging but opens up a new optimization opportunity within this work.

A further challenge in molten salt reactor operation will also be in the control and monitoring of the physical and chemical state of the reactor and the associated clean up processes. One application will be in salt clean-up and its feedback on reactor operation. This is discussed in [

24] in terms of the new optimization approaches made possible by integrated molten salt reactor systems, for which no pre- and post-processing of the fuel is required, as distinct from current technologies which use solid fuelled reactors and aqueous reprocessing. Another application will be in operational sensing and monitoring, which will be one of the most essential components of molten salt reactor systems in the short as well as the long term. This is because the fission process will result in a continuous evolution of the composition and potentially the chemical and physical properties of the salt through breeding, the fission process itself and fission product formation. Thus, monitoring and specific adjustment of this salt composition will likely be required for stable operation in addition to extraction for clean-up. A key challenge will be to keep the thermochemical, thermodynamic and redox environments as stable as possible for reliable operation. One example of the consequences of fission on reactor redox chemistry is the fission of one Uranium atom present as a U(IV) species in chloride, which results in Ba(II) and Kr(0) and the oxidation of 2 chloride ligands to produce free chlorine gas and/or the further conversion of U(III) to U(IV). Without control of such reactions, the operation could lead to significant deviation from the eutectic composition of 45%NaCl–17%UCl

3–38%UCl

4, with the consequent change in the thermo-physical and thermochemical properties of the molten salt. A worst-case scenario could include dramatic changes in heat transfer and fluid dynamic properties induced by solidification or segregation, as a result of the consequent increase in the melting point of the salt when deviating from the eutectic. Another aspect where coupled chemical consideration is required is in fission product solubility and the release of gaseous fission products (like the noble gases). As well as for all fission products, which could be released in the form of aerosols due to the high temperature of the molten salt pool. This can be relevant since the melting point of the eutectic is much lower than for other compositions, which means in the case the reactor is not operated at the eutectic, higher temperatures will be required. This just demonstrates the importance of close inter-disciplinary interactions and coupled chemical and physical considerations for the successful design and operation of such a molten salt reactor system. The chlorine balance alone will require a coupled modelling and simulation campaign, delivering fission product composition, as well as the number of fissions for reactor physical models into the chemistry model and its feedback from chemistry to physics, e.g., due to the solubility and release effect for gaseous fission products; systems based on fluorine molten salts would produce different chemistries but offer similar process development challenges. A molten salt reactor system, such as iMAGINE, operating on a closed fuel cycle on spent nuclear fuel without prior reprocessing should be seen as one approach to integrating a whole fuel without the requirement for storage, transport, or external solid fuel production. However, this approach will still require further essential chemical steps directly linked to reactor operation; the separation of fission products, their immobilization and the handling and control of the salt phase.

5. Conclusions and Outlook

Molten salt reactors, such as the proposed IMAGINE system provide new opportunities for large energy production, as well as for nuclear waste management in an integrated system. Ideally, this technology development will help to link these two objectives effectively for the first time since industrial energy production in fast reactors ceased in western countries. Molten salt reactor systems offer this opportunity due to a liquid phase core and absence of the requirement for pre- and post- processing of the fissile material compared to alternative classical solid fuelled reactor systems.

There is a clear opportunity and demand for a new type of reprocessing, which separates off those elements that reduce the efficiency of the neutron economy, thereby preventing long term reactor operation, in contrast to the established current approach of separating fissile and fertile materials. This new approach will deliver two major advantages; it will help to avoid proliferation concerns due to the absence of separated fissile material and it will avoid a so-called ‘plutonium economy’. This is due to Pu staying inside the reactor system at all times. Here, the Pu acts as a kind of catalyst enabling the use of U-238 as an almost unlimited energy resource through a breed and burn system, which should create a factor of up to 100 times more energy out of the given Uranium resource. This seems an attractive alternative to expensive and proliferation enhancing separation and reinsertion steps in the closed fuel cycle, as well as to solid fuel fabrication. The proposed new approach also could improve financial sustainability since it eliminates most of the costly and complex fuel cycle steps required in other reactor systems. Furthermore, this proposed, innovative approach could further reduce costs and complexity by avoiding the traditional requirements of extremely high separation rates and efficiencies for classical reprocessing. These demanding traditional requirements are a consequence of the impact of any residual TRUs into the final disposal stream with consequent implications for the waste management strategy and the required observation and active cooling times required in final disposal.

For this new, innovative approach an important first step outlined here is to identify the most harmful elements which poison the neutron chain reaction and affect core criticality since these are the elements for which the separation processes are likely to be most effective. A series of calculations of the amounts of the specific elements appearing in the core after a burnup of 100 GWd/tHM have identified Ruthenium and Molybdenum as elements with the highest influence on criticality, each formed after 100 GWd/tHM burnup at the reasonably high concentration of 2500 to almost 4000 ppm. The next elements identified were Caesium, Neodymium, and Palladium.

This work is an important first step; however, to be really successful in not only revolutionising the reactor design but also in creating effective fuel cycle integration, it is essential to create a much closer link between reactor physics, reactor design and operation, reactor chemistry and the chemistry of processing. Additional challenges include the requirement for a coupled modelling and simulation strategy which deals with changes in the chemical composition of the salt during burnup and the resulting effects on the physicochemical properties. For example, changes in chemical composition could lead to changes in physical properties, redox states, e.g., the amount of free and bound chloride in the salt, which needs to be monitored and potentially addressed through selected chemical addition, as well as targeted chemical extraction in such a system.

The modelling of all relevant physical and chemical processes and their potential interactions, including reactor operation, salt clean-up, and change in the salt composition is, therefore, required, which will necessitate an integrated, interlinked and dynamic procedure for modelling the complete reactor processes.