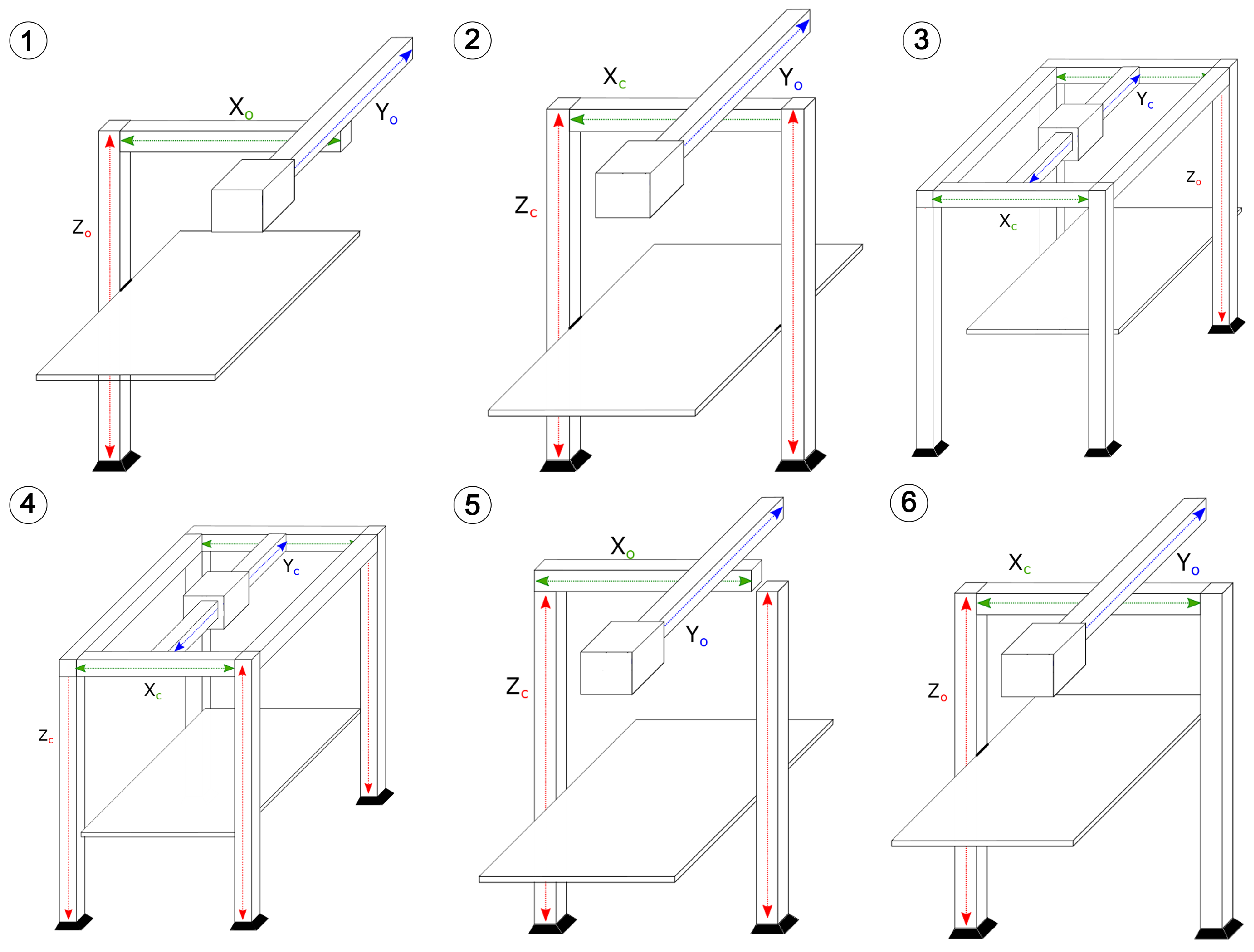

Cartesian 3D printers consist of two independent parts: the frame with the printhead mounted on it and the printbed.To distinguish between the coordinate axes of the printhead and the printbed, we denote them as , , for the printhead and , , for the printbed. These parts are separated in space by the printed part and move relative to each other. The system requires the mobility of 3D printer parts along three orthogonal axes to be functional. For example, if the coordinate system as a whole is stationarily attached to the printbed, then the printhead must move along the , and axes. Hereafter, for brevity, we will use the term “axis” not only for the direction in space but also to denote a set of mechanical elements (beams, guides) designed to move the printer’s working body along a given coordinate axis.

Kinematics of modern Cartesian printers implies variation of mobility and immobility of the axes. In our analysis, the actuated axis is designated (A) and the fixed axis is designated (F).

The closed axis provides more rigidity to the construction but needs a more complicated design with additional guides, motors, etc.

Table A1.

Variability in axis mobility of the Cartesian 3D printer. Cells for the printhead are filled gray. Rows 4 and 7 are not investigated further.

|

№ | Actuated Axis | Fixed Axis |

|---|

| 1 | | | | | | |

| 2 | | | | | | |

| 3 | | | | | | |

| | | | | | |

| 5 | | | | | | |

| 6 | | | | | | |

| | | | | | |

| 8 | | | | | | |

Appendix A.1. Classification of Cartesian Designs

In this subsection, we will overview all possible combinations of fixed and actuated axes and make a complete classification of Cartesian 3D printers. An example of the visual representation of each kinematics is presented in

Appendix A in

Figure A5,

Figure A6,

Figure A7,

Figure A8,

Figure A9, and

Figure A10. It should be noted that the kinematic schemes can be depicted differently depending on where the entire structure is mounted (e.g., standing on the table or attached to the wall). All illustrated constructions shown in

Appendix A are fixed on the floor.

Table A2,

Table A3,

Table A4,

Table A5,

Table A6 and

Table A7 show kinematic schemes with different variations. Since the

X and

Y axes are interchangeable, designs numbered 2 and 8 (marked yellow (*)) as well as 6 and 7 (marked red (**)) in some tables are the same, and one solution from each pair can be omitted. In

Table A4 and

Table A5, there are no interchangeable designs because the axes

and

(or

and

) belong to different 3D printer components.

Table A2.

Fixed axes , , and actuated axes , , .

Table A2.

Fixed axes , , and actuated axes , , .

|

№ | | | | | | |

|---|

| 1 | F | F | F | | | |

| 2 * | . | . | . | | | |

| 3 | . | . | . | | | |

| 4 | . | . | . | | | |

| 5 | . | . | . | | | |

| 6 ** | . | . | . | | | |

| 7 ** | . | . | . | | | |

| 8 * | F | F | F | | | |

Table A3.

Fixed axes , , and actuated axes , , .

Table A3.

Fixed axes , , and actuated axes , , .

|

№ | | | | | | |

|---|

| 1 | F | F | | | | F |

| 2 * | . | . | | | | . |

| 3 | . | . | | | | . |

| 4 | . | . | | | | . |

| 5 | . | . | | | | . |

| 6 ** | . | . | | | | . |

| 7 ** | . | . | | | | . |

| 8 * | F | F | | | | F |

Table A4.

Fixed axes , , and actuated axes , , .

Table A4.

Fixed axes , , and actuated axes , , .

|

№ | | | | | | |

|---|

| 1 | F | | F | | F | |

| 2 | . | | . | | . | |

| 3 | . | | . | | . | |

| 4 | . | | . | | . | |

| 5 | . | | . | | . | |

| 6 | . | | . | | . | |

| 7 | . | | . | | . | |

| 8 | F | | F | | F | |

Table A5.

Fixed axes , , and actuated axes , , .

Table A5.

Fixed axes , , and actuated axes , , .

|

№ | | | | | | |

|---|

| 1 | F | | | | F | F |

| 2 | . | | | | . | . |

| 3 | . | | | | . | . |

| 4 | . | | | ) | . | . |

| 5 | . | | | | . | . |

| 6 | . | | | | . | . |

| 7 | . | | | | . | . |

| 8 | F | | | | F | F |

Table A6.

Fixed axes , , and actuated axes , , .

Table A6.

Fixed axes , , and actuated axes , , .

|

№ | | | | | | |

|---|

| 1 | | | F | F | F | |

| 2 * | | | . | . | . | |

| 3 | | | . | . | . | |

| 4 | | | . | . | . | |

| 5 | | | . | . | . | |

| 6 ** | | | . | . | . | |

| 7 ** | | | . | . | . | |

| 8 * | | | F | F | F | |

Table A7.

Fixed axes , , and actuated axes , , .

Table A7.

Fixed axes , , and actuated axes , , .

|

№ | | | | | | |

|---|

| 1 | | | | F | F | F |

| 2 * | | | | . | . | . |

| 3 | | | | . | . | . |

| 4 | | | | . | . | . |

| 5 | | | | . | . | . |

| 6 ** | | | | . | . | . |

| 7 ** | | | | . | . | . |

| 8 * | | | | F | F | F |

Appendix A.2. Survey of Existing Mechanical Designs

A review of existing 3D printer solutions showed that many of the variants presented in

Table A2 of the kinematics are not used in practice, except for numbers three and four. Examples of a additive systems with closed

,

and open

axes (see

Figure A1a) are the machine painting systems [

53,

58]. The use of an open

here is due to the small movement requirement on the

Z coordinate. Examples of 3D printers with closed axes

,

, and open

(see

Figure A1a) primarily are building 3D printers, e.g., from companies Specavia ATM [

59], Winsun [

60], COBOD [

61], etc. Examples of 3D printers with closed axes

,

, and

are VORON 2.4 [

62] and a custom printer with Core-XYZ kinamtics [

63].

Creating 3D printers with bed fixation is sometimes not a convenient technical solution but rather a forced one. The choice of this configuration for architectural printers can be explained by the fact that we can not move the platform on which the building stands.

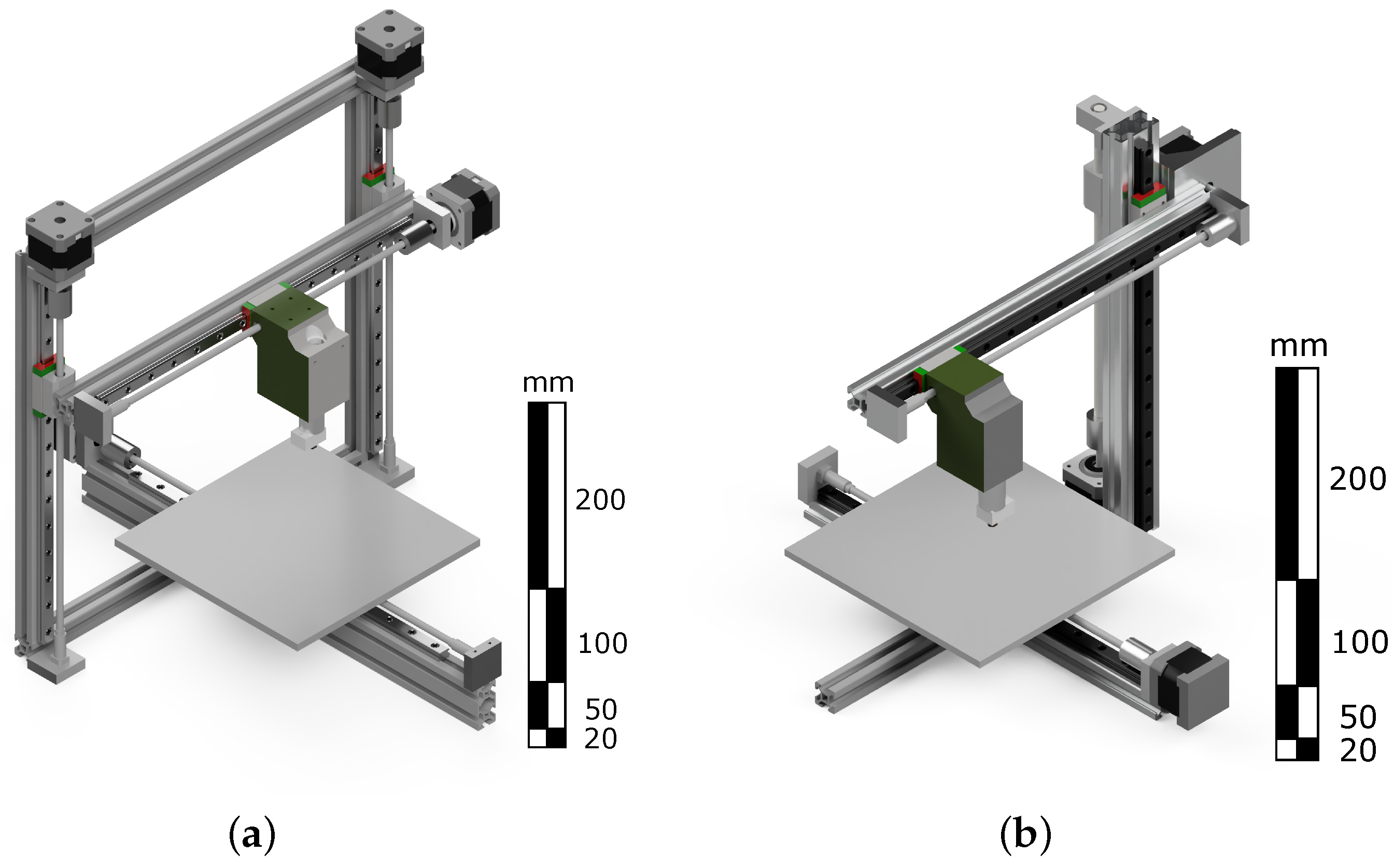

Figure A1.

3D model of 3D printers with fixed axes , , and actuated axes , , (a) with closed , and open axes (b) with closed axes , , .

Figure A1.

3D model of 3D printers with fixed axes , , and actuated axes , , (a) with closed , and open axes (b) with closed axes , , .

Table A3 illustrates two variants used in practice. Both variants are the most popular among all designs. An example of a 3D printer with closed

,

and open

axes (see

Figure A2a) is Anycubic 4max Pro [

51] or Ultimaker 3. An example of a 3D printer with closed

,

,

axes (see

Figure A2b) is the Total Z Anyform 3D printer [

64].These 3D printers differ only in the closed

Z axis of the table, which affects the stiffness of the table. As a rule, 3D printers with a closed

axis are often significantly more expensive, which is due to using more precise ball screw drives instead of a trapezoidal screw and is not fully determined by the printer kinematics.

Figure A2.

3D model of 3D printers with fixed axes , , and actuated axes , , (a) with closed , and open axes (b) with closed , , axes.

Figure A2.

3D model of 3D printers with fixed axes , , and actuated axes , , (a) with closed , and open axes (b) with closed , , axes.

Table A4 shows two variants used in practice. The first variant is the one with closed axes

,

and open

. This variant is trendy in the 3D-printers market due to its cheapness and simplicity of construction. Examples of a this type of 3D printers are Wanhao Duplicator i3 [

65] and Anycubic i3 Mega [

51] (see

Figure A3a). The second variant with open

,

axes and open

(see

Figure A3b) is a simplified version of the previous model, and one of the cheapest variations of Cartesian 3D printers. An example of such a 3D printer is the Wanhao Duplicator i3 Mini 3D printer [

66].

Figure A3.

3D model of 3D printers with fixed axes , , and actuated axes , , (a) with closed axes , and open (b) with open , axes and open .

Figure A3.

3D model of 3D printers with fixed axes , , and actuated axes , , (a) with closed axes , and open (b) with open , axes and open .

Examining the designs from

Table A5, we found only one variant of the existing 3D printer with two actuated printbed axes. It is Felix 3.0 [

67], a 3D printer with open

,

and closed

(see

Figure A4). The manufacturer claims that the 3D printer can develop a fairly high printing speed thanks to this design compared to its counterparts.

Figure A4.

3D model of 3D printer with fixed axes , , and actuated axes , , with closed axis , and open , .

Figure A4.

3D model of 3D printer with fixed axes , , and actuated axes , , with closed axis , and open , .

Three-dimensional printers with the designs shown in

Table A6 and

Table A7 were not found. Probably, such designs are not quite suitable for 3D printing. Moving the printing surface along all three axes can affect print quality since the printbed with the printed detail is much heavier than the printhead. However, it is possible that designs of this type are or will be used for other additive technologies, where complete fixation of the printhead is required due to its size and mass. A recent study published the design of a prototype 3D printer with a fully fixed extruder. However, this printer is not Cartesian and is not commercially available [

68].

Now, make a complete classification scheme of the existing Cartesian 3D printers. It is given in

Table A8. The classification scheme shows each case’s fixed and actuated axes and the closed and open axes for each actuated axis.

Table A8.

Full classification of existing Cartesian 3D printers.

Table A8.

Full classification of existing Cartesian 3D printers.

|

№ | | | | | | |

|---|

| 1 | F | F | | | | F |

| 2 | F | | F | | F | |

| 3 | F | | F | | F | |

| 4 | F | F | F | | | |

| 5 | F | F | F | | | |

| 6 | F | F | | | | F |

| 7 | F | | | | F | F |

Only seven of the 40 possible kinematics designs (8 interchangeable) were identified among existing designs.

Table A8 shows that the actuated axes are often closed for greater structural stiffness. Most of the actuated axes relate to the printhead.

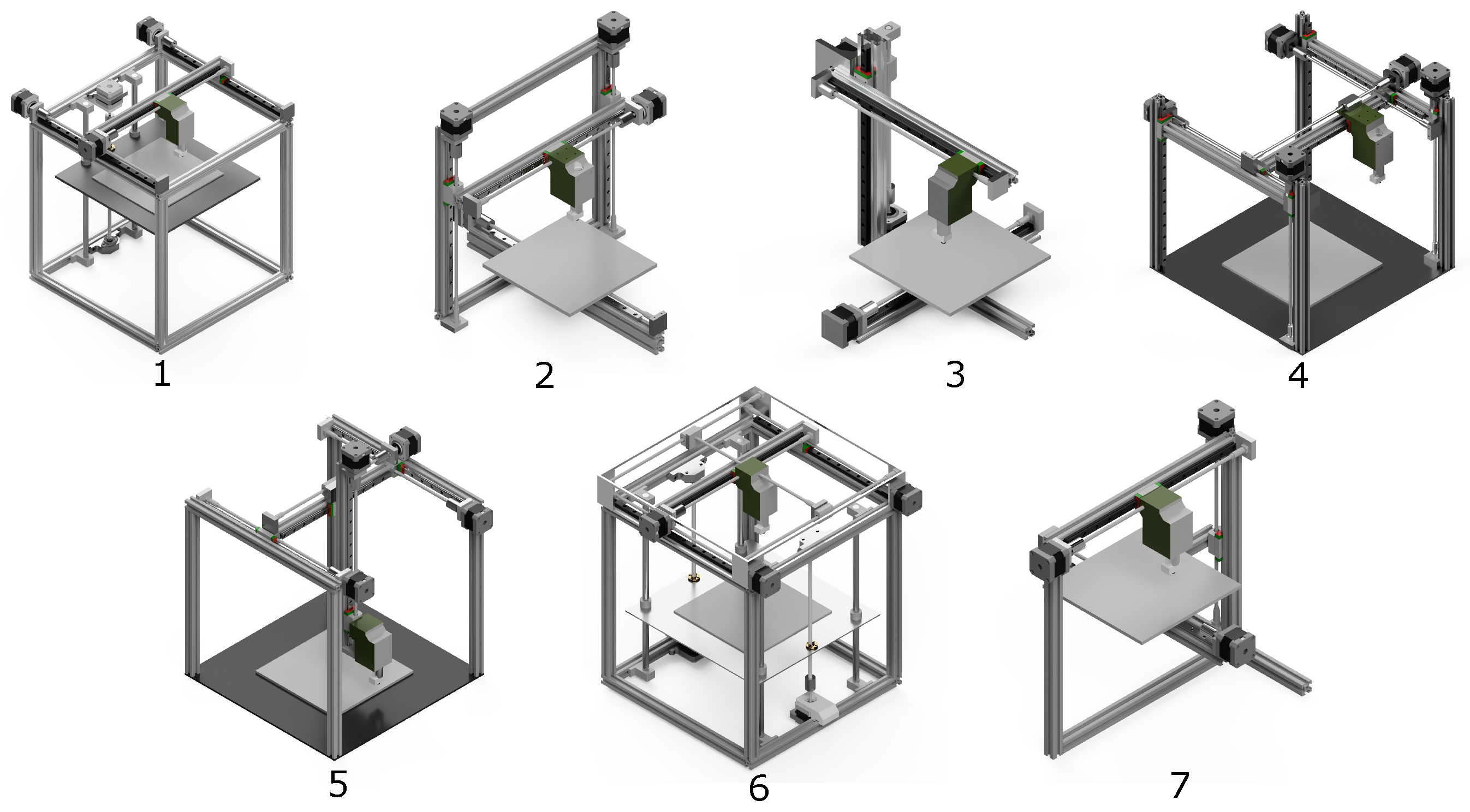

Figure A5.

Fixed axes , , and actuated axes , , . Existing designs are 3 and 4.

Figure A5.

Fixed axes , , and actuated axes , , . Existing designs are 3 and 4.

Figure A6.

Fixed axes , , and actuated axes , , . Existing designs are 3 and 4.

Figure A6.

Fixed axes , , and actuated axes , , . Existing designs are 3 and 4.

Figure A7.

Fixed axes , , and actuated axes , , . Existing designs are 1 and 3.

Figure A7.

Fixed axes , , and actuated axes , , . Existing designs are 1 and 3.

Figure A8.

Fixed axes , , and actuated axes , , . Existing design is 7.

Figure A8.

Fixed axes , , and actuated axes , , . Existing design is 7.

Figure A9.

Fixed axes , , and actuated axes , , .

Figure A9.

Fixed axes , , and actuated axes , , .

Figure A10.

Fixed axes , , and actuated axes , , .

Figure A10.

Fixed axes , , and actuated axes , , .

Figure A11.

Classification scheme for existing Cartesian 3D printer designs, yellow C stands for closed axis, red O stands for open axis.

Figure A11.

Classification scheme for existing Cartesian 3D printer designs, yellow C stands for closed axis, red O stands for open axis.