Microstructural Analysis and Mechanical Characterization of Shape Memory Alloy Ni-Ti-Ag Synthesized by Casting Route

Abstract

:1. Introduction

2. Experimental Procedures

3. Characterization

4. Results

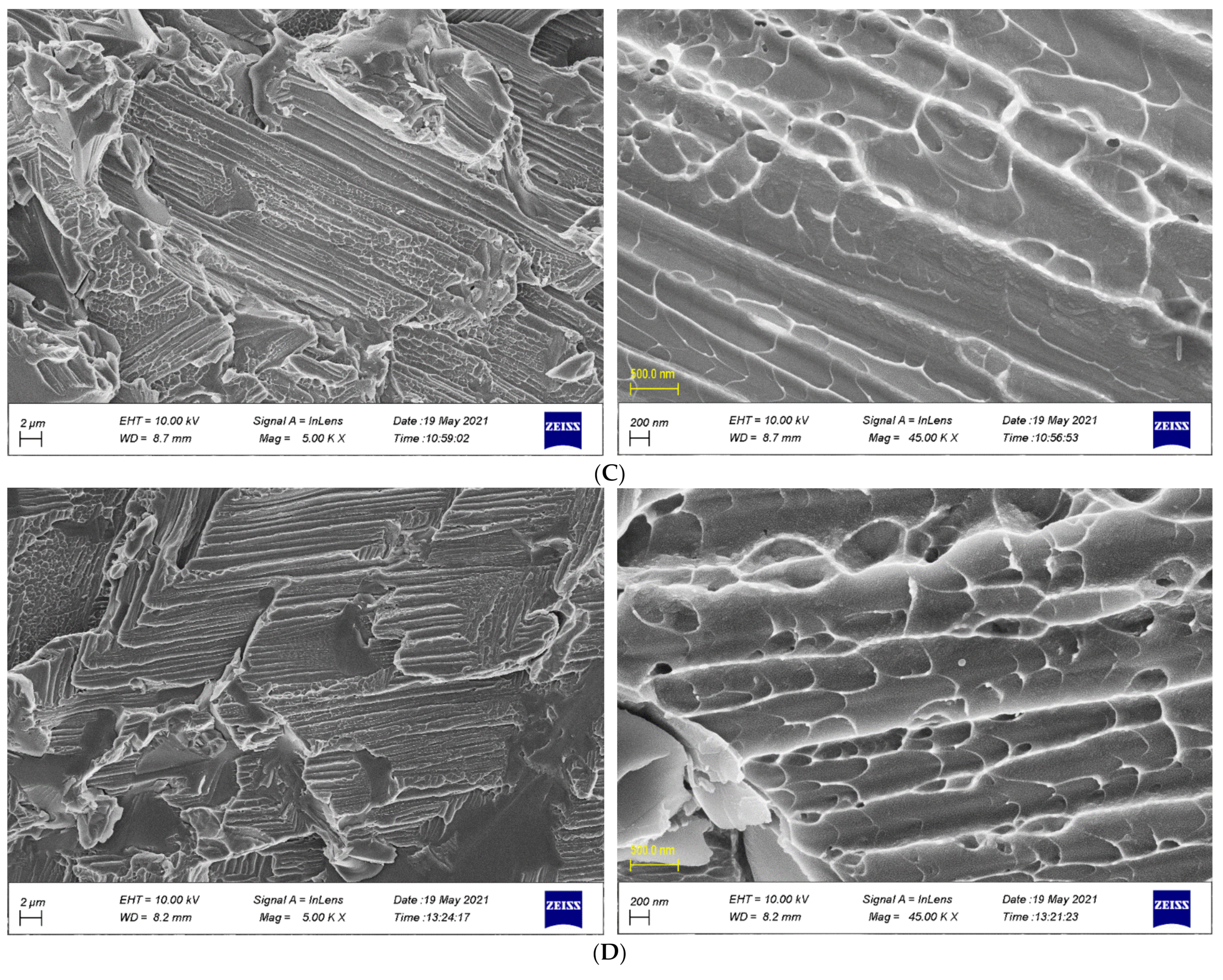

4.1. Microstructure Analysis

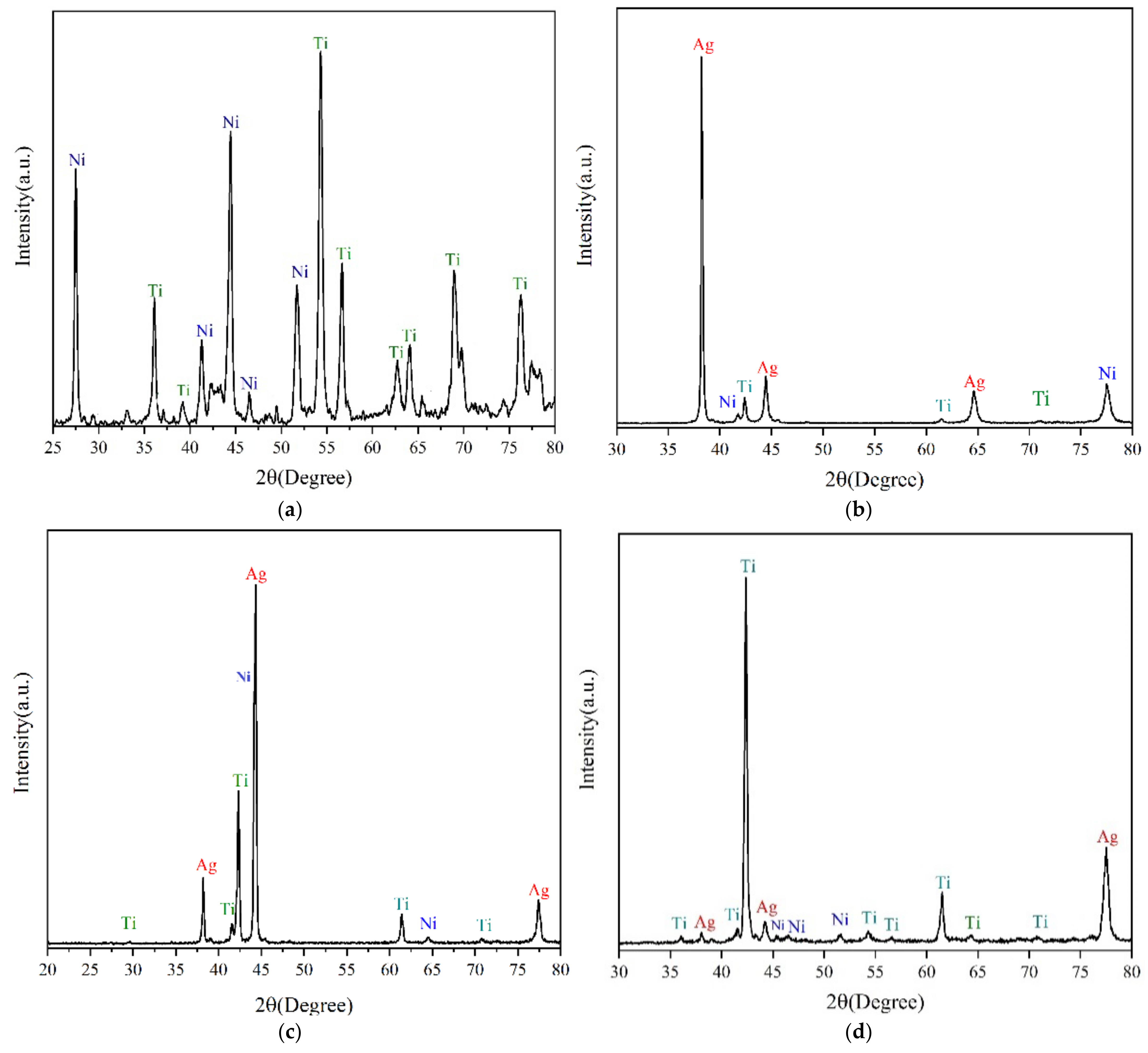

4.2. XRD Results

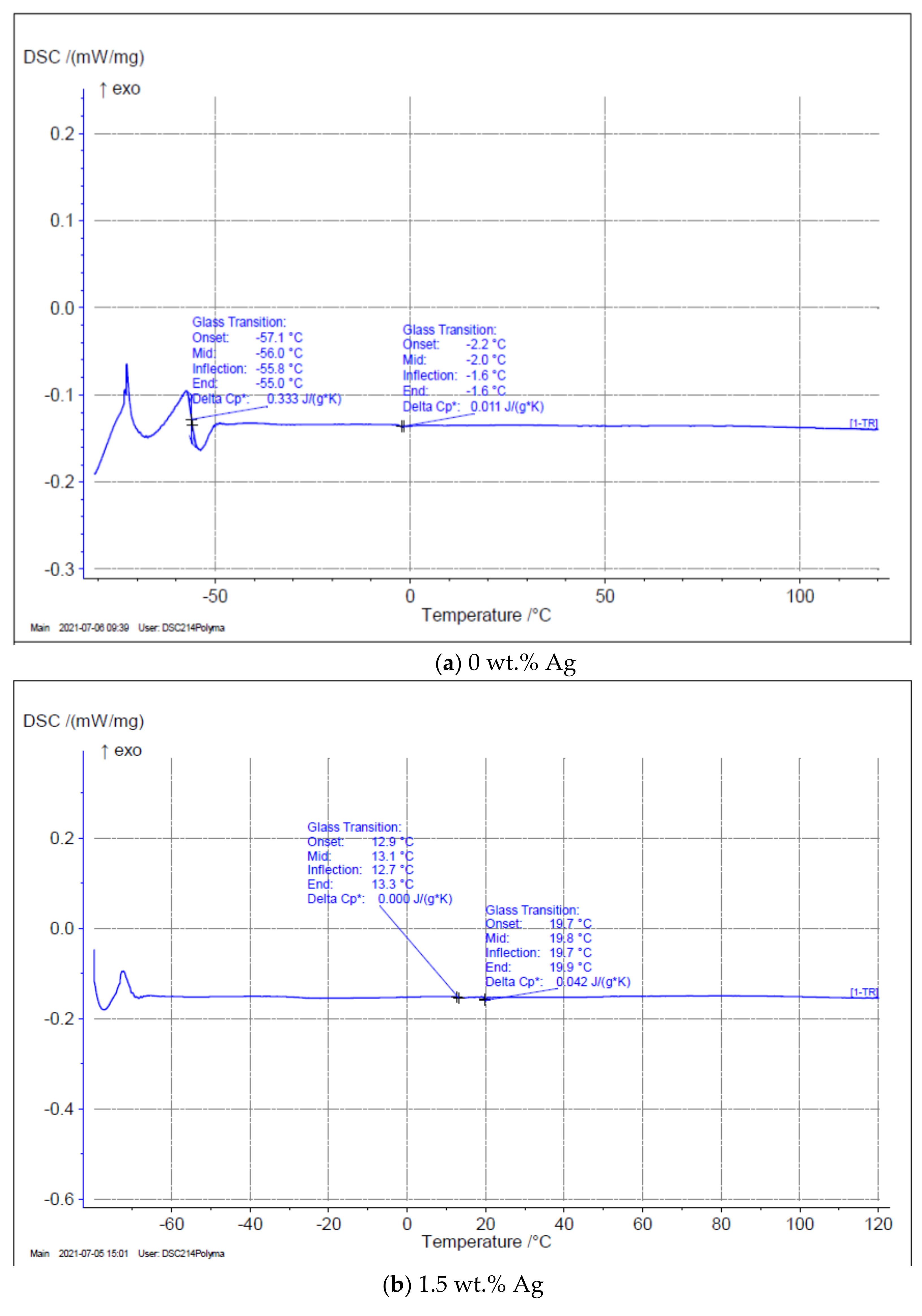

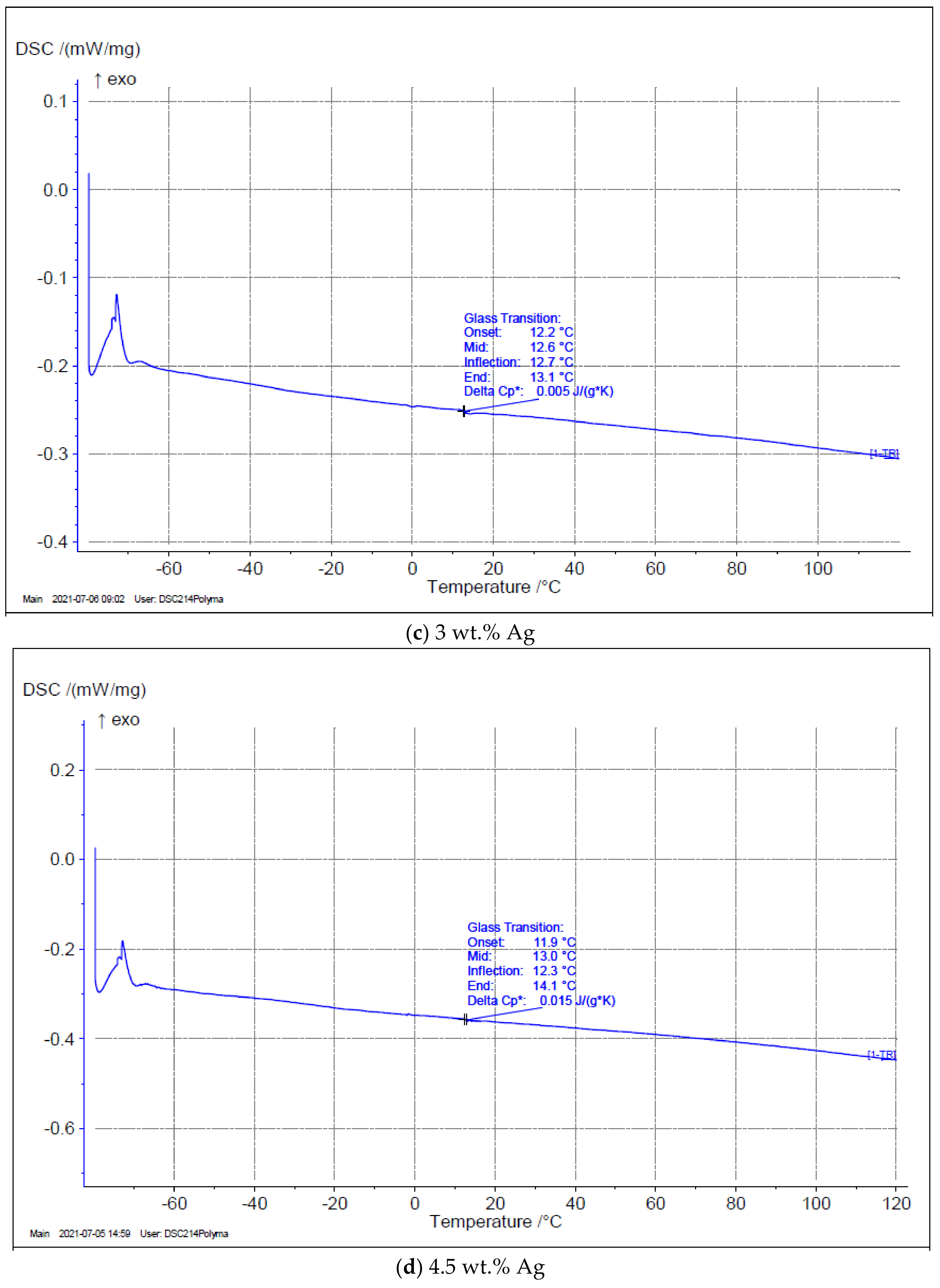

4.3. DSC Results

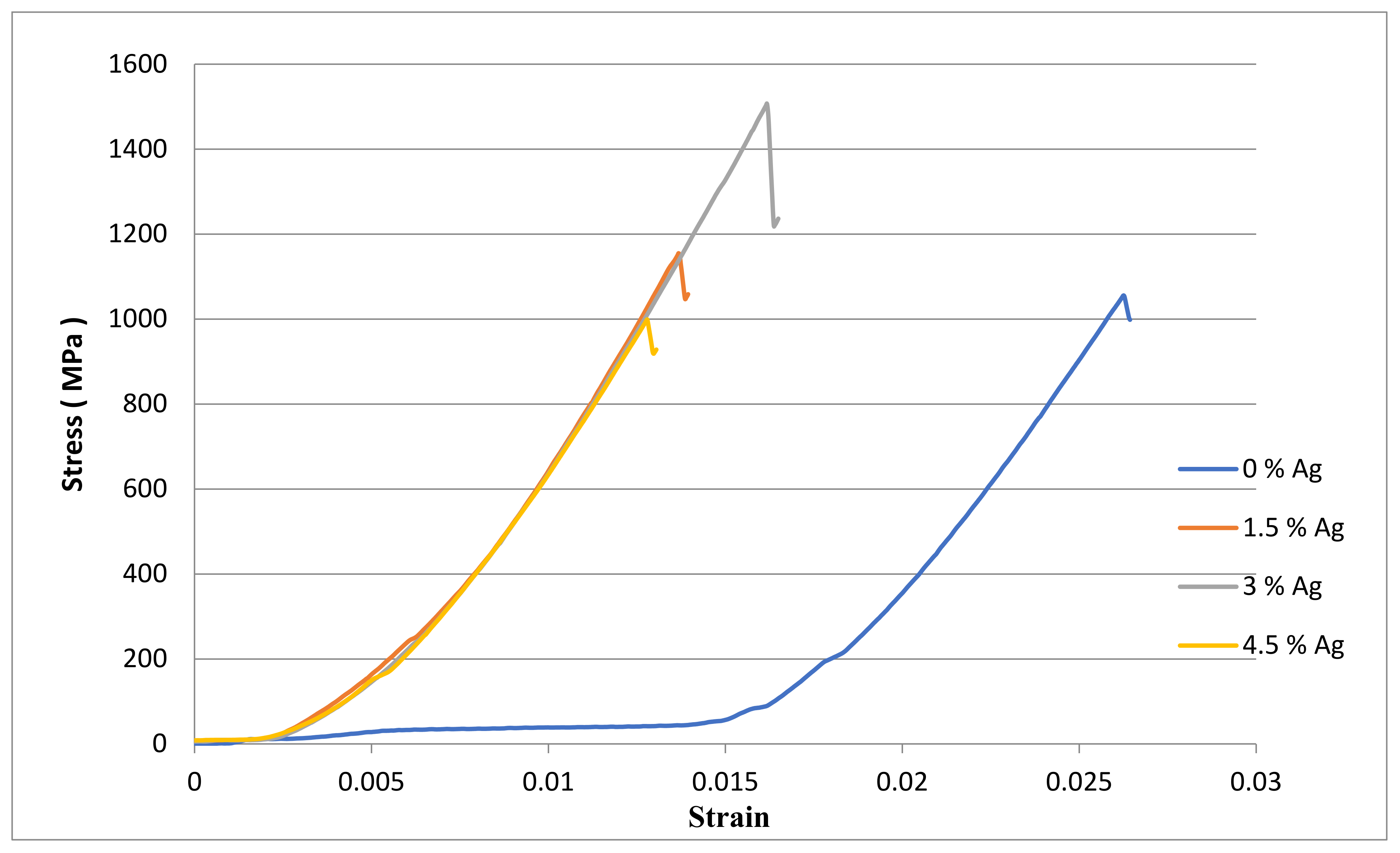

4.4. Compression Results

4.5. Micro-Hardness Results

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Riad, A.; Ben Zohra, M.; Mansouri, M.; Alhamany, A. The shape memory alloy controlled by the sun’s radiation effect. J. Comput. Methods Sci. Eng. 2018, 18, 117–127. [Google Scholar] [CrossRef]

- Wang, J.; Moumni, Z.; Zhang, W.; Zaki, W. A thermomechanically coupled finite deformation constitutive model for shape memory alloys based on Hencky strain. Int. J. Eng. Sci. 2017, 117, 51–77. [Google Scholar] [CrossRef]

- Vyavahare, P.V.; Karthikeyan, C.P. Shape memory effect and performance of a nitinol engine. Aust. J. Eng. Technol. Res. 2017, 2, 109–119. [Google Scholar]

- Wahhab, H.A.A.; Al-Maliki, W.A.K. Application of a Solar Chimney Power Plant to Electrical Generation in Covered Agri-cultural Fields. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Kerbala, Iraq, 2020; p. 012137. [Google Scholar]

- Al-Maliki, W.; Mahmoud, N.; Al-Khafaji, H.; Alobaid, F.; Epple, B. Design and Implementation of the Solar Field and Thermal Storage System Controllers for a Parabolic Trough Solar Power Plant. Appl. Sci. 2021, 11, 6155. [Google Scholar] [CrossRef]

- Sanaani, Y.T.; Alshorman, A.; Alshurman, K. A Novel Design of Flexure Based, Shape Memory Alloy Actuated Microgripper. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Tampa, FL, USA, 3–9 November 2017; American Society of Mechanical Engineers: Tampa, FL, USA, 2017; Volume 58370, p. V04AT05A023. [Google Scholar]

- Copaci, D.; Moreno, L.; Blanco, D. Two-Stage Shape Memory Alloy Identification Based on the Hammerstein–Wiener Model. Front. Robot. AI 2019, 6, 83. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shelyakov, A.; Sitnikov, N.; Borodako, K.; Koledov, V.; Khabibullina, I.; von Gratowski, S. Design of microgrippers based on amorphous-crystalline TiNiCu alloy with two-way shape memory. J. Micro-Bio Robot. 2020, 16, 43–51. [Google Scholar] [CrossRef]

- Hussain, S.; Pandey, A.; Dasgupta, R. Designed polycrystalline ultra-high ductile boron doped Cu–Al–Ni based shape memory alloy. Mater. Lett. 2019, 240, 157–160. [Google Scholar] [CrossRef]

- Al-Maliki, W.A.K.; Al-Hasnawi, A.G.T.; Wahhab, H.A.A.; Alobaid, F.; Epple, B. A Comparison Study on the Improved Operation Strategy for a Parabolic trough Solar Power Plant in Spain. Appl. Sci. 2021, 11, 9576. [Google Scholar] [CrossRef]

- Álvares da Silva, G.H.; Otubo, J. Designing NiTiAg Shape Memory Alloys by Vacuum Arc Remelting: First Practical Insights on Melting and Casting. Shape Mem. Superelast. 2018, 4, 402–410. [Google Scholar] [CrossRef]

- Zeng, Z.; Oliveira, J.P.; Ao, S.; Zhang, W.; Cui, J.; Yan, S.; Peng, B. Fabrication and characterization of a novel bionic manipulator using a laser processed NiTi shape memory alloy. Opt. Laser Technol. 2020, 122, 105876. [Google Scholar] [CrossRef]

- Khalil-Allafi, J.; Dlouhy, A.; Eggeler, G. Ni4Ti3-precipitation during aging of NiTi shape memory alloys and its influence on martensitic phase transformations. Acta. Mater. 2002, 50, 793. [Google Scholar] [CrossRef]

- Zheng, Y.; Zhang, B.; Wang, B.; Wang, Y.; Li, L.; Yang, Q.; Cui, L. Introduction of antibacterial function into biomedical TiNi shape memory alloy by the addition of element Ag. Acta. Biomater. 2011, 7, 2758–2767. [Google Scholar] [CrossRef]

- Baigonakova, G.; Marchenko, E.; Chekalkin, T.; Kang, J.-H.; Weiss, S.; Obrosov, A. Influence of Silver Addition on Structure, Martensite Transformations and Mechanical Properties of TiNi–Ag Alloy Wires for Biomedical Application. Materials 2020, 13, 4721. [Google Scholar] [CrossRef] [PubMed]

| Sample | 0% Ag | 1.5% Ag | 3% Ag | 4.5% Ag | |

|---|---|---|---|---|---|

| Test | |||||

| Compression stress (MPa) | 1055 | 1155 | 1507 | 1000 | |

| Hardness (HV) | 508 | 468 | 465 | 463 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salman, K.D.; Al-Maliki, W.A.K.; Alobaid, F.; Epple, B. Microstructural Analysis and Mechanical Characterization of Shape Memory Alloy Ni-Ti-Ag Synthesized by Casting Route. Appl. Sci. 2022, 12, 4639. https://doi.org/10.3390/app12094639

Salman KD, Al-Maliki WAK, Alobaid F, Epple B. Microstructural Analysis and Mechanical Characterization of Shape Memory Alloy Ni-Ti-Ag Synthesized by Casting Route. Applied Sciences. 2022; 12(9):4639. https://doi.org/10.3390/app12094639

Chicago/Turabian StyleSalman, Khansaa Dawood, Wisam Abed Kattea Al-Maliki, Falah Alobaid, and Bernd Epple. 2022. "Microstructural Analysis and Mechanical Characterization of Shape Memory Alloy Ni-Ti-Ag Synthesized by Casting Route" Applied Sciences 12, no. 9: 4639. https://doi.org/10.3390/app12094639

APA StyleSalman, K. D., Al-Maliki, W. A. K., Alobaid, F., & Epple, B. (2022). Microstructural Analysis and Mechanical Characterization of Shape Memory Alloy Ni-Ti-Ag Synthesized by Casting Route. Applied Sciences, 12(9), 4639. https://doi.org/10.3390/app12094639