Incorporating Artificial Intelligence Technology in Smart Greenhouses: Current State of the Art

Abstract

:1. Introduction

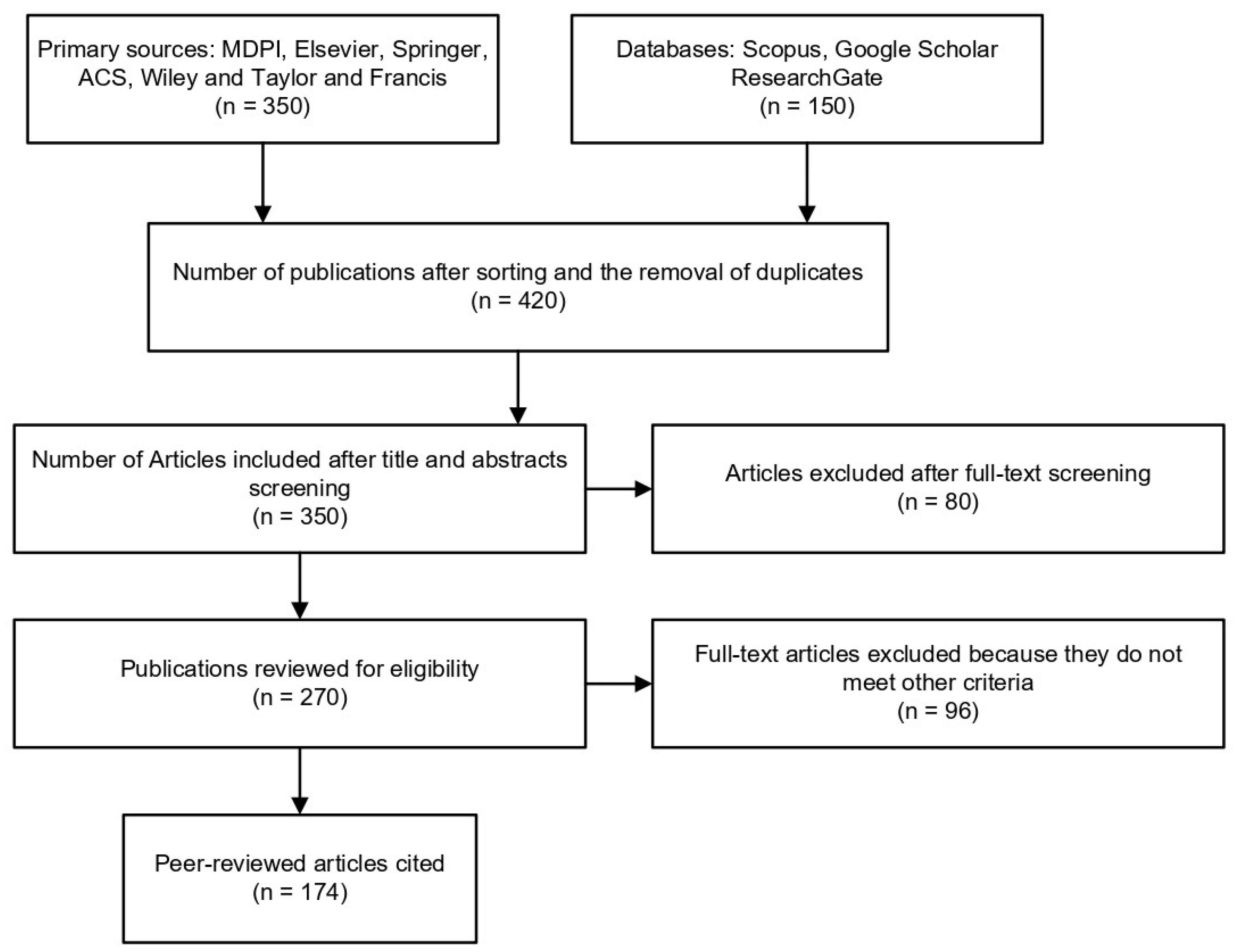

Method for Systematic Review

2. Artificial Intelligence Technologies for Smart Greenhouses

2.1. Historical Background of AI and ICTs in Agriculture

2.2. Current AI Technologies for Agriculture

2.2.1. Cost Benefits of AI Technologies for Agriculture

2.2.2. Water and Fertilizer Use Efficiency and Crop Yields with AI Systems

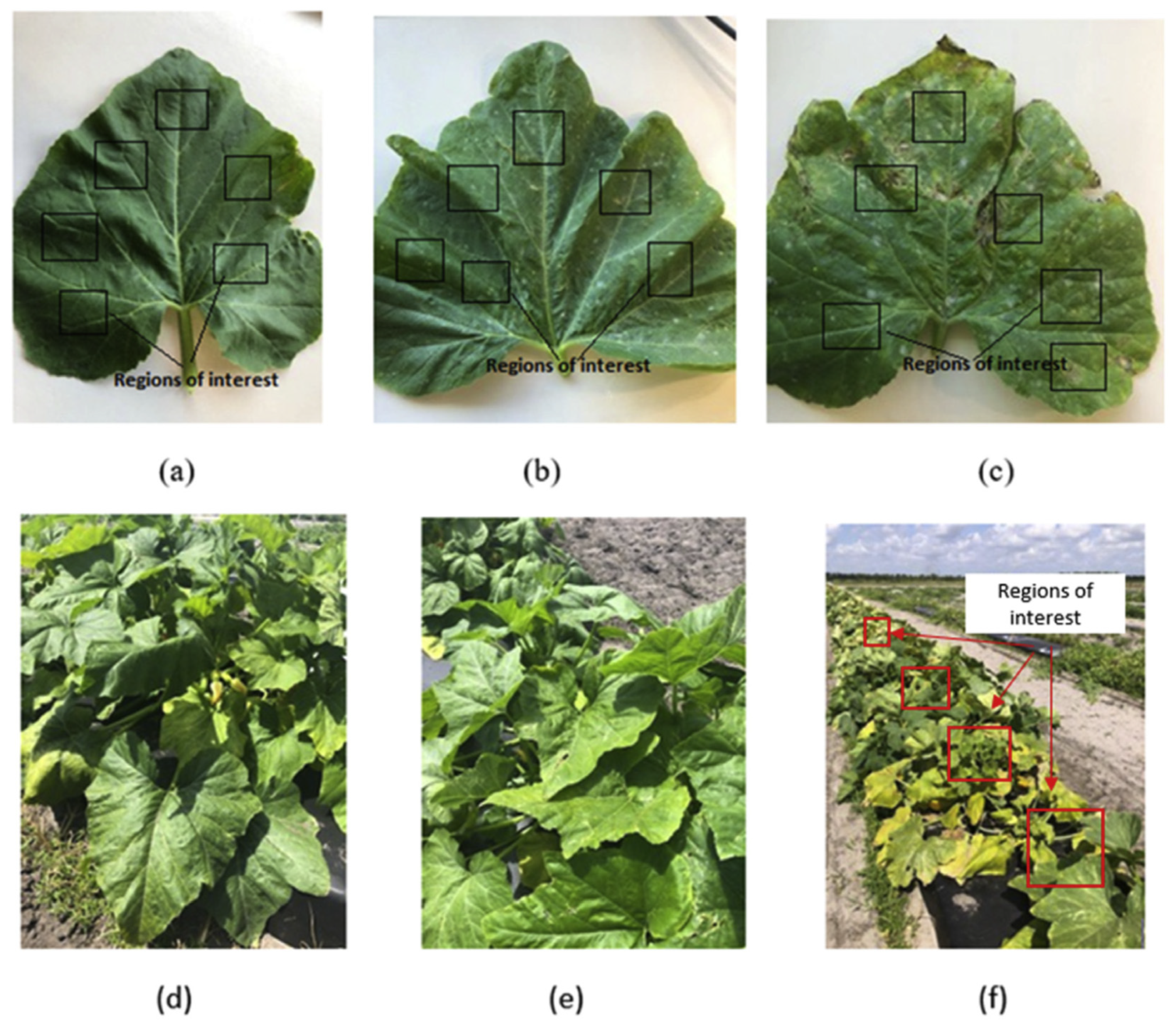

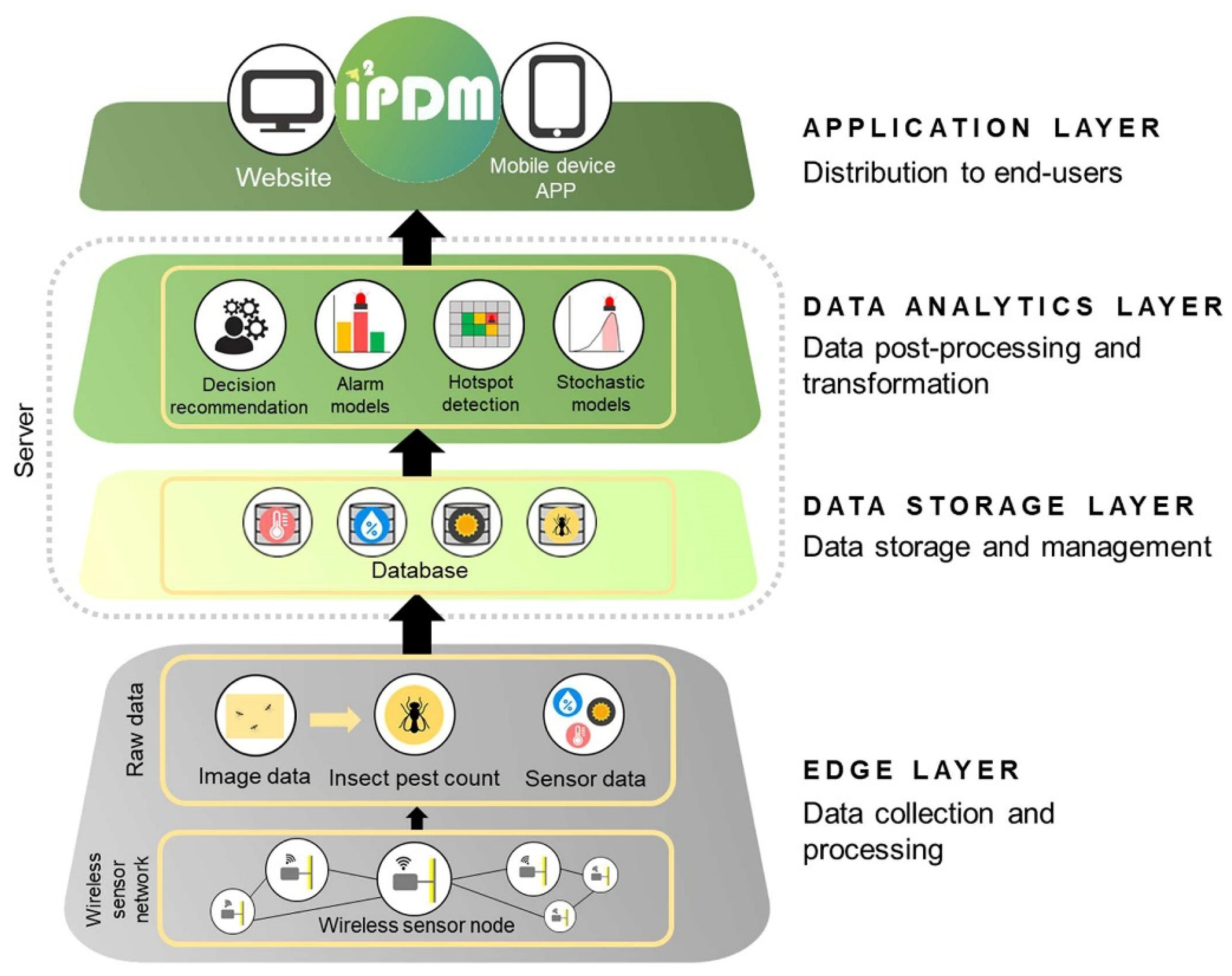

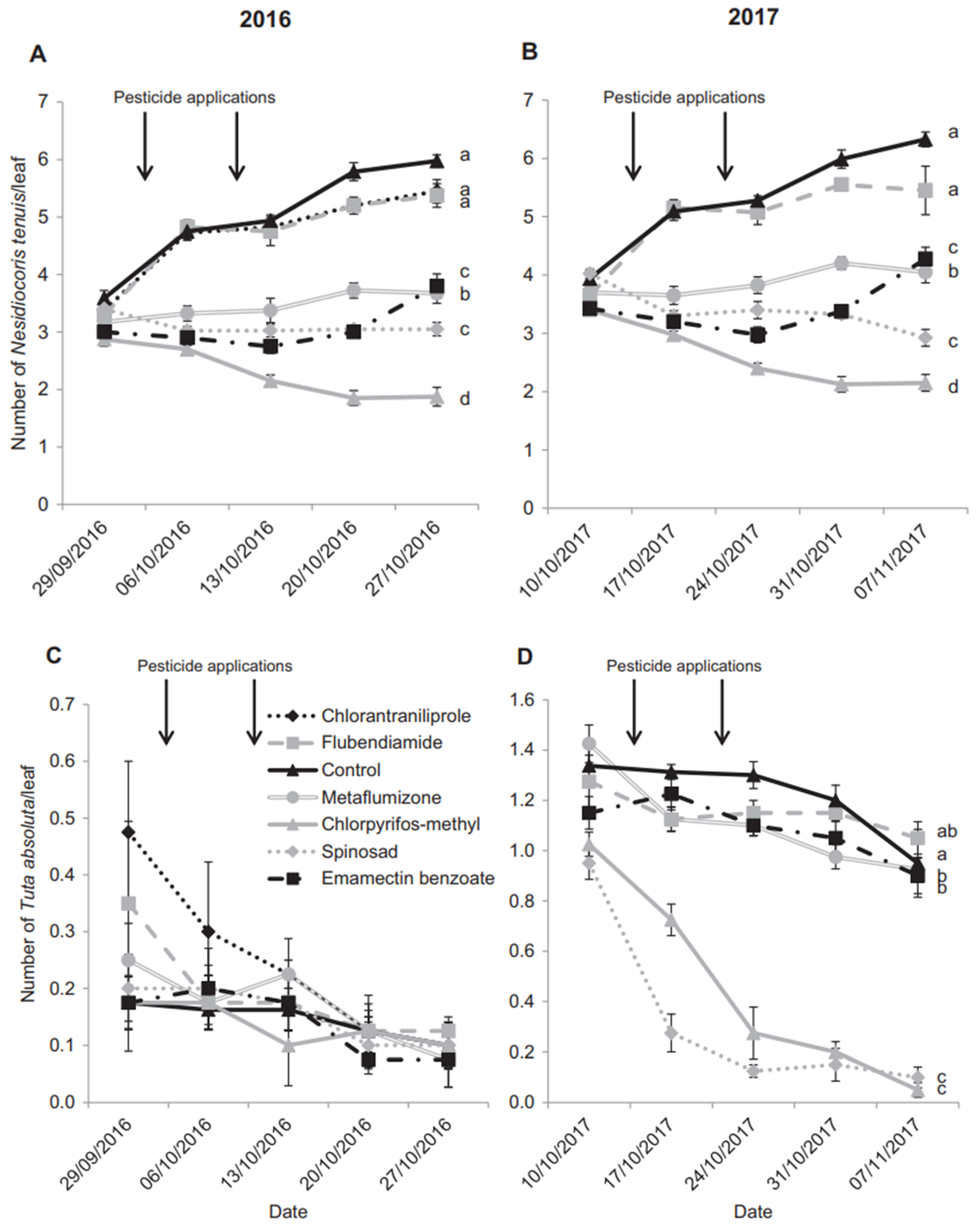

2.3. AI Systems for Integrated Pest Management

2.4. Robotics and Algorithms for Precision Agriculture and Smart Greenhouses

2.4.1. Role of AI Technologies and Biological Pesticide Compounds in IPM

2.4.2. Commercial Development of Robotic Systems for Smart Agriculture (Inhouse and Outdoors)

3. Digital AI Models for Energy Management in Greenhouses

3.1. Energy Demand in Smart Greenhouses and Energy Optimization Algorithms

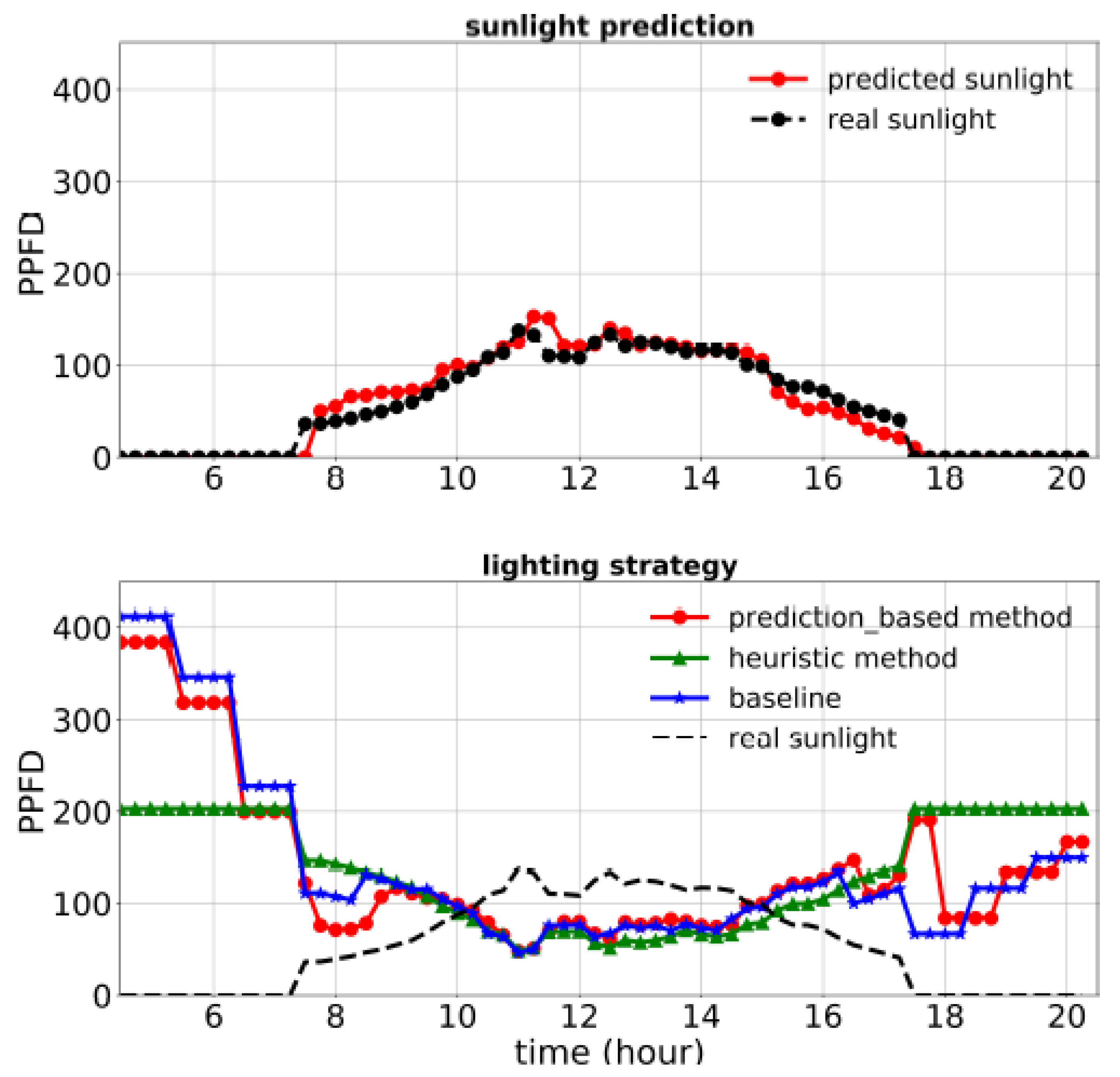

3.2. Alternative Energy Saving Measures—LoRa Transmission, PCOA-Lighting Management, PCMs, and LEDs

4. Barriers to Incorporating Artificial Intelligence Technology in Smart Greenhouses

4.1. Training and Test Accuracy of AI Systems in Smart Greenhouses and Precision Agriculture

4.2. Impact of Demographics and Socioeconomic Factors on AI Technology Adoption in Agriculture

4.3. Sensor Signal Failure and Communication Barriers

5. Future Perspectives

6. Conclusions

Funding

Conflicts of Interest

Abbreviations

| AI | Artificial intelligence |

| AIAGS | Artificial Intelligence Automated Greenhouse System |

| ANFIS | Adaptive neuro-fuzzy inference system |

| ANN | Artificial neural network |

| CEA | Controlled environment agriculture |

| CFD | Computational fluid dynamics |

| CNN | Convolutional Neural Network |

| DABACA | Dynamic Artificial Bee-Ant Colon Algorithm |

| DSS | Decision support systems |

| EA | Evolutionary Algorithm |

| ERNN | Elman Recurrent Neural Network |

| GA | Genetic Algorithm |

| GPS | Geographic positioning systems |

| GVA | Gross value added |

| IoT | Internet of things |

| IPM | Integrated pest management |

| ITU | International Telecommunication Union |

| LIDAR | Light imaging, detection, and ranging |

| LSTM | Long short-term memory (LSTM) networks |

| MAE | Mean of absolute value of errors |

| ML | Machine learning |

| MPC | Model predictive control |

| PBM | Prediction-based method |

| PID | Proportional-integral-derivative |

| PPFD | Photosynthetic photon flux density |

| PSO | Particle Swarm Optimization |

| RFID | Radiofrequency identification |

| RNN | Recurrent neural network |

| RSCS | Remote Sensing Assisted Control System |

| RSME | Relative standard mean error |

| S-DGPS | Satellite-differential geographic positioning systems |

| SVM | Support-vector machines |

| UAV | Unmanned aerial vehicle |

| VAR | Variable rate application |

| WSAN | Wireless sensors and actuators networks |

| WSN | Wireless sensor network |

References

- Ruan, J.; Hu, X.; Huo, X.; Shi, Y.; Chan, F.T.S.; Wang, X.; Manogaran, G.; Mastorakis, G.; Mavromoustakis, C.X.; Zhao, X. An IoT-based E-business model of intelligent vegetable greenhouses and its key operations management issues. Neural Comput. Appl. 2020, 32, 15341–15356. [Google Scholar] [CrossRef]

- Ewees, A.A.; Sahlol, A.T. Bio-Inspired Optimization Algorithms for Improving Artificial Neural Networks: A Case Study on Handwritten Letter Recognition. In Computational Linguistics, Speech and Image Processing for Arabic Language; World Scientific: Singapore, 2017; Volume 4, pp. 249–266. [Google Scholar]

- Jellason, N.P.; Robinson, E.J.Z.; Ogbaga, C.C. Agriculture 4.0: Is sub-Saharan Africa ready? Appl. Sci. 2021, 11, 5750. [Google Scholar] [CrossRef]

- European Institute of Innovation and Technology (EIT). Emerging AI and Data Driven Business Models in Europe; European Institute of Innovation and Technology (EIT): Budapest, Hungary, 2021; pp. 1–65. [Google Scholar]

- Munoz, J.M. AI in Agriculture: Is the Grass Greener? California Management Review. 2020. Available online: https://cmr.berkeley.edu/2020/03/ai-agriculture/ (accessed on 25 June 2022).

- Karnawat, M.; Trivedi, S.K.; Nagar, R. Future of AI in Agriculture. Biot. Res. Today 2020, 2, 927–929. [Google Scholar]

- Cuffaro, N.; Prota, L.; Bertini, R. Are Large-Scale Land Acquisitions in Africa Pro-development? A Network Analysis of FDI in Land and Agro-industry BT—The Palgrave Handbook of Africa’s Economic Sectors. In The Palgrave Handbook of Africa’s Economic Sectors; Wamboye, E.F., Fayissa, B., Eds.; Springer International Publishing: Cham, Switzerland, 2022; pp. 87–116. [Google Scholar]

- Zha, J. Artificial Intelligence in Agriculture. J. Phys. Conf. Ser. 2020, 22, 1693. [Google Scholar] [CrossRef]

- Cama-pinto, D.; Holgado-terriza, J.A.; Damas-hermoso, M.; Francisco, G.; Cama-pinto, A. Radio Wave Attenuation Measurement System Based on RSSI for Precision Agriculture: Application to Tomato Greenhouses. Inventions 2021, 6, 66. [Google Scholar] [CrossRef]

- Iddio, E.; Wang, L.; Thomas, Y.; McMorrow, G.; Denzer, A. Energy efficient operation and modeling for greenhouses: A literature review. Renew. Sustain. Energy Rev. 2020, 117, 109480. [Google Scholar] [CrossRef]

- Afzali, S.; Mosharafian, S.; van Iersel, M.W.; Velni, J.M. Development and implementation of an IoT-enabled optimal and predictive lighting control strategy in greenhouses. Plants 2021, 10, 2652. [Google Scholar] [CrossRef]

- Haque, M.A.; Haque, S.; Sonal, D.; Kumar, K.; Shakeb, E. Security Enhancement for IoT Enabled Agriculture. Mater. Today Proc. 2021. [Google Scholar] [CrossRef]

- Senavirathne, B.; Gunerathne, C.; Lanka, S.; Lanka, S. Greenhouse Automation with Artificial Intelligence and Industry 4.0 Integration. In Proceedings of the 12th International Research Conference 2019, KDU, Ratmalana, Sri Lanka, 11–12 September 2020; pp. 487–494. [Google Scholar]

- Karar, M.; Alsunaydi, F.; Albusaymi, S.; Alotaibi, S. A new mobile application of agricultural pests recognition using deep learning in cloud computing system. Alexandria Eng. J. 2021, 60, 4423–4432. [Google Scholar] [CrossRef]

- Lakshmi, V.; Corbett, J. How Artificial Intelligence Improves Agricultural Productivity and Sustainability: A Global Thematic Analysis. Int. Conf. Syst. Sci. 2020, 3, 5202–5211. [Google Scholar]

- Kollia, I.; Stevenson, J.; Kollias, S. AI-Enabled Efficient and Safe Food Supply Chain. Electronics 2021, 10, 1223. [Google Scholar] [CrossRef]

- Zhang, S.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D. Methodologies of control strategies for improving energy ef fi ciency in agricultural greenhouses. J. Clean. Prod. 2020, 274, 122695. [Google Scholar] [CrossRef]

- Cao, X.; Yao, Y.; Li, L.; Zhang, W.; An, Z.; Zhang, Z.; Xiao, L.; Guo, S.; Cao, X.; Wu, M.; et al. iGrow: A Smart Agriculture Solution to Autonomous Greenhouse Control. Artif. Intell. 2022, 36, 11837–11845. [Google Scholar] [CrossRef]

- Panaligan, N.A.P.; Aringo, M.Q.; Ella, V.B. Assessment of potential for adoption of wireless sensor network technology for irrigation water management of high value crops in the Philippines. IOP Conf. Ser. Earth Environ. Sci. 2022, 1038, 012027. [Google Scholar] [CrossRef]

- Rokade, A.; Singh, M. Analysis of Precise Green House Management System using Machine Learning based Internet of Things (IoT) for Smart Farming. In Proceedings of the 2021 2nd International Conference on Smart Electronics and Communication (ICOSEC), Trichy, India, 7–9 October 2021; pp. 21–28. [Google Scholar]

- Bekiaris, I.; Leonidis, A.; Korozi, M.; Stratakis, C.; Zidianakis, E.; Doxastaki, M.; Stephanidis, C. GRETA: Pervasive and AR Interfaces for Controlling Intelligent Greenhouses. In Proceedings of the 2021 17th International Conference on Intelligent Environments (IE), Dubai, United Arab Emirates, 21–24 June 2021. [Google Scholar]

- Zhang, W.; Cao, Y.; Yao, Y.; An, Z. Robust Model-based Reinforcement Learning for Autonomous Greenhouse Control. In Proceedings of the 13th Asian Conference on Machine Learning, Virtually, 17–19 November 2021; Volume 157, pp. 1–16. [Google Scholar]

- Maraveas, C.; Piromalis, D.; Arvanitis, K.G.; Bartzanas, T.; Loukatos, D. Applications of IoT for optimized greenhouse environment and resources management. Comput. Electron. Agric. 2022, 198, 106993. [Google Scholar] [CrossRef]

- Gołasa, P.; Wysokiński, M.; Bieńkowska-Gołasa, W.; Gradziuk, P.; Golonko, M.; Gradziuk, B.; Siedlecka, A.; Gromada, A. Sources of Greenhouse Gas Emissions in Agriculture, with Particular Emphasis on Emissions from Energy Used. Energies 2021, 14, 3784. [Google Scholar] [CrossRef]

- UNFCC. Climate Change Is an Increasing Threat to Africa. 2020. Available online: https://unfccc.int/news/climate-change-is-an-increasing-threat-to-africa (accessed on 26 July 2022).

- European Commission—Joint Research Centre. World Atlas of Desertification—Rethinking Land Degradation and Sustainable Management. 2020. Available online: https://reliefweb.int/report/world/world-atlas-desertification-rethinking-land-degradation-and-sustainable-management (accessed on 26 July 2022).

- Burrell, A.L.; Evans, J.P.; de Kauwe, M.G. Anthropogenic climate change has driven over 5 million km2 of drylands towards desertification. Nat. Commun. 2020, 11, 3853. [Google Scholar] [CrossRef]

- European Commission. Desertification and Agriculture; European Commission: Brussels, Belgium, 2020; pp. 1–12. [Google Scholar]

- Mikhailov, D.; Fedorov, V.; Mitrokhin, M.; Pronichkin, A.K.; Soytong, K. Using artificial intelligence systems for intensive safe cultivation of crops-short communication. Int. J. Agric. Technol. 2021, 17, 987–990. [Google Scholar]

- World Economic Forum. Artificial Intelligence for Agriculture Innovation; World Economic Forum: Cologny, Switzerland, 2021; pp. 1–32. [Google Scholar]

- Linaza, M.; Posada, J.; Bund, J.; Eisert, P.; Quartulli, M.; Döllner, J.; Pagani, A.; Olaizola, I.G.; Barriguinha, A.; Moysiadis, T.; et al. Data-Driven Artificial Intelligence Applications for Sustainable Precision Agriculture. Agronomy 2021, 11, 1227. [Google Scholar] [CrossRef]

- Amudha, T.; Thilagavathi, N.; Sangeetha, A. A systematic study on bio-inspired frameworks for fertilizer optimization. Int. J. Agric. Technol. 2021, 17, 1287–1304. [Google Scholar]

- Rao, N.S.; Soam, S.K.; Rao, C.S. Applications of Artificial Intelligence in Precision Agriculture. Gravida Rev. J. 2021, 7, 174–177. [Google Scholar]

- Rosenblatt, F. The Perceptron: A Probabilistic Model for Information Storage and Organization in the Brain. Psychol. Rev. 1958, 65, 386–408. [Google Scholar] [CrossRef] [Green Version]

- Asteris, P.G.; Gavriilaki, E.; Touloumenidou, T.; Koravou, E.-E.; Koutra, M.; Papayanni, P.G.; Pouleres, A.; Karali, V.; Lemonis, M.E.; Mamou, A.; et al. Genetic prediction of ICU hospitalization and mortality in COVID-19 patients using artificial neural networks. J. Cell. Mol. Med. 2022, 26, 1445–1455. [Google Scholar] [CrossRef] [PubMed]

- Rahimi, I.; Gandomi, A.H.; Asteris, P.G.; Chen, F. Analysis and Prediction of COVID-19 Using SIR, SEIQR, and Machine Learning Models: Australia, Italy, and UK Cases. Information 2021, 12, 109. [Google Scholar] [CrossRef]

- Mahanty, C.; Kumar, R.; Asteris, P.G.; Gandomi, A.H. COVID-19 Patient Detection Based on Fusion of Transfer Learning and Fuzzy Ensemble Models Using CXR Images. Appl. Sci. 2021, 11, 11423. [Google Scholar] [CrossRef]

- Gavriilaki, E.; Asteris, P.G.; Touloumenidou, T.; Koravou, E.-E.; Koutra, M.; Papayanni, P.G.; Karali, V.; Papalexandri, A.; Varelas, C.; Chatzopoulou, F.; et al. Genetic justification of severe COVID-19 using a rigorous algorithm. Clin. Immunol. 2021, 226, 108726. [Google Scholar] [CrossRef] [PubMed]

- Asteris, P.G.; Douvika, M.G.; Karamani, C.A.; Skentou, A.D.; Chlichlia, K.; Cavaleri, L.; Daras, T.; Armaghani, D.J.; Zaoutis, T.E. A Novel Heuristic Algorithm for the Modeling and Risk Assessment of the COVID-19 Pandemic Phenomenon. Comput. Model. Eng. Sci. 2020, 125, 815–828. [Google Scholar] [CrossRef]

- Litjens, G.; Sánchez, C.I.; Timofeeva, N.; Hermsen, M.; Nagtegaal, I.; Kovacs, I.; Hulsbergen-van de Kaa, C.; Bult, P.; Van Ginneken, B.; Van Der Laak, J. Deep learning as a tool for increased accuracy and efficiency of histopathological diagnosis. Sci. Rep. 2016, 6, 26286. [Google Scholar] [CrossRef] [Green Version]

- Tu, J.V. Advantages and disadvantages of using artificial neural networks versus logistic regression for predicting medical outcomes. J. Clin. Epidemiol. 1996, 49, 1225–1231. [Google Scholar] [CrossRef]

- Kononenko, I. Machine learning for medical diagnosis: History, state of the art and perspective. Artif. Intell. Med. 2001, 23, 89–109. [Google Scholar] [CrossRef] [Green Version]

- Kalogirou, S.A. Applications of artificial neural-networks for energy systems. Appl. Energy 2000, 67, 17–35. [Google Scholar] [CrossRef]

- Gandomi, A.H.; Yang, X.-S.; Alavi, A.H. Mixed variable structural optimization using Firefly Algorithm. Comput. Struct. 2011, 89, 2325–2336. [Google Scholar] [CrossRef]

- Huang, J.; Asteris, P.G.; Pasha, S.M.K.; Mohammed, A.S.; Hasanipanah, M. A new auto-tuning model for predicting the rock fragmentation: A cat swarm optimization algorithm. Eng. Comput. 2022, 38, 2209–2220. [Google Scholar] [CrossRef]

- Yang, X.; Gandomi, A.H. Bat algorithm: A novel approach for global engineering optimization. Eng. Comput. 2012, 29, 464–483. [Google Scholar] [CrossRef] [Green Version]

- Mirjalili, S.; Mirjalili, S.M.; Lewis, A. Grey Wolf Optimizer. Adv. Eng. Softw. 2014, 69, 46–61. [Google Scholar] [CrossRef]

- Mirjalili, S.; Gandomi, A.H.; Mirjalili, S.Z.; Saremi, S.; Faris, H.; Mirjalili, S.M. Salp Swarm Algorithm: A bio-inspired optimizer for engineering design problems. Adv. Eng. Softw. 2017, 114, 163–191. [Google Scholar] [CrossRef]

- Cavaleri, L.; Chatzarakis, G.E.; Di Trapani, F.; Douvika, M.G.; Roinos, K.; Vaxevanidis, N.M.; Asteris, P.G. Modeling of surface roughness in electro-discharge machining using artificial neural networks. Adv. Mater. Res. 2017, 6, 169–184. [Google Scholar]

- Psyllaki, P.; Stamatiou, K.; Iliadis, I.; Mourlas, A. Surface treatment of tool steels against galling failure. MATEC Web Conf. 2018, 188, 1–8. [Google Scholar] [CrossRef]

- Lu, S.; Koopialipoor, M.; Asteris, P.G.; Bahri, M.; Armaghani, D.J. A Novel Feature Selection Approach Based on Tree Models for Evaluating the Punching Shear Capacity of Steel Fiber-Reinforced Concrete Flat Slabs. Materials 2020, 13, 3902. [Google Scholar] [CrossRef]

- Harandizadeh, H.; Armaghani, D.J.; Asteris, P.G.; Gandomi, A.H. TBM Performance Prediction Developing a Hybrid ANFIS-PNN Predictive Model Optimized by Imperialism Competitive Algorithm. Neural Comput. Appl. 2021, 33, 16149–16179. [Google Scholar] [CrossRef]

- Abualigah, L.; Diabat, A.; Mirjalili, S.; Elaziz, M.A.; Gandomi, A.H. The Arithmetic Optimization Algorithm. Comput. Methods Appl. Mech. Eng. 2021, 376, 113609. [Google Scholar] [CrossRef]

- Taghizadeh-Mehrjardi, R.; Emadi, M.; Cherati, A.; Heung, B.; Mosavi, A.; Scholten, T. Bio-inspired hybridization of artificial neural networks: An application for mapping the spatial distribution of soil texture fractions. Remote Sens. 2021, 13, 1025. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Nguyen, L.V.; Jung, J.J.; Agbehadji, I.E.; Frimpong, S.O.; Millham, R.C. Bio-inspired approaches for smart energy management: State of the art and challenges. Sustainability 2020, 12, 8495. [Google Scholar] [CrossRef]

- Itano, M.K.; Omura, K.N.; Amazaki, T.Y.; Wao, T.I.; Aitou, M.S. Internet of Plants (IoP) Empowers Bottom-up Innovations. Environ. Control Biol. 2022, 60, 3–12. [Google Scholar]

- Rustia, D.J.A.; Chiu, L.; Lu, C.; Wu, Y.; Chen, S.; Chung, J.; Hsu, J.; Lin, T. Towards intelligent and integrated pest management through an AIoT-based monitoring system. Pest Manag. Sci. 2022, 78, 4288–4302. [Google Scholar] [CrossRef] [PubMed]

- Serale, G.; Gnoli, L.; Giraudo, E.; Fabrizio, E. A Supervisory Control Strategy for Improving Energy Efficiency of Artificial Lighting Systems in Greenhouses. Energies 2021, 14, 202. [Google Scholar] [CrossRef]

- Egorov, A.; Bubnov, A.; Pavluchenkova, L.; Partolina, A. Applying chemical control to suppress liverwort (Marchantia polymorpha L.) and other mosses when growing containerized seedlings of pine and spruce. Balt. For. 2021, 27, 114–120. [Google Scholar] [CrossRef]

- Raatz, L.; Walzl, K.P.; Müller, M.E.H.; Scherber, C.; Joshi, J. Who is the culprit: Is pest infestation responsible for crop yield losses close to semi–natural habitats? Ecol. Evol. 2021, 11, 13232–13246. [Google Scholar] [CrossRef]

- Beatriz, D.; Colomer, I.; Medina, P.; Vi, E. Compatibility of early natural enemy introductions in commercial pepper and tomato greenhouses with repeated pesticide applications. Insect Sci. 2020, 27, 1111–1124. [Google Scholar]

- Chlorpyrifos-Methyl. National Library of Medicine. 2022. Available online: https://pubchem.ncbi.nlm.nih.gov/compound/Chlorpyrifos-methyl (accessed on 1 August 2022).

- Sharma, A.; Tripathi, P. Artificial Intelligence in Agriculture: A Literature Survey. Int. J. All Res. Educ. Sci. Methods 2021, 9, 510–513. [Google Scholar]

- Tang, J.; Liu, G.; Pan, Q. A Review on Representative Swarm Intelligence Algorithms for Solving Optimization Problems: Applications and Trends. IEEE/CAA J. Autom. Sin. 2021, 8, 1627–1643. [Google Scholar] [CrossRef]

- Maraveas, C.; Loukatos, D.; Bartzanas, T.; Arvanitis, K.G. Applications of artificial intelligence in fire safety of agricultural structures. Appl. Sci. 2021, 11, 7716. [Google Scholar] [CrossRef]

- Solmaz, E.; Çevik, B.; Ay, R. Abamectin resistance and resistance mechanisms in Tetranychus urticae populations from cut flowers greenhouses in Turkey. Int. J. Acarol. 2020, 46, 94–99. [Google Scholar] [CrossRef]

- European Social and Economic Committee. Boosting the Use of Artificial Intelligence in Europe’s Micro, Small and Medium-Sized Enterprises; European Social and Economic Committee: Brussels, Belgium, 2021; pp. 1–137. [Google Scholar]

- Aggarwal, N.; Singh, D. Technology assisted farming: Implications of IoT and AI. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1022, 012080. [Google Scholar] [CrossRef]

- Loudjani, P.; Devos, W.; Baruth, B.; Lemoine, G. Artificial Intelligence and EU Agriculture. Eur. Comm. Jt. Res. Cent. 2020, 1–28. Available online: https://marswiki.jrc.ec.europa.eu/wikicap/images/c/c8/JRC-Report_AIA_120221a.pdf (accessed on 25 August 2022).

- Kendall, H.; Clark, B.; Li, W.; Jin, S.; Jones, G.D.; Chen, J.; Taylor, J.; Li, Z.; Frewer, L.J. Precision Agriculture Technology Adoption: A Qualitative Study of Small-Scale Commercial “Family Farms” Located in the North China Plain; Springer: New York, NY, USA, 2022; Volume 23. [Google Scholar]

- Maloku, D. Adoption of Precision Farming Technologies: Usa and Eu Situation. SEA Pract. Appl. Sci. 2020, VIII, 7–14. [Google Scholar]

- Cisco and the International Telecommunication Union (ITU). Harnessing the Internet of Things for Global Development; Cisco and the International Telecommunication Union (ITU): Geneva, Switzerland, 2015. [Google Scholar]

- Chung, S. Survey of actuators for environment management in Korean smart greenhouses. Precis. Agric. Sci. Technol. 2020, 2, 1–7. [Google Scholar]

- Otazua, N.I. AI-Powered DSS for Resource-Efficient Nutrient, Irrigation, and Microclimate Management in Greenhouses. Chem. Proc. 2022, 10, 63. [Google Scholar]

- Cui, B.; Niu, W.; Du, Y.; Zhang, Q. Response of yield and nitrogen use e fficiency to aerated irrigation and N application rate in greenhouse cucumber. Sci. Hortic. 2020, 265, 109220. [Google Scholar] [CrossRef]

- Lin, N.; Wang, X.; Zhang, Y.; Hu, X.; Ruan, J. Fertigation management for sustainable precision agriculture based on Internet of Things. J. Clean. Prod. 2020, 277, 124119. [Google Scholar] [CrossRef]

- Briciu-Burghina, C.; Zhou, J.; Ali, M.I.; Regan, F. Demonstrating the Potential of a Low-Cost Soil Moisture Sensor Network. Sensors 2022, 22, 987. [Google Scholar] [CrossRef] [PubMed]

- Shamshiri, R.R.; Balasundram, S.K.; Rad, A.K.; Sultan, M.; Hameed, I.A. An Overview of Soil Moisture and Salinity Sensors for Digital Agriculture Applications. In Digital Agriculture, Methods and Applications; IntechOpen: London, UK, 2022. [Google Scholar]

- Sharma, S.; Kaur, G.; Singh, P.; Alamri, S.; Kumar, R.; Siddiqui, M.H. Nitrogen and potassium application effects on productivity, profitability and nutrient use efficiency of irrigated wheat (Triticum aestivum L.). PLoS ONE 2022, 17, e0264210. [Google Scholar] [CrossRef] [PubMed]

- Facchinetti, D.; Santoro, S.; Galli, L.; Fontana, G.; Fedeli, L.; Parisi, S.; Bonacchi, L.; Šušnjar, S.; Salvai, F.; Coppola, G.; et al. Reduction of Pesticide Use in Fresh-Cut Salad Production through Artificial Intelligence. Appl. Sci. 2021, 11, 1992. [Google Scholar] [CrossRef]

- Claver, H. AI Precision Spraying Technology to Cut Herbicide Use by 78%. Future Farming. 2020. Available online: https://www.futurefarming.com/crop-solutions/weed-pest-control/ai-precision-spraying-technology-to-cut-herbicide-use-by-78/ (accessed on 12 September 2022).

- Shankar, P.; Werner, N.; Selinger, S.; Janssen, O. Artificial Intelligence Driven Crop Protection Optimization for Sustainable Agriculture. In Proceedings of the IEEE ITU International Conference on Artificial Intelligence for Good (AI4G), Geneva, Switzerland, 21–25 September 2020; pp. 1–8. [Google Scholar]

- Araújo, M. Infrastructure Deployment in Unprofitable Areas: A Techno-Economic Model for Multiple Criteria Decision Analysis under the European Union Telecommunications Regulatory Framework; Stock University: Galloway, NJ, USA, 2020; p. 74. [Google Scholar]

- Placidi, P.; Morbidelli, R.; Fortunati, D.; Papini, N.; Gobbi, F.; Scorzoni, A. Monitoring soil and ambient parameters in the iot precision agriculture scenario: An original modeling approach dedicated to low-cost soil water content sensors. Sensors 2021, 21, 5110. [Google Scholar] [CrossRef]

- Liu, L.W.; Ma, X.; Wang, Y.M.; Lu, C.T.; Lin, W.S. Using artificial intelligence algorithms to predict rice (Oryza sativa L.) growth rate for precision agriculture. Comput. Electron. Agric. 2021, 187, 106286. [Google Scholar] [CrossRef]

- Singh, K.U.; Kumar, A.; Raja, L.; Kumar, V.; Kushwaha, A.K.S.; Vashney, N.; Chhetri, M. An Artificial Neural Network-Based Pest Identification and Control in Smart Agriculture Using Wireless Sensor Networks. J. Food Qual. 2022, 2022, 5801206. [Google Scholar] [CrossRef]

- Singh, R.K.; Berkvens, R.; Weyn, M. Energy efficient wireless communication for IoT enabled Greenhouses. In Proceedings of the 2020 International Conference on COMmunication Systems & NETworkS (COMSNETS), Bengaluru, India, 7–11 January 2020; pp. 885–887. [Google Scholar]

- Sacaleanu, D.; Rosu, S.-G.; Matache, M.-G.; Manciu, I.-P.; Perisoara, L.-A. Wireless actuator node for greenhouse microclimate control. In Proceedings of the 2022 14th International Conference on Electronics, Computers and Artificial Intelligence (ECAI), Ploiesti, Romania, 30 June–1 July 2022; pp. 1–4. [Google Scholar]

- Qiang, W. Research on data transmission model of agricultural wireless sensor network based on game theory. Acta Agric. Scand. Sect. B Soil Plant Sci. 2022, 72, 67–80. [Google Scholar] [CrossRef]

- Grum, M. Humans Still Crucial as AI Image Analysis for Crop Pest and Disease Management Has a Long Way to Go; Scarab-Solutions, 2022; pp. 1–2. Available online: https://www.scarab-solutions.com/humans-still-crucial-as-ai-image-analysis-for-crop-pest-and-disease-management-has-a-long-way-to-go (accessed on 30 November 2022).

- Kootstra, G.; Wang, X.; Blok, P.M.; Hemming, J.; van Henten, E. Selective Harvesting Robotics: Current Research, Trends, and Future Directions. Curr. Robot. Rep. 2021, 2, 95–104. [Google Scholar] [CrossRef]

- Lee, J.; Nazki, H.; Baek, J.; Hong, Y.; Lee, M. Artificial Intelligence Approach for Tomato Detection and Mass Estimation in Precision Agriculture. Sustainability 2020, 12, 9138. [Google Scholar] [CrossRef]

- Vidwath, S.M.G.; Rohith, P.; Dikshithaa, R.; Suraj, N.N.; Chittawadigi, R.G.; Sambandham, M. Soft Robotic Gripper for Agricultural Harvesting BT. In Machines, Mechanism and Robotics; Springer: Berlin, Germany, 2022; pp. 1347–1353. [Google Scholar]

- Navas, E.; Fernández, R.; Sepúlveda, D.; Armada, M.; Gonzalez-De-santos, P. Soft grippers for automatic crop harvesting: A review. Sensors 2021, 21, 2689. [Google Scholar] [CrossRef]

- Tianhua, L.; Ni, Z.; Shi, G.; Zhou, J. Design and Testing of an Inter-row Sprayer in a Chinese Solar Greenhouse. J. Eng. Sci. Technol. Rev. 2020, 13, 32–41. [Google Scholar]

- Homayoonzadeh, M.; Ghamari, M.; Torabi, E.; Talebi, K.; Nozari, J. A Novel Biopesticide Formulation for Organic Management of Aphis gossypii. In Proceedings of the First International Online Conference on Agriculture—Advances in Agricultural Science and Technology, Basel, Switzerland, 10–15 February 2022; Volume 4, pp. 1–4. [Google Scholar]

- Hou, J.; Zhang, J.; Wu, W.; Jin, T.; Zhou, K. Research on Agricultural Machinery Rental Optimization Based on the Dynamic Artificial Bee-Ant Colony Algorithm. Algorithms 2022, 15, 88. [Google Scholar] [CrossRef]

- Cao, R.; Li, S.; Ji, Y.; Zhang, Z.; Xu, H.; Zhang, M.; Li, M.; Li, H. Task assignment of multiple agricultural machinery cooperation based on improved ant colony algorithm. Comput. Electron. Agric. 2021, 182, 105993. [Google Scholar] [CrossRef]

- Huang, Y. Research status and applications of nature-inspired algorithms for agri-food production. Int. J. Agric. Biol. Eng. 2020, 13, 1–9. [Google Scholar] [CrossRef]

- Roy, D.K.; Lal, A.; Sarker, K.K.; Saha, K.K.; Datta, B. Optimization algorithms as training approaches for prediction of reference evapotranspiration using adaptive neuro fuzzy inference system. Agric. Water Manag. 2021, 255, 107003. [Google Scholar] [CrossRef]

- Proietti, M.; Bianchi, F.; Marini, A.; Menculini, L.; Termite, L.; Garinei, A.; Biondi, L.; Marconi, M. Edge Intelligence with Deep Learning in Greenhouse Management. In Proceedings of the 10th International Conference on Smart Cities and Green ICT Systems, Online, 28–30 April 2021; pp. 180–187. [Google Scholar]

- Gao, L.; Gong, D.; Cui, N.; Lv, M. Evaluation of bio-inspired optimization algorithms hybrid with artificial neural network for reference crop evapotranspiration estimation. Comput. Electron. Agric. 2021, 190, 106466. [Google Scholar] [CrossRef]

- Hu, P.; Sun, Y.; Zhang, Y.; Dong, J.; Zhang, X. Application of WDNN for Photosynthetic Rate Prediction in Greenhouse. In Proceedings of the 2021 IEEE 2nd International Conference on Big Data, Artificial Intelligence and Internet of Things Engineering (ICBAIE), Nanchang, China, 26–28 March 2021. [Google Scholar]

- Tao, T.; Wei, X. A hybrid CNN-SVM classifier for weed recognition in winter rape field. Plant Methods 2022, 18, 29. [Google Scholar] [CrossRef]

- Qasim, W.A.; Mitras, B.A. A Hybrid Algorithm Based on Invasive Weed Optimization Algorithm and Grey Wolf Optimization Algorithm. Int. J. Artif. Intell. Appl. 2020, 11, 30–44. [Google Scholar]

- Emamgholizadeh, S.; Mohammadi, B. New hybrid nature-based algorithm to integration support vector machine for prediction of soil cation exchange capacity. Soft Comput. 2021, 25, 13451–13464. [Google Scholar] [CrossRef]

- Codeluppi, G.; Davoli, L.; Ferrari, G. Forecasting Air Temperature on Edge Devices with. Sensors 2021, 21, 3973. [Google Scholar] [CrossRef]

- Ibrahim, A.; Anayi, F.; Packianather, M.; Alomari, O.A. New Hybrid Invasive Weed Optimization and Machine Learning Approach for Fault Detection. Energies 2022, 15, 1488. [Google Scholar] [CrossRef]

- Wu, L.; Zhou, H.; Ma, X.; Fan, J.; Zhang, F. Daily reference evapotranspiration prediction based on hybridized extreme learning machine model with bio-inspired optimization algorithms: Application in contrasting climates of China. J. Hydrol. 2019, 577, 123960. [Google Scholar] [CrossRef]

- Chahidi, L.O.; Fossa, M.; Priarone, A.; Mechaqrane, A. Evaluation of Supervised Learning Models in Predicting Greenhouse Energy Demand and Production for Intelligent and Sustainable Operations. Energies 2021, 14, 6297. [Google Scholar] [CrossRef]

- Liu, K.; Zhang, C.; Yang, X.; Diao, M.; Liu, H.; Li, M. Development of an Occurrence Prediction Model for Cucumber Downy Mildew in Solar Greenhouses Based on Long Short-Term Memory Neural Network. Agronomy 2022, 12, 442. [Google Scholar] [CrossRef]

- Han, G.D.; Choi, J.M.; Choi, I.; Kim, Y.; Heo, S.; Chung, Y.S. From crop specific to variety specific in crop modeling for the smart farm: A case study with blueberry. PLoS ONE 2022, 17, e0273845. [Google Scholar] [CrossRef]

- Abdulridha, J.; Ampatzidis, Y.; Roberts, P. Detecting powdery mildew disease in squash at different stages using UAV-based hyperspectral imaging and artificial intelligence. Biosyst. Eng. 2020, 197, 135–148. [Google Scholar] [CrossRef]

- Pane, C.; Manganiello, G.; Nicastro, N.; Cardi, T. Powdery Mildew Caused by Erysiphe cruciferarum on Wild Rocket (Diplotaxis tenuifolia): Hyperspectral Imaging and Machine Learning Modeling for Non-Destructive Disease Detection. Agriculture 2021, 11, 337. [Google Scholar] [CrossRef]

- Ni, L.; Punja, Z.K. Management of powdery mildew on greenhouse cucumber (Cucumis sativus L.) plants using biological and chemical approaches. Can. J. Plant Pathol. 2021, 43, 35–42. [Google Scholar] [CrossRef]

- el Arnaouty, S.A.; Afifi, A.I.; Heikal, I.H.; Kortam, M.N. Comparative study between biological and chemical control programs of certain sweet pepper pests in greenhouses. Egypt. J. Biol. Pest Control 2020, 30, 28–34. [Google Scholar] [CrossRef]

- Glinushkin, A.P.; Yakovleva, I.N.; Meshkov, Y.I. Toxicity Pesticides used in Greenhouses and Promising for Predatory Mite Neoseiulus Barkeri (Mesostigmata: Phytoseiidae). J. Phys. Conf. Ser. 2021, 1942, 012071. [Google Scholar] [CrossRef]

- Kirisik, M.; Dagli, F. Resistance To Bifenazate And Abamectin In Tetranychus Urticae (Acari:Tetranycidae) Greenhouse Populations Collected From Coastal Regions of Turkey in 2016. Fresenius Environ. Bull. 2022, 30, 7672–7679. [Google Scholar]

- Alpkent, Y.N.; Inak, E.; Ulusoy, S.; Ay, R. Acaricide resistance and mechanisms in Tetranychus urticae populations from greenhouses in Turkey. Syst. Appl. Acarol. 2020, 25, 155–168. [Google Scholar]

- Eurostats. 346,000 Tonnes of Pesticides Sold in 2020 in the EU. 2022. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/ddn-20220502-1 (accessed on 21 October 2022).

- Liu, Z.; Gao, Z.; Geng, X.; Wen, L.; Kiprop, E. Risk aversion, marketing outlets, and biological control practice adoption: Insight from pear farmers in China. Environ. Sci. Pollut. Res. 2022, 29, 84798–84813. [Google Scholar] [CrossRef] [PubMed]

- Helepciuc, F.-E.; Todor, A. Evaluating the effectiveness of the EU’s approach to the sustainable use of pesticides. PLoS ONE 2021, 16, e0256719. [Google Scholar] [CrossRef] [PubMed]

- Australian Government. Bugs for Bugs—Creating Biological Alternatives to Chemical Pesticides. 2022. Available online: https://business.gov.au/grants-and-programs/research-and-development-tax-incentive/how-the-rdti-has-helped-other-companies/bugs-for-bugs (accessed on 22 October 2022).

- Jacquet, F.; Jeuffroy, M.-H.; Jouan, J.; Le Cadre, E.; Litrico, I.; Malausa, T.; Reboud, X.; Huyghe, C. Pesticide-free agriculture as a new paradigm for research. Agron. Sustain. Dev. 2022, 42, 8. [Google Scholar] [CrossRef]

- Thomine, E.; Mumford, J.; Rusch, A.; Desneux, N. Using crop diversity to lower pesticide use: Socio-ecological approaches. Sci. Total Environ. 2022, 804, 150156. [Google Scholar] [CrossRef]

- Neumeister, L. Locked-in Pesticides. The European Union’s Dependency on Harmful Pesticides and How to Overcome It; Food Watch, 2022; pp. 1–116. Available online: https://www.foodwatch.org/en/reports/2022/locked-in-pesticides-europes-dependency-on-harmful-pesticides-and-how-to-overcome-it/?cookieLevel=not-set (accessed on 12 November 2022).

- European Commission. Farm to Fork: New Rules to Reduce the Risk and Use of Pesticides in the EU. 2022. Available online: https://ec.europa.eu/commission/presscorner/detail/en/qanda_22_3694 (accessed on 12 November 2022).

- Agarwal, M.; Verma, A. Modern Technologies for Pest Control: A Review. In Heavy Metals—Their Environmental Impacts and Mitigation; Intechopen: London, UK, 2021. [Google Scholar]

- Ayanoğlu, F.B.; Elçin, A.E.; Elçin, Y.M. Bioethical issues in genome editing by CRISPR-Cas9 technology. Turkish J. Biol. = Turk Biyol. Derg. 2020, 44, 110–120. [Google Scholar] [CrossRef]

- Deere, J. John Deere Reveals Fully Autonomous Tractor at CES 2022. 2022. Available online: https://www.deere.com/en/news/all-news/autonomous-tractor-reveal/ (accessed on 11 November 2022).

- Beloev, I.; Kinaneva, D.; Georgiev, G.; Hristov, G.; Zahariev, P. Artificial intelligence-driven autonomous robot for precision agriculture. Acta Technol. Agric. 2021, 24, 48–54. [Google Scholar] [CrossRef]

- Rahmadian, R.; Widyartono, M. Autonomous Robotic in Agriculture: A Review. In Proceedings of the 2020 Third International Conference on Vocational Education and Electrical Engineering, Surabaya, Indonesia, 3–4 October 2020; pp. 1–6. [Google Scholar]

- Aghelpour, P.; Bahrami-Pichaghchi, H.; Kisi, O. Comparison of three different bio-inspired algorithms to improve ability of neuro fuzzy approach in prediction of agricultural drought, based on three different indexes. Comput. Electron. Agric. 2020, 170, 105279. [Google Scholar] [CrossRef]

- Soheli, S.J.; Jahan, N.; Hossain, M.; Adhikary, A.; Khan, D.M.A.; Wahiduzzaman, M. Smart Greenhouse Monitoring System Using Internet of Things and Artificial Intelligence. Wirel. Pers. Commun. 2022, 124, 3603–3634. [Google Scholar] [CrossRef]

- Salam, A.; Javaid, Q. Bio-inspired cluster-based optimal target identification using multiple unmanned aerial vehicles in smart precision agriculture. Int. J. Distrib. Sens. Netw. 2021, 17, 1–17. [Google Scholar] [CrossRef]

- Howard, D.A.; Ma, Z.; Veje, C.; Clausen, A.; Aaslyng, J.M.; Jørgensen, B.N. Greenhouse industry 4.0—Digital twin technology for commercial greenhouses. Energy Inform. 2021, 4, 37. [Google Scholar] [CrossRef]

- Jiang, X.; Liu, B.; Guan, X.; Wang, Z.; Wang, B.; Zhao, S.; Song, Y.; Zhao, Y.; Bi, J. Proper deficit irrigation applied at various stages of growth can maintain yield and improve the comprehensive fruit quality and economic return of table grapes grown in greenhouses*. Irrig. Drain. 2021, 70, 1056–1072. [Google Scholar] [CrossRef]

- Bersani, C.; Ouammi, A.; Sacile, R.; Zero, E. Model Predictive Control of Smart Greenhouses as the Path towards Near Zero Energy Consumption. Energies 2020, 13, 3647. [Google Scholar] [CrossRef]

- Ben, R.; Bouadila, S.; Mami, A. Experimental validation of the dynamic thermal behavior of two types of agricultural greenhouses in the Mediterranean context. Renew. Energy 2020, 147, 118–129. [Google Scholar] [CrossRef]

- Achour, Y.; Ouammi, A.; Zejli, D. Technological progresses in modern sustainable greenhouses cultivation as the path towards precision agriculture. Renew. Sustain. Energy Rev. 2021, 147, 111251. [Google Scholar] [CrossRef]

- Ullah, I.; Fayaz, M.; Aman, M.; Kim, D. An optimization scheme for IoT based smart greenhouse climate control with efficient energy consumption. Computing 2022, 104, 433–457. [Google Scholar] [CrossRef]

- Zhang, K.; Yu, J.; Ren, Y. Demand side management of energy consumption in a photovoltaic integrated greenhouse. Int. J. Electr. Power Energy Syst. 2022, 134, 107433. [Google Scholar] [CrossRef]

- Jia, W.; Liu, M.; Zhou, J. Adaptive Chaotic Ant Colony Optimization for Energy Optimization in Smart Sensor Networks. J. Sens. 2021, 2021, 5051863. [Google Scholar] [CrossRef]

- Chen, J.; Cai, Y.; Xu, F.; Hu, H.; Ai, Q. Analysis and Optimization of the Fan-Pad Evaporative Cooling System for Greenhouse Based on CFD. Adv. Mech. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef] [Green Version]

- Rasakhodzhaev, B.S.; Akhmadjanov, U.Z.; Boboeva, M.O.; Mashrapova, I.R.; Tokonova, T.S. Investigation of solar greenhouses with transformable (adjustable) body depending on indoor and outdoor air temperature. IOP Conf. Ser. Earth Environ. Sci. 2022, 1070, 012030. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Khalilpourazary, S.; Özyüksel, A.; Weber, G.; Weber, G. Designing Energy-Efficient High-Precision Multi-pass Turning Processes via Robust Optimization and Artificial Intelligence. J. Intell. Manuf. 2021, 32, 1621–1647. [Google Scholar] [CrossRef]

- An, Z.; Cao, X.; Yao, Y.; Zhang, W.; Li, L.; Wang, Y.; Guo, S.; Luo, D. A Simulator-based Planning Framework for Optimizing Autonomous Greenhouse Control Strategy. In Proceedings of the Thirty-First International Conference on Automated Planning and Scheduling, Guangzhou, China, 2–13 August 2021. [Google Scholar]

- Bersani, C.; Ruggiero, C.; Sacile, R.; Soussi, A.; Zero, E. Internet of Things Approaches for Monitoring and Control of Smart Greenhouses in Industry 4.0. Energies 2022, 15, 3834. [Google Scholar] [CrossRef]

- Chen, C.; Huang, Y.; Li, Y.; Chang, C.; Huang, Y. An AIoT Based Smart Agricultural System for Pests Detection. IEEE Access 2020, 8, 180750–180761. [Google Scholar] [CrossRef]

- Henningsson, A. Survey of the Application of Machine Learning to Automated Greenhouses; Uppsala University: Uppsala, Sweden, 2021; pp. 1–43. [Google Scholar]

- Siskandar, R.; Santosa, S.H.; Wiyoto, W.; Kusumah, B.R.; Hidayat, A.P. Control and Automation: Insmoaf (Integrated Smart Modern Agriculture and Fisheries) on The Greenhouse Model. J. Ilmu Pertan. Indones. 2022, 27, 141–152. [Google Scholar] [CrossRef]

- Mu, M.; Zhang, S.; Yang, S.; Wang, Y. Phase change materials applied in agricultural greenhouses. J. Energy Storage 2022, 49, 104100. [Google Scholar] [CrossRef]

- Elsayed, M.; Ran, Y.; Ai, P.; Azab, M.; Mansour, A.; Jin, K.; Zhang, Y.; Abomohra, A.E.-F. Innovative integrated approach of biofuel production from agricultural wastes by anaerobic digestion and black soldier fly larvae. J. Clean. Prod. 2020, 263, 121495. [Google Scholar] [CrossRef]

- Kong, Q.; Mu, H.; Han, Y.; Wu, W.; Tong, C.; Fang, X.; Liu, R.; Chen, H.; Gao, H. Biodegradable phase change materials with high latent heat: Preparation and application on Lentinus edodes storage. Food Chem. 2021, 364, 130391. [Google Scholar] [CrossRef]

- Siti, G.; Abdul, A.; Shima, J.S.; Zainal, A.S. Waste materials as the potential phase change material substitute in thermal energy storage system: A review. Chem. Eng. Commun. 2020, 208, 687–707. [Google Scholar]

- Aira, J.R.; Gallardo-Saavedra, S.; Eugenio-Gozalbo, M.; Alonso-Gómez, V.; Muñoz-García, M.Á.; Hernández-Callejo, L. Analysis of the viability of a photovoltaic greenhouse with semi-transparent amorphous silicon (A-si) glass. Agronomy 2021, 11, 1097. [Google Scholar] [CrossRef]

- Varjovi, A.E.; Babaie, S. Green Internet of Things (GIoT): Vision, applications and research challenges. Sustain. Comput. Inform. Syst. 2020, 28, 100448. [Google Scholar] [CrossRef]

- Al-helal, I.; Alsadon, A.; Marey, S.; Ibrahim, A.; Shady, M.; Abdel-ghany, A. Geothermal Energy Potential for Cooling / Heating Greenhouses in Hot Arid Regions. Atmosphere 2022, 13, 105. [Google Scholar] [CrossRef]

- Mirzamohammadi, S.; Jabarzadeh, A.; Shahrabi, M.S. Long-term planning of supplying energy for greenhouses using renewable resources under uncertainty. J. Clean. Prod. 2020, 264, 121611. [Google Scholar] [CrossRef]

- University of Georgia. ‘Smart’ Greenhouses Could Slash Electricity Costs. 2022. Available online: https://www.sciencedaily.com/releases/2022/02/220202165939.htm (accessed on 14 September 2022).

- Mohr, S.; Kühl, R. Acceptance of artificial intelligence in German agriculture: An application of the technology acceptance model and the theory of planned behavior. Precis. Agric. 2021, 22, 1816–1844. [Google Scholar] [CrossRef]

- Fernando, S.; Nethmi, R.; Silva, A.; Perera, A.; De Silva, R.; Abeygunawardhana, P.W.K. AI Based Greenhouse Farming Support System with Robotic Monitoring. In Proceedings of the 2020 IEEE Region 10 Conference (TENCON), Osaka, Japan, 16–19 November 2020; pp. 1368–1373. [Google Scholar]

- Yaqot, M.; Meneze, B.C. Unmanned Aerial Vehicle (UAV) in Precision Agriculture: Business Information Technology Towards Farming as a Service. In Proceedings of the 2021 1st International Conference on Emerging Smart Technologies and Applications (eSmarTA), Sana’a, Yemen, 10–12 August 2021; pp. 1–7. [Google Scholar]

- Saddik, A.; Latif, R.; el Ouardi, A.; Elhoseny, M. Computer development based embedded systems in precision agriculture: Tools and application. Acta Agric. Scand. Sect. B—Soil Plant Sci. 2022, 72, 586–611. [Google Scholar] [CrossRef]

- Yun, W.; Kumar, J.P.; Lee, S.; Kim, D.S.; Cho, B.K. Deep learning-based system development for black pine bast scale detection. Sci. Rep. 2022, 12, 606. [Google Scholar] [CrossRef]

- Nanni, L.; Maguolo, G.; Pancino, F. Insect pest image detection and recognition based on bio-inspired methods. Ecol. Inform. 2020, 57, 101089. [Google Scholar] [CrossRef] [Green Version]

- Xasanov, S. Analysis of Methods for Detecting Phytophthora, Mildew Diseases of Tomatoes and Cucumbers in Greenhouses. EPRA Int. J. Clim. Resour. Econ. Rev. 2021, 9, fnz199. [Google Scholar]

- Ruzzante, S.; Labarta, R.; Bilton, A. Adoption of agricultural technology in the developing world: A meta-analysis of the empirical literature. World Dev. 2021, 146, 105599. [Google Scholar] [CrossRef]

- Kondoyanni, M.; Loukatos, D.; Maraveas, C.; Drosos, C.; Arvanitis, K.G. Bio-Inspired Robots and Structures toward Fostering the Modernization of Agriculture. Biomimetics 2022, 7, 69. [Google Scholar] [CrossRef]

- Aytenfsu, S.A.; Beyene, A.M.; Getaneh, T.H. Controlling the interior of greenhouses using Elman recurrent neural network. In Proceedings of the 2020 Fourth World Conference on Smart Trends in Systems, Security and Sustainability (WorldS4), London, UK, 27–28 July 2020; pp. 32–39. [Google Scholar]

- Cai, B.; Ning, Y.; Li, Q.; Li, Q.; Ai, X. Effects of the Chloroplast Fructose-1, 6-Bisphosphate Aldolase Gene on Growth and Low-Temperature Tolerance of Tomato. Int. J. Mol. Sci. 2022, 23, 728. [Google Scholar] [CrossRef] [PubMed]

- Zamora-Izquierdo, M.A.; Martı, J.A.; Skarmeta, A.F. Intelligent Systems for Environmental Applications Smart farming IoT platform based on edge and cloud computing. Biosyst. Eng. 2018, 177, 4–17. [Google Scholar] [CrossRef]

- Jim, R.; Aguilar, F.J.; Nemmaoui, A.; Aguilar, M.A. Remote Sensing of Agricultural Greenhouses and Plastic-Mulched Farmland: An Analysis of Worldwide Research. Remote Sens. 2020, 12, 2649. [Google Scholar]

- Hasituya; Zhongxin, C.; Fei, L.; Yuncai, H. Mapping plastic-mulched farmland by coupling optical and synthetic aperture radar remote sensing. Int. J. Remote Sens. 2020, 41, 7757–7778. [Google Scholar] [CrossRef]

| Station/ Model | Training | Validation | Testing | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| R2 | RMSE | NRMSE (%) | MAE | R2 | RMSE | NRMSE (%) | MAE | R2 | RMSE | NRMSE (%) | MAE | |

| (mm d−1) | (mm d−1) | (mm d−1) | (mm d−1) | (mm d−1) | (mm d−1) | |||||||

| ELM | 0.995 | 0.150 | 5.020 | 0.122 | 0.994 | 0.189 | 6.332 | 0.132 | 0.988 | 0.288 | 9.532 | 0.200 |

| ELM-GA | 0.995 | 0.149 | 4.983 | 0.117 | 0.995 | 0.176 | 5.882 | 0.125 | 0.988 | 0.281 | 9.280 | 0.193 |

| ELM-ACO | 0.995 | 0.149 | 4.981 | 0.117 | 0.996 | 0.166 | 5.575 | 0.122 | 0.988 | 0.279 | 9.256 | 0.191 |

| ELM-CSA | 0.996 | 0.148 | 4.981 | 0.117 | 0.996 | 0.159 | 5.320 | 0.121 | 0.988 | 0.274 | 9.232 | 0.191 |

| ELM-FPA | 0.996 | 0.144 | 4.967 | 0.116 | 0.996 | 0.155 | 5.189 | 0.119 | 0.989 | 0.272 | 9.112 | 0.190 |

| Pesticides and Active Ingredients (AI) | Field Recommended Rates | Content of Active Ingredient, mcg/mL | Original Number Experiences (N0) | Cumulative Dead Mites (N1) | Mortality Rate (Xcp ± St), % | |

|---|---|---|---|---|---|---|

| Pesticides used in greenhouses | ||||||

| Fitoverm | EC | 1.0 | 20 | 146 | 9 | 93.7 ± 6.7 |

| (avermectin C, 2 g/L) | 0.2 | 10 | 208 | 68 | 33.1 ± 8.8 | |

| 0.1 | 5 | 154 | 27 | 16.3 ± 3.2 | ||

| Confidor | Extra, | 0.015 | 105 | 102 | 23 | 21.7 ± 4.0 |

| WDP | ||||||

| (imidacloprid, g/kg) | 700 | 0.0075 | 525 | 89 | 16 | 18.2 ± 3.7 |

| Actellic, (pirimiphos-methyl 500 g/L) | EC | 0.2 | 1000 | 217 | 86 | 39.5 ± 4.7 |

| 0.1 | 500 | 260 | 65 | 24.8 ± 5.4 | ||

| Novaction, (malathion, 440 g/L) | WE | 0.15 | 660 | 66 | 49 | 42.1 ± 7.3 |

| 0.075 | 330 | 172 | 38 | 20.7 ± 11.5 | ||

| Promising pesticides for use in greenhouses | ||||||

| Scelta (cyflumetofen, g/L) | SC | 0.2 | 40 | 104 | 7 | 6.9 ± 3.1 |

| 20 | ||||||

| 0.1 | 20 | 106 | 7 | 4.4 ± 0.8 | ||

| 0.05 | 10 | 79 | 4 | 5.4 ± 3.8 | ||

| Nocturne, | SC | 0.1 | 100 | 404 | 86 | 23.0 ± 8.3 |

| (pyridalyl, 100 g/L) | ||||||

| 0.05 | 50 | 319 | 48 | 16.9 ± 8.2 | ||

| Proclaim, | WSP | 0.2 | 100 | 158 | 111 | 70.5 ± 3.1 |

| (emamectin benzoate, 50 g/kg) | ||||||

| 0.1 | 50 | 151 | 62 | 40.7 ± 4.0 | ||

| 0.05 | 25 | 68 | 7 | 9.3 ± 1.4 | ||

| Oberon, | SC | 0.05 | 120 | 136 | 55 | 42.2 ± 9.8 |

| (spiromesifen, g/L) | 240 | |||||

| 0.025 | 60 | 74 | 18 | 25.9 ± 9.2 | ||

| Control | - | - | 352 | 20 | 6.3 ± 5.3 | |

| (water) | ||||||

| Optimizers | Learning Rates | Training Set Accuracy (%) | Test Set Accuracy (%) |

|---|---|---|---|

| Nadam | 0.001 | 96 | 89 |

| Adamax | 0.001 | 93 | 89 |

| RMSprop | 0.001 | 95 | 89 |

| Adam | 0.001 | 96 | 90 |

| Adam | 0.0001 | 89 | 86 |

| Adam | 0.01 | 91 | 85 |

| ANN Testing | ANN Training | ANN CV | GEP Testing | GEP Training | GEP CV | ||

|---|---|---|---|---|---|---|---|

| RMSE | 0.070 | 0.068 | 0.070 | 0.095 | 0.091 | 0.095 | |

| r-RMSE | 13.07% | 12.67% | 14.25% | 17.87% | 17.13% | 19.42% | |

| MAE | 0.052 | 0.051 | 0.052 | 0.070 | 0.066 | 0.068 | |

| Stage 2 | 0.933 | 0.969 | 0.968 | 0.970 | 0.930 | 0.930 | 0.943 |

| RMSE | 0.050 | 0.053 | 0.049 | 0.077 | 0.078 | 0.069 | |

| r-RMSE | 3.33% | 3.47% | 3.26% | 5.06% | 5.10% | 4.57% | |

| MAE | 0.039 | 0.040 | 0.038 | 0.058 | 0.058 | 0.054 | |

| Stage 3 | 0.840 | 0.910 | 0.912 | 0.922 | 0.848 | 0.853 | 0.857 |

| RMSE | 0.087 | 0.086 | 0.081 | 0.114 | 0.113 | 0.113 | |

| r-RMSE | 3.44% | 3.43% | 3.18% | 4.51% | 4.48% | 4.41% | |

| MAE | 0.067 | 0.067 | 0.063 | 0.088 | 0.086 | 0.089 | |

| Stage 4 | 0.849 | 0.911 | 0.908 | 0.911 | 0.860 | 0.856 | 0.843 |

| RMSE | 0.086 | 0.091 | 0.083 | 0.109 | 0.113 | 0.110 | |

| r-RMSE | 2.44% | 2.58% | 2.38% | 3.09% | 3.23% | 3.17% | |

| MAE | 0.063 | 0.065 | 0.061 | 0.087 | 0.090 | 0.091 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maraveas, C. Incorporating Artificial Intelligence Technology in Smart Greenhouses: Current State of the Art. Appl. Sci. 2023, 13, 14. https://doi.org/10.3390/app13010014

Maraveas C. Incorporating Artificial Intelligence Technology in Smart Greenhouses: Current State of the Art. Applied Sciences. 2023; 13(1):14. https://doi.org/10.3390/app13010014

Chicago/Turabian StyleMaraveas, Chrysanthos. 2023. "Incorporating Artificial Intelligence Technology in Smart Greenhouses: Current State of the Art" Applied Sciences 13, no. 1: 14. https://doi.org/10.3390/app13010014

APA StyleMaraveas, C. (2023). Incorporating Artificial Intelligence Technology in Smart Greenhouses: Current State of the Art. Applied Sciences, 13(1), 14. https://doi.org/10.3390/app13010014