Analysis of Surface Deformation Induced by Backfill Mining Considering the Compression Behavior of Gangue Backfill Materials

Abstract

:1. Introduction

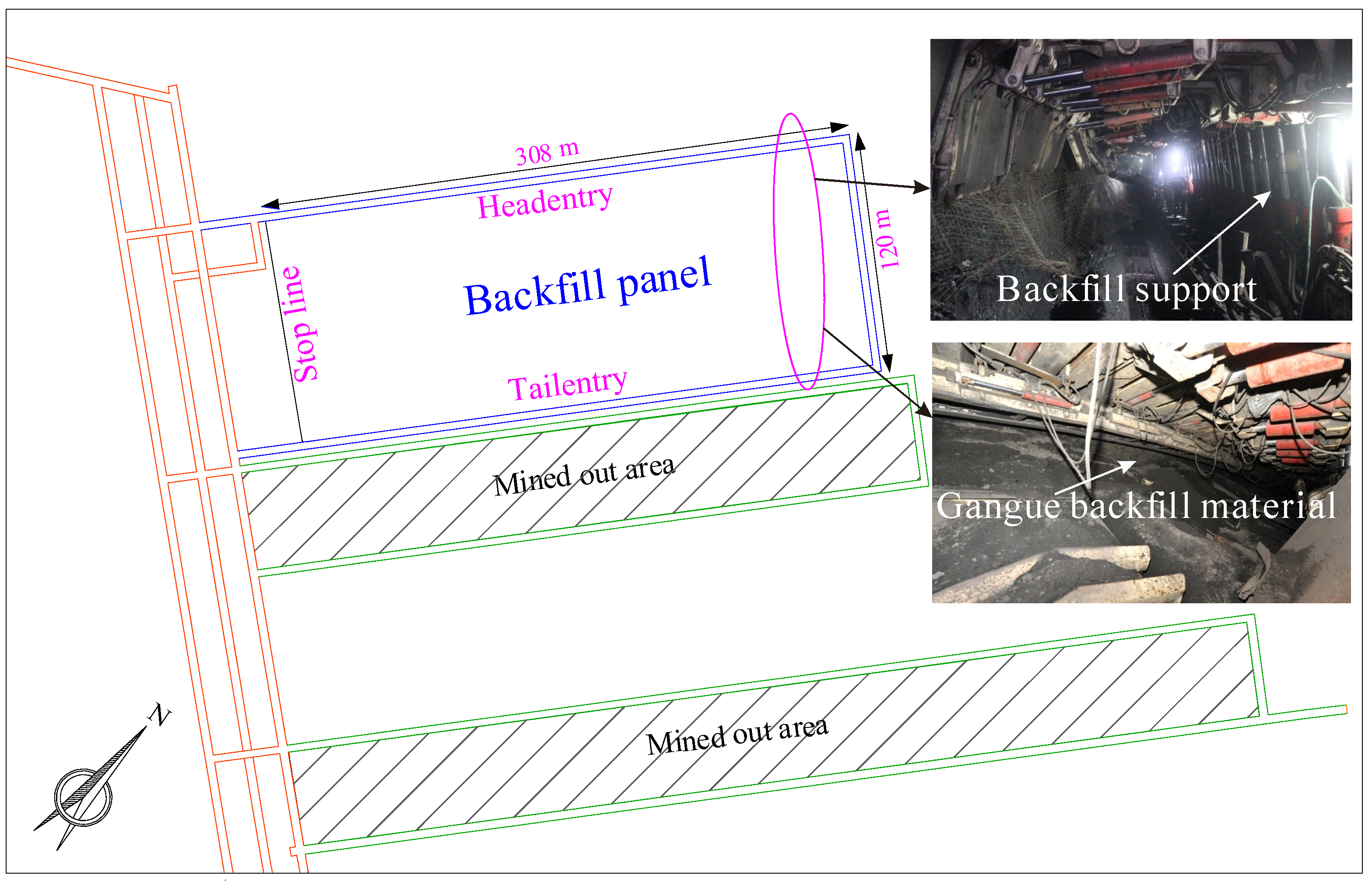

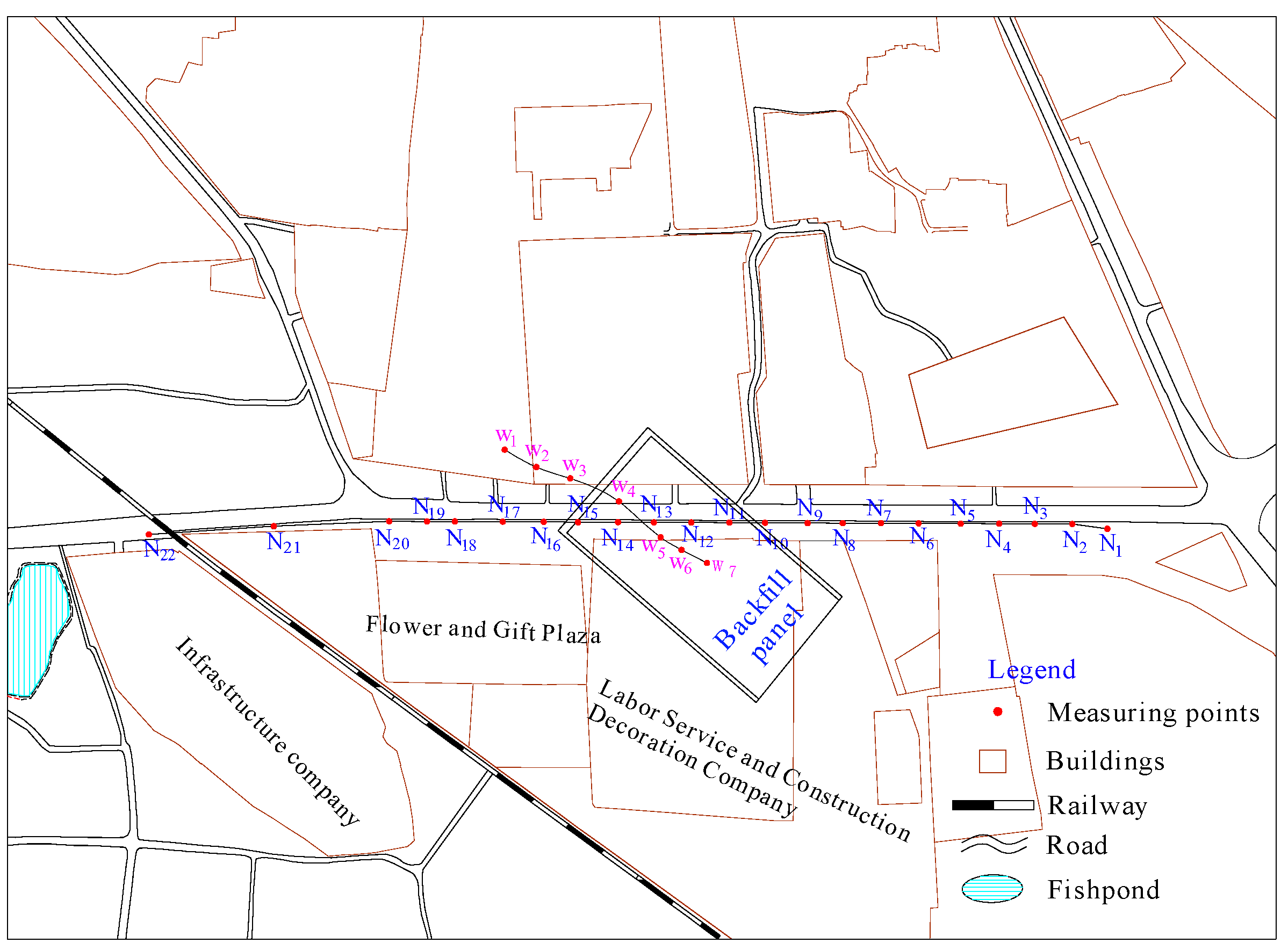

2. Engineering Background

2.1. Mining and Geological Conditions

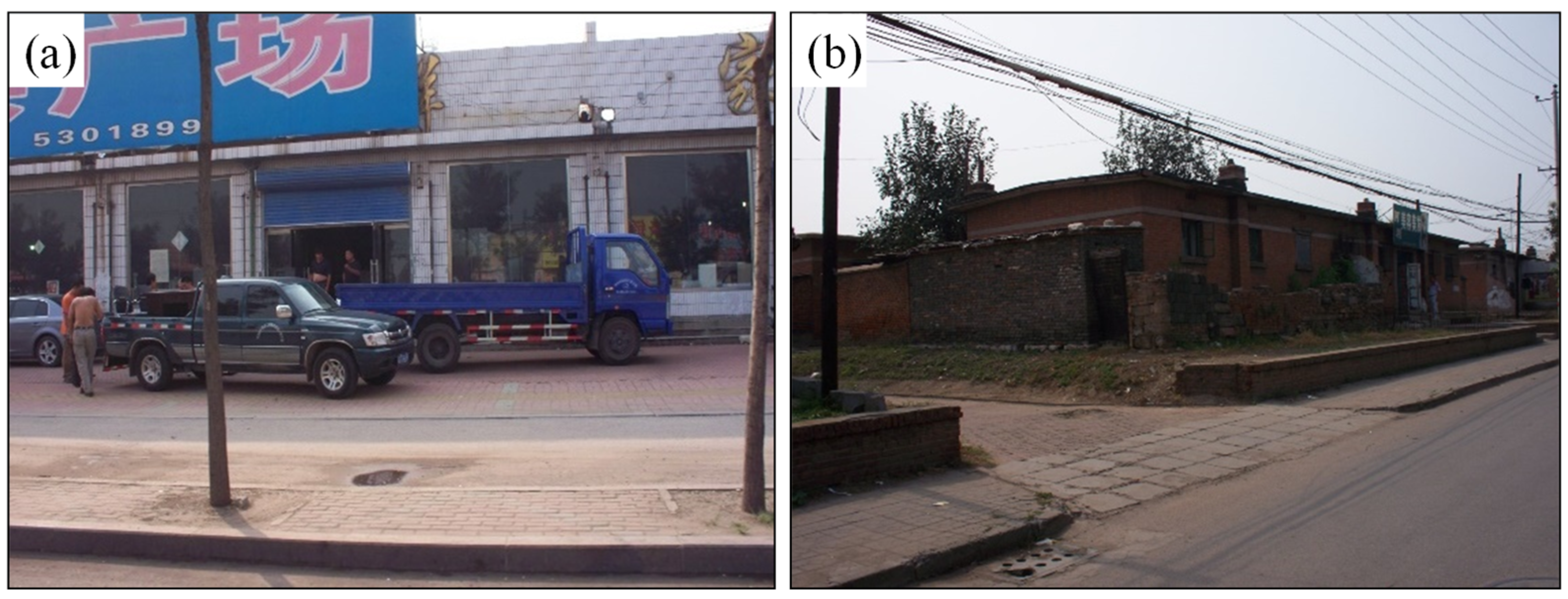

2.2. Surface Buildings and Structures and Control Criterion

3. Creep Compression Characteristics of Gangue Backfill Materials

3.1. Specimen Preparation and Test Schemes

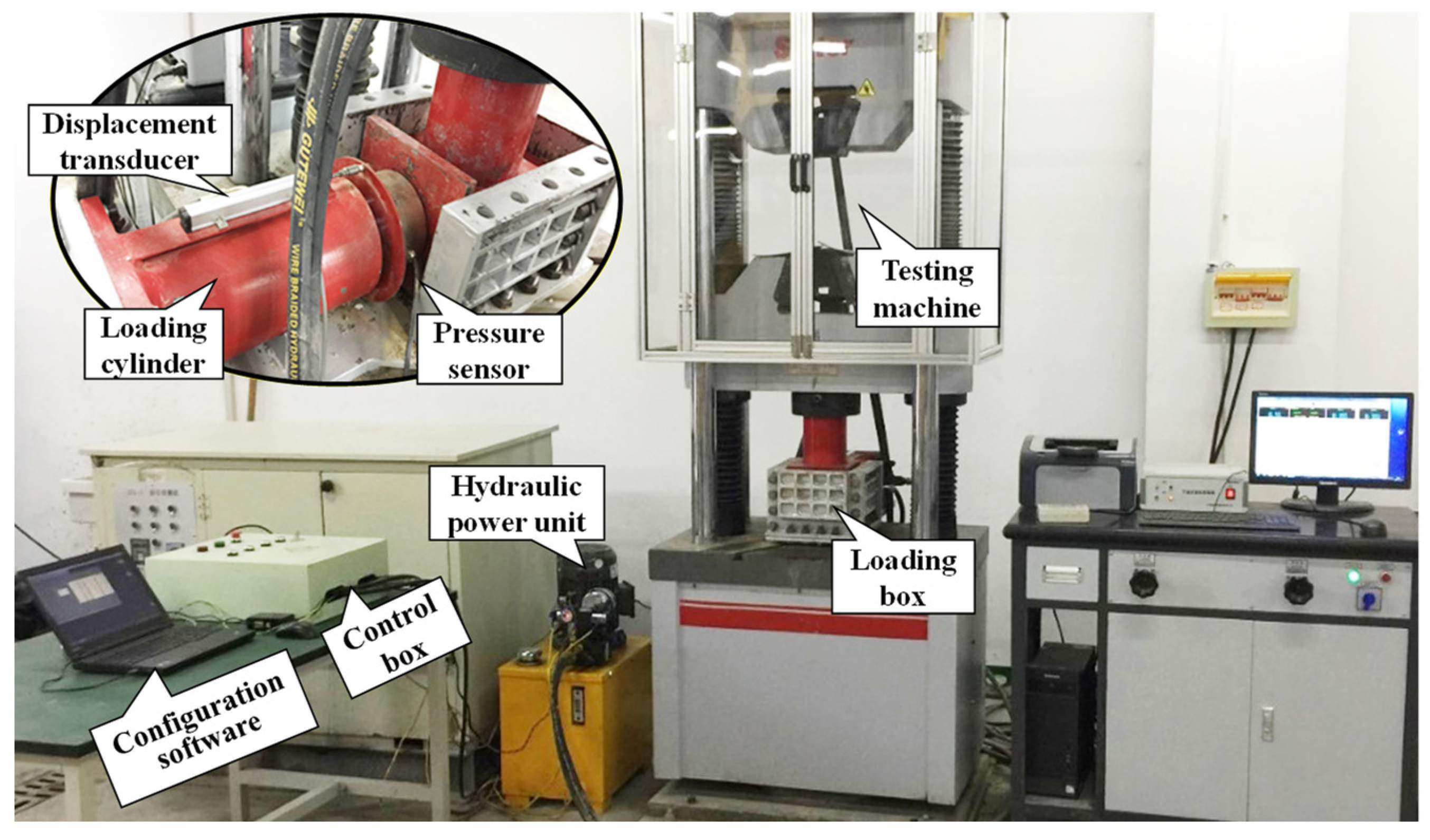

3.2. Test Devices and Test Procedure

- Preparing specimens of gangue backfill materials

- 2.

- Putting prepared specimens of gangue backfill materials in the loading box in layers

- 3.

- Lateral loading and unloading of specimens of gangue backfill materials

- 4.

- Axial multi-stage loading of specimens of gangue backfill materials.

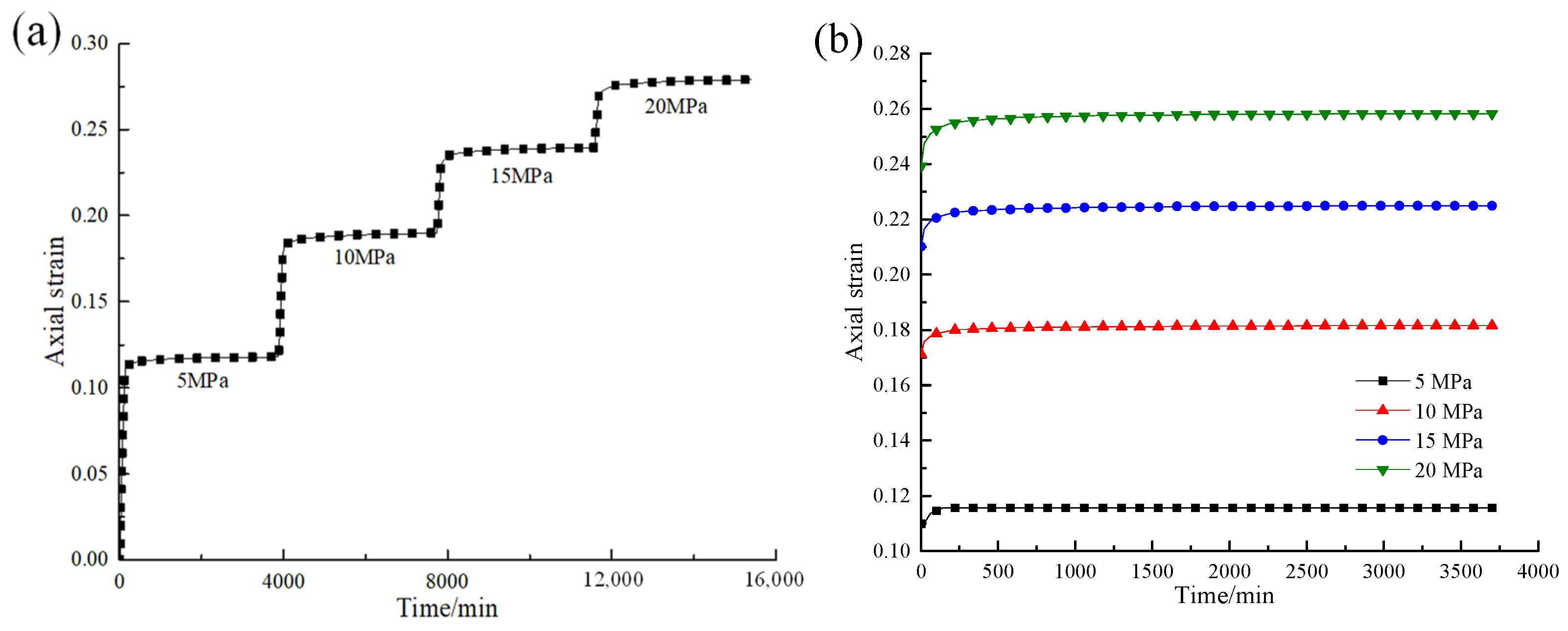

3.3. Analysis of Test Results

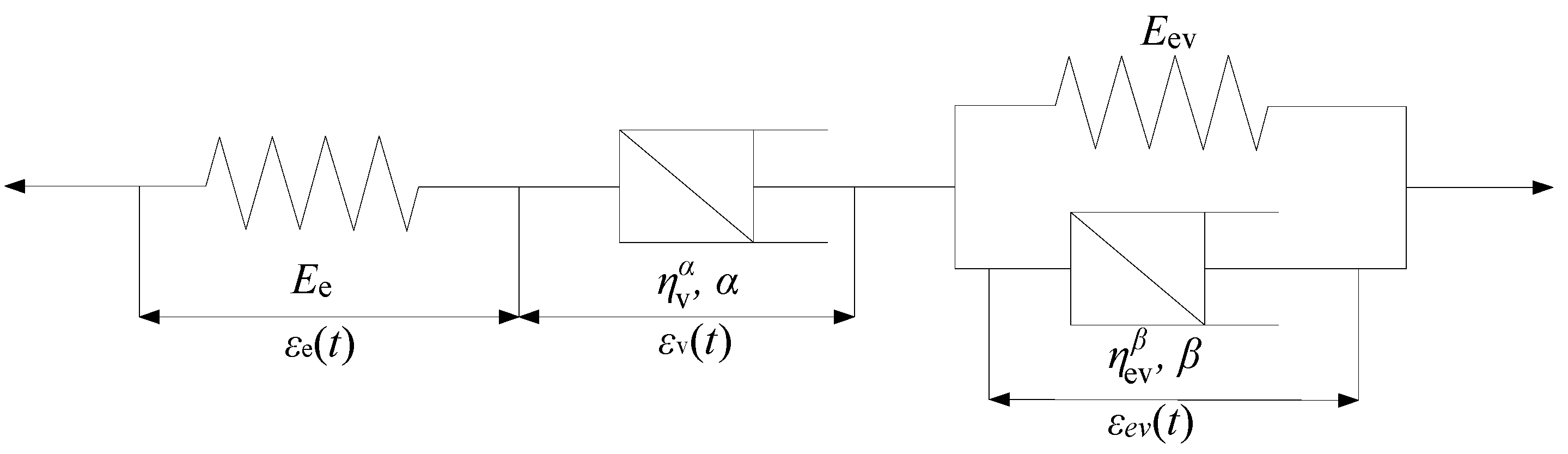

3.4. Constitutive Equation of Compression

4. Numerical Simulation of Surface Deformation Induced by Backfill Mining

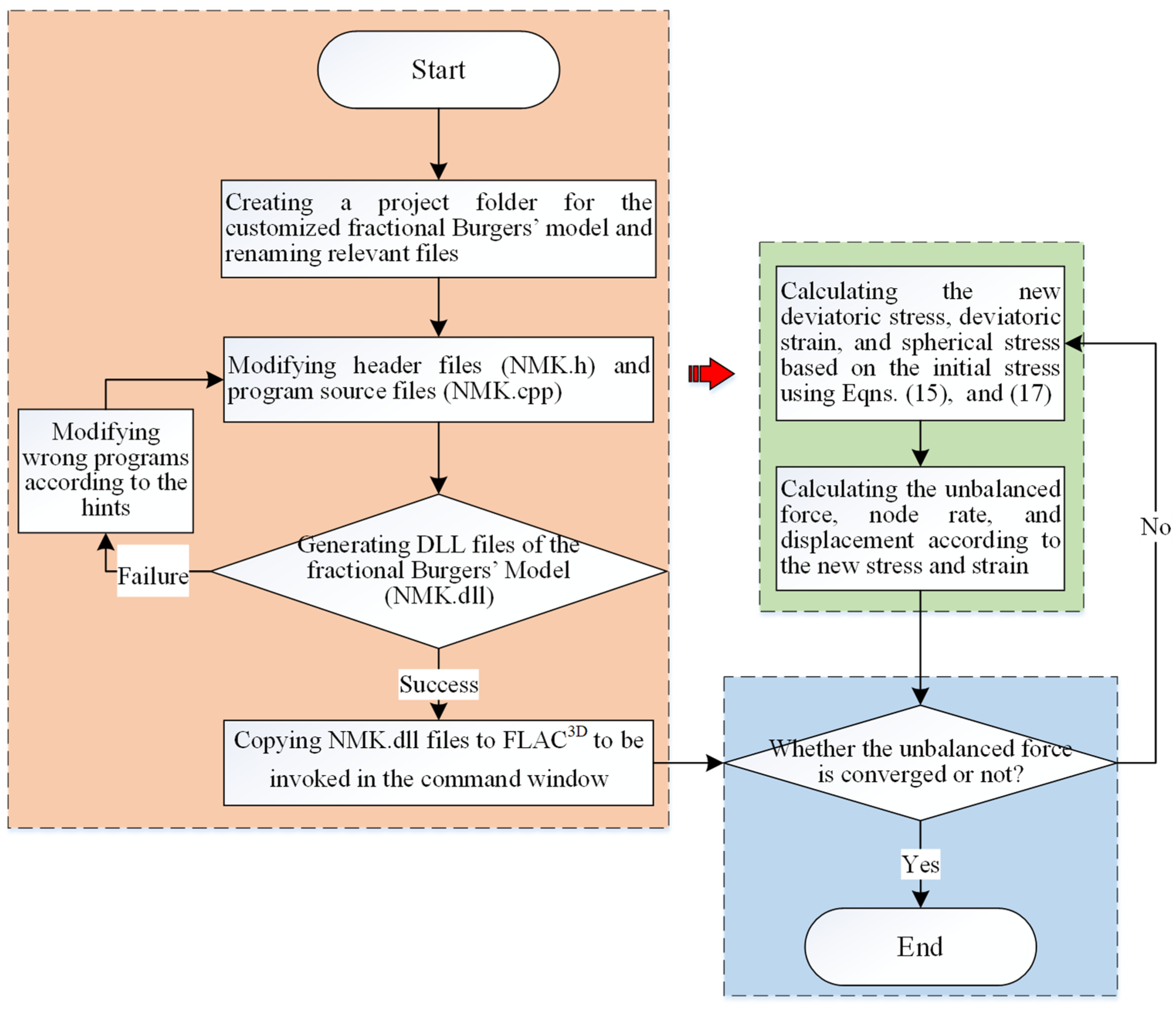

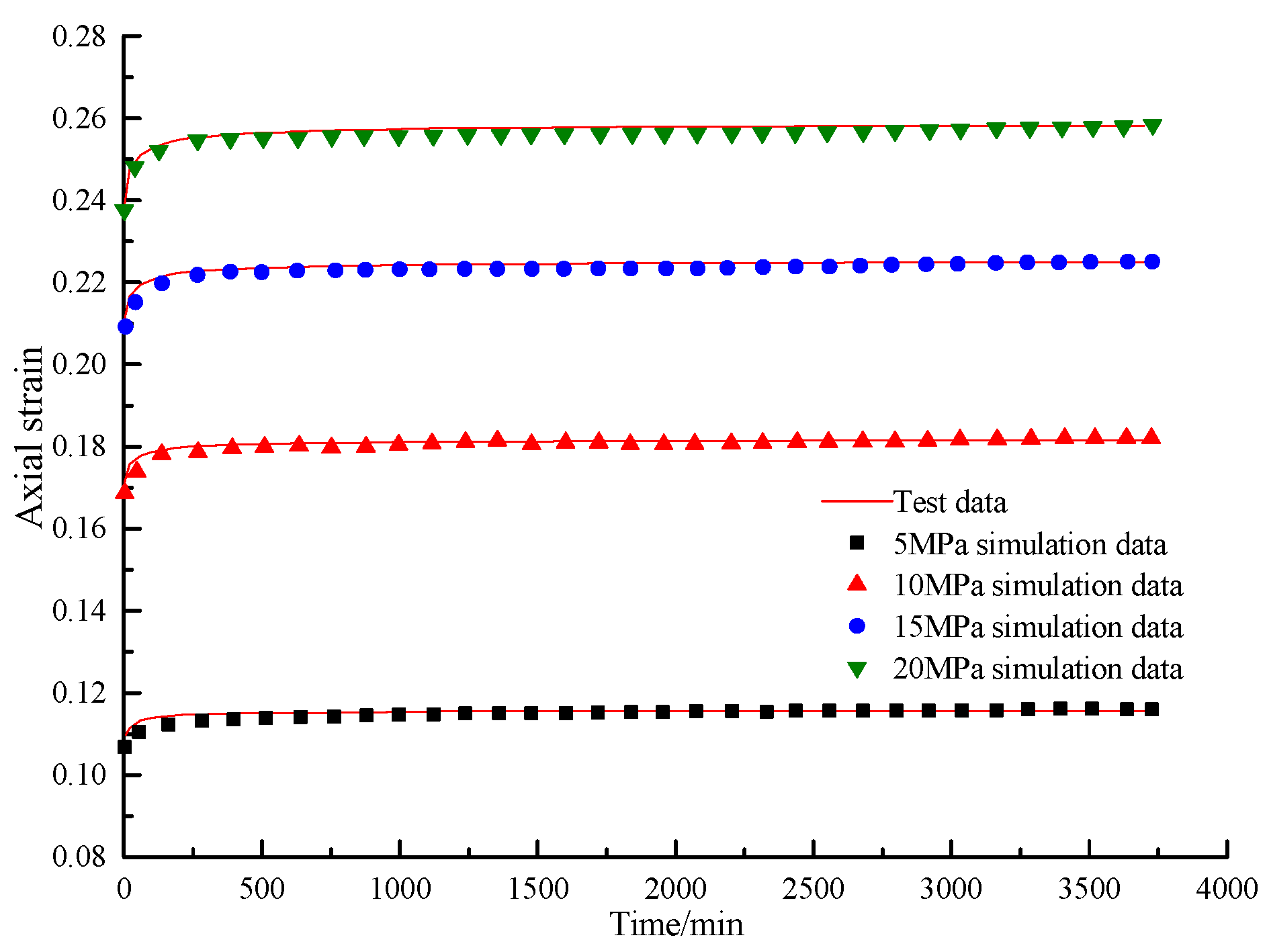

4.1. Simulation Methods of Gangue Backfill Materials

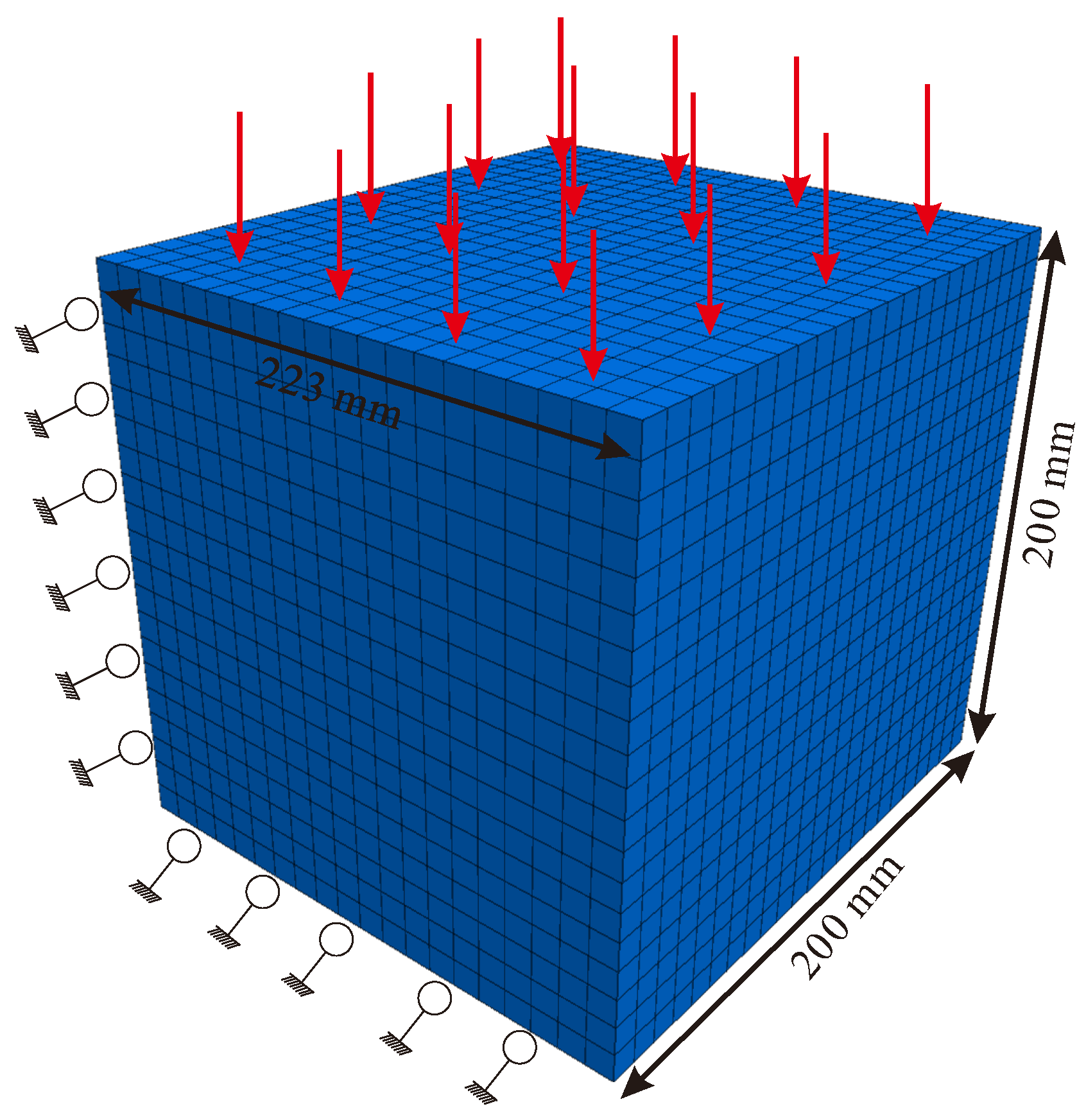

4.2. Model Establishment and Simulation Schemes

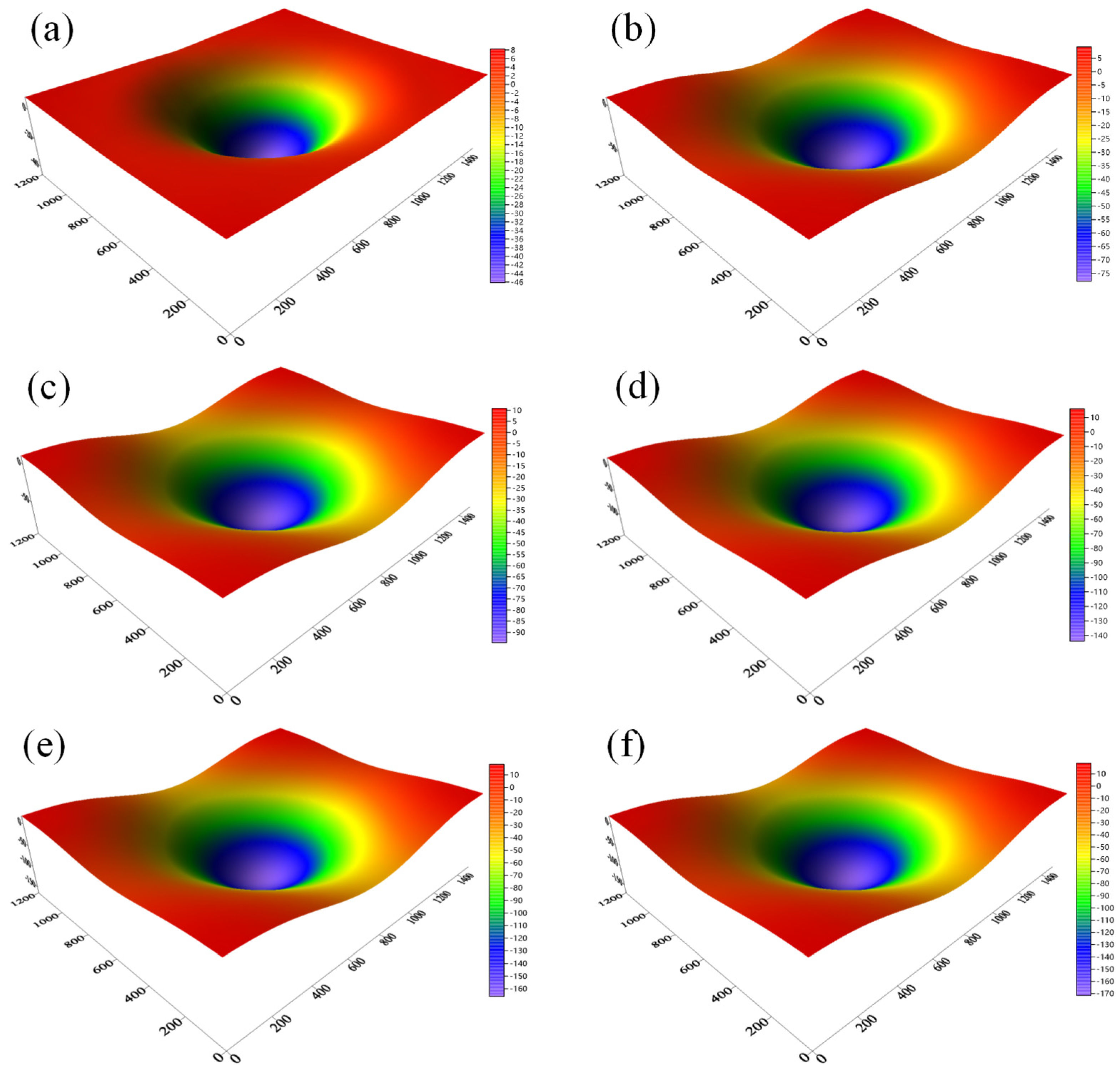

4.3. Simulation Results and Analysis

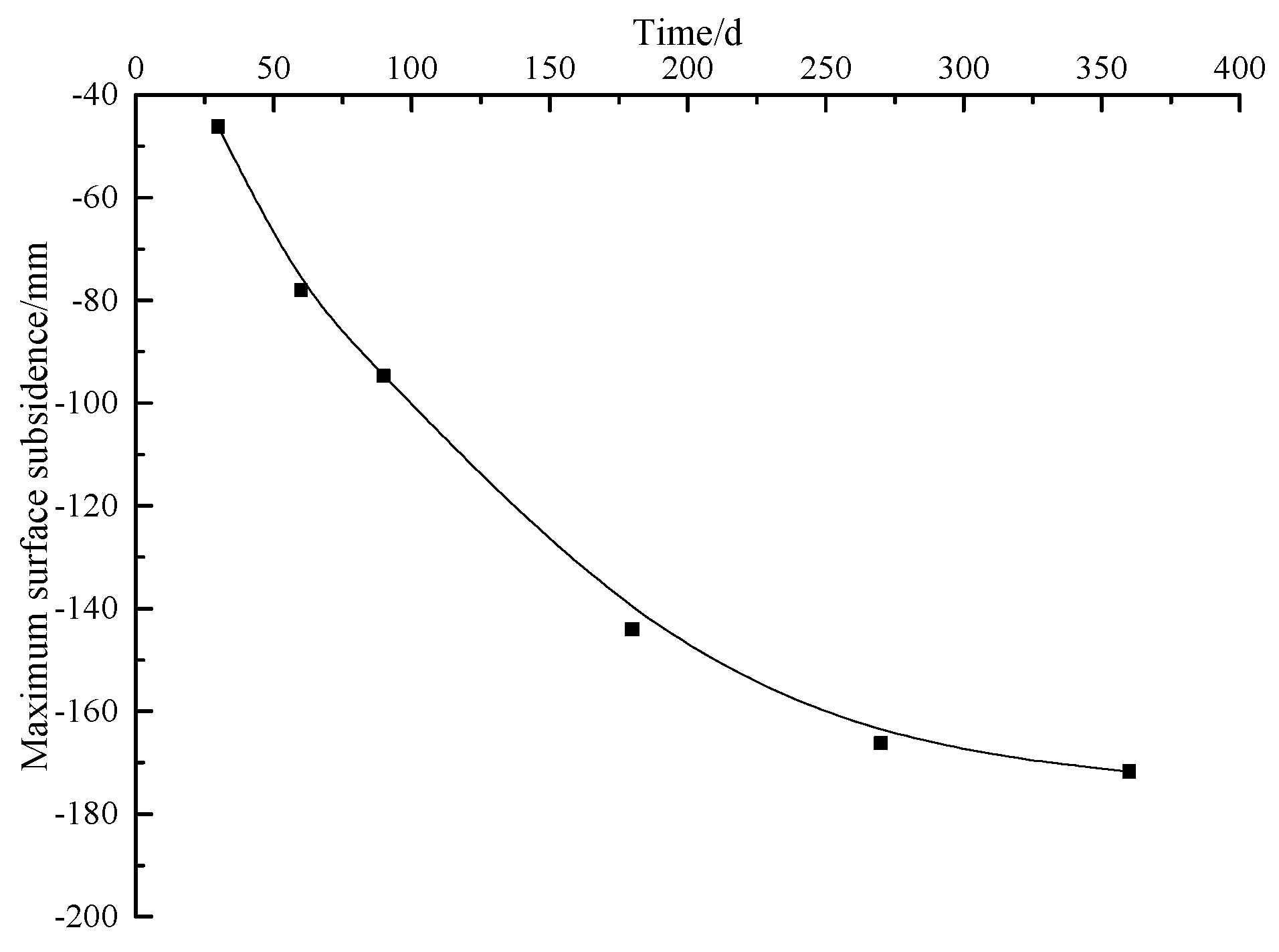

- With the increase in the creep duration, the maximum surface subsidence gradually increases, while the increase amplitude constantly decreases. The surface subsidence reaches the maximum at the central area of the goaf of the backfill panel.

- When the creep durations are 30, 60, 90, 180, 270, and 360 d, the maximum surface subsidence are 46.18, 78.04, 94.76, 144.11, 166.31, and 171.82 mm, respectively. Once the creep duration exceeds 270 d, the rate of surface subsidence decreases and finally tends to stabilize.

5. Monitoring and Analysis of Surface Subsidence

6. Conclusions

- According to conditions of surface buildings and structures above the backfill panel in Tangshan Coal Mine, the control criterion of backfill mining for surface buildings was proposed; the compressive deformation, tensile deformation, and surface subsidence should not exceed −2.0 mm/m, 1.5 mm/m, and 500 mm, respectively. Coal gangue was collected from Tangshan Coal Mine and formed into test specimens in the laboratory. The creep compression characteristics of the gangue backfill materials were measured, the deformation characteristics during creep compression were explored, and the corresponding constitutive equation of creep compression was established.

- Based on the constitutive equation of creep compression of gangue backfill materials, a method for the simulation of the materials was proposed. In addition, the numerical model for surface deformation induced by backfill mining was established to simulate and assess surface subsidence above the backfill panel after different creep durations of backfill materials. As the creep duration prolonged, the maximum surface subsidence increased (albeit at a decreasing rate). When the creep duration exceeded 270 d, the rate of surface subsidence decreased gradually and then tended to stabilize.

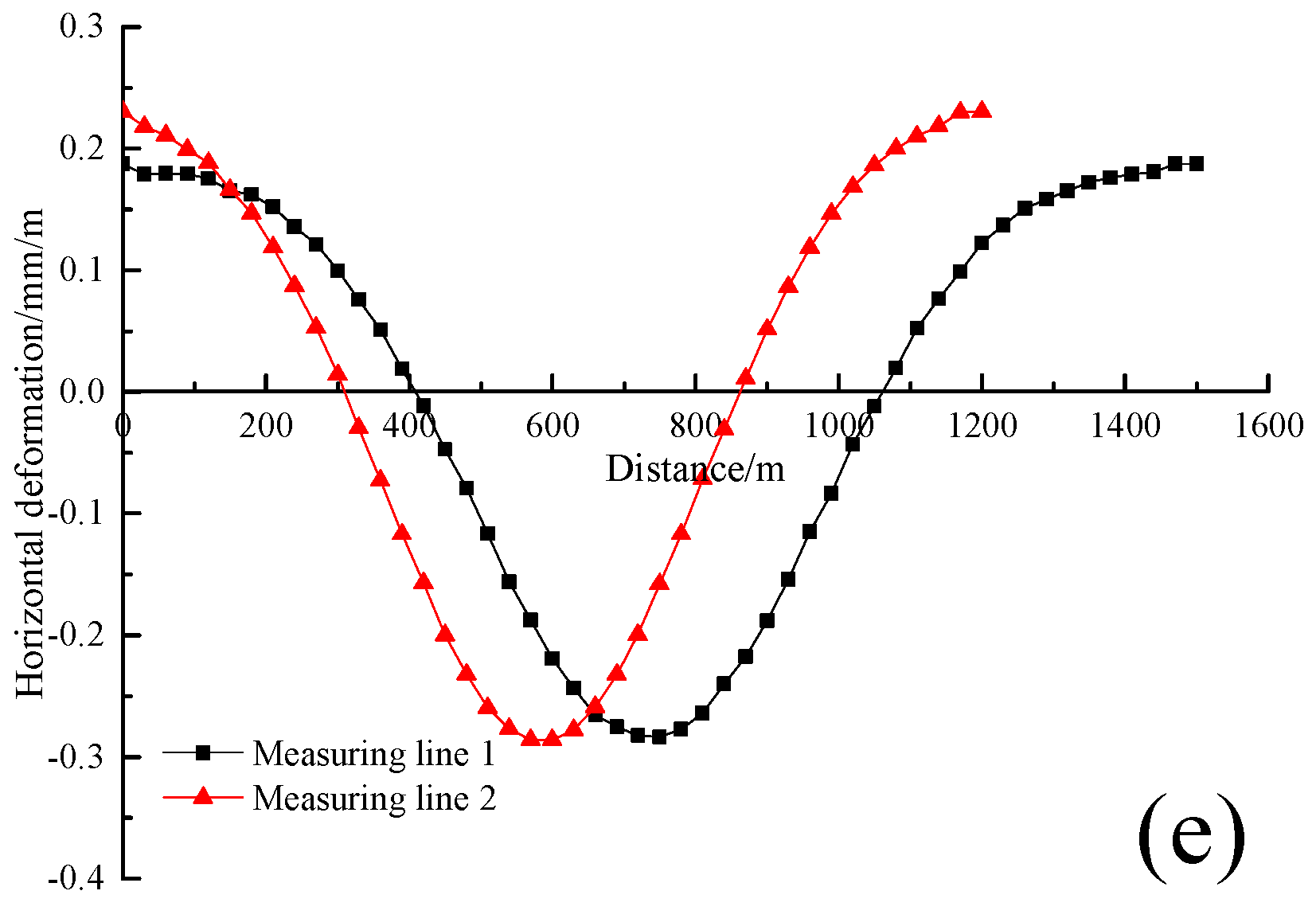

- Through simulation, it is found the maximum values of surface subsidence, horizontal movement, inclination, curvature, and horizontal deformation above the backfill panel were separately 171.82 mm, 56.38 mm, 0.38 mm/m, 0.002 mm/m2, and 0.29 mm/m. The maximum surface subsidence and horizontal deformation both met the fortification criterion for buildings on the ground surface above a mine.

- By arranging two measuring lines above the backfill mining area, the cumulative surface subsidence along the two measuring lines was plotted; after the surface subsidence stabilized, the maximum surface subsidence reached 163.4 mm, satisfying the fortification criterion for surface buildings above the backfill panel. This indicates backfill mining basically does not influence the buildings on the ground surface above a mine. The measured values are consistent with the results of numerical simulation.

- From the research results, it is clear the creep compression deformation of gangue backfill materials has a determining impact on the surface deformation. The particle size distribution can be adjusted and optimized to improve the creep compression deformation of gangue backfill materials. Especially for the particle size distribution of 0–30 mm, it has relatively small compressive deformation and can be the first choice for mine backfill. The reason is the existence of the small particles increases the coordination numbers of the large particles and decreases the amounts of the broken large particles, which effectively improves the deformability of gangue backfill materials.

- Backfill mining of gangue is an effective method to control the surface subsidence and reduce the gangue waste accumulation. Because the mined-out space can be backfilled by gangue backfill materials, after that, the deformation induced by the creep compression of gangue backfill materials is gradually transferred to the surface. The results can provide reference to the surface deformation analysis under the support of gangue backfill materials in practical engineering for protecting the stability of buildings and structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, S.J.; Yin, D.W.; Cao, F.W.; Liu, Y.; Ren, K.Q. An overview of integrated surface subsidence-reducing technology in mining areas of China. Nat. Hazards 2016, 81, 1129–1145. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.Y.; Zhang, J.X.; Bai, H.B. A state-of-the-art review on rock seepage mechanism of water inrush disaster in coal mines. Int. J. Coal Sci. Technol. 2022, 9, 50. [Google Scholar] [CrossRef]

- Ma, D.; Duan, H.Y.; Zhang, J.X. Solid grain migration on hydraulic properties of fault rocks in underground mining tunnel: Radial seepage experiments and verification of permeability prediction. Tunn. Undergr. Sp. Technol. 2022, 126, 104525. [Google Scholar] [CrossRef]

- Deck, O.; Baroudi, H.; Hosni, A.; Gueniffey, Y. A time dependency prediction of the number of mining subsidence events over a large mining field with uncertainties considerations. Int. J. Rock Mech. Min. Sci. 2018, 105, 62–72. [Google Scholar] [CrossRef]

- Salmia, E.F.; Nazemb, M.; Karakusc, M. Numerical analysis of a large landslide induced by coal mining subsidence. Eng. Geol. 2017, 217, 141–152. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Li, A.L.; Zhou, N. Reutilisation of coal gangue and fly ash as underground backfill materials for surface subsidence control. J. Clean Prod. 2020, 254, 120113. [Google Scholar] [CrossRef]

- Skierszkan, E.K.; Mayer, K.U.; Weis, D.; Beckie, R.D. Molybdenum and zinc stable isotope variation in mining waste rock drainage and waste rock at the Antamina mine. Peru. Sci. Total Environ. 2016, 550, 103–113. [Google Scholar] [CrossRef]

- Xiao, M.; Ju, F.; He, Z.Q. Research on shotcrete in mine using non-activated waste coal gangue aggregate. J. Clean Prod. 2020, 259, 120810. [Google Scholar] [CrossRef]

- Li, J.M.; Huang, Y.L.; Gao, H.D.; Ouyang, S.Y.; Guo, Y.C. Transparent characterization of spatial-temporal evolution of gangue solid wastes’ void structures during compression based on CT scanning. Powder Technol. 2020, 376, 477–485. [Google Scholar] [CrossRef]

- Welch, C.; Barbour, S.L.; Hendry, M.J. The geochemistry and hydrology of coal waste rock dumps: A systematic global review. Sci. Total Environ. 2021, 795, 148798. [Google Scholar] [CrossRef]

- Hou, J.F.; Guo, Z.P.; Li, J.B.; Zhao, L.J. Study on triaxial creep test and theoretical model of cemented gangue-fly ash backfill under seepage-stress coupling. J. Clean Prod. 2020, 273, 121722. [Google Scholar] [CrossRef]

- Wu, J.Y.; Jing, H.W.; Meng, Q.B.; Yin, Q.; Yu, L.Y. Assessment of cemented waste rock backfill for recycling gangue and controlling strata: Creep experiments and models. Environ. Sci. Pollut. R. 2021, 28, 5924–35940. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.X.; Zhang, Q.; Spearing, A.J.S.; Miao, X.X.; Guo, S.; Sun, Q. Green coal mining technique integrating mining-dressing-gas draining-backfilling-mining. Int. J. Min. Sci. Technol. 2017, 27, 17–27. [Google Scholar] [CrossRef]

- Feng, G.R.; Ran, H.Y.; Guo, J.; Guo, Y.X.; Li, C.Q. Experimental investigation on the deformation and strength properties of cemented gangue backfill column under long-term axial compression. Structures 2022, 43, 1558–1572. [Google Scholar] [CrossRef]

- Li, M.; Peng, Y.F.; Zhang, J.X.; Zhu, C.L.; Ma, D.; Huang, P. Effects of compressive deformation of backfill materials on strata movement and stress evolution in deep gangue backfill mining. B. Eng. Geol. Environ. 2022, 81, 361. [Google Scholar] [CrossRef]

- Tapsiev, A.P.; Freidin, A.M.; Filippov, P.A.; Neverov, A.A.; Neverov, S.A.; Artemenko, Y.u.V.; Uskov, V.A.; Ufatova, Z.G. Extraction of gold-bearing ore from under the open pit bottom at the Makmal deposit by room-and-pillar mining with backfill made of production waste. J. Min. Sci. 2011, 47, 324. [Google Scholar] [CrossRef]

- Rybak, J.; Adigamov, A.; Kongar-Syuryun, C.; Khayrutdinov, M.; Tyulyaeva, Y. Renewable-Resource Technologies in Mining and Metallurgical Enterprises Providing Environmental Safety. Minerals 2021, 11, 1145. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The potential re-use of Saudi mine tailings in mine backfill: A path towards sustainable mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Shear Behaviour of Rock–Tailings Backfill Interface: Effect of Cementation, Rock Type, and Rock Surface Roughness. Geotech. Geol. Eng. 2021, 39, 1753–1770. [Google Scholar] [CrossRef]

- Fang, K.; Fall, M. Chemically Induced Changes in the Shear Behaviour of Interface Between Rock and Tailings Backfill Undergoing Cementation. Rock Mech. Rock Eng. 2019, 52, 3047–3062. [Google Scholar] [CrossRef]

- Behera, S.K.; Ghosh, C.N.; Mishra, K.; Mishra, D.P.; Singh, P.; Mandal, P.K.; Buragohain, J.; Sethi, M.K. Utilisation of lead–zinc mill tailings and slag as paste backfill materials. Environ. Earth Sci. 2020, 79, 389. [Google Scholar] [CrossRef]

- Guo, G.L.; Zhu, X.J.; Zha, J.F.; Wang, Q. Subsidence prediction method based on equivalent mining height theory for solid backfilling mining. T. Nonferr. Metal. Soc. 2014, 24, 3302–3308. [Google Scholar] [CrossRef]

- Kostecki, T.; Spearing, A.J.S. Influence of backfill on coal pillar strength and floor bearing capacity in weak floor conditions in the Illinois Basin. Int. J. Rock Mech. Min. 2015, 76, 55–67. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, J.X.; Duan, H.Y.; Huang, Y.L.; Li, M.; Sun, Q.; Zhou, N. Reutilization of gangue wastes in underground backfilling mining: Overburden aquifer protection. Chemosphere 2021, 264, 128400. [Google Scholar] [CrossRef]

- Zhu, X.J.; Guo, G.L.; Liu, H.; Yang, X.Y. Surface subsidence prediction method of backfill-strip mining in coal mining. B. Eng. Geol. Environ. 2019, 78, 6235–6248. [Google Scholar] [CrossRef]

- Zhang, J.X.; Zhang, Q.; Sun, Q.; Gao, R.; Germain, D.; Abro, S. Surface subsidence control theory and application to backfill coal mining technology. Environ. Earth Sci. 2015, 74, 1439–1448. [Google Scholar] [CrossRef]

- Yadav, A.; Behera, B.; Sahoo, S.K.; Singh, G.S.P.; Sharma, S.K. Numerical analysis of the gob stress distribution using a modified elastic model as the gob constitutive model. J. Inst. Eng. India Ser. D. 2020, 101, 127–139. [Google Scholar] [CrossRef]

- Qi, C.C.; Fourie, A. Numerical investigation of the stress distribution in backfilled stopes considering creep behaviour of rock mass. Rock Mech. Rock Eng. 2019, 52, 3353–3371. [Google Scholar] [CrossRef]

- Mohammadali, S.; Derek, B.A.; Robert, A.H. Prediction of mining-induced surface subsidence and ground movements at a Canadian diamond mine using an elastoplastic finite element model. Int. J. Rock Mech. Min. Sci. 2017, 100, 73–82. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Huang, Y.L.; Zhou, N. Effects of particle size of crushed gangue backfill materials on surface subsidence and its application under buildings. Environ. Earth Sci. 2017, 76, 603. [Google Scholar] [CrossRef]

- Xu, Y.; Chang, Q.L.; Zhou, H.Q.; Cao, Z.; Li, X.S.; Chen, J.H. Movement and deformation laws of the overlying strata in paste filling stope. Min. Sci. Technol. 2011, 21, 863–868. [Google Scholar] [CrossRef]

- Mo, S.; Canbulat, I.; Zhang, C.; Oh, J.; Shen, B.; Hagan, P. Numerical investigation into the effect of backfilling on coal pillar strength in highwall mining. Int. J. Min. Sci. Technol. 2018, 28, 281–286. [Google Scholar] [CrossRef]

- Xuan, D.Y.; Xu, J.L.; Wang, B.L.; Teng, H. Borehole investigation of the effectiveness of grout injection technology on coal mine subsidence control. Rock Mech. Rock Eng. 2015, 48, 2435–2445. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Sun, K.; Zhang, S. Influence of lateral loading on compaction characteristics of crushed waste rock used for backfilling. Minerals 2018, 8, 552. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Zhang, J.X.; Song, W.J.; Germain, D.M. Recycling of crushed waste rock as backfilling material in coal mine: Effects of particle size on compaction behaviours. Environ. Sci. Pollut. R. 2019, 26, 8789–8797. [Google Scholar] [CrossRef] [PubMed]

- Feng, W.Q.; Yin, J.H.; Chen, W.B.; Tan, D.Y.; Wu, P.C. A new simplified method for calculating consolidation settlement of multi-layer soft soils with creep under multi-stage ramp loading. Eng. Geol. 2020, 264, 105322. [Google Scholar] [CrossRef]

- Ma, L.J.; Wang, Y.X.; Wang, M.Y.; Xue, B.; Duan, L.Q. Mechanical properties of rock salt under combined creep and fatigue. Int. J. Rock Mech. Min. Sci. 2021, 141, 104654. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Meng, G.H.; Gao, Y.; Li, A.L. Testing and modelling creep compression of waste rocks for backfill with different lithologies. Int. J. Rock Mech. Min. 2020, 125, 104170. [Google Scholar] [CrossRef]

- Sene, N. Mittag-Leffler input stability of fractional differential equations and its applications. Discrete. Contin. Dyn. Syst. Ser. A. 2020, 13, 867–880. [Google Scholar] [CrossRef] [Green Version]

- Corkum, A.G.; Board, M.P. Numerical analysis of longwall mining layout for a Wyoming Trona mine. Int. J. Rock Mech. Min. 2016, 89, 94–108. [Google Scholar] [CrossRef]

- Sears, M.M.; Slaker, B.; Rashed, G.; Miller, J. Analysis of the impacts of mining sequence and overburden depth on stability at a dipping limestone mine. Min. Metall. Explor. 2021, 38, 959–965. [Google Scholar] [CrossRef]

| Applied Stress/MPa | Model Parameter | ||||||

|---|---|---|---|---|---|---|---|

| Ke/MPa | Ge/MPa | /MPa·min | α | Gev/MPa | /MPa·min | β | |

| 5 | 51.71 | 11.08 | 40,565.17 | 0.36 | 208.63 | 4745.79 | 0.77 |

| 10 | 74.61 | 15.99 | 71,385.55 | 0.38 | 267.21 | 3454.55 | 0.66 |

| 15 | 94.79 | 20.31 | 100,886.91 | 0.38 | 286.92 | 2580.14 | 0.56 |

| 20 | 115.26 | 24.69 | 91,656.83 | 0.38 | 320.48 | 4405.27 | 0.65 |

| Applied Stress/MPa | Model Parameter | ||||||

|---|---|---|---|---|---|---|---|

| Ke/MPa | Ge/MPa | /MPa·min | α | Gev/MPa | /MPa·min | β | |

| 18 | 108.83 | 23.32 | 97,853.49 | 0.38 | 315.01 | 3651.44 | 0.61 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, M.; Peng, Y.; Ding, L.; Zhang, J.; Ma, D.; Huang, P. Analysis of Surface Deformation Induced by Backfill Mining Considering the Compression Behavior of Gangue Backfill Materials. Appl. Sci. 2023, 13, 160. https://doi.org/10.3390/app13010160

Li M, Peng Y, Ding L, Zhang J, Ma D, Huang P. Analysis of Surface Deformation Induced by Backfill Mining Considering the Compression Behavior of Gangue Backfill Materials. Applied Sciences. 2023; 13(1):160. https://doi.org/10.3390/app13010160

Chicago/Turabian StyleLi, Meng, Yifan Peng, Luwei Ding, Jixiong Zhang, Dan Ma, and Peng Huang. 2023. "Analysis of Surface Deformation Induced by Backfill Mining Considering the Compression Behavior of Gangue Backfill Materials" Applied Sciences 13, no. 1: 160. https://doi.org/10.3390/app13010160

APA StyleLi, M., Peng, Y., Ding, L., Zhang, J., Ma, D., & Huang, P. (2023). Analysis of Surface Deformation Induced by Backfill Mining Considering the Compression Behavior of Gangue Backfill Materials. Applied Sciences, 13(1), 160. https://doi.org/10.3390/app13010160