An Approach for Predicting the Apparent Color of Carpets under Different Illuminants

Abstract

1. Introduction

2. Materials and Methods

2.1. Carpet Selection

2.2. Carpet Dyeing Process

2.2.1. Scouring and Bleaching

2.2.2. Dyeing

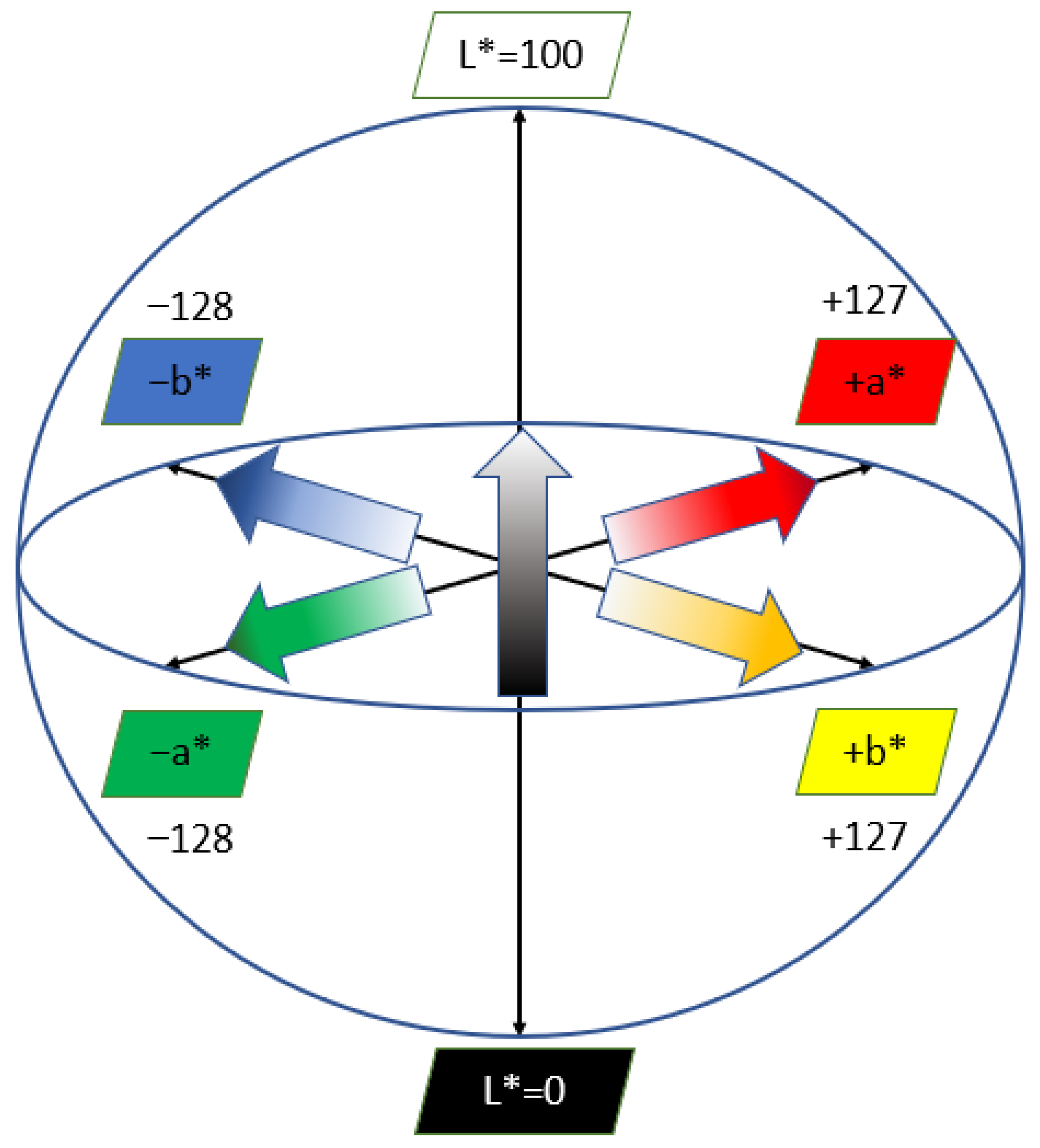

2.3. Evaluation of Carpet Color Appearance under Different Illuminants

2.4. Procedure of Data Analysis

3. Results and Discussion

3.1. Characterizing the Color Appearance of Carpets under Different Illuminants

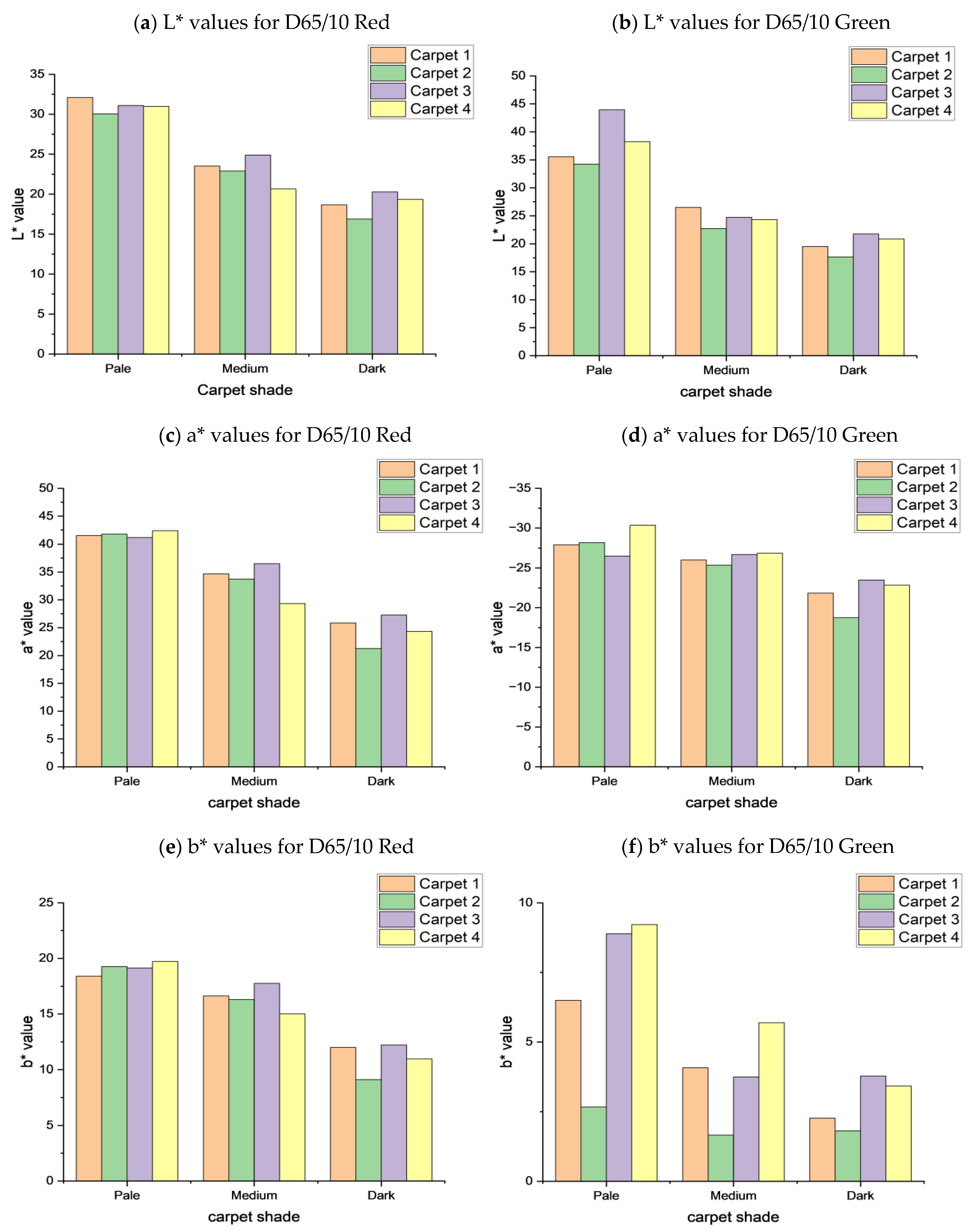

3.1.1. Illuminant 01: Noon Daylight (D65/10)

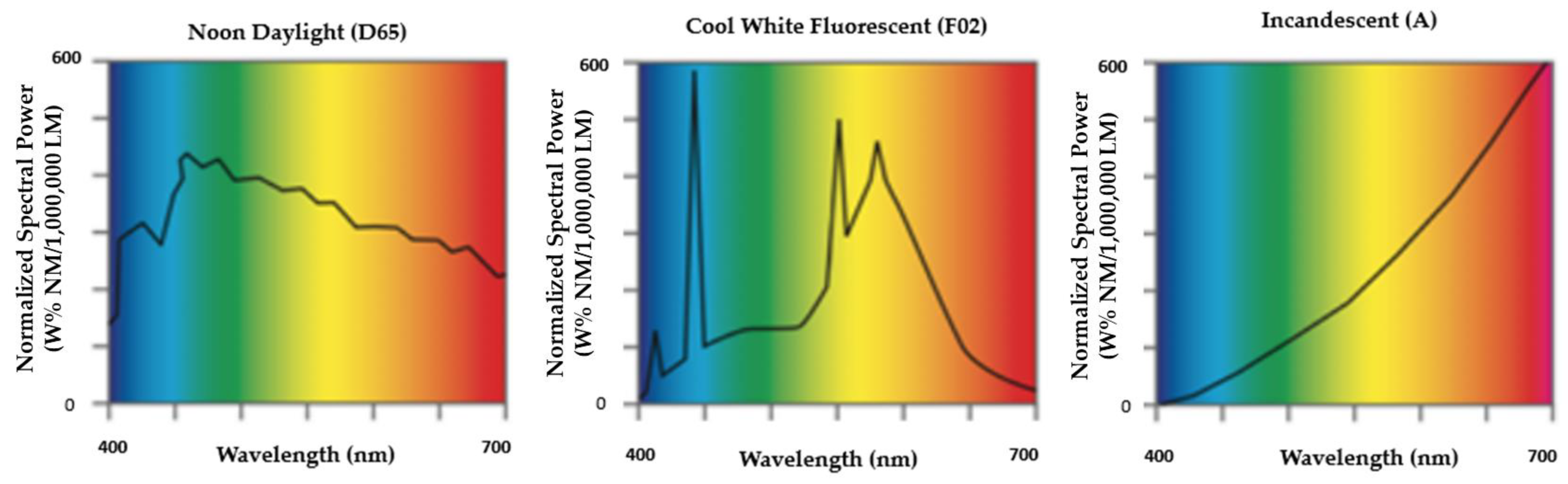

3.1.2. Illuminant 02: Incandescent (A/10)

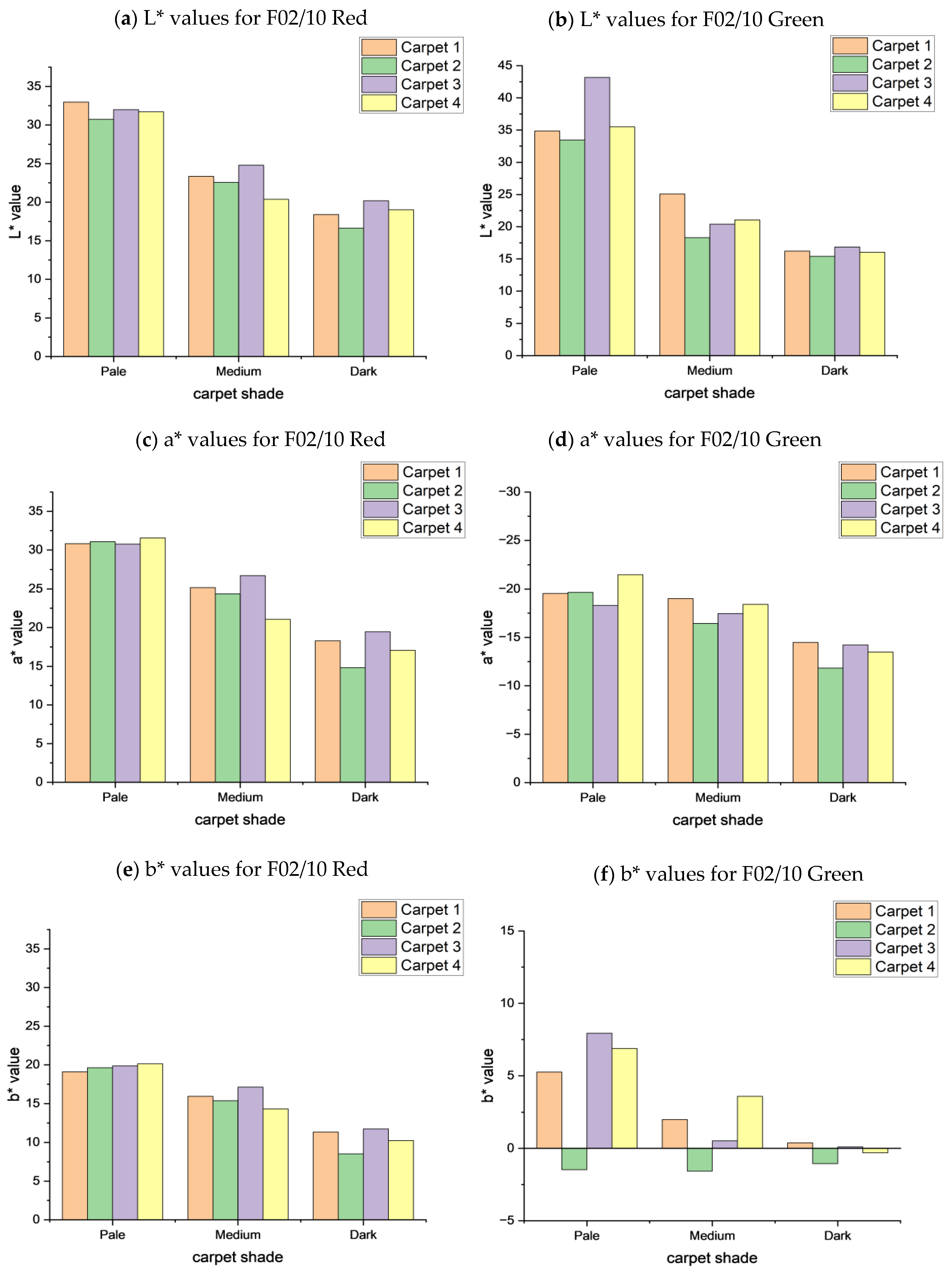

3.1.3. Illuminant 02: Cool White Fluorescent (F02/10)

3.2. Modeling the Color Appearance of Carpets

4. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kerfoot, S.; Davies, B.; Ward, P. Visual merchandising and the creation of discernible retail brands. Int. J. Retail Distrib. Manag. 2003, 31. [Google Scholar] [CrossRef]

- Hinks, D.; Draper, S.; Che, Q.; Nakpathom, M.; El-Shafel, A.; Connelly, A. Assessment of the effect of lighting variability on color difference. AATCC Rev. 2000, 32, 16–20. [Google Scholar]

- Kadolph, S.J.; Marcketti, S.B. Textiles; Pearson: New York City, NY, USA, 2016. [Google Scholar]

- Kulappurath, S.K.; Shamey, R. The effect of luminance on the perception of small color differences. Color Res. Appl. 2021, 46, 929–942. [Google Scholar] [CrossRef]

- Hoover, K.D. The Demise of Cool White Fluorescent—An Opportunity to Reassess Illuminant Specification. Text. Chem. Color. 1997, 29, 23–27. [Google Scholar]

- Pegler, M.M.; Bliss, L.L. Visual Merchandising and Display; Fairchild Publications: New York, NY, USA, 2006. [Google Scholar]

- Chu, A.; Rahman, O.; Mandal, S. A cross-cultural study of the relationships between colours and products. In Proceedings of the International Colour Association (AIC) Conference, Zurich, Switzerland, 7–10 June 2011. [Google Scholar]

- Hinks, D.; Shamey, R. Review of retail store lighting: Implications for colour control of products. Color. Technol. 2011, 127, 121–128. [Google Scholar] [CrossRef]

- Yaoyuneyong, G.; Moore, M.A. The impact of lighting on textile color: Controlling quality from the supply chain to retail display. Text. Light Ind. Sci. Technol. 2016, 5, 16–28. [Google Scholar] [CrossRef]

- Petrova, A.; Hébert, P.R. Exploration of new light and color instruments for design education: Exploring the effect of light on color samples. In Proceedings of the Western Social Science Association (WSSA) Virtual Conference, Online, 4 April 2020. [Google Scholar]

- Hebert, P.R.; Mandal, S.; Chowdhury, I.; Petrova, A. Considering the Color of Carpets under Different Light Sources. In 7th Building Technology Alliance; WordPress: Khon Kaen, Thailand, 2022; pp. 82–86. [Google Scholar]

- Hébert, P.R.; Petrova, A.; Clare, G.; Pei, Y. Exploring New Light and Color Instrumentsfor Multidisciplinary Students’ Use: Empirical Properties of Existing Building Illumination and the Effects of Light on Color Samples. J. Build. Energy Environ. 2018, 1, 5–16. [Google Scholar]

- Öktem, T.; Gürel, A.; Akdemir, H. The Characteristic Attributes and Performance of Naturally Colored Cotton. AATCC Rev. 2003, 3, 24–27. [Google Scholar]

- Huang, Z.; Chen, W.; Liu, Q.; Wang, Y.; Pointer, M.R.; Liu, Y.; Liang, J. Towards an optimum colour preference metric for white light sources: A comprehensive investigation based on empirical data. Opt. Express 2021, 29, 6302–6319. [Google Scholar] [CrossRef]

- Tang, J.; Guo, Y.; Xu, C. Color effect of light sources on peridot based on CIE1976 L* a* b* color system and round RGB diagram system. Color Res. Appl. 2019, 44, 932–940. [Google Scholar] [CrossRef]

- Nitse, P.S.; Parker, K.R.; Krumwiede, D.; Ottaway, T. The impact of color in the e-commerce marketing of fashions: An exploratory study. Eur. J. Mark. 2004, 38. [Google Scholar] [CrossRef]

- Parker, K.R.; Nitse, P.S.; Tay, S.M.A. The impact of inaccurate color on customer retention and CRM. Inf. Sci. 2009, 12, 105. [Google Scholar]

- Clare, G.P.; Hebert, P.; Lee, H.-J.; Kang, M.; Chung, Y.; Leong, J.; Slevitch, L. Seeing the Light: Consumer Perceptions of Ground Beef Packages. Management 2014, 4, 77–89. [Google Scholar] [CrossRef]

- Luo, L.; Tsang, K.M.; Shen, H.L.; Shao, S.J.; Xin, J.H. An investigation of how the texture surface of a fabric influences its instrumental color. Color Res. Appl. 2015, 40, 472–482. [Google Scholar] [CrossRef]

- Lin, J.; Shamey, R.; Trussell, J. The Effect of Texture on Perception and Measurement of Whiteness. AATCC Rev. 2012, 12, 61–68. [Google Scholar]

- Schüpbach, R.L.; Reisinger, M.; Schrader, B. Influence of lighting conditions on the appearance of typical interior materials. Color Res. Appl. 2015, 40, 50–61. [Google Scholar] [CrossRef]

- Wood, E.J. Description and measurement of carpet appearance. Text. Res. J. 1993, 63, 580–594. [Google Scholar] [CrossRef]

- Shams-Nateri, A.; Hajipour, A.; Veysian, M. The optical properties of hand-woven carpet. J. Text. Inst. 2020, 111, 694–700. [Google Scholar] [CrossRef]

- Abdullayeva, G.; Kazim-Zada, A. Recognition and identification of plane color images in the case of carpet designs. Autom. Control Comput. Sci. 2008, 42, 288–294. [Google Scholar] [CrossRef]

- Pourdeyhimi, B. Evaluating carpet appearance loss: Color change. Text. Res. J. 1994, 64, 485–490. [Google Scholar] [CrossRef]

- Önder, E.; Berkalp, Ö.B. Effects of different structural parameters on carpet physical properties. Text. Res. J. 2001, 71, 549–555. [Google Scholar] [CrossRef]

- Bleaching Wool Using Hydrogen Peroxide. Available online: https://prochemicalanddye.net/downloads/dl/file/id/89/product/0/bleaching_wool_directions.pdf (accessed on 15 June 2022).

- Immersion Dyeing on Wool Using WashFast Acid Dyes. Available online: https://prochemicalanddye.net/downloads/dl/file/id/192/product/0/immersion_dyeing_on_wool_using_pro_washfast_acid_dyes.pdf (accessed on 15 June 2022).

- Chavolla, E.; Zaldivar, D.; Cuevas, E.; Perez, M.A. Color spaces advantages and disadvantages in image color clustering segmentation. In Advances in Soft Computing and Machine Learning in Image Processing; Springer: Cham, Switzerland, 2018; pp. 3–22. [Google Scholar]

- Ganesan, P.; Rajini, V.; Rajkumar, R.I. Segmentation and edge detection of color images using CIELAB color space and edge detectors. In Proceedings of the INTERACT-2010, Chennai, India, 3–5 December 2010; pp. 393–397. [Google Scholar]

- Davis, W.; Ohno, Y. Color quality scale. Opt. Eng. 2010, 49, 033602. [Google Scholar] [CrossRef]

- Robertson, A.R. Computation of correlated color temperature and distribution temperature. JOSA 1968, 58, 1528–1535. [Google Scholar] [CrossRef]

- Shams-Nateri, A. Evaluating textile fabric color variation by scanner. Res. J. Text. Appar. 2007, 11. [Google Scholar] [CrossRef]

- Safi, M.; Soleymanian, T. Scanner colorimetric characterization for concentration estimation in single-component dyeing systems. J. Text. Inst. 2017, 108, 2040–2045. [Google Scholar] [CrossRef]

- Džimbeg-Malčić, V.; Barbarić-Mikočević, Ž.; Itrić, K. Kubelka-Munk theory in describing optical properties of paper (I). Teh. Vjesn. 2011, 18, 117–124. [Google Scholar]

- Kokhanovsky, A.A. Physical interpretation and accuracy of the Kubelka–Munk theory. J. Phys. D Appl. Phys. 2007, 40, 2210. [Google Scholar] [CrossRef]

- Yang, L.; Kruse, B. Revised Kubelka–Munk theory. I. Theory and application. JOSA A 2004, 21, 1933–1941. [Google Scholar] [CrossRef]

- Hossen, M.; Imran. Study on Color Strength of Different Reactive Dyes. J. Text. Sci. Eng. 2017, 7, 2. [Google Scholar] [CrossRef]

- Becerir, B. Color concept in textiles: A review. J Text. Eng Fash. Technol. 2017, 1, 240–244. [Google Scholar] [CrossRef][Green Version]

- Holmes, W.C. The Influence of Variation in Concentration on the Absorption Spectra of Dye Solutions. Ind. Eng. Chem. 1924, 16, 35–40. [Google Scholar] [CrossRef]

- Chakraborty, J. Fundamentals and Practices in Colouration of Textiles; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar]

- Oulton, D.; Chen, P. Colour change sensitivity of dye recipes. J. Soc. Dye. Colour. 1995, 111, 237–244. [Google Scholar] [CrossRef]

- Two Essential Components of a Great Color Program. Available online: https://www.xrite.com/blog/two-essential-components-color-program (accessed on 23 July 2022).

- Corbalan-Fuertes, M.; Garcia-Verela, M.S.M.; Yzuel, M.J. Color measurement in standard CIELAB coordinates using a 3CCD camera: Correction for the influence of the light source. Opt. Eng. 2000, 39, 1470–1476. [Google Scholar]

- Becerir, B. Assessment of colour properties of reactive dyed cotton fabrics under different illuminants by using cielab and hunter systems. Tekst. Konfeksiyon 2010, 20, 145–154. [Google Scholar]

| Carpet Type No. | Yarn Weight (Oz) | Gauge (Inch) | Stitch Rate (per Inch) | Pile Height (Inch) | Carpet Density (Oz/Yard3) |

|---|---|---|---|---|---|

| 1 | 33 | 0.16 | 7.67 | 0.1875 | 6336 |

| 2 | 50 | 0.3125 | 5.5 | 0.3125 | 5760 |

| 3 | 60 | 0.3125 | 3.75 | 0.3125 | 6912 |

| 4 | 54 | 0.5 | 5 | 0.3125 × 0.375 (pattern loop with two different loop heights) | 5634 |

| Carpet Type No | Average Sample Weight | Water 4 L/lbs | Scouring | Bleaching | Neutralizing | |||

|---|---|---|---|---|---|---|---|---|

| Sodium Carbonate 2.5 gm/lbs * | Detergent 2.5 mL/lbs | Sodium Carbonate 68 gm/lbs * | Detergent 2.5 mL/lbs | Hydrogen Peroxide | White Vinegar | |||

| 1 | 75.5 gm | 0.67 L | 0.33 gm | 0.42 mL | 11.39 gm | 0.84 mL | 41.88 mL | 27.63 mL |

| 2 | 62.8 gm | 0.55 L | 0.27 gm | 0.35 mL | 9.35 gm | 0.69 mL | 34.38 mL | 22.69 mL |

| 3 | 84.33 gm | 0.74 L | 0.37 gm | 0.46 mL | 12.58 gm | 0.93 mL | 46.25 mL | 30.53 mL |

| 4 | 85.97 gm | 0.76 L | 0.38 gm | 0.47 mL | 12.92 gm | 0.95 mL | 47.5 mL | 31.35 mL |

| Total | 308.6 gm | 2.72 L | 1.35 gm | 1.47 mL | 46.24 gm | 3.41 mL | 170.01 mL | 112.2 mL |

| Shade | Light | Medium | Dark | |||

|---|---|---|---|---|---|---|

| Chemicals | Water 250 mL/lbs | Dye 1.2 gm/lbs * | Water 250 mL/lbs | Dye 4.5 gm/lbs * | Water 500 mL/lbs | Dye 9 gm/lbs * |

| Required amount | 169.9 mL | 0.816 gm | 169.9 mL | 3.06 gm | 340 mL | 6.12 gm |

| Dyeing Protocols | Dye Bath Preparation | Improving Dye Take Up | ||

|---|---|---|---|---|

| Chemicals | Water 14 L/lbs | White Vinegar 165 mL/lbs | Common Salt 15 gm/lbs * | White Vinegar 100 mL/lbs |

| Required amount | 9.52 L | 112.16 mL | 10.2 gm | 68 mL |

| Shade | Light | Medium | Dark |

|---|---|---|---|

| Dye Concentration in the Dye Bath | 0.08 g/Liter | 0.32 g/Liter | 0.62 g/Liter |

| Illuminants | Light Temperatures | CRI |

|---|---|---|

| A (incandescent) | ≈2850 K | 100 |

| D65 (noon daylight) | ≈6500 K | 96 |

| F02 (Cool White Fluorescent) | ≈100 K | 62 |

| Illuminant | Color | Dependent Variable | R Square | p-Value of Gauge | p-Value of Stitch Rate | p-Value of Pile Height | p-Value of Dye Concentration | Equation (g = Gauge of the Carpet, s = Stitch Rate of the Carpet, p = Pile Height of the Carpet, and d = Dye Concentration.) |

|---|---|---|---|---|---|---|---|---|

| D65 | Red | L* | 0.87 | >0.05 | 0.04 | 0.03 | 0.00 | L = 44.76 − 22.33 d − s − 25.59 p |

| a* | 0.92 | >0.05 | 0.01 | 0.00 | 0.00 | a = 63.30 − 31.47 d − 1.48 s − 38.55 p | ||

| b* | 0.88 | >0.05 | 0.03 | 0.03 | 0.00 | b = 28.94 − 15.05 d − 0.69 s − 15.58 p | ||

| Green | L* | 0.77 | >0.05 | >0.05 | >0.05 | 0.00 | L = 38.61 − 32.68 d | |

| a* | 0.66 | >0.05 | >0.05 | >0.05 | 0.00 | a = −29.54 + 12.16 d | ||

| b* | 0.74 | 0.00 | 0.00 | 0.00 | 0.00 | b = 33.65 − 7.23 d + 31.64 g − 1.96 s − 90.44 p | ||

| A10 | Red | L* | 0.88 | >0.05 | 0.02 | 0.02 | 0.00 | L = 53.91 − 26.75 d − 1.21 s − 30.89 p |

| a* | 0.90 | >0.05 | 0.01 | 0.01 | 0.00 | a = 59.38 − 26.57 d − 1.23 s − 32.03 p | ||

| b* | 0.90 | >0.05 | 0.01 | 0.01 | 0.00 | b = 46.50 − 24 d − 1.10 s − 26.41 p | ||

| Green | L* | 0.76 | >0.05 | >0.05 | >0.05 | 0.00 | L = 35.97 − 31.89 d | |

| a* | 0.66 | >0.05 | >0.05 | >0.05 | 0.00 | a = −24.11 + 10.8 d | ||

| b* | 0.60 | 0.00 | 0.00 | 0.00 | 0.00 | b = 26.06 − 4.65 d + 29.73 g − 1.95 s − 87.75 p | ||

| F02/10 | Red | L* | 0.86 | >0.05 | 0.04 | 0.03 | 0.00 | L = 46.74 − 24.18 d − 1.1 s − 28.02 p |

| a* | 0.92 | >0.05 | 0.00 | 0.00 | 0.00 | a = 48.42 − 25.19 d − 1.21 s − 30.92 p | ||

| b* | 0.92 | >0.05 | 0.00 | 0.01 | 0.00 | b = 30.86 − 17.08 d − 0.81 s − 18.5 p | ||

| Green | L* | 0.76 | >0.05 | >0.05 | >0.05 | 0.00 | L = 35.98 − 32.38 d | |

| a* | 0.79 | 0.00 | 0.05 | 0.01 | 0.00 | a = −31.58 + 10.41 d − 14.95 g + 0.75 s + 39.02 p | ||

| b* | 0.70 | 0.00 | 0.00 | 0.00 | 0.00 | b = 33.78 − 7.94 d + 33.17 g − 2.16 s − 96.93 p |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandal, S.; Chowdhury, I.Z.; Hebert, P.R.; Petrova, A.; Tushar, S.I.; Islam, M.M.; Boorady, L.M. An Approach for Predicting the Apparent Color of Carpets under Different Illuminants. Appl. Sci. 2023, 13, 500. https://doi.org/10.3390/app13010500

Mandal S, Chowdhury IZ, Hebert PR, Petrova A, Tushar SI, Islam MM, Boorady LM. An Approach for Predicting the Apparent Color of Carpets under Different Illuminants. Applied Sciences. 2023; 13(1):500. https://doi.org/10.3390/app13010500

Chicago/Turabian StyleMandal, Sumit, Ishmam Zahin Chowdhury, Paulette R. Hebert, Adriana Petrova, Shariful Islam Tushar, MD. Momtaz Islam, and Lynn M. Boorady. 2023. "An Approach for Predicting the Apparent Color of Carpets under Different Illuminants" Applied Sciences 13, no. 1: 500. https://doi.org/10.3390/app13010500

APA StyleMandal, S., Chowdhury, I. Z., Hebert, P. R., Petrova, A., Tushar, S. I., Islam, M. M., & Boorady, L. M. (2023). An Approach for Predicting the Apparent Color of Carpets under Different Illuminants. Applied Sciences, 13(1), 500. https://doi.org/10.3390/app13010500