Experimental Analysis of the Behaviour of Piled Raft Foundations in Loose Sand

Abstract

1. Introduction

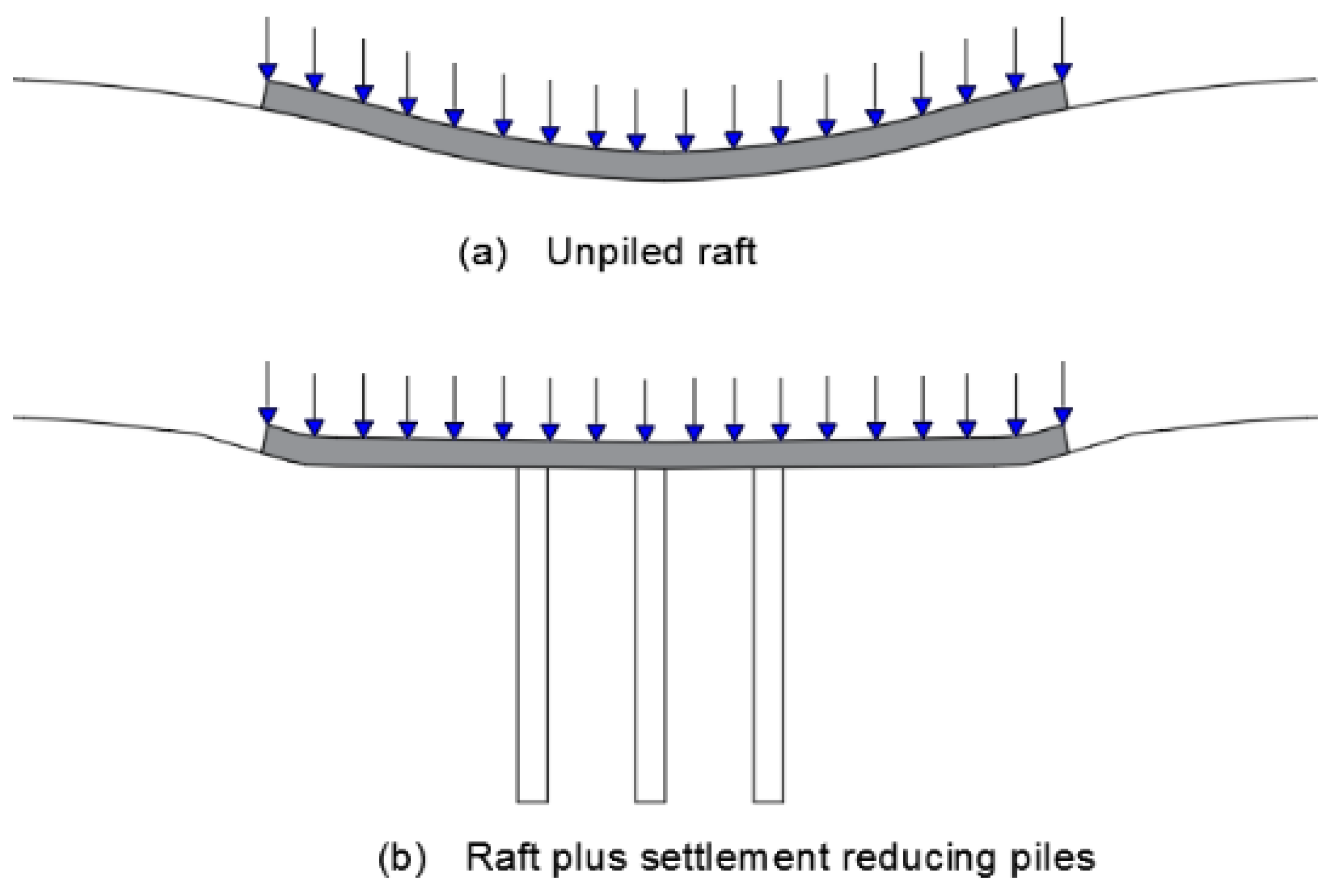

1.1. Foreword

1.2. Introduction

2. Materials and Methods

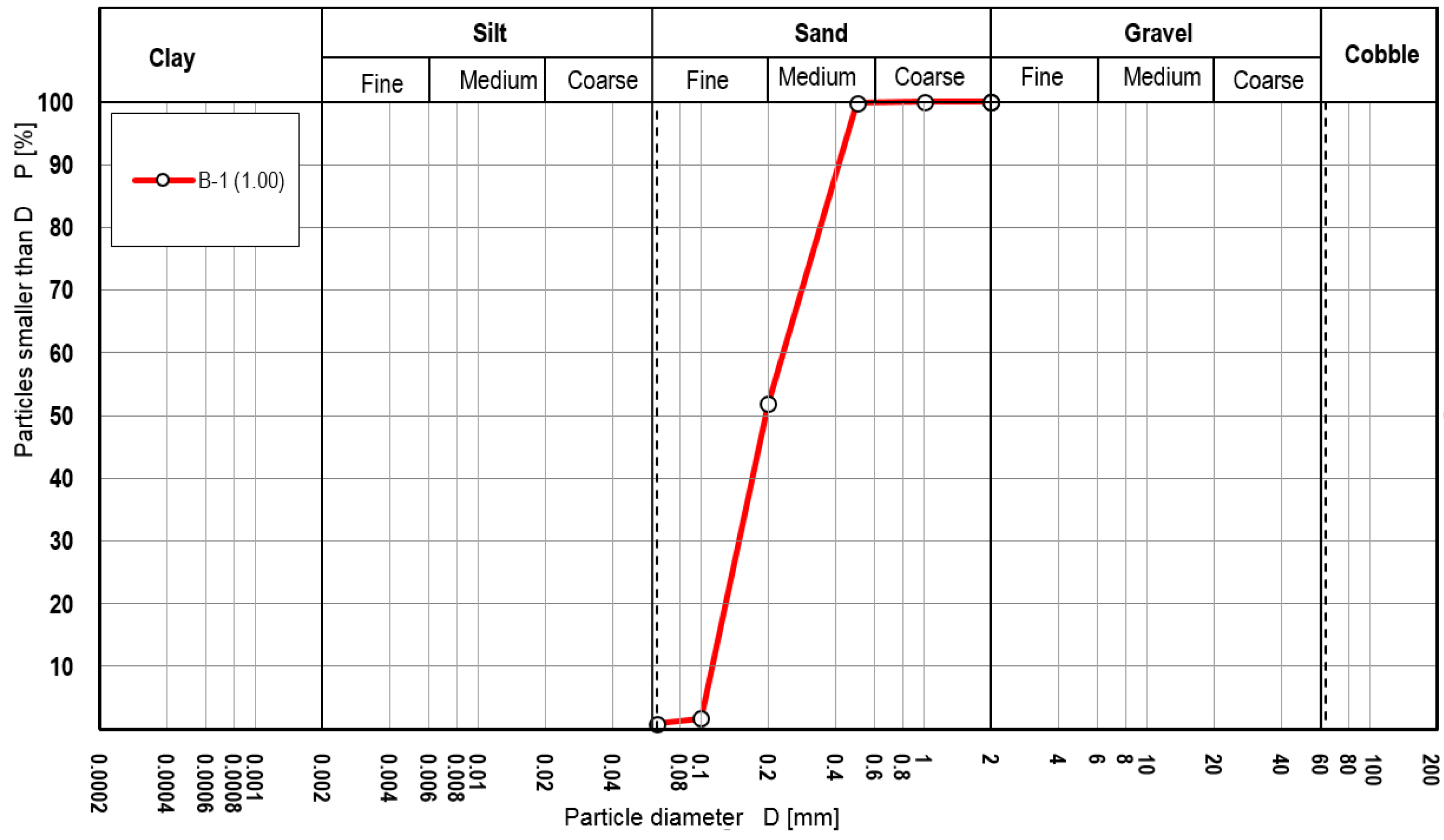

2.1. Soil Parameters

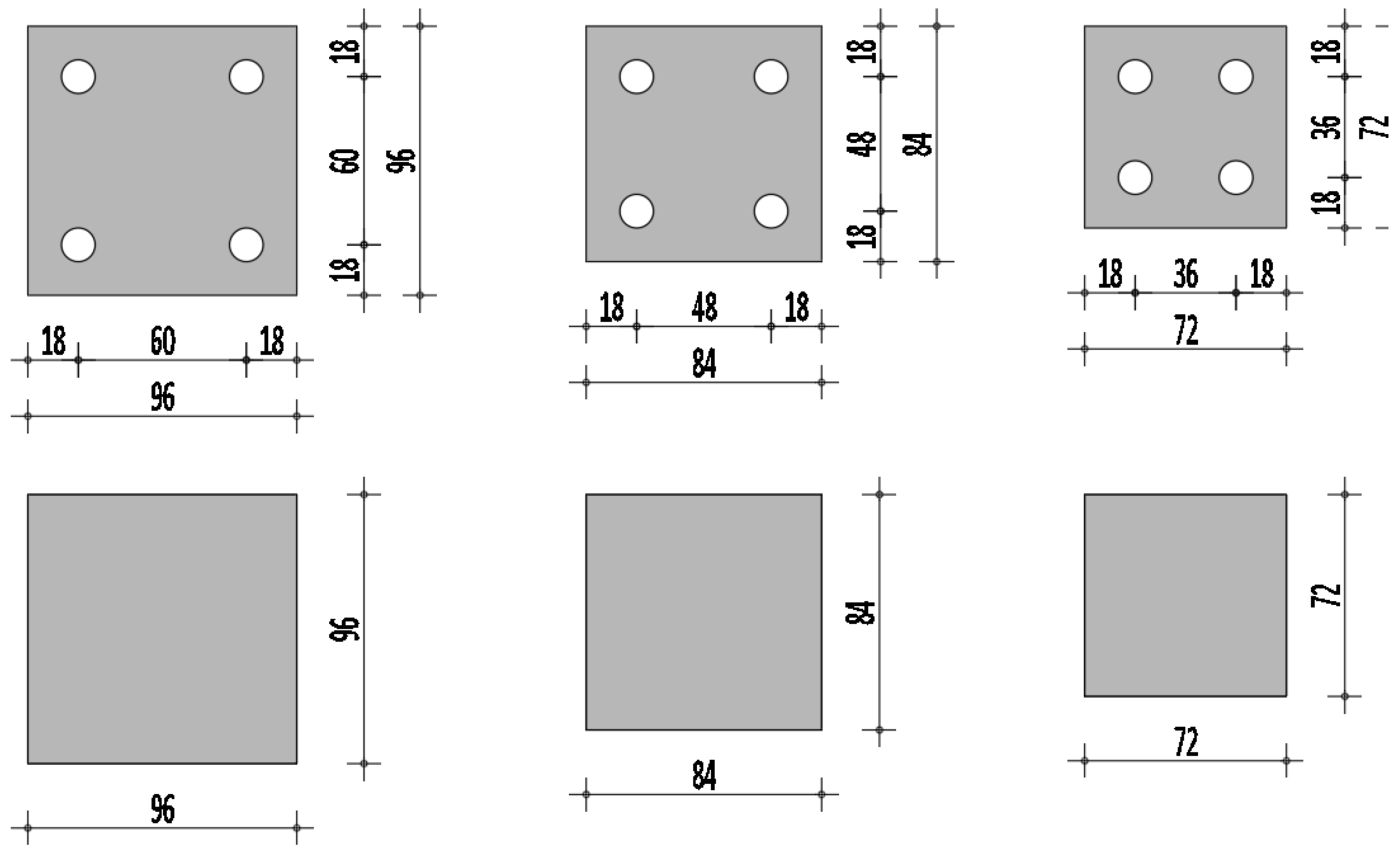

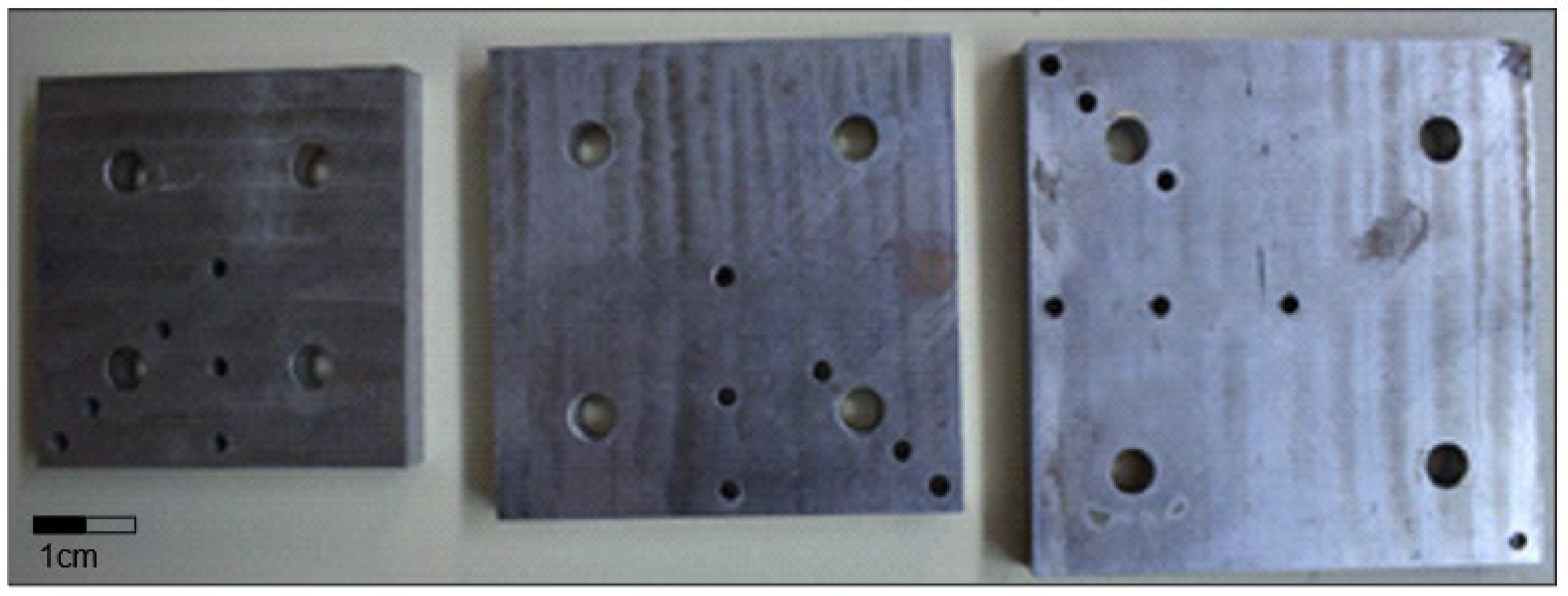

2.2. Models of Piled Raft Foundations

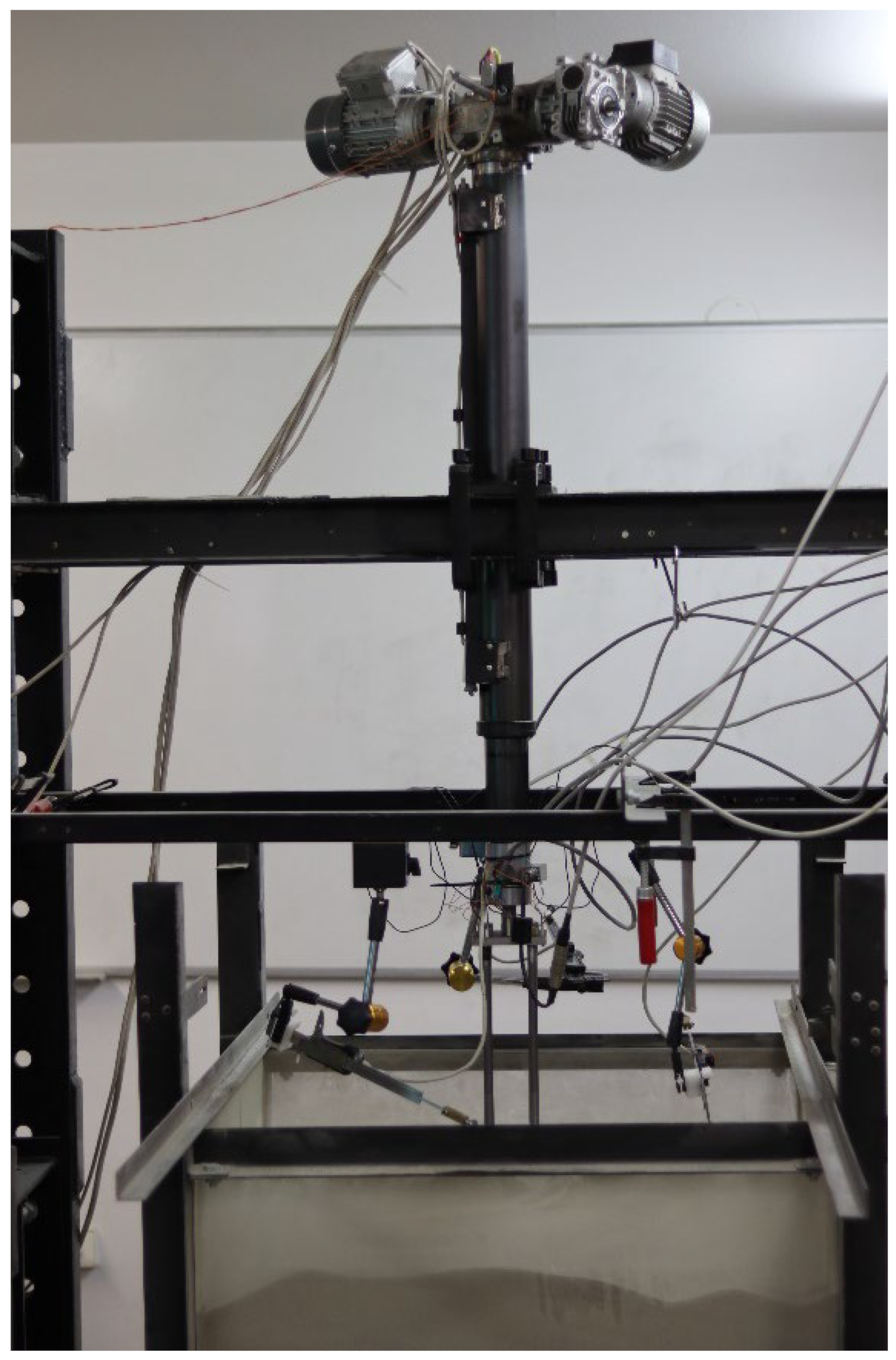

2.3. Measuring Instruments and Equipment

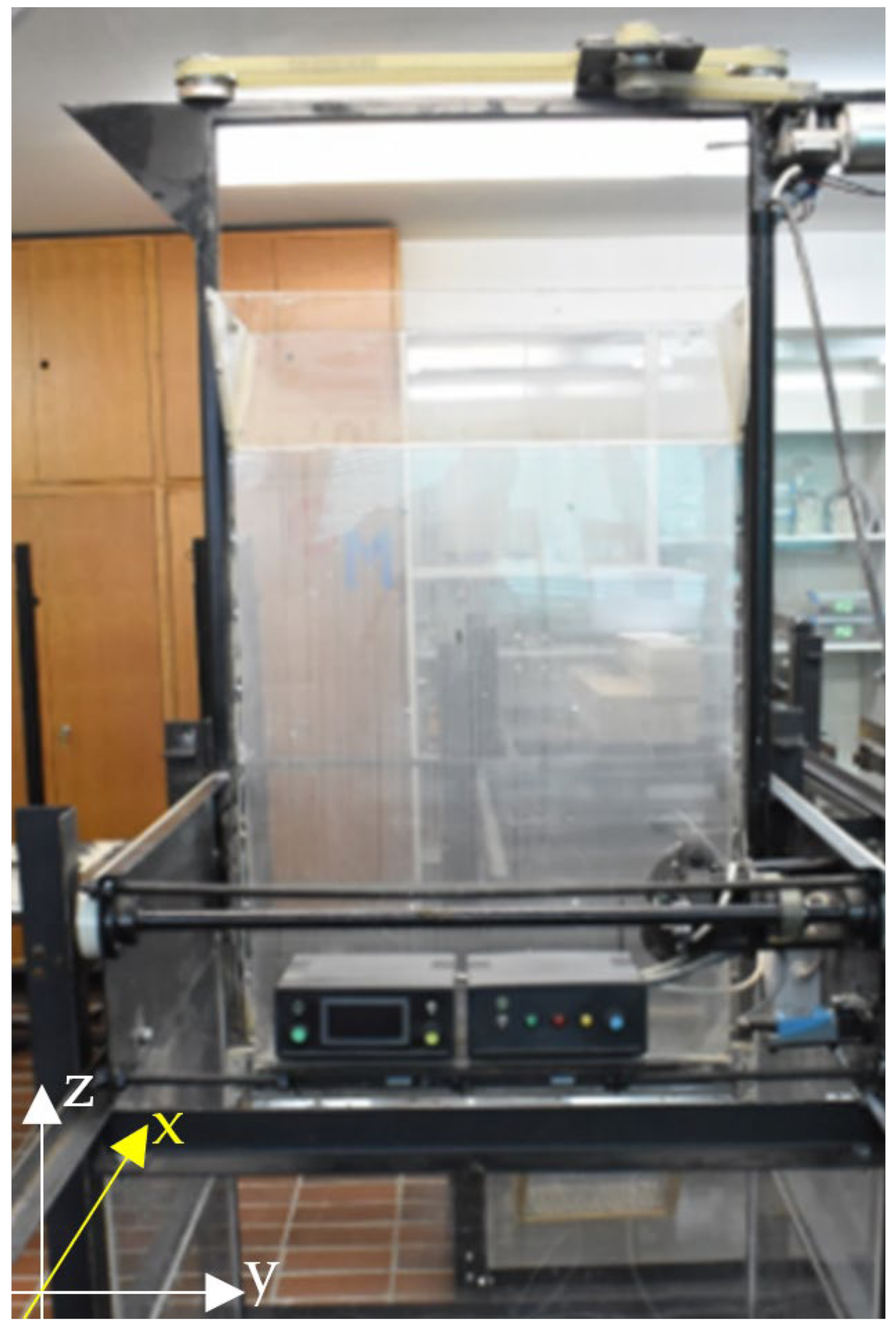

2.3.1. Test Box

2.3.2. Data Logger

2.3.3. Digital Callipers

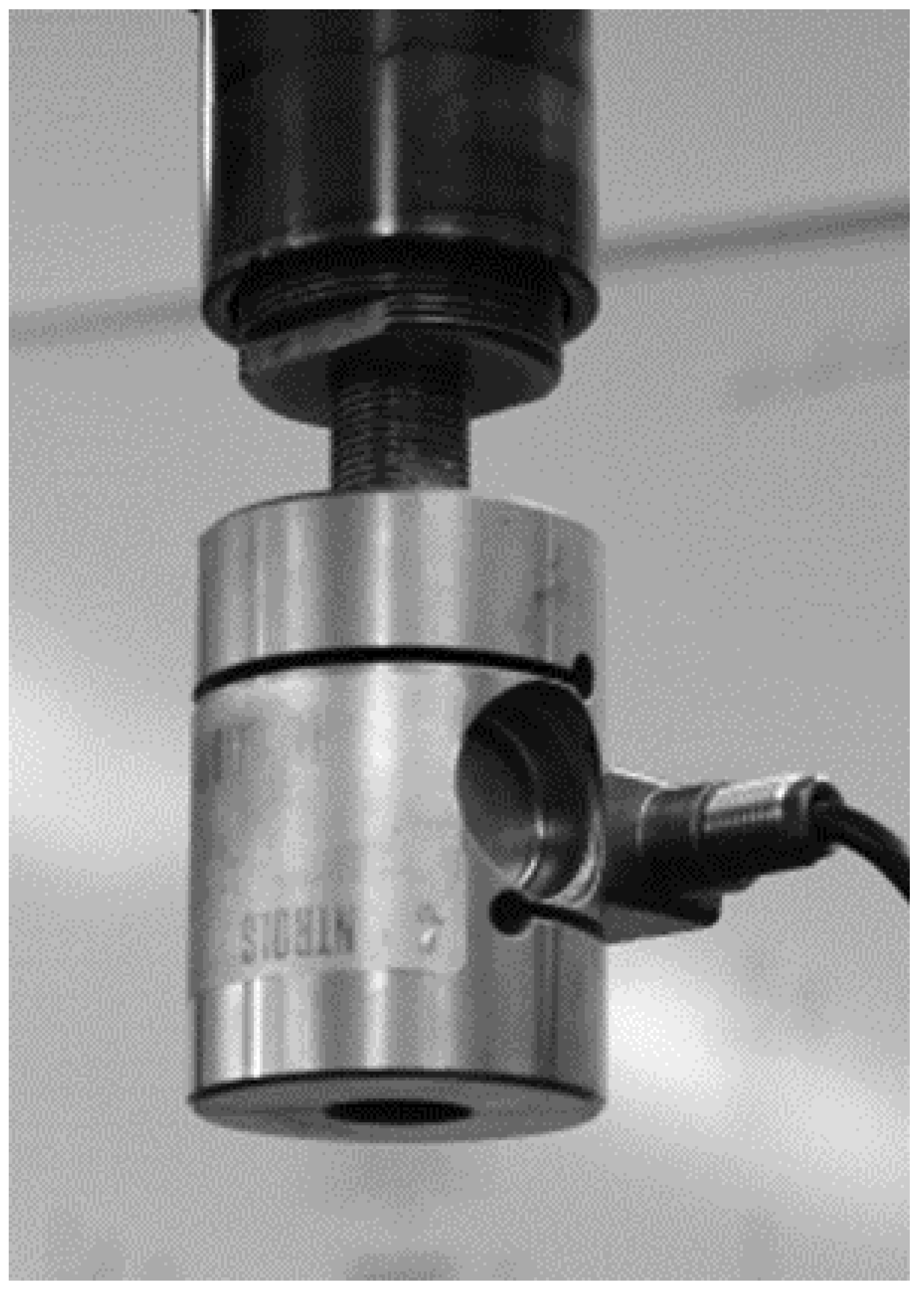

2.3.4. Load Cell

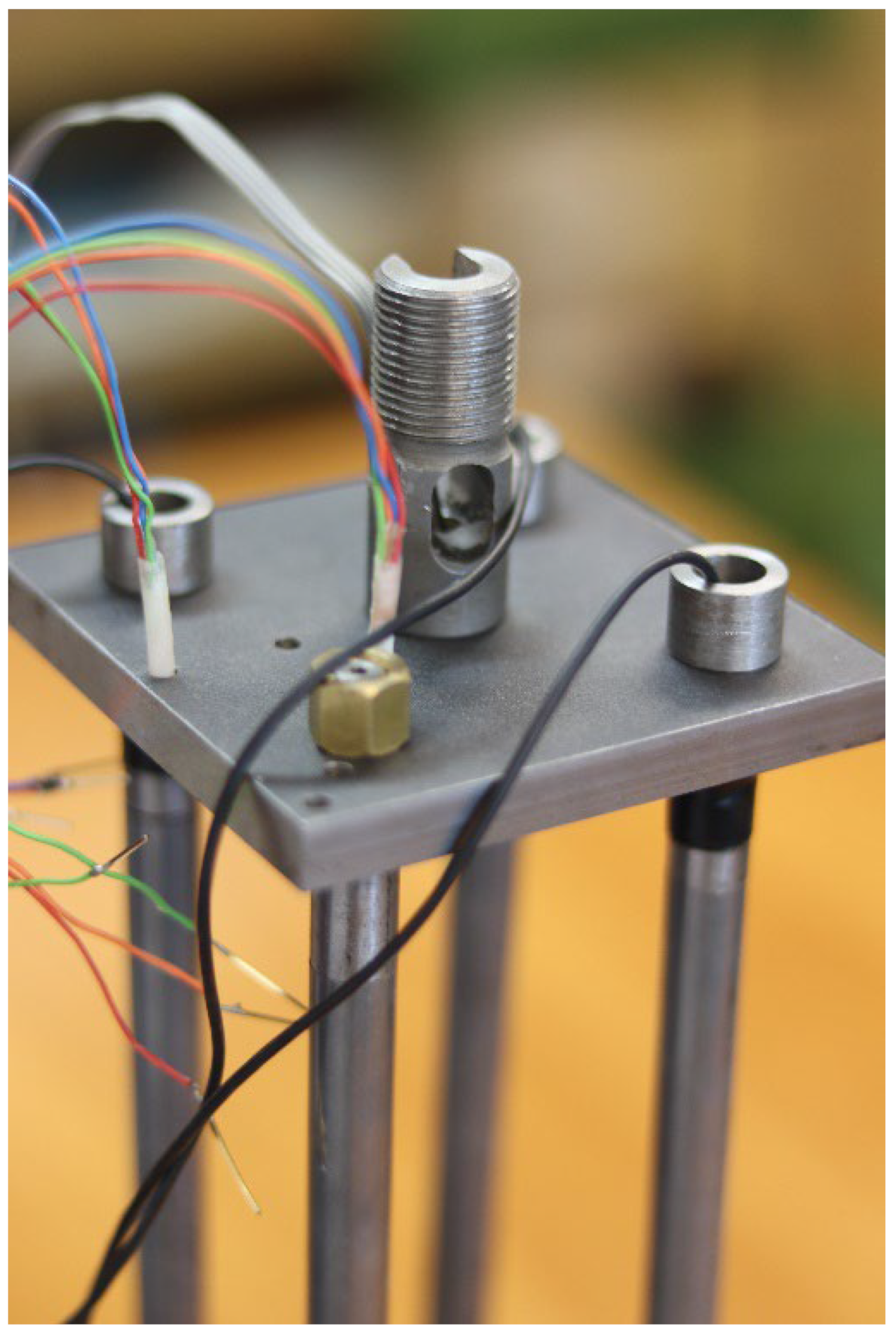

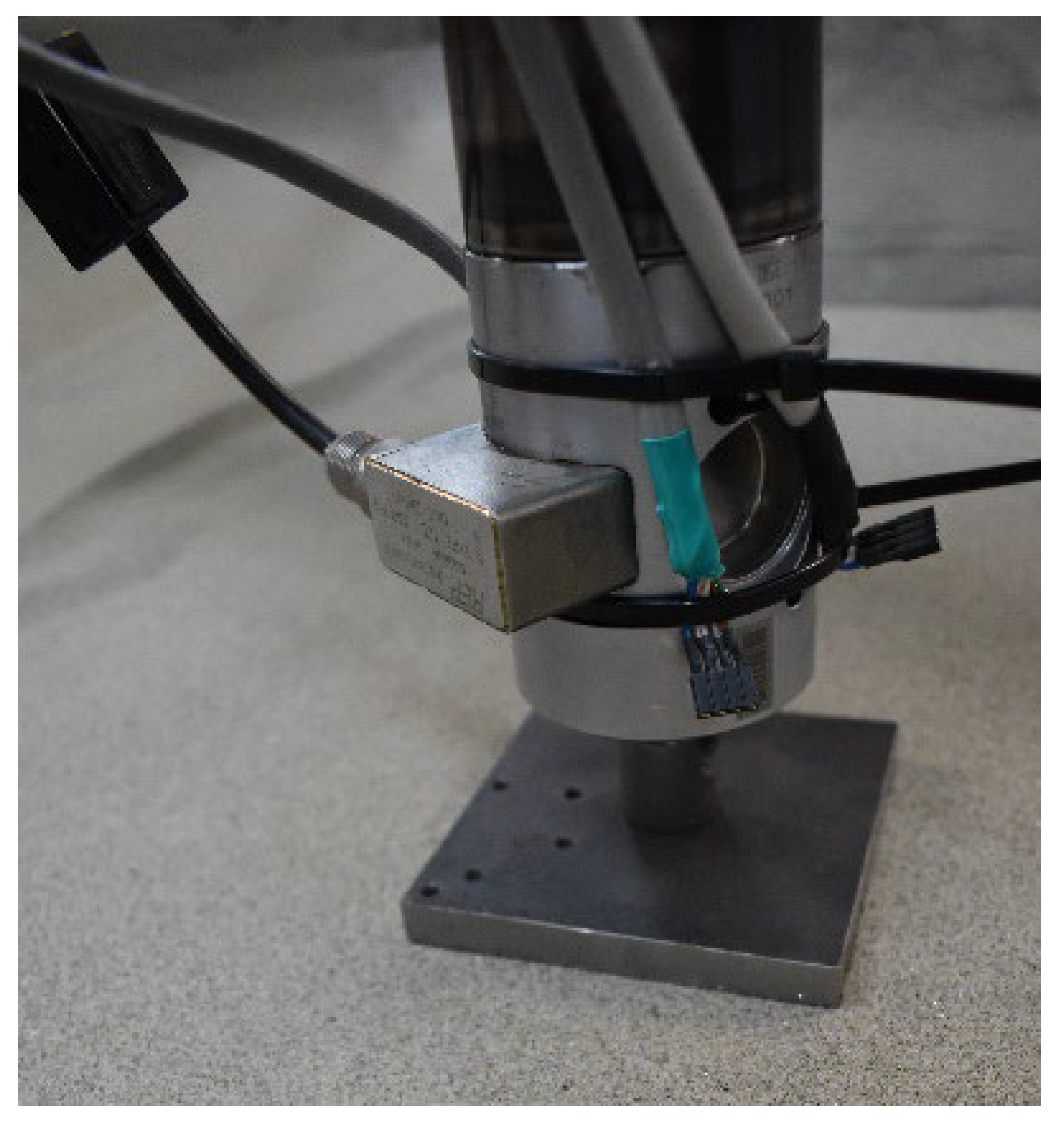

2.3.5. Sensor for Measuring the Force in the Pile

2.3.6. Spreader

2.4. Testing Procedure

3. Results and Discussion

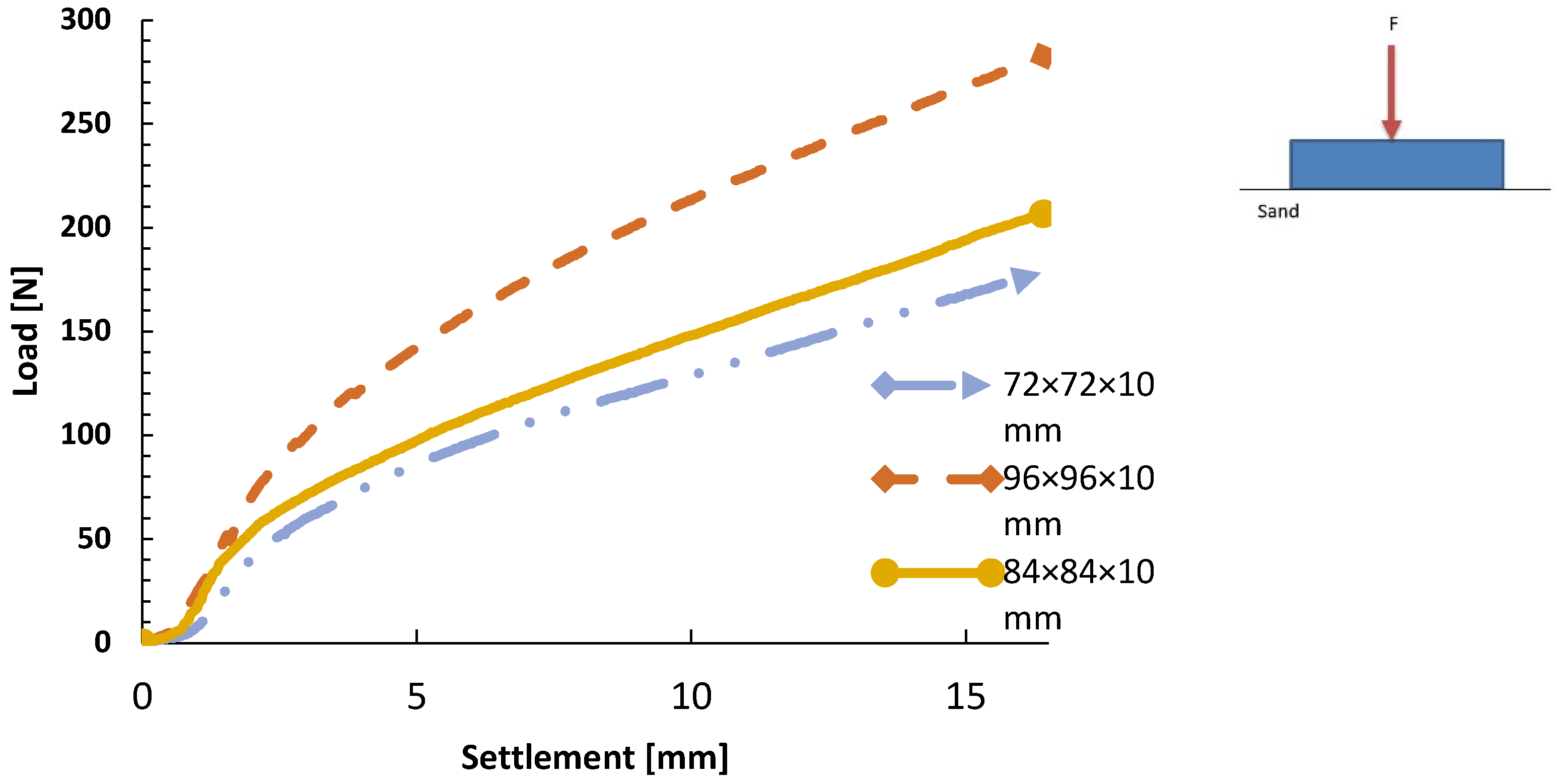

3.1. Rafts without Piles

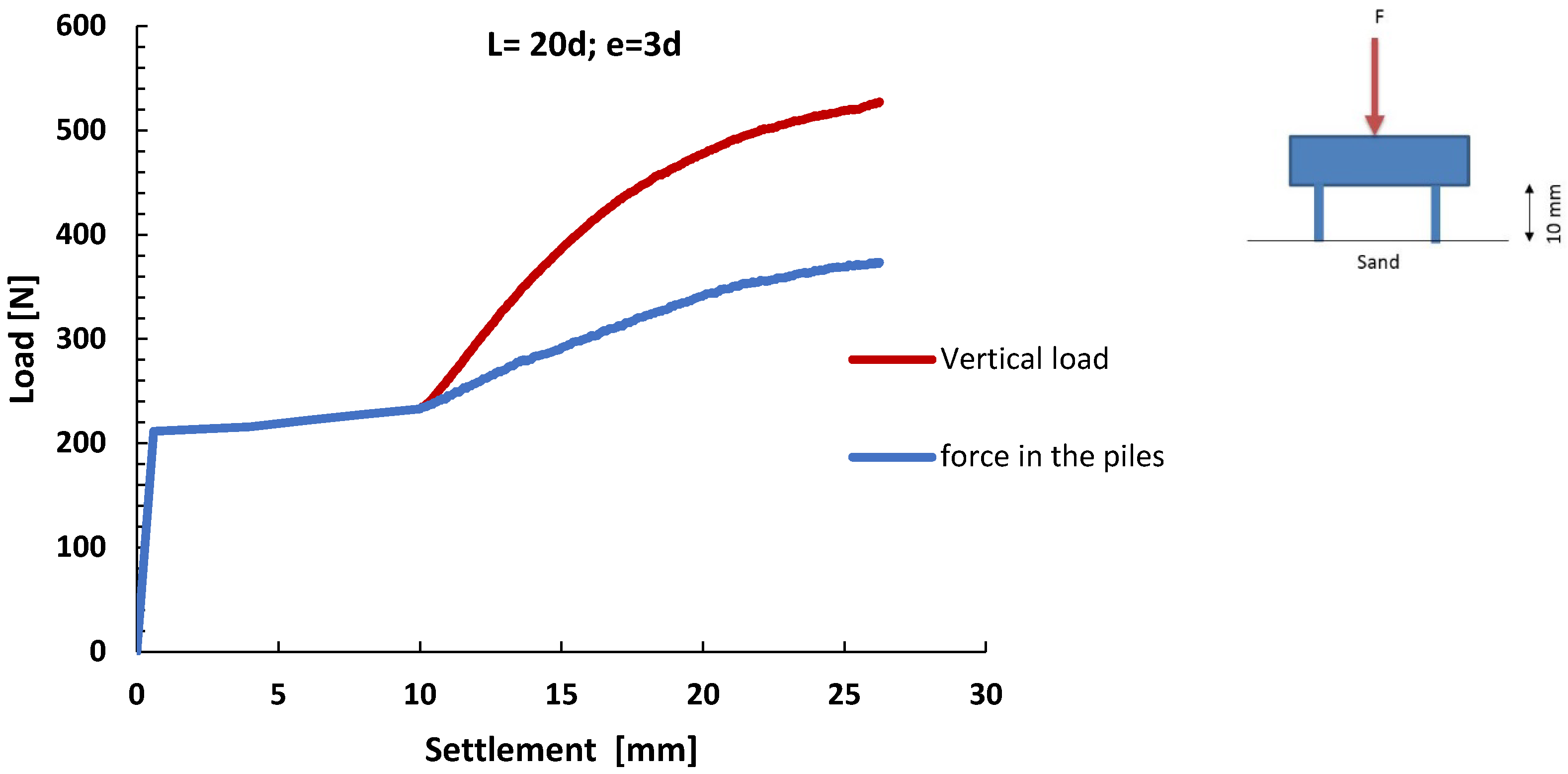

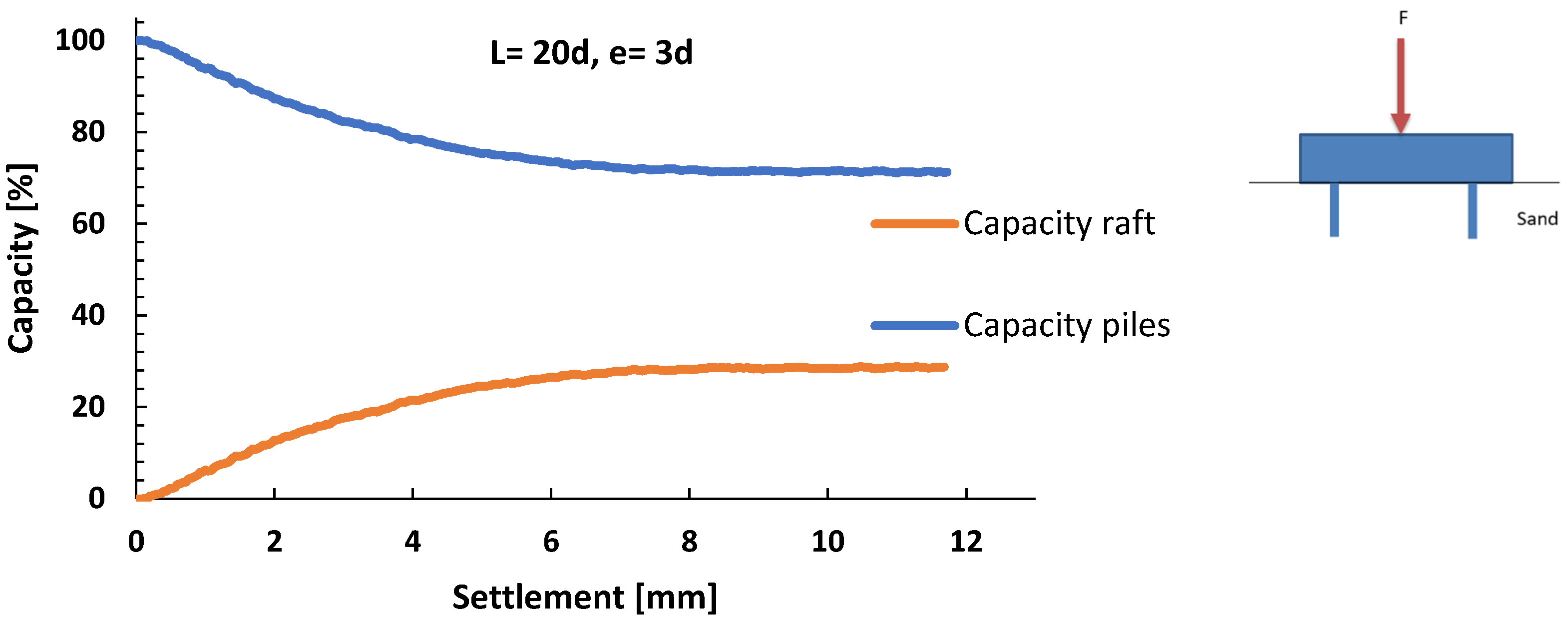

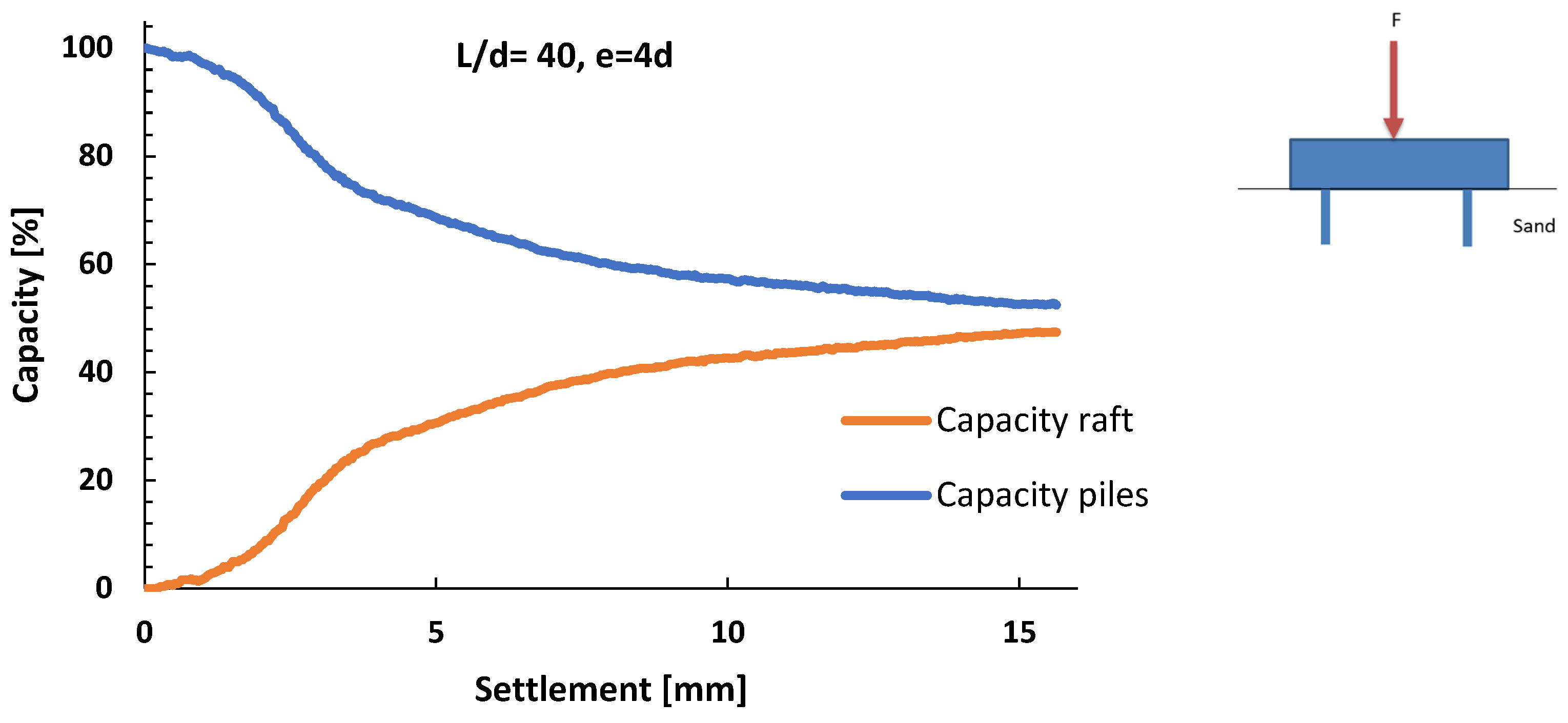

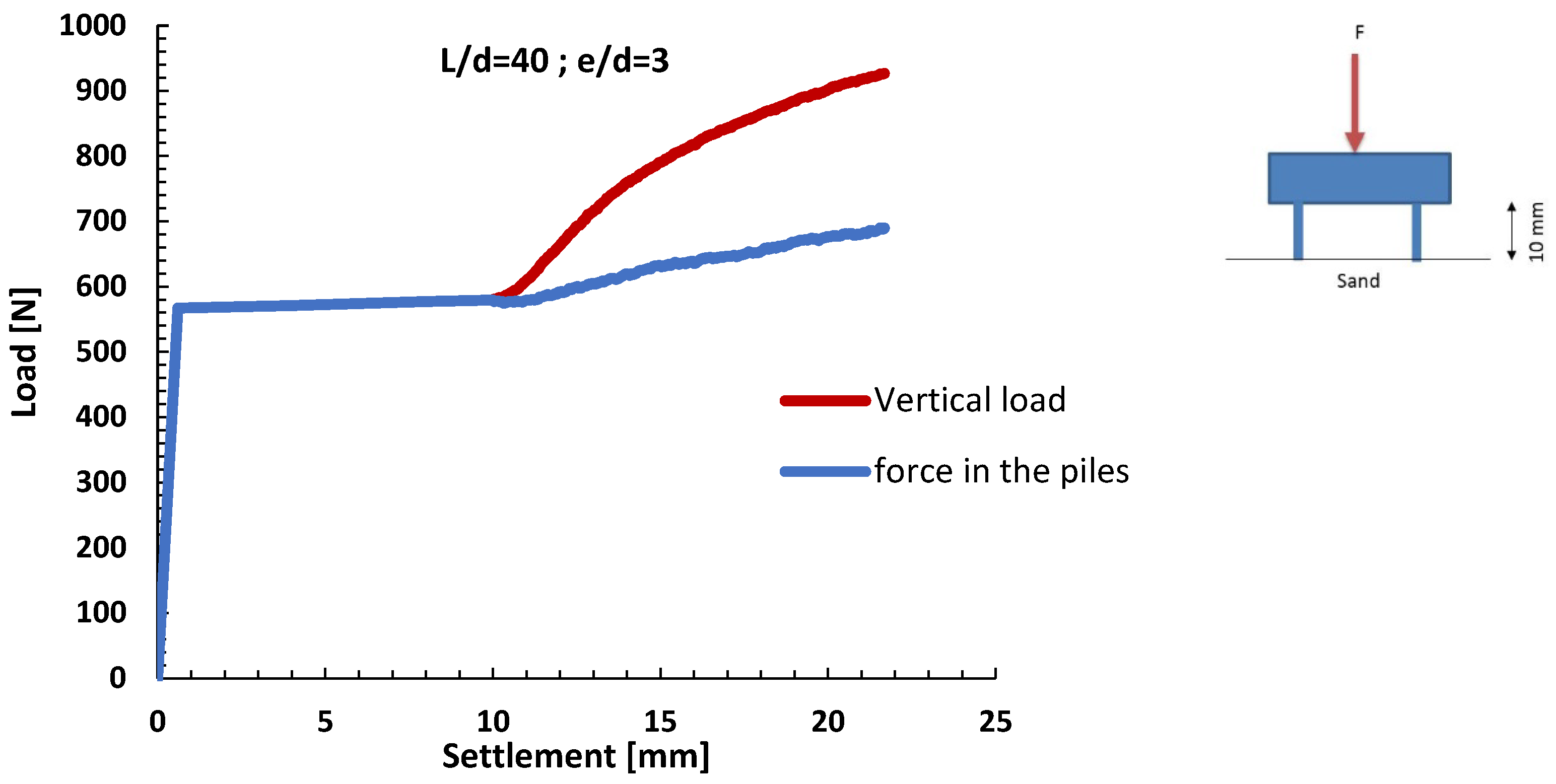

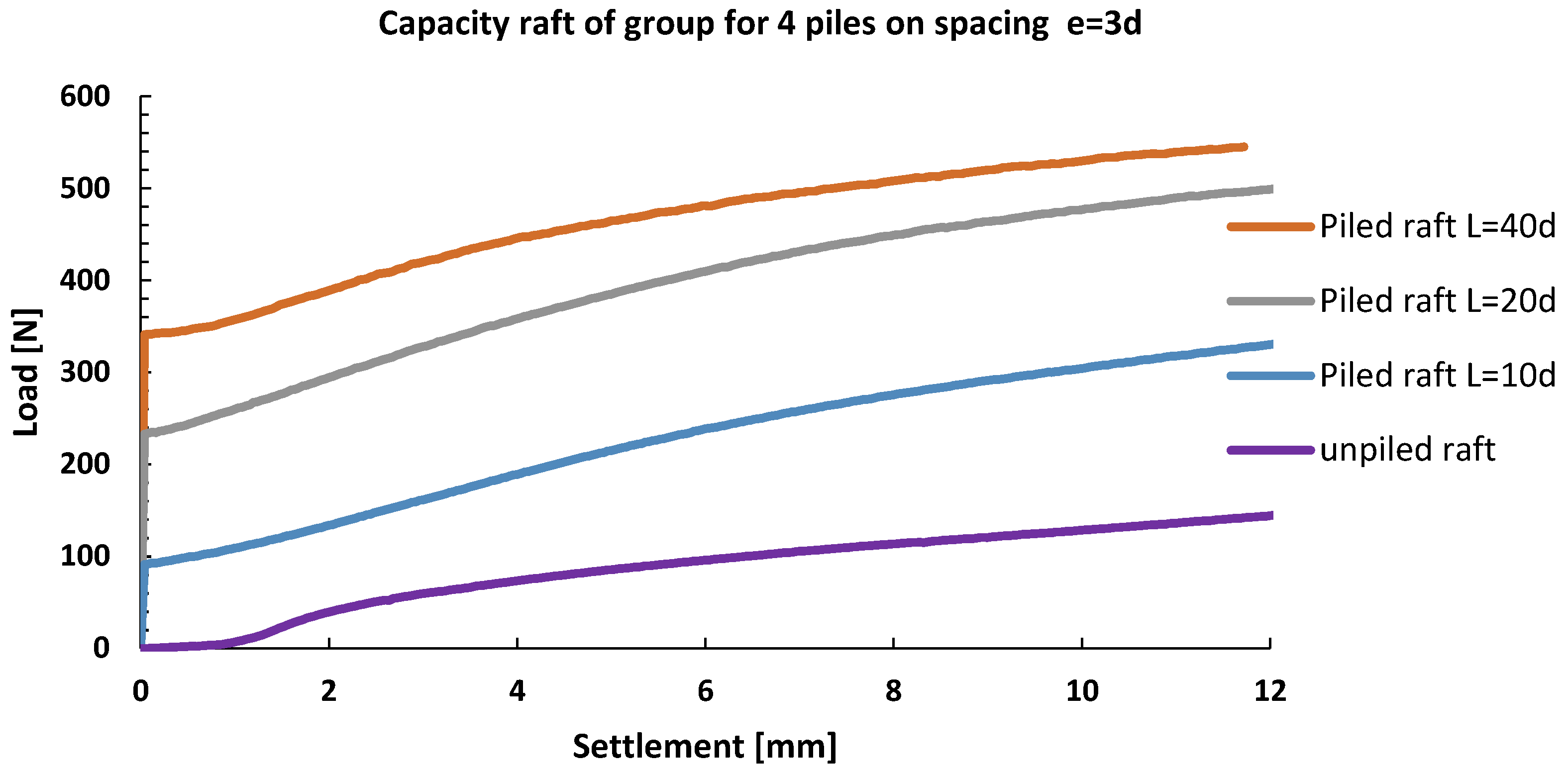

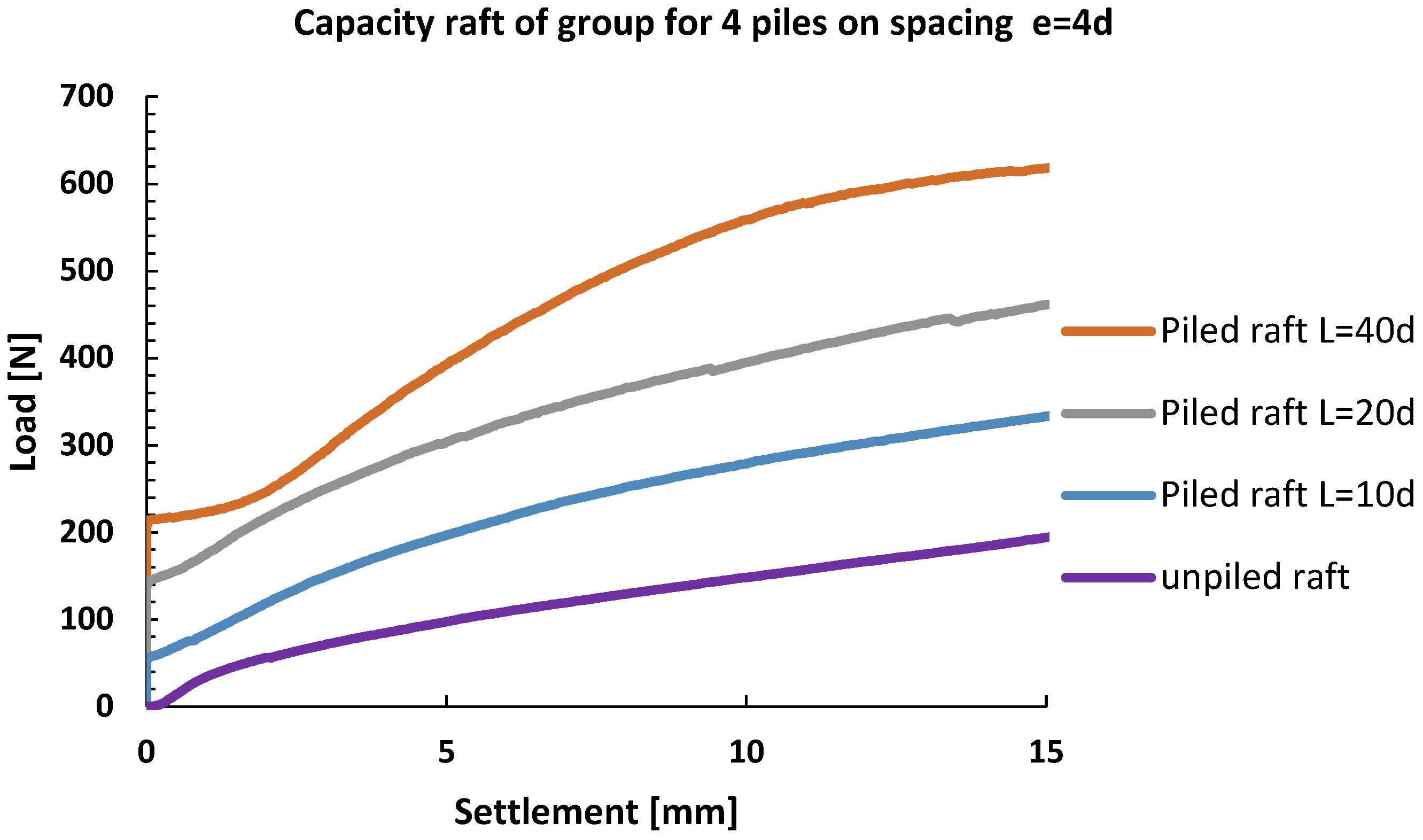

3.2. Piled Raft

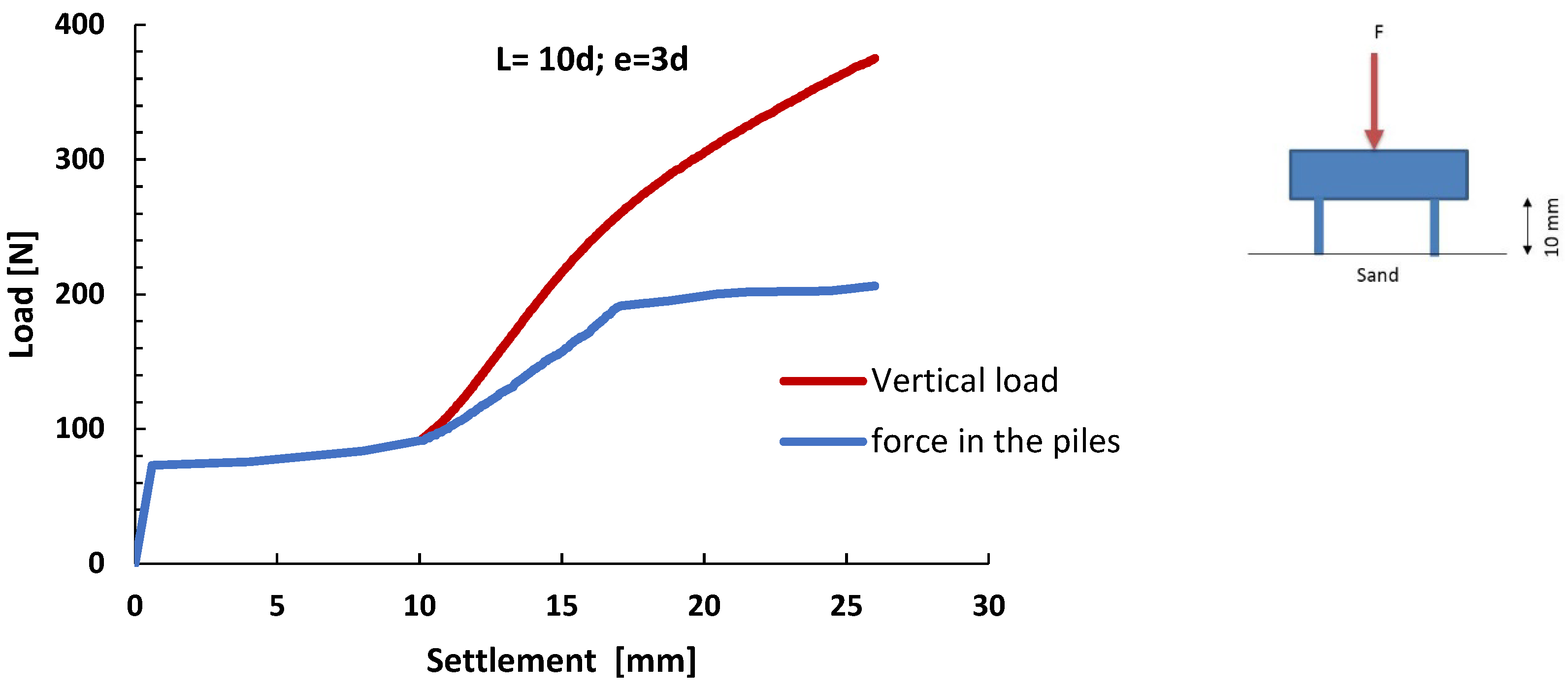

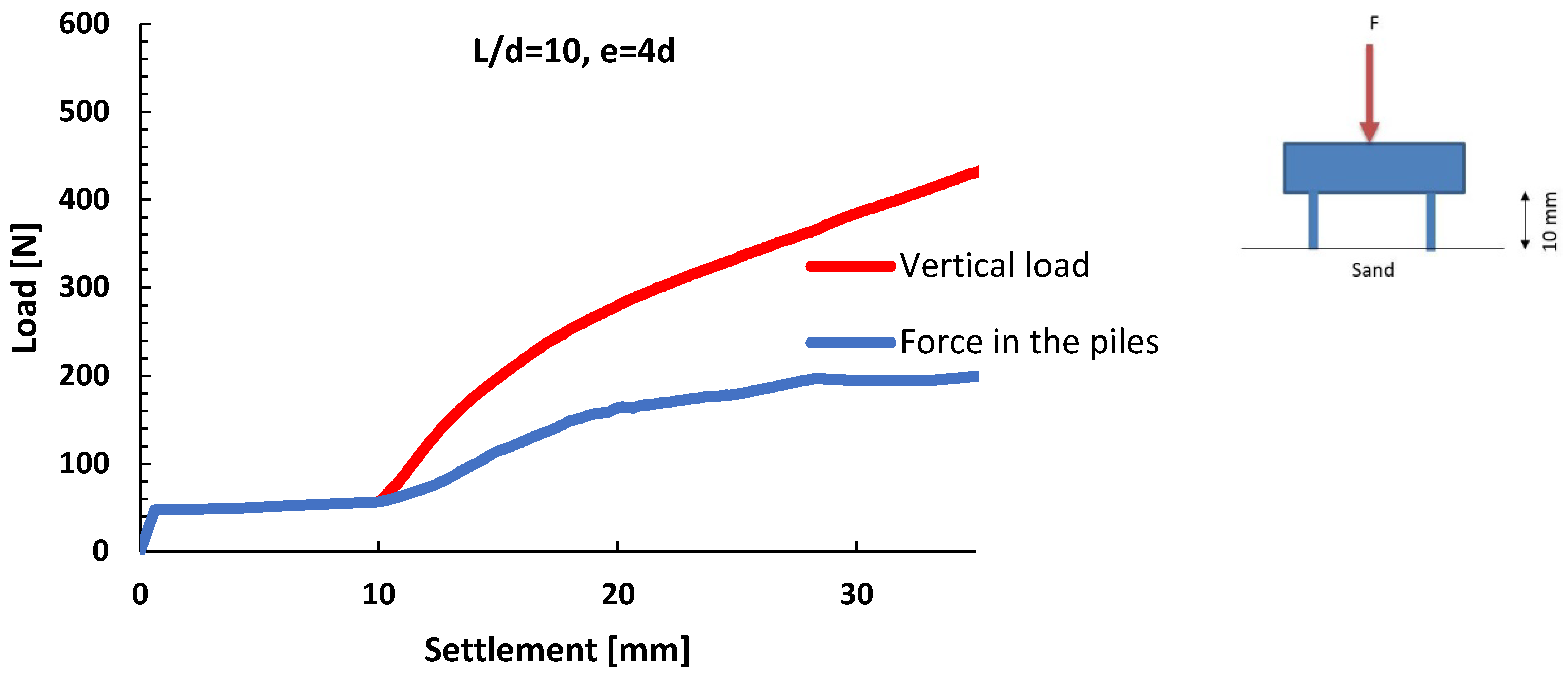

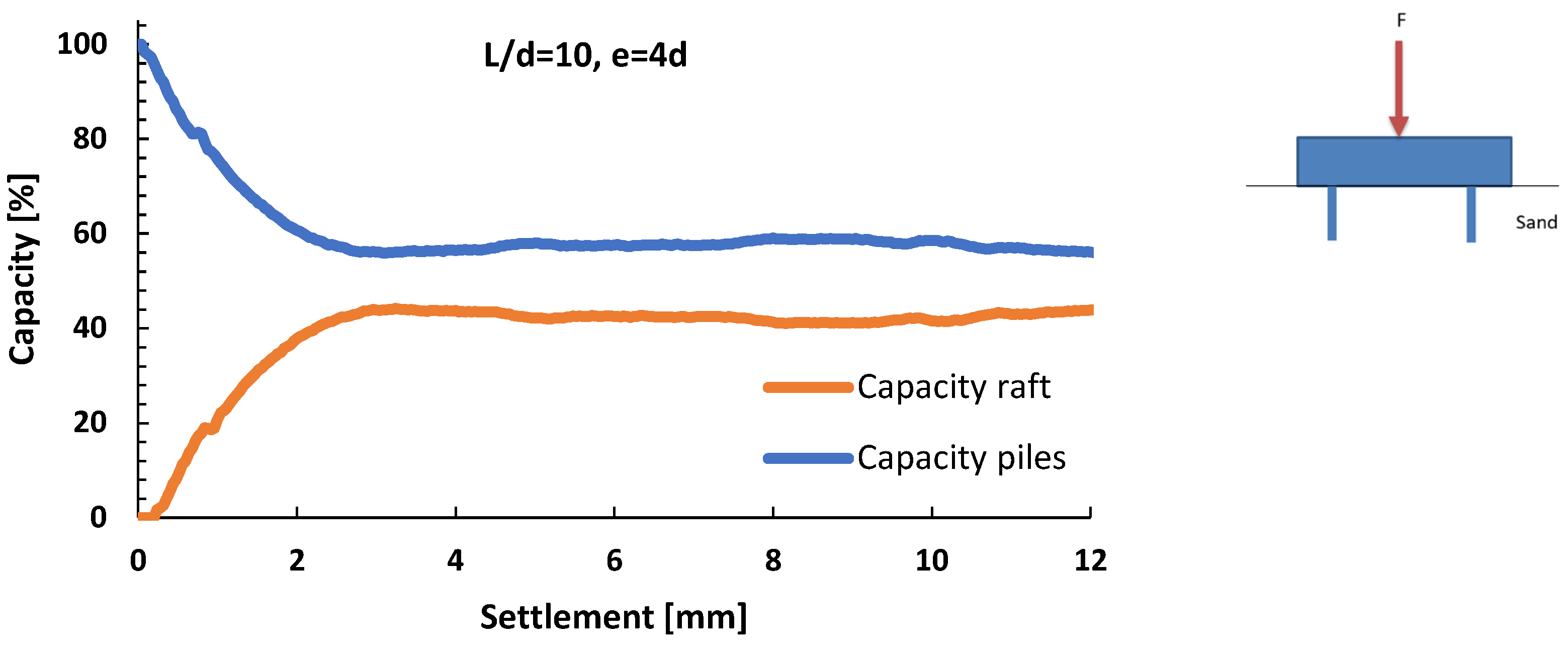

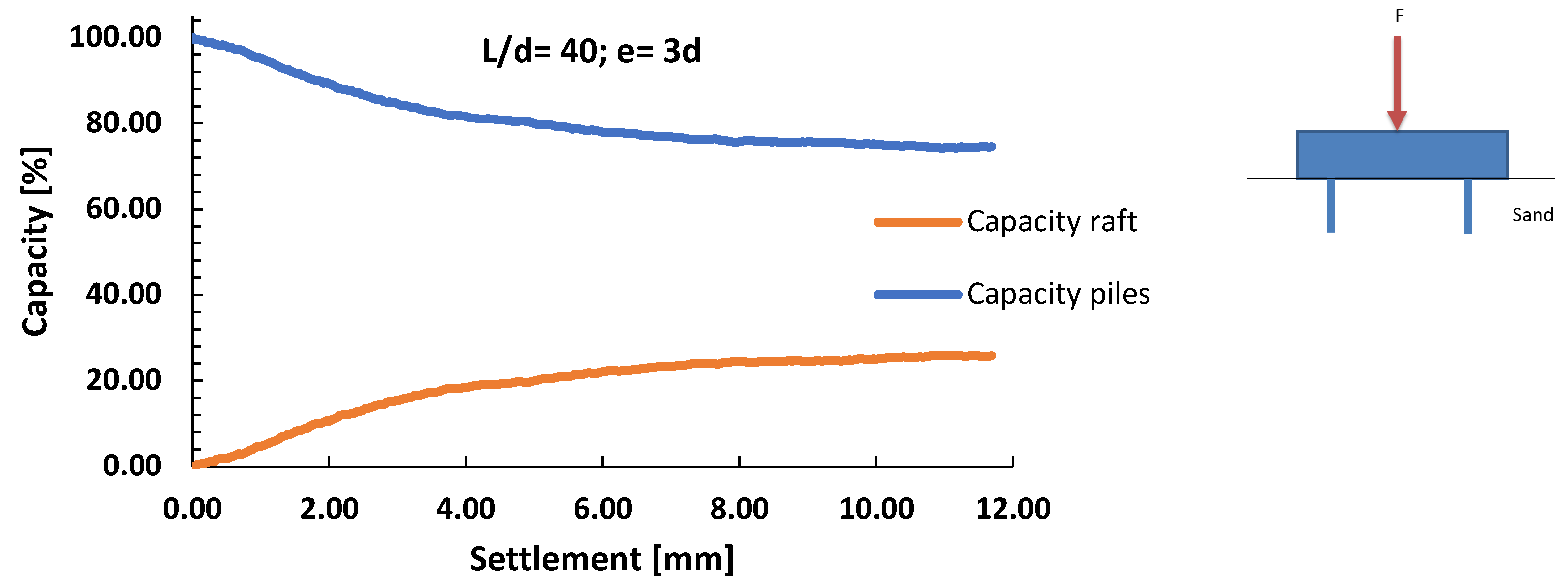

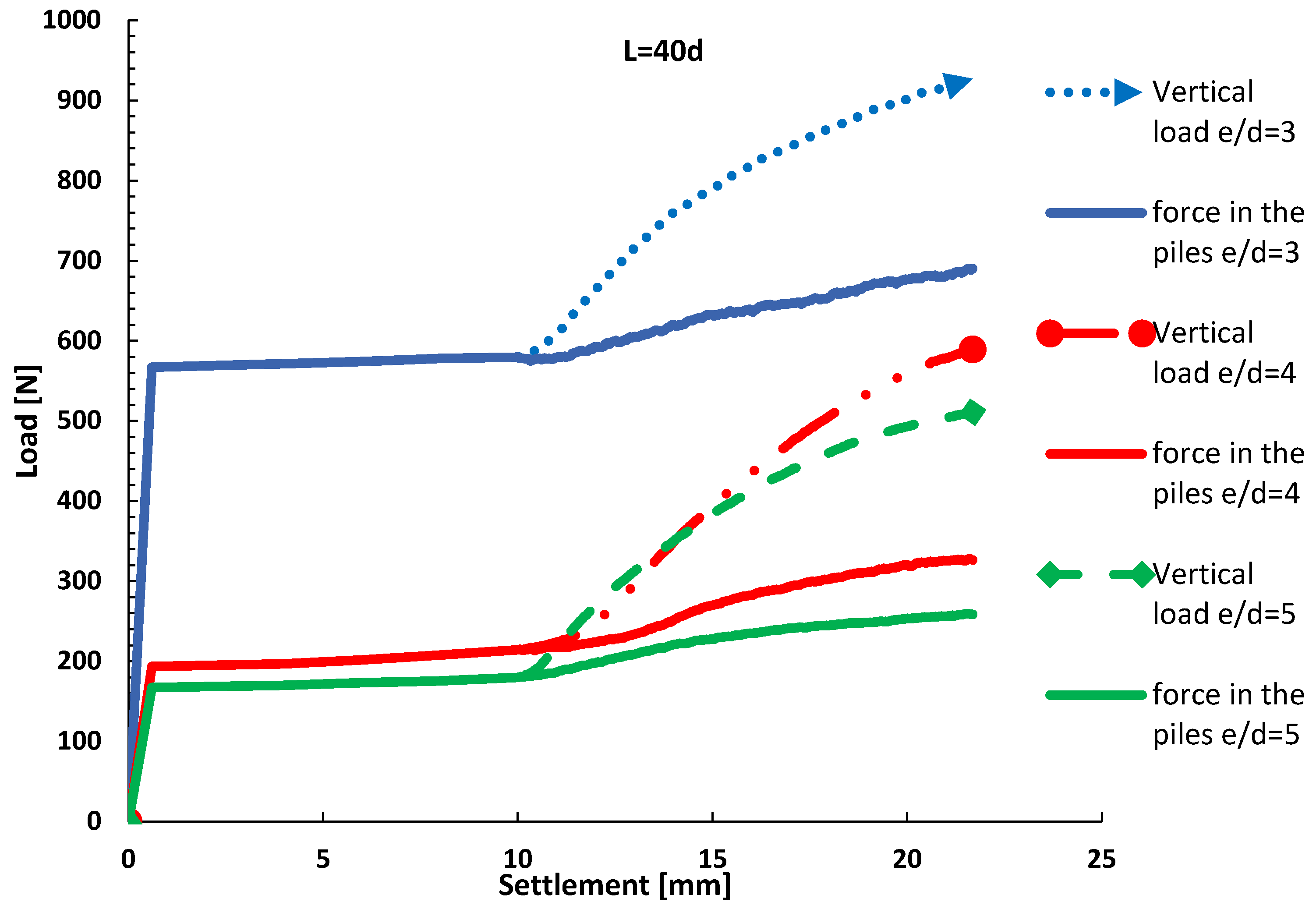

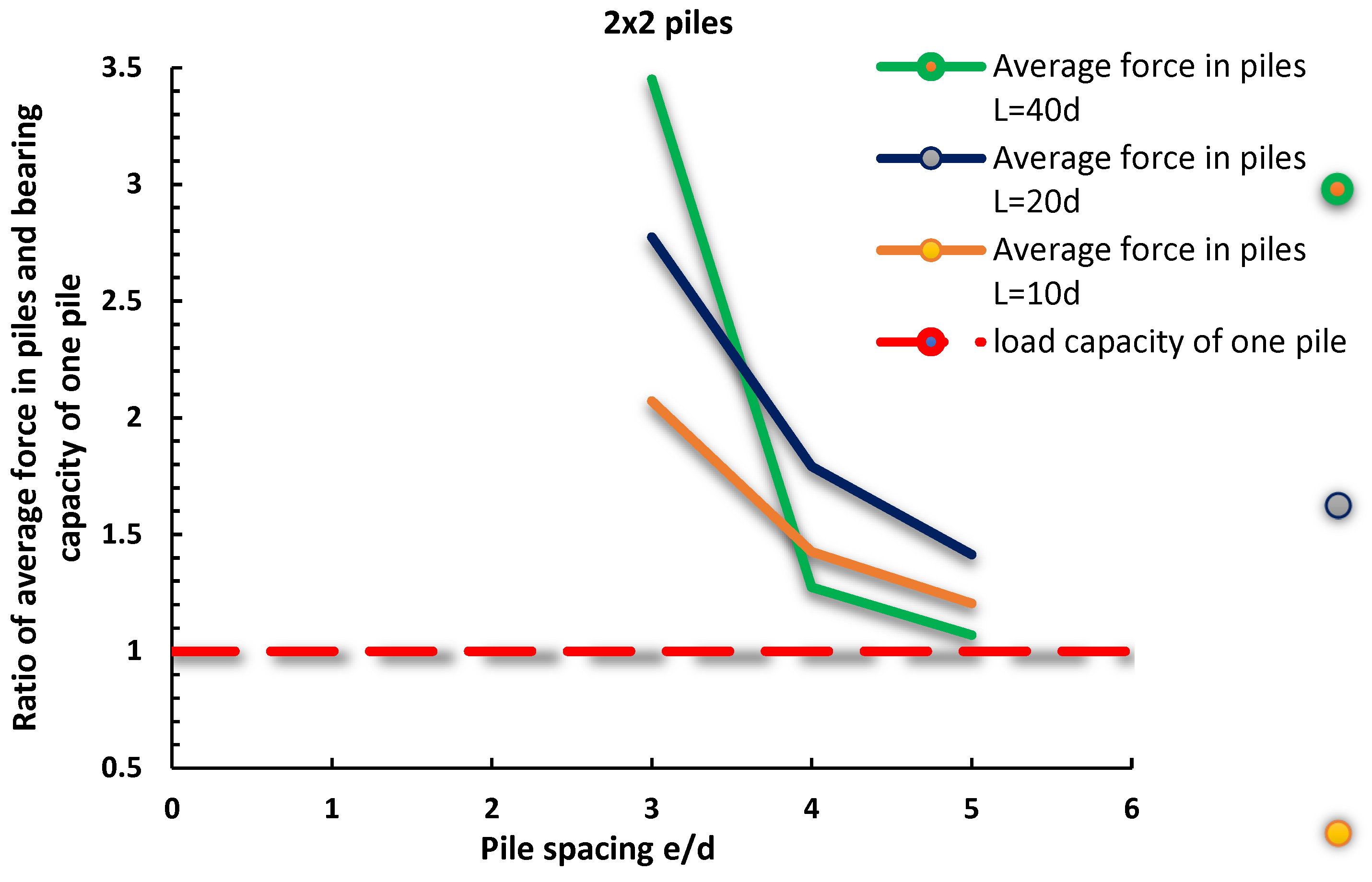

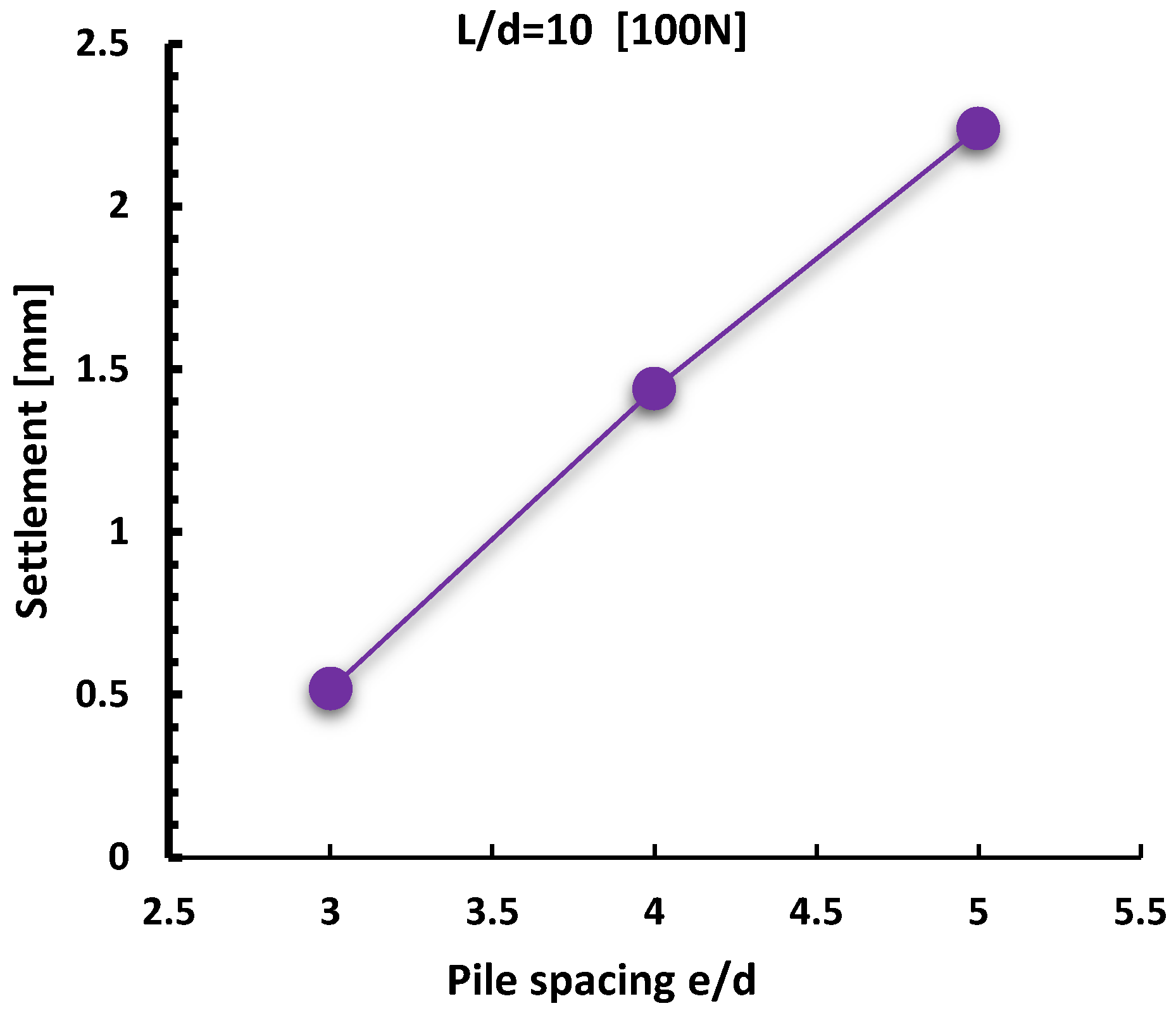

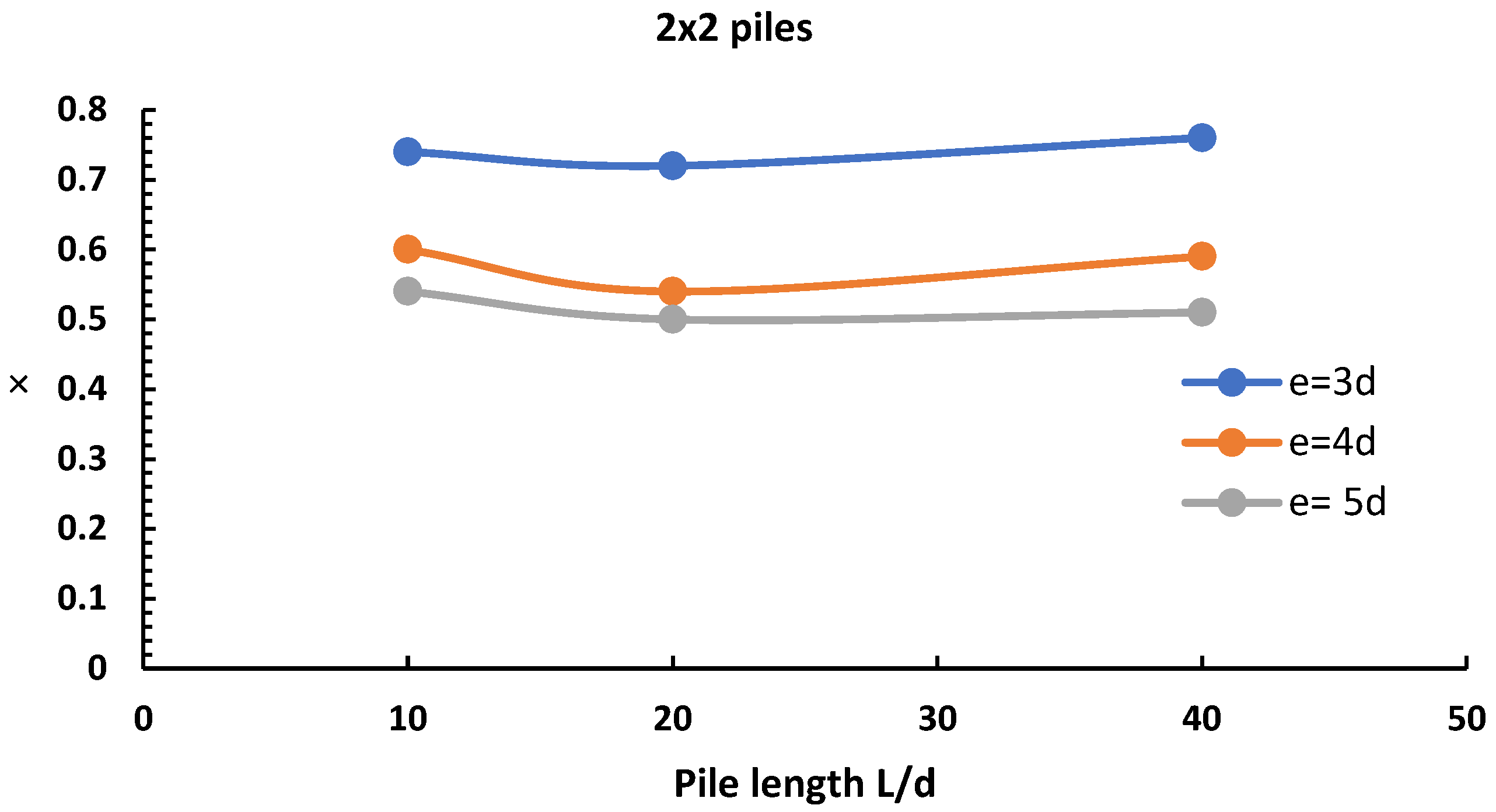

3.3. Influence of Pile Distance—Group Effect

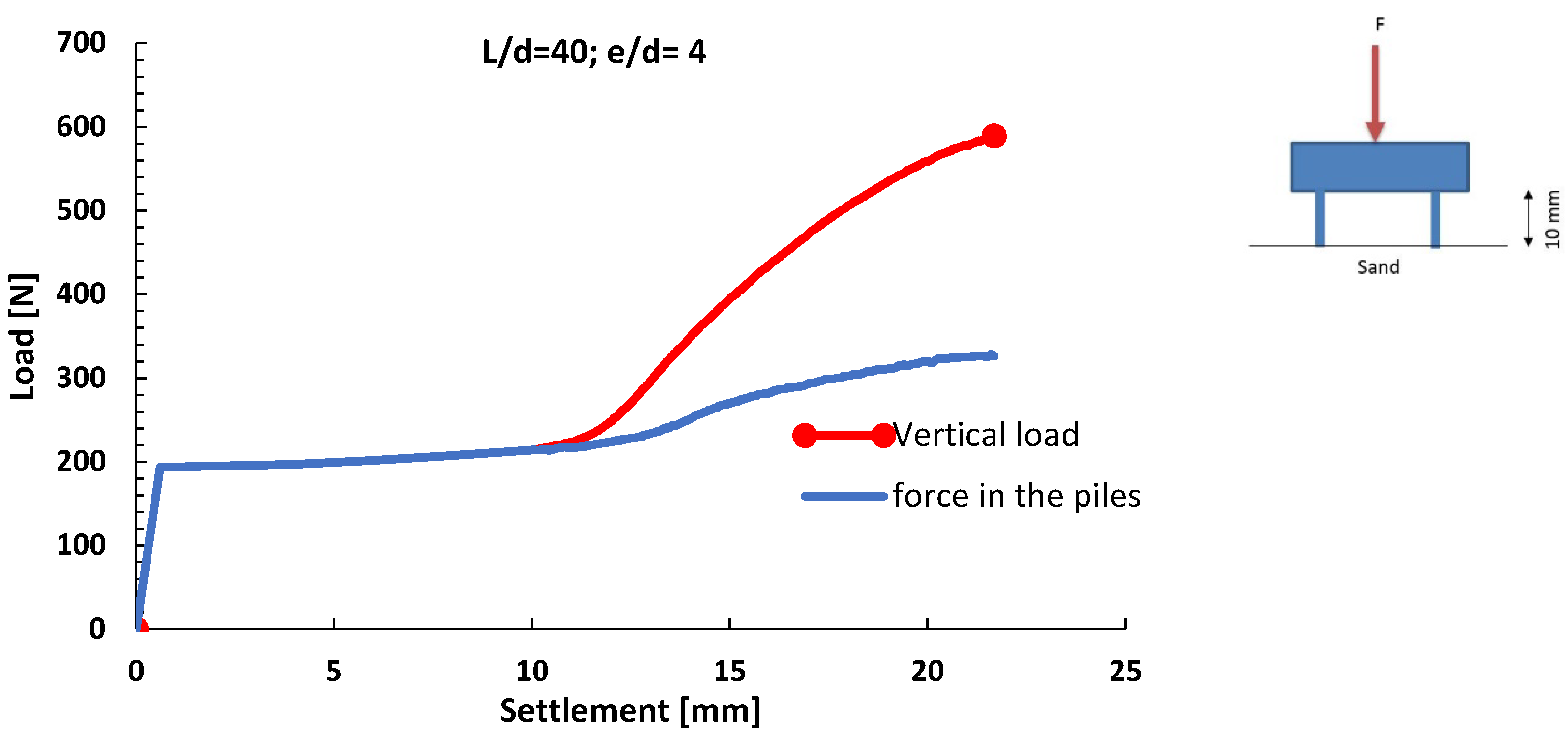

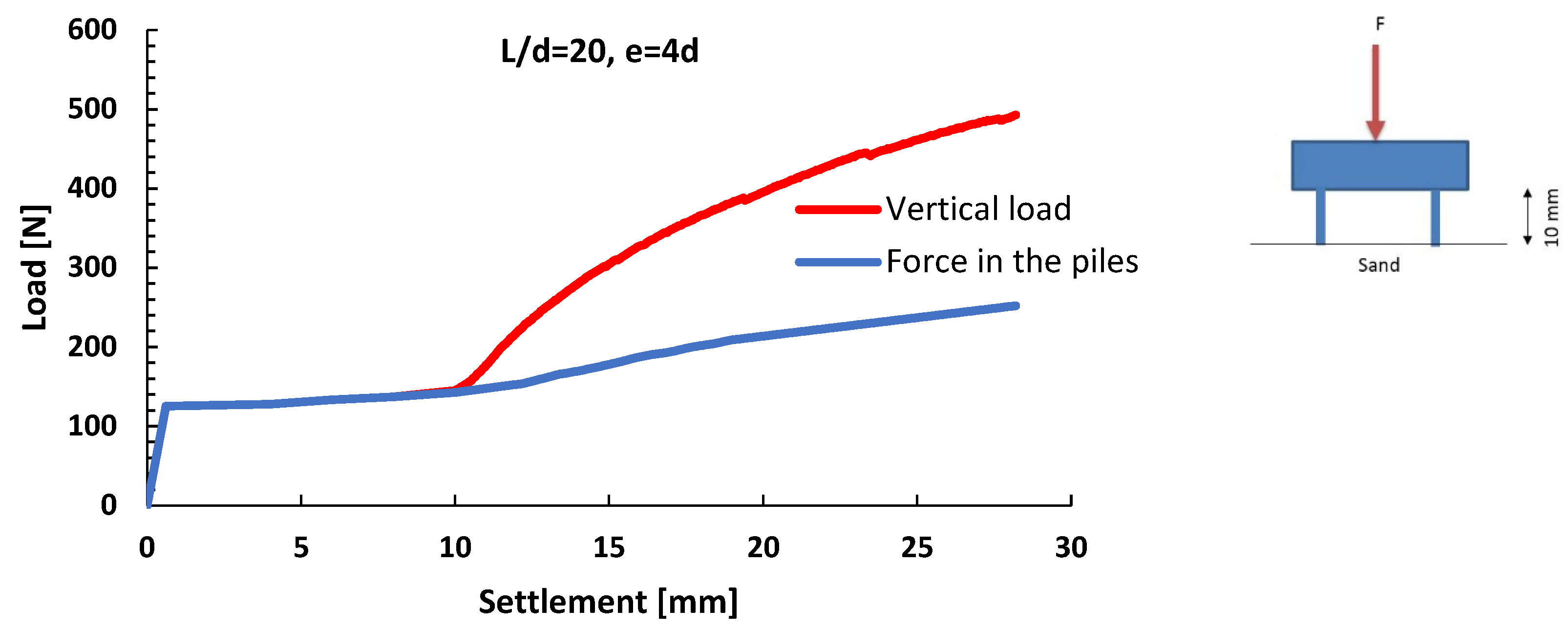

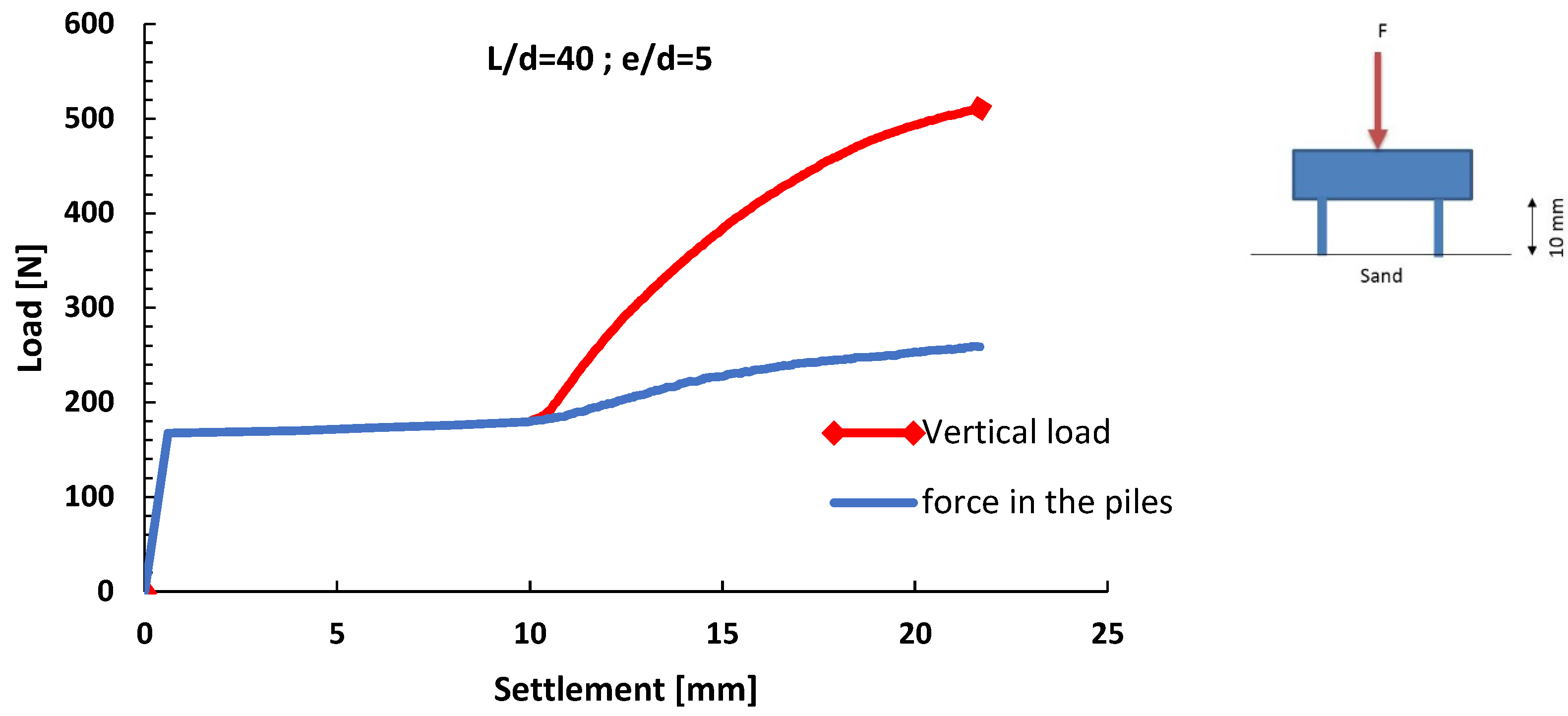

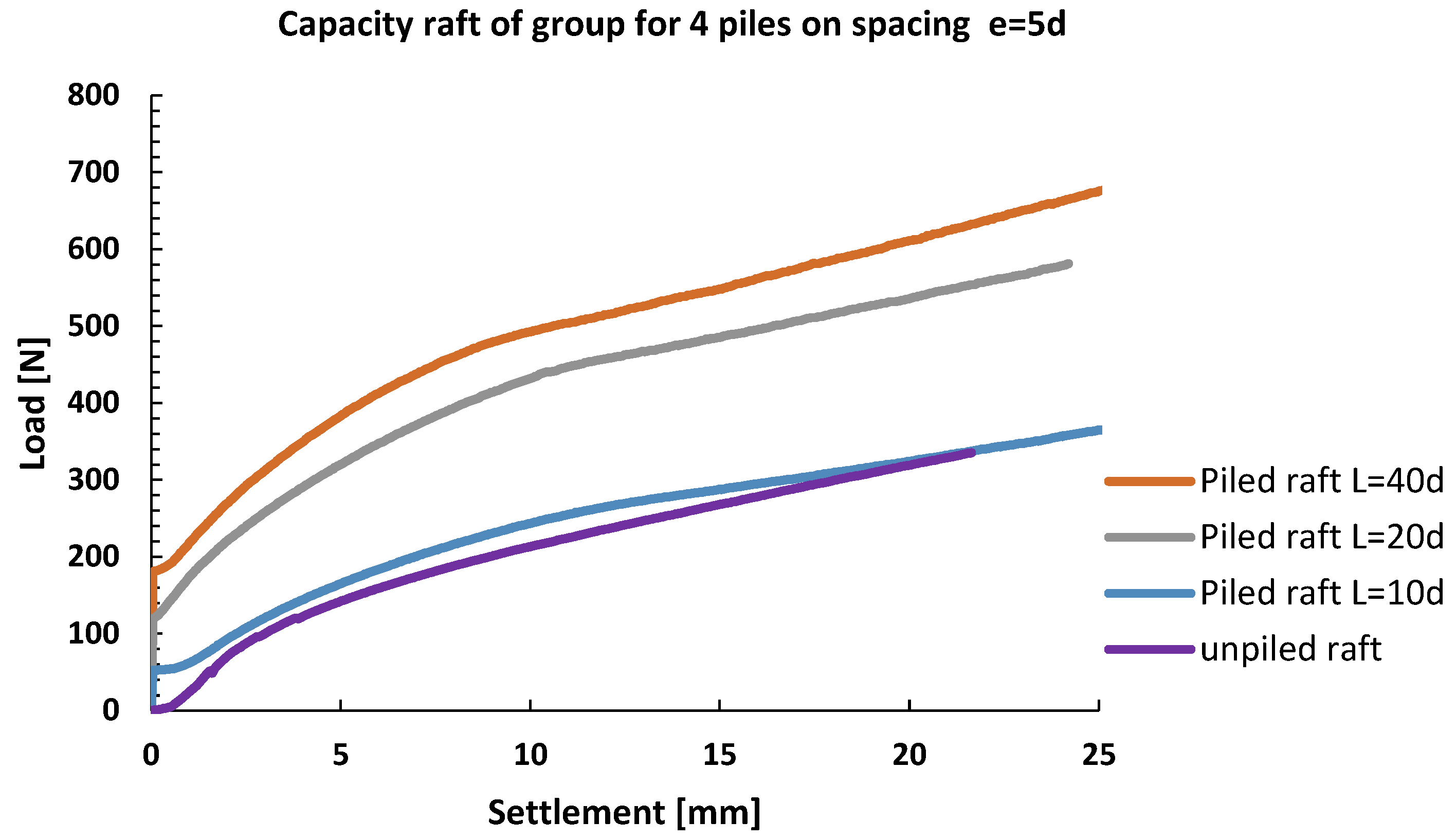

3.4. The Effect of Length

3.5. Load Bearing Capacity of the Raft with and without Rafts

4. Conclusions

- Application of small-scale 1g models for pile bearing capacity estimation in loose sand is justified for this research because there is no significant scale effect that could originate from the curved strength envelope for dense sand.

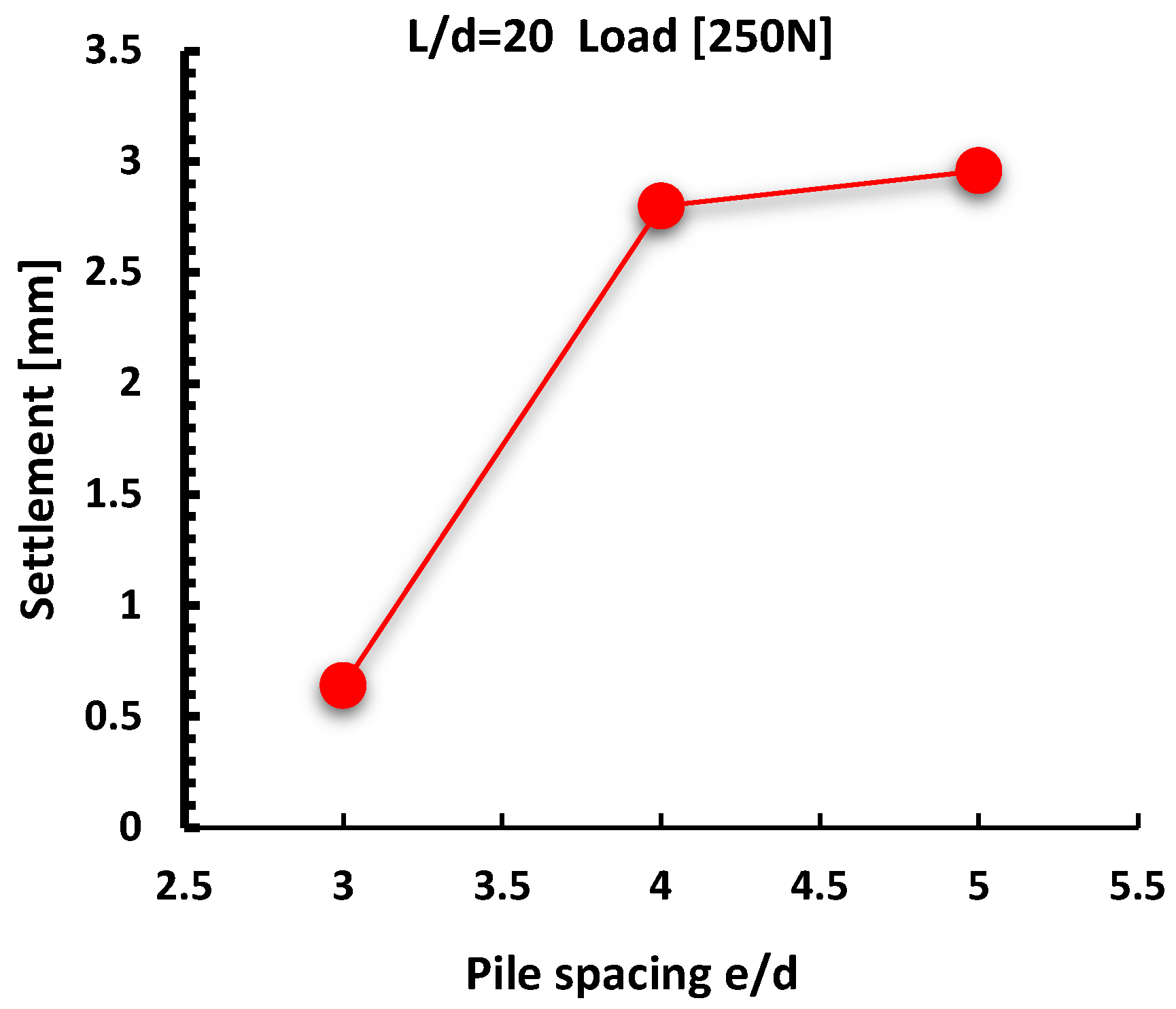

- For the same external force, a raft with smaller contact area, i.e., smaller e/d ratio, and smaller pile slenderness (L/d) has higher settlements.

- For the same external force and same e/d ratio, an increase in pile slenderness ratio L/d reduces settlement of the raft.

- The scientific contribution of this paper is showing that the influence of scale effect on estimation of pile bearing capacity in loose sand that has a constant value of the angle of shearing resistance is negligible. In other words, application of 1g models on assessment of the bearing capacity of piles in loose sand is not essentially related to the size of the model. By contrast, in dense sand, the shear resistance envelope is curved. This means that the mobilized angle of shearing resistance at smaller pile dimensions is smaller; i.e., the average normal stress is lower and vice versa, or, in other words, the scale effects become significant.

- Piled raft foundation systems with smaller contact surfaces at the same load levels have higher settlements than systems with larger contact surfaces; the increase in the raft contact surface improves the load bearing capacity of the piled raft foundation system at the same settlement values. This improvement in performance is caused by the horizontal pressures in the soil beneath the raft, which increase the friction between the soil and the pile surface, therefore increasing the load bearing capacity of the whole piled raft foundation system.

- When driving in a group of piles, as soon as the raft makes contact with the sand, the raft is activated, and its load bearing contribution increases as settlement increases.

- For the case of raft settlement at a value of 0.1B, where B is the width of the pile, depending on the distance between the piles, the pile carries about 24% to 50% of the total load acting on the foundation system.

- The length of the piles does not play a significant role in the distribution of the load between the raft and the piles.

- For the pile spacing of 3d, the pile group effect is very pronounced, while, as the spacing increases, the pile group effect decreases. It was concluded that the pile spacing of 5d represents the upper boundary value, after which the pile group effect contribution to the load bearing capacity is lost.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Du, D.; Zhuang, Y.; Sun, Q.; Yang, X.; Dias, D. Bearing Capacity Evaluation for Shallow Foundations on Unsaturated Soils Using. Comput. Geotech. 2021, 137, 104309. [Google Scholar] [CrossRef]

- Rui, Z.; Feng, Z.; Zhihui, W.; Shengjun, D.; Xin, D.; Zekun, Z.; Wei, X. Improving the Performance of Piled Raft Foundations Using Deformation Adjustors: A Case Study. Buildings 2022, 12, 1903. [Google Scholar]

- Wu, J.T.; El Naggar, M.H.; Zhao, S.; Wen, M.J.; Wang, K.H. Beam-unequal length piles-soil coupled vibrating system considering pile-soil-pile interaction. J. Bridge Eng. 2021, 26, 04021086. [Google Scholar] [CrossRef]

- Zhang, Y.P.; Wu, W.B.; Zhang, H.K.; El Naggar, M.H.; Wang, K.H.; Jiang, G.H.; Mei, G.X. A novel soil-pile interaction model for vertical pile settlement prediction. Appl. Math. Model. 2021, 99, 478–496. [Google Scholar] [CrossRef]

- El-Garhy, B.; Galil, A.A.; Youssef, A.F.; Raia, M.A. Behavior of raft on settlement reducing piles: Experimental model study. J. Rock Mech. Geotech. 2013, 5, 389–399. [Google Scholar] [CrossRef]

- Burland, J.B.; Kantez, B.A.; Broms, B.B. Behaviour of foundations and structures. In Proceedings of the 9th ICSMFE, Tokyo, Japan, 11–15 July 1977; pp. 495–546. [Google Scholar]

- Berezantzev, V. Load Bearing Capacity and Deformation of Piled Foundations. In Proceedings of the Fifth International Conference on Soil Mechanics and Foundation Engineering, Paris, France, 17–22 July 1961. [Google Scholar]

- Burland, J. Shaft Friction of Piles in Clay—A Simple Fundamental Approach; Ground Engineering: London, UK, 1973. [Google Scholar]

- Poulos, H.G. Pile Behaviour—Theory and Application. Geotechnique 1989, 39, 365–415. [Google Scholar] [CrossRef]

- Poulos, H.; Small, J.; Chow, H. Piled Raft Foundations for Tall Buildings. Geotech. Eng. J. SEAGS AGSSEA 2011, 42, 78–84. [Google Scholar]

- Poulos, H.G.; Bunce, G. Foundation Design for the Burj Dubai—The World’s Tallest Building. In Proceedings of the 6th International Conference on Case Histories in Geotechnical Engineering, Arlington, VA, USA, 11–16 August 2008. [Google Scholar]

- Irfan, J.; Irshad, A.; Wali, U.; Mahmood, A.; Mohanad, M.; Sabri, S.; Ali, M. Experimental Study on Lateral and Vertical Capacity of Piled Raft and Pile Group System in Sandy Soil. Appl. Sci. 2022, 12, 8853. [Google Scholar]

- Bhartiya, P.; Chakraborty, T.; Basu, D. Load-settlement response of piled raft foundations in sand. Geomech. Geoengin. 2021, 17, 1260–1283. [Google Scholar] [CrossRef]

- Jose, M.; Krishnan, K.D.; Ravichandran, P. Behaviour of vertically loaded piled raft system on cohesionless soil. Mater. Today Proc. 2020, 40, S167–S171. [Google Scholar] [CrossRef]

- Diptesh, C.; Rajib, S.; Sumanta, H. Behaviour of piled raft foundation in sand subjected to combined V-M-H loading. Ocean Eng. 2020, 2016, 107596. [Google Scholar]

- Zhi, Y.A.; Zhong, H.C.; Yi, C.C. Time effect of vertically loaded piled rafts in layered cross-anisotropic viscoelastic saturated soils. Comput. Geotech. 2020, 119, 103384. [Google Scholar]

- Banerjee, R.; Bandyopadhyay, S.; Sengupta, A.; Reddy, G.R. Settlement behaviour of a pile raft subjected to vertical loadings in multilayered soil. Geomech. Geoengin. 2022, 17, 282–296. [Google Scholar] [CrossRef]

- Rajib, M.; Baleshwar, S. A parametric study of large piled raft foundations on clay soil. Ocean Eng. 2022, 262, 112251. [Google Scholar]

- Bayram, A.; Erol, Ş. Experimental and Numerical Investigation of Load Sharing Ratio for Piled Raft Foundation in Granular Soils. KSCE J. Civ. Eng. 2022, 26, 1662–1673. [Google Scholar]

- Chow, H.; Small, J. Behaviour of Piled Rafts with Piles of Different Lengths and Diameters under Vertical Loading. In Advances in Deep Foundations, Proceedings of the Geo-Fronties Congress, Austin, TX, USA, 24–26 January 2005; American Society of Civil Engineers (ASCE): Reston, VA, USA, 2005; pp. 1–15. [Google Scholar]

- Barreto, E.D.S.; Stafanato, K.V.; Marvila, M.T.; de Azevedo, A.R.G.; Ali, M.; Pereira, R.M.L.; Monteiro, S.N. Clay Ceramic Waste as Pozzolan Constituent in Cement for Structural Concrete. Materials 2021, 14, 2917. [Google Scholar] [CrossRef]

- De Azevedo, A.R.; Marvila, M.T.; Ali, M.; Khan, M.I.; Masood, F.; Vieira, C.M.F. Effect of the Addition and Processing of Glass Polishing Waste on the Durability of Geopolymeric Mortars. Case Stud. Constr. Mater. 2021, 15, e00662. [Google Scholar] [CrossRef]

- Gad, M.A.; Riad, A.M.; Nikbakht, E.; Ali, M.; Ghanem, G.M. Structural Behavior of Slender Reinforced Concrete Columns Wrapped with Fiber Reinforced Polymers Subjected to Eccentric Loads. In Proceedings of the 2020 Second International Sustainability and Resilience Conference, Technology and Innovation in Building Designs, Sakheer, Bahrain, 11–12 November 2020; pp. 1–5. [Google Scholar]

- Li, L.; Liu, X.; Liu, H.; Wu, W.; Lehane, B.M.; Jiang, G.; Xu, M. Experimental and numerical study on the static lateral performance of monopile and hybrid pile foundation. Ocean Eng. 2022, 255, 111461. [Google Scholar] [CrossRef]

- Khurshed, R.D.; Abbas, J.M. An Experimental Investigation the Response of Pile Groups to Inclined Cyclic Loading in Sandy Soil. Geotech. Eng. Sustain. Constr. 2022, 1, 435–446. [Google Scholar]

- Qiang, F.; Jie, Y. Experimental and Numerical Study of the Dynamic Response of XCC Pile–Raft Foundation under High-Speed Train Loads. Appl. Sci. 2022, 11, 9260. [Google Scholar]

- Meena, N.K.; Nimbalkar, S.; Fatahi, B.; Yang, G. Effects of soil arching on behavior of pile-supported railway embankment: 2D FEM approach. Comput. Geotech. 2020, 123, 1–16. [Google Scholar] [CrossRef]

- Deb, P.; Pal, S.K. Nonlinear analysis of lateral load sharing response of piled raft subjected to combined V-L loading. Mar. Georesour. Geotechnol. 2021, 39, 994–1014. [Google Scholar] [CrossRef]

- Plaban, D.; Barnali, D.; Rai, B.R.; Sujit, K.P. Structural analysis of piled raft foundation in soft soil: An experimental simulation and parametric study with numerical method. Ocean Eng. 2022, 261, 112139. [Google Scholar]

- Wenxuan, Z.; Guanlin, Y.; Linlin, G.; Feng, Z. 1g model test of piled-raft foundation subjected to vibration load and its simulation considering small confining stress. Soil Dyn. Earthq. Eng. 2022, 156, 107212. [Google Scholar]

- Syed, M.F.R.; Kuihua, W.; Fazal, E.J. Evaluating the response of piles subjected to static and multiple dynamic. Structures 2022, 40, 187–201. [Google Scholar]

- Hakro, M.R.; Kumar, A.; Almani, Z.; Ali, M.; Aslam, F.; Fediuk, R.; Klyuev, S.; Klyuev, A.; Sabitov, L. Numerical Analysis of Piled-Raft Foundations on Multi-Layer Soil Considering Settlement and Swelling. Buildings 2022, 12, 356. [Google Scholar] [CrossRef]

- Reul, O.; Randolph, M.F. Design Strategies for Piled Rafts Subjected to Nonuniform Vertical Loading. J. Geotech. Geoenviron. Eng. 2004, 130, 1125–1128. [Google Scholar] [CrossRef]

- Long, P.D. Piled Raft—A Cost-Effective Foundation Method for High-Rises. Geotech. Eng. J. SEAGS AGSSEA 2010, 41, 149. [Google Scholar]

- Bajad, S.P.; Sahu, R.B. An Experimental Study on the Behaviour of Vertically Loaded Piled. In Proceedings of the 12th International Conference of International Association for Computer Methods and Advances in Geomechanics (IACMAG), Goa, India, 1–6 October 2008. [Google Scholar]

- De Sanctis, L.; Mandolini, A. Bearing Capacity of Piled Rafts on Soft Clay Soils. J. Geotech. Geoenviron. Eng. 2006, 132, 1600–1610. [Google Scholar] [CrossRef]

- Fleming, K.; Weltman, A.; Randolph, M.; Elson, K. Piling Engineering; Taylor & Francis Group: New York, NY, USA, 2009; p. 95. [Google Scholar]

- Clancy, R. An Approximate Analysis Procedure for Piled Raft Foundations. Int. J. Numer. Anal. Methods Geomech. 1993, 17, 849–869. [Google Scholar] [CrossRef]

- Zhanabayeva, A.; Sagidullina, N.; Kim, J.; Satyanaga, A.; Lee, D.; Moon, S.-W. Comparative Analysis of Kazakhstani and European Design Specifications: Raft Foundation, Pile Foundation, and Piled Raft Foundation. Appl. Sci. 2021, 11, 3099. [Google Scholar] [CrossRef]

- Burland, J.; Burbidge, M.; Wilson, E.; Terzaghi, K. Settlement of Foundations on Sand and Gravel. Proc. Inst. Civ. Eng. 1985, 78, 1325–1381. [Google Scholar] [CrossRef]

- Ali, M.; Abbas, S.; Khan, M.I.; Gad, M.A.; Ammad, S.; Khan, A. Experimental Validation of Mander’s Model for Low Strength Confined Concrete Under Axial Compression. In Proceedings of the 2020 Second International Sustainability and Resilience Conference, Technology and Innovation in Building Designs, Sakheer, Bahrain, 11–12 November 2020; pp. 1–6. [Google Scholar]

- Mandolini, A.; di Laora, R.; Mascarucci, Y. Rational Design of Piled Raft. Procedia Eng. 2013, 57, 45–52. [Google Scholar] [CrossRef]

- Clancy, P.; Randolph, M.F. Simple design tools for piled raft foundations. Geotechnique 1996, 46, 313–328. [Google Scholar] [CrossRef]

- Zhao, T.-H.; Wang, M.-K.; Hai, G.-J.; Chu, Y.-M. Landen inequalities for Gaussian hypergeometric function. Rev. Real Acad. Cienc. Exactas Fís. Nat. Ser. A Mat. 2021, 116, 1–23. [Google Scholar] [CrossRef]

- Nazeer, M.; Hussain, F.; Khan, M.I.; Rehman, A.U.; El-Zahar, E.R.; Chu, Y.-M.; Malik, M. Theoretical study of MHD electro-osmotically flow of third-grade fluid in micro channel. Appl. Math. Comput. 2022, 420, 126868. [Google Scholar] [CrossRef]

- Chu, Y.-M.; Shankaralingappa, B.; Gireesha, B.; Alzahrani, F.; Khan, M.I.; Khan, S.U. Combined impact of Cattaneo-Christov double diffusion and radiative heat flux on bio-convective flow of Maxwell liquid configured by a stretched nano-material surface. Appl. Math. Comput. 2021, 419, 126883. [Google Scholar] [CrossRef]

- Kavitha, P.E.; Beena, K.S.; Narayanan, K.P. A review on soil–structure interaction analysis of laterally loaded piles. Innov. Infrastruct. Solut. 2016, 1, 14. [Google Scholar] [CrossRef]

- Bourgeois, E.; de Buhan, P.; Hassen, G. Settlement analysis of piled-raft foundations by means of a multiphase model accounting for soil-pile interactions. Comput. Geotech. 2012, 46, 26–38. [Google Scholar] [CrossRef]

- Conte, G.; Mandolini, A.; Randolph, M. Centrifuge modelling to investigate the performance of piled rafts. In Deep Foundations on Bored and Auger Piles, Proceedings of the 4th International Geotechnical Seminar on Bored and Auger Piles, Ghent, Belgium, 2–4 June 2003; Millpress: Rotterdam, The Netherlands, 2003; pp. 359–366. [Google Scholar]

- Davisson, M.T. High capacity piles. In Soil Mechanics Lecture Series on Innovation in Foundation Construction; ASCE Illinois Section: Chicago, IL, USA, 1972; pp. 81–112. [Google Scholar]

- Lee, J.; Salgado, R. Determination of pile base resistance in sands. Geotech. Geoenviron. Eng. 1999, 125, 673–683. [Google Scholar] [CrossRef]

- Han, J.; Ye, S.-L. A field study on the behavior of a foundation underpinned by micropiles. Can. Geotech. J. 2006, 43, 30–42. [Google Scholar] [CrossRef]

- Liu, J.L.; Yuan, Z.L.; Zhang, K.P. Cap-pile-soil interaction of bored pile groups. In Proceedings of the 11th International Conference on Soil Mechanics and Foundation Engineering, San Francisco, CA, USA, 12–16 August 1985; Volume 3, pp. 1433–1436. [Google Scholar]

- Long, P.D. Footings with Settlement-Reducing Piles in Non-Cohesive Soil. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 1993. [Google Scholar]

- Duc, P.L.; Bakar, Z. Settlement analysis for piled raft foundations—A case study. In Proceedings of the Geotechnics for Sustainable Development—Geotec Hanoi 2013, Hanoi, Vietnam, 28–29 November 2013. [Google Scholar]

- Lin, D.-G.; Feng, Z.-Y. A Numerical study of piled raft foundations. J. Chin. Inst. Eng. 2006, 29, 1091–1097. [Google Scholar] [CrossRef]

- Oh, E.Y.N.; Huang, M.; Surarak, C.; Adamec, R.; Balasurbamaniam, A.S. Finite element modelling for piled raft foundation in sand. In Proceedings of the EASEC-11-Eleventh East Asia-Pacific Conference on Structural Engineering and Construction “Building a Sustainable Environment”, Taipei, Taiwan, 19–21 November 2008. [Google Scholar]

- Dung, N.T.; Chung, S.G.; Kim, S.R. Settlement of Piled Foundations Using Equevalent Raft Approach. Proc. Inst. Civ. Eng. Geotech. Eng. 2010, 163, 65–81. [Google Scholar] [CrossRef]

- Raut, J.M.; Khadeshwar, S.R.; Bajad, S.P.; Kadu, M.S. Simplified Design Method for Piled Raft Foundations. In Proceedings of the Geo-Shanghai 2014 International Conference, Shanghai, China, 26–28 May 2014; pp. 462–471. [Google Scholar]

- Comodromos, E.M.; Papadopoulou, M.C.; Laloui, L. Contribution to the Design Methodologies of Piled Raft Foundations under Combined Loadings. Can. Geotech. J. 2016, 53, 559–577. [Google Scholar] [CrossRef]

- Huang, M.; Jiu, Y.; Jiang, J.; Li, B. Nonlinear Analysis of Flexibile Piled Raft Foundations Subjected to Vertical Loads in Layered Soils. Soils Found. 2017, 57, 632–644. [Google Scholar] [CrossRef]

- Mosa, J.; Mohammed, Y. Experimental observations on the behavior of a piled raft foundation. J. Eng. 2011, 17, 807–828. [Google Scholar]

- Marlapalle, V.; Hege, R.; Dasgupta, R.; Shaikh, W. Experimental Investigation on Behavior of Piled-Raft. Int. J. Sci. Adv. Res. Technol. 2017, 3, 666–669. [Google Scholar]

- Long, P.D. Foundation peer-review for Mega Tower at MTRC Kowloon Station Development Package 7. WSP Report. Jul 2002, Hong Kong.

- Sharafkhah, M.; Shooshpasha, I. A laboratory study of the effect of piles asymmetric arrangement on the behavior of piled raft foundation in sand. Int. J. Geotech. Eng. 2018, 14, 1–12. [Google Scholar] [CrossRef]

- Omeman, Z.M. Load Sharing of Piled-Raft Foundations in Sand Subjected to Vertical Loads. Ph.D. Thesis, Department of Building, Civil and Environmental Engineering, Concordia University, Montreal, QC, Canada, September 2012. [Google Scholar]

- El Sawwaf, M. Experimental Study of Eccentrically Loaded Raft with Connected and Unconnected Short Piles. J. Geotech. Geoenviron. Eng. 2010, 136, 1394–1402. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bralović, N.; Despotović, I.; Kukaras, D. Experimental Analysis of the Behaviour of Piled Raft Foundations in Loose Sand. Appl. Sci. 2023, 13, 546. https://doi.org/10.3390/app13010546

Bralović N, Despotović I, Kukaras D. Experimental Analysis of the Behaviour of Piled Raft Foundations in Loose Sand. Applied Sciences. 2023; 13(1):546. https://doi.org/10.3390/app13010546

Chicago/Turabian StyleBralović, Nemanja, Iva Despotović, and Danijel Kukaras. 2023. "Experimental Analysis of the Behaviour of Piled Raft Foundations in Loose Sand" Applied Sciences 13, no. 1: 546. https://doi.org/10.3390/app13010546

APA StyleBralović, N., Despotović, I., & Kukaras, D. (2023). Experimental Analysis of the Behaviour of Piled Raft Foundations in Loose Sand. Applied Sciences, 13(1), 546. https://doi.org/10.3390/app13010546