Evaluation of Fire Resistance of Polymer Composites with Natural Reinforcement as Safe Construction Materials for Small Vessels

Abstract

:1. Introduction

- –

- A fire in the hull resulting from improper use of equipment or a leaking gas system.

- –

- –

- –

- A fire involving wooden elements or laminates resulting from the improper handling of an open fire on the vessel.

2. Research Material and Research Methodology

2.1. Research Material

- –

- GFRP (Glass Fiber Reinforced Polymer) produced with the use of commercial reinforcement in the form of roving fabric (plain weave 1/1) with a medium grammage of 452 g/m2 by KROSGLASS.

- –

- HFRP (Hemp Fibers Reinforced Polymer) manufactured using commercial reinforcement in the form of a woven thread fabric (plain weave 1/1) a with medium grammage of 478 g/m2 by S.C. CAV-VAS LIMITED S.R.L. with the same number of 12 layers of fabric.

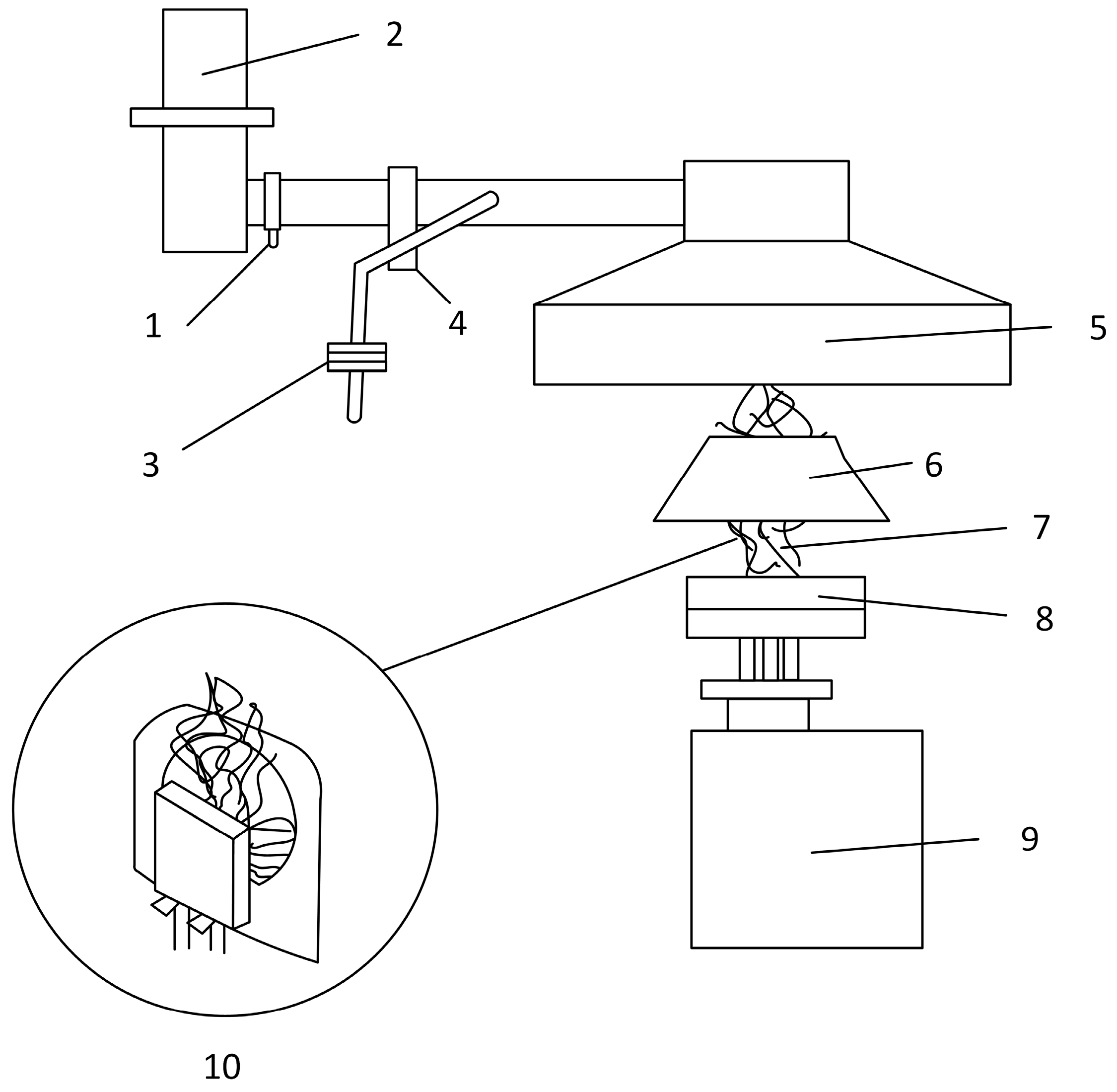

2.2. Research Methodology

3. Results

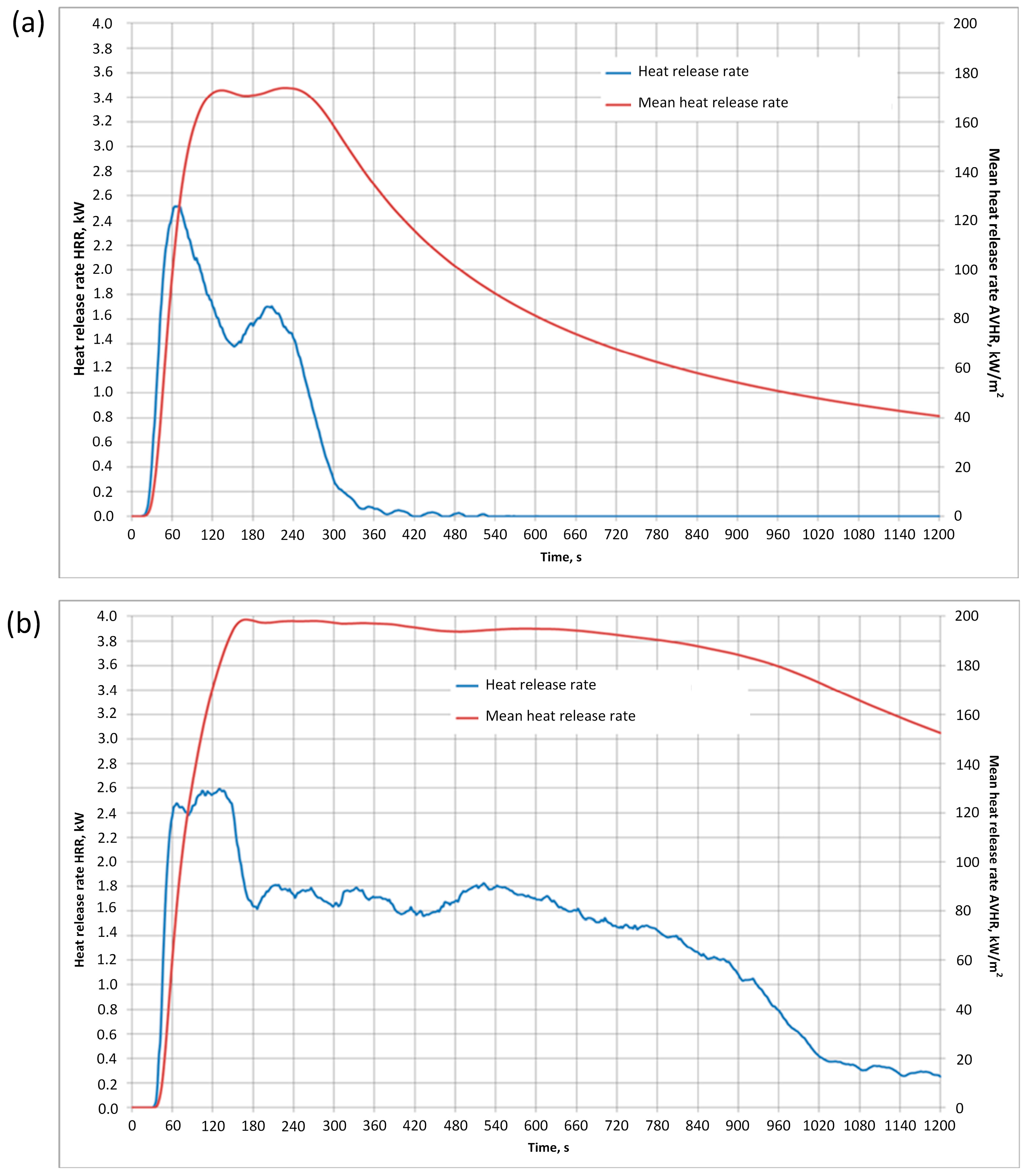

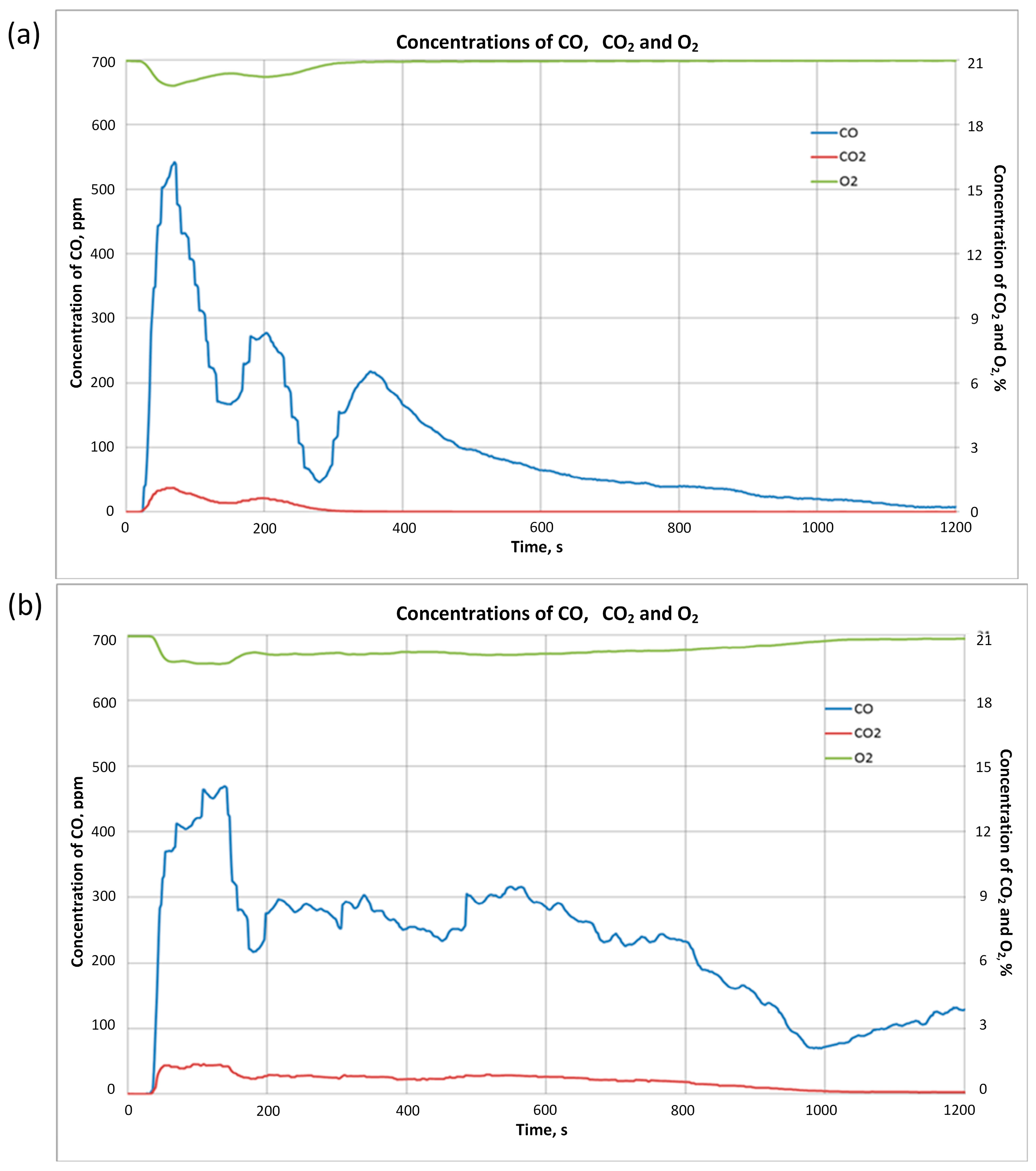

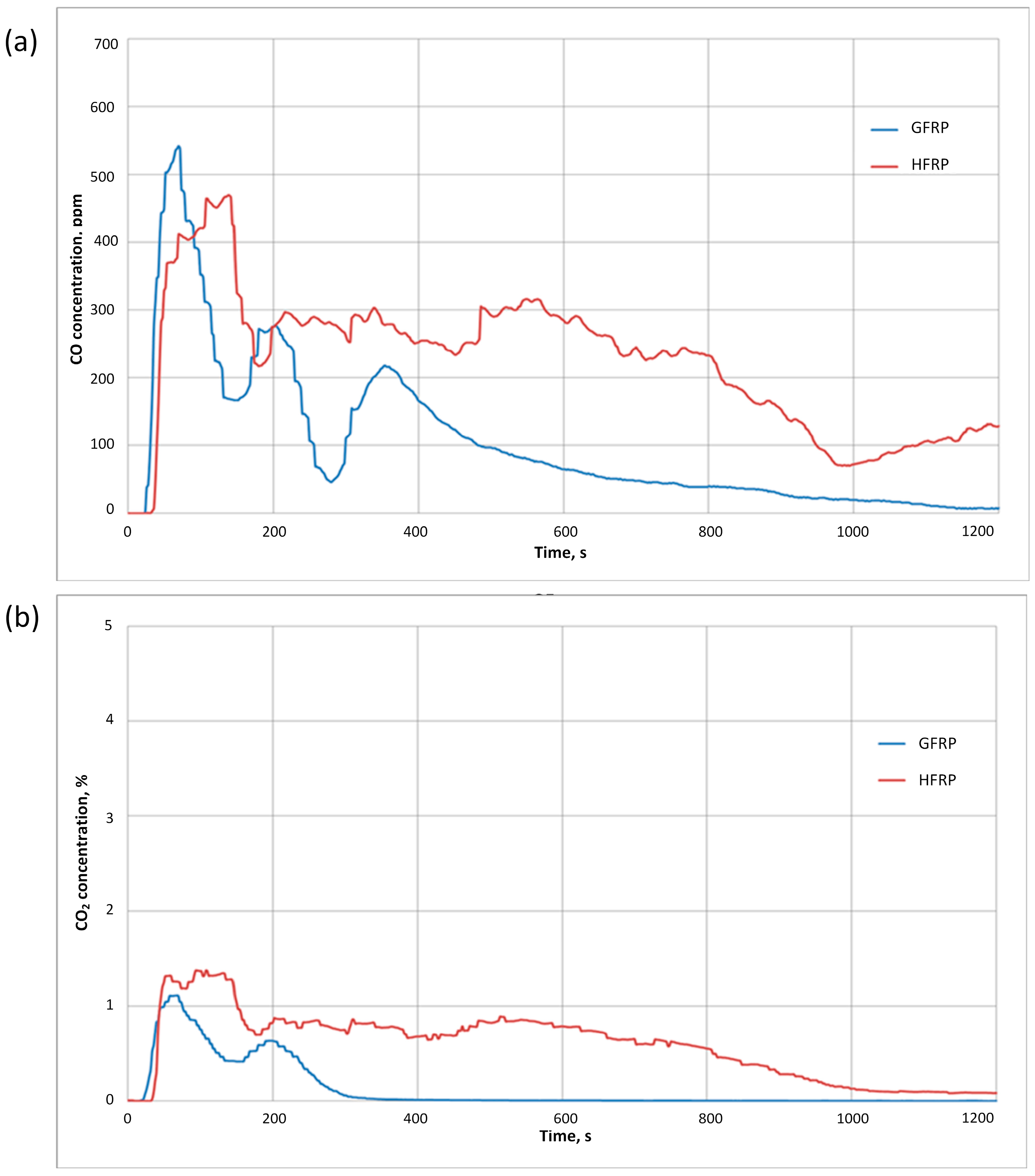

Research Results and Their Analysis

4. Discussion and Conclusions

- –

- The use of natural (hemp) fiber allows the amount of waste to be minimized compared to traditional composites reinforced with glass fiber, which is extremely desirable from an ecological point of view. The mass of the maximum waste for GFRP was 57.2% of the mass of the initial sample, and in the case of HFRP, it was only 2% of the mass of the initial sample (Table 3).

- –

- The use of hemp fiber made it possible to obtain more heat while increasing the amount of smoke and extending the ignition time, which is extremely important from the point of view of the safety of the people on a recreational vessel. The heat released during the combustion of the tested composite reinforced with hemp fabric (183 [MJ/m2]) was four times higher than 48.8 [MJ/m2] of the composite reinforced with glass fabric [MJ/m2].

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Udo, K. (Ed.) ICOMIA Statistics Book 2017; Liquid Scope Limited: Auckland, New Zealand, 2017. [Google Scholar]

- Gniadek, J. Polish Yachts Sail around the World. PIE Economic Weekly, 25 November 2021; Volume 47. (In Polish) [Google Scholar]

- Dz.U. 2016 Poz. 807 Regulation of the Minister of Development of 2 June 2016 on Additional Regulations for Recreational Watercraft and Water Scooters. 2016. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20160000807 (accessed on 15 December 2022). (In Polish)

- Non-Combustible Materials. Available online: https://bariery-ogniowe.pl/slownik-pojec-ppoz/materialy-niepalne/ (accessed on 28 January 2023). (In Polish).

- The Annual Overview of Marine Casualties and Incidents 2014–2020. Available online: https://www.emsa.europa.eu/publications/item/4378-preliminary-annual-overview-of-marine-casualties-and-incidents-2014-2020.html (accessed on 8 February 2023).

- Recreational-Boating-Statistics-2012–2021. Available online: https://uscgboating.org/library/accident-statistics/USCGBoatingStatistics2012.pdf (accessed on 2 February 2023).

- Chybowski, L.; Wiaterek, D.; Jakubowski, A. The Impact of Marine Engine Component Failures upon an Explosion in the Starting Air Manifold. J. Mar. Sci. Eng. 2022, 10, 1850. [Google Scholar] [CrossRef]

- Chybowski, L. Explosions in Crankcases of Marine Engines—Causes, Prevention and Minimization of Effects; Wydawnictwo Naukowe Akademii Morskiej w Szczecinie: Szczecin, Poland, 2022. (In Polish) [Google Scholar]

- Gawdzińska, K.; Kwiecińska, B.; Przetakiewicz, W.; Pelczar, M. Causes of Accidents and Fires on Sea Ships. Zesz. Nauk. Akad. Mor. W Gdyni 2015, 91, 21–29. [Google Scholar]

- Tarnapowicz, D.; German-Galkin, S. Analysis of the Topology of “Shore to Ship” Systems—Power Electronic Connection of Ships with Land. New Trends Prod. Eng. 2018, 1, 325–333. [Google Scholar] [CrossRef]

- Nicewicz, G.; Sosinski, M.; Tarnapowicz, D. Identification of Power Factor in Marine Electrical Grid. In Geoconference on Energy and Clean Technologies; Book Series International Multidisciplinary Scientific Geo Conference-SGEM; SGEM: Vienna, Austria, 2013; Volume 2, pp. 391–398. [Google Scholar]

- Nachtane, M.; Tarfaoui, M.; Abichou, M.A.; Vetcher, A.; Rouway, M.; Aâmir, A.; Mouadili, H.; Laaouidi, H.; Naanani, H. An Overview of the Recent Advances in Composite Materials and Artificial Intelligence for Hydrogen Storage Vessels Design. J. Compos. Sci. 2023, 7, 119. [Google Scholar] [CrossRef]

- Scheibe, M. Analysis of the Applicability of Natural Fiber Reinforced Polymer Composites for the Construction of Selected Types of Vessels. Ph.D. Dissertation, Maritime University of Szczecin, Szczecin, Poland, 2022. (In Polish). [Google Scholar]

- Shah, D.U. Developing Plant Fibre Composites for Structural Applications by Optimising Composite Parameters: A Critical Review. J. Mater. Sci. 2013, 48, 6083–6107. [Google Scholar] [CrossRef]

- Dinu, O.; Ilie, A.M. Maritime Vessel Obsolescence, Life Cycle Cost and Design Service Life. IOP Conf. Ser. Mater. Sci. Eng. 2015, 95, 012067. [Google Scholar] [CrossRef]

- Brożek, P.; Złoczowska, E.; Staude, M.; Baszak, K.; Sosnowski, M.; Bryll, K. Study of the Combustion Process for Two Refuse-Derived Fuel (RDF) Streams Using Statistical Methods and Heat Recovery Simulation. Energies 2022, 15, 9560. [Google Scholar] [CrossRef]

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain. Directives (Text. with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/ALL/?uri=CELEX%3A32008L0098 (accessed on 20 January 2023).

- Scheibe, M.; Urbaniak, M.; Goracy, K.; Bledzki, A.K. Problems Connected with Utilization of Polymer Composite Products and Waste Materials. Part II. “Scrapping” of Composite Recreational Vessels in the World in the Perspective of 2030. Polimery 2019, 64, 788–794. [Google Scholar] [CrossRef]

- Jastrzębska, M. Issues of Polyester and Glass Waste Management. Zesz. Nauk. Akad. Mor. Gdyni 2016, 93, 129–133. (In Polish) [Google Scholar]

- Jastrzębska, M.; Jurczak, W. Recycling of Composites from Marine Units. Logistyka 2011, 5, 663–667. (In Polish) [Google Scholar]

- Hedlund-Åström, A.; Luttropp, C.; Reinholdsson, P. Environmental Friendly Recycling of FRP-Sandwich Ship Hulls. In Royal Institution of Naval Architects International Conference—Recycling of Ships and other Marine Structures; The Royal Institution of Naval Architects: London, UK, 2005; pp. 119–125. [Google Scholar]

- EuCIA: Glass Fibre Reinforced Thermosets: Recyclable and Compliant with the EU Legislation. Available online: http://www.eucia.org/ (accessed on 12 December 2022).

- Sustainable Cement Production—Co-Processing of Alternative Fuels and Raw Materials in the European Cement Industry, Cembureau, January 2009. Available online: http://www.cembureau.eu (accessed on 8 January 2023).

- European Composite Recycling Service Company (ECRC). Available online: http://www.ecrc-greenlabel.org (accessed on 28 December 2022).

- Błędzki Andrzej, K.; Gorący, K.U.M.S.M. Problems Connected with Utilization of Polymer Composite Products and Waste Materials Part I. Production Volume, Utilization of Composites with Carbon Fibres, Legislative Aspects, Industrial Recycling. Polimery 2019, 64, 777–787. [Google Scholar] [CrossRef]

- Contest Yachts. Available online: https://www.contestyachts.com/facts-figures (accessed on 16 April 2023).

- Sunreef Yachts. Available online: https://www.sunreef-yachts.com/pl/news/a-viable-solution-for-responsible-boating-flax-fiber-yachts (accessed on 21 April 2023).

- Corradi, S.; Isidori, T.; Corradi, M.; Soleri, F.; Olivari, L. Composite Boat Hulls with Bamboo Natural Fibres. Int. J. Mater. Prod. Technol. 2009, 36, 73. [Google Scholar] [CrossRef]

- Mouritz, A.P.; Gellert, E.; Burchill, P.; Challis, K. Review of Advanced Composite Structures for Naval Ships and Submarines. Compos. Struct. 2001, 53, 21–42. [Google Scholar] [CrossRef]

- Czarnecka-Komorowska, D.; Bryll, K.; Kostecka, E.; Tomasik, M.; Piesowicz, E.; Gawdzińska, K. The Composting of PLA/HNT Biodegradable Composites as an Eco-Approach to the Sustainability. Bull. Pol. Acad. Sci. Tech. Sci. 2021, 69, e136720. [Google Scholar] [CrossRef]

- Konecki, M. Influence of the Rate of Heat. Release and Smoke Emission on the Development of Fire in the Layout of Rooms; Szkoła Główna Służby Pożarniczej: Warszawa, Poland, 2007. (In Polish) [Google Scholar]

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural Fiber Reinforced Composites: Sustainable Materials for Emerging Applications. Results Eng. 2021, 11, 100263. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Urbaniak, M.; Jaszkiewicz, A.; Feldmann, M. Cellulose Fibres as an Alternative for Glass Fibres in Polymer Composites. Polimery 2014, 59, 372–382. [Google Scholar] [CrossRef]

- Madsen, B.; Hoffmeyer, P.; Thomsen, A.B.; Lilholt, H. Hemp Yarn Reinforced Composites—I. Yarn Characteristics. Compos. Part. A Appl. Sci. Manuf. 2007, 38, 2194–2203. [Google Scholar] [CrossRef]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A Review of Recent Developments in Natural Fibre Composites and Their Mechanical Performance. Compos. Part. A Appl. Sci. Manuf. 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Stelea, L.; Filip, I.; Lisa, G.; Ichim, M.; Drobotă, M.; Sava, C.; Mureșan, A. Characterisation of Hemp Fibres Reinforced Composites Using Thermoplastic Polymers as Matrices. Polymers 2022, 14, 481. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp Fiber and Its Composites—A Review. J. Compos. Mater. 2012, 46, 973–986. [Google Scholar] [CrossRef]

- Marrot, L.; Lefeuvre, A.; Pontoire, B.; Bourmaud, A.; Baley, C. Analysis of the Hemp Fiber Mechanical Properties and Their Scattering (Fedora 17). Ind. Crops Prod. 2013, 51, 317–327. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Wang, K.; Le Duigou, A.; Yao, S.; Chen, C. Quasi-Static Penetration Property of 3D Printed Woven-like Ramie Fiber Reinforced Biocomposites. Compos. Struct. 2023, 303, 116313. [Google Scholar] [CrossRef]

- Cheng, P.; Peng, Y.; Li, S.; Rao, Y.; Le Duigou, A.; Wang, K.; Ahzi, S. 3D Printed Continuous Fiber Reinforced Composite Lightweight Structures: A Review and Outlook. Compos. B Eng. 2023, 250, 110450. [Google Scholar] [CrossRef]

- Elkington, M.; Bloom, D.; Ward, C.; Chatzimichali, A.; Potter, K. Hand Layup: Understanding the Manual Process. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 138–151. [Google Scholar] [CrossRef]

- Takizawa, Y.; Chung, D.D.L. Through-Thickness Thermal Conduction in Glass Fiber Polymer–Matrix Composites and Its Enhancement by Composite Modification. J. Mater. Sci. 2016, 51, 3463–3480. [Google Scholar] [CrossRef]

- Lekavicius, V.; Shipkovs, P.; Ivanovs, S.; Rucins, A. Thermo-Insulation Properties Of Hemp-Based Products. Latv. J. Phys. Tech. Sci. 2015, 52, 38–51. [Google Scholar] [CrossRef]

- Sair, S.; Oushabi, A.; Kammouni, A.; Tanane, O.; Abboud, Y.; El Bouari, A. Mechanical and Thermal Conductivity Properties of Hemp Fiber Reinforced Polyurethane Composites. Case Stud. Constr. Mater. 2018, 8, 203–212. [Google Scholar] [CrossRef]

- Takagi, H.; Nakagaito, A.N.; Liu, K. Heat Transfer Analyses of Natural Fibre Composites. In High Performance and Optimum Design of Structures and Materials; Wit Press: Southampton, UK, 2014; pp. 237–243. [Google Scholar]

| Research Method | ISO5660-1:2015 | |

|---|---|---|

| Material Name | GFRP | HFRP |

| The test was performed | with a lighter | with a lighter |

| Heat flux intensity [kW/m2] | 50 | 50 |

| Calorimeter constant | 0.037 | 0.037 |

| Measurement time [s] | 1200 | 1200 |

| Initial mass of the sample [g] | 71.29 | 137.80 |

| Sample thickness [mm] | 5.60 | 17.32 |

| Crucible size [mm] | 100 × 100 | 100 × 100 |

| Research Methodology | ISO 5660-1:2015 | |

|---|---|---|

| Material Name | GFRP | HFRP |

| Maximum mass loss [g] | 30.53 | 135.04 |

| Remaining reinforcement after the completion of the flammability test [%] | 57.2 | 2 |

| Maximum rate of weight loss [g/s] | 10.9 | 15.3 |

| Sample ignition time [s] | 18 | 30 |

| Sample end-of-burning time [s] | 332 | 1200 |

| Measurement time [s] | 1200 | 1200 |

| CO2 maximum concentration [%] | 1.112 | 1.375 |

| CO maximum concentration [ppm] | 1.542 | 469 |

| Maximum O2 depletion [%] | 14 | 1.27 |

| CO2 initial concentration [%] | 0 | 0 |

| CO initial concentration [ppm] | 0 | 0 |

| O2 initial concentration [%] | 20.95 | 20.95 |

| Heat release rate HRR [kW] | 2.515 | 2.593 |

| Maximum mean rate of heat release [kW/m2] | 173.83 | 198.7 |

| Maximum light attenuation [%] | 67.15 | 59.07 |

| Maximum smoke emission rate [m2/s] | 0.1403 | 0.1096 |

| Total amount of smoke produced [m2] | 20.4 | 53.7 |

| Heat released [MJ/m2] | 48.8 | 183 |

| CO specific emission [kg/kg] | 0.176 | 0.164 |

| CO2 specific emission [kg/kg] | 3.27 | 6.751 |

| Reaction to Fire Results | Energy Recycling | Crew Safety |

|---|---|---|

| Maximum weight loss | HFRP (+) Smaller amount of waste be used compared to GFRP, including heavy metal compounds after the energy recycling process | HFRP (0) No impact on crew safety |

| The maximum rate of weight loss [g/s] | HFRP (+) A higher rate of weight loss compared to GFRP favors the recycling process. | HFRP (−) Higher rate of mass loss compared to GFRP, which may promote the rate of fire spread on a small craft |

| Sample ignition time [s] | HFRP (−) The longer ignition time compared to GFRP extends the time of the recycling process | HFRP (+) A longer ignition time compared to GFRP can increase the time and possibility of evacuation |

| The maximum average intensity of heat release MARHE [kW/m2] | HFRP (+) A 12.5% higher maximum heat release rate compared to GFRP can favor the combustion process, accelerating the energy recycling process. | HFRP (−) The higher maximum intensity of heat release compared to |

| GFRP may favor burns among the crew during an evacuation | ||

| Maximum light attenuation [%] | HFRP (0) No significant impact on the course of the recycling process | HFRP (+) Less attenuation of light compared to GFRP can facilitate and favor the evacuation of the crew from the vessel |

| Maximum smoke emission rate SPR [m2/s] | HFRP (0) No significant impact on the course of the recycling process | HFRP (+) The maximum rate of smoke emission, 28% lower than GFRP, can facilitate the evacuation of the crew from the unit |

| The total amount of smoke produced by S.C. [m2] | HFRP (−) Total smoke output 62% higher than GFRP requires longer filtering of exhaust gases | HFRP (−) The total amount of smoke emitted, 62% higher than for GFRP, may make it difficult to evacuate the crew from the vessel in the event of a delayed fire discovery |

| Heat released [MJ/m2] | HFRP (+) The heat released by 73% higher than for GFRP increases the profitability of the energy recycling process | HFRP (−) Higher heat released than for GFRP may make it difficult to evacuate the crew from the unit and increase the number of people injured as a result of fire or fatal accidents |

| Specific CO emissions [kg/kg] | HFRP (0) No significant impact on the course of the recycling process because the requirements regarding the emission of pollutants are imposed on waste incineration plants, which means that the emission of pollutants from the incineration plant is always lower than from the combustion of other solid fuels | HFRP (+) CO emissions 7% lower than for GFRP can facilitate the evacuation of the crew from the unit and the number of people poisoned by this gas |

| CO2 specific emission [kg/kg] | HFRP (0) No significant impact on the course of the recycling process because the requirements regarding the emission of pollutants are imposed on waste incineration plants, which means that the emission of pollutants from the incineration plant is always lower than from the combustion of other solid fuels | HFRP (0) A level of 40,000 ppm of carbon dioxide is considered dangerous to health (with the standard being up to 1000 ppm). Higher CO2 emissions than for GFRP may contribute to headaches, fatigue and distraction, but should not have a significant impact on the evacuation process |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bryll, K.; Kostecka, E.; Scheibe, M.; Dobrzyńska, R.; Kostecki, T.; Ślączka, W.; Korczyńska, I. Evaluation of Fire Resistance of Polymer Composites with Natural Reinforcement as Safe Construction Materials for Small Vessels. Appl. Sci. 2023, 13, 5832. https://doi.org/10.3390/app13105832

Bryll K, Kostecka E, Scheibe M, Dobrzyńska R, Kostecki T, Ślączka W, Korczyńska I. Evaluation of Fire Resistance of Polymer Composites with Natural Reinforcement as Safe Construction Materials for Small Vessels. Applied Sciences. 2023; 13(10):5832. https://doi.org/10.3390/app13105832

Chicago/Turabian StyleBryll, Katarzyna, Ewelina Kostecka, Mieczysław Scheibe, Renata Dobrzyńska, Tomasz Kostecki, Wojciech Ślączka, and Iga Korczyńska. 2023. "Evaluation of Fire Resistance of Polymer Composites with Natural Reinforcement as Safe Construction Materials for Small Vessels" Applied Sciences 13, no. 10: 5832. https://doi.org/10.3390/app13105832