Research and Implementation of CPS for Transmission Front Middle Case Assembly Line

Abstract

1. Introduction

2. Literature Review

3. Transmission Front and Middle Case Assembly Line

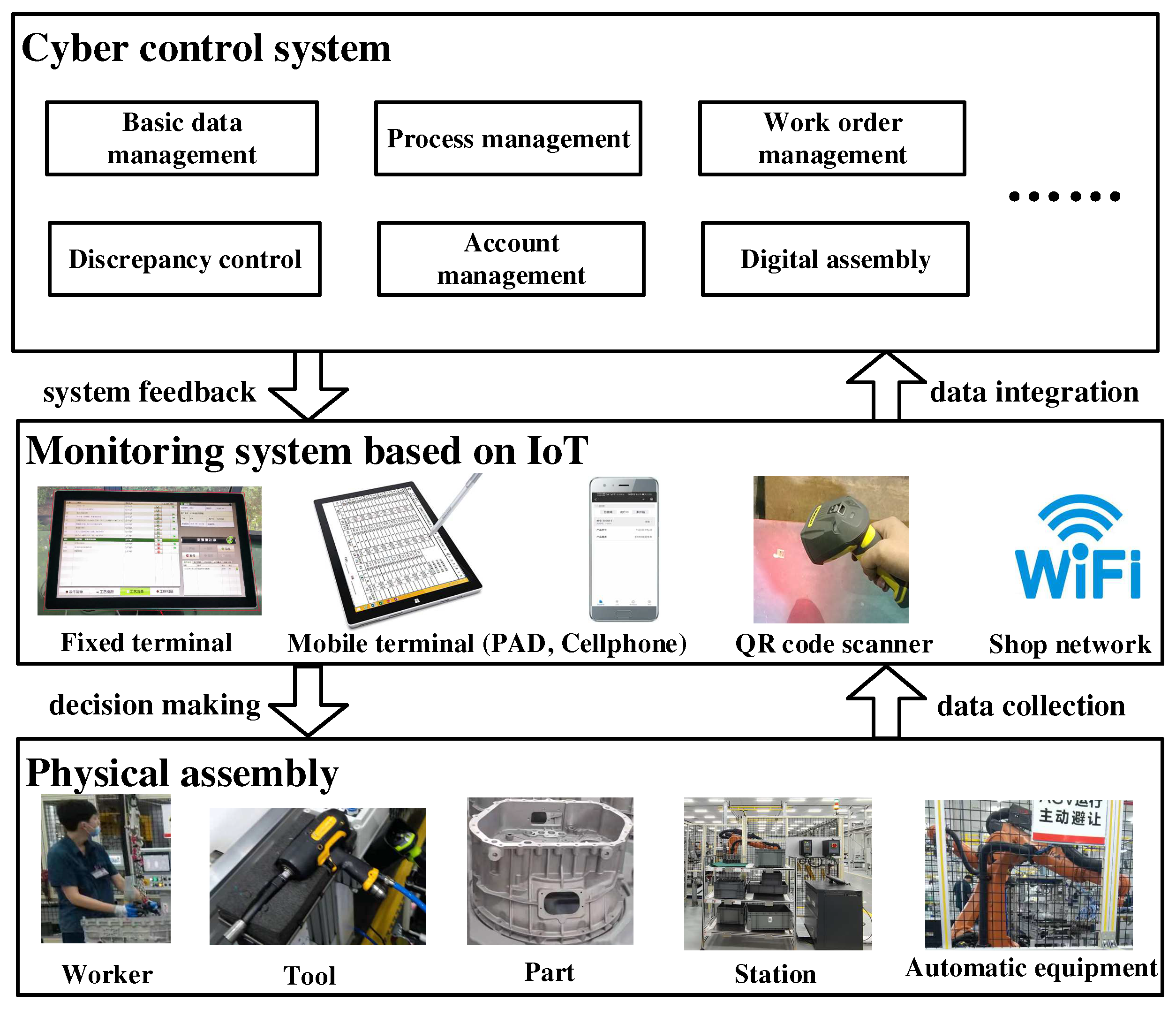

4. IoT-Based CPS Framework

4.1. The Overall CPS Framework

4.2. Monitoring System of the Assembly Process Based on IoT

4.3. The Management and Control System

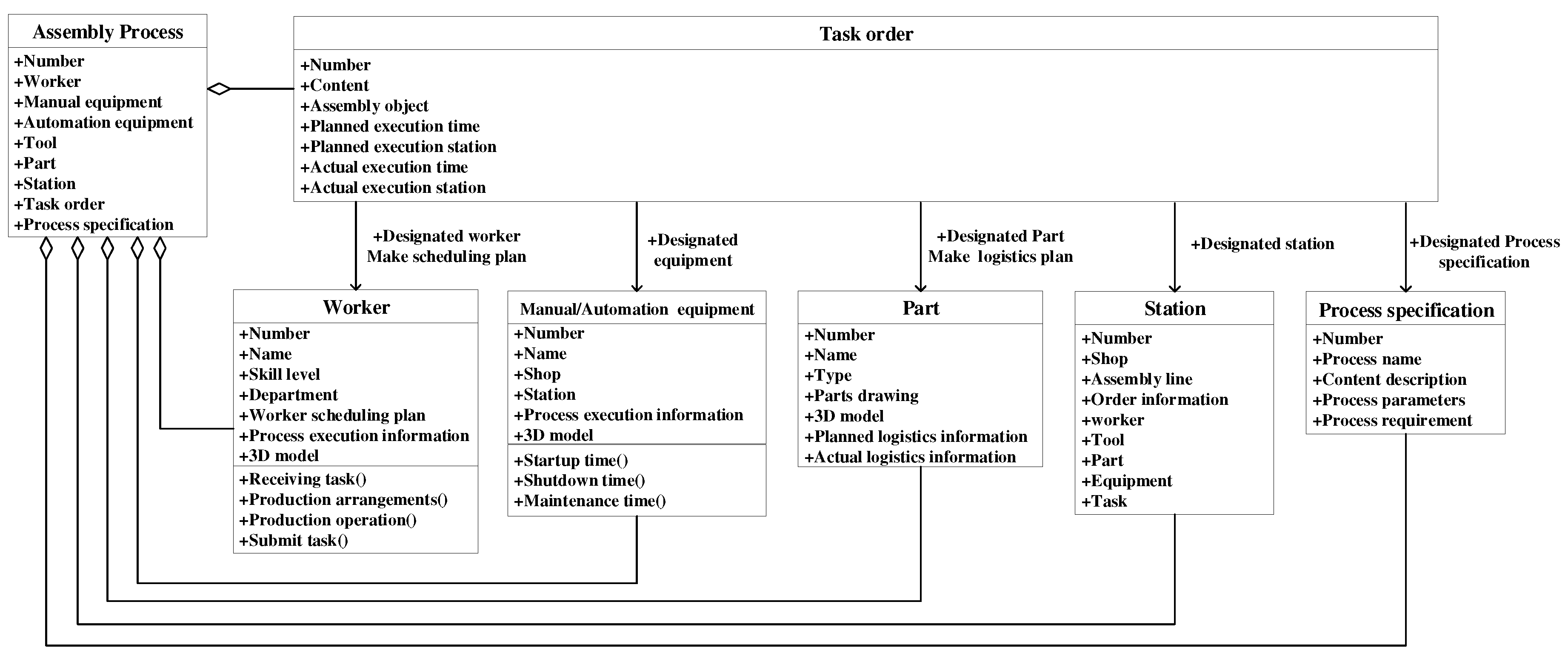

4.3.1. Structured Process Data Model

4.3.2. System Function Design and Implementation

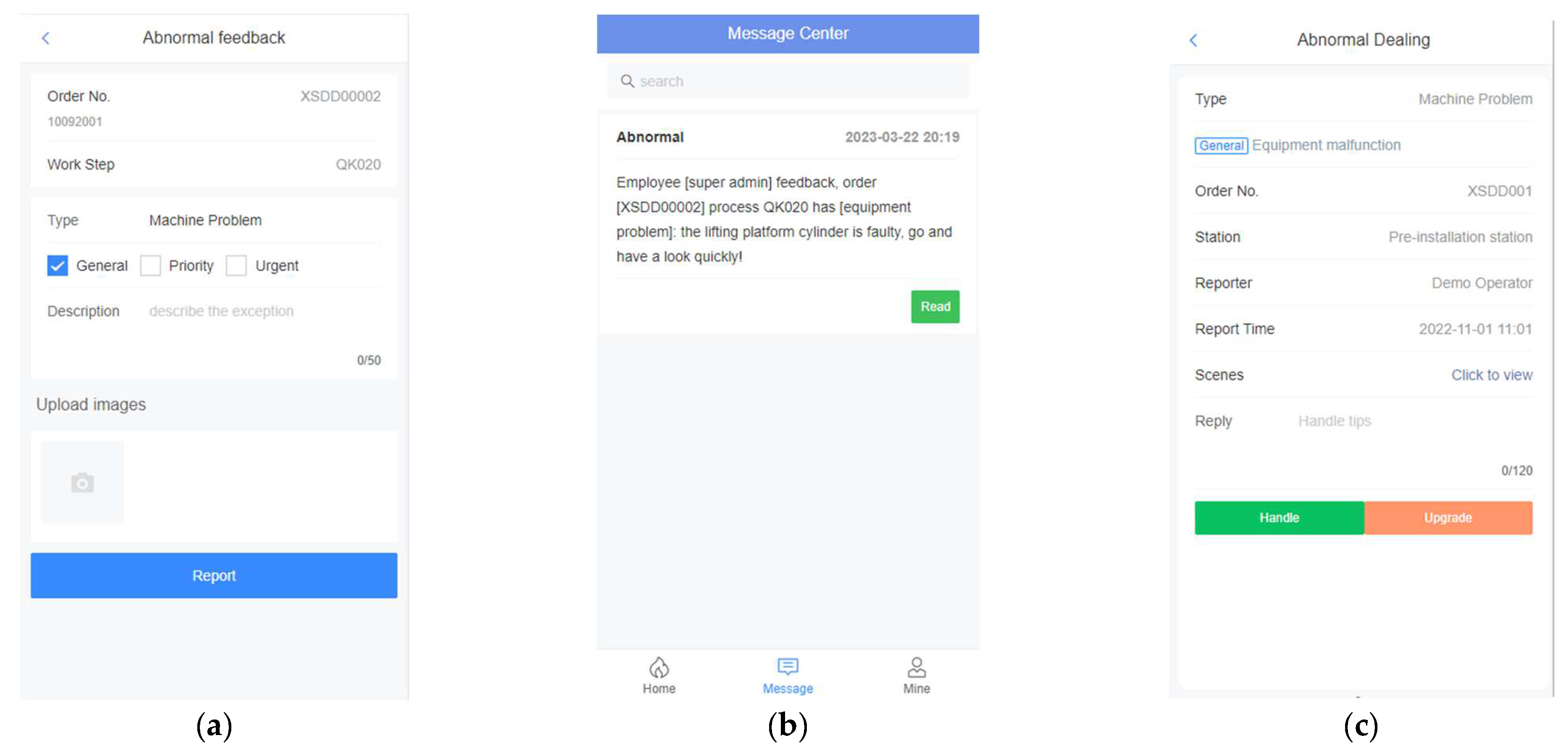

- (1)

- Implementation of the executive terminal function

- (2)

- Implementation of the management and control terminal function

5. Application Results and Discussions

5.1. Implementation of the Proposed System

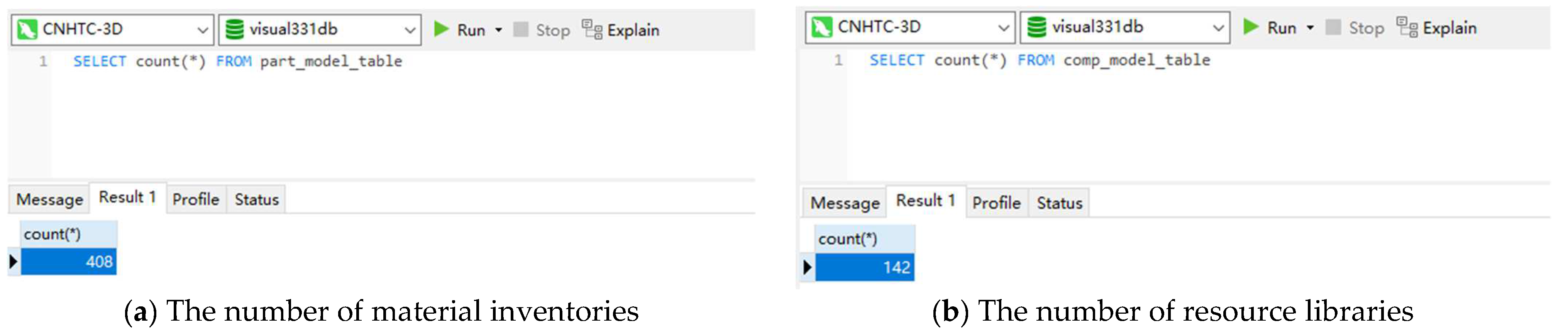

- (1)

- Data integrated management

- (2)

- Monitor of assembly worker

- (3)

- Monitor of logistics

- (4)

- Monitor of assembly progress

5.2. Performance Analysis of the Proposed System

- (1)

- Completion rate of process data

- (2)

- Production factor coverage rate

- (3)

- Physical control ratio

- (4)

- Line balance rate

- (5)

- Downtime ratio

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gamberini, R.; Grassi, A.; Rimini, B. A new multi-objective heuristic algorithm for solving the stochastic assembly line re-balancing problem. Int. J. Prod. Econ. 2006, 102, 226–243. [Google Scholar] [CrossRef]

- Antoine, M.; El-Haouzi, H.B.; Cherif-Khettaf, W.R.; Mohand, L.B. Iterated Local Search for dynamic assembly line rebalancing problem. IFAC-Pap. 2016, 49, 515–519. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, X.; Wu, C. A modified multi-objective genetic algorithm for two-sided assembly line re-balancing problem of a shovel loader. Int. J. Prod. Res. 2018, 56, 3043–3063. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, X.; Wu, C. Improved imperialist competitive algorithms for rebalancing multi objective two-sided assembly lines with space and resource constraints. Int. J. Prod. Res. 2020, 58, 3589–3617. [Google Scholar] [CrossRef]

- Zha, J.; Yu, J. A Hybrid Ant Colony Algorithm for U-Line Balancing and Rebalancing in Just-in-Time Production Environment. J. Manuf. Syst. 2014, 33, 93–102. [Google Scholar] [CrossRef]

- Reis, J.; Melão, N. Digital transformation: A meta-review and guidelines for future research. Heliyon 2023, 9, e12834. [Google Scholar] [CrossRef]

- Dallaora, N.; Alamin, K.; Fraccaroli, E.; Poncino, M.; Quaglia, D.; Vinco, S. Digital Transformation of a Production Line: Network Design, Online Data Collection and Energy Monitoring. IEEE Trans. Emerg. Top. Comput. 2022, 10, 46–59. [Google Scholar] [CrossRef]

- Gokalp, E.; Martinez, V. Digital transformation maturity assessment: Development of the digital transformation capability maturity model. Int. J. Prod. Res. 2022, 60, 6282–6302. [Google Scholar] [CrossRef]

- Lee, E.A. Cyber-physical systems: Design challenges. In Proceedings of the 11th IEEE International Symposium on Object and Component-Oriented Real-Time Distributed Computing (ISORC), Orlando, FL, USA, 5–7 May 2008; pp. 363–369. [Google Scholar]

- Hu, X.; Wan, J.; Wang, T.; Zhang, Y. An IoT-Based Cyber-Physical Framework for Turbine Assembly Systems. IEEE Access 2020, 8, 59732–59740. [Google Scholar] [CrossRef]

- Gill, H. NSF Workshop on Cyber-Physical Systems; Carnegie Melon University: Austin, TX, USA, 2006; Available online: http://varma.ece.cmu.edu/cps/ (accessed on 28 November 2022).

- Cardin, O. Classification of cyber-physical systems developments: Proposition of an analysis framework. Comput. Ind. 2018, 104, 11–21. [Google Scholar] [CrossRef]

- Pivoto, D.; Fernandes, L.F.; Righi, R.D.R.; Rodrigues, J.; Alberti, A.M. Cyber-physical systems frameworks for industrial internet of things applications in Industry 4.0: A literature review. J. Manuf. Syst. 2020, 58, 176–192. [Google Scholar] [CrossRef]

- Chen, G.; Wang, P.; Feng, B.; Li, Y.; Liu, D. The framework design of smart factory in discrete manufacturing industry based on cyber-physical system. Int. J. Comput. Integr. Manuf. 2020, 33, 79–101. [Google Scholar] [CrossRef]

- Zhang, C.; Jiang, P.; Cheng, K.; Xu, W.X.; Ma, Y. Configuration Design of the Add-on Cyber-physical System with CNC Machine Tools and its Application Perspectives. Procedia CIRP 2016, 56, 360–365. [Google Scholar] [CrossRef]

- Iarovyi, S.; Mohammed, W.M.; Lobov, A.; Ferrer, B.R.; Lastra, J.L.M. Cyber–Physical Systems for Open-Knowledge-Driven Manufacturing Execution Systems. Proc. IEEE 2016, 104, 1142–1154. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, B.; Li, Y.; Yaman, O.; Roy, U. Development and utilization of a Process-oriented Information Model for sustainable manufacturing. J. Manuf. Syst. 2015, 37, 459–466. [Google Scholar] [CrossRef]

- Wan, J.; Yin, B.; Li, D.; Celesti, A.; Tao, F.; Hua, Q. An Ontology-Based Resource Reconfiguration Method for Manufacturing Cyber-Physical Systems. IEEE/ASME Trans. Mechatron. 2018, 23, 2537–2546. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, Q.; Xu, W.; Wu, X.; Jiang, X.; Zhou, Z.; Pham, D.T. Dynamic and unified modelling of sustainable manufacturing capability for industrial robots in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2017, 93, 5–8. [Google Scholar] [CrossRef]

- Rahul, R.; Kumaraswamy, A. Integrating the automated car manufacturing system based on RFID and analysis using modules. IOP Conf. Ser. Mater. Sci. Eng. 2020, 912, 32013. [Google Scholar] [CrossRef]

- Zhuang, C.B.; Liu, J.H.; Tang, C.T.; Xing, X.Y. Material dynamic tracking and management technology for discrete assembly process of complex product. Comput. Integr. Manuf. Syst. 2015, 21, 108–122. [Google Scholar]

- Zhen, X.; Wang, A.M.; Fan, R.C.; Zhou, J. Barcode-Based Service-Oriented Material Flow Technology for Complex Product Assembly. Appl. Mech. Mater. 2014, 3560, 93–97. [Google Scholar] [CrossRef]

- Kleanthis, T.; Danai, C.; Vachtsevanou, I.K. CPuS-IoT: A cyber-physical microservice and IoT-based framework for manufacturing assembly systems. Annu. Rev. Control 2019, 47, 237–248. [Google Scholar]

- Schulze, C.; Thiede, S.; Thiede, B.; Kurle, D.; Blume, S.; Herrmann, C. Cooling tower management in manufacturing companies: A cyber- physical system approach. J. Clean. Prod. 2019, 211, 428–441. [Google Scholar] [CrossRef]

- Ying, K.C.; Pourhejazy, P.; Cheng, C.Y.; Wang, C.H. Cyber-physical assembly system-based optimization for robotic assembly sequence planning. J. Manuf. Syst. 2021, 58, 452–466. [Google Scholar] [CrossRef]

- Huang, G.; Chen, J.; Khojasteh, Y. A cyber-physical system deployment based on pull strategies for one-of-a-kind production with limited resources. J. Intell. Manuf. 2021, 32, 579–596. [Google Scholar] [CrossRef]

- Son, Y.H.; Park, K.T.; Lee, D.; Jeon, S.W.; Do Noh, S. Digital twin-based cyber-physical system for automotive body production lines. Int. J. Adv. Manuf. Technol. 2021, 115, 291–310. [Google Scholar] [CrossRef]

| Process | Element Point |

|---|---|

| Person (P) | Each process requires designated person (type of work and quantity), each record counts as a “point”. |

| Machine (Mac) | Each process binding equipment at the station, each equipment counts as a “point”; each process requires a variety of cutting tools, measuring tools, fixtures, etc., and one record counts as a “point”. |

| Material (Mat) | Each process requires a variety of materials, and one record counts as a “point”. |

| Method (Met) | Process drawings, Operating procedures, work steps, appendix, etc., each work step counts as a “point”, and appendix count as a “point”. |

| Quality inspection (QI) | Quality inspection records for each process, each record counts as a “point”. |

| Category | Physical Entities Should Be Controlled | Actual Physical Entities Be Controlled |

|---|---|---|

| assembly worker | The total number of workers of worker team for the assembly line. | There are five manual stations in the line, each of which should record one worker at least. |

| tooling and equipment | The number of tooling and equipment recorded in the Line Planning Map. | The total number of tooling and equipment actually used in the line. |

| Product and parts | The total number of products and parts according to MES of the workshop. | Product order number and part order number from BoM. |

| Station No. | Operation Contents | Operation Time (s) |

|---|---|---|

| 1 | Automatic loading | 142 |

| 2 | Preload the front case | 156 |

| 3 | Dowel installation | 167 |

| 4 | Preinstall front case cylinder head bolts A | 178 |

| 5 | Preinstall front case cylinder head bolts B | 115 |

| 6 | Heat front case bearing hole | 85 |

| 7 | Lifting shaft assembly | 100 |

| 8 | Press the shafting to the front housing | 46 |

| 9 | Preinstall idler wheel and middle case | 159 |

| 10 | middle case pressing | 40 |

| 11 | Tighten the front case nut | 177 |

| 12 | Press and install idler shaft and countershaft bearing | 115 |

| Station No. | Operation Contents | Operation Time (s) |

|---|---|---|

| 1 | Automatic loading | 120 |

| 2 | Preload the front case | 120 |

| 3 | Dowel installation | 120 |

| 4 | Preinstall front case cylinder head bolts | 136 |

| 5 | shafting installation | 110 |

| 6 | middle case on-line | 129 |

| 7 | Tighten the front case nut | 122 |

| 8 | Press and install idler shaft and countershaft bearing | 115 |

| Types of Exceptions | Notes |

|---|---|

| Robot failure | This occurs on robotic arm R1 or R2. |

| Turret fault | This occurs on station 1. |

| Servo motor alarm | This occurs on pressing devices. |

| Performance | Not CPS | CPS |

|---|---|---|

| completeness rate of process data | 56% | 85% |

| production factor coverage rate | 41% | 92% |

| physical control ratio | 60% | 92% |

| line balance rate | 69.27% | 87.43% |

| downtime ratio | 1‰ | 0.3‰ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Cao, X.; Jin, Z.; Zhang, Y.; Hu, X.; Wu, C. Research and Implementation of CPS for Transmission Front Middle Case Assembly Line. Appl. Sci. 2023, 13, 5912. https://doi.org/10.3390/app13105912

Zhang D, Cao X, Jin Z, Zhang Y, Hu X, Wu C. Research and Implementation of CPS for Transmission Front Middle Case Assembly Line. Applied Sciences. 2023; 13(10):5912. https://doi.org/10.3390/app13105912

Chicago/Turabian StyleZhang, Dianping, Xianfeng Cao, Zengzhi Jin, Yahui Zhang, Xiaofeng Hu, and Chuanxun Wu. 2023. "Research and Implementation of CPS for Transmission Front Middle Case Assembly Line" Applied Sciences 13, no. 10: 5912. https://doi.org/10.3390/app13105912

APA StyleZhang, D., Cao, X., Jin, Z., Zhang, Y., Hu, X., & Wu, C. (2023). Research and Implementation of CPS for Transmission Front Middle Case Assembly Line. Applied Sciences, 13(10), 5912. https://doi.org/10.3390/app13105912