Study of Regression Algorithms and Influent Factors between Intelligent Compaction Measurement Values and In-Situ Measurement Values

Abstract

:1. Introduction

2. Methods

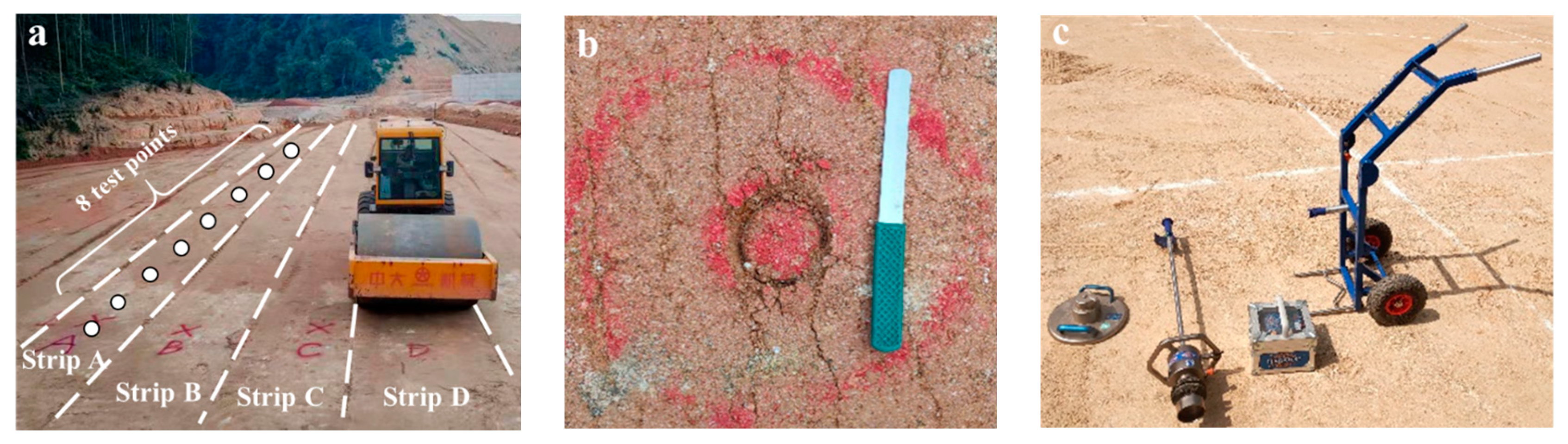

2.1. Construction Information

2.2. Soil Properties

2.3. Calculation Method of ICMV

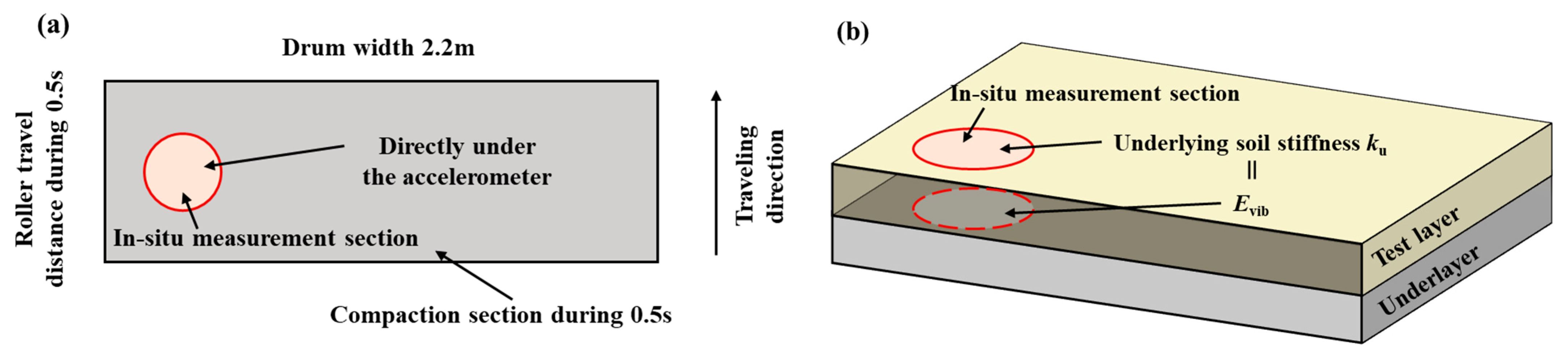

2.4. Considering of Roller Rocking Motion and Underlying Soil Stiffness

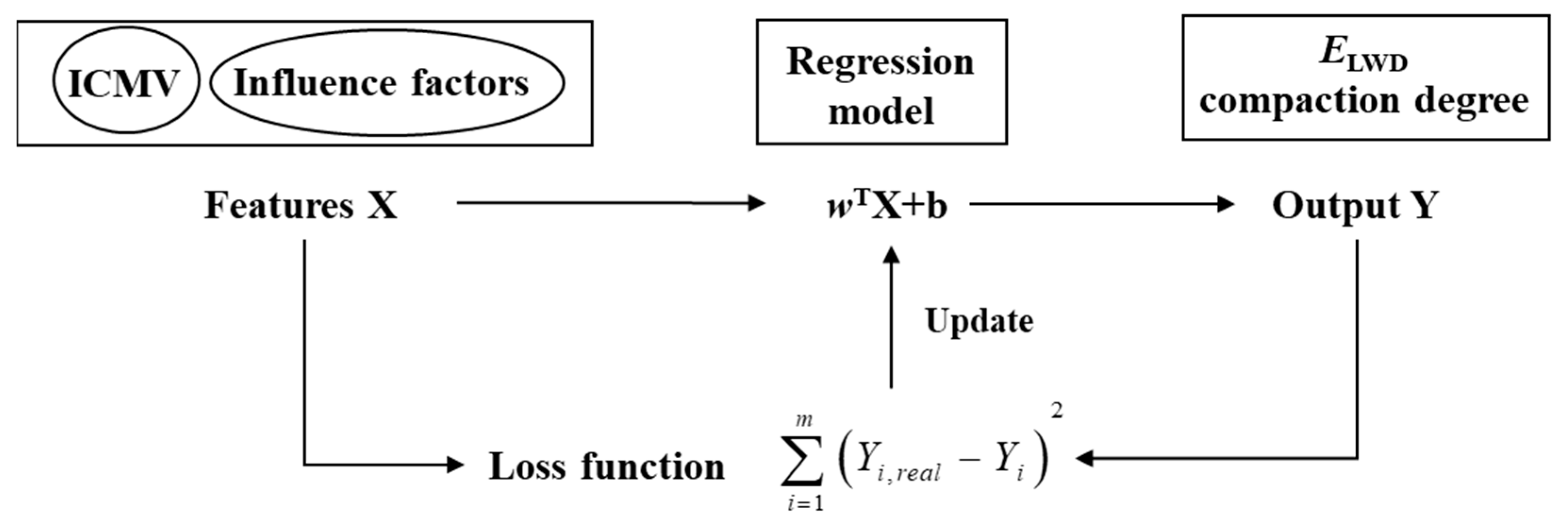

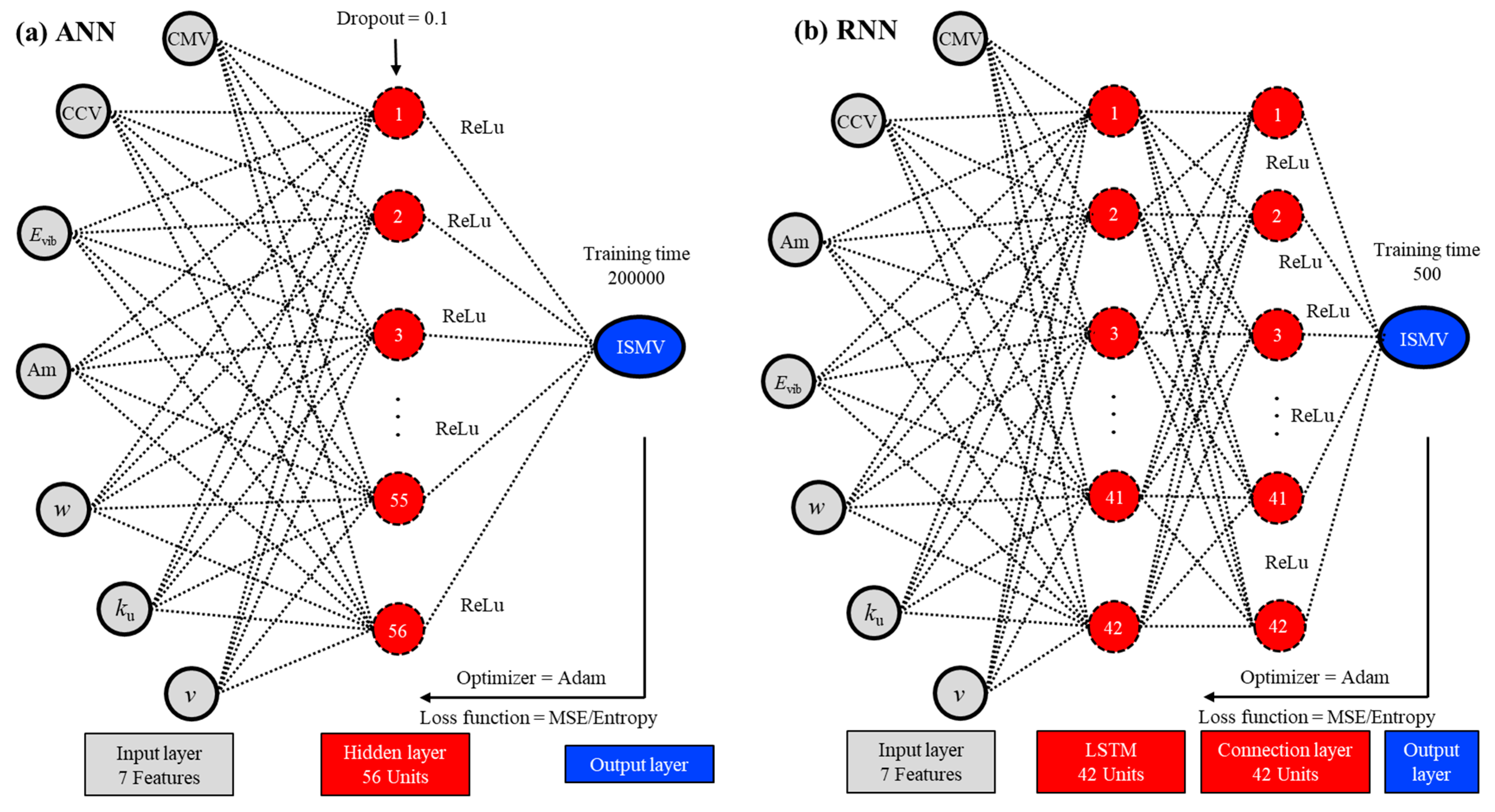

2.5. Regression Algorithms

3. Results and Discussion

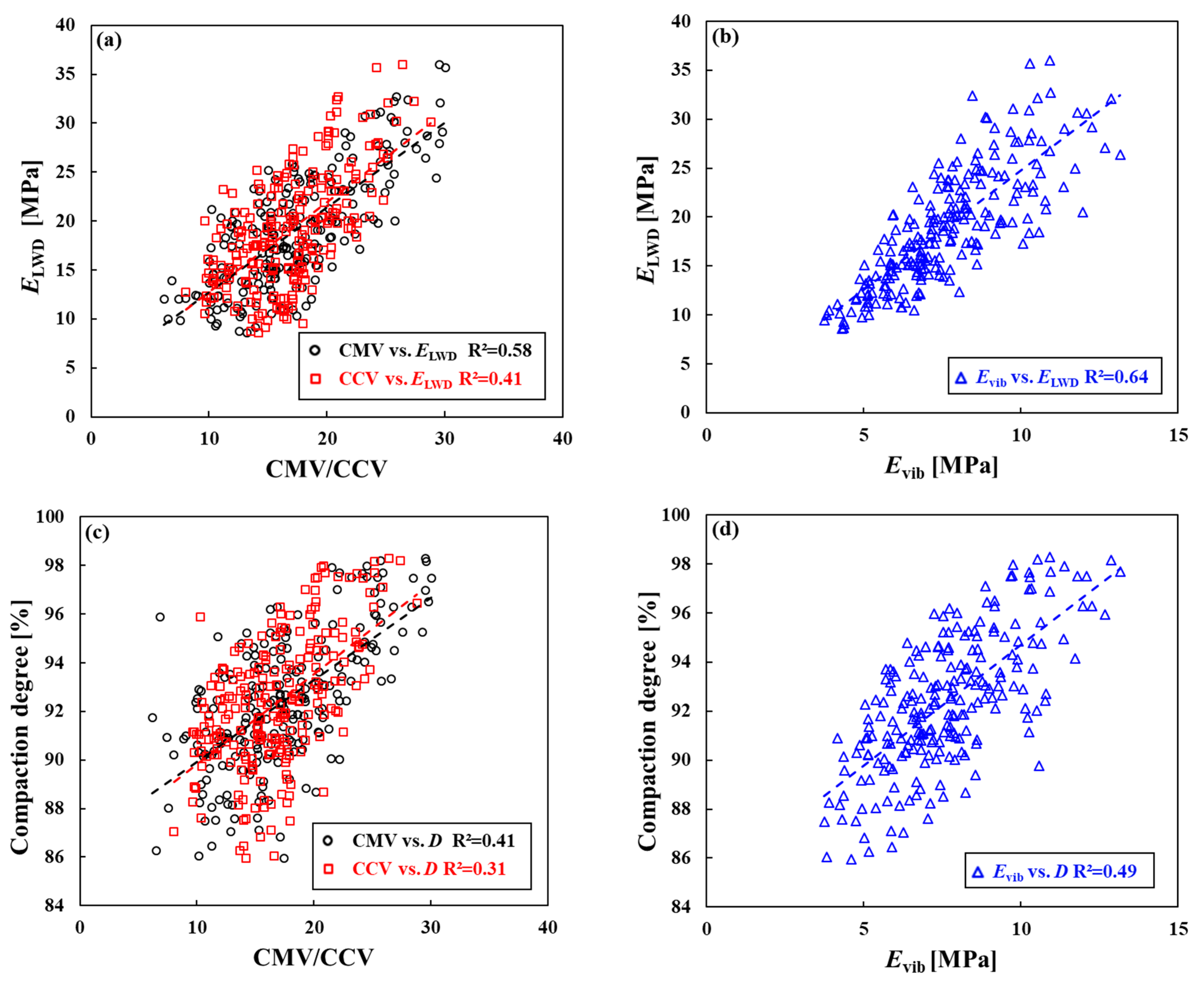

3.1. Regressions of Different ICMV

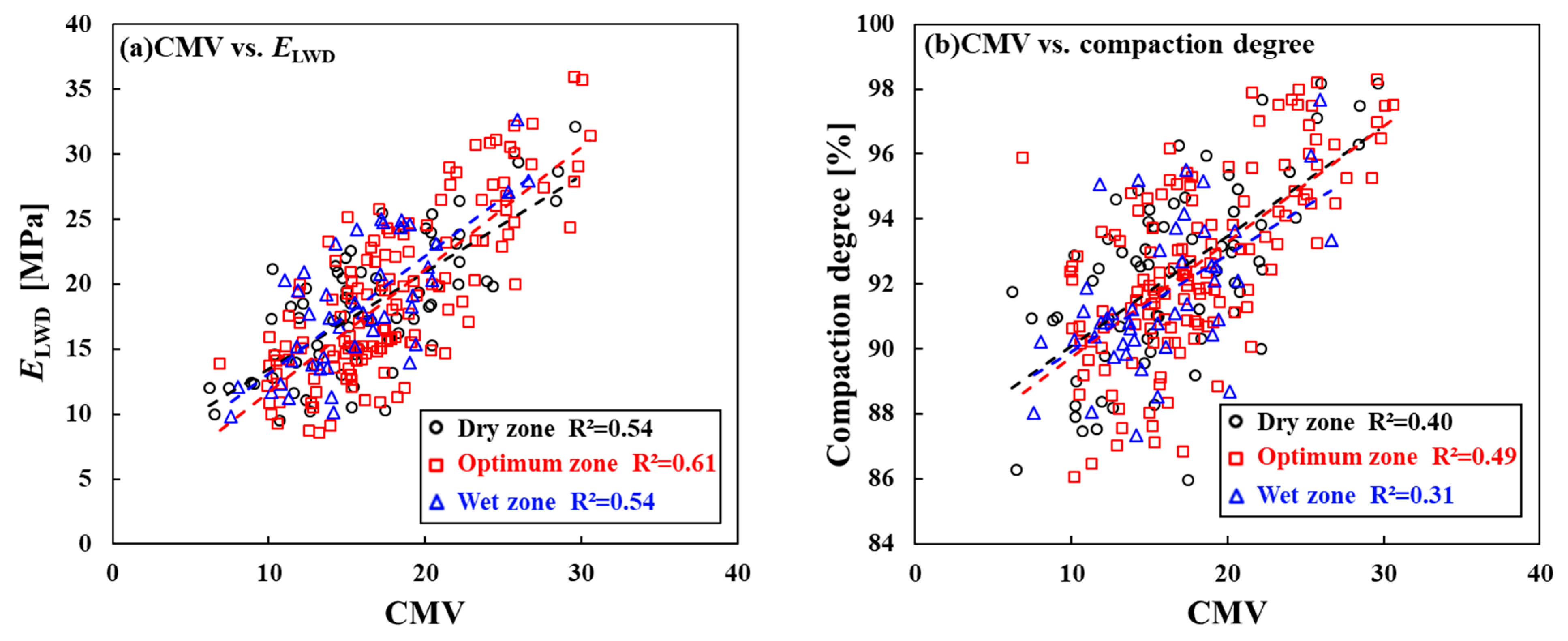

3.2. Influence of Roller Parameters and Subgrade Properties

3.3. Comparison of Regression Algorithms

3.4. Limitations and Future Goals

- This paper used moisture content as an input in the regression, but the continuous detection method of subgrade moisture content in practical engineering still needs further research. Therefore, when using the regression method proposed in this paper, moisture content can be removed from the regression input as appropriate, however, it will reduce the accuracy of ISMV estimation.

- In the analysis of the drum vibration signal, this paper adopted the conventional indicators in the field of IC technology, namely CMV, CCV and Evib. Other parameters of vibration signal are not considered, such as shape factor, kurtosis, skewness etc. It may lead to the inadequacy of the analysis of vibration signals. Thus, further discussion and research are necessary to address this issue in future studies.

4. Conclusions

- From the monadic regression results of ICMV and ISMV, using mechanical method ICMV to predict ISMV was more accurate than using empirical method ICMV. R2 values between ICMV and compaction degree were lower than the R2 values between ICMV and ELWD. It meant that ICMV reflected the stiffness of subgrade better than the density of subgrade.

- According to the feature importance, subgrade properties were more significant than roller parameters in the regression of ICMV and ISMV. Particularly, when the regression target was compaction degree, the importance of w even became higher than the importance of CMV and CCV.

- The influence on correlations between ICMV and ISMV of ku and w were nonlinear whereas v and Am were linear. Therefore, multiple regression algorithms should be introduced into IC technology implementation to establish the correlation between ICMV and ISMV.

- From the comparison among linear and 5 nonlinear algorithms, the results of RF had the best performance while the results of linear algorithms had the worst performance. Moreover, the combination of RF and linear algorithm could further improve the predicted accuracy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Federal Highway Administration. FHWA/TPF Research Project Accelerated Implementation of Intelligent Compaction Technology for Embankment Subgrade Soils, Aggregate Base, and Asphalt Pavement Materials; Earthworks Engineering Research Center (EERC): Ames, IA, USA, 2011. [Google Scholar]

- Xie, Y.M. Control Principle and Technology of Subgrade Compaction and Variability Based on Vibration Response. Master’s Thesis, Tongji University, Shanghai, China, 2019. [Google Scholar]

- Mooney, M.A. Intelligent Soil Compaction Systems; NCHRP21-09 Final Report; Transportation Research Board: Washington, DC, USA, 2010. [Google Scholar]

- Zhang, D.; Jiang, H.; Gao, M.; Zhang, J.; Xiang, W.; Yan, X.; Guo, D.; Zhao, C.; Wu, L. Quality Acceptance Methods and Standards for Continuous Compaction Control Technology. Int. J. Transp. Eng. Technol. 2019, 5, 82–87. [Google Scholar]

- Upreti, K.; Leong, E. Dynamic Properties of Residual Soil over a Wide Range of Strain; Second Pan-American Conference on Unsaturated Soils: Dallas, TX, USA, 2018; pp. 388–397. [Google Scholar]

- Yoo, T.S.; Selig, E.T. Dynamics of Vibratory-Roller Compaction. J. Geotech. Eng. Div. 1979, 105, 1211–1231. [Google Scholar] [CrossRef]

- Tehrani, F.S. An Investigation of Continuous Compaction Control Systems. Ph.D. Thesis, The University of Delaware, Newark, NJ, USA, 2009. [Google Scholar]

- Vennapusa, P.K.R.; White, D.J.; Gieselman, H. Influence of Support Conditions on Roller-Integrated Machine Drive Power Measurements for Granular Base. In Contemporary Topics in Ground Modification, Problem Soils, and Geo-Support; ASCE Library: Orlando, FL, USA, 2009; pp. 425–432. [Google Scholar]

- Cacciola, D.V.; Meehan, C.L.; Baker, W.J.; Tehrani, F. A Comparison of Continuous Compaction Control Measurements with Localized In Situ Test Results; American Society of Civil Engineers IFCEE: Orlando, FL, USA, 2018; Volume 5, pp. 64–74. [Google Scholar]

- Xu, Q.W.; Chang, G.K. Adaptive Quality Control and Acceptance of Pavement Material Density for Intelligent Road Construction. Autom. Constr. 2016, 62, 78–88. [Google Scholar] [CrossRef]

- Graettinger, A.J.; Doherty, W.B.; Herron, M.; Siekmeier, J.; Petersen, L. Locating Soil Tests with Intelligent Compaction Data and Geographic Information System Technology. Transp. Res. Rec. 2018, 2310, 10–17. [Google Scholar] [CrossRef]

- Xue, Z.; Cao, W.; Liu, S.; Ren, F.; Wu, Q. Artificial Neural Network-Based Method for Real-Time Estimation of Compaction Quality of Hot Asphalt Mixes. Appl. Sci. 2021, 11, 7136. [Google Scholar] [CrossRef]

- Imran, S.A.; Barman, M.; Commuri, S.; Zaman, M.; Nazari, M. Artificial Neural Network-Based Intelligent Compaction Analyzer for Real-Time Estimation of Subgrade Quality. Int. J. Geomech. 2018, 18, 04018048.1–04018048.14. [Google Scholar]

- Ministry of Railways, PRC. Technical Specification for Continuous Compaction Control of Fill Engineering of Railway Earth Structure (Q/CR 9210-2015); China Railway Publishing House Co., Ltd.: Beijing, China, 2015.

- Tang, J.W.; Jiang, H.H.; Zhang, D.X.; Gao, M.X.; Wu, L.L.; Xiang, W.G. Technical Features and References of European and American Continuous Compaction Control Technical Regulations. J. Civ. Eng. Manag. 2020, 37, 59–66. [Google Scholar]

- Cai, H.B.; Kuczek, T.; Dunston, P.S.; Li, S. Correlating Intelligent Compaction Data to In Situ Soil Compaction Quality Measurements. J. Constr. Eng. Manag. 2017, 143, 4017038.1. [Google Scholar] [CrossRef]

- White, D.J.; Vennapusa, P.K.R.; Gieselman, H.H. Field Assessment and Specification Review for Roller-Integrated Compaction Monitoring Technologies. Adv. Civ. Eng. 2011, 2, 1–15. [Google Scholar] [CrossRef]

- Ling, J.; Lin, S.; Qian, J.; Zhang, J.; Han, B.; Liu, M. Continuous Compaction Control Technology for Granite Residual Subgrade Compaction. J. Mater. Civ. Eng. 2018, 30, 04018316.1–04018316.9. [Google Scholar] [CrossRef]

- Meehan, C.L.; Cacciola, D.V.; Tehrani, F.S.; Baker, W.J., III. Assessing Soil Compaction using Continuous Compaction Control and Location-Specific In Situ Tests. Autom. Constr. 2017, 73, 31–44. [Google Scholar] [CrossRef]

- Facas, N.W.; Rinehart, R.V.; Mooney, M.A. Development and Evaluation of Relative Compaction Specifications Using Roller-Based Measurements. Geotech. Test. J. 2011, 34, 102915. [Google Scholar]

- Hu, W.; Shu, X.; Huang, B.; Woods, M.E. An Examination of Compaction Meter Value for Asphalt Pavement Compaction Evaluation. Int. J. Pavement Eng. 2018, 19, 447–455. [Google Scholar] [CrossRef]

- Zhu, X.; Bai, S.; Xue, G.; Yang, J.; Cai, Y.; Hu, W.; Jia, X.; Huang, B. Assessment of Compaction Quality of Multi-Layer Pavement Structure Based on Intelligent Compaction Technology. Constr. Build. Mater. 2018, 161, 316–329. [Google Scholar] [CrossRef]

- Cao, L.P.; Zhou, J.; Li, T.; Chen, F.; Dong, Z. Influence of Roller-Related Factors on Compaction Meter Value and Its Prediction Utilizing Artificial Neural Network. Constr. Build. Mater. 2020, 268, 121078. [Google Scholar] [CrossRef]

- Caruana, R.; Niculescu, M.A.; Crew, G.; Ksikes, A. Ensemble Selection from Libraries of Models. In Proceedings of the Twenty-first International Conference (ICML 2004), Banff, AB, Canada, 4–8 July 2004; ACM: Banff, AB, Canada, 2004. [Google Scholar]

- Commuri, S.; Zaman, M. A Novel Neural Network-Based Asphalt Compaction Analyzer. Int. J. Pavement Eng. 2006, 7, 1–32. [Google Scholar] [CrossRef]

- Commuri, S.; Mai, A.T.; Zaman, M. Neural Network–Based Intelligent Compaction Analyzer for Estimating Compaction Quality of Hot Asphalt Mixes. J. Constr. Eng. Manag. 2011, 137, 634–644. [Google Scholar] [CrossRef]

- Nazarian, S.; Fathi, A.; Tirado, C.; Kreinovich, V.; Rocha, S.; Mazari, M. Evaluating Mechanical Properties of Earth Material During Intelligent Compaction; Research Report 933; NCHRP: Washington, DC, USA, 2020. [Google Scholar]

- Fathi, A.; Tirado, C.; Rocha, S.; Mazari, M.; Nazarian, S. A Machine-Learning Approach for Extracting Modulus of Compacted Unbound Aggregate Base and Subgrade Materials Using Intelligent Compaction Technology. Infrastructures 2021, 6, 142. [Google Scholar] [CrossRef]

- Ke, G.L.; Meng, Q.; Finley, T.; Wang, T.; Chen, W.; Ma, W.; Ye, Q.; Liu, T.Y. Lightgbm: A Highly Efficient Gradient Boosting Decision Tree. In Proceedings of the 31st Conference on Neural Information Processing Systems, Long Beach, CA, USA, 3–9 December 2017; pp. 3146–3154. [Google Scholar]

- Chen, T.Q.; Guestrin, C. XGBoost: A Scalable Tree Boosting System; ACM: San Francisco, CA, USA, 2016; pp. 785–794. [Google Scholar]

- Thurner, H.; Forssblad, L. The Compaction Meter-A Modern Method for the Surveillance and Control of Compaction. Rev. Gen. Routes Aerodr. 1979, 36, 67–71. [Google Scholar]

- Scherocman, J.A.; Rakowski, S.; Uchiyama, K. Intelligent Compaction, Does It Exist? Proc. Annu. Conf. Can. Tech. Asph. Assoc. 2007, 52, 373. [Google Scholar]

- Anderegg, R.; Kaufmann, K. Intelligent Compaction with Vibratory Rollers: Feedback Control Systems in Automatic Compaction and Compaction Control. Transp. Res. Rec. 2004, 1868, 124–134. [Google Scholar] [CrossRef]

- Kröber, W.; Floss, E.H.R.; Wallrath, W. Dynamic Soil Stiffness as Quality Criterion for Soil Compaction. In Geotechnics for Roads, Rail Tracks and Earth Structures; A. A. Balkema: Lisse, The Netherlands, 2001; pp. 189–199. [Google Scholar]

- Facas, N.W.; Paul, J.S.; Mooney, M.A. Influence of Rocking Motion on Vibratory Roller-Based Measurement of Soil Stiffness. J. Eng. Mech. 2010, 136, 898–905. [Google Scholar] [CrossRef]

- Abeywickrama, T.; Cheema, M.A.; Taniar, D. K-Nearest Neighbors on Road Networks: A Journey in Experimentation and In-Memory Implementation. Proc. VLDB Endow. 2016, 9, 492–503. [Google Scholar] [CrossRef]

- Svetnik, V. Random Forest: A Classification and Regression Tool for Compound Classification and Qsar Modeling. J. Chem. Inf. Comput. Sci. 2003, 43, 1947–1958. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.J.; Xue, L.; Xu, Y.M.; Zhang, L. Overview of deep learning. Appl. Res. Comput. 2012, 29, 8. [Google Scholar]

- Wu, L.L.; Jiang, H.H.; Tang, J.W.; Fan, S.F.; Yan, X.X. Continuous Compaction Monitoring Technology Based on Multiple Regression Analysis. Rock Soil Mech. 2020, 41, 2081–2090. [Google Scholar]

- Chen, C.; Hu, Y.B.; Jia, F.; Wang, X. Intelligent Compaction Quality Evaluation Based on Multi-Domain Analysis and Artificial Neural Network. Constr. Build. Mater. 2022, 341, 127583. [Google Scholar] [CrossRef]

- Wang, X.; Dong, X.; Zhang, Z.; Zhang, J.; Ma, G.; Yang, X. Compaction Quality Evaluation of Subgrade Based on Soil Characteristics Assessment using Machine Learning. Transp. Geotech. 2021, 32, 100703. [Google Scholar] [CrossRef]

- Wang, X.; Cheng, C.; Li, J.; Zhang, J.; Ma, G.; Jin, J. Automated Monitoring and Evaluation of Highway Subgrade Compaction Quality using Artificial Neural Networks. Autom. Constr. 2023, 145, 104663. [Google Scholar] [CrossRef]

| Weight | Excitation Force | Frequency | Amplitude | Drum Width | Drum Radius |

|---|---|---|---|---|---|

| 21 t | 450 kN | 32 Hz | 1.10 mm | 2.2 m | 0.8 m |

| wopt from Standard Proctor | γd from Standard Proctor | Natural Moisture Content | Liquid Limit | Plasticity Index | Cu | Cc | CBR | Soil Type |

|---|---|---|---|---|---|---|---|---|

| 10.5% | 1.88 g/cm3 | 6~14% | 34% | 9.8% | 21.58 | 0.54 | 8.2 | SM |

| Linear Algorithms | Nonlinear Algorithms | |

|---|---|---|

| Machine Learning (ML) | Deep Learning (DL) | |

| Linear regression | K-nearest neighbour (KNN) [36], Random forest (RF) [37], Light gradient boosting model (LGBM) [29] | Artificial neural network (ANN), Recurrent neural network (RNN) [38] |

| Type of ISMV | Type of ICMV | Influence Factor | R2 of Different Power Number of Influence Factor | ||

|---|---|---|---|---|---|

| Power Number = 1 | Power Number = 2 | Power Number = 3 | |||

| ELWD | CMV | w | 0.5991 | 0.6341 | 0.6766 |

| v | 0.6007 | 0.6470 | 0.6862 | ||

| Am | 0.6011 | 0.6014 | 0.6024 | ||

| ku | 0.6089 | 0.6091 | 0.6094 | ||

| CCV | w | 0.4399 | 0.4753 | 0.4950 | |

| v | 0.4364 | 0.4682 | 0.4981 | ||

| Am | 0.4314 | 0.4320 | 0.4335 | ||

| ku | 0.4306 | 0.4309 | 0.4314 | ||

| Evib | w | 0.6617 | 0.6931 | 0.7535 | |

| v | 0.6662 | 0.7081 | 0.7746 | ||

| Am | 0.6548 | 0.6563 | 0.6583 | ||

| ku | 0.6489 | 0.6504 | 0.6512 | ||

| Compaction degree | CMV | w | 0.4361 | 0.4764 | 0.5308 |

| v | 0.4392 | 0.4713 | 0.5236 | ||

| Am | 0.4466 | 0.4462 | 0.4487 | ||

| ku | 0.4274 | 0.4279 | 0.4293 | ||

| CCV | w | 0.3313 | 0.3667 | 0.4171 | |

| v | 0.328 | 0.3629 | 0.4097 | ||

| Am | 0.3481 | 0.3493 | 0.3504 | ||

| ku | 0.3334 | 0.3389 | 0.3414 | ||

| Evib | w | 0.5158 | 0.5535 | 0.5901 | |

| v | 0.5093 | 0.5499 | 0.6004 | ||

| Am | 0.5100 | 0.518 | 0.5183 | ||

| ku | 0.5117 | 0.5128 | 0.5128 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pang, J.; Yang, J.; Zhu, B.; Qian, J. Study of Regression Algorithms and Influent Factors between Intelligent Compaction Measurement Values and In-Situ Measurement Values. Appl. Sci. 2023, 13, 5953. https://doi.org/10.3390/app13105953

Pang J, Yang J, Zhu B, Qian J. Study of Regression Algorithms and Influent Factors between Intelligent Compaction Measurement Values and In-Situ Measurement Values. Applied Sciences. 2023; 13(10):5953. https://doi.org/10.3390/app13105953

Chicago/Turabian StylePang, Jinsong, Jingli Yang, Bin Zhu, and Jinsong Qian. 2023. "Study of Regression Algorithms and Influent Factors between Intelligent Compaction Measurement Values and In-Situ Measurement Values" Applied Sciences 13, no. 10: 5953. https://doi.org/10.3390/app13105953