1. Introduction

CNC machine tool is a kind of high precision and high efficiency machining equipment, and its servo feed system is one of the most important control systems in machine tools. The system enables precise control of parameters such as feed speed, position and force during machine tool machining by using components such as sensors, actuators and controllers, resulting in higher accuracy and stability of the machine tool machining process [

1]. With the continuous development of the aviation industry, automotive industry and mold manufacturing, the performance of CNC machine tools has put forward higher requirements. Typically, the drive model of a servo feed system can be equated to a rigid model. Although the rigid body model of the system is simple, it can only reflect the dynamic characteristics of the system during low-speed operation. When the servo feed system operates at high speed, the screw drive components generate axial vibration and torsional deformation, causing structural vibration [

2]. The generation of structural vibrations then limits the achievable bandwidth and is a decisive factor in the tracking and positioning accuracy in the feed system [

3]. In real systems, both parameter uncertainty and external perturbations are important factors that affect high accuracy positioning and tracking performance [

4]. In addition, external disturbances dominate the nonlinear friction and cutting forces [

5].

Structural vibrations, external disturbances and parameter uncertainties of the servo-feed system are the main factors that lead to the inability of the classical controller to meet the requirements of high precision control [

6]. In response to these challenges, a range of advanced control strategies and advanced technologies are required to develop faster and higher tracking performance servo-feed systems [

7]. The literature [

8,

9] investigated various control issues of servo position systems, including their stability, output regulation capability, and interference immunity. To address the system uncertainty, Msukwa et al. [

10] proposed a nonlinear sliding mode controller with a feedforward compensator, which led to a significant improvement in the tracking performance of the feed drive system. By means of Lyapunov stability theory, the stability of the system is analyzed and confirmed, and its convergence to the sliding surface is ensured. For the high-precision position control of electro-hydraulic servo pump control system, Song et al. [

11] proposed a compensation control algorithm based on fuzzy control theory on the basis of classical PID control algorithm for reducing the influence of system by load disturbance and enhancing the anti-interference capability of the system. Chen et al. [

12] proposed a composite nonlinear feedback adaptive integral sliding mode controller with convergence law (CNF-AISMRL) for fast and accurate control of a servo position control system subject to external disturbances. Zhang et al. [

13] applied an autoturbation controller (ADRC) to motor position control of a servo-driven feed system to suppress vibration and disturbances, and used a simple PI controller to achieve accurate position control of the motion table. Rajabi et al. [

14] proposed a sliding mode control method based on extended Kalman filter and traceless Kalman filter online state estimation to ensure the tracking accuracy at high speed feed in the presence of noise, friction and uncertainty factors in the ball screw feed system, but the isokinetic convergence law it uses leads to jitter problems.

The sliding mode control algorithm has a fast response to the system, is less affected by internal and external disturbances, and has good robustness [

15], and is widely used to control servo-feed systems [

16]. However, chattering is easy to occur in the controlled system because of the switching control behavior near the sliding mode surface. The presence of chattering makes it difficult to improve the performance of the control system and limits the application of sliding mode control [

17]. To solve the jitter problem, domestic and foreign scholars have tried to reduce jitter by reconstructing sliding modes, constructing state observers and adjusting sliding mode parameters [

18,

19,

20]. The main methods are the dynamic sliding mode method [

21], the improved convergence law parameter method [

22], the quasi-sliding mode boundary layer thickness adjustment method [

23], the signal filtering method [

24], and the applied interference observer method [

25]. They all weaken the jitter phenomenon to some extent. Among them, the design of convergence law can not only improve the motion quality when the sliding mode function converges to the sliding mode surface, but also can effectively reduce the jitter. In the literature [

26], an improved fast approximation law is proposed to shorten the time to reach the slip surface and speed up the convergence of the system. In the literature [

6], a new segmentation function is applied to the power convergence law to replace the symbolic function in the traditional sliding mode control, which improves the speed of system convergence to the sliding mode surface and effectively reduces the high frequency chattering of the system. An adaptive timing fault-tolerant control scheme is proposed in the literature [

27]. Using inverse trigonometric functions, a new double power convergence law is constructed to reduce the chattering phenomenon while accelerating the state stability. In the literature [

28,

29], an improved power exponential convergence law sliding mode velocity controller was designed to adjust the convergence law parameters of the sliding mode control using the integral term and fuzzy control, which not only improved the convergence velocity but also weakened the chattering to some extent.

In the above-mentioned literature, some scholars have not conducted experimental studies on the adopted convergence law method, and the convergence law is less applied in the sliding mode control of servo-feed systems. In this paper, we address the problem of fixed convergence parameters in the traditional exponential convergence law, which leads to large sliding mode jitter and tracking errors, and use fuzzy algorithm to soften the sliding mode control signal from the perspective of combining sliding mode variable structure control with intelligent algorithm. An adaptive fuzzy sliding mode controller (FSMC) is designed for the position tracking control of a servo-feed drive system. Experiments are conducted to verify the effectiveness of the designed control strategy compared to PID controllers and sliding mode controllers.

2. Flexible Dynamics Modeling of the Feed System

The rigid body model can better describe the dynamic characteristics of the system in the low frequency band of the system, which is easy to implement the control method. However, under high-speed operating conditions, the ball screw drive sub of the servo feed system will inevitably undergo elastic deformation, making the system susceptible to shaft–torsion coupling vibration, which will have a great impact on the tracking performance of the system. Therefore, the flexible body characteristics exhibited by the system in the high frequency band must be fully considered to establish the flexible body dynamics model of the servo-feed system.

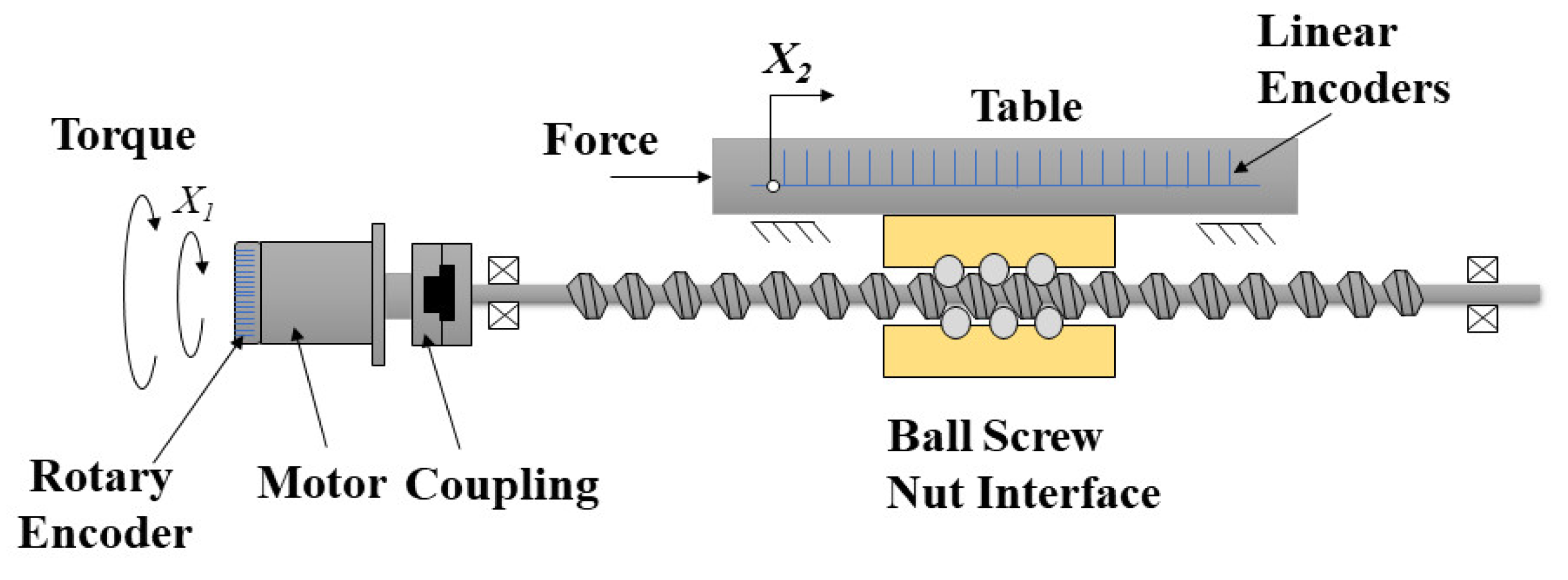

Figure 1 shows the servo feed system model: the AC servo motor drives the screw to rotate through the coupling, the nut on the screw is fixed to the table by the nut sleeve, both ends of the platform are supported by rolling linear guides and the servo motor generates motor torque through a closed-loop servo control system, which controls the position of the table.

Several two-dimensional models have been proposed in the literature [

30] to simulate the rigid body model and the first vibration pattern of the ball screw drive. In these methods, the concentrated mass model can effectively capture the stiffness characteristics and the main vibration pattern on the ball screw feed drive system and be easily used for controller design [

31]. According to the concentrated mass method, the servo-feed system model is equated to a two-degree-of-freedom mass-spring-damping system, as shown in

Figure 2, and the physical significance of each parameter is shown in

Table 1.

In

Figure 2, the equation of motion for the concentrated mass model can be written as:

The transfer dynamics between the motor and the table can be derived from the equation of motion (1) and transformed by Laplace as:

and are the transfer functions between motor torque to motor position and motor torque to table position, respectively.

Equation (2) describes the overall transfer dynamics of the servo-feed system. Since the characteristic equations are of fourth order, they are converted into state-space form by selecting four state quantities. In servo feed system installations, the position and speed of the motor and table are measured by rotary encoder and scale systems, respectively [

32]. Select the state vector as

, then Equation (2) can be rewritten as the equation of state for the two-degree-of-freedom flexible body model:

4. Simulation Analysis

In order to verify the control performance of the fuzzy convergence law sliding mode control method proposed in this paper, a flexible body model of the servo feed system is established and model simulation comparison experiments are conducted. The structure of the fuzzy convergence law sliding mode control system is shown in

Figure 5.

The main parameters of the flexible body model of the servo-feed system are shown in

Table 5.

The smooth reference trajectory helps to suppress the vibration, and the cubic acceleration trajectory is chosen as the reference command for the table position. The maximum displacement is 0.065 m, the maximum velocity is 0.1 m/s, and the maximum acceleration is 1 m/s

2, as shown in

Figure 6.

The flexible body model of the servo feed system is added to the controller designed in this paper, and the given reference trajectory is tracked and compared with the sliding mode control and PID control to verify the feasibility and control effect of the fuzzy convergence law sliding mode control algorithm. The simulation model built by MATLAB /Simulink simulation module is shown in

Figure 7.

The fuzzy convergence law sliding mode controller is implemented by programming the S-function. The system inputs are the reference command xr, the ball screw rotational equivalent displacement x1, the table linear displacement x2, and the convergence law parameters and . The outputs are the slide surface function σ, the slide surface derivative dσ, and the voltage signal ut for controlling the torque. σ and dσ are used as inputs to the fuzzy controller to adjust the parameters and in the exponential convergence law adaptively through fuzzy rules to reduce the chattering phenomenon of the system.

Take the coefficients λ1, λ2, λ3 and λ4 of the sliding mode function as 30, 1, 30 and 0.1, respectively, without considering the interference term, so that d1 = d2 = 0, then the simulation results of dynamic regulation of parameters ε and h are shown in

Figure 8.

The fuzzy controller feeds the adjusted parameters

and

back to the fuzzy convergence law sliding mode controller in real time for the voltage signal adjustment. The voltage signal is passed through the AC servo motor output to control the torque signal of the load. The voltage signal outputs the torque signal of the control load through the AC servo motor, so as to accurately locate the table. The simulation results of the position trajectory tracking of the table are shown in

Figure 9.

As can be seen from

Figure 9, the table generates significant tracking errors when it is in the speed rise and fall phase. In order to compare the performance of the controller more intuitively, the tracking error and control voltage signal of the platform are simulated, and the simulation results are shown in

Figure 10 and

Figure 11.

From

Figure 10 and

Figure 11, it can be seen that the maximum tracking error of PID control is 0.541 mm, and there is a steady-state error of 0.046 mm in the stage of uniform travel of the table, and the response to the control voltage signal is also slow. The maximum tracking error of the sliding mode control is 0.101 mm, and there is obvious chattering in the control voltage signal during the table acceleration and deceleration phase. With the fuzzy convergence law sliding mode controller designed in this paper, the voltage signal is significantly smoother and less chattering, and the maximum tracking error is reduced to 0.051 mm, the comparison results are shown in

Table 6. Compared with the previous two, the fuzzy convergence law sliding mode controller has better speed and stability, and the position tracking performance of the table is significantly improved.

Considering the influence of the interference term on the precise positioning of the table, adding d

1 = d

2 = sin(πt) in the simulation, the simulation results are shown in

Figure 12 and

Figure 13.

From

Figure 12 and

Figure 13, it can be seen that the maximum tracking error of all three control methods increases after adding the perturbation term to the simulation model. The maximum tracking error of PID control is 1.10 mm, which is 1.054 mm higher than that without disturbance. The maximum tracking error of sliding mode control is 0.615 mm, which is 0.514 mm higher than that without disturbance. However, after the table stops moving, the steady-state errors of 0.304 mm and 0.234 mm exist for the PID control and sliding mode control, respectively, and the tracking accuracy is significantly reduced. Compared with the previous two, the maximum tracking error of the fuzzy convergence law sliding mode control is 0.268 mm, which only increases 0.217 mm. The tracking error curve does not change much from before the disturbance was added, and it can still track the reference trajectory accurately.

Combining the above simulation results and analysis, the fuzzy convergence law sliding mode controller designed in this paper can effectively improve the position tracking accuracy of the servo feed system and suppress the chattering phenomenon of the control voltage signal. Its good robustness can effectively eliminate the steady-state error of the system and achieve high accuracy position tracking of the table when there is disturbance in the system.

5. Experimental Validation

In order to verify the actual control effect of the sliding mode control method based on the fuzzy convergence law on the servo feed system, experiments are conducted under the parallel moving platform [

33] test system shown in

Figure 14.

The system consists of table, upper computer, linear scale, servo motor, motion controller, AC servo driver, and power supply system. In order to meet the requirements of precise positioning of the platform, the transmission amplitude grating ruler WTB0.5-0300 is used for real-time position feedback of the table. The GTS-400-PV-PCI-G motion controller supports calling dynamic link libraries and compiling the controller code on the PC side using Visual Studio. The motion controller and servo driver are controlled by analog control method. The DAC of the motion controller outputs analog voltage signals to the servo motor driver, and then controls the position of the table.

The trajectory tracking experiments of the table were conducted using PID, sliding mode and fuzzy convergence law sliding mode control methods, respectively, and the motion process of the table was planned according to the curve in

Figure 6. The trajectory tracking error and control voltage signal are recorded, and the experimentally collected results are shown in

Figure 15,

Figure 16 and

Figure 17.

Figure 15 shows the experimental results of the PID controller, the tracking error of the table in the acceleration and deceleration stages varies greatly, the maximum tracking error is 0.065 mm, and there is obvious chattering in the control signal;

Figure 16 shows the experimental results of the sliding mode controller, the maximum tracking error is 0.054 mm, using the sliding mode control method compared with the PID control method to reduce the tracking error, but the chattering phenomenon of the control signal is not significantly improved.

Figure 17 shows the experimental results of the sliding mode controller with fuzzy convergence law, the maximum tracking error is reduced to 0.037 mm, and the chattering of the control signal is significantly reduced.

In order to further compare the control effects of PID controller, sliding mode controller and the fuzzy convergence law sliding mode controller designed in this paper, the experimental results of the three methods are compared, as shown in

Figure 18.

After calculation, the maximum tracking error of the table under the fuzzy convergence law sliding mode control is reduced by about 43.1% compared with the PID control method and about 31.5% compared with the sliding mode control method. This control method can further reduce the maximum tracking error of the table, improve the control accuracy, weaken the chattering in the control signal, and have better control effect and better controller performance. The comparison results of the experimental data of the maximum tracking error are shown in

Table 7.