Stretching and Forming Limit Curve of Steel–Glass Fibre Reinforced and Non-Reinforced Polyamide–Steel Sandwich Materials

Abstract

:1. Introduction

2. Materials and Experimental Work

2.1. Materials and Sandwich Production

2.2. Warm Forming: Tool Design and Technical Issues

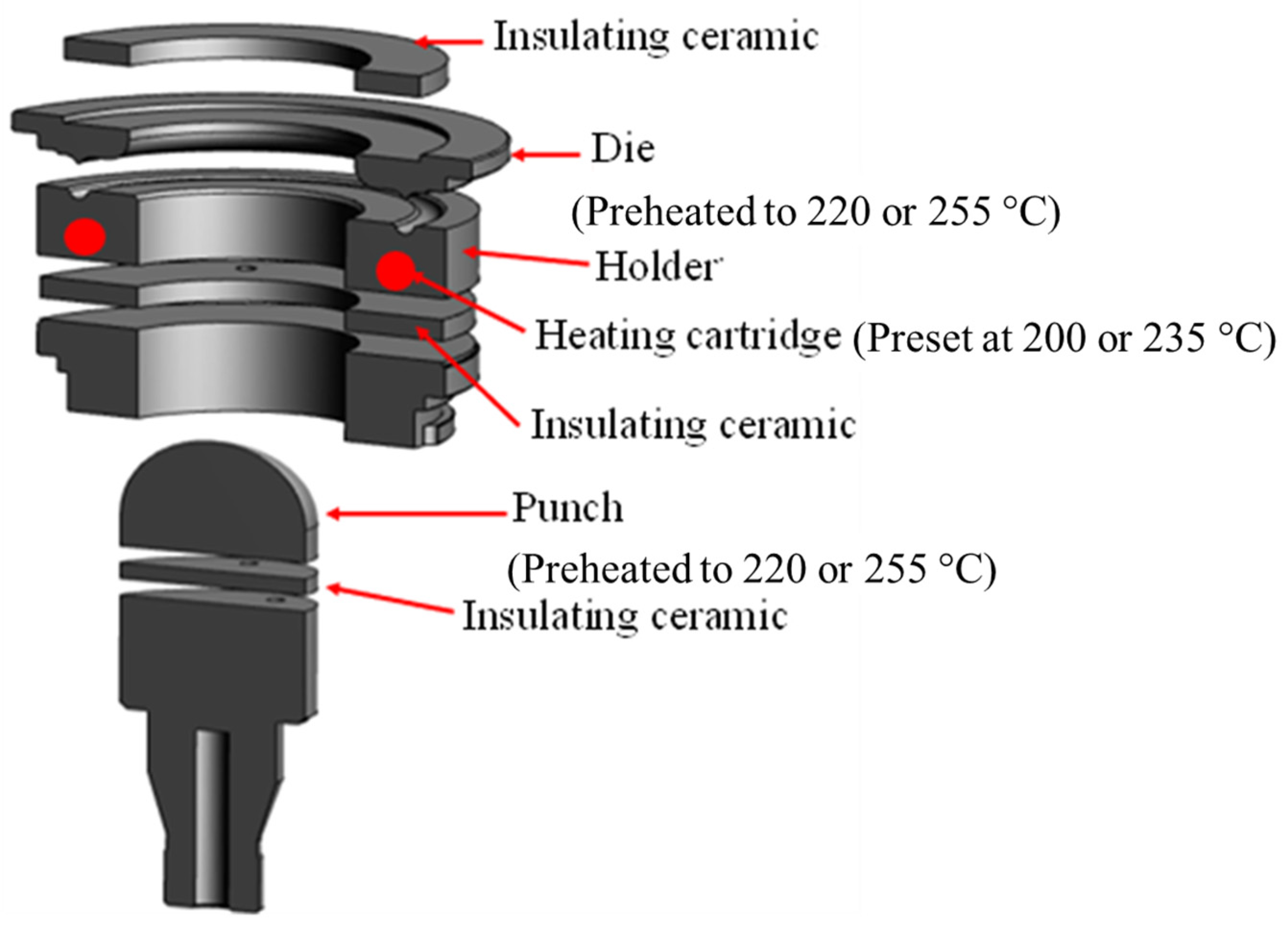

2.2.1. Tool Design

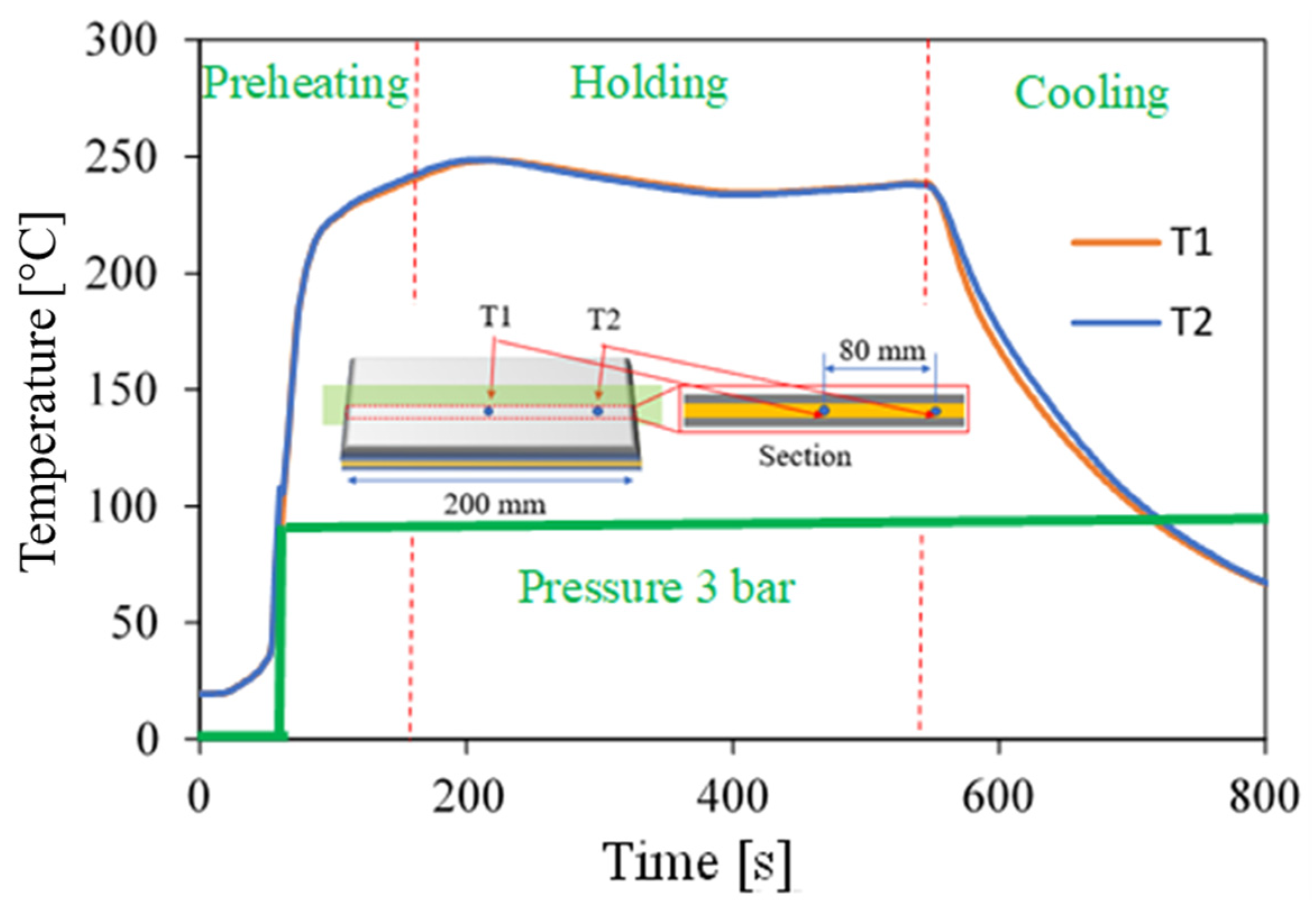

2.2.2. Temperature Profile

2.2.3. Lubrication

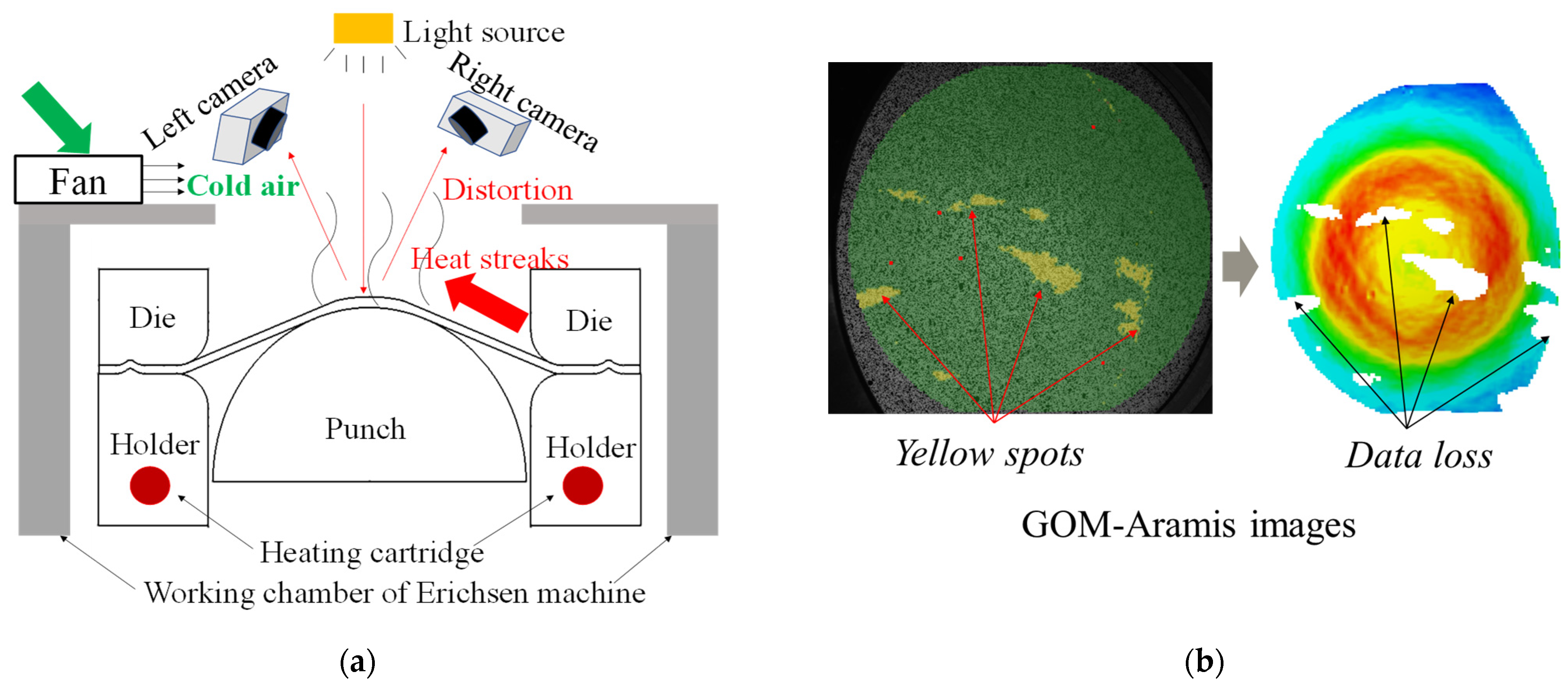

2.2.4. Digital Image Correlation (DIC) Analysis and Heat Streaks

2.3. Evaluation of the Stretch-Forming Behaviour

- Semi-products of the sheet-like specimens of MPM and FML are prepared via hot pressing, as is described in Section 2.1 (i.e., the stretch forming is performed on pre-bonded sandwich panels).

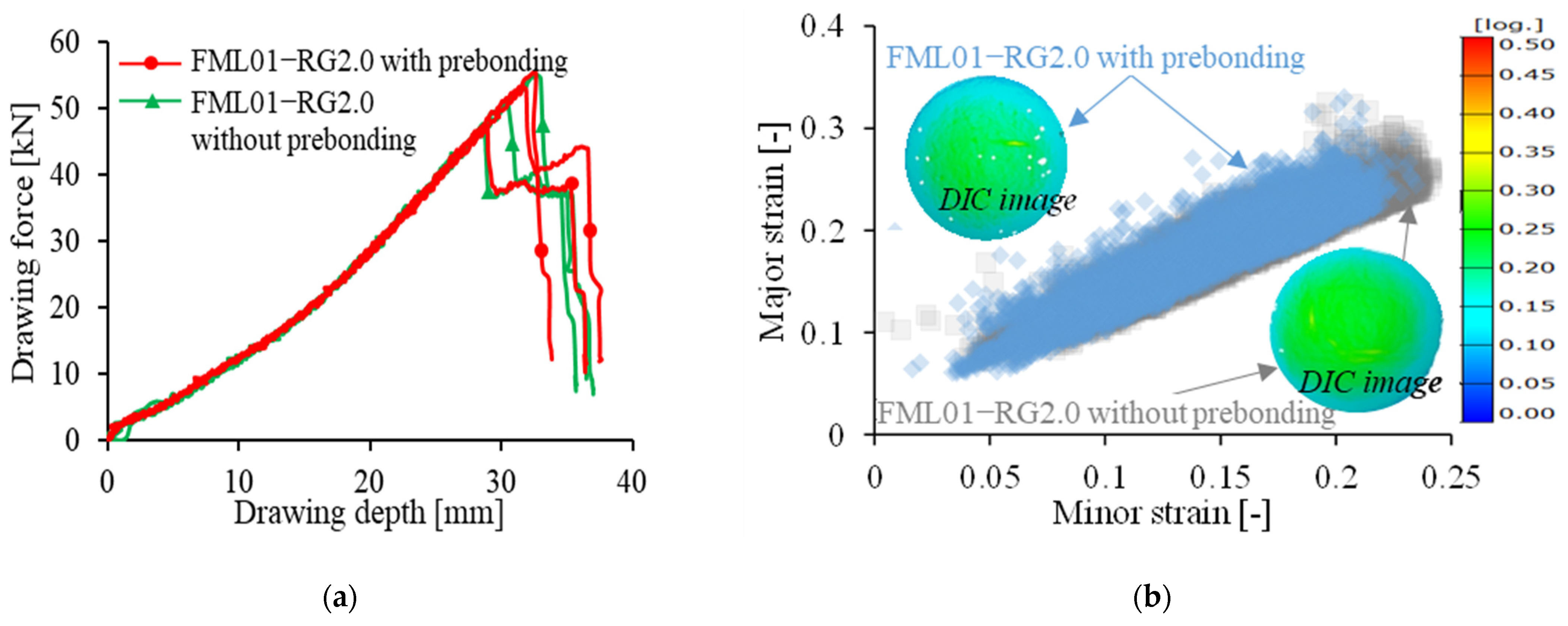

- The stretch forming of FML without pre-bonding is performed at 235 °C, i.e., the separated cover and core layers are pre-treated, according to Figure 2, and heated up in an external furnace without hot-pressing. The aim of the approach is to investigate the effect of the one-step forming and bonding condition on the stretch forming of the sandwich panels. In this case, at a temperature above the melting point of PA6, free sliding and shearing of the fibre-reinforced polyamide core layer between the two metallic skin sheets is enabled during the forming step. The trial without pre-bonding resembles the one-step thermoforming method that is earlier developed [43,44].

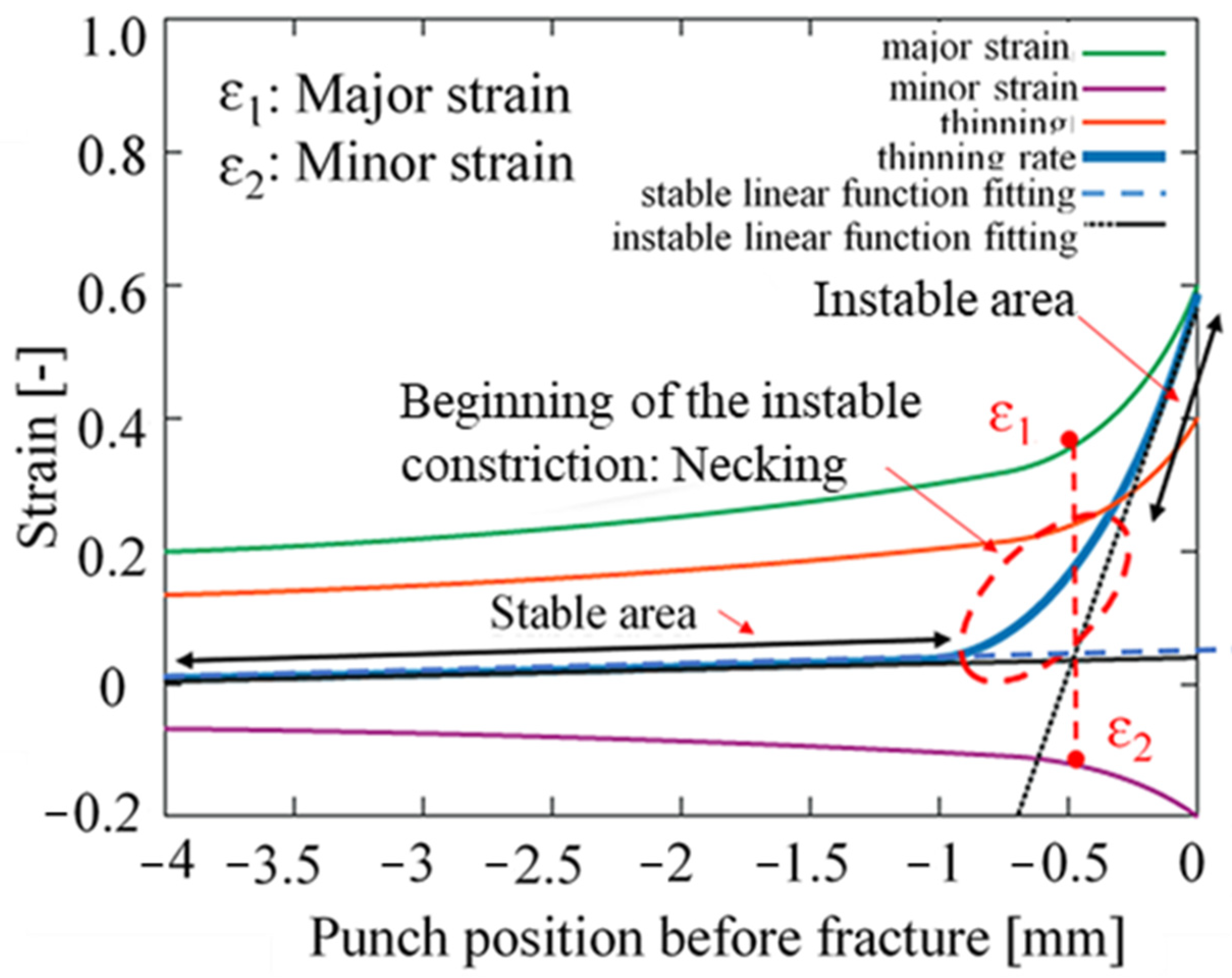

2.4. FLC Investigation

3. Results and Discussion

3.1. Stretch Forming

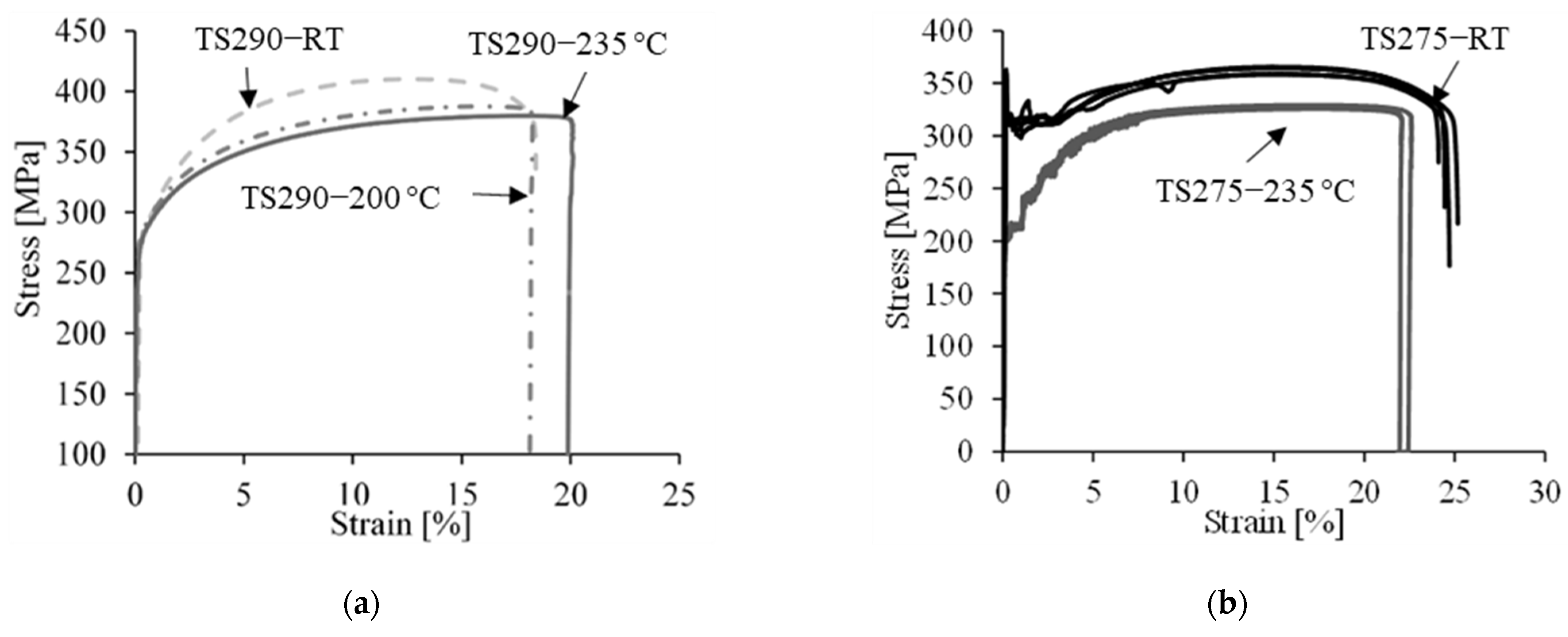

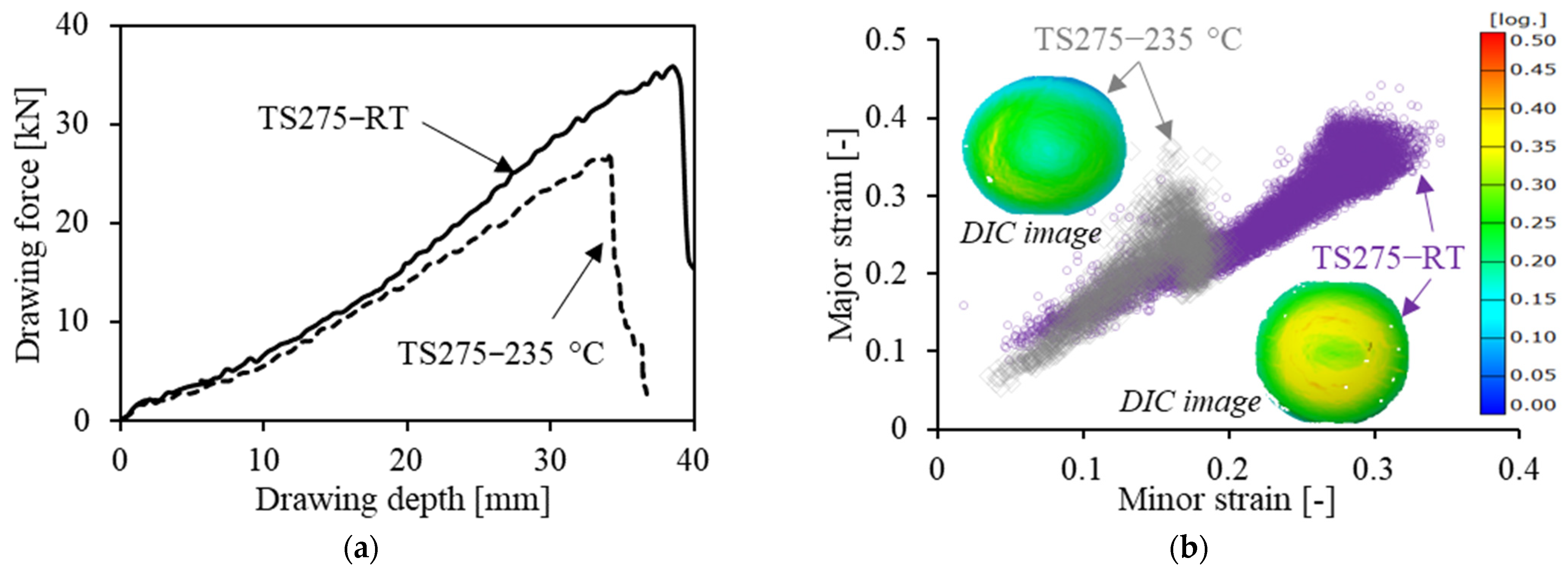

3.1.1. Forming Force and Strain Evolution of the Mono-Materials

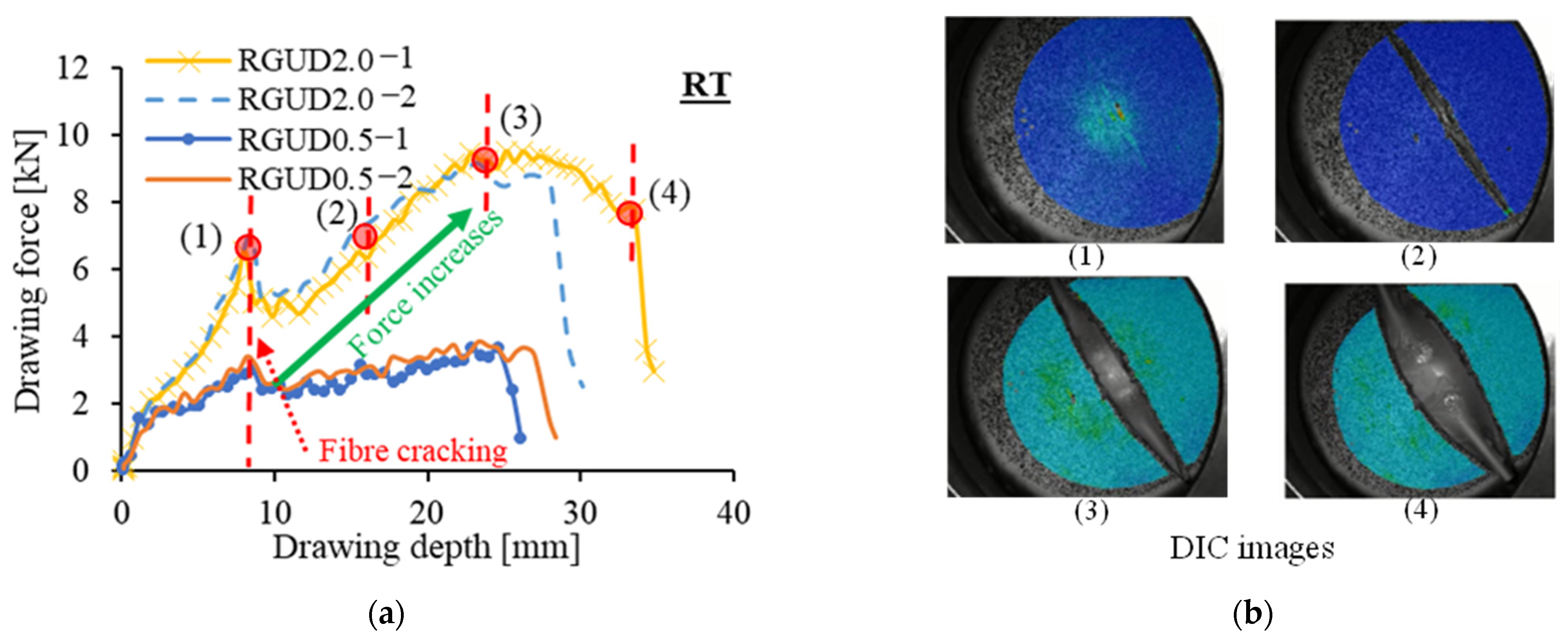

3.1.2. Force and Strain Evolution of MPM

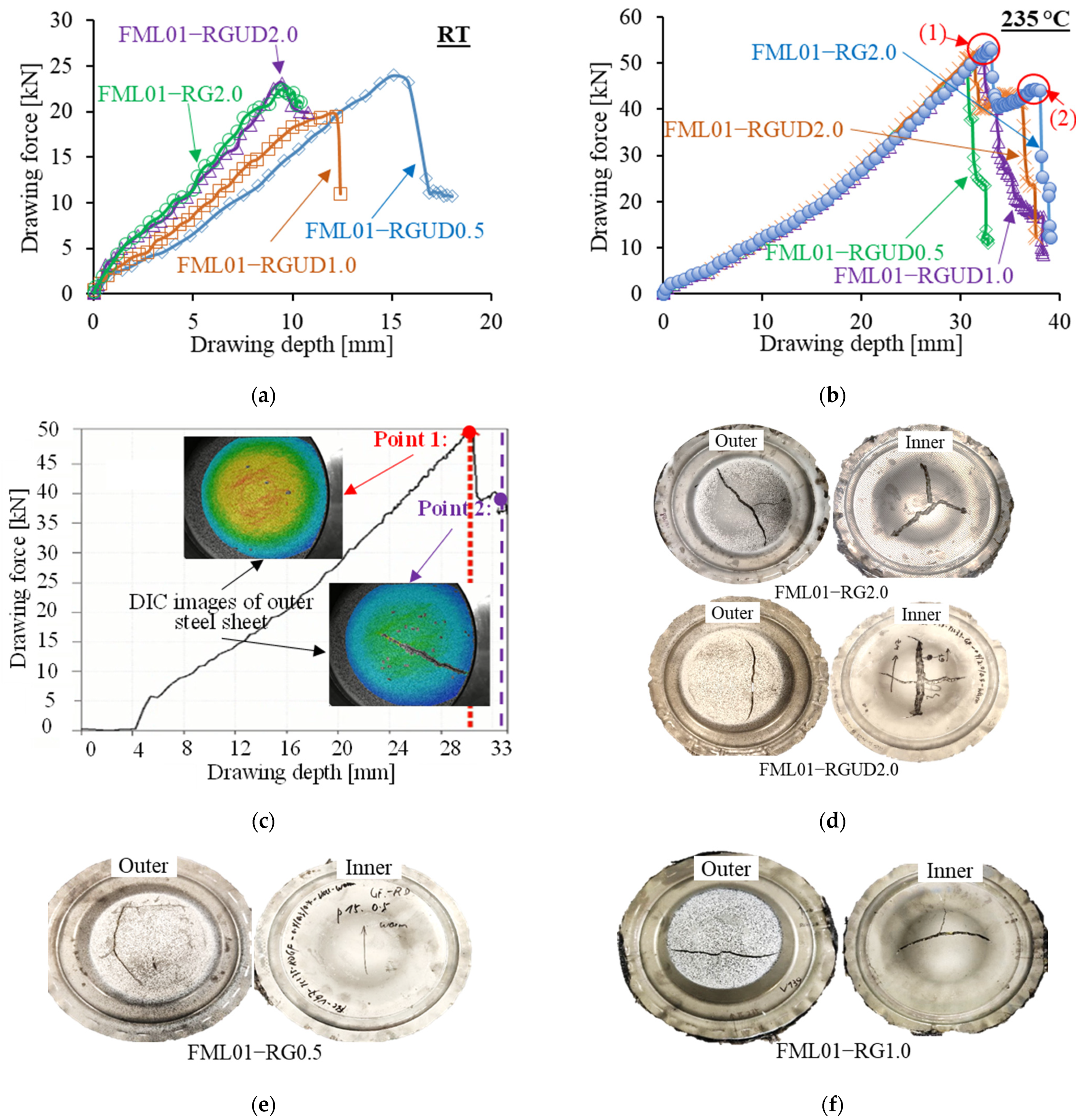

3.1.3. Force and Strain Evolution of FML

3.1.4. One-Step Stretch Forming

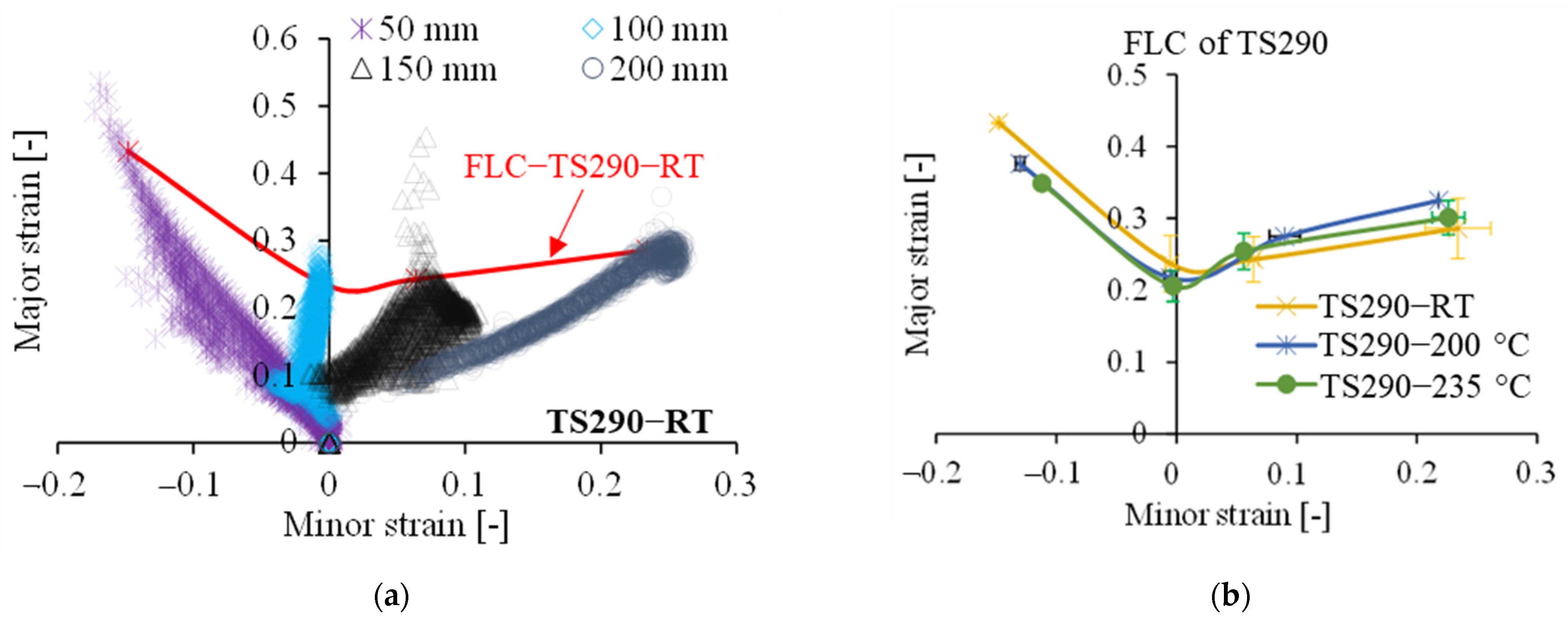

3.2. FLC Determination

- 3.

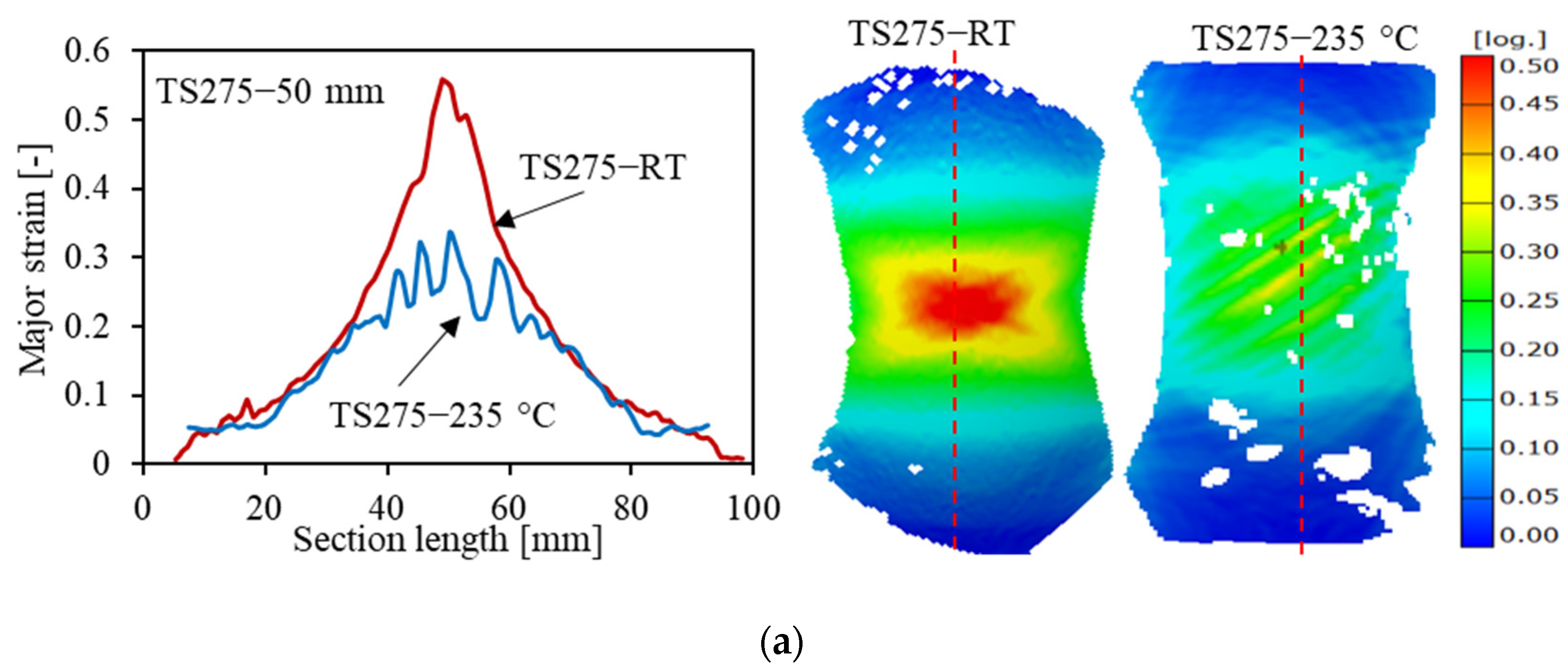

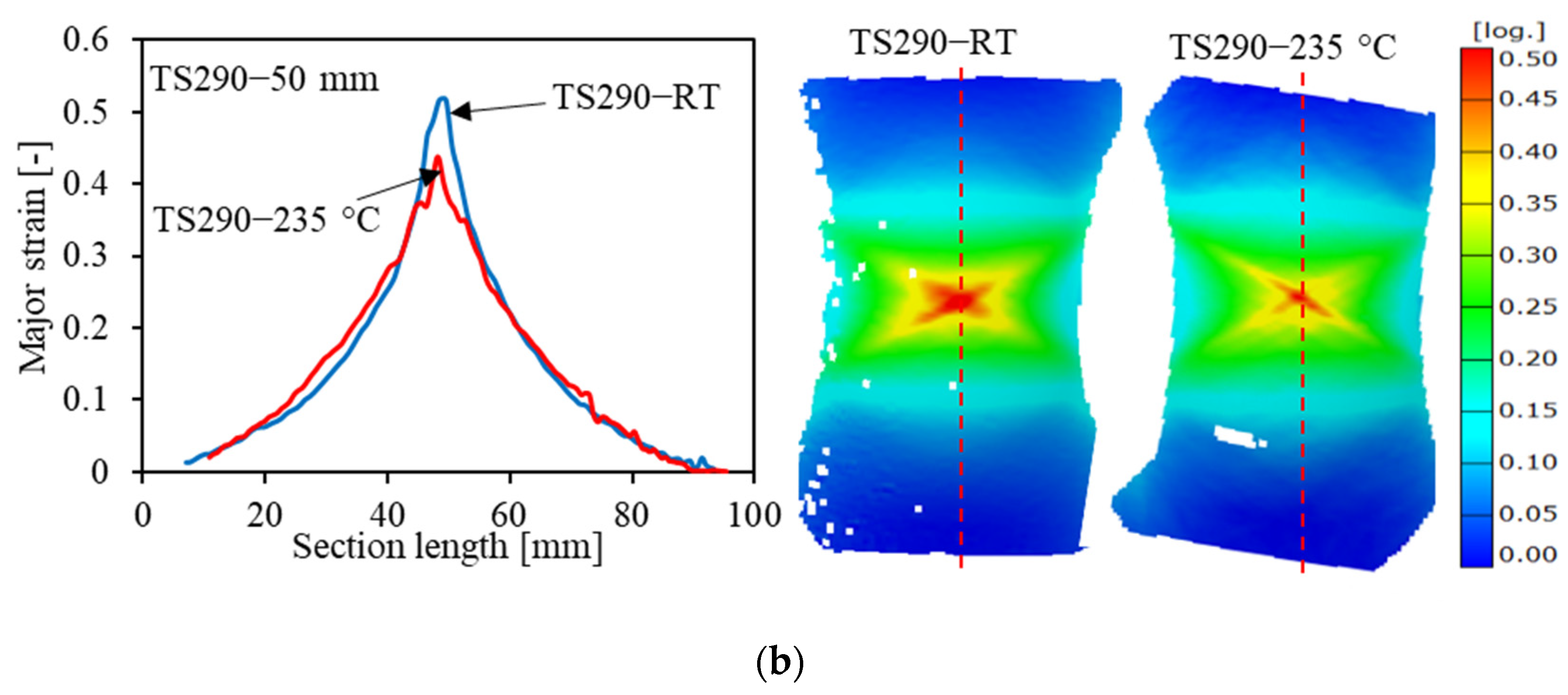

- At RT, the development of the plastic zone of both TS290 and TS275 revolves around the centre of the specimen, where the strain evolution along the cross-section lines (the red dotted lines in the figure) shows a smooth progression (Figure 20a,b).

- 4.

- However, at 235 °C intermittent slant strain localization bands are detected, indicating the presence of PLC flip-flopped bands for TS275 at elevated temperatures [42] and leading to a reduction in elongation at failure. In contrast, the strain evolution of TS290 at 235 °C is similar to that at RT, with no detected slant strain localization bands, see Figure 20b.

4. Conclusions and Outlook

- Stretch forming of the organosheets at RT was highly restricted. A further increase of the stretching force was due to its resistance of unfractured fibres in warp direction of RGUD.

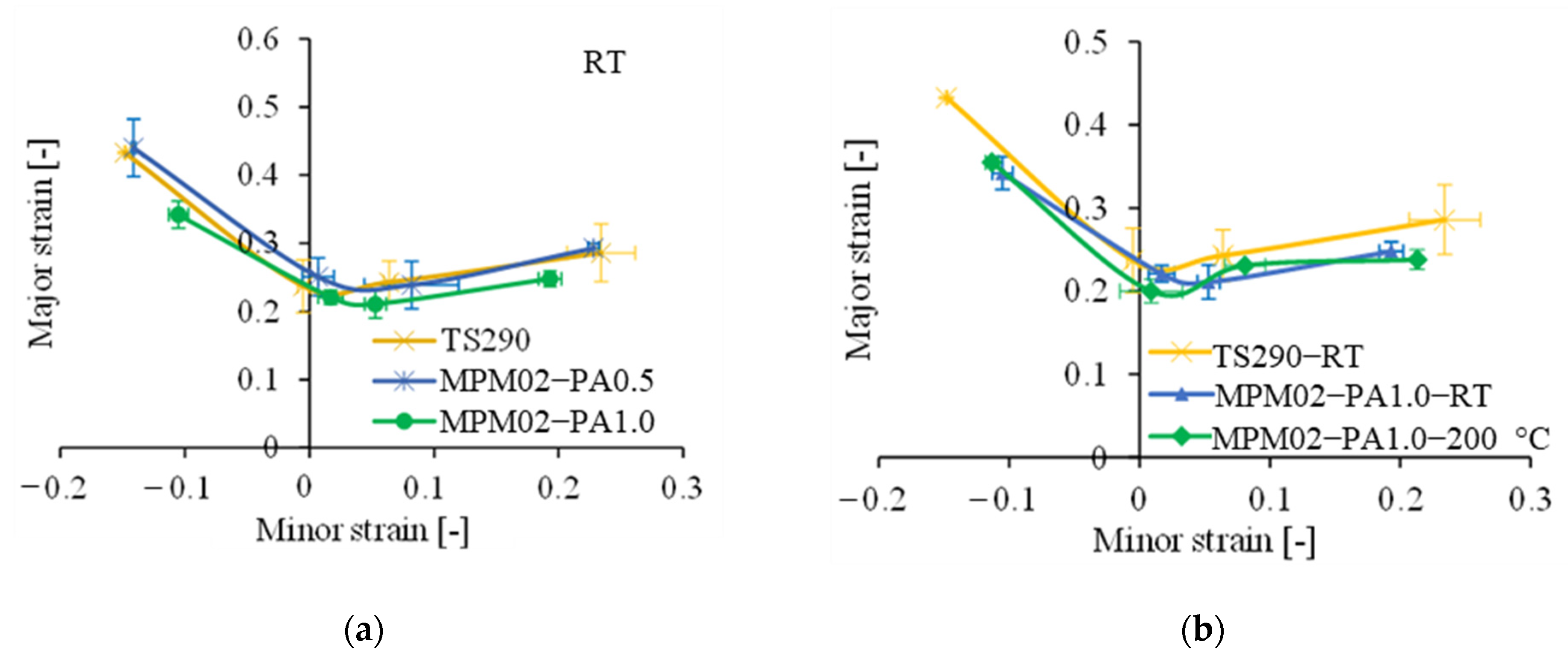

- The formability of the MPMs was found to be comparable to that of their monolithic steel cover sheets, yet it decreased when core thickness increased. The same effect was found regarding the FLC-levels.

- The stiffness of FML increased when core thickness increased, but its formability decreased accordingly.

- At 235 °C, i.e., above the melting point of PA6, no remarkable difference of drawing depth and stiffness of FML with varied core thicknesses and different organosheets RG and RGUD can be stated. The formability of FML was comparable to that of the monolithic steel covers.

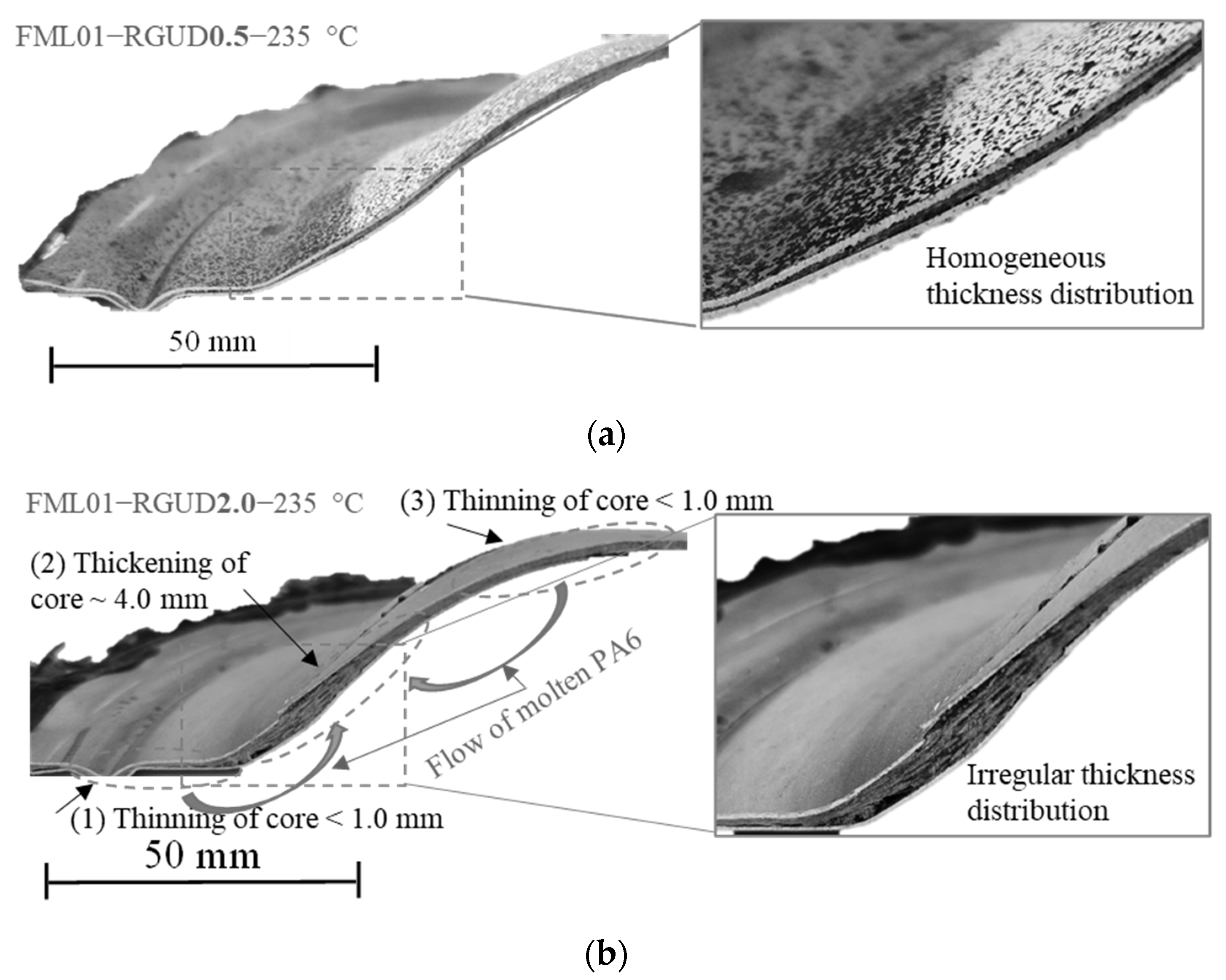

- At 235 °C, irregular thickness distribution of thicker core layer (>1.0 mm) in FML led to decreasing the dynamic friction coefficient and earlier failure of the inner steel sheet.

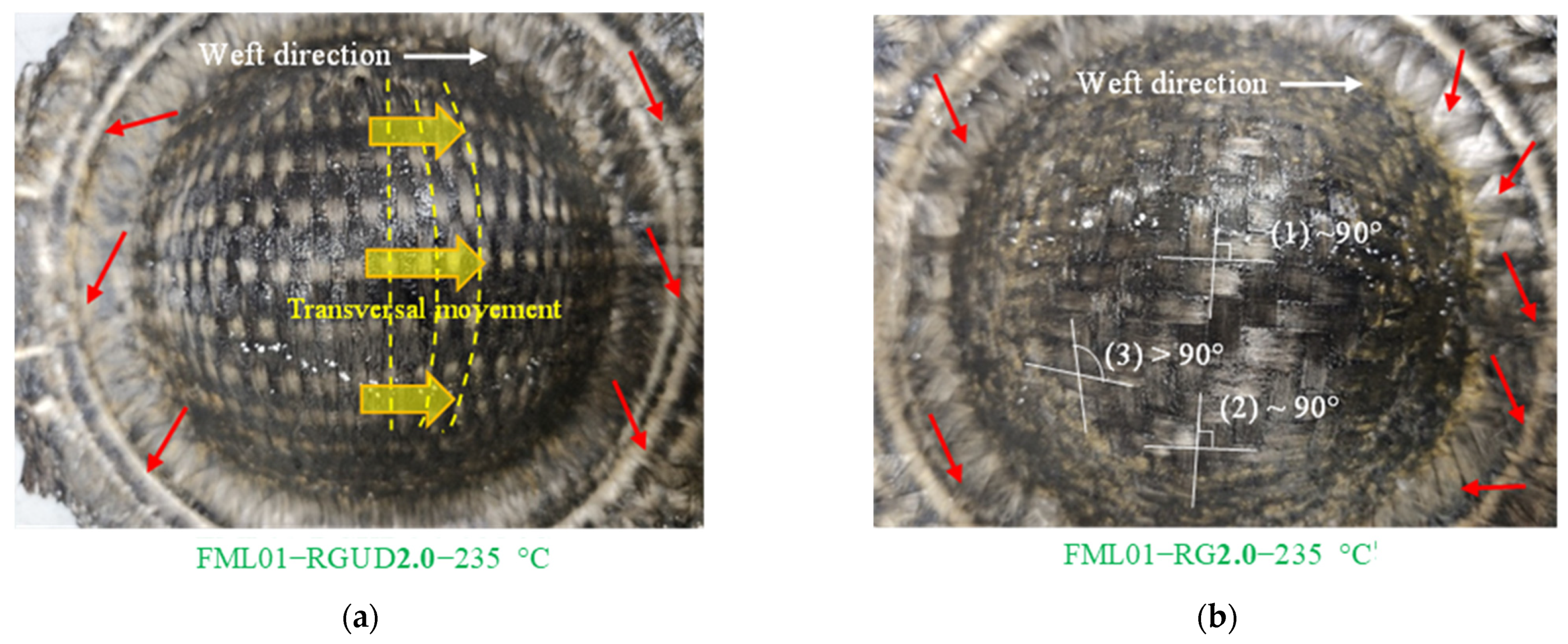

- At 235 °C, no fibre cracking in the FML was detected, but severe distortion in the flange region due to the restriction of the fibres’ movement due to the drawing beads was seen.

- Regarding the FLC of MPM, no remarkable improvement of the FLC-level was observed by increasing the forming temperature.

- The FLC-levels of FML significantly improved (almost > 300%) at the elevated forming temperatures. The influence of the core thickness (0.5~1.0 mm) on the FLC-level was ignorable at RT, 200 and 235 °C. However, organosheets dominated the FLC-level at RT and the steel cover sheets dominated at elevated temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Burchitz, I.; Boesenkool, R.; van der Zwaag, S.; Tassoul, M. Highlights of Designing with Hylite—A New Material Concept. Mater. Des. 2005, 26, 271–279. [Google Scholar] [CrossRef]

- Wiesbaden, S.F. Application potential of Litecor in the body. In ATZextra Worldwide; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2014; Volume 19, pp. 108–111. [Google Scholar]

- Alderliesten, R. (Ed.) Fatigue and Fracture of Fibre Metal Lminates: Solid Mechanics and Its Applications; Springer International Publishing: Cham, Switzerland, 2017; ISBN 978-3-319-56226-1. [Google Scholar]

- Vogelesang, L.B.; Gunnink, J.W. ARALL: A Aaterials Challenge for the next Generation of Aircraft. Mater. Des. 1986, 7, 287–300. [Google Scholar] [CrossRef]

- Vlot, A.; Vogelesang, L.B.; Vries, T.J. Towards Application of Fibre Metal Laminates in Large Aircraft. Aircr. Eng. Aerosp. Technol. 1999, 71, 558–570. [Google Scholar] [CrossRef]

- Wanhill, R.J.H. Aerospace Materials and Material Technologies: GLARE®: A Versatile Fibre Metal Laminate (FML) Concept; Springer: Singapore, 2017; Volume 5, pp. 291–307. [Google Scholar]

- Rendigs, K.H. Airbus and Current Aircrafts Metal Technologies; Airbus Germany: Bremen, Germany, 2008. [Google Scholar]

- van Rooijen, R.G.J.; Sinke, J.; van der Zwaag, S. Improving the Adhesion of Thin Stainless Steel Sheets for Fibre Metal Laminate (FML) Applications. J. Adhes. Sci. Technol. 2005, 19, 1387–1396. [Google Scholar] [CrossRef]

- Alderlieste, R.; Rans, C.; Benedictus, R. The Applicability of Magnesium based Fibre Metal Laminates in Aerospace Structures. Compos. Sci. Technol. 2008, 68, 2983–2993. [Google Scholar] [CrossRef]

- Reyes, G.; Kang, H. Mechanical Behavior of Lightweight Thermoplastic Fiber–Metal Laminates. J. Mater. Process. Technol. 2007, 186, 284–290. [Google Scholar] [CrossRef]

- Reyes, G.; Cantwell, W.J. The Mechanical Properties of Fibre-Metal Laminates based on Glass Fibre Reinforced Polypropylene. Compos. Sci. Technol. 2000, 6, 1085–1094. [Google Scholar] [CrossRef]

- Wiedemann, S.; Wesseks, H.; Wetterau, H.-J.; Eckstein, L.; Schulte, S.; Modler, N.; Jaschinski, J.; Weber, T.; Wollmann, T.; Kawalla, R.; et al. Effiziente Mischbauweisen für Leichtbau-Karosserien-LEIKA: Final Report (German); Plattform FOREL. 2017. Available online: www.plattform-FOREL.de (accessed on 17 April 2023).

- Jahn, K.; Kolonko, A.; Buschner, N.; Scholze, M.; Nestler, D.; Roth-Panke, I.; Lampke, T.; Kroll, L.; Tröltzsch, J. Interface Design of Hybrid Laminates. In Merge Technologies for Multifunctional Lightweight Structures; TU Chemnitz: Chemnitz, Germany, 2017. [Google Scholar]

- Nestler, D. Innovative Material, Preform and Technology Development for Large Series; TU Chemnitz: Chemnitz, Germany, 2020. [Google Scholar]

- Nestler, D.; Trautmann, M.; Zopp, C.; Tröltzsch, J.; Osiecki, T.; Nendel, S.; Wagner, G.; Kroll, L. Continuous Film Stacking and Thermoforming Process for Hybrid CFRP/Aluminum Laminates. Procedia CIRP 2017, 66, 107–112. [Google Scholar] [CrossRef]

- Wielage, B.; Nestler, D.; Steger, H.; Kroll, L.; Tröltzsch, J.; Nendel, S. CAPAAL and CAPET—New Materials of high-strength, high-stiff Hybrid Laminates. In Integrated Systems, Design and Technology 2010; Springer: Berlin/Heidelberg, Germany, 2001; pp. 23–25. [Google Scholar]

- Scholz, P.; Schieck, F.; Müller, R.; Seidlitz, H.; Gerstenberger, C.; Osiecki, T.; Grbic, N.; Behrens, B.A.; Vucetic, M.; Neumann, A. Umformprozessketten für Bauteile aus Faser-Kunststoff/Metall-Verbunden. In EFB T40-Intermezzo der Hybriden Werkstofflösungen: Hat Blech eine Zukunft? Europäische Forschungsgesellschaft für Blechverarbeitung eV: Hanover, Germany, 2015; pp. 151–171. [Google Scholar]

- Tekkaya, A.E.; Hahn, M.; Hiegemann, L.; Weddeling, C. Umformen Faserverstärkter Thermoplastischer Kunststoff-Halbzeuge mit Metallischen Deckblechen für den Leichtbau; Europäische Forschungsgesellschaft für Blechverarbeitung: Hannover, Germany, 2015; pp. 185–199. [Google Scholar]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A Review: Fibre Metal Laminates, Background, Bonding Types and Applied Test Methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Botelhoa, E.C.; Silva, R.A.; Pardini, L.C.; Rezende, M.C. A Review on the Development and Properties of Continuous Fiber/Epoxy/Aluminum Hybrid Composites for Aircraft Structures. Mater. Res. 2006, 9, 247–256. [Google Scholar] [CrossRef]

- Harhash, M.; Fischer, T.; Grubenmann, M.; Hua, W.; Heingärtner, J.; Hora, P.; Ziegmann, G.; Palkowski, H. Top-hat Crashboxes of Thermoplastic Fibre-Metal-Laminates Processed in One-step Thermoforming: Experimental and Numerical Study. Compos. Part B Eng. 2021, 226, 109367. [Google Scholar] [CrossRef]

- Harhash, M.; Carrade, A.; Palkowski, H. Forming Limit Diagram of Steel/Polymer/Steel Sandwich Systems for the Automotive Industry. In Advanced Composites for Aerospace, Marine, and Land Applications; Springer: Cham, Switzerland, 2014; pp. 243–254. [Google Scholar]

- Sherkatghanad, E.; Lang, L.H.; Liu, S.C.; Wang, Y. Innovative Approach to Mass Production of Fiber Metal Laminate Sheets. Mater. Manuf. Process. 2018, 33, 552–563. [Google Scholar] [CrossRef]

- Dong, A.Q.; Zhao, Y.; Zhao, X.Q.; Yu, Q.Y. Cure Cycle Optimization of Rapidly Cured out-of-Autoclave Composites. Materials 2018, 11, 421. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.C.; Lang, L.H.; Sherkatghanad, E.; Wang, Y.; Xu, W.C. Investigation into the Fiber Orientation Effect on the Formability of GLARE Materials in the Stamp Forming Process. Appl. Compos. Mater. 2018, 25, 255–267. [Google Scholar] [CrossRef]

- Kalyanasundaram, S.; DharMalingam, S.; Venkatesan, S.; Sexton, A. Effect of Process Parameters during Forming of Self Reinforced—PP based Fiber Metal Laminate. Compos. Struct. 2013, 97, 332–337. [Google Scholar] [CrossRef]

- Wollman, T.; Hahn, M.; Wiedermann, S.; Zeiser, A.; Jaschinski, J.; Modler, N.; Khalifa, N.B.; Meißen, F.; Paul, C. Thermoplastic Fibre Metal Laminates: Stiffness Properties and Forming Behaviour by Means of Deep Drawing. Arch. Civ. Mech. Eng. 2018, 18, 442–450. [Google Scholar] [CrossRef]

- Guo, Y.Q.; Zhai, C.P.; Li, F.Z.; Zhu, X.F.; Xu, F.; Wu, X.L. Formability, Defects and Strengthening Effect of Steel/CFRP Structures Fabricated by using the Differential Temperature Forming Process. Compos. Struct. 2019, 216, 32–38. [Google Scholar] [CrossRef]

- Heggemann, T.; Homberg, W.; Sapli, H. Combined Curing and Forming of Fiber Metal Laminates. Procedia Manuf. 2020, 47, 36–42. [Google Scholar] [CrossRef]

- Behrens, B.A.; Hübner, S.; Grbic, N.; Micke-Camuz, M.; Wehrhane, T.; Neumann, A. Forming and Joining of Carbon-Fiber-Reinforced Thermoplastics and Sheet Metal in One Step. Procedia Eng. 2017, 183, 227–232. [Google Scholar]

- Ding, Z.R.; Wang, H.Y.; Luo, J.M.; Li, N. A Review on Forming Technologies of Fibre Metal Laminates. Int. J. Lightweight Mater. Manuf. 2021, 4, 110–126. [Google Scholar] [CrossRef]

- Keeler, S.; Backhofen, W. Plastic Instability and Fracture in Sheets Stretched over Rigid Punches. ASM Trans. Q. 1964, 56, 25–48. [Google Scholar]

- Liu, J.G.; Xue, W. Formability of AA5052/polyethylene/AA5052 Sandwich Sheets. Trans. Nonferrous Met. Soc. China 2013, 23, 964–969. [Google Scholar] [CrossRef]

- Kazemi, F.; Hashemi, R.; Niknam, S.A. Formability and Fractography of AA5754/Polyethylene/AA5754 Sandwich Composites. Mech. Based Des. Struct. Mach. 2020, 50, 1253–1267. [Google Scholar] [CrossRef]

- Harhash, M.; Carrade, A.; Palkowski, H. Deep- and Stretch Forming of Steel/Polymer/Steel Laminates. In Proceedings of the Euro Hybrid Materials and Structures, Kaiserslautern, Germany, 20–21 April 2016; pp. 69–74. [Google Scholar]

- Jalali Aghchai, A.; Khatami, S. Experimental and Numerical Formability Investigation of FML Sheets with Glass Fiber Reinforced Core. Int. J. Adv. Manuf. Technol. 2018, 96, 3881–3891. [Google Scholar] [CrossRef]

- Sexton, A.; Cantwell, W.; Kalyanasundaram, S. Stretch Forming Studies on a Fibre Metal Laminate based on a Self-reinforcing Polypropylene Composite. Compos. Struct. 2012, 94, 431–437. [Google Scholar] [CrossRef]

- Propex Fabrics Curv™—Technical Data Sheet, C100A. Available online: www.curvonline.com (accessed on 1 May 2023).

- Rahiminejad, D.; Compston, P. The Effect of Pre-heat Temperature on the Formability of a Glass-fibre/Polypropylene and Steel-based Fibre–Metal Laminate. Int.J. Mater. 2020, 9, 211. [Google Scholar] [CrossRef]

- Hua, W.; Fischer, T.; Harhash, M.; Ziegmann, G.; Palkowski, H. Study on Processing Galvanized Steel/PA6 Sandwich Composites by Hot-pressing: Influence of Interface Properties and Surface Treatment on the Adhesion Strength. Compos. Struct. 2020, 236, 111779. [Google Scholar] [CrossRef]

- Hua, W. Forming Behaviour of Sandwich Materials made of Steel Covers and Polyamide Cores with or without Glass Fibre Reinforcements. Doctoral Dissertation, Clausthal University of Technology, Clausthal-Zellerfeld, Germany, May 2022. [Google Scholar]

- Ren, S.C.; Morgeneyer, T.F.; Mazière, M.; Forest, S.; Rousselier, G. Effect of Lüders and Portevin–Le Chatelier Localization Bands on Plasticity and Fracture of Notched Steel Specimens Studied by DIC and FE Simulations. Int. J. Plast. 2021, 136, 102880. [Google Scholar] [CrossRef]

- Fischer, T.; Grubenmann, M.; Harhash, M.; Hua, W.; Heingärtner, J.; Hora, P.; Palkowski, H.; Ziegmann, G. Experimental and Numerical Investigations on the Quasi-static Structural Properties of Fibre Metal Laminates Processed by Thermoforming. Compos. Struct. 2021, 258, 113418. [Google Scholar] [CrossRef]

- Behrens, B.A.; Hübner, S.; Bonk, C.; Bohne, F.; Micke-Camuz, M. Development of a Combined Process of Organic Sheet Forming and GMT Compression Molding. Procedia Eng. 2017, 207, 101–106. [Google Scholar] [CrossRef]

- Volk, W.; Hora, P. New Algorithm for a Robust user-independent Evaluation of Beginning Instability for the Experimental FLC Determination. Int. J. Mater. 2011, 4, 339–346. [Google Scholar] [CrossRef]

- Yang, L.X.; Smith, L.; Gothekar, A.; Chen, X. Measure Strain Distribution Using Digital Image Correlation (DIC) for Tensile Tests; Oakland University: Rochester, MI, USA, 2010. [Google Scholar]

- Schirmaier, F.J.; Weidenmann, K.A.; Kärger, L.; Henning, F. Characterisation of the Draping Behaviour of Unidirectional Non-crimp Fabrics (UD-NCF). Compos. Part A Appl. Sci. Manuf. 2016, 80, 28–38. [Google Scholar] [CrossRef]

- Galkin, S.; Kunze, E.; Kärger, L.; Böhm, R.; Gude, M. Experimental and Numerical Determination of the Local Fiber Volume Content of Unidirectional Non-Crimp Fabrics with Forming Effects. J. Compos. Sci. 2019, 3, 19. [Google Scholar] [CrossRef]

- Grubenmann, M. Hybrid Thermoforming of Body in White Parts. Doctoral Dissertation, ETH, Zürich, Switzerland, 2020. [Google Scholar]

| Materials/Abbreviation | Thickness [mm] | Coating | Fibre Content [vol.-%] | Supplier |

|---|---|---|---|---|

| TS275 | 0.4 | Zinc | – | thyssenkrupp Steel Europe AG |

| TS290 | 0.3 | Zinc | – | |

| PA6 | 0.5 | – | – | Infiana Germany GmbH & Co. KG |

| Twill 2/2 (50/50)–RG | 0.5, 1.0, 2.0 | – | 47 | LANXESS Deutschland GmbH, Köln, Germany |

| Unidirectional (80/20)–RGUD | 0.5, 1.0, 2.0 | – | 47 |

| Blank Diameter (mm) | Punch Diameter (mm) | Die Radius (mm) | Test Speed (mm/s) | Holding Force (kN) | Temperatures (°C) |

|---|---|---|---|---|---|

| 200 | 100 | 10 | 1.5 | 100 | RT, 200, 235 |

| Abbreviation | Sandwich Panels |

|---|---|

| MPM01-PAx | MPM based on TS275/PA6/TS275 with core layer thickness x |

| MPM02-PAx | MPM based on TS290/PA6/TS290 with core layer thickness x |

| FML01-RGx | FML based on TS275/RG/TS275 with core layer thickness x |

| FML02-RGx | FML based on TS290/RG/TS290 with core layer thickness x |

| FML01-RGUDx | FML based on TS275/RGUD/TS275 with core layer thickness x |

| FML02-RGUDx | FML based on TS290/RGUD/TS290 with core layer thickness x |

| Paint Spray | Testing Temperature | Product |

|---|---|---|

| White paint spray | RT | Dupli color®, 252570 aqua white 9010 |

| White paint spray | 200 °C and 235 °C | Ulfalux®, Ofenfarben 1190 white-perlmatt |

| Black paint spray | RT, 200 °C and 235 °C | Contact Chemistry® Graphit 33 76009-AA |

| Material/ Abbreviation | Cover Sheet | Core Layer | Test | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TS275 (mm) | TS290 (mm) | PA6 (mm) | RG (mm) | RGUD (mm) | Stretch Forming | FLC | |||||||

| 0.4 | 0.3 | 0.5 | 1.0 | 1.5 | 0.5 | 1.0 | 2.0 | 0.5 | 1.0 | 2.0 | |||

| TS275 | x | x 1 | x 1 | ||||||||||

| TS290 | x | x 3 | |||||||||||

| RG | x | x | x | x 1 | |||||||||

| RGUD | x | x | x | x 1 | |||||||||

| MPM01 | x | x | x 2 | ||||||||||

| x | x | x 2 | |||||||||||

| x | x | x 2 | |||||||||||

| MPM02 | x | x | x 4 | ||||||||||

| x | x | x 4 | |||||||||||

| FML01 | x | x | x 1 | x 1 | |||||||||

| x | x | x 1 | |||||||||||

| x | x | x 1 | |||||||||||

| x | x | x 1* | |||||||||||

| x | x | x 1 | |||||||||||

| x | x | x 1 | |||||||||||

| x | x | x 1 | |||||||||||

| FML02 | x | x | x 3 | ||||||||||

| x | x | x 3 | |||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hua, W.; Harhash, M.; Ziegmann, G.; Carradò, A.; Palkowski, H. Stretching and Forming Limit Curve of Steel–Glass Fibre Reinforced and Non-Reinforced Polyamide–Steel Sandwich Materials. Appl. Sci. 2023, 13, 6611. https://doi.org/10.3390/app13116611

Hua W, Harhash M, Ziegmann G, Carradò A, Palkowski H. Stretching and Forming Limit Curve of Steel–Glass Fibre Reinforced and Non-Reinforced Polyamide–Steel Sandwich Materials. Applied Sciences. 2023; 13(11):6611. https://doi.org/10.3390/app13116611

Chicago/Turabian StyleHua, Wei, Mohamed Harhash, Gerhard Ziegmann, Adele Carradò, and Heinz Palkowski. 2023. "Stretching and Forming Limit Curve of Steel–Glass Fibre Reinforced and Non-Reinforced Polyamide–Steel Sandwich Materials" Applied Sciences 13, no. 11: 6611. https://doi.org/10.3390/app13116611

APA StyleHua, W., Harhash, M., Ziegmann, G., Carradò, A., & Palkowski, H. (2023). Stretching and Forming Limit Curve of Steel–Glass Fibre Reinforced and Non-Reinforced Polyamide–Steel Sandwich Materials. Applied Sciences, 13(11), 6611. https://doi.org/10.3390/app13116611