1. Introduction

Granite residual soil (GRS), a product of the in situ weathering of igneous parent rocks, is widely distributed in the humid tropical regions of southern China [

1,

2], especially in the Fujian province. GRS covers approximately three-fifths of areas in many cities such as Xiamen, Fuzhou, Quanzhou, etc. Since the essential mineral grains of GRS are quartz and kaolinite, while the secondary mineral grains are feldspar, chlorite and other ferric minerals, GRS is characterized by high mica content, loose structure, water sensitivity, and low cohesion [

3,

4,

5]. GRS can satisfy most engineering conditions under dry conditions, but its mechanical and compressive properties change drastically after exposure to water. However, the degradation of the mechanical properties for GRS in the railway subgrade is strongly influenced by the rise of moisture content, which causes an interlayer of coarse and fine particles due to the release of contacts between the soil particles subjected to cyclic loading [

6,

7]. Owing to the subgrade interlayer, the reduction of the shear strength and compressibility of GRS results in severe damage to the roadbed, such as uneven settlement, track irregularity and mud pumping of the railway subgrade.

The cyclic loads, such as seismic actions, periodic waves, tide forces, and traffic or train loads, have a significant influence on the dynamic properties of soils. During cyclic loading, the pore water and soil particles in saturated soils assigned to the load will vary continuously with time, and different fines contents will change the capability of pore water to bear the load [

8]. Several studies reported that the fines contents can significantly affect the dynamic properties of the soil [

9,

10]. This is due to the fact that fine particles change the contact style and skeleton structure between soil particles [

11,

12]. When the fines content is low, these fine particles exist with coarse particles on the skeleton nodes to play the role of a ball, making the contact surface between coarse particles reduce the inter-grain friction. When the fines content becomes high, the soil tends to a dense state, and the static friction between particles increases, which then prevents the misaligned slip between particles [

13]. Moreover, the GRS subgrades are commonly subjected to seasonal drying and wetting (D–W) cycles in southern China because of the subtropical climate [

14,

15,

16]. After repeated D–W cycles, GRS is prone to cracking due to a series of changes, such as reduced fine particles, coarsened pores, and loose structure, among other characteristics [

1,

17,

18]. The reciprocating migration of the pore water, caused by both cyclic loading of train vibration and D–W cycles, drives a further movement of the internal fine particles and contributes to the development of original cracks [

19,

20,

21]. The occurrence of cracks and changes in pore space affect the soil water characteristic curve (SWCC) and the hysteresis curve of unsaturated GRS [

22,

23,

24,

25], and the shear modulus can be predicted by matrix suction with the help of the SWCC curve. All these factors not only accelerate the formation of coarse-fine grain interlayers of GRS but also cause irreversible structural damage and fatigue failure of the subgrade. Therefore, it is important to understand the dynamic properties of GRS under D–W cycles for different fines contents of GRS.

The hysteresis curve describes the dynamic stress–strain relationship curve of soils under cyclic loadings. Its morphology provides a concise visualization of the dynamic soil performance, such as the dynamic deformation, viscous hysteresis, stiffness change, and energy loss. The hysteresis curve and backbone curve together constitute the viscoelastic dynamic constitutive model. It is a well-known fact that dynamic parameters such as the shear modulus

Gd, damping ratio

λ, and accumulative plastic strain

εsp are important indexes to evaluate the safety and stability of subgrade constructions.

Gd and

λ can be easily extracted from the evolution of hysteresis curves. The present study on hysteresis curves mainly focuses on frozen clay, peaty soils, swelling soils, etc. It is noted that a series of works on the hysteresis curves of frozen clay has been completed by Luo et al. [

26]. They first considered the effect of stress loading conditions on the hysteresis curve morphology [

26] and then investigated the negative temperature after realizing that the melting of ice crystals under negative temperature affects the mechanical properties [

27]. Later, they also took into account the confining pressure and loading frequency [

28].

In the study on peaty soils, Huang et al. [

29] considered the effect of confining pressure and loading frequency on the hysteresis curve. Zhu et al. [

30] took into account the stress amplitude on this basis and the factors affecting the hysteresis curve of expansive soils, which mainly include the confining pressure and loading frequency [

31,

32]. Different test factors can greatly affect the dynamic elastic modulus

Ed and damping ratio

λ. For example, Xu et al. [

33] considered the effects of loading frequency, stress amplitude, initial partial stress and confining pressure on the dynamic elastic modulus

Ed of soft clays and showed that

Ed increases with the increase of cyclic stress amplitude, initial partial stress, and confining pressure; the lower the vibration frequency, the faster the decay of

Ed. Wang et al. [

34] analyzed the effect of dynamic stress ratio and confining pressure on

Ed of saturated gravel sands and found that

Ed increases with increasing confining pressure and dynamic stress ratio. Wu et al. [

35] studied the effects of sea sand admixture, loading frequency and dynamic stress on

Ed and

λ of cured silts, which demonstrated that

Ed increases with the growing sand admixture and loading frequency. It first increases and then decreases with the increase of dynamic stress, while

λ follows the opposite relationship. Hysteresis curves have strong variability for different types of soils in different regions, and so do the dynamic parameters. Chen et al. [

36] investigated the effect of

Gd and

λ of GRS under different confining pressure and stress amplitude and found that

Gd decreases with the increase of stress amplitude and

λ inversely. In addition, increasing the surrounding pressure can suppress the decay of

Gd with dynamic stress. The results of Yin et al. [

37] on the effect of confining pressure and dynamic stress amplitude on

Gd showed the same trends as those of Chen et al. [

36]. Furthermore, Yin et al. [

37] also found that the greater the water content in the soil, the faster

Gd decays.

The development of a dynamic constitutive model to quantitatively describe the dynamic deformation characteristics of soil under cyclic loading is a key issue [

38]. The common soil models can be divided into three categories. The first type is the Masing model [

39], which assumes that the hysteresis curve is obtained by doubling the skeleton curve, and defines the “upper skeleton curve criterion” and the “upper great circle criterion”. The second type is the equivalent linear model, which assumes that the soil is a viscoelastic material, and introduces

Ed and

λ as dynamic model parameters into the dynamic stress–strain model, for example, the Hardin–Drnevich model [

40] and Ramberg–Osgood model [

41], etc. The third type is the Iwan model [

42], which describes the dynamic stress–strain relationship of the soil by combining different elastoplastic units either in series or in parallel. Except for the above three categories, there are also empirical models of

Ed with the number of load cycles, often denoted by

N, confining pressure and deviator stress dynamic intrinsic relationship proposed by scholars. Wu et al. [

43] and Xu et al. [

33] established the empirical models for

Ed versus

N in the study of soft clay soils, both in the form of

Ed =

aln

N +

b. In addition, Xu et al. [

33] correlated the fitted parameters a and b with the stress amplitude, confining pressure and loading frequency on this basis. Mu et al. [

44] divided the stability zone, damage zone, and critical zone based on the law of accumulated deformation of undisturbed red clays under different confining pressures and stress amplitudes. Based upon this, the concept of equivalent dynamic elastic modulus

Ed-equal was proposed, and an empirical model was established. The model is

Ed-equal =

aln

N +

b (stability zone a > 0, damage zone a < 0). Although this type of model is not directly associated with strain, it can also better reflect the dynamic property changes and can be associated with the studied factors, which is easy for practical application.

Previous works focused on the effect of confining pressure, loading frequency, or stress amplitude on the hysteresis curve and dynamic parameters for peaty soils, soft soils or GRS. In the meantime, the empirical models of Ed with the number of load cycles are proposed according to the influencing factors for specific soils. It is noted that the D–W cycles and fine particles have a large influence on the dynamic characteristics of GRS, and the process of D–W cycles will affect the change of fines content. However, few studies describe in detail the dynamic properties and explain the dynamic mechanism of GRS under the D–W cycles and fines content.

In view of the phenomenon of pulping and mudging under the train cyclic dynamic load in a hot and rainy climate, this work focuses on the dynamic characteristics of GRS under cyclic loading by D–W cycles and fines content through hysteresis curves and further reveals the mechanism underlying the effect of fine particles and D–W cycles on the dynamic characteristics of GRS. Through the experimental data analysis, the characteristics of the hysteresis curve and the variation of parameters are revealed. It supports the comprehensive understanding of the dynamic properties of GRS. In addition, the dynamic shear modulus and dynamic damping ratio models established based on the dynamic triaxial experimental data can provide the prediction of dynamic parameters of residual soil considering the influence of D–W cycles and fines content. It is helpful to carry out dynamic analysis of railway subgrade stability and provide theoretical support for the construction of the railroad subgrade in the residual soil area.

5. Conclusions

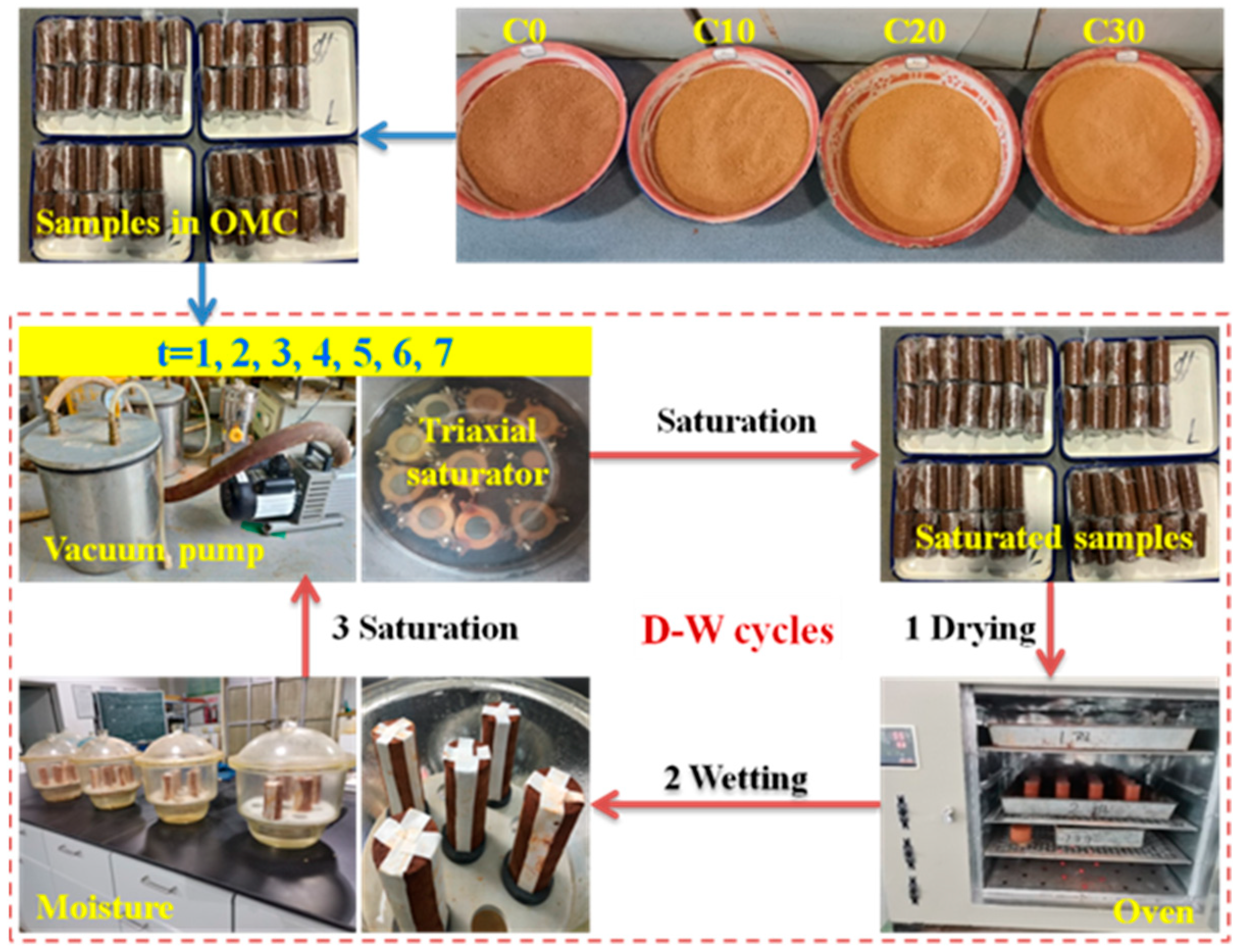

The dynamic behaviors of GRS in Southern China were experimentally studied. The effects of load cycles, fines content, and D–W cycles were investigated through the dynamic triaxial tests, where four fines contents and seven D–W cycles were considered. The main conclusions are as follows:

(1) The morphology of the hysteresis curve changes with the numbers of load and D–W cycles, as well as the fines content. The hysteresis curve area S, center offset d, and residual strain εsp of GRS vary similarly with the increase of load cycles. They all decrease sharply in the early stage(N < 20), and the reduction rate slows down in the later load stage (20 ≤ N ≤ 1000) and finally stabilizes in the end(N > 1000). The major axis gradient k increases with the number of load cycles and approximately changes linearly with log N. At the same time, as the fines content increases, S, d and εsp increase and k decreases. All of these properties fluctuate with the increase of D–W cycles and tend to be stable after about seven D–W cycles.

(2) The growth of dynamic shear modulus and the reduction of damping ratio with the number of load cycles can be divided into the rapid change stage(N < 20) and the slow change stage (20 ≤ N ≤ 1000). Moreover, the dynamic shear modulus and damping ratio show a good linear relationship with the logarithmic number of load cycles and two prediction equations were obtained by the data fitting. With the increase of fines content, the dynamic shear modulus shows a trend of decreasing while the damping ratio shows an increasing trend. The dynamic shear modulus changes with D–W cycles, and it decreases after several D–W cycles. However, the damping ratio is less affected by D–W cycles.

(3) The dynamic characteristics of GRS are influenced by the number of load cycles, fines content, as well as the number of D–W cycles. Among them, the number of load cycles has the dominant influence and the number of D–W cycles has the least influence. The influence of fines content is more pronounced for the low number of load cycles than for the high number of load cycles. In addition, the effects of fines content and the number of D–W cycles are not independent.

(4) Fitting models are proposed to estimate the dynamic shear modulus and damping ratio based on the number of load cycles. These models can predict dynamic shear modulus and damping ratio considering the effects of fines content and D–W for dynamic stability analysis of railway subgrade.