High Frequency Transformers for Solid-State Transformer Applications

Abstract

:1. Introduction

2. Modulation of the Converter System

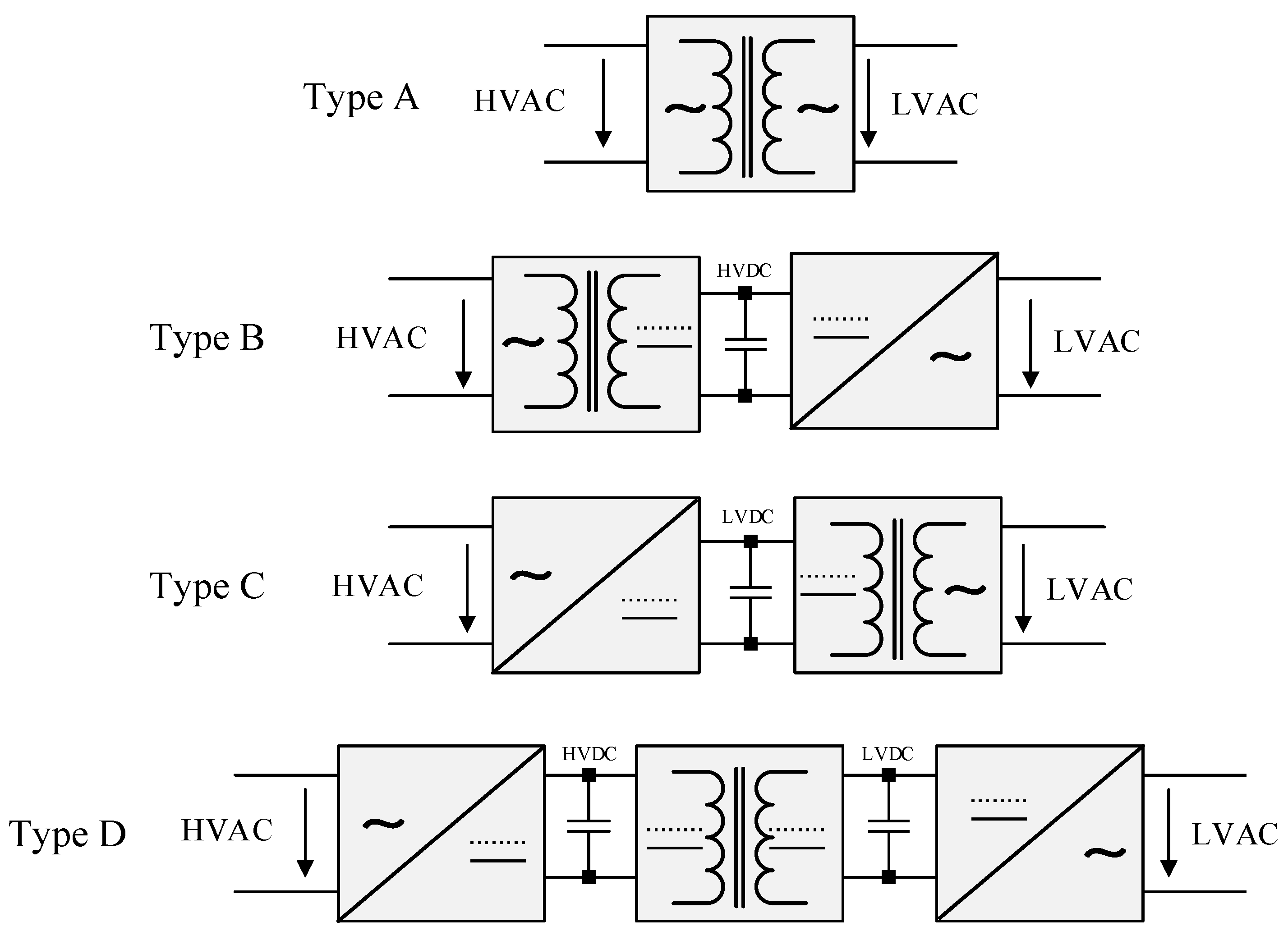

2.1. Solid-State Transformer

- Skin effect: the passage of an alternating current through a conductor causes a time-varying magnetic field, which, according to Faraday’s law, causes an electric field. The electric field induces eddy currents in the conductor, which oppose the variation in current density. The combination of the magnetic field and the induced electric field, both time-varying, creates electromagnetic induction in the conductor. This forces most of the electric current to flow at the surface of the conductor, instead of flowing uniformly. The skin effect is aggravated with increased operating frequency [20,21];

- Proximity effect: when two conductors close to each other are crossed by an alternating current, the current distribution in each conductor is affected by the changing magnetic field of the other conductor. Due to the induced eddy currents, the current will flow in undesired patterns, and this effect is also aggravated with increasing frequency [20,21].

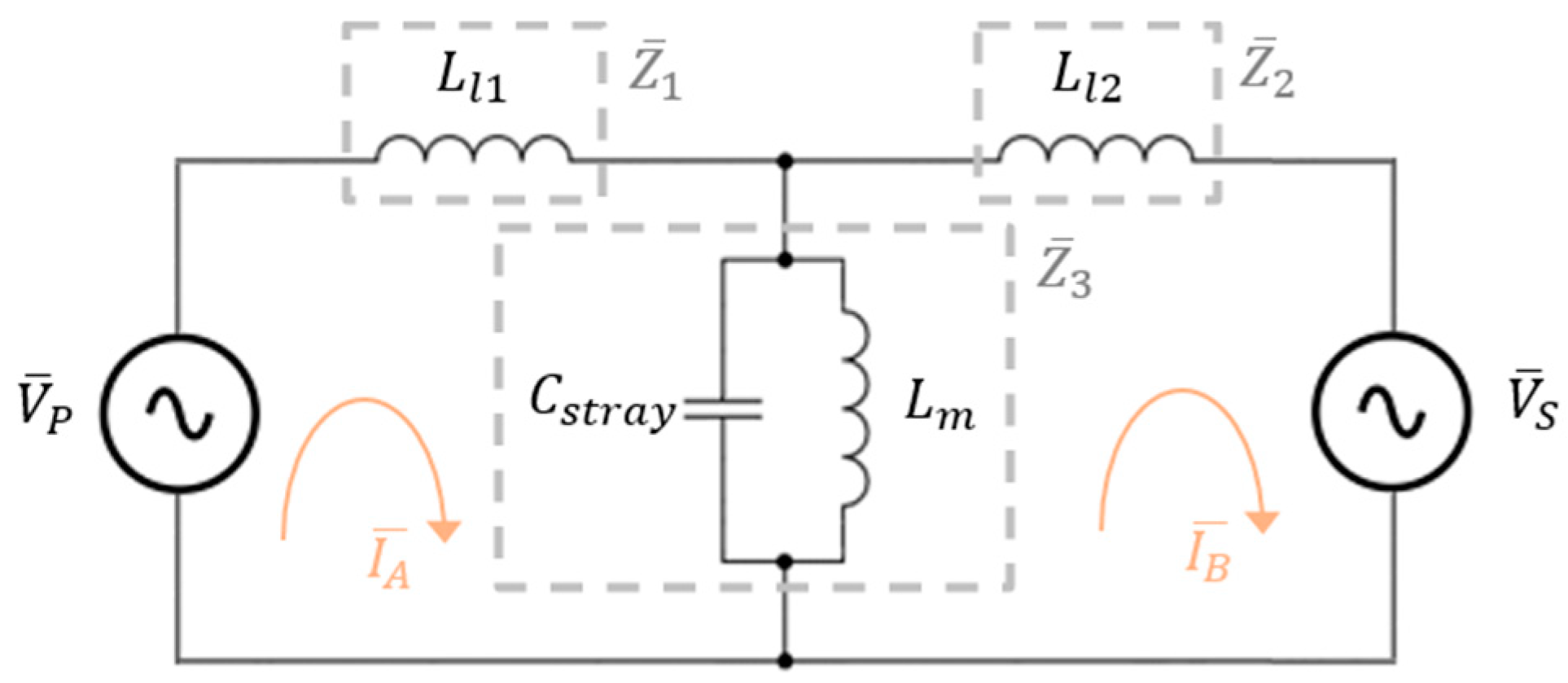

2.2. Transformer Modeling

- System and Topology Specifications: Definition of the main system specifications, namely: apparent power (), primary voltage (), secondary voltage (), operating frequency (f), ambient temperature (), admissible temperature variation (ΔT), wave factor (), window utilization factor () and stacking factor ();

- Magnetic Core Properties: Selection of the material to be used for the magnetic core to find the saturation flux density () and parameters of the constants α, β and Kc of the respective material, essential parameters for the following steps; most common cores, such as amorphous, ferrite, and nanocrystalline magnetic materials are compared in [29] for core losses at 10, 20, 50, and 100 kHz, respectively.

- Calculate Optimum Flux Density: The optimal flux density corresponds to the flux density value that minimizes the sum of copper losses with iron losses. Knowing the expression that describes the losses in copper and iron, as a function of the frequency and flux density, and after numerical simplification, it is possible to obtain the expression of the optimal flux density by Equation (1), as laid out in [30].

- 4.

- Magnetic Core Sizing: For the optimal flux density, determined in the previous point, the dimensions of the magnetic core of the transformer are selected based on the product of the window area () by the cross-sectional area (); this product is given the nomenclature , usually expressed in . For the analytical determination of this parameter, it is necessary to perform a comparison between the value of the optimal flux density () and the saturation flux density value (). Based on the exposition in [30]:

- If , the value of the parameter is given by Equation (2).

- If , the value of the parameter is given by Equation (3).

- 5.

- Calculate the Number of Turns: The number of turns of each winding can be described by Equation (7).

- 6.

- Conductor Sizing: For the dimensioning of the conductors to be used it is necessary to determine the current density (). To determine this parameter, it is necessary to compare the value of the optimum flux density () and the value of the saturation flux density (). Based on [30]:

- If , the value of is given by Equation (8).

- If , the value of is given by Equation (9).

- 7.

- Estimation of Leakage Inductance: The estimation of leakage inductance can be obtained through Dowell’s model, but this model was designed to calculate the leakage inductance in a transformer composed of foil conductor windings. Considering that the model under study uses Litz wire windings, it will first be necessary to perform the equivalence between Litz wire and foil conductors and subsequently estimate the leakage inductance value through Dowell’s model.

- 8.

2.3. Converter Modeling

3. Control System

4. Simulation Results

4.1. Introduction

- “Three-phase bridge rectifiers”, fed from the conventional three-phase grid (400 V 50 Hz), composed of fully controlled semiconductors. For simulation purposes, consider an ideal DC voltage source of equal effective value;

- To simplify the analysis, the power requested by the “Charger/Battery” will be considered as a pure resistive load with equal power value. Consider that the charger should be powered with 1000 V DC.

4.2. Numerical Simulation Results

- Test 1—Constant Load: Consider that the system feeds a constant, purely resistive load in the direct power direction and that the load has a power of 50 kVA.

- Test 2—Variable load: Consider that the system is feeding a variable load, purely resistive, in the direct power direction. The initial load presents a power of and, at instant the load doubles, resulting in a power of . All the analysis performed for Test 1 is valid for Test 2. The focus of the analysis described below is the impact of varying the value of the load on the system under study.

- Test 3—Power Bidirectionality: Consider that the system is supplying a purely resistive load with a power of in the direct power direction, and at instant , the power flow changes from the direct direction to the reverse direction, at which point the load is supplying the grid with a power of .

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hannan, M.A.; Ker, P.J.; Lipu, M.S.H.; Choi, Z.H.; Muttaqi, K.M.; Blaabjerg, F. State of the Art of Solid-State Transformers: Advanced Topologies, Implementation Issues, Recent Progress and Improvements. IEEE Access 2020, 8, 19113–19132. [Google Scholar] [CrossRef]

- Agheb, E.; Høidalen, H.K. Medium Frequency High Power Transformers, State of Art and Challenges. In Proceedings of the 2012 International Conference on Renewable Energy Research and Applications (ICRERA), Nagasaki, Japan, 11–14 November 2012. [Google Scholar] [CrossRef]

- Joshi, A.; Nath, S. Effect of High-Frequency Transformer Parasitic Capacitances on Operation of Solid-State Transformers. In Proceedings of the 2022 Second International Conference on Power, Control and Computing Technologies (ICPC2T), Raipur, India, 1–3 March 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Olowu, T.O.; Jafari, H.; Moghaddami, M.; Sarwat, A.I. Physics-Based Design Optimization of High Frequency Transformers for Solid State Transformer Applications. In Proceedings of the 2019 IEEE Industry Applications Society Annual Meeting, Baltimore, MD, USA, 29 September–3 October 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Rashidi, M.; Bani-Ahmed, A.; Nasiri, R.; Mazaheri, A.; Nasiri, A. Design and implementation of a multi winding high frequency transformer for MPSST application. In Proceedings of the 2017 IEEE 6th International Conference on Renewable Energy Research and Applications (ICRERA), San Diego, CA, USA, 5–8 November 2017; pp. 491–494. [Google Scholar] [CrossRef]

- Peng, Z.; Wang, G.; Zhai, X.; Zhang, X.; Zhou, H.; Yi, C. Optimum Design of High Frequency Transformer Based on Winding Spacing. In Proceedings of the 2019 22nd International Conference on Electrical Machines and Systems (ICEMS), Harbin, China, 11–14 August 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Guo, S.; Liu, P.; Zhang, L.; Huan, A.Q. Design and optimization of the high frequency transformer for a 800V/1.2MHz SiC LLC resonant converter. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017; pp. 5317–5323. [Google Scholar] [CrossRef]

- Wen, H.; Liu, Y.; Jiao, D.; Yeh, C.-S.; Lai, J.-S. Design Principles and Optimization Considerations of a High Frequency Transformer in GaN Based 1 MHz 2.8 kW LLC Resonant Converter with over 99% Efficiency. In Proceedings of the 2021 IEEE Applied Power Electronics Conference and Exposition (APEC), Phoenix, AZ, USA, 14–17 June 2021; pp. 1939–1944. [Google Scholar] [CrossRef]

- Di Noia, L.P.; Rizzo, R. Comparison Between Different High-Frequency Transformer for Resonant Power Converter. In Proceedings of the 2022 IEEE 16th International Conference on Compatibility, Power Electronics, and Power Engineering (CPE-POWERENG), Birmingham, UK, 29 June–1 July 2022; pp. 1–5. [Google Scholar] [CrossRef]

- Kawaguchi, Y.; Furukawa, K.; Shimada, T.; Kusukawa, J. Feasibility Study of High-Frequency Transformer with High-Voltage Insulation Structure for SST Based Medium-Voltage Multi-Level Converter. In Proceedings of the 2022 International Power Electronics Conference (IPEC-Himeji 2022-ECCE Asia), Himeji, Japan, 15–19 May 2022; pp. 1769–1774. [Google Scholar] [CrossRef]

- Zhao, B.; Song, Q.; Li, J.; Xu, X.; Liu, W. Comparative Analysis of Multilevel-High-Frequency-Link and Multilevel-DC-Link DC–DC Transformers Based on MMC and Dual-Active Bridge for MVDC Application. IEEE Trans. Power Electron. 2018, 33, 2035–2049. [Google Scholar] [CrossRef]

- Grzejszczak, P.; Wolski, K.; Brzostek, K.; Sitnik, A. Comparative study of two types of high-frequency transformers in a 20-kW Phase-Shifted Full Bridge converter application. In Proceedings of the 2022 Progress in Applied Electrical Engineering (PAEE), Koscielisko, Poland, 27 June–1 July 2022; pp. 1–4. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, Z.; Wang, X.; Fu, Q.; Xing, Z. Analysis of Electromagnetic Characteristics of High Frequency Transformer Based on C Type Nanocrystalline Magnetic Core. In Proceedings of the 2019 11th International Conference on Measuring Technology and Mechatronics Automation (ICMTMA), Qiqihar, China, 28–29 April 2019; pp. 132–135. [Google Scholar] [CrossRef]

- Cao, Z.; Chen, W.; Jiang, J.; Zhang, K.; Chen, Y.; Shen, Z. Design of Dry-type High-power High-frequency Transformer Based on Triangular Closed Core. In Proceedings of the 2021 IEEE Sustainable Power and Energy Conference (iSPEC), Nanjing, China, 23–25 December 2021; pp. 3336–3341. [Google Scholar] [CrossRef]

- Djuric, S.; Stojanovic, G.; Damnjanovic, M.; Radovanovic, M.; Laboure, E. Design, Modeling, and Analysis of a Compact Planar Transformer. IEEE Trans. Magn. 2012, 48, 4135–4138. [Google Scholar] [CrossRef]

- Barbini, N.; Colavitto, A.; Vicenzutti, A.; Contin, A.; Sulligoi, G. High Frequency Modeling of Foil Type Transformers for Shipboard Power Electronic Power Distribution Systems. In Proceedings of the 2019 AEIT International Annual Conference (AEIT), Florence, Italy, 18–20 September 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Elrajoubi, A.M.; Ang, S.S. High-Frequency Transformer Review and Design for Low-Power Solid-State Transformer Topology. In Proceedings of the 2019 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 7–8 March 2019. [Google Scholar] [CrossRef]

- She, X.; Burgos, R.; Wang, G.; Wang, F.; Huang, A.Q. Review of Solid State Transformer in the Distribution System: From Components to Field Application. In Proceedings of the 2012 IEEE Energy Conversion Congress and Exposition (ECCE), Raleigh, NC, USA, 15–20 September 2012. [Google Scholar] [CrossRef]

- Falcones, S.; Mao, X.; Ayyanar, R. Topology Comparison for Solid State Transformer Implementation. In Proceedings of the IEEE PES General Meeting, Minneapolis, MN, USA, 25–29 September 2010. [Google Scholar] [CrossRef]

- Sullivan, C.R. Optimal Choice for Number of Strands in a Litz-Wire Transformer Winding. IEEE Trans. Power Electron. 1999, 14, 283–291. [Google Scholar] [CrossRef] [Green Version]

- Clement, C. Skin Effect in Electrical Conductors: Any Commercially Viable Solution; University of Aberdeen: Aberdeen, Scotland, 2014. [Google Scholar] [CrossRef]

- McLyman, C.W.T. Transformer and Inductor Design Handbook; Kg Magnetics, Inc.: Idyllwild, CA, USA, 2004; ISBN 0-8247-5393-3. [Google Scholar]

- Banumathy, J.R.; Veeraraghavalu, R. High Frequency Transformer Design and Optimization using Bio-inspired Algorithms. Appl. Artif. Intell. 2018, 32, 707–726. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, D.; Bai, B. Study of a High-Power Medium Frequency Transformer Using Amorphous Magnetic Material. Symmetry 2022, 14, 2129. [Google Scholar] [CrossRef]

- Banumathy, J.R.; Veeraraghavalu, R. Optimal Design of Minimal Footprint High Frequency Transformer. Serb. J. Electr. Eng. 2021, 18, 303–320. [Google Scholar] [CrossRef]

- Deepak, S.; Mohanrajan, S.R. High-Frequency Transformer design for a Bi-directional isolated DC-DC converter for Electric Vehicles. In Proceedings of the 2022 IEEE 7th International Conference on Recent Advances and Innovations in Engineering (ICRAIE), Mangalore, India, 1–3 December 2022; pp. 428–432. [Google Scholar] [CrossRef]

- Dey, S.; Chakraborty, S.S.; Singh, S.; Hatua, K. Design of High Frequency Transformer for a Dual Active Bridge (DAB) Converter. In Proceedings of the 2022 IEEE Global Conference on Computing, Power and Communication Technologies (GlobConPT), New Delhi, India, 23–25 September 2022; pp. 1–6. [Google Scholar] [CrossRef]

- Zhang, X.; Xiao, F.; Wang, R.; Kang, W.; Yang, B. Modeling and Design of High-Power Enhanced Leakage-Inductance-Integrated Medium-Frequency Transformers for DAB Converters. Energies 2022, 15, 1361. [Google Scholar] [CrossRef]

- Garcia, R.; Escobar-Mejía, A.; George, K.; Balda, J.C. Loss comparison of selected core magnetic materials operating at medium and high frequencies and different excitation voltages. In Proceedings of the 2014 IEEE 5th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Galway, Ireland, 24–27 June 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Hurley, W.H.W.G. Transformers and Inductors for Power Electronics: Theory, Design and Applications; WILEY: Hoboken, NJ, USA, 2013; ISBN 978-1-119-95057-8. [Google Scholar]

- Sullivan, C.R.; Zhang, R.Y. Simplified Design Method for Litz Wire. In Proceedings of the 2014 IEEE Applied Power Electronics Conference and Exposition—APEC 2014, Fort Worth, TX, USA, 16–20 March 2014. [Google Scholar] [CrossRef]

- Mogorovic, M.; Dujic, D. Medium Frequency Transformer Leakage Inductance Modeling and Experimental Verification. In Proceedings of the 2017 IEEE Energy Conversion Congress and Exposition (ECCE), Cincinnati, OH, USA, 1–5 October 2017. [Google Scholar] [CrossRef] [Green Version]

- Cougo, B.; Kolar, J.W. Integration of Leakage Inductance in Tape Wound Core Transformers for Dual Active Bridge Converters. In Proceedings of the 2012 7th International Conference on Integrated Power Electronics Systems (CIPS), Nuremberg, Germany, 6–8 March 2012; ISBN 978-3-8007-3414-6. [Google Scholar]

- Karthikeyan, V.; Blaabjerg, F.; Rajasekar, S.; Pragaspathy, S. Core Loss Estimation of Magnetic Links in DAB Converter Operated in High-Frequency Non-Sinusoidal Flux Waveforms. In Proceedings of the 2018 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Chennai, India, 18–21 December 2018. [Google Scholar] [CrossRef]

- Wojda, R.P. Winding Resistance and Power Loss for Inductors with Litz and Solid-Round Wires. In Proceedings of the 2016 IEEE International Power Electronics and Motion Control Conference (PEMC), Varna, Bulgaria, 25–28 November 2016. [Google Scholar] [CrossRef]

- Dalessandro, L.; Cavalcante, F.S.; Kolar, J.W. Self-Capacitance of High-Voltage Transformers. IEEE Trans. Power Electron. 2007, 22, 2081–2092. [Google Scholar] [CrossRef]

- Massarini, A.; Kazimierczuk, M.K. Self-Capacitance of Inductors. IEEE Trans. Power Electron. 1997, 12, 671–676. [Google Scholar] [CrossRef] [Green Version]

- Laveuve, E.; Keradec, J.-P.; Bensoam, M. Electrostatic of wound components: Analytical results, simulation and experimental validation of the parasitic capacitance. In Proceedings of the 1991 IEEE Industry Applications Society Annual Meeting, Dearborn, MI, USA, 28 September–4 October 1991. [Google Scholar] [CrossRef]

- Saket, M.A.; Shafiei, N.; Ordonez, M. LLC Converters with Planar Transformers: Issues and Mitigation. IEEE Trans. Power Electron. 2017, 32, 4524–4542. [Google Scholar] [CrossRef]

- Mohammadi, P.; Samanbakhsh, R.; Koohi, P.; Ibanez, F. High Frequency Transformer Design for Specific Static Magnetising and Leakage Inductances Using Combination of Multi-Layer Perceptron Neural Networks and FEM. In Proceedings of the 2019 IEEE 10th International Symposium on Power Electronics for Distributed Generation Systems (PEDG), Xi’an, China, 3–6 June 2019. [Google Scholar] [CrossRef]

- Guru, B.S.; Hiziroglu, H.R. Electric Machinery and Transformers; Oxford University Press: New York, NY, USA, 2001; ISBN 978-0-19-513890-0. [Google Scholar]

- Wang, Y.; de Haan, S.W.H.; Ferreira, J.A. Optimal Operating Ranges of three Modulation Methods in Dual Active Bridge Converters. In Proceedings of the 2009 IEEE 6th International Power Electronics and Motion Control Conference, Wuhan, China, 17–20 May 2009. [Google Scholar] [CrossRef]

- Kayaalp, I.; Demirdelen, T.; Koroglu, T.; Cuma, M.U.; Bayindir, K.C.; Tumay, M. Comparison of Different Phase-Shift Control Methods at Isolated Bidirectional DC-DC Converter. Int. J. Appl. Math. Electron. Comput. 2016, 4, 68–73. [Google Scholar] [CrossRef] [Green Version]

- Ellis, G. Control System Design Guide: Using Your Computer to Understand and Diagnose Feedback Controllers—Fourth Edition; Elsevier Inc.: Hoboken, NJ, USA, 2012; ISBN 978-0-12-385920-4. [Google Scholar]

| Cross section area of the core () | Average length of a coil (m) | ||

| Product between and () | Power losses in iron (W) | ||

| Optimal density flux (T) | Power losses in copper (W) | ||

| Maximum density flux (T) | Apparent power (VA) | ||

| Saturation density flux (T) | Ambient temperature (K) | ||

| Operation frequency (Hz) | Primary voltage (V) | ||

| Convective heat-transfer coefficient (KW2/m); | Secondary voltage (V) | ||

| Current density (A/m2) | Core volume () | ||

| Dimensionless constants | Window volume () | ||

| Window area () | |||

| Temperature variation (K) | |||

| Magnetic material loss coefficient | Magnetic core material parameters | ||

| Stacking factor | |||

| Window utilization factor | |||

| Wave factor | Electrical resistance of the conductor | ||

| Average length of the magnetic part of the core | Vacuum Permeability (H/m) | ||

| Leakage inductance (H) | Relative permeability |

| Parameter | Value | |

|---|---|---|

| Apparent power | ||

| Effective voltage applied to the primary | ||

| Effective voltage applied to the secondary | ||

| Operating frequency | 1 kHz | |

| Admissible temperature variation | ||

| Magnetic core: core type, amorphous material, manufacturer Transmart, model CACC-3604 | --- | |

| Saturation flux | ||

| Optimum saturation flux | ||

| Value concerning the model CACC-3604 | ||

| kf | Stacking factor | 0.9 |

| Number of primary coils | ||

| Number of secondary windings | ||

| Current density | 0.81 A/mm2 |

| Primary Winding: Litz Wire | |

| № of Single Conductors | |

| Construction | |

| Equivalent Copper Section | |

| Secondary Winding: Litz Wire | |

| № of Single Conductors | |

| Construction | |

| Equivalent Section | |

| Parameter | Value |

|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Santos, N.; Chaves, M.; Gamboa, P.; Cordeiro, A.; Santos, N.; Pinto, S.F. High Frequency Transformers for Solid-State Transformer Applications. Appl. Sci. 2023, 13, 7262. https://doi.org/10.3390/app13127262

Santos N, Chaves M, Gamboa P, Cordeiro A, Santos N, Pinto SF. High Frequency Transformers for Solid-State Transformer Applications. Applied Sciences. 2023; 13(12):7262. https://doi.org/10.3390/app13127262

Chicago/Turabian StyleSantos, Nuno, Miguel Chaves, Paulo Gamboa, Armando Cordeiro, Nelson Santos, and Sónia Ferreira Pinto. 2023. "High Frequency Transformers for Solid-State Transformer Applications" Applied Sciences 13, no. 12: 7262. https://doi.org/10.3390/app13127262

APA StyleSantos, N., Chaves, M., Gamboa, P., Cordeiro, A., Santos, N., & Pinto, S. F. (2023). High Frequency Transformers for Solid-State Transformer Applications. Applied Sciences, 13(12), 7262. https://doi.org/10.3390/app13127262