Clinching of High-Strength Steel Sheets with Local Preheating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Materials

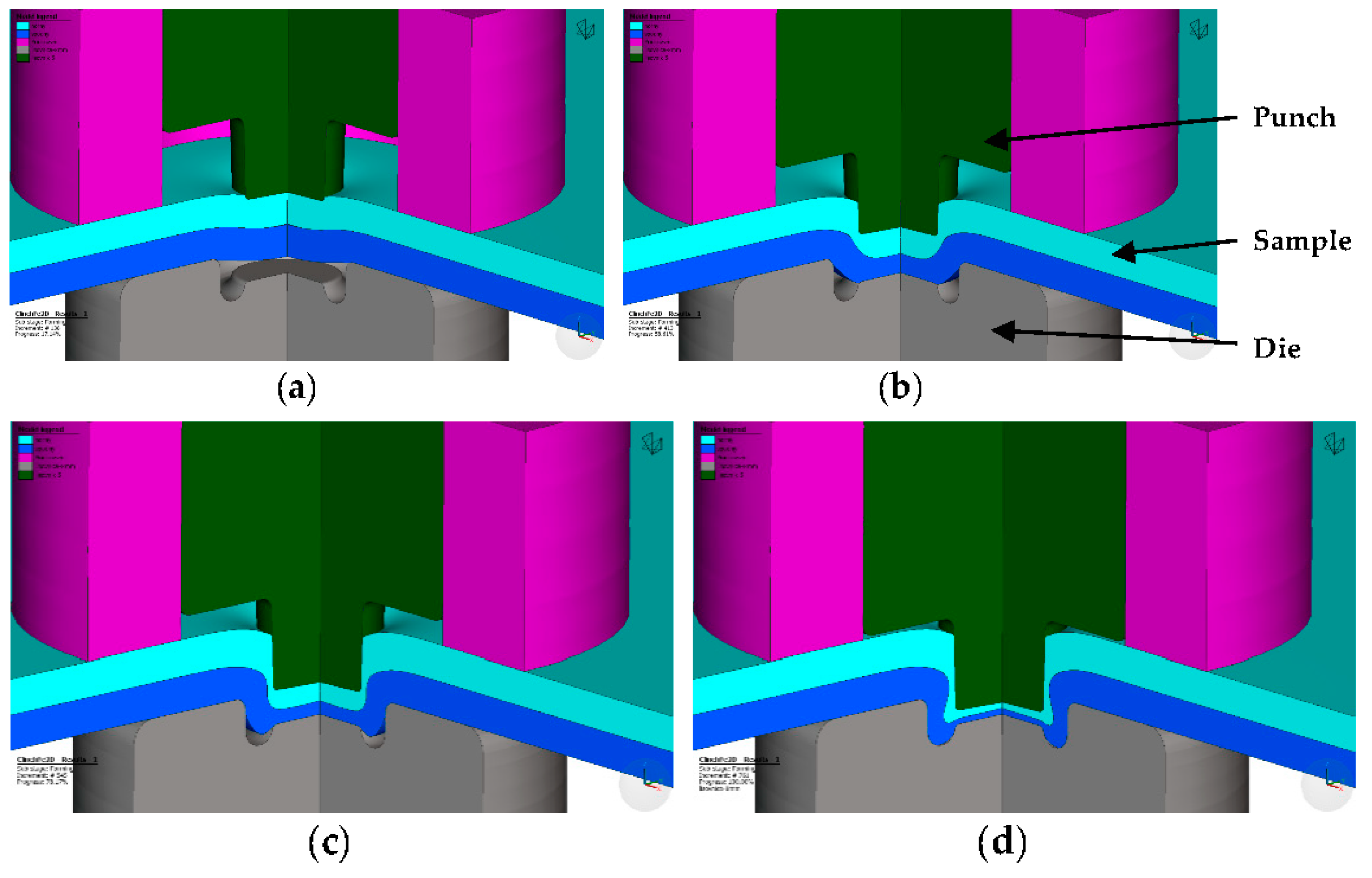

2.2. Numerical Simulation

2.3. Local Preheating

- Welding current of I = 3.9 kA;

- Welding time of T = 36 periods (1 per. = 0.02 s);

- Pressing force of electrodes of Fz = 6 kN.

2.4. Tensile Test

2.5. Light and Scanning Electron Microscopy

2.6. Microhardness Measurement

3. Results and Discussion

3.1. Material Flow in Clinched Joint

3.2. Microstructure of Joined Materials

3.3. Clinched Joints

3.4. Local Preheating of the Clinched Joint Zone

3.4.1. Zones with Gradient Microstructure Prior to Clinching, Steel No. 1.0941

3.4.2. Zones with Gradient Microstructure Prior to Clinching, Steel No. 1.0935

3.5. Analysis of Clinched Joints with Local Preheating

4. Conclusions

- Trial tests of clinched joints with a locally modified microstructure from ferritic–martensitic to fine-grained ferritic–sorbitic and fine-grained sorbitic–martensitic microstructures and increased strength values were carried out in order to localize them in particular regions of the compression joint.

- The microstructure distribution of the clinched joint region was analyzed by light and scanning electron microscopy and microhardness measurement techniques in the clinched joint.

- In the entire clinched joint, no discontinuities were observed in the material of the clinched joint by light and scanning electron microscopy.

- Fine-grained ferritic–sorbitic and fine-grained sorbitic microstructures were observed in the clinched joint at the neck when local heating technology was used.

- Two grades of materials were tested with a chemical concept corresponding to micro-alloyed steels and two-phase ferritic–martensitic steels. For each grade, five groups of seven samples were tested under the same experimental conditions of local heating (RSW) and clinching. The application of RSW to the clinched joint area increased the load-carrying capacity by an average of 17% for material No. 1.0941, and by an average of 25% for material No. 1.0935.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Abe, Y.; Maeda, T.; Yoshioka, D.; Mori, K.-I. Mechanical Clinching and Self-Pierce Riveting of Thin Three Sheets of 5000 Series Aluminium Alloy and 980 MPa Grade Cold Rolled Ultra-High Strength Steel. Materials 2020, 13, 4741. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H.; Peng, H.; Ran, X.; Pan, Q. Investigation of the Restored Joint for Aluminum Alloy. Metals 2020, 10, 97. [Google Scholar] [CrossRef] [Green Version]

- Li, Y.B.; Li, D.L.; Lin, Z.Q.; David, S.A.; Feng, Z.; Tang, W. Review: Magnetically assisted resistance spot welding. Sci. Technol. Weld. Join. 2016, 21, 59–74. [Google Scholar] [CrossRef]

- Mohammed, H.G.; Ginta, T.L.; Mustapha, M. The investigation of microstructure and mechanical properties of resistance spot welded AISI 316L austenitic stainless steel. Mater. Today-Proc. 2021, 46, 1640–1644. [Google Scholar] [CrossRef]

- Nasiłowska, B.; Bogusz, P.; Skrzeczanowski, W. The influence of shot peening on structure and mechanical properties of 5754 aluminium alloy joints welded with TIG method. Proc. Struct. Integr. 2019, 23, 583–588. [Google Scholar] [CrossRef]

- Ghatei-Kalashami, A.; Zhang, S.; Shojaee, M.; Midawi, A.R.H.; Goodwin, F.; Zhou, N.Y. Failure behavior of resistance spot welded advanced high strength steel: The role of surface condition and initial microstructure. J. Mater. Process. Technol. 2022, 299, 117370. [Google Scholar] [CrossRef]

- Midhun, S.; Ramesh, C.; Chellamuthu, K.; Yokeswaran, R. Dissimilar resistance spot welding process on AISI 304 and AISI 202 by investigation metals. Mater. Today-Proc. 2022, 69, 1213–1217. [Google Scholar] [CrossRef]

- Viňáš, J.; Kaščák, Ľ.; Greš, M. Optimization of resistance spot welding parameters for microalloyed steel sheets. Open Eng. 2016, 6, 504–510. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Senkara, J. Resistance Welding: Fundamentals and Application, 2nd ed.; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2011; 452p. [Google Scholar]

- Ma, N.; Murakawa, H. Numerical and experimental study on nugget formation in resistance spot welding for three pieces of high strength steel sheets. J. Mater. Process. Technol. 2010, 210, 2045–2052. [Google Scholar] [CrossRef]

- Kaščák, Ľ.; Spišák, E. Effect of Welding Parameters on the Quality of Spot Welds Combining AHSS Steel and HSLA Steel. Key Eng. Mat. 2013, 586, 162–165. [Google Scholar] [CrossRef]

- Oikawa, H.; Murayama, G.; Hiwatashi, S.; Matsuyama, K. Resistance Spot Weldability of High Strength Steel Sheets for Automobiles and the Quality Assurance of Joints. Weld. World 2007, 51, 7–18. [Google Scholar] [CrossRef]

- Midawi, A.R.H.; Shojaee, M.; Mohamadizadeh, A.; Bourque, C.; Ghassemi-Aramki, H.; Worswick, M.; Butcher, C.; Biro, E. A novel technique to measure the local mechanical properties of third generation advanced high strength steel resistance spot welds. Forces Mech. 2022, 9, 100150. [Google Scholar] [CrossRef]

- Eftekharimilani, P.; van der Aa, E.M.; Hermans, M.J.M.; Richardson, I.M. Microstructural characterisation of double pulse resistance spot welded advanced high strength steel. Sci. Technol. Weld. Joi. 2017, 22, 545–554. [Google Scholar] [CrossRef] [Green Version]

- Chung, K.; Noh, W.; Yang, X.; Han, H.N.; Lee, M. Practical failure analysis of resistance spot welded advanced high-strength steel sheets. Int. J. Plasticity. 2017, 94, 122–147. [Google Scholar] [CrossRef]

- Wan, X.; Wang, Y.; Zhang, P. Modelling the effect of welding current on resistance spot welding of DP600 steel. J. Mater. Process. Technol. 2014, 214, 2723–2729. [Google Scholar] [CrossRef]

- Moshayedi, H.; Sattari-Far, I. Numerical and experimental study of nugget size growth in resistance spot welding of austenitic stainless steels. J. Mater. Process. Technol. 2012, 212, 347–354. [Google Scholar] [CrossRef]

- Eshraghi, M.; Tschopp, M.A.; Zaeem, M.A.; Felicelli, S.D. Effect of resistance spot welding parameters on weld pool properties in a DP600 dual-phase steel: A parametric study using thermomechanically-coupled finite element analysis. Mater. Design. 2014, 56, 387–397. [Google Scholar] [CrossRef]

- Varbai, B.; Sommer, C.; Szabó, M.; Tóth, T.; Májlinger, K. Shear tension strength of resistant spot welded ultra high strength steels. Thin Wall. Struct. 2019, 142, 64–73. [Google Scholar] [CrossRef]

- Mucha, J.; Kaščák, Ľ. Waldemar Witkowski: Research on the Influence of the AW 5754 Aluminum Alloy State Condition and Sheet Arrangements with AW 6082 Aluminum Alloy on the Forming Process and Strength of the ClinchRivet Joints. Materials 2021, 14, 2980. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.D.; Cui, M.C.; Han, X.L.; Fan, S.Q. Mechanical properties of the two-steps clinched joint with a clinch-rivet. J. Mater. Process. Technol. 2016, 237, 361–370. [Google Scholar] [CrossRef]

- Eshtayeh, M.M.; Hrairi, M. Multi objective optimization of clinching joints quality using Grey-based Taguchi method. Int. J. Adv. Manuf. Technol. 2016, 87, 233–249. [Google Scholar] [CrossRef]

- He, X.; Lei, L.; Zhang, Y.; Xing, B. Mechanical properties and fracture analysis of clinched joints in titanium sheet materials. Acta Phys. Pol. 2017, 131, 16–19. [Google Scholar] [CrossRef]

- Chen, Y.K.; Han, L.; Chrysanthou, A.; O’Sullivan, J.M. Fretting wear in self-piercing riveted aluminium alloy sheet. Wear 2003, 255, 1463–1470. [Google Scholar] [CrossRef] [Green Version]

- Langrand, B.; Deletombe, E.; Markiewicz, E.; Drazétic, P. Riveted joint modeling for numerical analysis of airframe crashworthiness. Finite Elem. Anal. Des. 2001, 38, 21–44. [Google Scholar] [CrossRef]

- Carboni, M.; Beretta, S.; Monno, M. Fatigue behaviour of tensile-shear loaded clinched joints. Eng. Fract. Mech. 2006, 73, 178–190. [Google Scholar] [CrossRef]

- Pedreschi, R.F.; Sinha, B.P. An experimental study of cold formed steel trusses using mechanical clinching. Constr. Build. Mater. 2008, 22, 921–931. [Google Scholar] [CrossRef]

- Mucha, J.; Kaščák, Ľ.; Spišák, E. Joining the car-body sheets using clinching process with various thickness and mechanical property arrangements. Arch. Civ. Mech. Eng. 2011, 11, 135–148. [Google Scholar] [CrossRef]

- Abe, Y.; Kato, T.; Mori, K.; Nishino, S. Mechanical clinching of ultra-high strength steel sheets and strength of joints. J. Mater. Process. Technol. 2014, 214, 2112–2118. [Google Scholar] [CrossRef]

- Kaščák, Ľ.; Mucha, J.; Witkowski, W. Plastic formed and spot welded joints strength of S350GD+Z steel. Teh. Vjesn. 2018, 25, 1623–1630. [Google Scholar]

- Zhanga, Y.; Zhang, X.; Guo, J.; Manladan, S.M.; Luo, Z.; Li, Y. Effects of local stiffness on the spot joints mechanical properties: Comparative study between resistance spot welding and resistance spot clinching joints. J. Manuf. Process. 2019, 39, 93–101. [Google Scholar] [CrossRef]

- Lei, L.; He, X.; Zhao, D.; Zhang, Y.; Gu, F.; Ball, A. Clinch-bonded hybrid joining for similar and dissimilar copper alloy, aluminium alloy and galvanised steel sheets. Thin Wall. Struct. 2018, 131, 393–403. [Google Scholar] [CrossRef] [Green Version]

- Ma, Y.; Abe, Y.; Geng, P.; Akita, R.; Ma, N.; Mori, K. Adhesive dynamic behavior in the clinch-bonding process of aluminum alloy A5052-H34 and advanced high-strength steel JSC780. J. Mater. Process. Technol. 2022, 305, 117602. [Google Scholar] [CrossRef]

- Balawender, T.; Sadowski, T.; Golewski, P. Numerical analysis and experiments of the clinch-bonded joint subjected to uniaxial tension. Comp. Mater. Sci. 2012, 64, 270–272. [Google Scholar] [CrossRef]

- Nourani, S.A.; Stilwell, G.; Pons, D.J. Shear testing of clinch joints at different temperatures: Explanation of the failure sequence. J. Adv. Join. Process. 2023, 7, 100140. [Google Scholar] [CrossRef]

- Zeuner, A.T.; Ewenz, L.; Kalich, J.; Schöne, S.; Füssel, U.; Zimmermann, M. The Influence of Heat Treatment on the Microstructure, Surface Roughness and Shear Tensile Strength of AISI 304 Clinch Joints. Metals 2022, 12, 1514. [Google Scholar] [CrossRef]

- Kaczyński, P.; Skwarski, M. Partial heating as a new method for increasing the strength of clinch joints of thin-walled elements. Thin Wall. Struct. 2020, 148, 106610. [Google Scholar] [CrossRef]

- Zhang, Y.; Shan, H.; Li, Y.; Guo, J.; Luo, Z.; Ma, C.Y. Joining aluminum alloy 5052 sheets via novel hybrid resistance spot clinching process. Mater. Des. 2017, 118, 36–43. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Y.; Wang, S.; Lu, G.; Zheng, C.; Zhong, J. Experimental and numerical investigation on incremental laser shock clinching for joining three sheets of copper/aluminum/stainless steel. Opt. Laser Technol. 2021, 141, 107141. [Google Scholar] [CrossRef]

- Chen, L.-W.; Cai, M.-J. Development of a hot stamping clinching tool. J. Manuf. Process. 2018, 34, 650–658. [Google Scholar] [CrossRef]

- Babalo, V.; Fazli, A.; Soltanpour, M. Electro-Hydraulic Clinching: A novel high speed joining process. J. Manuf. Process. 2018, 35, 559–569. [Google Scholar] [CrossRef]

- Abe, Y.; Saito, T.; Nakagawa, K.; Mori, K. Rectangular shear clinching for joining of ultra-high strength steel sheets. Procedia Manuf. 2018, 15, 1354–1359. [Google Scholar] [CrossRef]

- Abe, Y.; Nihsino, S.; Mori, K.; Saito, T. Improvement of joinability in mechanical clinching of ultra-high strength steel sheets using counter pressure with ring rubber. Procedia Eng. 2014, 81, 2056–2061. [Google Scholar] [CrossRef] [Green Version]

- Haque, R. Quality of self-piercing riveting (SPR) joints from cross-sectional perspective: A review. Arch. Civ. Mech. Eng. 2018, 18, 83–93. [Google Scholar] [CrossRef]

- BS EN 10346; Continuously Hot-Dip Coated Steel Flat Products for Cold Forming—Technical Delivery Conditions. BE European Standards: London, UK, 2015.

- ISO 6892-1; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. ISO: Geneva, Switzerland, 2016.

- Das, B.; Singh, A.; Paul, S.K. Low cycle fatigue performance of DP600 steel under various pre-straining paths. Int. J. Fatig. 2020, 132, 105331. [Google Scholar] [CrossRef]

- Haslberger, P.; Holly, S.; Ernst, W.; Schnitzer, R. Microstructure and mechanical properties of high-strength steel welding consumables with a minimum yield strength of 1100 MPa. J. Mater. Sci. 2018, 53, 6968–6979. [Google Scholar] [CrossRef] [Green Version]

- Kejian, H.; Baker, T.N. The effects of small titanium additions on the mechanical properties and the microstructures of controlled rolled niobium-bearing HSLA plate steels. Mater. Sci. Eng. 1993, A169, 53–65. [Google Scholar] [CrossRef]

- Vaikar, S.J.; Narayanan, V.; George, J.C.; Kanish, D.C.; Ramkumar, K.D. Effect of weld microstructure on the tensile properties and impact toughness of the naval, marine-grade steel weld joints. J. Mater. Res. Technol. 2022, 19, 3724–3737. [Google Scholar] [CrossRef]

- Yıldırım, H.C. Recent results on fatigue strength improvement of high-strength steel welded joints. Int. J. Fatig. 2017, 101, 408–420. [Google Scholar] [CrossRef]

- Džupon, M.; Kaščák, Ľ.; Spišák, E.; Kubík, R.; Majerníková, J. Wear of Shaped Surfaces of PVD Coated Dies for Clinching. Metals 2017, 7, 515. [Google Scholar] [CrossRef] [Green Version]

- Bielak, C.R.; Böhnke, M.; Beck, R.; Bobbert, M.; Meschut, G. Numerical analysis of the robustness of clinching process considering the pre-forming of the parts. J. Adv. Join. Process. 2021, 3, 100038. [Google Scholar] [CrossRef]

- Hamel, V.; Roelandt, J.M.; Gacel, J.N.; Schmit, F. Finite element modeling of clinch forming with automatic remeshing. Comput. Struct. 2000, 77, 185–200. [Google Scholar] [CrossRef]

- ISO 12996:2013; Mechanical Joining—Destructive Testing of Joints—Specimen Dimensions and Test Procedure for Tensile Shear Testing of Single Joints. ISO: Geneva, Switzerland, 2013.

- Lei, L.; He, X.; Yu, T.; Xing, B. Failure modes of mechanical clinching in metal sheet materials. Thin Wall. Struct. 2019, 144, 106281. [Google Scholar] [CrossRef]

| C | Mn | Si | P | S | Al | Cu | Ni | Cr | Ti | V | Nb | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.075 | 1.880 | 0.016 | 0.015 | 0.005 | 0.055 | 0.022 | 0.009 | 0.208 | 0.001 | 0.003 | 0.003 | 0.170 |

| C | Mn | Si | P | S | Al | Cu | Ni | Cr | Ti | V | Nb | Mo |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.083 | 1.214 | 0.013 | 0.015 | 0.005 | 0.040 | 0.035 | 0.010 | 0.024 | 0.014 | 0.032 | 0.058 | 0.002 |

| Material | Thickness (mm) | Rp0.2 (MPa) | Rm (MPa) | A80 |

|---|---|---|---|---|

| HX420LAD+Z | 1.5 | 503 | 565 | 19.5 |

| HCT600X+Z | 1.5 | 343 | 593 | 27.5 |

| Sample Series | Welding Current I (mm) | Welding Time T (per.) | Pressing Force Fz (kN) |

|---|---|---|---|

| I | 3.5 | 12 | 6 |

| II | 3.5 | 18 | 6 |

| III | 3.5 | 24 | 6 |

| IV | 3.5 | 30 | 6 |

| V | 3.5 | 36 | 6 |

| VI | 3.9 | 12 | 6 |

| VII | 3.9 | 18 | 6 |

| VIII | 3.9 | 24 | 6 |

| IX | 3.9 | 30 | 6 |

| X | 3.9 | 36 | 6 |

| XI | 4.3 | 12 | 6 |

| XII | 4.3 | 18 | 6 |

| XIII | 4.3 | 24 | 6 |

| XIV | 4.3 | 30 | 6 |

| XV | 4.3 | 36 | 6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Džupon, M.; Kaščák, Ľ.; Cmorej, D.; Čiripová, L.; Mucha, J.; Spišák, E. Clinching of High-Strength Steel Sheets with Local Preheating. Appl. Sci. 2023, 13, 7790. https://doi.org/10.3390/app13137790

Džupon M, Kaščák Ľ, Cmorej D, Čiripová L, Mucha J, Spišák E. Clinching of High-Strength Steel Sheets with Local Preheating. Applied Sciences. 2023; 13(13):7790. https://doi.org/10.3390/app13137790

Chicago/Turabian StyleDžupon, Miroslav, Ľuboš Kaščák, Denis Cmorej, Lucia Čiripová, Jacek Mucha, and Emil Spišák. 2023. "Clinching of High-Strength Steel Sheets with Local Preheating" Applied Sciences 13, no. 13: 7790. https://doi.org/10.3390/app13137790

APA StyleDžupon, M., Kaščák, Ľ., Cmorej, D., Čiripová, L., Mucha, J., & Spišák, E. (2023). Clinching of High-Strength Steel Sheets with Local Preheating. Applied Sciences, 13(13), 7790. https://doi.org/10.3390/app13137790