Temperature-Dependent Sheet Resistance and Surface Characterization of Thin Copper Films Bonded to FR4 Composite under Mechanical Vibrations

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

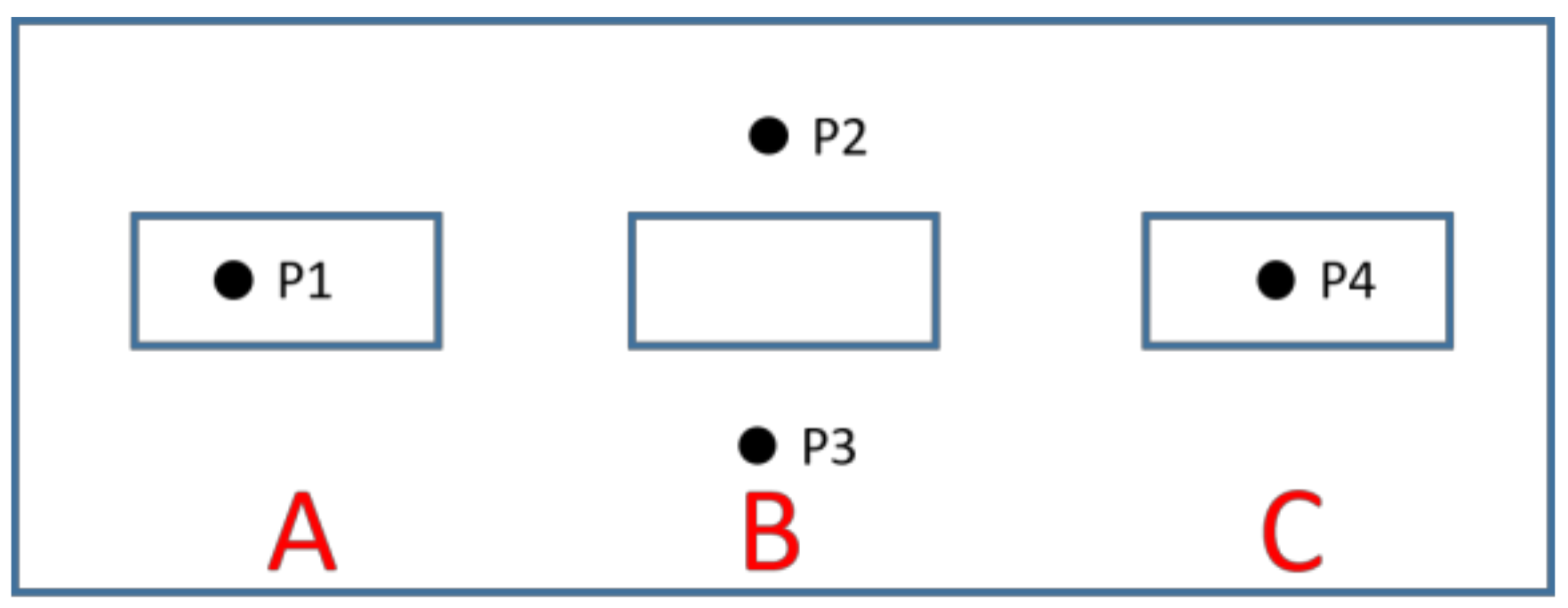

2.2. Experimental Sheet Resistance Analysis

- DA4PP

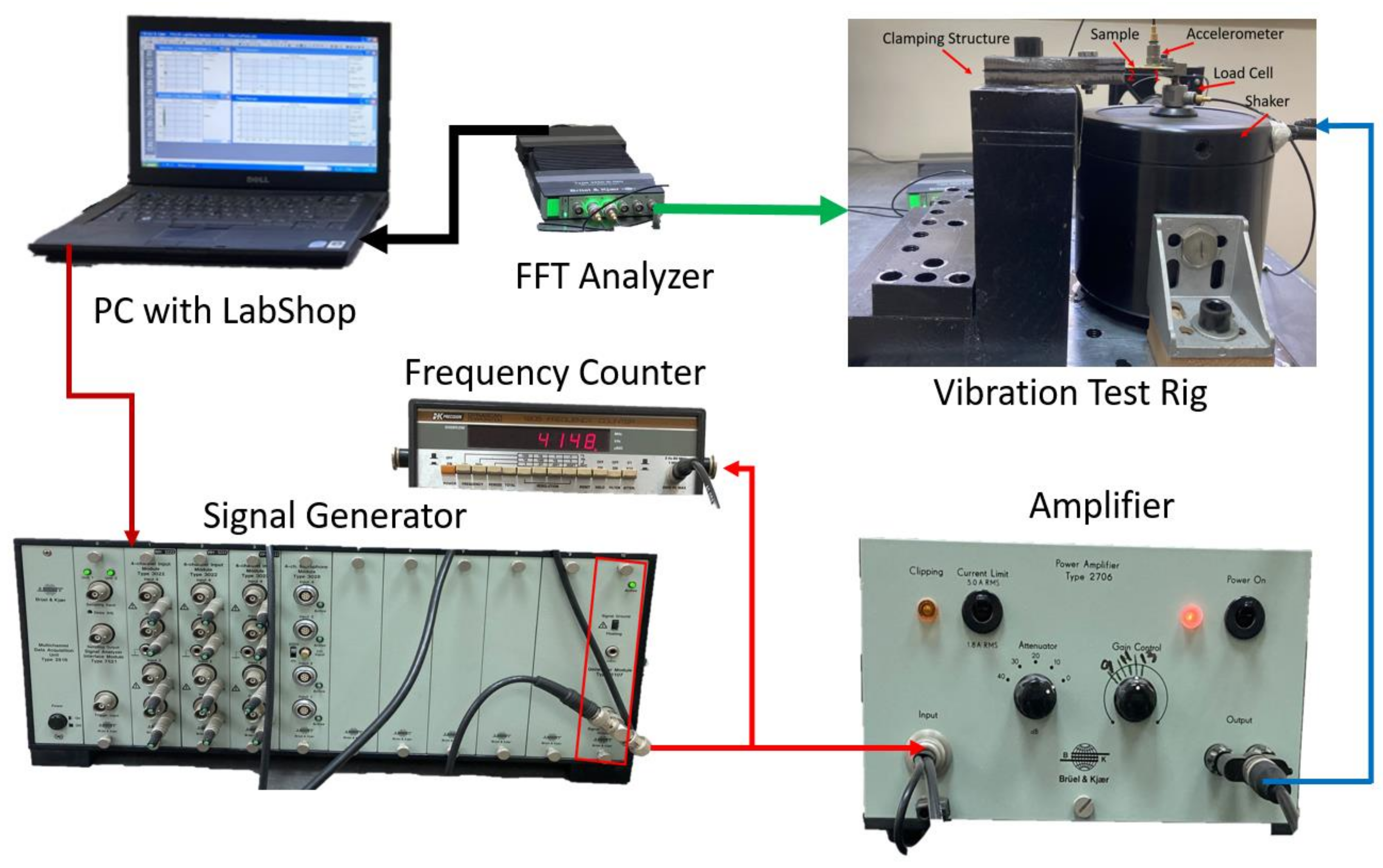

- High Cycle Vibration Test Rig

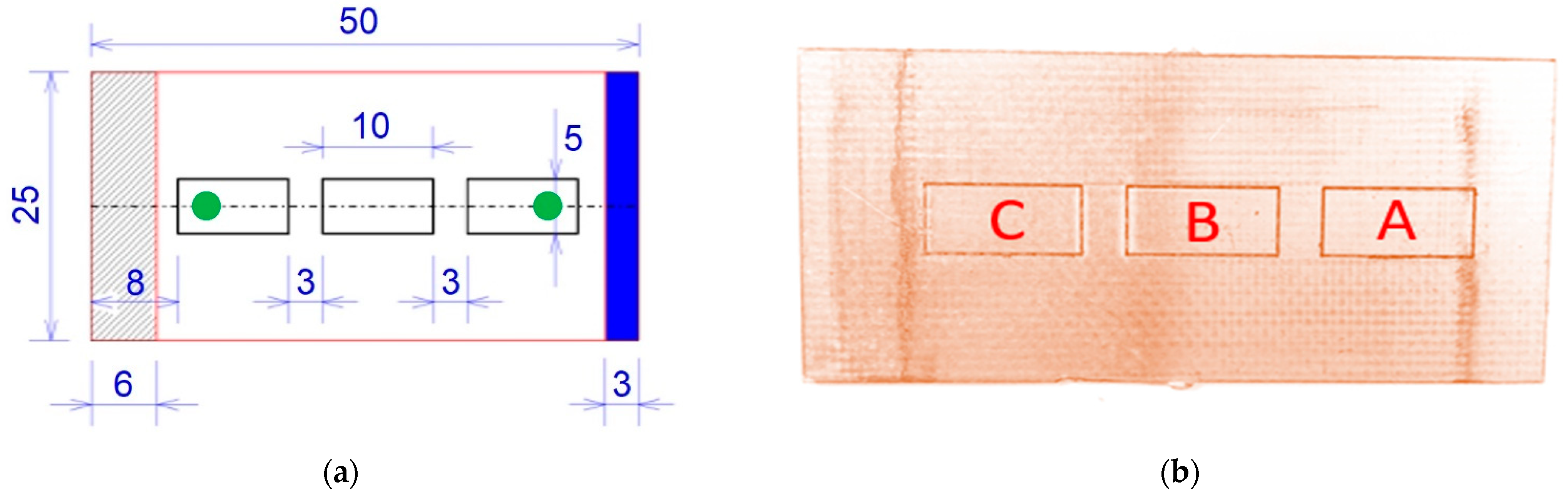

2.2.1. DA4PP Design

2.2.2. High Cycle Vibration Test Rig

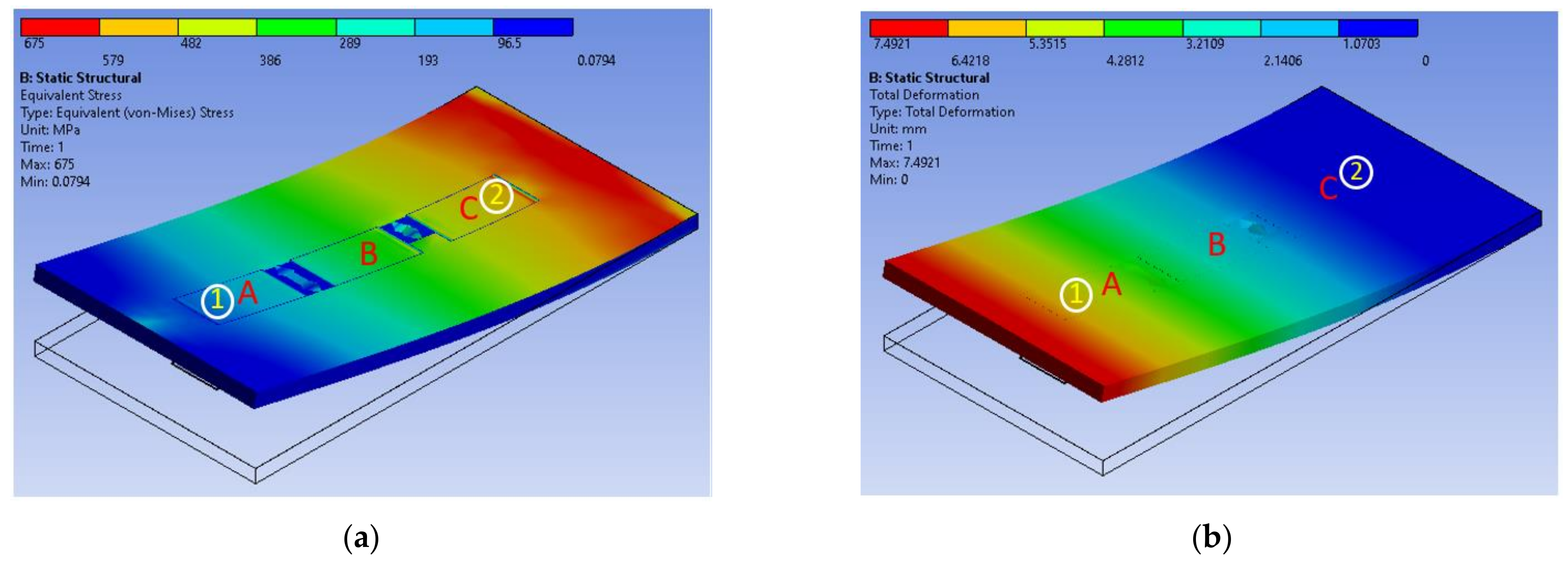

2.3. Theoretical Model

2.4. Experimental Surface Analysis

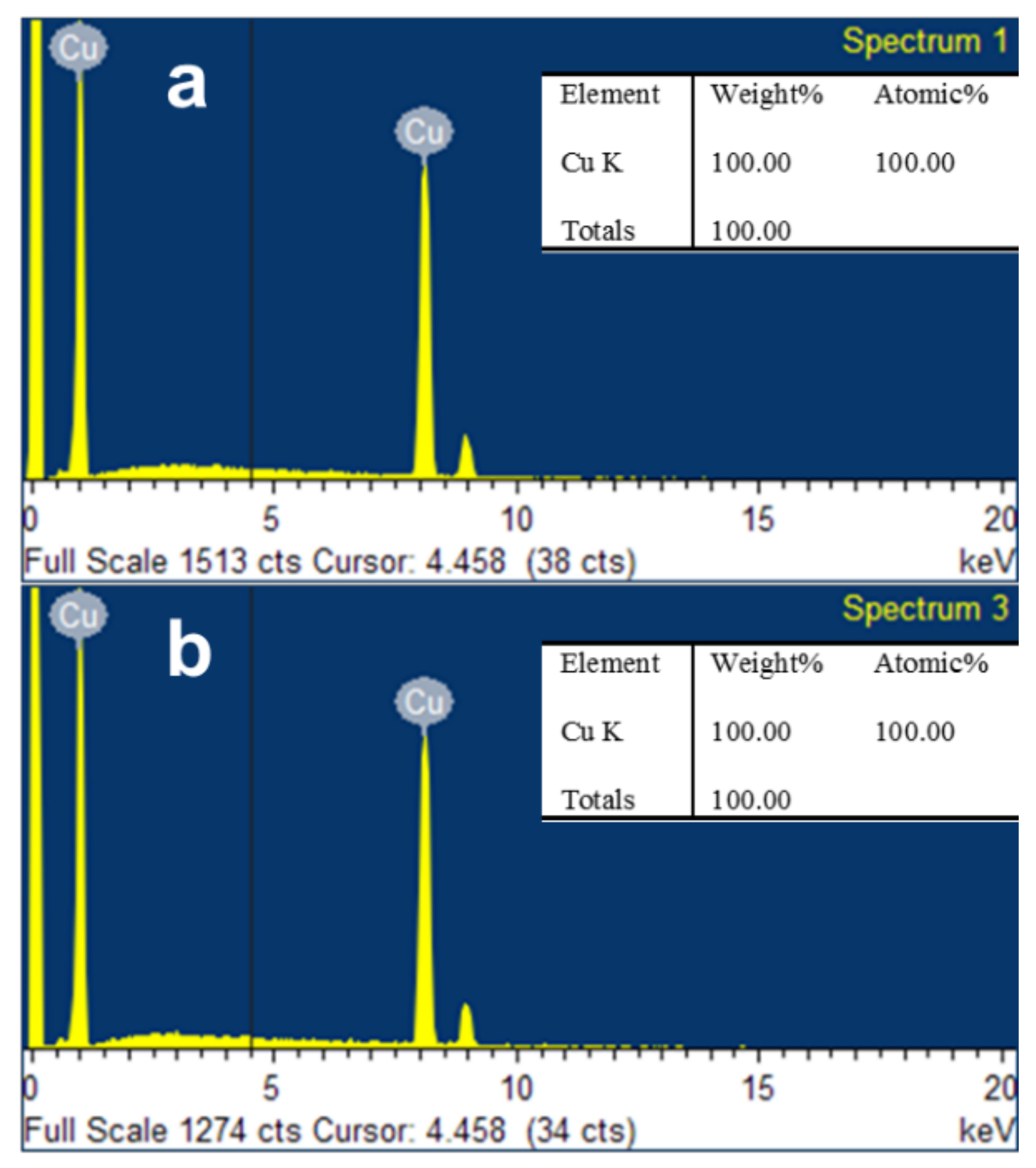

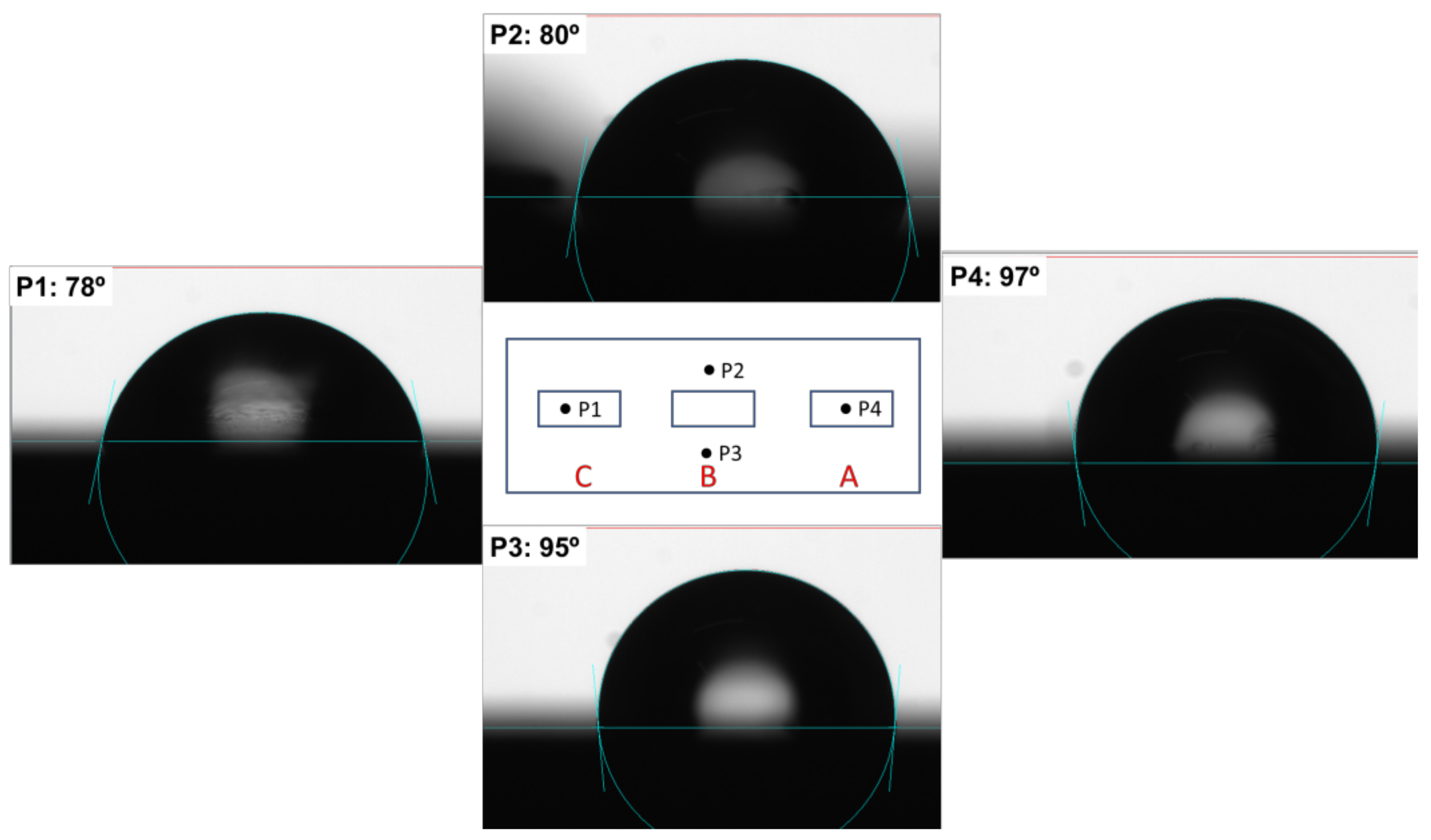

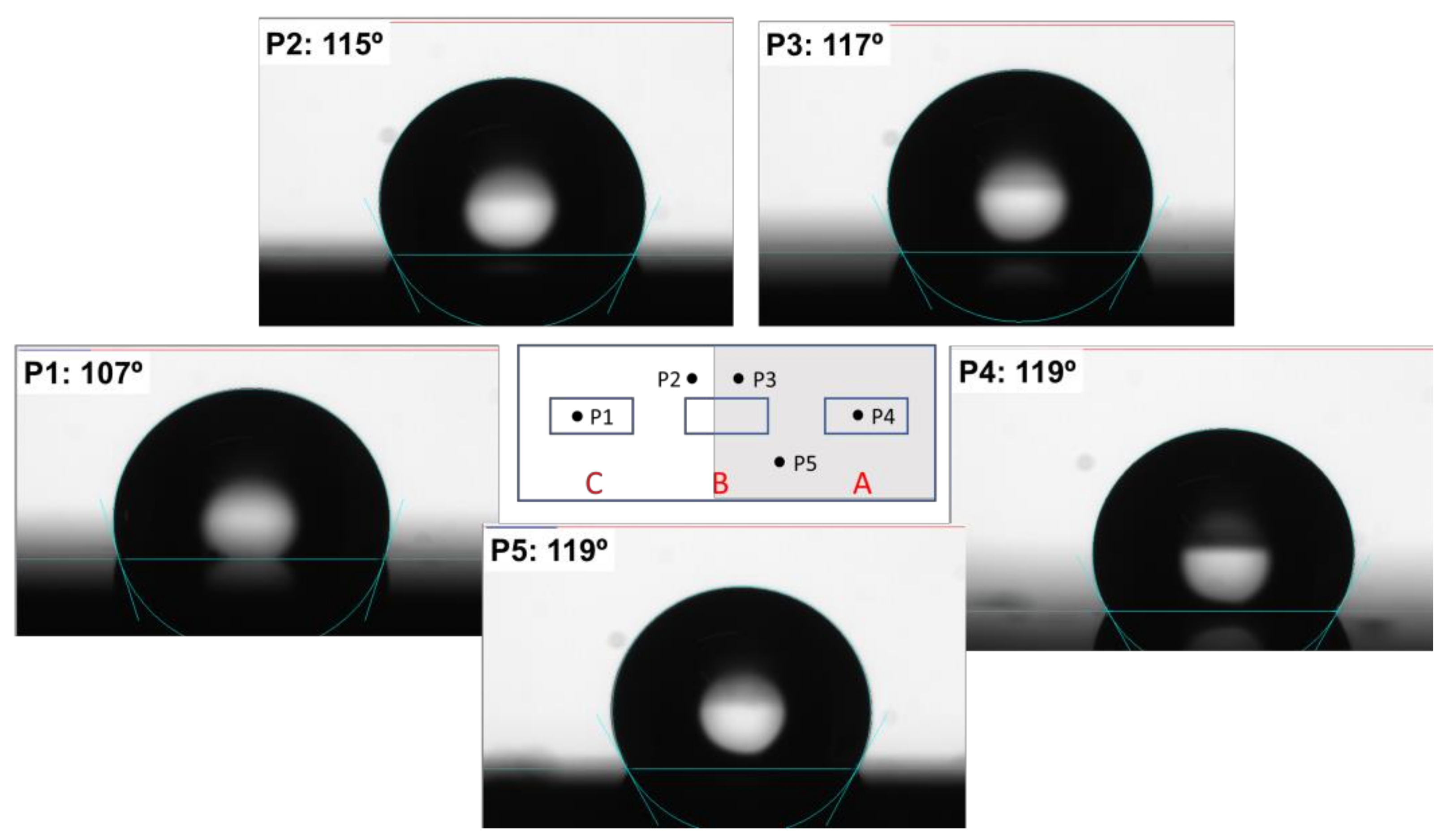

3. Results

3.1. Validation and Repeatability

3.2. Electrical Properties under Mechanical Vibrations at Different Temperatures

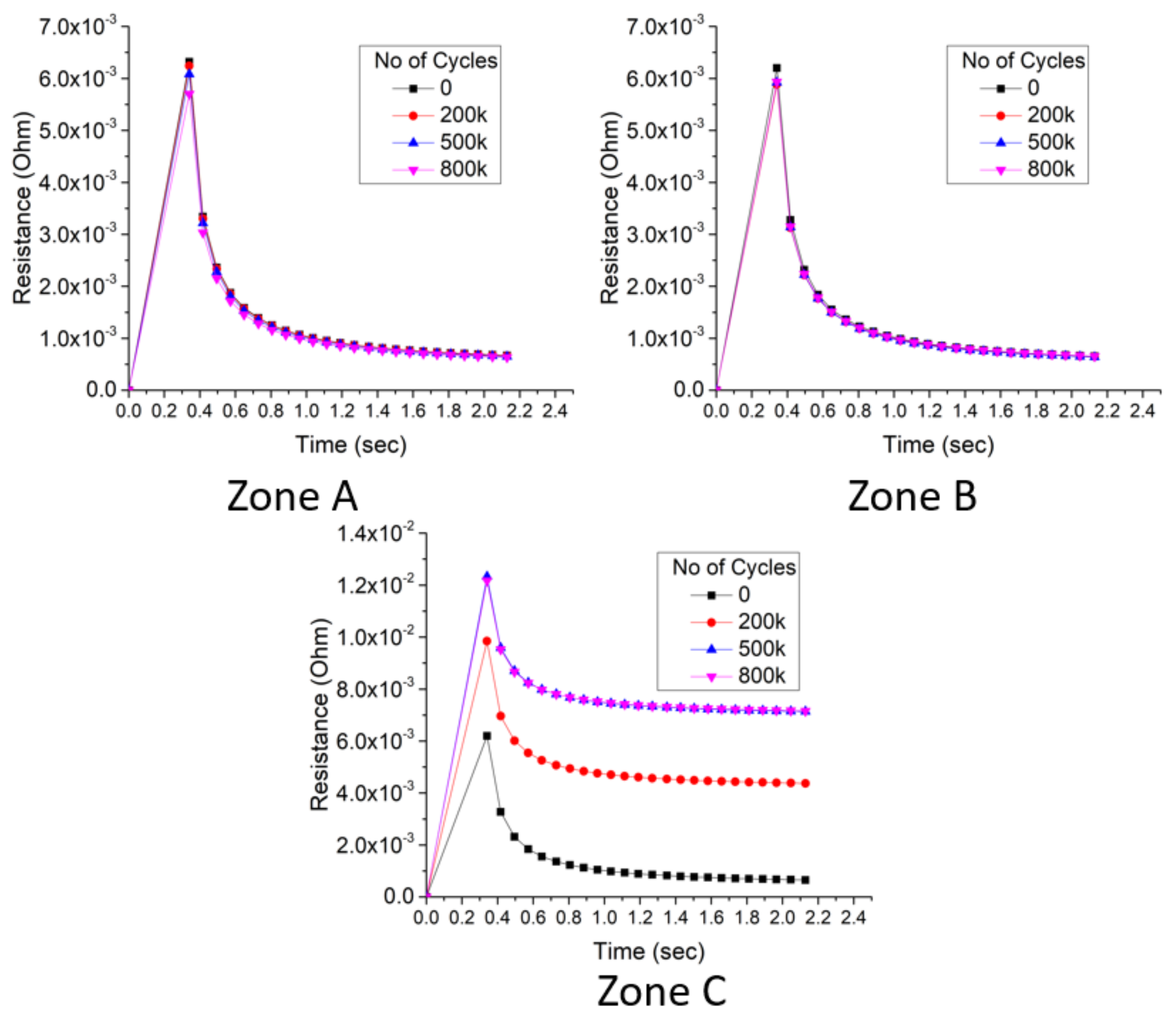

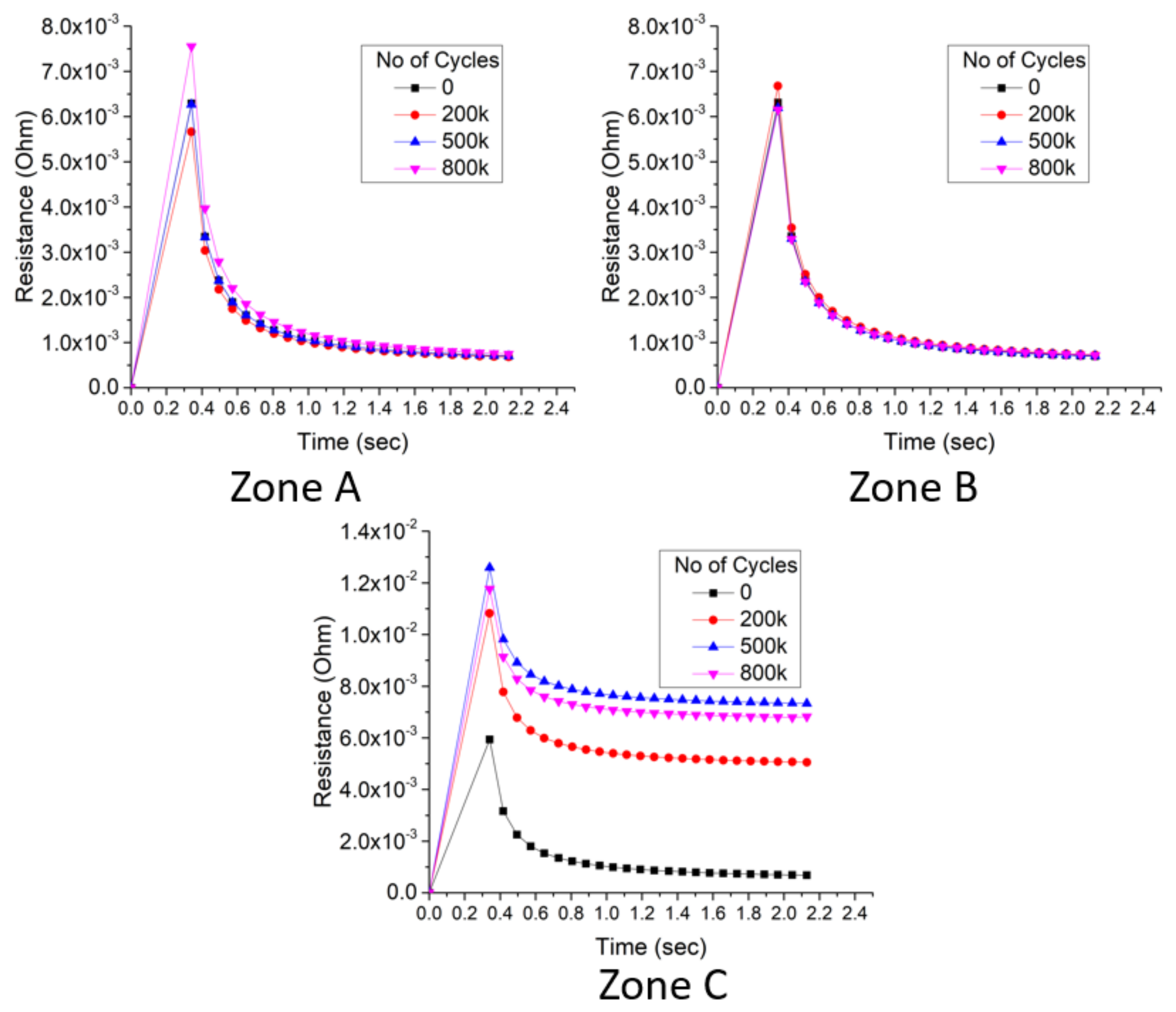

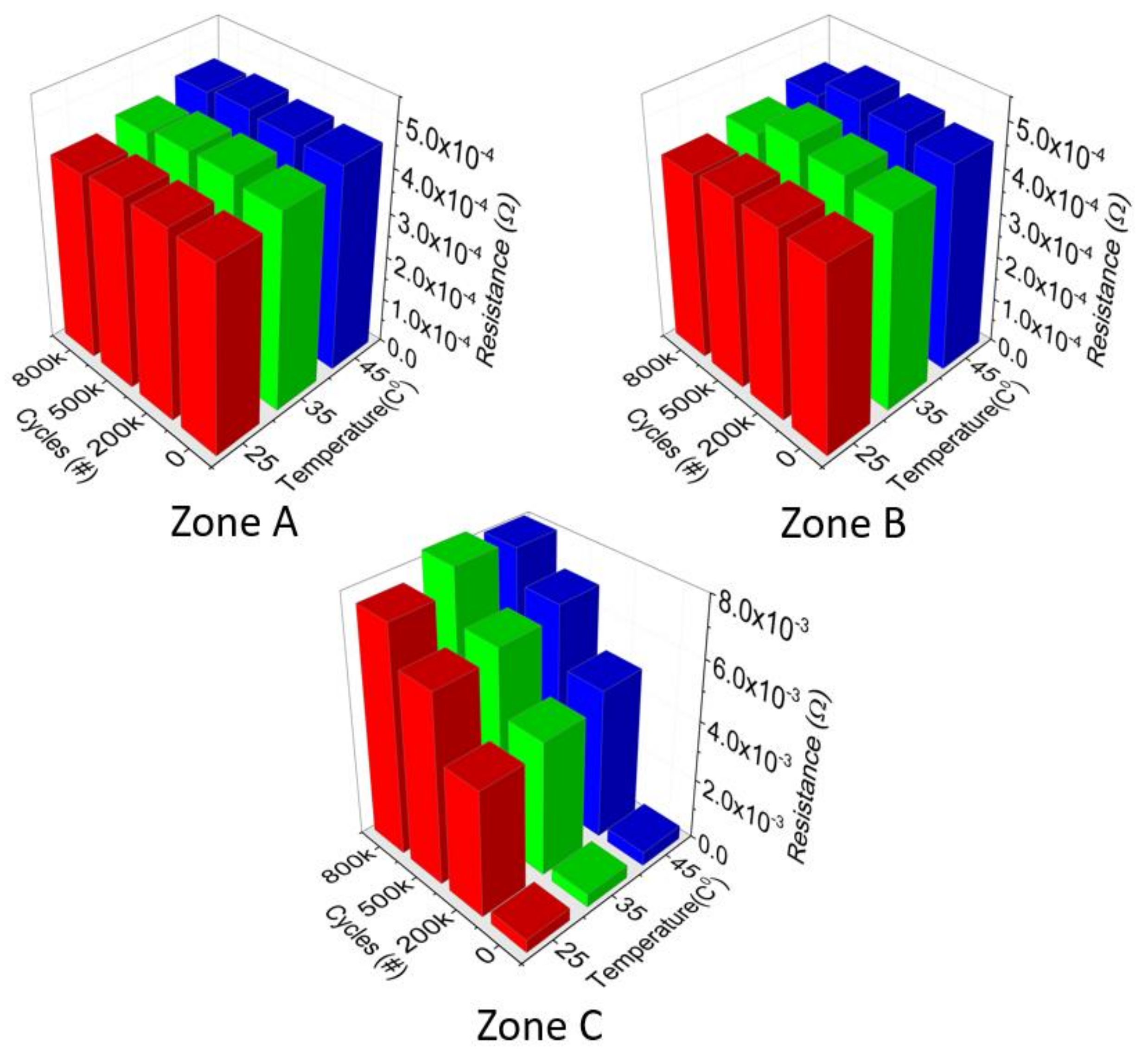

3.2.1. Resistance

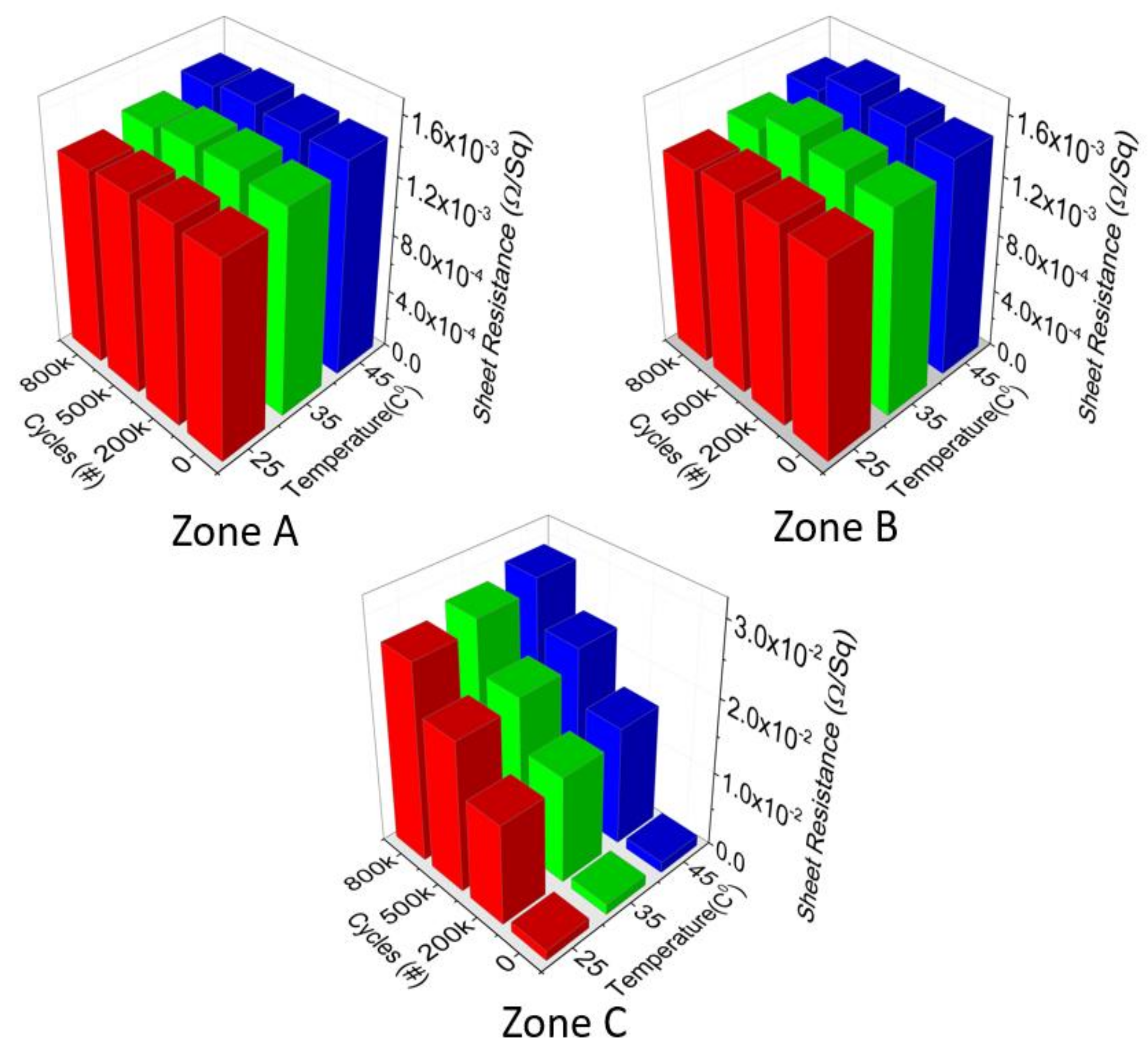

3.2.2. Sheet Resistance, Resistivity, and Conductivity

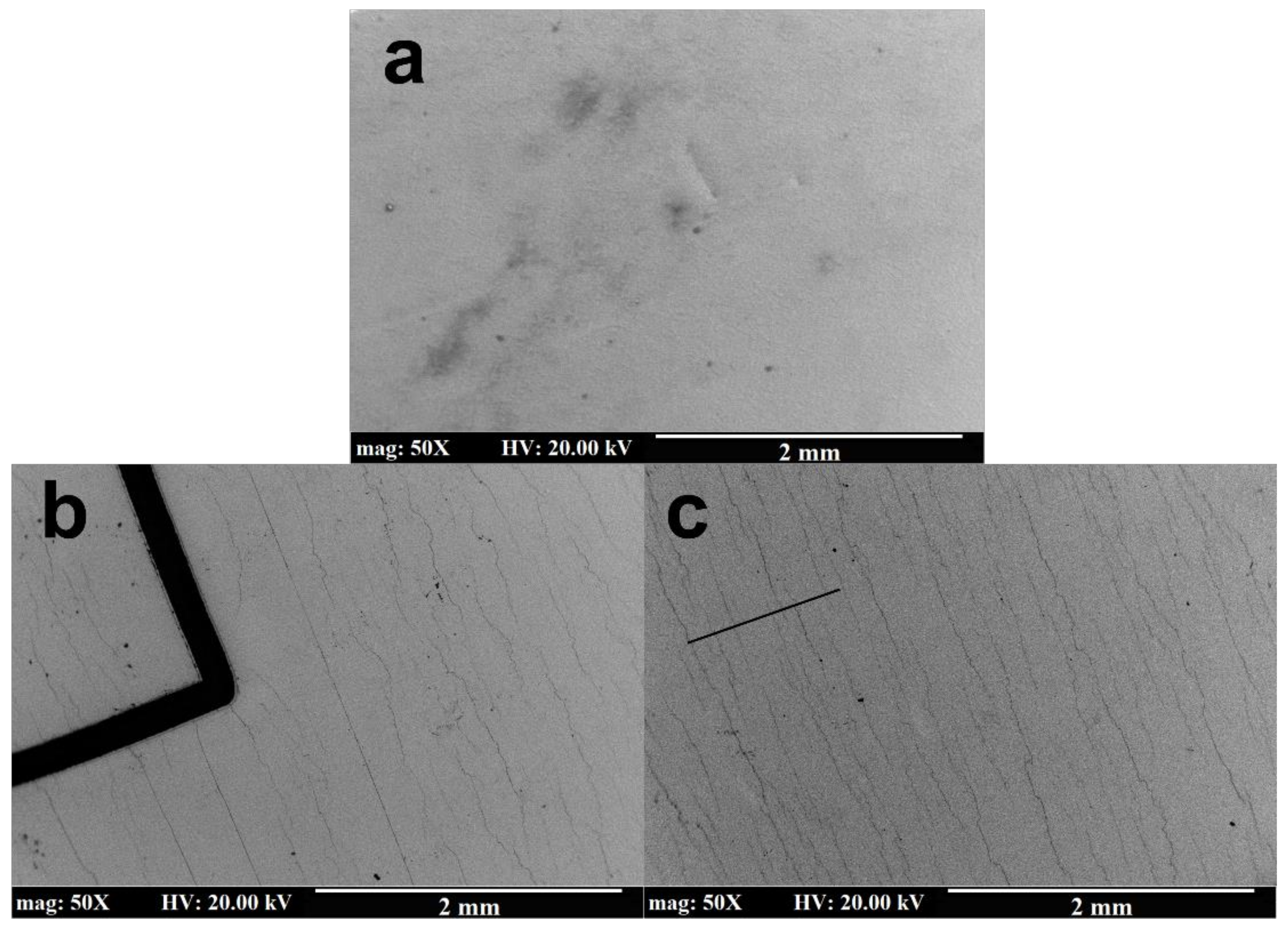

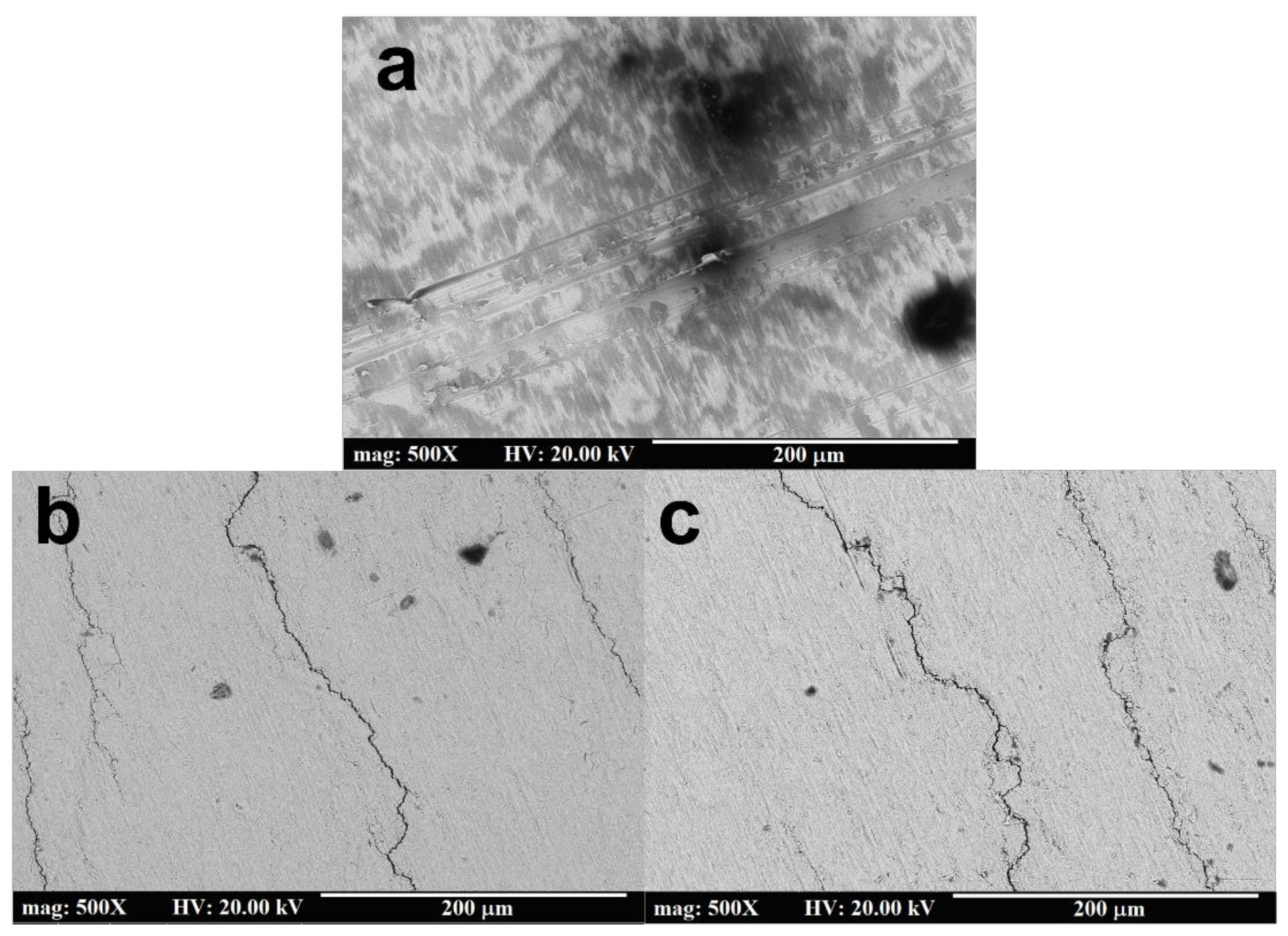

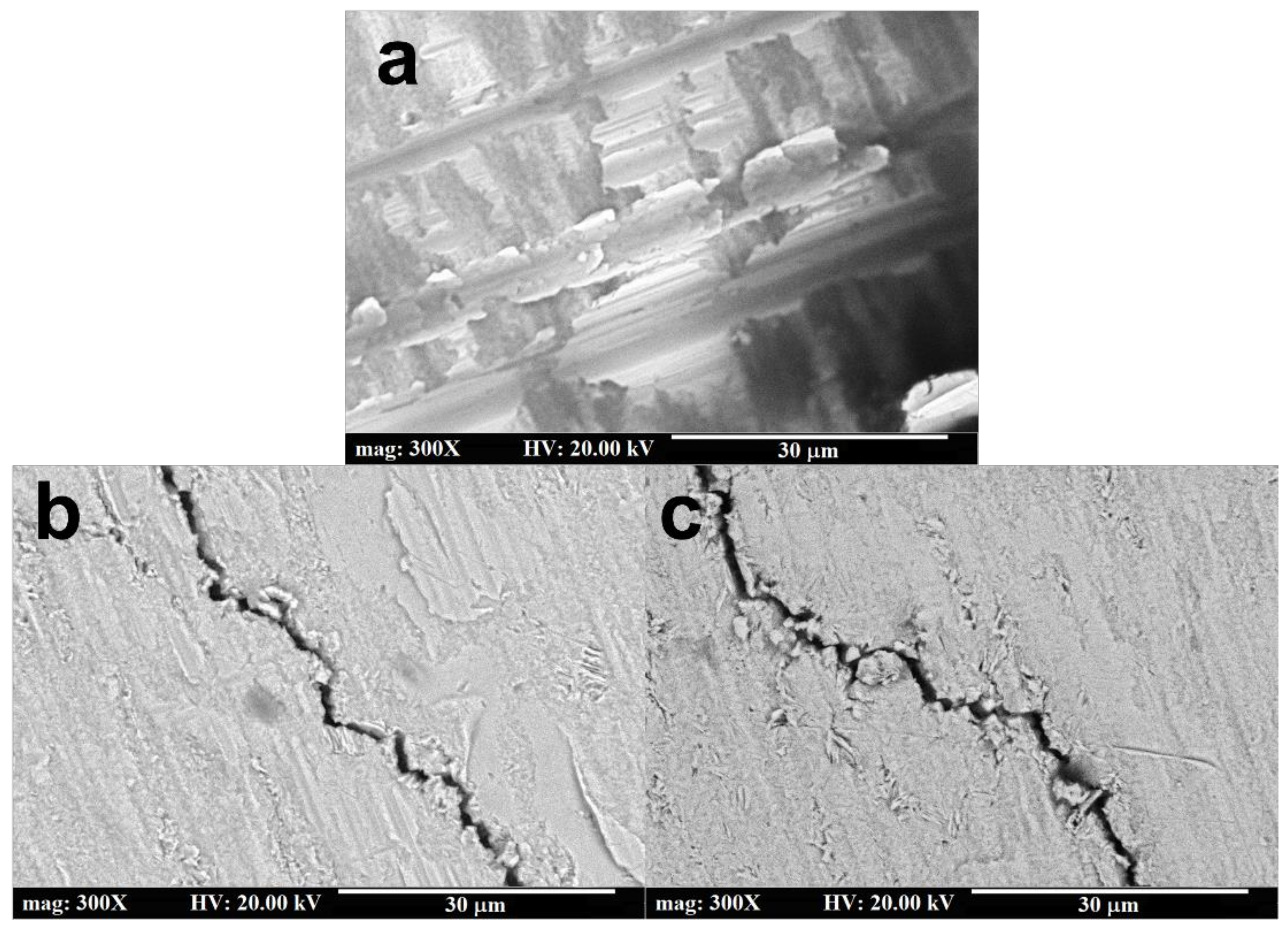

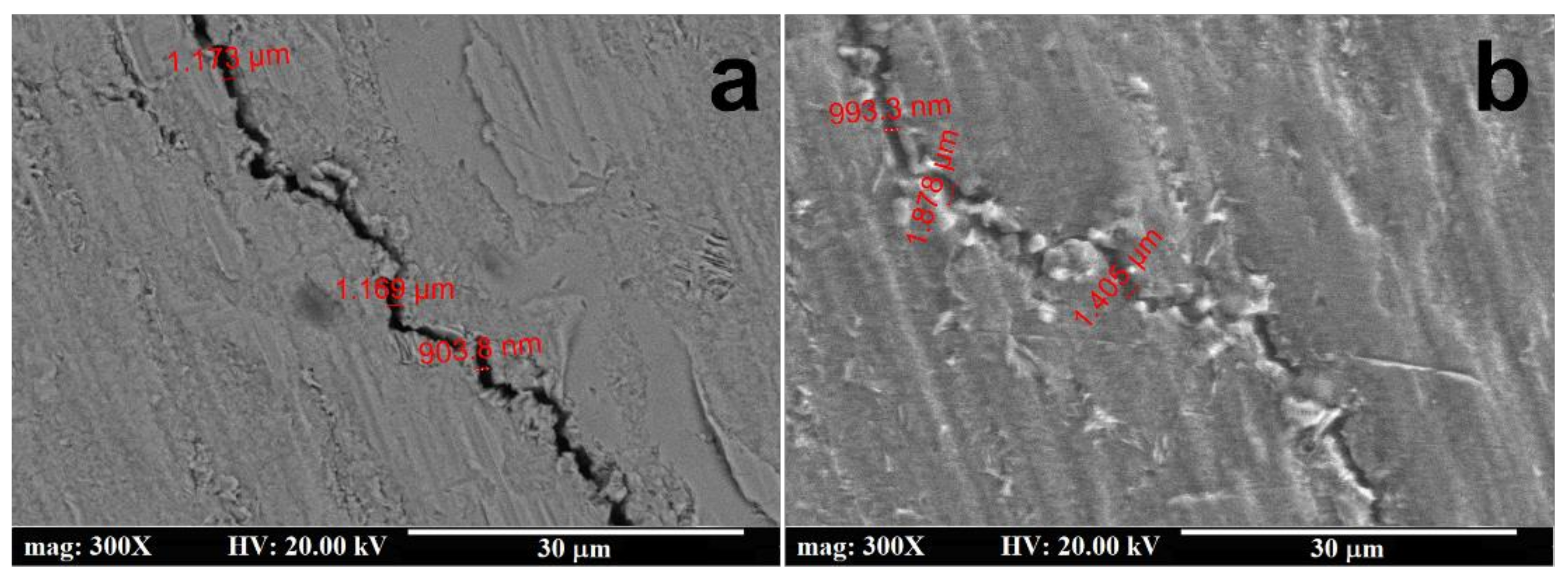

3.3. Surface Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Canal Marques, A.; Cabrera, J.-M.; de Fraga Malfatti, C. Printed circuit boards: A review on the perspective of sustainability. J. Environ. Manag. 2013, 131, 298–306. [Google Scholar] [CrossRef] [PubMed]

- Sankar, V.U.; Lakshmi, G.; Sankar, Y.S. A Review of Various Defects in PCB. J. Electron. Test. 2022, 38, 481–491. [Google Scholar] [CrossRef]

- Jillek, W.; Yung, W.K.C. Embedded components in printed circuit boards: A processing technology review. Int. J. Adv. Manuf. Technol. 2005, 25, 350–360. [Google Scholar] [CrossRef]

- LaDou, J. Printed circuit board industry. Int. J. Hyg. Environ. Health 2006, 209, 211–219. [Google Scholar] [CrossRef] [PubMed]

- Zhou, S.; Lin, Z.; Qiu, B.; Wang, H.; Xiong, J.; He, C.; Zhou, B.; Pan, Y.; Huang, R.; Bao, Y.; et al. Evaluation of Solder Joint Reliability in 3D Packaging Memory Devices under Thermal Shock. Electronics 2022, 11, 2556. [Google Scholar] [CrossRef]

- Jiao, J.; De, X.; Chen, Z.; Zhao, T. Integrated circuit failure analysis and reliability prediction based on physics of failure. Eng. Fail. Anal. 2019, 104, 714–726. [Google Scholar] [CrossRef]

- Connolley, T.; McHugh, P.E.; Bruzzi, M. A review of deformation and fatigue of metals at small size scales. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 1119–1152. [Google Scholar] [CrossRef]

- O’Reilly, M.; Jiang, X.; Beechinor, J.T.; Lynch, S.; NíDheasuna, C.; Patterson, J.C.; Crean, G.M. Investigation of the oxidation behaviour of thin film and bulk copper. Appl. Surf. Sci. 1995, 91, 152–156. [Google Scholar] [CrossRef]

- Baker-Jarvis, J.; Jones, C.A. Dielectric Measurements on Printed-Wiring And Circuit Boards, Thin Films, And Substrates: An Overview. MRS Online Proc. Libr. 1995, 381, 153–164. [Google Scholar] [CrossRef]

- Gunda, M.; Kumar, P.; Katiyar, M. Review of Mechanical Characterization Techniques for Thin Films Used in Flexible Electronics. Crit. Rev. Solid State Mater. Sci. 2017, 42, 129–152. [Google Scholar] [CrossRef]

- Vinci, R.P.; Zielinski, E.M.; Bravman, J.C. Thermal strain and stress in copper thin films. Thin Solid Films 1995, 262, 142–153. [Google Scholar] [CrossRef]

- Girard, G.; Martiny, M.; Mercier, S. Experimental characterization of rolled annealed copper film used in flexible printed circuit boards: Identification of the elastic-plastic and low-cycle fatigue behaviors. Microelectron. Reliab. 2020, 115, 113976. [Google Scholar] [CrossRef]

- Fellner, K.; Fuchs, P.F.; Pinter, G.; Antretter, T.; Krivec, T. Method development for the cyclic characterization of thin copper layers for PCB applications. Circuit World 2014, 40, 53–60. [Google Scholar] [CrossRef]

- Park, J.H.; An, J.H.; Kim, Y.J.; Huh, Y.H.; Lee, H.J. Tensile and high cycle fatigue test of copper thin film. Mater. Werkst. 2008, 39, 187–192. [Google Scholar] [CrossRef]

- Han, S.W.; Seo, K.J.; Kim, W.D.; Lee, H.J.; Lee, H.W.; Shin, J.H.; Lee, J.J. Fatigue Behavior of Thin Cu Foils for Flexible Printed Circuit Board. Solid State Phenom. 2007, 124–126, 1369–1372. [Google Scholar] [CrossRef]

- Shin, H.-K.; Kim, S.-H.; Park, H.; Lee, H.-J. Multilayer Laminated Copper Electrodeposits and Their Mechanical Properties. J. Electrochem. Soc. 2022, 169, 102502. [Google Scholar] [CrossRef]

- Trost, C.O.W.; Wurster, S.; Freitag, C.; Steinberger, A.; Cordill, M.J. A new approach to evaluate the elastic modulus of metallic foils. Mater. Des. 2020, 196, 109149. [Google Scholar] [CrossRef]

- Lee, Y.-S.; Ha, S.; Park, J.-H.; Lee, S.-B. Structure-dependent mechanical behavior of copper thin films. Mater. Charact. 2017, 128, 68–74. [Google Scholar] [CrossRef]

- Walter, T.; Khatibi, G.; Nelhiebel, M.; Heinz, W.; Robl, W. High cycle fatigue properties of Cu films. Microelectron. Eng. 2015, 137, 64–69. [Google Scholar] [CrossRef]

- Menon, S.; Chen, D.Y.; Osterman, M.; Pecht, M.G. Copper Trace Fatigue Life Modeling for Rigid Electronic Assemblies. IEEE Trans. Device Mater. Reliab. 2021, 21, 79–86. [Google Scholar] [CrossRef]

- Zhang, S.; Sakane, M.; Nagasawa, T.; Kobayashi, K. Mechanical Properties of Copper Thin Films Used in Electronic Devices. Procedia Eng. 2011, 10, 1497–1502. [Google Scholar] [CrossRef] [Green Version]

- Min, H.-G.; Kang, D.-J.; Park, J.-H. Comparison of Tensile and Fatigue Properties of Copper Thin Film Depending on Process Method. Appl. Sci. 2020, 10, 388. [Google Scholar] [CrossRef] [Green Version]

- Vandevelde, B.; Willems, G. Early fatigue failures in copper wire bonds inside packages with low CTE green mold compounds. In Proceedings of the 2012 4th Electronic System-Integration Technology Conference, Amsterdam, The Netherlands, 17–20 September 2012; pp. 1–4. [Google Scholar]

- Alzoubi, K.; Hamasha, M.M.; Lu, S.; Sammakia, B. Bending Fatigue Study of Sputtered ITO on Flexible Substrate. J. Disp. Technol. 2011, 7, 593–600. [Google Scholar] [CrossRef]

- Su, B.; Qu, J. Fatigue Behavior of Electrically Conductive Adhesives. J. Adhes. Sci. Technol. 2008, 22, 927–946. [Google Scholar] [CrossRef]

- Kim, H.; Park, M.; Hsieh, K. Fatigue fracture of embedded copper conductors in multifunctional composite structures. Compos. Sci. Technol. 2006, 66, 1010–1021. [Google Scholar] [CrossRef]

- Simon, M.; Sze, K.K.N. Physics of Semiconductor Devices, 3rd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Wenner, F. A Method of Measuring Earth Resistivity. Bull. Bur. Stand. 1915, 12, 469–478. [Google Scholar] [CrossRef]

- Valdes, L.B. Resistivity Measurements on Germanium for Transistors. Proc. IRE 1954, 42, 420–427. [Google Scholar] [CrossRef]

- Michael, D.K. I-V Software (c). Available online: http://www.kelzenberg.net/software/IV (accessed on 3 March 2023).

- Ossila Four-Point Probe System. Available online: https://tinyurl.com/y6xttjwl (accessed on 5 March 2023).

- Eargle, J.M. Resistance Change with Temperature for Copper. In Electroacoustical Reference Data; Springer: Boston, MA, USA, 1994; pp. 106–107. [Google Scholar] [CrossRef]

- Smits, F.M. Measurement of sheet resistivities with the four-point probe. Bell Syst. Tech. J. 1958, 37, 711–718. [Google Scholar] [CrossRef]

- Shiraiwa, T.; Enoki, M. Fatigue crack behavior of thin copper sheet and its application for smart stress-memory patch. Strength Fract. Complex. 2011, 7, 205–214. [Google Scholar] [CrossRef]

- Judelewicz, M.; Künzi, H.U.; Merk, N.; Ilschner, B. Microstructural development during fatigue of copper foils 20–100 μm thick. Mater. Sci. Eng. A 1994, 186, 135–142. [Google Scholar] [CrossRef]

- Meng, B.; Fu, M.W. Size effect on deformation behavior and ductile fracture in microforming of pure copper sheets considering free surface roughening. Mater. Des. 2015, 83, 400–412. [Google Scholar] [CrossRef]

- Law, K.-Y.; Zhao, H. Surface Wetting Characterization, Contact Angle, and Fundamentals, 1st ed.; Springer: Cham, Switzerland, 2015; pp. 7–34. [Google Scholar]

- Martinez-Urrutia, A.; Fernandez de Arroiabe, P.; Ramirez, M.; Martinez-Agirre, M.; Mounir Bou-Ali, M. Contact angle measurement for LiBr aqueous solutions on different surface materials used in absorption systems. Int. J. Refrig. 2018, 95, 182–188. [Google Scholar] [CrossRef]

- Gadre, K.S.; Alford, T.L. Contact angle measurements for adhesion energy evaluation of silver and copper films on parylene-n and SiO2 substrates. J. Appl. Phys. 2002, 93, 919–923. [Google Scholar] [CrossRef]

| Specimen Set | Test Temperature (°C) | Number of Cycles |

|---|---|---|

| S11 | 25 | 200,000 |

| S12 | 35 | 200,000 |

| S13 | 45 | 200,000 |

| S21 | 25 | 500,000 |

| S22 | 35 | 500,000 |

| S23 | 45 | 500,000 |

| S31 | 25 | 800,000 |

| S32 | 35 | 800,000 |

| S33 | 45 | 800,000 |

| Resistance (Ω) | ||||||

|---|---|---|---|---|---|---|

| Temperature | Length | Width | Thickness | Rth 1 | Rexp 2 | Difference |

| (°C) | (mm) | (mm) | (µm) | (Ω) | (Ω) | % |

| 25 | 5 | 10 | 18 | 4.638 × 10−4 | 4.317 × 10−4 | 7.46 |

| 35 | 4.821 × 10−4 | 4.559 × 10−4 | 5.74 | |||

| 45 | 5.003 × 10−4 | 4.801 × 10−4 | 4.21 | |||

| Zone A | Zone B | Zone C | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Replicate 1 | Resistance | SD 2 | CV 3 | Resistance | SD 2 | CV 3 | Resistance | SD 2 | CV 3 |

| (Ω) | (Ω) | (%) | (Ω) | (Ω) | (%) | (Ω) | (Ω) | (%) | |

| Before cycling at 25 °C | |||||||||

| I | 4.218 × 10−4 | 4.233 × 10−4 | 4.589 × 10−4 | ||||||

| II | 4.207 × 10−4 | 2.44 × 10−6 | 0.58 | 4.151 × 10−4 | 3.92 × 10−6 | 0.94 | 4.591 × 10−4 | 1.03 × 10−6 | 0.22 |

| III | 4.161 × 10−4 | 4.149 × 10−4 | 4.568 × 10−4 | ||||||

| After 800 k cycles of loading at 25 °C | |||||||||

| I | 1.906 × 10−3 | 1.961 × 10−3 | 3.432 × 10−2 | ||||||

| II | 1.904 × 10−3 | 1.09 × 10−5 | 0.57 | 1.904 × 10−3 | 5.45 × 10−5 | 2.87 | 3.434 × 10−2 | 6.02 × 10−5 | 0.17 |

| III | 1.882 × 10−3 | 1.828 × 10−3 | 3.421 × 10−2 | ||||||

| Before cycling at 45 °C | |||||||||

| I | 4.636 × 10−4 | 4.744 × 10−4 | 4.653 × 10−4 | ||||||

| II | 4.623 × 10−4 | 4.42 × 10−6 | 0.96 | 4.554 × 10−4 | 8.50 × 10−6 | 1.84 | 4.520 × 10−4 | 5.58 × 10−6 | 1.22 |

| III | 4.536 × 10−4 | 4.576 × 10−4 | 4.562 × 10−4 | ||||||

| After 800 k cycles of loading at 45 °C | |||||||||

| I | 2.091 × 10−3 | 2.153 × 10−3 | 3.543 × 10−2 | ||||||

| II | 2.110 × 10−3 | 1.23 × 10−5 | 0.58 | 2.063 × 10−3 | 6.72 × 10−5 | 3.25 | 3.668 × 10−2 | 8.29 × 10−4 | 2.27 |

| III | 2.121 × 10−3 | 1.989 × 10−3 | 3.745 × 10−2 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Azam, S.; Munshi, S.; Hassan, M.K.; Fragoso, A. Temperature-Dependent Sheet Resistance and Surface Characterization of Thin Copper Films Bonded to FR4 Composite under Mechanical Vibrations. Appl. Sci. 2023, 13, 7941. https://doi.org/10.3390/app13137941

Azam S, Munshi S, Hassan MK, Fragoso A. Temperature-Dependent Sheet Resistance and Surface Characterization of Thin Copper Films Bonded to FR4 Composite under Mechanical Vibrations. Applied Sciences. 2023; 13(13):7941. https://doi.org/10.3390/app13137941

Chicago/Turabian StyleAzam, Sufyan, Shadi Munshi, Mohamed K. Hassan, and Alex Fragoso. 2023. "Temperature-Dependent Sheet Resistance and Surface Characterization of Thin Copper Films Bonded to FR4 Composite under Mechanical Vibrations" Applied Sciences 13, no. 13: 7941. https://doi.org/10.3390/app13137941

APA StyleAzam, S., Munshi, S., Hassan, M. K., & Fragoso, A. (2023). Temperature-Dependent Sheet Resistance and Surface Characterization of Thin Copper Films Bonded to FR4 Composite under Mechanical Vibrations. Applied Sciences, 13(13), 7941. https://doi.org/10.3390/app13137941