Study on the Internal Mechanics and Energy Characteristics of Soil under Different Failure Modes

Abstract

:1. Introduction

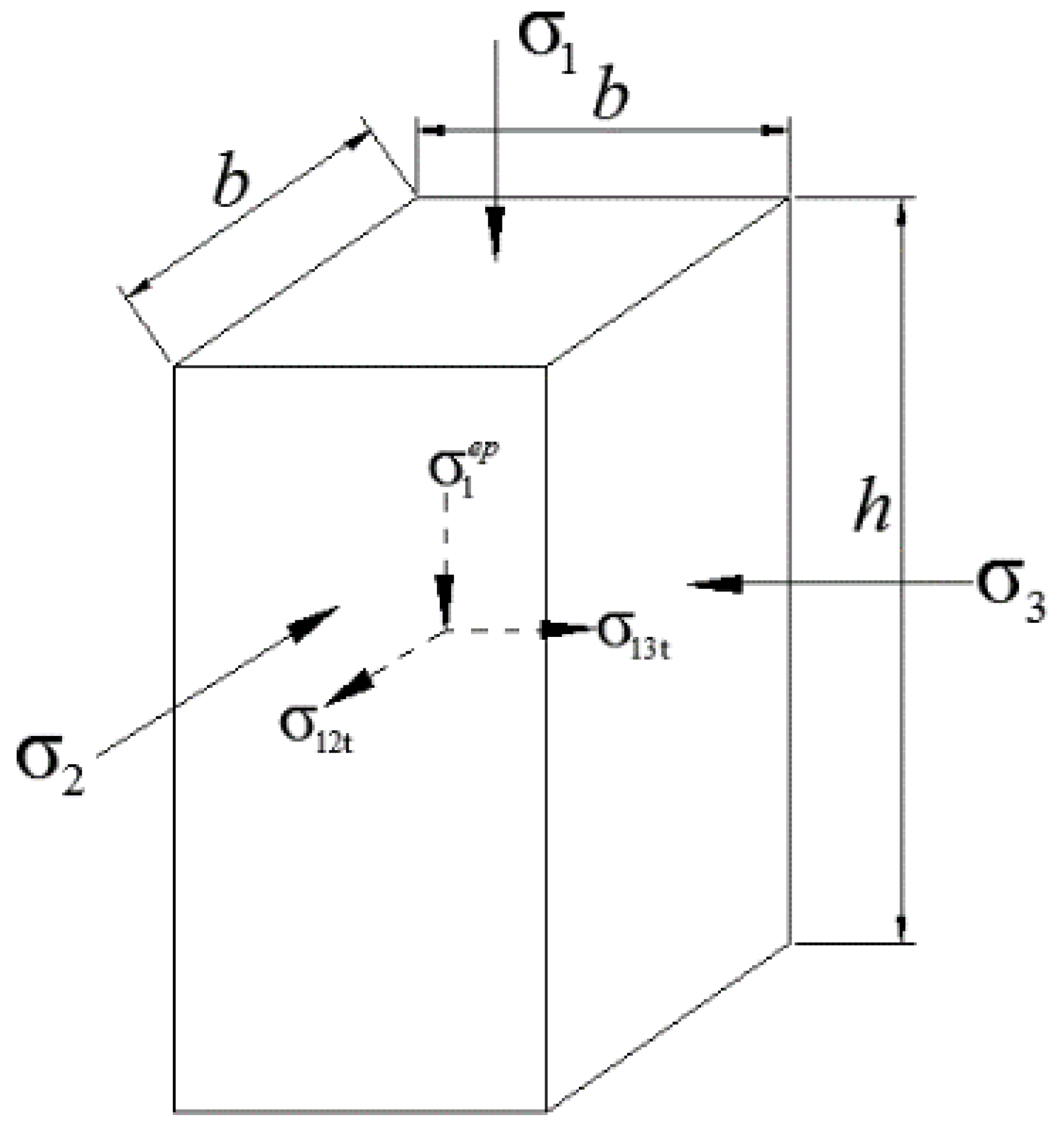

2. Measurement of the Stress Conversion Coefficient

2.1. Test Material

2.2. Experiment Content

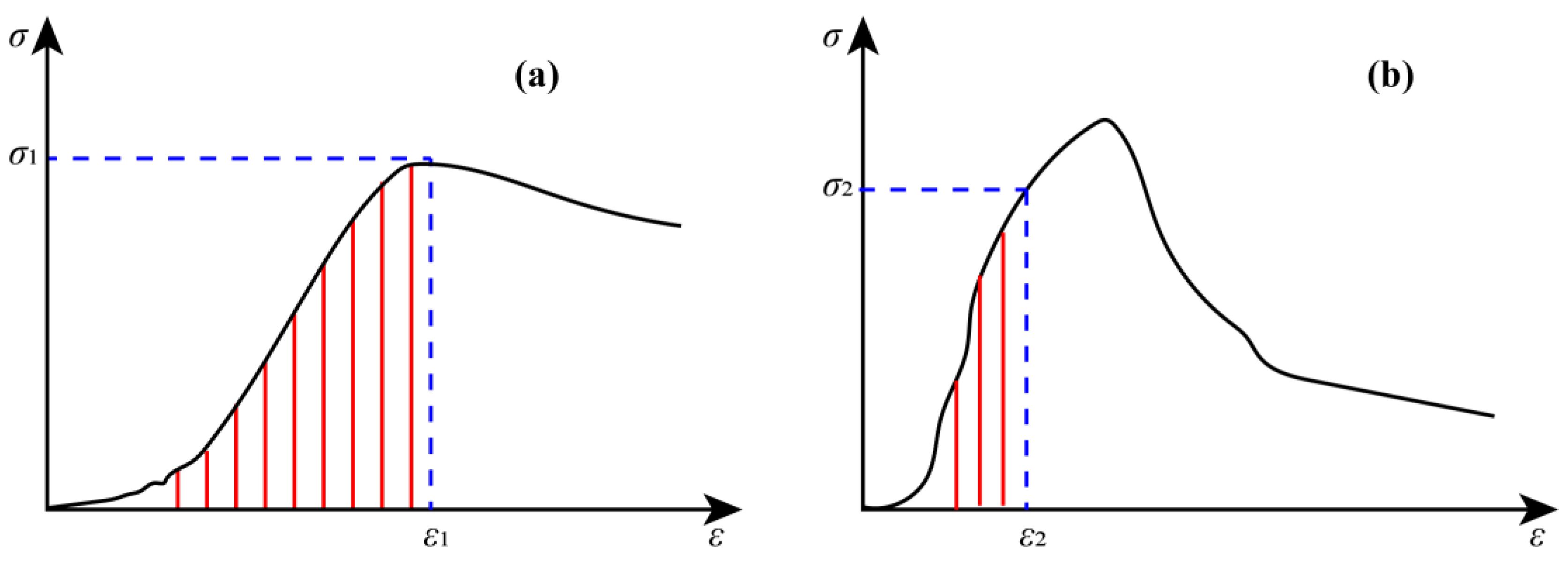

2.2.1. Definition of the Stress Conversion Coefficient

2.2.2. Methods of Measuring the Stress Conversion Coefficient

- (1)

- Uniaxial compression experiment

- (2)

- Tensile strain measuring system

- (3)

- Equivalent tensile test

3. Experimental Results and Discussion

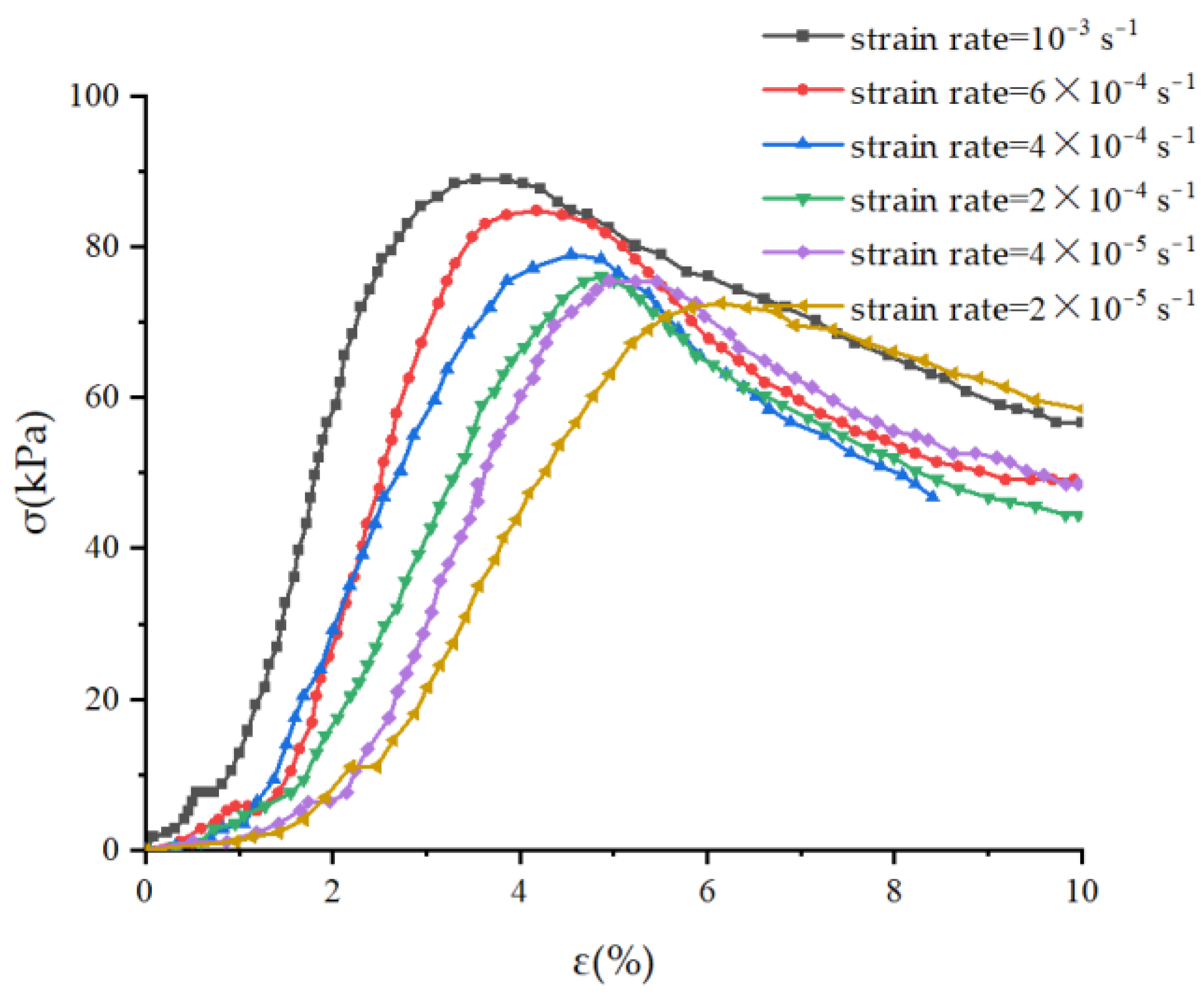

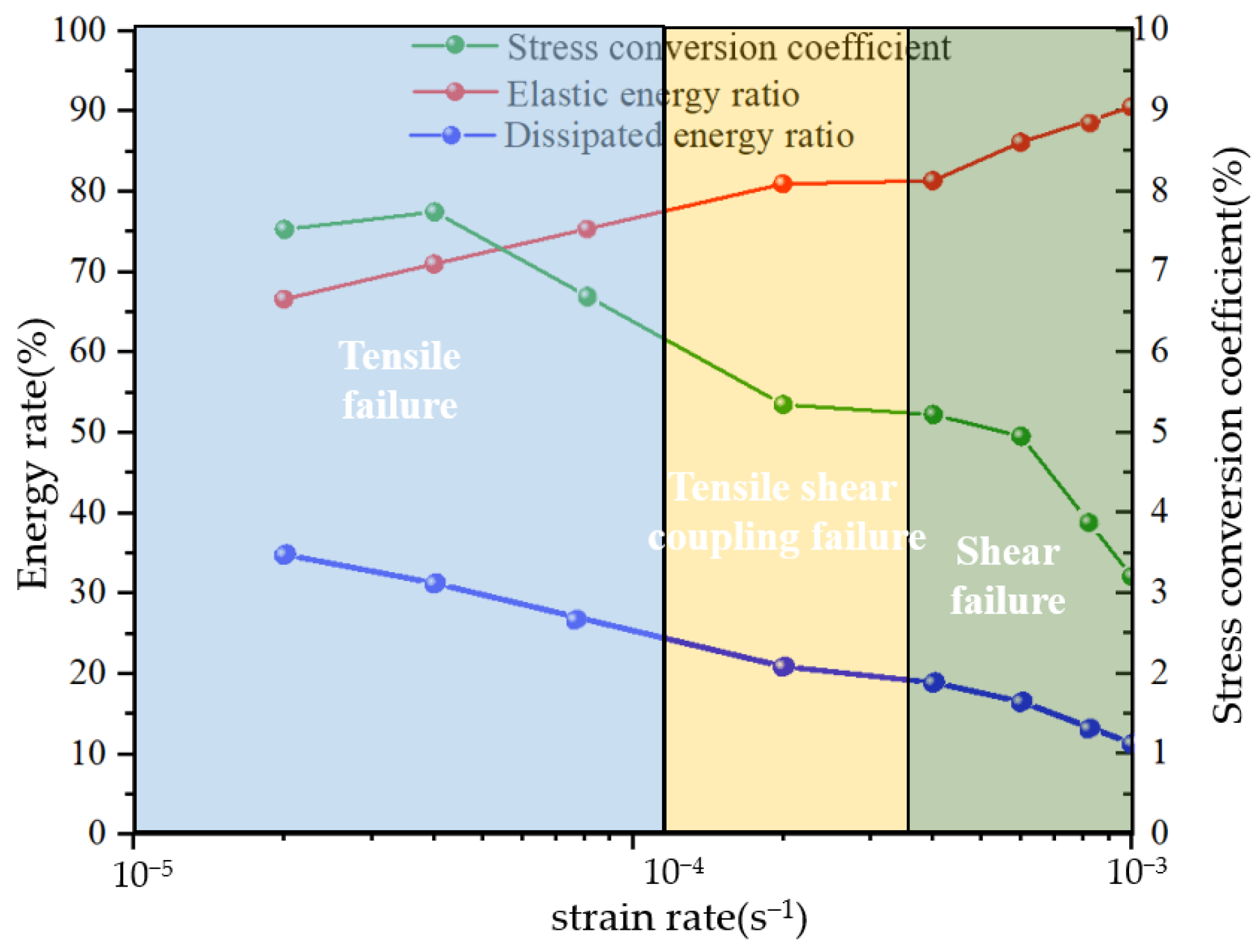

3.1. Effect of the Loading Rate on the Conversion Coefficient

3.2. Effect of Water Content on the Conversion Coefficient

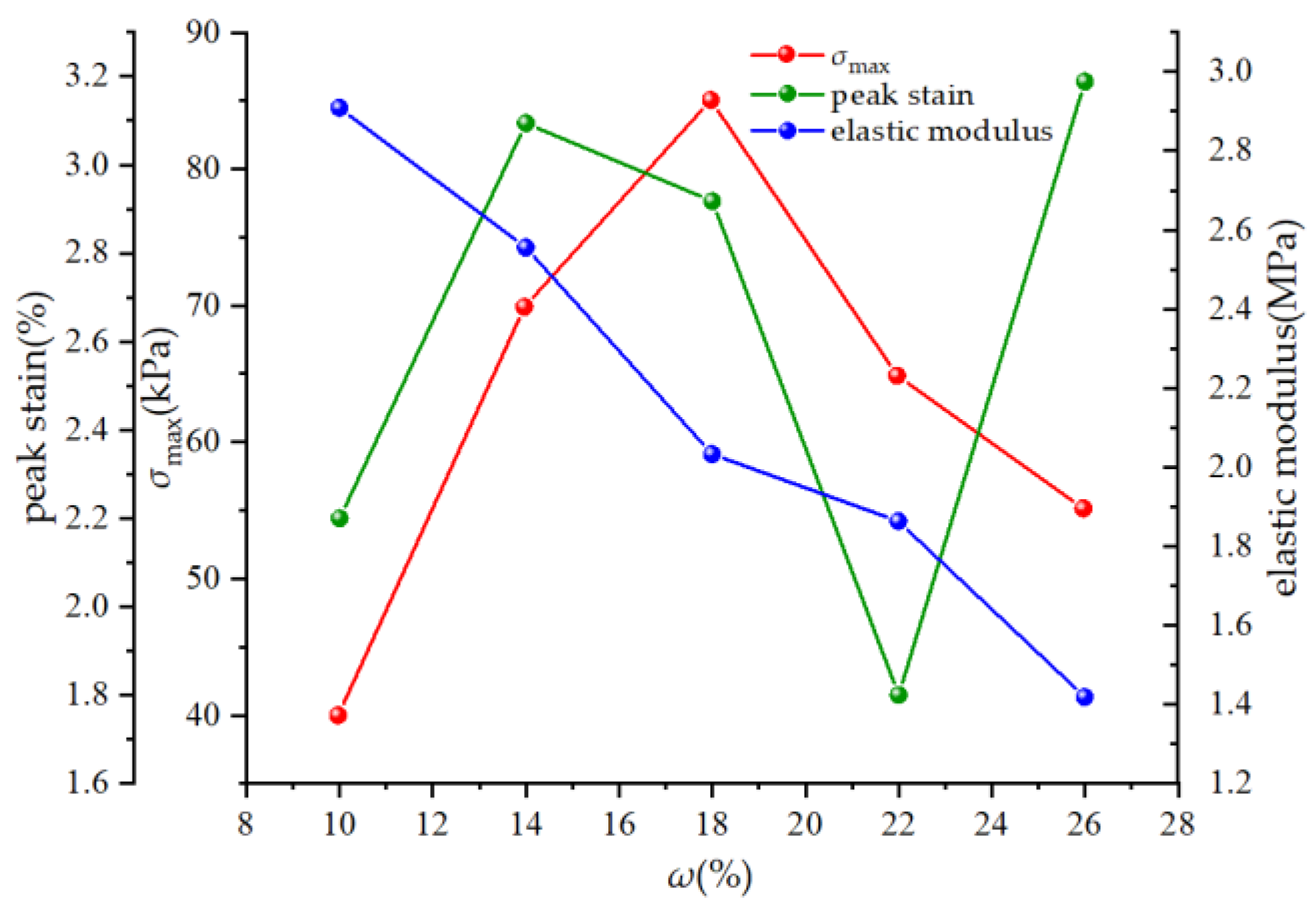

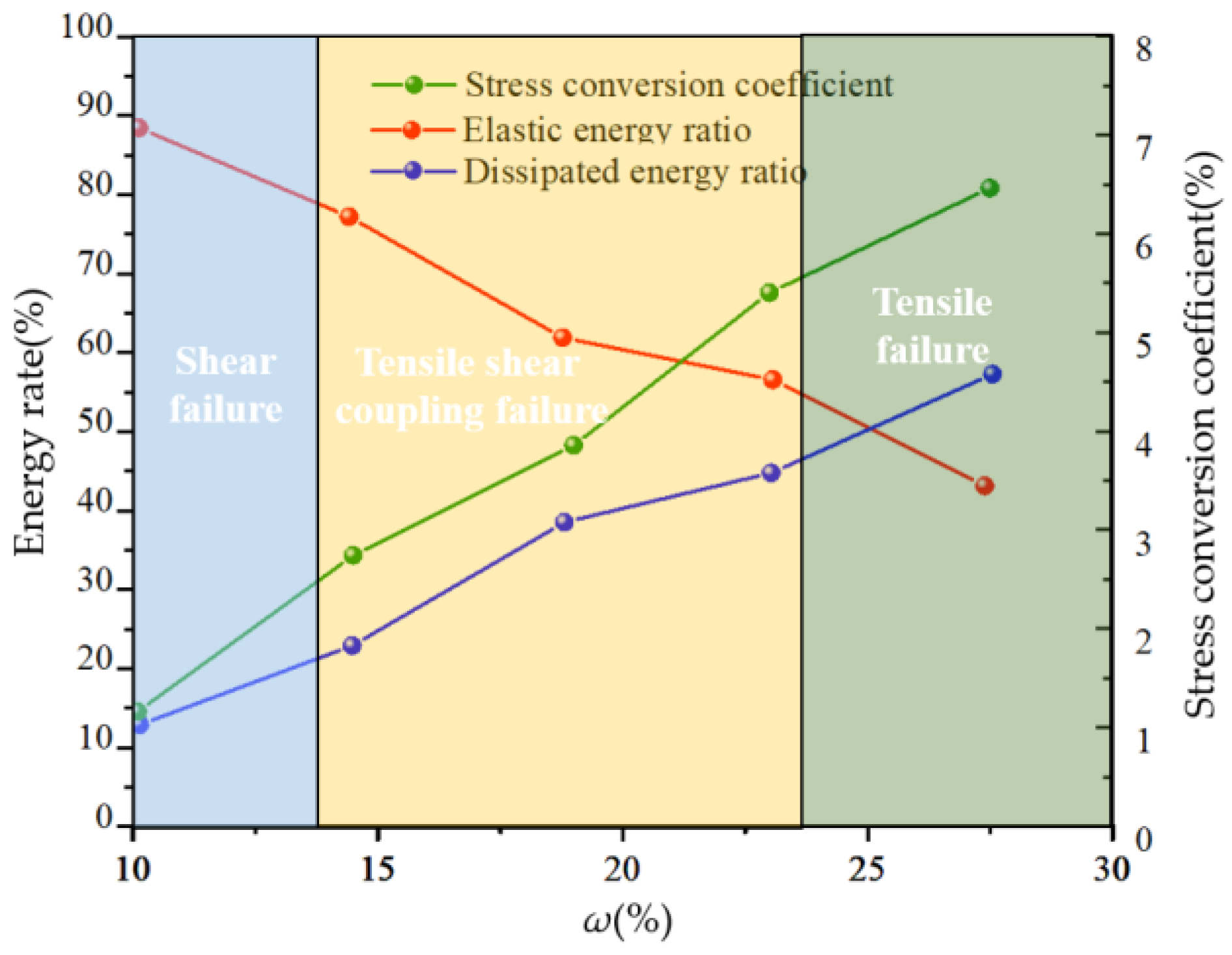

3.3. Effect of Water Content on Energy Conversion

4. Microstructure and Stress Transfer Mechanism of Compressed Soil

4.1. Microstructure Observation

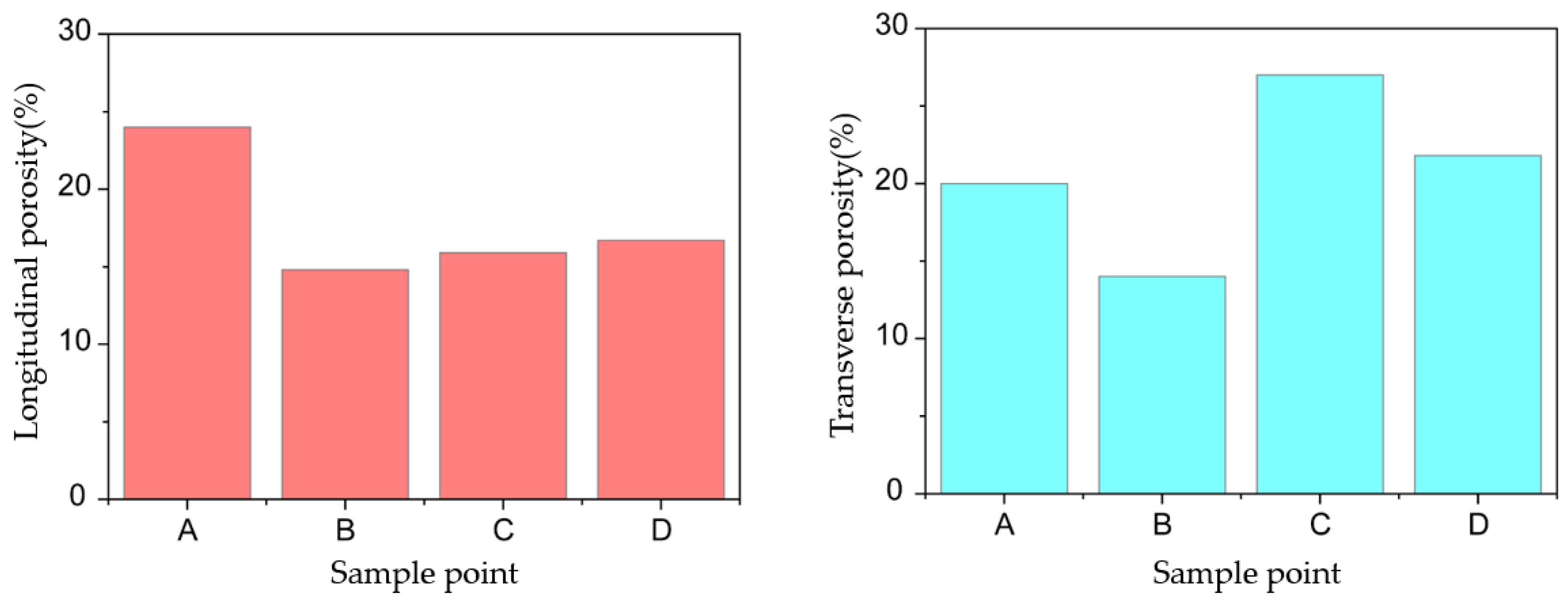

4.2. Microscopic Pore Structure Analysis

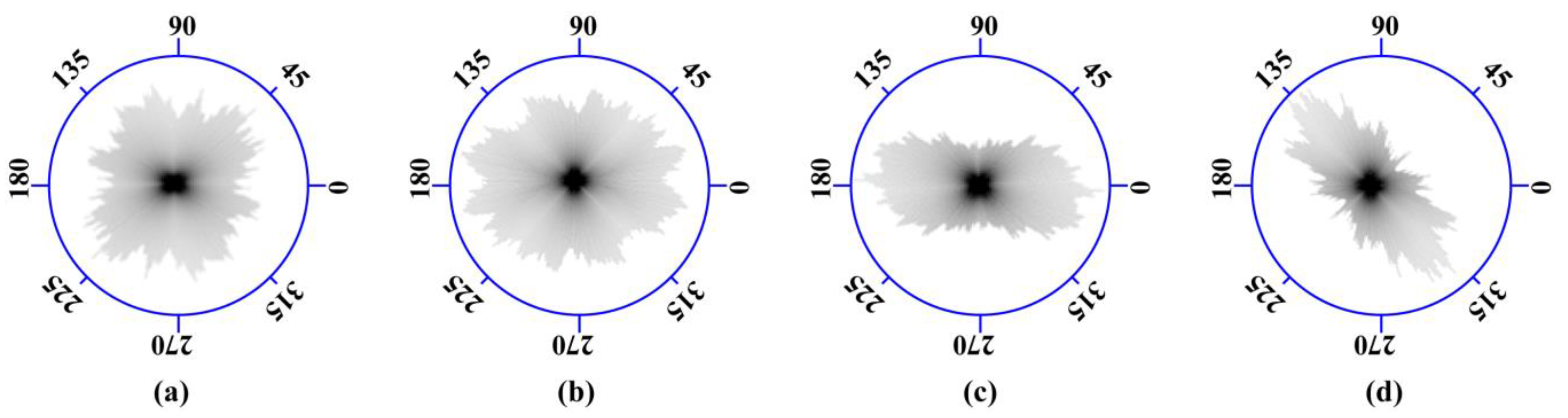

4.3. Analysis of Particle Arrangement Characteristics

4.4. Analysis of Stress Transfer Mechanism

- (1)

- If the mechanical property of the soil is relatively plastic and cementation force Ft still has a certain residual strength after a certain distance between the particles, the upper and lower soil particles will completely invade the middle soil particles via insertion such that the middle soil particles are extruded and retain their structure, resulting in local swelling (tension) failure within this area.

- (2)

- If the mechanical properties of the soil are brittle, when cementation force Ft reaches its tensile strength, the cementation of the soil particles will be completely broken, and the connection between 1–2, 3–4, and 2–5 will be broken. The upper soil particles invade the middle soil particles in the form of shear failure, resulting in local shear failure within this area.

5. Conclusions

- (1)

- The tensile stress generated in the soil under compression is affected by two factors: axial stress and the stress conversion coefficient. The stress conversion coefficient of soil under pressure is not constant, which is why the strength envelope of soil is a nonlinear envelope, such as Mohr’s envelope, rather than a straight Coulomb envelope. For the same type of soil, the value of the stress conversion coefficient changes with a change in stress states and soil properties. Among them, an increase in loading rate increases the elastic energy ratio of the soil mass and decreases the dissipative energy ratio, and the stress characteristics of soil mass are brittle, which results in a reduction in the stress conversion coefficient of the soil mass during the compression failure process; moreover, the soil mass changes from the tension failure (bulging failure) mode to the shear failure mode under a uniaxial state. However, an increase in soil water content causes a decrease in the elastic energy ratio of the soil and an increase in the dissipative energy ratio; the stress characteristics of soil exhibits more plastic behavior; the stress conversion coefficient increases; the soil changes from the shear failure mode to the tension failure (bulging failure) mode.

- (2)

- With an increase in loading rate, the peak stress increases gradually, the peak strain decreases gradually when the peak stress is reached, and the elastic modulus decreases gradually. However, with an increase in water content, only the elastic modulus of soil decreases monotonically, and the peak stress and strain of soil increase first and then decrease.

- (3)

- The tensile stress in the compressed soil is caused by the invasion and extrusion of soil particles. When the soil is under compression deformation, the soil particles in the upper layer of the internal soil particles invade the lower soil particles via insertion or shear force, and the lower soil particles are extruded, resulting in local tensile failure or local shear failure. In the compressed soil body, the distribution of tensile stress is not uniform, and tensile stress forms stress concentrations on the soil’s surface such that the soil on the surface of the sample is subjected to increased tensile stress than the soil inside the sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tang, L.S.; Wang, Y.X.; Sun, Y.L.; Chen, Y.; Zhao, Z.L. Review on the Failure Modes of Rock and Soil Mass under Compression and the Exploration about Constitutive Equations of Rock and Soil Mass. J. Adv. Civ. Eng. 2022, 2022, 7481767. [Google Scholar] [CrossRef]

- Tang, L.S.; Sang, H.T.; Song, J.; Luo, Z.G.; Sun, Y.L. Mechanical model for failure modes of rock and soil under compression. J. Trans. Nonferrous Met. Soc. China 2016, 26, 2711–2723. [Google Scholar] [CrossRef]

- Taylor, D.W. Fundamentals of Soil Mechanics; Wiley: New York, NY, USA, 1948. [Google Scholar]

- Ng, C.W.W.; Chiu, C.F. Laboratory study of loose saturated and unsaturated decomposed granitic soil. J. Geotech. Geoenvironmental Eng. 2003, 129, 550–559. [Google Scholar] [CrossRef]

- Luo, K.T.; Nie, Q.; Zhang, S.Y.; Liu, E.L. Investigation on artificially structured soils with initial stress-induced anisotropy. J. Rock Soil Mech. 2013, 34, 2815–2820. [Google Scholar] [CrossRef]

- Liu, W.L.; Tian, Z.H.; Lu, Y.; Xu, J.; Gong, Z.D.; Wu, Y.J. Study on triaxial compression characteristics of improved aeolian sand mixed with cement silt. J. Adv. Sci. Technol. Water Resour. 2023, 43, 51–57. [Google Scholar] [CrossRef]

- Timoshenko, S.P. History of Strength of Materials; McGrawHill: New York, NY, USA, 1953. [Google Scholar]

- Li, X.L.; Li, J.; Huang, H.; Li, L.B. Effect of loading rate splitting characteristics of weakly cemented sandstone. J. China Min. Mag. 2023, 32, 165–172. [Google Scholar] [CrossRef]

- Li, X.; Jiang, S.X.; Chen, Y.; Weng, S.X.; Wang, C.Q.; Chen, Z.B.; Guo, X.W.; Dai, M.L. Strength Influencing Factors of Sodium Carboxymethyl Cellulose Modified Soil. J. Water Resour. Archit. Eng. 2022, 20, 55–60. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Yu, Z.Q.; Cui, L.Z. Expermintal study on compressive behavior of cemented paste backfill material with different water contents. J. Coal Sci. Technol. 2022, 50, 219–224. [Google Scholar] [CrossRef]

- Lu, W.Y.; Liu, Q.; Qu, L.N.; Zhang, H.J. Study on coal crack propagation and failure mode with different moisture content under Uniaxial compression. J. Mine Autom. 2022, 48, 85–91. [Google Scholar] [CrossRef]

- Shikawa, T.; Fuku, S.; Nakamura, T.; Tokoro, T. Influence of water content on shear behavior of unsaturated fouled ballast. J. Procedia Eng. 2016, 143, 268–275. [Google Scholar] [CrossRef] [Green Version]

- Khalili, N.; Khabbaz, M.H. A unique relation-ship for the determination of the shear strength of unsaturated soils. J. Geotech. 1998, 48, 681–687. [Google Scholar] [CrossRef]

- Reto, S.; Harianto, R.; Hans, R.S. Controlling parameter for unsaturated soil property functions: Validated on the unsaturated shear strength. Can. Geotech. J. 2015, 52, 374–381. [Google Scholar] [CrossRef]

- Wang, H.Q.; Sun, J.L.; Li, D.W.; Yang, H.X.; Song, T. Experimental Study on Shear Strength of High Fill Loess under Different Moisture Content. J. Geotech. Eng. Tech. 2022, 36, 507–510. [Google Scholar] [CrossRef]

- Wu, D.Y.; Qu, B.B.; Li, J.F.; Zhao, J.H. Experimental study on variation law of shear strength of river dredged silt with water content. J. Port Waterw. Eng. 2022, 599 (Suppl. S2), 22–28. [Google Scholar] [CrossRef]

- Li, Z.Y. Expermental Study on Tensile Strength of Unsaturated Cohesive Soil. Master’s Thesis, Hubei University of Technology, Wuhan, China, 2021. [Google Scholar] [CrossRef]

- Tang, L.S.; Wang, H.; Sun, Y.L.; Liu, Q.X. Change of tensile strength of granite residual soil during drying and wetting. J. Rock Soil Mech. 2022, 43, 1749–1760. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, L.S.; Ye, Y.H.; Cheng, Z.H.; Zhou, Z.X. Effects of different chloride salts on granite residual soil: Properties and water–soil chemical interaction mechanisms. J. Soils Sediments 2023, 23, 1844–1856. [Google Scholar] [CrossRef]

- Lu, W. Mechanical Properties of Shear Strength of Unsaturated Granite Residual Soil in South China. Ph.D. Thesis, Sun Yat-sen University, Guangzhou, China, 2017. [Google Scholar]

| Void Ratio | Liquid Limit/% | Plasticity Index | Cohesion/kPa | Internal Friction Angle/(°) |

|---|---|---|---|---|

| 0.78 | 41.2 | 11.7 | 31.5 | 32.2 |

| Loading Rate | Strain Rate | Stress Dissipation Coefficient/% | Elastic Energy Ratio/% | ||||||

|---|---|---|---|---|---|---|---|---|---|

| mm/min | s-1 | Test Value | Mean Value | Test Value | Mean Value | ||||

| 0.3 | 2 × 10−5 | 33.55 | 31.53 | 37.52 | 34.2 | 66.45 | 68.47 | 62.48 | 65.8 |

| 0.6 | 4 × 10−5 | 28.03 | 29.53 | 31.96 | 29.84 | 71.97 | 70.47 | 68.04 | 70.16 |

| 1.5 | 2 × 10−4 | 19.08 | 19.20 | 22.49 | 20.26 | 80.92 | 80.80 | 77.51 | 79.74 |

| 3 | 4 × 10−4 | 17.46 | 17.94 | 19.59 | 18.33 | 82.54 | 82.06 | 80.41 | 81.67 |

| 10 | 6 × 10−4 | 14.37 | 13.82 | 17.46 | 15.22 | 85.63 | 86.18 | 82.54 | 84.78 |

| 15 | 10−3 | 9.79 | 10.34 | 11.18 | 10.44 | 90.21 | 89.66 | 88.82 | 89.56 |

| Strain Rate | Loading Rate | Total Energy | Stress Conversion Coefficient × 10−2 | Failure Mode | |

|---|---|---|---|---|---|

| s-1 | mm/min | J | Test Value | Mean Value | |

| 2 × 10−5 | 0.3 | 14.42 | 6.98 | 7.56 | Tensile failure |

| 16.11 | 7.46 | Tensile failure | |||

| 16.71 | 8.24 | Tensile failure | |||

| 4 × 10−5 | 0.6 | 14.85 | 7.41 | 7.72 | Tensile failure |

| 14.74 | 7.16 | Tensile failure | |||

| 16.95 | 8.59 | Tensile failure | |||

| 2 × 10−4 | 1.5 | 16.35 | 5.21 | 5.25 | Shear failure |

| 15.26 | 5.10 | Tensile failure | |||

| 16.44 | 5.44 | Shear failure | |||

| 4 × 10−4 | 3 | 16.84 | 4.90 | 5.18 | Shear failure |

| 16.99 | 5.06 | Shear failure | |||

| 17.01 | 5.58 | Tensile failure | |||

| 6 × 10−4 | 10 | 17.24 | 4.51 | 4.89 | Shear failure |

| 15.41 | 4.46 | Shear failure | |||

| 15.86 | 5.70 | Shear failure | |||

| 10−3 | 15 | 17.39 | 2.84 | 3.15 | Shear failure |

| 16.75 | 2.95 | Shear failure | |||

| 17.38 | 3.66 | Shear failure | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tang, L.-S.; Wang, Y.-X. Study on the Internal Mechanics and Energy Characteristics of Soil under Different Failure Modes. Appl. Sci. 2023, 13, 8648. https://doi.org/10.3390/app13158648

Tang L-S, Wang Y-X. Study on the Internal Mechanics and Energy Characteristics of Soil under Different Failure Modes. Applied Sciences. 2023; 13(15):8648. https://doi.org/10.3390/app13158648

Chicago/Turabian StyleTang, Lian-Sheng, and Yu-Xi Wang. 2023. "Study on the Internal Mechanics and Energy Characteristics of Soil under Different Failure Modes" Applied Sciences 13, no. 15: 8648. https://doi.org/10.3390/app13158648

APA StyleTang, L.-S., & Wang, Y.-X. (2023). Study on the Internal Mechanics and Energy Characteristics of Soil under Different Failure Modes. Applied Sciences, 13(15), 8648. https://doi.org/10.3390/app13158648