Mechanical Properties and Microscopic Study of Steel Slag–Fly Ash-Solidified Loess under Alkaline Conditions

Abstract

:1. Introduction

2. Materials and Methods

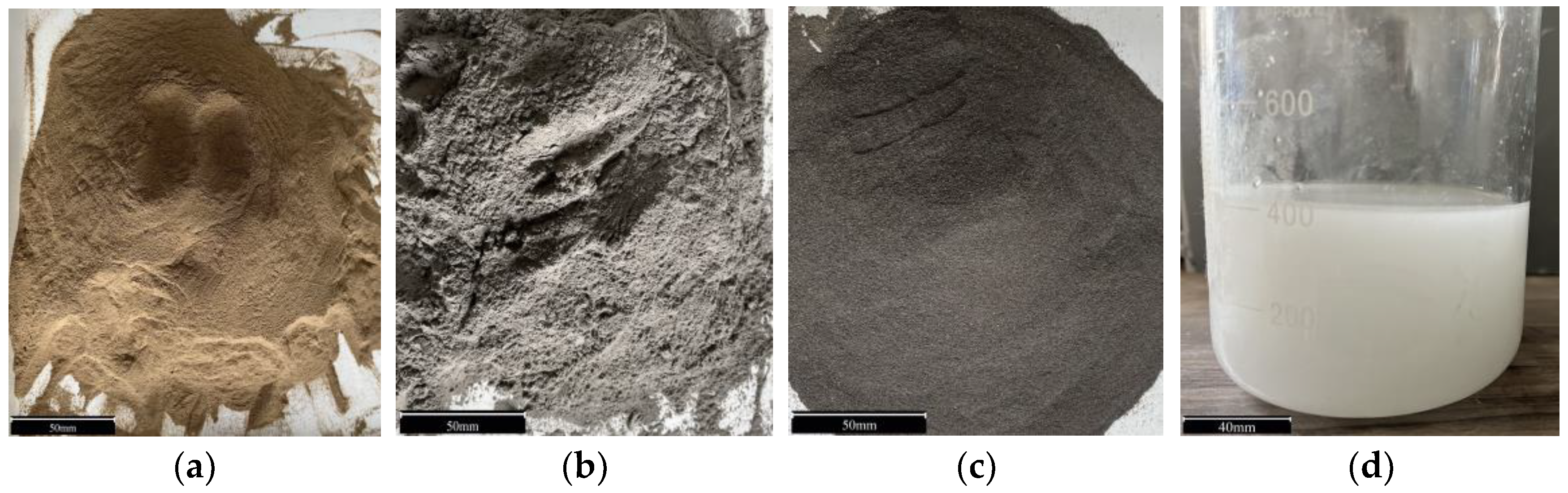

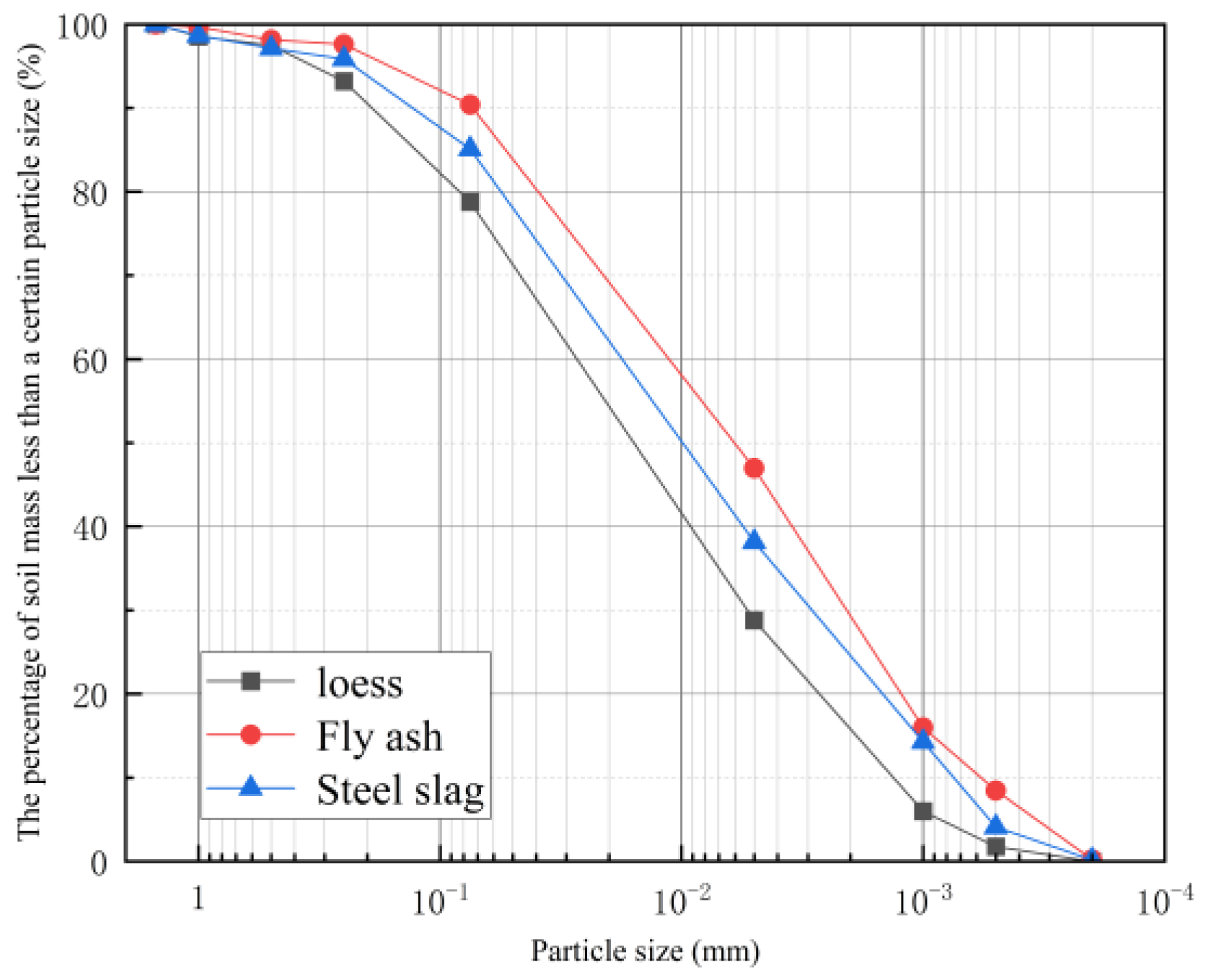

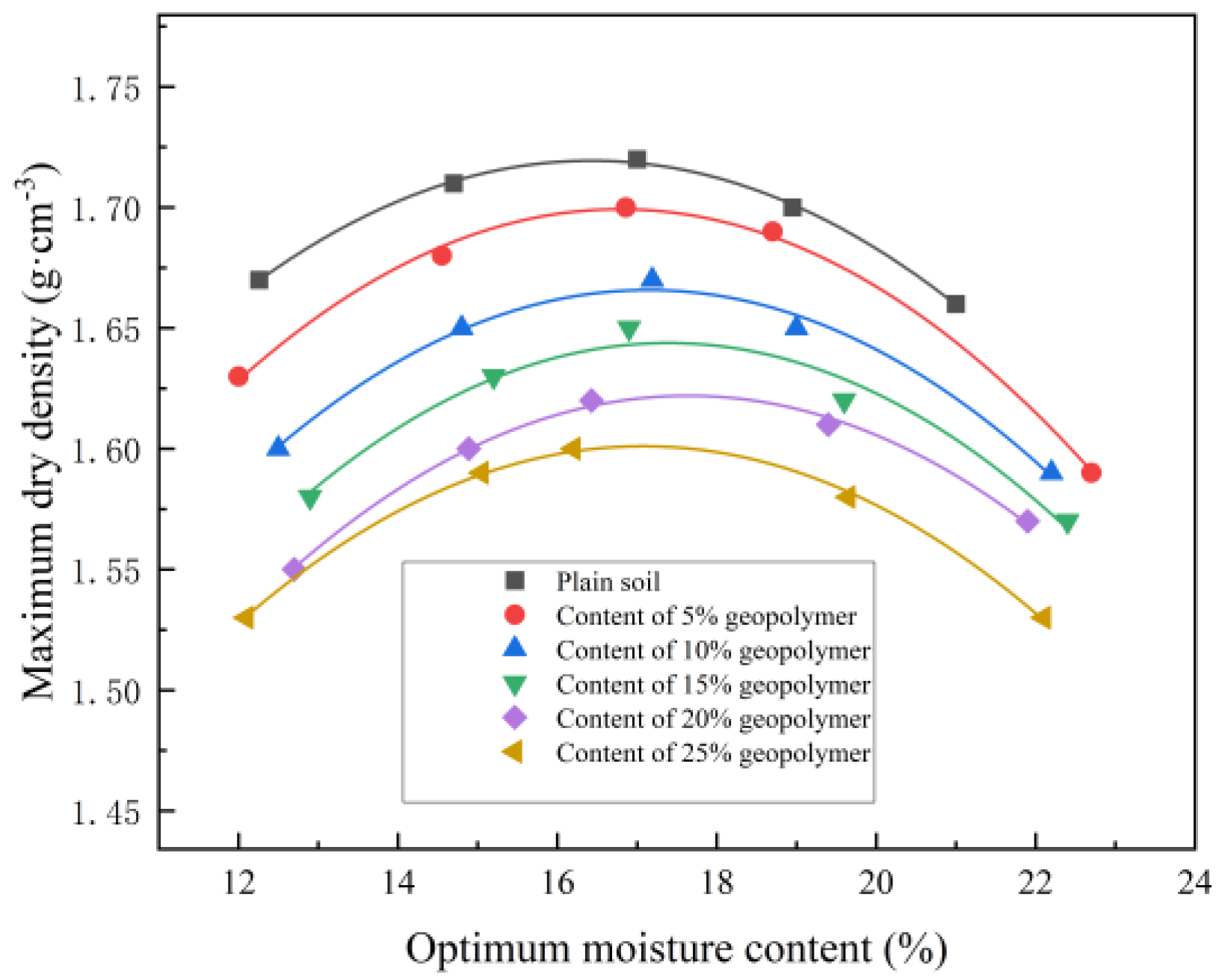

2.1. Test Material

2.2. Sample Preparation

2.3. Test Scheme

2.3.1. Direct Shear Test

2.3.2. Unconfined Compressive Strength Test

2.3.3. Disintegration Test

2.3.4. XRD and SEM Tests

3. Analysis and Discussion of Test Results

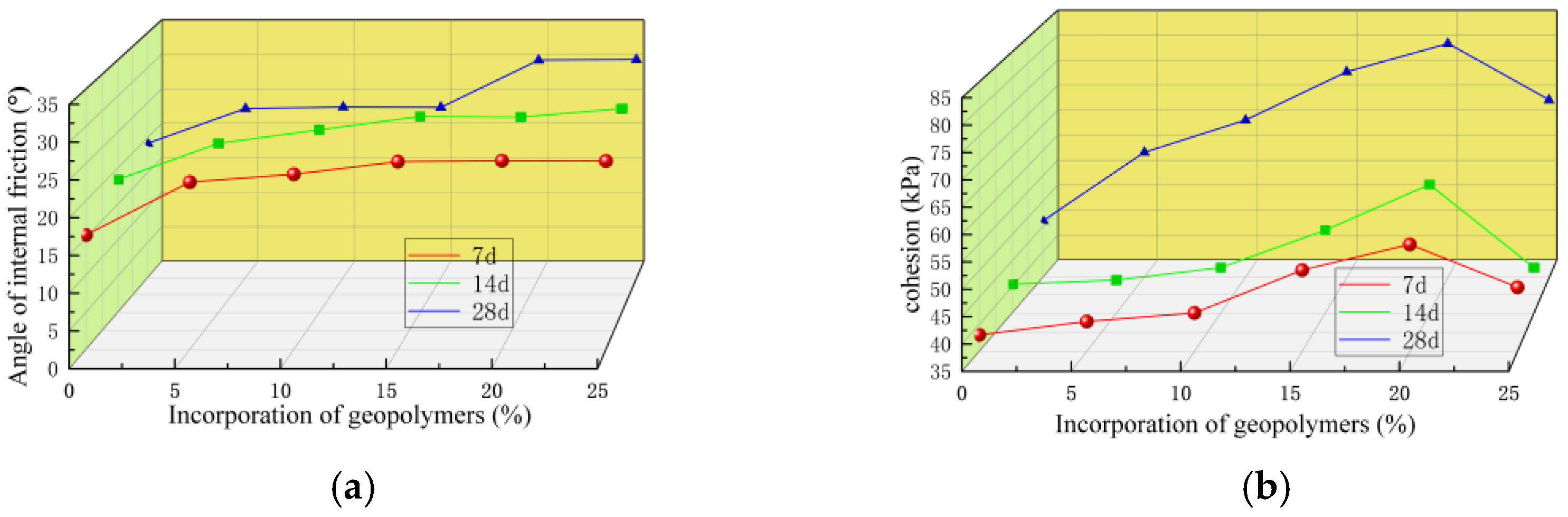

3.1. Analysis of Internal Friction Angle and Cohesive Force Results

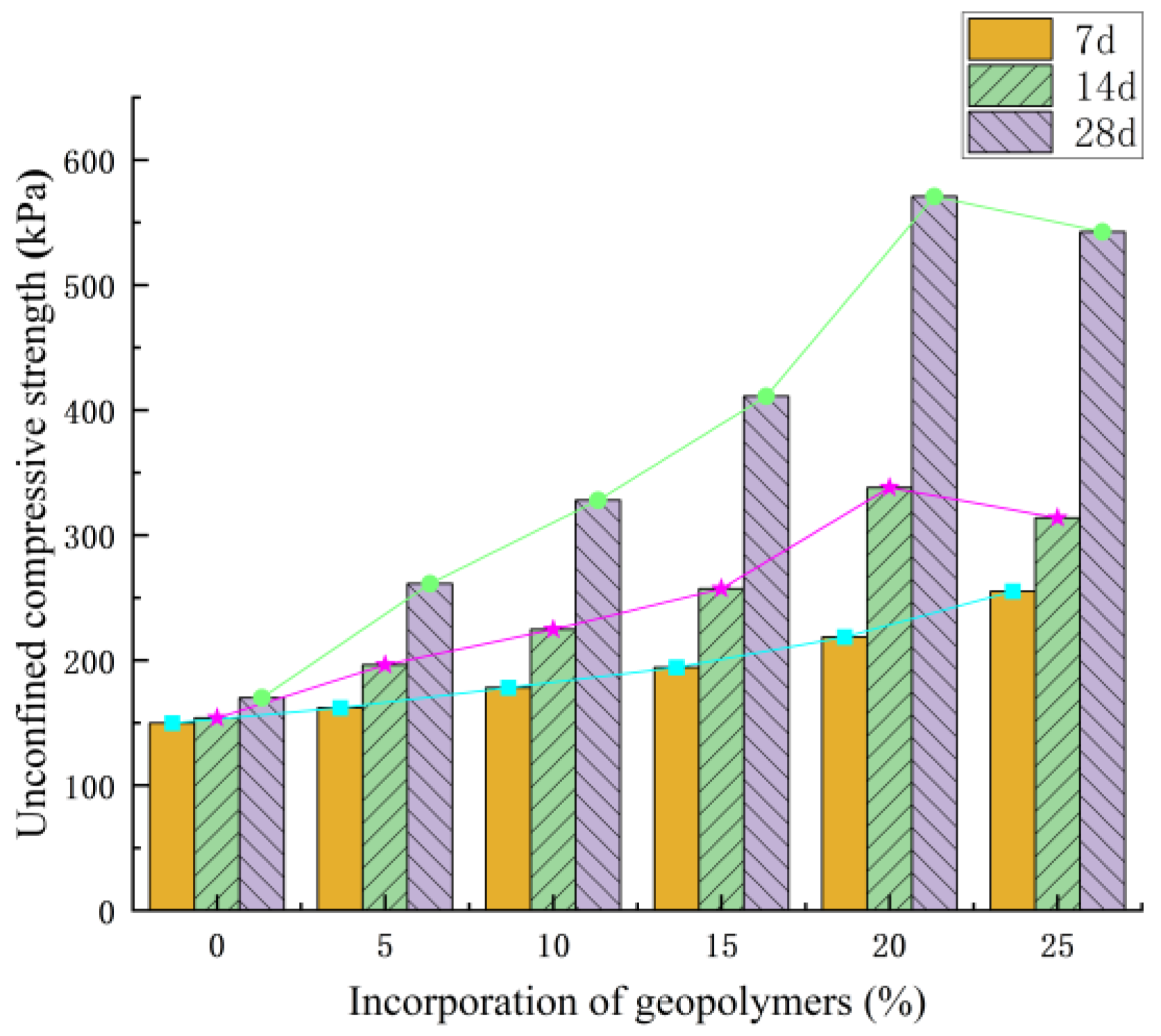

3.2. Analysis of Unconfined Compressive Strength Results

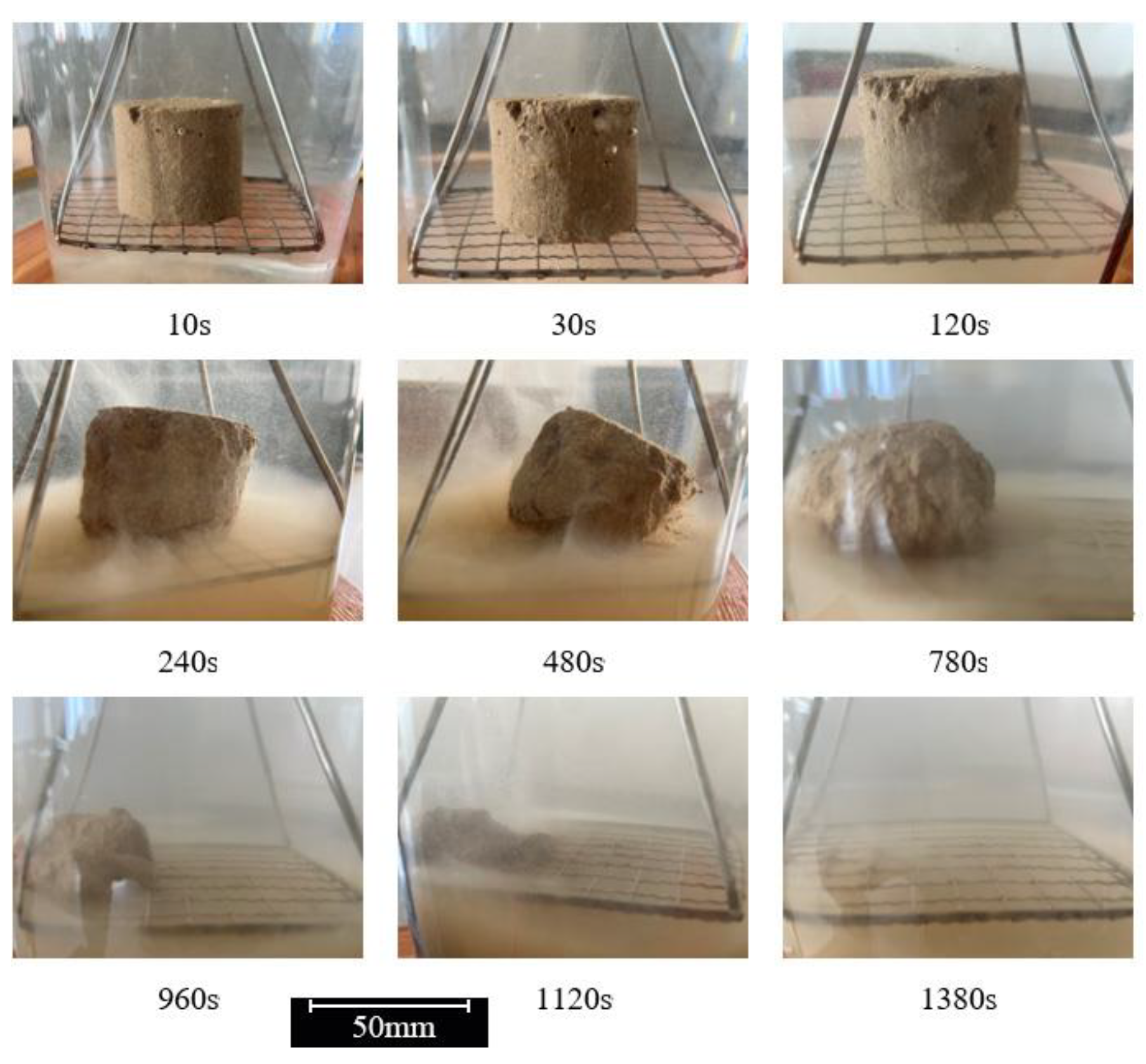

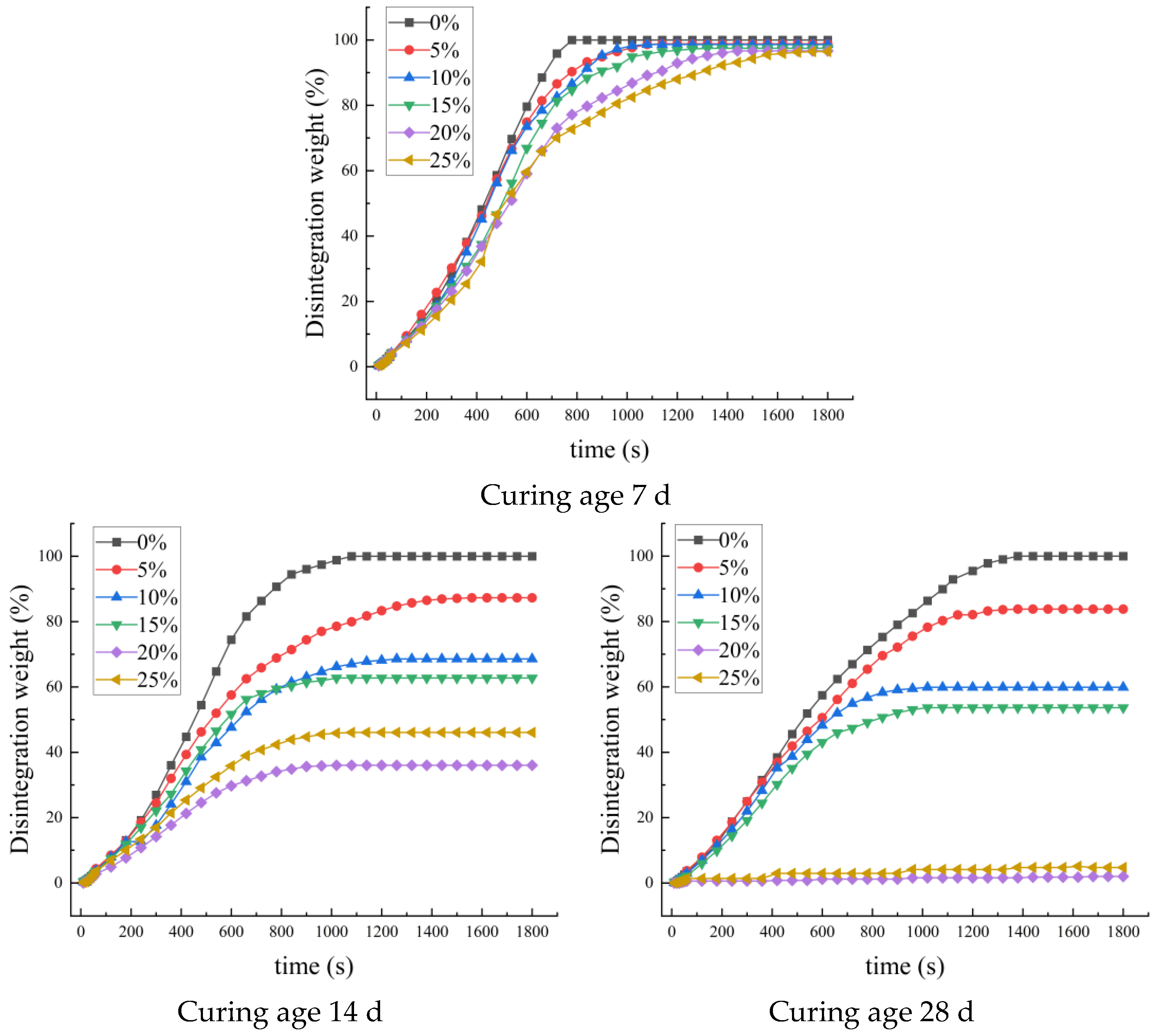

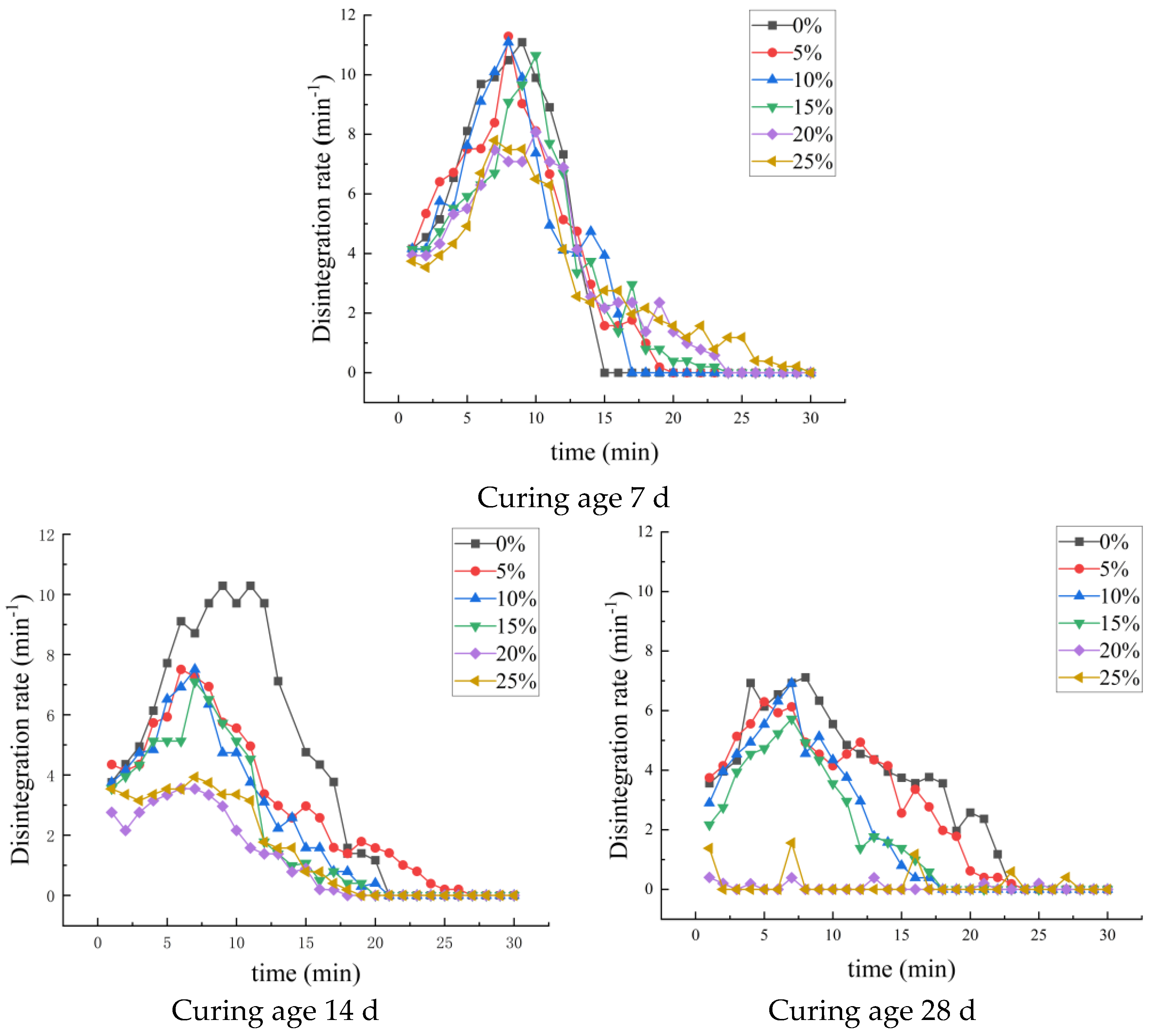

3.3. Analysis of Disintegration Test Results

3.4. XRD and SEM Results

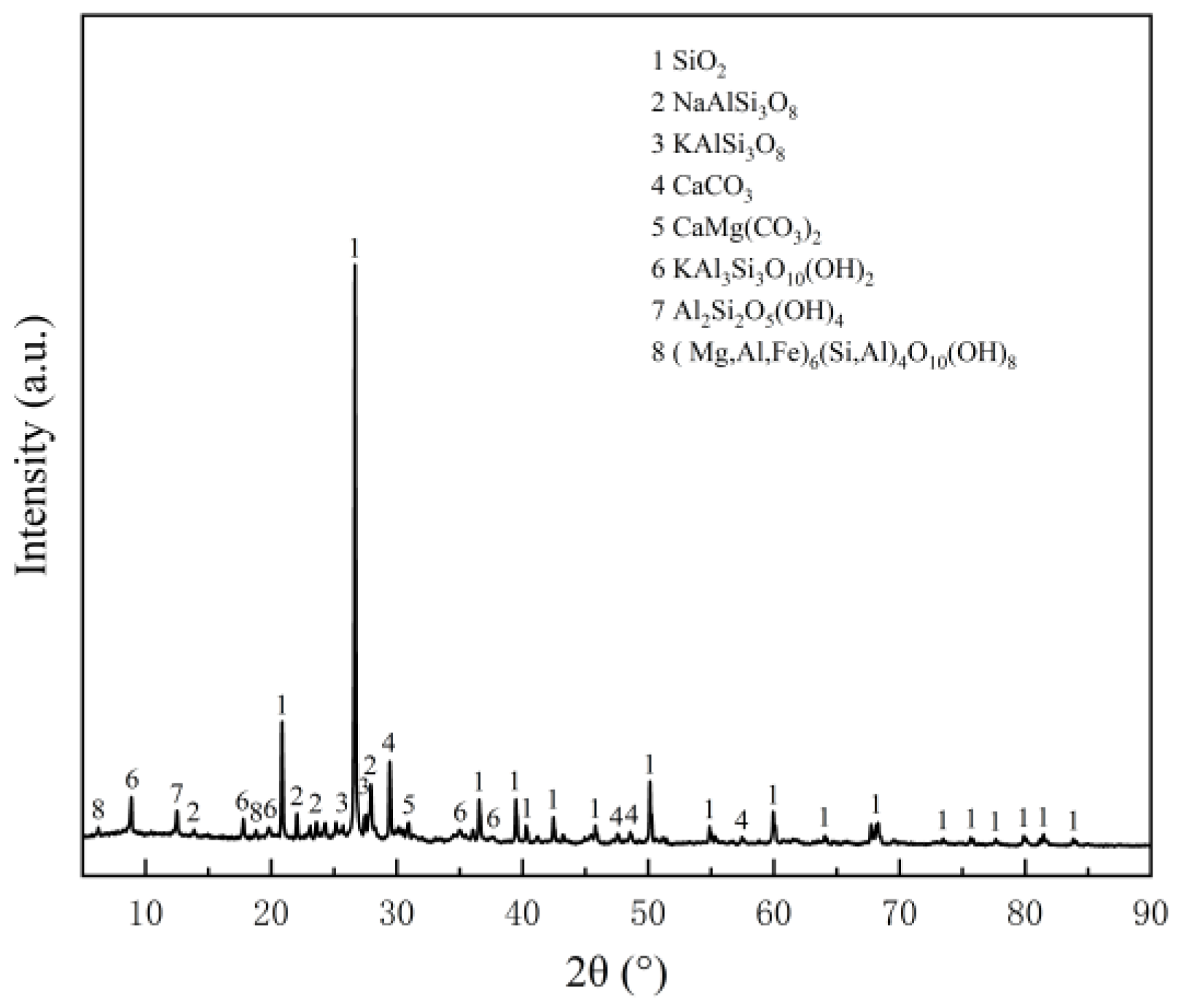

3.4.1. XRD X-ray Diffraction Analysis

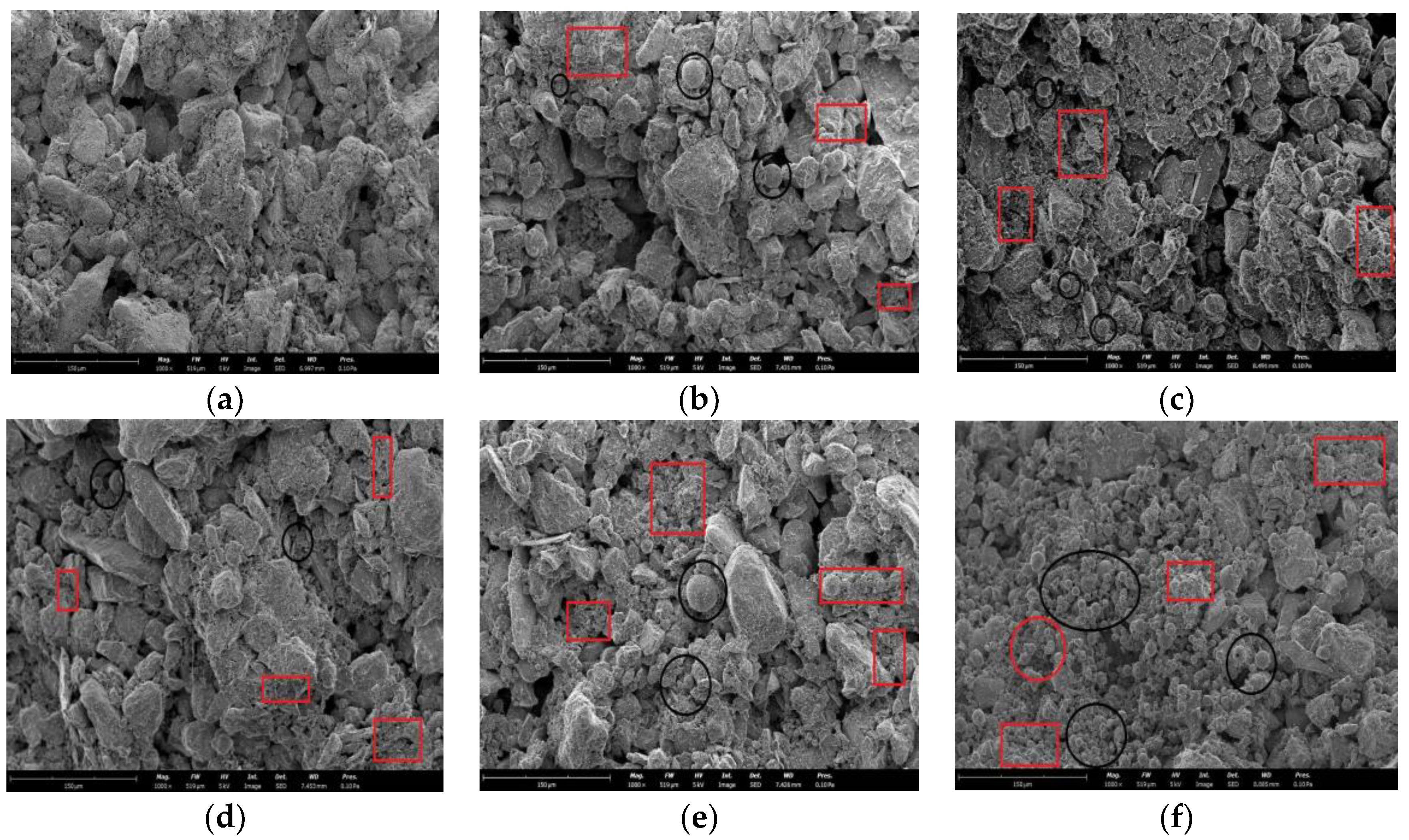

3.4.2. SEM Analysis

4. Conclusions

- (1)

- The addition of fly ash–steel slag geopolymer as an admixture to loess has been found to effectively enhance the mechanical properties of the solidified soil and improve its internal structure. After a curing period of 28 days, the largest cohesion value of the solidified soil, reaching 81.09 kPa, is achieved with the addition of 20% geopolymer, which is 75.32% higher than that of plain soil. The internal friction angle is also increased to 31.12°, surpassing that of plain soil by 62.08%. Furthermore, the unconfined compressive strength of the consolidated soil is enhanced to 570.86 kPa, which is 236% higher than that of the plain soil. Incorporating 20% geopolymer into the stabilized soil not only effectively improves its internal friction angle and cohesion but also aligns with the principles of green environmental protection and economic rationality.

- (2)

- Compared to remolded loess, the hydration of geopolymer becomes better with an increase in curing age. This leads to an effective reduction in the disintegration of solidified soil. For instance, when the geopolymer content is 20%, the solidified soil shows minimal disintegration in water even after 300 min. In scenarios involving rainfall and water accumulation, the addition of geopolymers can effectively decrease the likelihood of loess collapse, thereby reducing the occurrence of engineering accidents.

- (3)

- The analysis of XRD composition and SEM structure reveals that under the alkaline activation condition of a water glass solution, steel slag and fly ash exhibit synergistic effects. Steel slag powder releases a significant amount of Ca2+ ions, which then combine with the silicon (aluminum) oxygen tetrahedron formed by the hydration process in fly ash. This combination results in the formation of amorphous gels such as calcium silicate hydrate (C-S-H) and calcium aluminosilicate hydrate (C-A-S-H), which effectively fill the pores in loess particles. As the curing time increases, the hydration products of geopolymers become more abundant, and the gelled substances of C-S-H and C-A-S-H are more plentiful. Consequently, the geopolymer vitreous body becomes enveloped by C-S-H and C-A-S-H gelling substances, effectively filling the pores and creating a more compact microstructure. This ultimately enhances the mechanical properties of the solidified soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, P.P.; Zhang, M.S.; Jia, J.; Cheng, X.J.; Zhu, L.F.; Xue, Q.; Wang, J.Y. Progress of geological hazard investigation in loess region of western China. Northwest Geol. 2022, 55, 96–107. [Google Scholar]

- Zhang, M.S.; Li, T.L. Study on induced factors and formation mechanism of loess landslide. J. Eng. Geol. 2011, 19, 530–540. [Google Scholar]

- Li, C.J. Road construction technology and innovative practice of special soil sections. Eng. Constr. Des. 2022, 12, 219–221. [Google Scholar]

- Wang, Q.; Liu, Z.Z.; Wang, L.M.; Zhong, X.M.; Su, Y.Q.; Ma, H.P. Research progress and prospect of seismic treatment technology of loess foundation. J. Disaster Prev. Mitig. Eng. 2021, 41, 1366–1381. [Google Scholar]

- Zhou, J.; Zhang, S.F.; Jia, M.C.; Wang, G.Y. Research status of dynamic compaction theory and the latest technical progress. Undergr. Space Eng. J. 2006, 2, 510–516. [Google Scholar]

- Feng, S.J.; Du, F.L.; Shi, Z.M.; Shui, W.H.; Tan, K. Field study on the reinforcement of collapsible loess using dynamic compaction. Eng. Geol. 2015, 185, 105–115. [Google Scholar] [CrossRef]

- Wu, W.B.; Yang, Z.J.; Liu, X.; Zhang, Y.P.; Liu, H.; Hesham, E.N.M.; Xu, M.J.; Mei, G.X. Horizontal dynamic response of pile in unsaturated soil considering its construction disturbance effect. Ocean Eng. 2022, 245, 110483. [Google Scholar] [CrossRef]

- Wang, S.J.; Han, W.F.; Wang, Y.M. Experimental study on loess reinforced by LD rock-soil cementing agent. J. Rock Mech. Eng. 2003, 22, 2888–2893. [Google Scholar]

- Peng, B.; Li, W.Y.; Dai, J.L. Study on soil reinforced by liquid curing agent. J. Xi’an Univ. Highw. Commun. 2001, 21, 15–18. [Google Scholar]

- Wang, J.F.; Fu, H.Y.; Yan, X.T.; Wang, L.; Wang, P.C. Research status of steel slag comprehensive utilization. China Nonferr. Metall. 2021, 50, 77–82. [Google Scholar]

- Zhao, L.J.; Zhang, F. Comprehensive utilization and development prospect of steel slag resources. Mater. Rev. 2020, 34, 1319–1322, 1333. [Google Scholar]

- Editorial Department of China Journal of Highway and Transport. Review of academic research on pavement engineering in China. China J. Highw. Transp. 2020, 33, 1–66. [Google Scholar]

- Yu, C.S.; Zhang, L.L.; Zheng, D.W.; Yang, F.H.; Wang, Q.G.; Wu, W.T.; Wang, C.X.; Cang, D.Q. Research and application progress of solid waste base polymer. Sci. China Tech. Sci. 2022, 52, 529–546. [Google Scholar]

- Phummiphan, I.; Horpibulsuk, S.; Rachan, R.; Arulrajah, A.; Shen, S.L.; Chindaprasirt, P. High calcium fly ash geopolymer stabilized lateritic soil and granulated blast furnace slag blends as a pavement base material. J. Hazard. Mater. 2018, 341, 257–267. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Long, W.J.; Wu, Z.R.; Khayat, K.H.; Wei, J.J.; Dong, B.Q.; Xing, F.; Zhang, J.R. Design, dynamic performance and ecological efficiency of fiber-reinforced mortars with different binder systems: Ordinary Portland cement, limestone calcined clay cement and alkali-activated slag. J. Clean. Prod. 2022, 337, 130478. [Google Scholar] [CrossRef]

- Long, W.J.; Wei, J.J.; Gu, Y.C.; Xing, F. Research on dynamic mechanical properties of alkali activated slag concrete under temperature-loads coupling effects. Constr. Build. Mater. 2017, 154, 687–696. [Google Scholar] [CrossRef]

- Long, W.J.; Li, H.D.; Wei, J.J.; Xing, F.; Han, N.X. Sustainable use of recycled crumb rubbers in eco-friendly alkali activated slag mortar: Dynamic mechanical properties. J. Clean. Prod. 2018, 204, 1004–1015. [Google Scholar] [CrossRef]

- Xu, Y.H.; Lu, W.X.; Wang, X.J.; Shao, X. Research status and development of activated steel slag. J. Shanghai Univ. Nat. Sci. Ed. 2004, 10, 91–95. [Google Scholar]

- Cui, C.Y.; Yu, C.Y.; Zhao, J.Y.; Zheng, J.J. Steel Slag/Precarbonated Steel Slag as a Partial Substitute for Portland Cement: Effect on the Mechanical Properties and Microstructure of Stabilized Soils. KSCE J. Civ. Eng. 2022, 26, 3803–3814. [Google Scholar] [CrossRef]

- Long, W.J.; Zhang, X.H.; Xie, J.; Kou, S.C.; Luo, Q.L.; Wei, J.J. Recycling of waste cathode ray tube glass through fly ash-slag geopolymer mortar. Constr. Build. Mater. 2022, 322, 126454. [Google Scholar] [CrossRef]

- Syahril, S.; Somantri, A.K.; Haziri, A.A. Study of stabilized soil clay soil characteristics using volcanic ash and tailing as subgrade layers. IOP Conf. Ser. Mater. Sci. Eng. 2020, 830, 022043. [Google Scholar] [CrossRef]

- Cristelo, N.; Glendinning, S.; Pinto, A.T. Deep soft soil improvement by alkaline activation. Proc. Inst. Civ. Eng. Ground Improv. 2011, 164, 73–82. [Google Scholar] [CrossRef] [Green Version]

- Liu, Z.; Cai, C.S.; Liu, F.Y.; Fan, F.H. Feasibility study of loess stabilization with fly ash-based geopolymer. J. Mater. Civ. Eng. 2016, 28, 04016003. [Google Scholar] [CrossRef]

- Wu, Y.K.; Shi, K.J.; Hu, X.S.; Han, T.; Yu, J.L.; Li, D.D. Experimental study on strength deterioration of cement solidified soil under seawater erosion. Chin. J. Rock Soil Eng. 2019, 41, 1014–1022. [Google Scholar]

- Wu, Y.K.; Hu, X.S.; Hu, R.; Shi, Y.B.; Han, T.; Yu, J.L. Experimental study of steel slag powder excited by caustic soda in silty soil. Chin. J. Geotech. Eng. 2017, 39, 2187–2194. [Google Scholar]

- Deng, Y.F.; Zhao, Y.; Liu, Q.W.; Gu, X.Y.; Cha, F.S.; Zhu, C.D. Silicon and composite excitation of Steel Slag and its Application to soft soil solidification. China J. Highw. Transp. 2018, 31, 11–20. [Google Scholar]

- Cao, W.; Yi, Y.R.; Ma, Z.; Wang, L.; Li, T.T.; Li, S. Experimental study on compressive strength of alkali excited fly Ash and steel slag geopolymer. Environ. Sci. Technol. 2014, 37, 205–208. [Google Scholar]

- Tong, G.Q.; Zhang, W.Y.; Gao, Y.T.; Tang, X.Y. Study on mechanical properties and microscopic mechanism of alkali excited fly Ash polymers. Mater. Rev. 2022, 36, 129–134. [Google Scholar]

- Zhao, Y.X.; Xiang, J.R.; Lv, Q.F.; Shan, X.K.; Chen, Y. Effects of alkali activators on engineering characteristics of geopolymer solidified loess. J. Beijing Univ. Technol. 2021, 47, 636–643. [Google Scholar]

- Li, M.; Wang, Q.; Yang, J.D.; Guo, X.L.; Zhou, W.J. Strength and mechanism of carbonated solidified clay with steel slag curing agent. KSCE J. Civ. Eng. 2021, 25, 805–821. [Google Scholar] [CrossRef]

- Zhou, M.K.; Cheng, X.; Chen, X. Studies on the volumetric stability and mechanical properties of cement-fly-ash-stabilized steel slag. Materials 2021, 14, 495. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.S.; Tao, H.Z.; Tu, C.H. Study on activation method of fly Ash in Steel Slag. J. Wuhan Univ. Technol. 2001, 23, 4–7. [Google Scholar]

- Ministry of Transport. Highway Geotechnical Test Code; Standards Press of China: Beijing, China, 2020.

- Hou, Y.F.; Wang, D.M.; Li, Q.; Lu, H.B. Effect of water glass properties on fly ash based mineral polymer. J. Chin. Silic. 2008, 36, 61–64, 68. [Google Scholar]

- Jiang, Y.; Jia, L.J.; Wen, M.Y.; Niu, Y.H. Preparation of alkali excited fly ash/steel slag cementifier. Bull. Chin. Ceram. 2019, 38, 2152–2156, 2161. [Google Scholar]

- Wang, H.S. Study on Durability of Sulphate Soil under Freeze-Thawing Dry-Wet Action; Lanzhou University: Gansu, China, 2016. [Google Scholar]

- Lv, Q.F.; Wu, Z.M.; Wang, S.X.; Sun, Z.Z. Study on the mechanism of temperature modified sodium silicate curing loess. Rock Soil Mech. 2013, 34, 1293–1298. [Google Scholar]

- Darshan, C.S.; Sitaram, N. SEM and XRD investigations on lithomargic clay stabilized using granulated blast furnace slag and cement. Int. J. Geotech. Eng. 2019, 13, 615–629. [Google Scholar]

- Li, S.J.; Chang, L.J. Mechanical properties and micro-mechanism of loess-like saline soil solidified by recycled micro-powder. China Powder Technol. 2022, 28, 30–39. [Google Scholar]

- Wang, J.L.; Wang, X.; Li, J.D.; Zhang, Y.J.; Jiang, D.J.; Liu, D.R.; Li, X. The mechanism of the change of physical and mechanical properties of the test loess reinforced by F1 ion curing agent. Mater. Bull. 2021, 35, 8070–8075. [Google Scholar]

- Tian, W.; Li, T.; Jia, N.; He, L.; Zhang, X.K.; Zhang, X.D. Study on the performance of EICP solution solidified subgrade loess. Mater. Introd. 2022, 36, 78–85. [Google Scholar]

- Wu, Z.M.; Lv, Q.F.; Wang, S.X. Study on the microscopic characteristics of loess reinforced by composite modified sodium silicate. Geotech. Mech. 2016, 37, 301–308. [Google Scholar]

| Plastic Limit/% | Liquid Limit/% | Plasticity Index | Maximum Dry Density/(g·cm−3) | Optimal Moisture Content/% |

|---|---|---|---|---|

| 17.4 | 24.3 | 6.9 | 1.72 | 17.0 |

| Material | SiO2 | CaO | Na2O | Fe2O3 | MgO | Al2O3 |

|---|---|---|---|---|---|---|

| Steel slag | 16.28% | 36.6% | 2.6% | 25.1% | 3.6% | 4.35% |

| Fly ash | 53.97% | 4.02% | 0.9% | 4.16% | 1.01% | 31.2% |

| Addition Amount | 0% | 5% | 10% | 15% | 20% | 25% |

|---|---|---|---|---|---|---|

| Maximum dry density (%) Optimal moisture content (g/cm3) | 1.72 16.45 | 1.7 16.88 | 1.69 17.19 | 1.65 17.64 | 1.64 17.93 | 1.62 17.3 |

| Addition Amount | 0% | 5% | 10% | 15% | 20% | 25% |

|---|---|---|---|---|---|---|

| Theoretical density (g/cm3) | 2.32 | 2.34 | 2.37 | 2.39 | 2.41 | 2.43 |

| Test Method | Curing Agent and Curing Cycle | Geopolymer Content Mass Fraction/% |

|---|---|---|

| Direct shear test Unconfined compressive strength test Disintegration test | Geopolymer, 7 d, 14 d, 28 d | 0 |

| 5 | ||

| 10 | ||

| 15 | ||

| 20 | ||

| 25 |

| Curing Age | Addition Amount | 0% | 5% | 10% | 15% | 20% | 25% |

|---|---|---|---|---|---|---|---|

| 7 d | Cohesion (kPa) | 38.05 | 40.55 | 42.14 | 50.09 | 54.86 | 46.9 |

| Angle of internal friction (°) | 15.38 | 22.50 | 23.55 | 25.25 | 25.38 | 25.34 | |

| 14 d | Cohesion (kPa) | 40.55 | 41.34 | 43.7 | 50.88 | 59.63 | 43.73 |

| Angle of internal friction (°) | 18.42 | 23.46 | 25.3 | 27.19 | 27.11 | 28.27 | |

| 28 d | Cohesion (kPa) | 46.11 | 59.62 | 65.99 | 75.53 | 81.09 | 69.96 |

| Angle of internal friction (°) | 19.2 | 24.18 | 24.4 | 24.36 | 31.12 | 31.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Tang, X.; Zhang, X.; Li, M. Mechanical Properties and Microscopic Study of Steel Slag–Fly Ash-Solidified Loess under Alkaline Conditions. Appl. Sci. 2023, 13, 8737. https://doi.org/10.3390/app13158737

Li H, Tang X, Zhang X, Li M. Mechanical Properties and Microscopic Study of Steel Slag–Fly Ash-Solidified Loess under Alkaline Conditions. Applied Sciences. 2023; 13(15):8737. https://doi.org/10.3390/app13158737

Chicago/Turabian StyleLi, Haojie, Xianxi Tang, Xujun Zhang, and Mingze Li. 2023. "Mechanical Properties and Microscopic Study of Steel Slag–Fly Ash-Solidified Loess under Alkaline Conditions" Applied Sciences 13, no. 15: 8737. https://doi.org/10.3390/app13158737