Modern Technologies for Waste Management: A Review

Abstract

:1. Introduction

2. Overview of Technologies

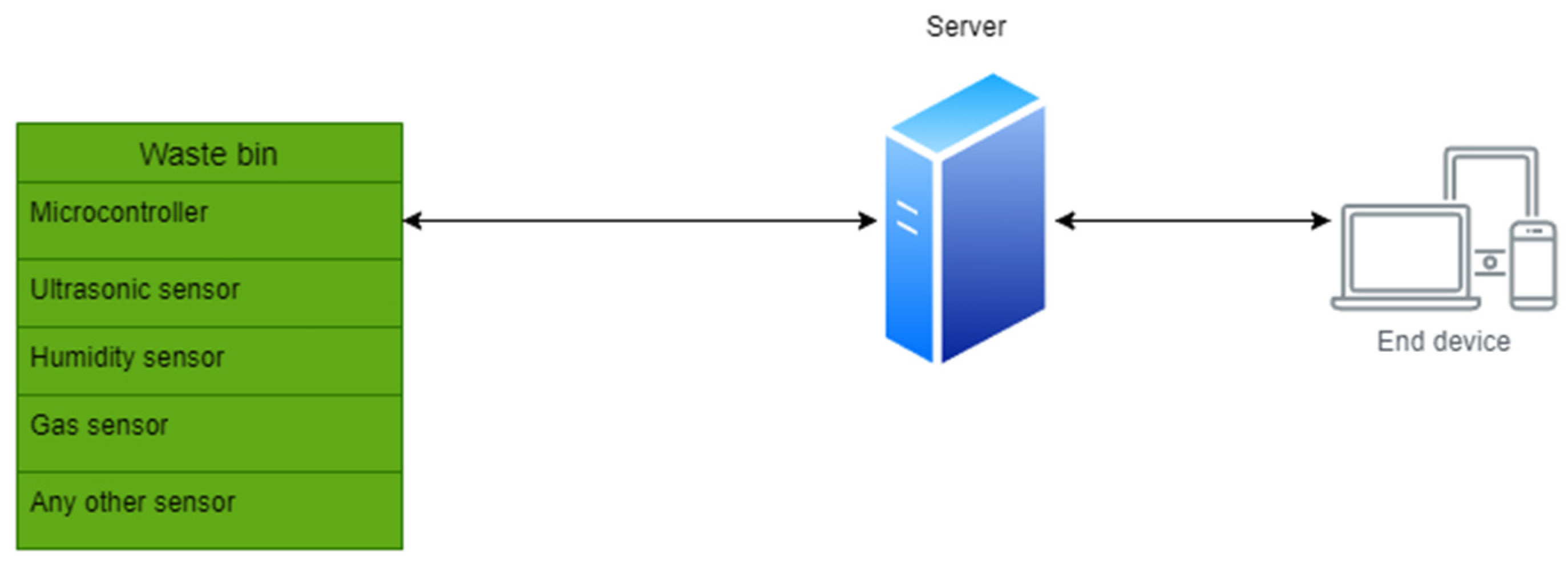

2.1. Smart Waste Bins

- MQTT (Message Queuing Telemetry Transport): A lightweight messaging protocol that is designed for low-power IoT applications. It uses the publish/subscribe model, where devices publish data to a broker, which then dispenses data to subscribers [28]. This protocol uses TCP/IP for data transmission and has very strong delivery guarantees. Each waste bin can be a client to the gateway which communicates with the cloud using an MQTT bridge [29].

- LoRaWAN (Low Power Wide Area Network): LoRaWAN is a wireless communication protocol that is being used for low-power, long-range IoT applications. It is a great choice for smart waste bins due to its long-distance data transmission and minimal power usage [30].

- GSM (Global System for Mobile Communications): A cellular network technology that is commonly used for communication between smart bins. It provides high bandwidth and fast data-transfer rates [31]. It is also low-cost and easy to implement.

2.2. Artificial Intelligence and Robots

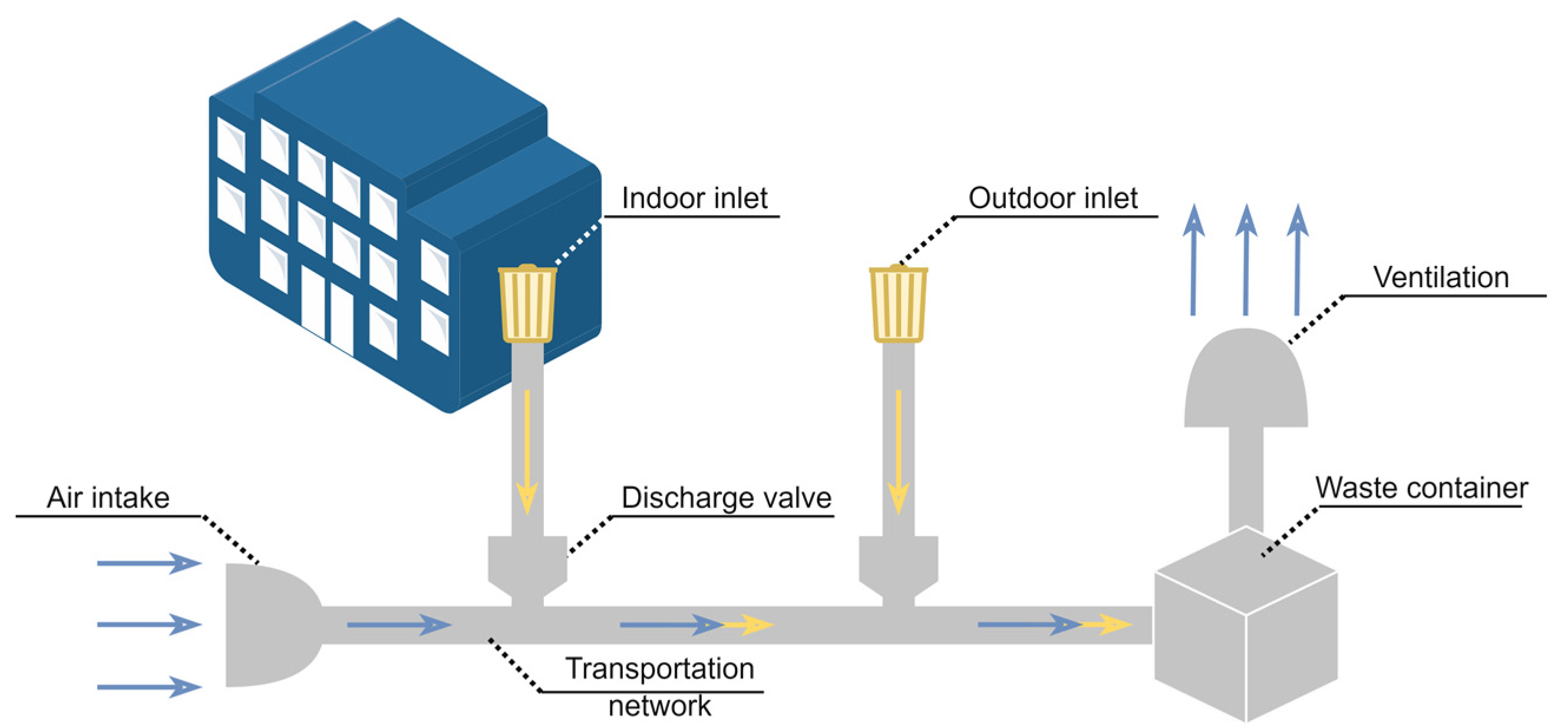

2.3. Automated Vacuum Collection System

2.4. E-Waste

- A harmonized charging port for electronic devices: USB-C will be the common port. This will allow consumers to charge their devices with the same USB-C charger, regardless of the device brand.

- Harmonized fast-charging technology will help prevent that different producers unjustifiably limit the charging speed and will help to ensure that the charging speed is the same when using any compatible charger for a device.

- Unbundling the sale of a charger from the sale of the electronic device: consumers will be able to purchase a new electronic device without a new charger. This will limit the number of unwanted chargers purchased or left unused.

- Improved information for consumers: producers will need to provide relevant information about charging performance, including information on the power required by the device and if it supports fast charging. This will make it easier for consumers to see if their existing chargers meet the requirements of their new device or help them to select a compatible charger [55].

2.5. Software in Waste Management

- Availability of an updated waste-collection calendar, indicating which type of waste is collected during each day of the week.

- Possibility to receive reminders with relevant collection information the day before or even during the same day.

- Access to a recycling guide, to support them during the recycling process, providing relevant information in a clear and accessible way.

- Possibility to locate waste bins near a specific place or location, together with the possibility to receive the corresponding walking directions.

- Possibility to locate nearby drop-off locations and have access to relevant information such as opening hours, provided services, and associated costs [63].

3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Czekała, W. Biogas as a Sustainable and Renewable Energy Source. In Clean Fuels for Mobility; Di Blasio, G., Agarwal, A.K., Belgiorno, G., Shukla, P.C., Eds.; Springer: Singapore, 2022; pp. 201–214. [Google Scholar] [CrossRef]

- Saeedi, K.; Visvizi, A.; Alahmadi, D.; Babour, A. Smart Cities and Households’ Recyclable Waste Management: The Case of Jeddah. Sustainability 2023, 15, 6776. [Google Scholar] [CrossRef]

- Czekała, W.; Janczak, D.; Pochwatka, P.; Nowak, M.; Dach, J. Gases Emissions during Composting Process of Agri-Food Industry Waste. Appl. Sci. 2022, 12, 9245. [Google Scholar] [CrossRef]

- Wierzbowska, J.; Sienkiewicz, S.; Załuski, D. Nitrogen Fractions in Soil Fertilized with Waste Organic Materials. Agronomy 2021, 11, 1474. [Google Scholar] [CrossRef]

- Czekała, W.; Pulka, J.; Jasiński, T.; Szewczyk, P.; Bojarski, W.; Jasiński, J. Waste as substrates for agricultural biogas plants: A case study from Poland. J. Water Land Dev. 2023, 56, 1–6. [Google Scholar] [CrossRef]

- Matuszewska, A.; Owczuk, M.; Biernat, K. Current Trends in Waste Plastics’ Liquefaction into Fuel Fraction: A Review. Energies 2022, 15, 2719. [Google Scholar] [CrossRef]

- Obidziński, S.; Joka Yildiz, M.; Dąbrowski, S.; Jasiński, J.; Czekała, W. Application of Post-Flotation Dairy Sludge in the Production of Wood Pellets: Pelletization and Combustion Analysis. Energies 2022, 15, 9427. [Google Scholar] [CrossRef]

- Maluf Filho, D.; Coelho, S.T.; Perecin, D. Opportunities and Challenges of Gasification of Municipal Solid Waste (MSW) in Brazil. Energies 2022, 15, 2735. [Google Scholar] [CrossRef]

- Zacho, K.O.; Mosgaard, M.A. Understanding the Role of Waste Prevention in Local Waste Management: A Literature Review. Waste Manag. Res. 2016, 34, 980–994. [Google Scholar] [CrossRef]

- Tadesse, T.; Ruijs, A.; Hagos, F. Household Waste Disposal in Mekelle City, Northern Ethiopia. Waste Manag. 2008, 28, 2003–2012. [Google Scholar] [CrossRef]

- Iqbal, A.; Liu, X.; Chen, G.-H. Municipal Solid Waste: Review of Best Practices in Application of Life Cycle Assessment and Sustainable Management Techniques. Sci. Total Environ. 2020, 729, 138622. [Google Scholar] [CrossRef]

- Iqbal, A.; Zan, F.; Liu, X.; Chen, G.-H. Integrated Municipal Solid Waste Management Scheme of Hong Kong: A Comprehensive Analysis in Terms of Global Warming Potential and Energy Use. J. Clean. Prod. 2019, 225, 1079–1088. [Google Scholar] [CrossRef]

- Lu, D.; Iqbal, A.; Zan, F.; Liu, X.; Chen, G. Life-Cycle-Based Greenhouse Gas, Energy, and Economic Analysis of Municipal Solid Waste Management Using System Dynamics Model. Sustain. Sci. Pract. Policy 2021, 13, 1641. [Google Scholar] [CrossRef]

- Goutam Mukherjee, A.; Ramesh Wanjari, U.; Chakraborty, R.; Renu, K.; Vellingiri, B.; George, A.; CR, S.R.; Valsala Gopalakrishnan, A. A Review on Modern and Smart Technologies for Efficient Waste Disposal and Management. J. Environ. Manag. 2021, 297, 113347. [Google Scholar] [CrossRef]

- Mingaleva, Z.; Vukovic, N.; Volkova, I.; Salimova, T. Waste Management in Green and Smart Cities: A Case Study of Russia. Sustain. Sci. Pract. Policy 2019, 12, 94. [Google Scholar] [CrossRef] [Green Version]

- Eurostat. Municipal Waste Statistics. 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Municipal_waste_statistics (accessed on 13 April 2023).

- Eurostat. Waste Statistics. 2023. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics (accessed on 13 April 2023).

- Mbom, H.I.; Raji, A.; Omiyale, A.D. Design and Implementation of an IoT Based Smart Waste Bin for Fill Level and Biodegradability Monitoring. J. Eng. Res. 2022, 25, 84–95. [Google Scholar]

- Shyam, G.K.; Manvi, S.S.; Bharti, P. Smart Waste Management Using Internet-of-Things (IoT). In Proceedings of the 2017 2nd International Conference on Computing and Communications Technologies (ICCCT), Chennai, India, 23–24 February 2017. [Google Scholar] [CrossRef]

- Noiki, A.; Afolalu, S.A.; Abioye, A.A.; Bolu, C.A.; Emetere, M.E. Smart Waste Bin System: A Review. IOP Conf. Ser. Earth Environ. Sci. 2021, 655, 012036. [Google Scholar] [CrossRef]

- Aguila, J.M.U.; Dimayuga, H.S.; Pineda, K.O.F.; Magwili, G.V. Development of Smart Waste Bin with Integrated Volume and Weight Sensor. In Proceedings of the 2019 IEEE 11th International Conference on Humanoid, Nanotechnology, Information Technology, Communication and Control, Environment, and Management (HNICEM), Laoag, Philippines, 29 November–1 December 2019. [Google Scholar] [CrossRef]

- Ali, T.; Irfan, M.; Alwadie, A.S.; Glowacz, A. IoT-Based Smart Waste Bin Monitoring and Municipal Solid Waste Management System for Smart Cities. Arab. J. Sci. Eng. 2020, 45, 10185–10198. [Google Scholar] [CrossRef]

- Hoque, M.A.; Azad, M.; Ashik-Uz-Zaman, M. IoT and Machine Learning Based Smart Garbage Management and Segregation Approach for Bangladesh. In Proceedings of the 2019 2nd International Conference on Innovation in Engineering and Technology (ICIET), Dhaka, Bangladesh, 23–24 December 2019. [Google Scholar] [CrossRef]

- Chowdhury, B.; Chowdhury, M.U. RFID-Based Real-Time Smart Waste Management System. In Proceedings of the 2007 Australasian Telecommunication Networks and Applications Conference, Christchurch, New Zealand, 2–5 December 2007; pp. 175–180. [Google Scholar]

- Pardini, K.; Rodrigues, J.J.P.C.; Hassan, S.A.; Kumar, N.; Furtado, V. Smart Waste Bin: A New Approach for Waste Management in Large Urban Centers. In Proceedings of the 2018 IEEE 88th Vehicular Technology Conference (VTC-Fall), Chicago, IL, USA, 27–30 August 2018. [Google Scholar] [CrossRef]

- Joshi, S.; Singh, U.K.; Yadav, S. Smart Dustbin Using GPS Tracking. Int. Res. J. Eng. Technol. 2019, 6, 156–170. [Google Scholar]

- Fadel, F. The Design and Implementation of Smart Trash Bin. Acad. J. Nawroz Univ. 2017, 6, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Fawwaz, D.Z.; Chung, S.-H.; Ahn, C.-W.; Kim, W.-S. Optimal Distributed MQTT Broker and Services Placement for SDN-Edge Based Smart City Architecture. Sensors 2022, 22, 3431. [Google Scholar] [CrossRef]

- Bharadwaj, A.S.; Rego, R.; Chowdhury, A. IoT Based Solid Waste Management System: A Conceptual Approach with an Architectural Solution as a Smart City Application. In Proceedings of the 2016 IEEE Annual India Conference (INDICON), Bangalore, India, 16–18 December 2016. [Google Scholar] [CrossRef]

- Baldo, D.; Mecocci, A.; Parrino, S.; Peruzzi, G.; Pozzebon, A. A Multi-Layer LoRaWAN Infrastructure for Smart Waste Management. Sensors 2021, 21, 2600. [Google Scholar] [CrossRef]

- Wijaya, A.S.; Zainuddin, Z.; Niswar, M. Design a Smart Waste Bin for Smart Waste Management. In Proceedings of the 2017 5th International Conference on Instrumentation, Control, and Automation (ICA), Yogyakarta, Indonesia, 9–11 August 2017; pp. 62–66. [Google Scholar]

- Harkut, D.G.; Kasat, K. Introductory Chapter: Artificial Intelligence—Challenges and Applications. In Artificial Intelligence—Scope and Limitations; IntechOpen: London, UK, 2019; ISBN 9781789859355. [Google Scholar]

- Wang, Z.; Li, H.; Zhang, X. Construction Waste Recycling Robot for Nails and Screws: Computer Vision Technology and Neural Network Approach. Autom. Constr. 2019, 97, 220–228. [Google Scholar] [CrossRef]

- Dabholkar, A.; Muthiyan, B.; Srinivasan, S.; Ravi, S.; Jeon, H.; Gao, J. Smart Illegal Dumping Detection. In Proceedings of the 2017 IEEE Third International Conference on Big Data Computing Service and Applications (BigDataService), Redwood City, CA, USA, 6–9 April 2017. [Google Scholar] [CrossRef]

- Yonezawa, C. Maximum Likelihood Classification Combined with Spectral Angle Mapper Algorithm for High Resolution Satellite Imagery. Int. J. Remote Sens. 2007, 28, 3729–3737. [Google Scholar] [CrossRef]

- Fayomi, G.U.; Mini, S.E.; Chisom, C.M.; Fayomi, O.S.I.; Udoye, N.E.; Agboola, O.; Oomole, D. Smart Waste Management for Smart City: Impact on Industrialization. IOP Conf. Ser. Earth Environ. Sci. 2021, 655, 012040. [Google Scholar] [CrossRef]

- Lu, W.; Chen, J. Computer Vision for Solid Waste Sorting: A Critical Review of Academic Research. Waste Manag. 2022, 142, 29–43. [Google Scholar] [CrossRef] [PubMed]

- Bogue, R. Robots in Recycling and Disassembly. Ind. Robot. Int. J. Robot. Res. Appl. 2019, 46, 461–466. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, Y.; Yang, Z.; Gong, H. Computer Vision Based Two-Stage Waste Recognition-Retrieval Algorithm for Waste Classification. Resour. Conserv. Recycl. 2021, 169, 105543. [Google Scholar] [CrossRef]

- Aschenbrenner, D.; Gros, J.; Fangerow, N.; Werner, T.; Colloseus, C.; Taha, I. Recyclebot—Using Robots for Sustainable Plastic Recycling. Procedia CIRP 2023, 116, 275–280. [Google Scholar] [CrossRef]

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gómez, L.S.; Prieto, E.G. Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources 2021, 10, 28. [Google Scholar] [CrossRef]

- Vu, H.L.; Ng, K.T.W.; Fallah, B.; Richter, A.; Kabir, G. Interactions of Residential Waste Composition and Collection Truck Compartment Design on GIS Route Optimization. Waste Manag. 2020, 102, 613–623. [Google Scholar] [CrossRef] [PubMed]

- Project INTHERWASTE. Bergen Underground Waste Collection System. 2019. Available online: https://www.interregeurope.eu/good-practices/bergen-underground-waste-collection-system (accessed on 13 April 2023).

- MetroTaifun References. Available online: https://metrotaifun.com/automatic_solid_waste_collection_system/en/references/selected-references.html (accessed on 13 April 2023).

- Miller, B.; Spertus, J.; Kamga, C. Costs and Benefits of Pneumatic Collection in Three Specific New York City Cases. Waste Manag. 2014, 34, 1957–1966. [Google Scholar] [CrossRef] [PubMed]

- Farré, J.A.; Salgado-Pizarro, R.; Martín, M.; Zsembinszki, G.; Gasia, J.; Cabeza, L.F.; Barreneche, C.; Fernández, A.I. Case Study of Pipeline Failure Analysis from Two Automated Vacuum Collection System. Waste Manag. 2021, 126, 643–651. [Google Scholar] [CrossRef] [PubMed]

- Laso, J.; García-Herrero, I.; Margallo, M.; Bala, A.; Fullana-i-Palmer, P.; Irabien, A.; Aldaco, R. LCA-Based Comparison of Two Organic Fraction Municipal Solid Waste Collection Systems in Historical Centres in Spain. Energies 2019, 12, 1407. [Google Scholar] [CrossRef] [Green Version]

- Teerioja, N.; Moliis, K.; Kuvaja, E.; Ollikainen, M.; Punkkinen, H.; Merta, E. Pneumatic vs. Door-to-Door Waste Collection Systems in Existing Urban Areas: A Comparison of Economic Performance. Waste Manag. 2012, 32, 1782–1791. [Google Scholar] [CrossRef]

- Fernández, C.; Manyà, F.; Mateu, C.; Sole-Mauri, F. Approximate Dynamic Programming for Automated Vacuum Waste Collection Systems. Environ. Model. Softw. 2015, 67, 128–137. [Google Scholar] [CrossRef]

- World Economic Forum. A New Circular Vision for Electronics: Time for a Global Reboot. 2019. Available online: https://www3.weforum.org/docs/WEF_A_New_Circular_Vision_for_Electronics.pdf (accessed on 15 April 2023).

- Salhofer, S. E-Waste Collection and Treatment Options: A Comparison of Approaches in Europe, China and Vietnam. In Source Separation and Recycling: Implementation and Benefits for a Circular Economy; Maletz, R., Dornack, C., Ziyang, L., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 227–243. ISBN 9783319690728. [Google Scholar]

- Blumbergs, E.; Serga, V.; Shishkin, A.; Goljandin, D.; Shishko, A.; Zemcenkovs, V.; Markus, K.; Baronins, J.; Pankratov, V. Selective Disintegration–Milling to Obtain Metal-Rich Particle Fractions from E-Waste. Metals 2022, 12, 1468. [Google Scholar] [CrossRef]

- Hsu, E.; Barmak, K.; West, A.C.; Park, A.-H.A. Advancements in the Treatment and Processing of Electronic Waste with Sustainability: A Review of Metal Extraction and Recovery Technologies. Green Chem. 2019, 21, 919–936. [Google Scholar] [CrossRef]

- Tiwary, C.S.; Kishore, S.; Vasireddi, R.; Mahapatra, D.R.; Ajayan, P.M.; Chattopadhyay, K. Electronic Waste Recycling via Cryo-Milling and Nanoparticle Beneficiation. Mater. Today 2017, 20, 67–73. [Google Scholar] [CrossRef]

- European Commission. Pulling the Plug on Consumer Frustration and E-Waste: Commission Proposes a Common Charger for Electronic Devices. 2021. Available online: https://ec.europa.eu/commission/presscorner/detail/en/IP_21_4613 (accessed on 13 April 2023).

- Ankalkoti, P.; Santhosh, S.G. A Relative Study on Bitcoin Mining. Imp. J. Interdiscip. Res. 2017, 3, 1757–1761. [Google Scholar]

- de Vries, A.; Stoll, C. Bitcoin’s Growing e-Waste Problem. Resour. Conserv. Recycl. 2021, 175, 105901. [Google Scholar] [CrossRef]

- Bitcoin Energy Consumption Index—Digiconomist. Available online: https://digiconomist.net/bitcoin-energy-consumption/ (accessed on 15 May 2023).

- Sheng, T.J.; Islam, M.S.; Misran, N.; Baharuddin, M.H.; Arshad, H.; Islam, M.R.; Chowdhury, M.E.H.; Rmili, H.; Islam, M.T. An Internet of Things Based Smart Waste Management System Using LoRa and Tensorflow Deep Learning Model. IEEE Access 2020, 8, 148793–148811. [Google Scholar] [CrossRef]

- Epifancev, K.; Hvan, D.; Morokina, G.; Baranov, I. Development Software Platform for Collection and Exchange of Data in the Field of Waste Management. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 062077. [Google Scholar] [CrossRef]

- Burger, C.; Kalverkamp, M.; Pehlken, A. Decision Making and Software Solutions with Regard to Waste Management. J. Clean. Prod. 2018, 205, 210–225. [Google Scholar] [CrossRef]

- Global Connectivity Report. International Telecommunication Union. 2022. Available online: https://www.itu.int/dms_pub/itu-d/opb/ind/d-ind-global.01-2022-pdf-e.pdf (accessed on 13 April 2023).

- Bonino, D.; Alizo, M.T.D.; Pastrone, C.; Spirito, M. WasteApp: Smarter Waste Recycling for Smart Citizens. In Proceedings of the 2016 International Multidisciplinary Conference on Computer and Energy Science (SpliTech), Split, Croatia, 13–15 July 2016; pp. 1–6. [Google Scholar]

- Shan, X.; Ang, W.L.; Yang, E.-H. Mobile App-Aided Risks, Attitudes, Norms, Abilities and Self-Regulation (RANAS) Approach for Recycling Behavioral Change in Singapore. Resour. Conserv. Recycl. 2020, 162, 105049. [Google Scholar] [CrossRef]

- Noori, M.A.; Al-Janabi, T.A.; Hussien, S.A.S. Solid Waste Recycling and Management Cost Optimization Algorithm. Bull. Electr. Eng. Inform. 2022, 11, 2225–2232. [Google Scholar] [CrossRef]

- Manoharam, G.; Ismail, M.T.; Abir, I.A.; Majahar Ali, M.K. Efficient Solid Waste Management in Prai Industrial Area through GIS Using Dijkstra and Travelling Salesman Problem Algorithms. Pertanika J. Sci. Technol. 2021, 29, 1397–1418. [Google Scholar] [CrossRef]

- Eriksson, O.; Frostell, B.; Björklund, A.; Assefa, G.; Sundqvist, J.-O.; Granath, J.; Carlsson, M.; Baky, A.; Thyselius, L. ORWARE—A Simulation Tool for Waste Management. Resour. Conserv. Recycl. 2002, 36, 287–307. [Google Scholar] [CrossRef]

- LoRa Alliance. Available online: https://lora-alliance.org/wp-content/uploads/2021/05/RP-2-1.0.3.pdf (accessed on 19 July 2023).

- The Merge Ethereum.Org. Available online: https://ethereum.org. (accessed on 14 May 2023).

- Nightingale, E.B.; Douceur, J.R.; Orgovan, V. Cycles, Cells and Platters: An Empirical Analysisof Hardware Failures on a Million Consumer PCs. In Proceedings of the Sixth Conference on Computer Systems, Salzburg, Austria, 10–13 April 2011; Association for Computing Machinery: New York, NY, USA, 2011; pp. 343–356. [Google Scholar]

| Purpose | Type (Mobile, Website) | Name |

|---|---|---|

| Reducing food loss and waste. | Mobile | Too Good To Go |

| Finding recycling locations (US only). | Website | Recyclenation |

| Creating database of illegal waste dumps and removals of them based on community reports. | Mobile | TrashOut |

| Generating recipes from selected products. | Website | Supercook |

| Recycling education platform | Mobile | Recycle Coach |

| Recipes for ecological cleaning products and tips on recycling. | Mobile | Ecolife |

| An application enabling users to easily find water refill stations for their reusable bottles. | Mobile | Refill |

| Disadvantages | Advantages | Technology |

|---|---|---|

| Higher maintenance cost, need for device maintenance | Optimization of waste management processes, real-time data delivery | Smart waste bin |

| Uncertainty about the long-term impact on work | Improved efficiency, and security, predicting illegal waste dumping, distinguishing types of waste | Artificial Intelligence |

| Higher energy consumption, Failure rate of the pipeline system | Improved waste collection efficiency, worldwide implementation possible | Automated vacuum collection system |

| Difficulties in verifying the content of the application | Processes automation, real-time data analysis, ease of interaction | Software |

| The complexity of the e-waste processing | Efficient material recovery, low environmental impact | Cryo-milling |

| Need for a change at the legislative level. | Reducing the amount of e-waste | Electronic standardization |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czekała, W.; Drozdowski, J.; Łabiak, P. Modern Technologies for Waste Management: A Review. Appl. Sci. 2023, 13, 8847. https://doi.org/10.3390/app13158847

Czekała W, Drozdowski J, Łabiak P. Modern Technologies for Waste Management: A Review. Applied Sciences. 2023; 13(15):8847. https://doi.org/10.3390/app13158847

Chicago/Turabian StyleCzekała, Wojciech, Jędrzej Drozdowski, and Piotr Łabiak. 2023. "Modern Technologies for Waste Management: A Review" Applied Sciences 13, no. 15: 8847. https://doi.org/10.3390/app13158847

APA StyleCzekała, W., Drozdowski, J., & Łabiak, P. (2023). Modern Technologies for Waste Management: A Review. Applied Sciences, 13(15), 8847. https://doi.org/10.3390/app13158847