Effect of Crude Oil on the Geotechnical Properties of Various Soils and the Developed Remediation Methods

Abstract

:1. Introduction

Research Significance

2. Impact of Oil Pollution on Geotechnical Features of Soil

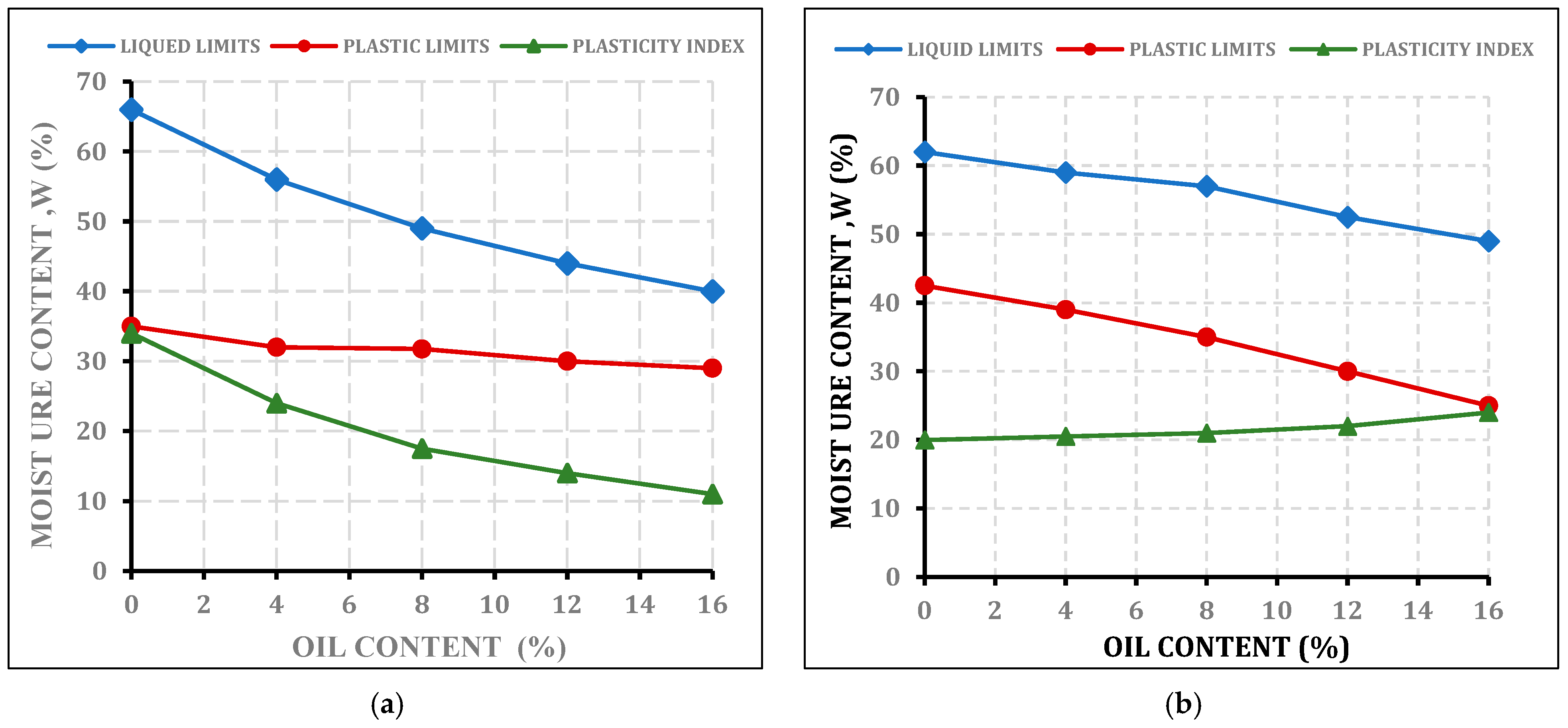

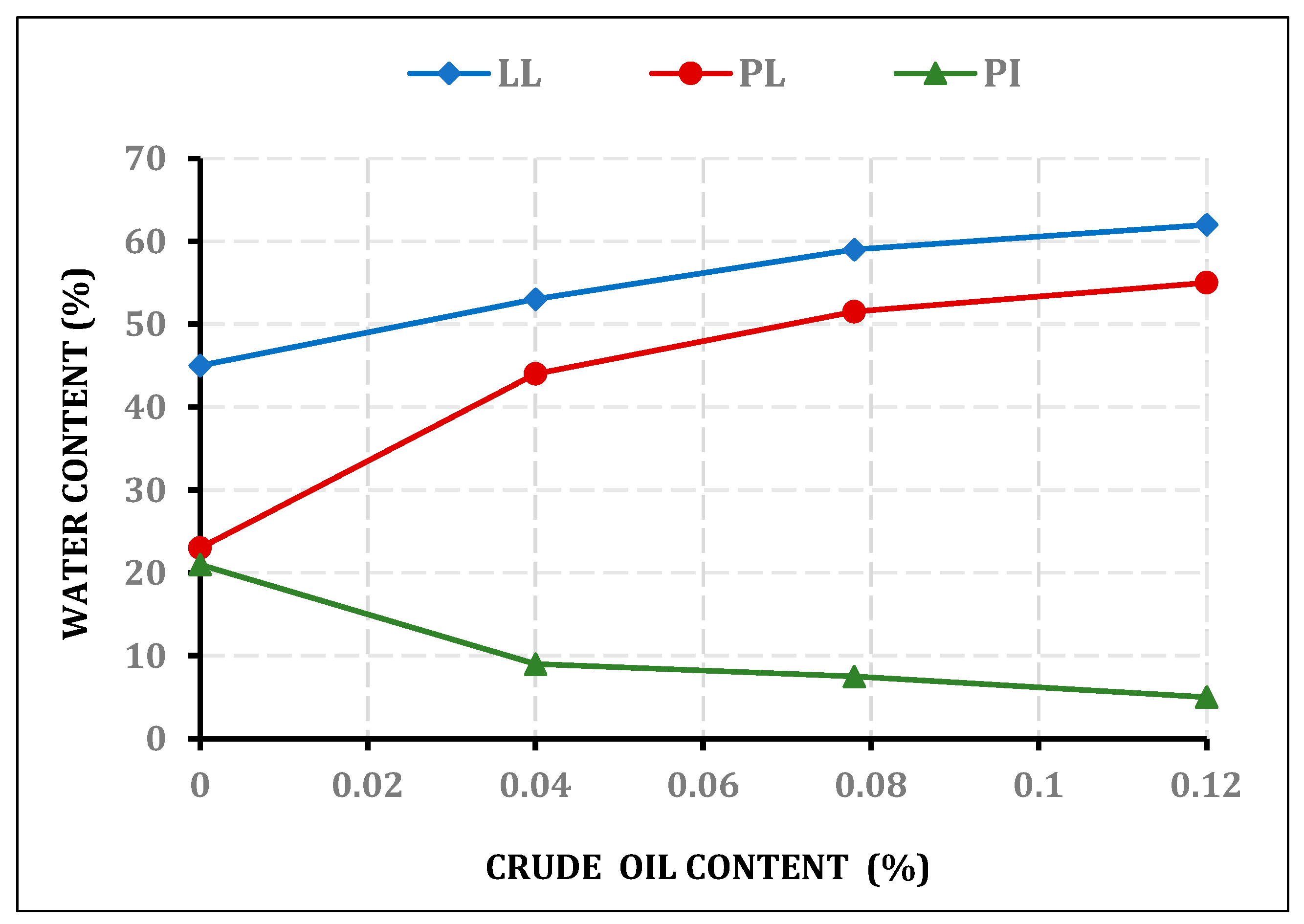

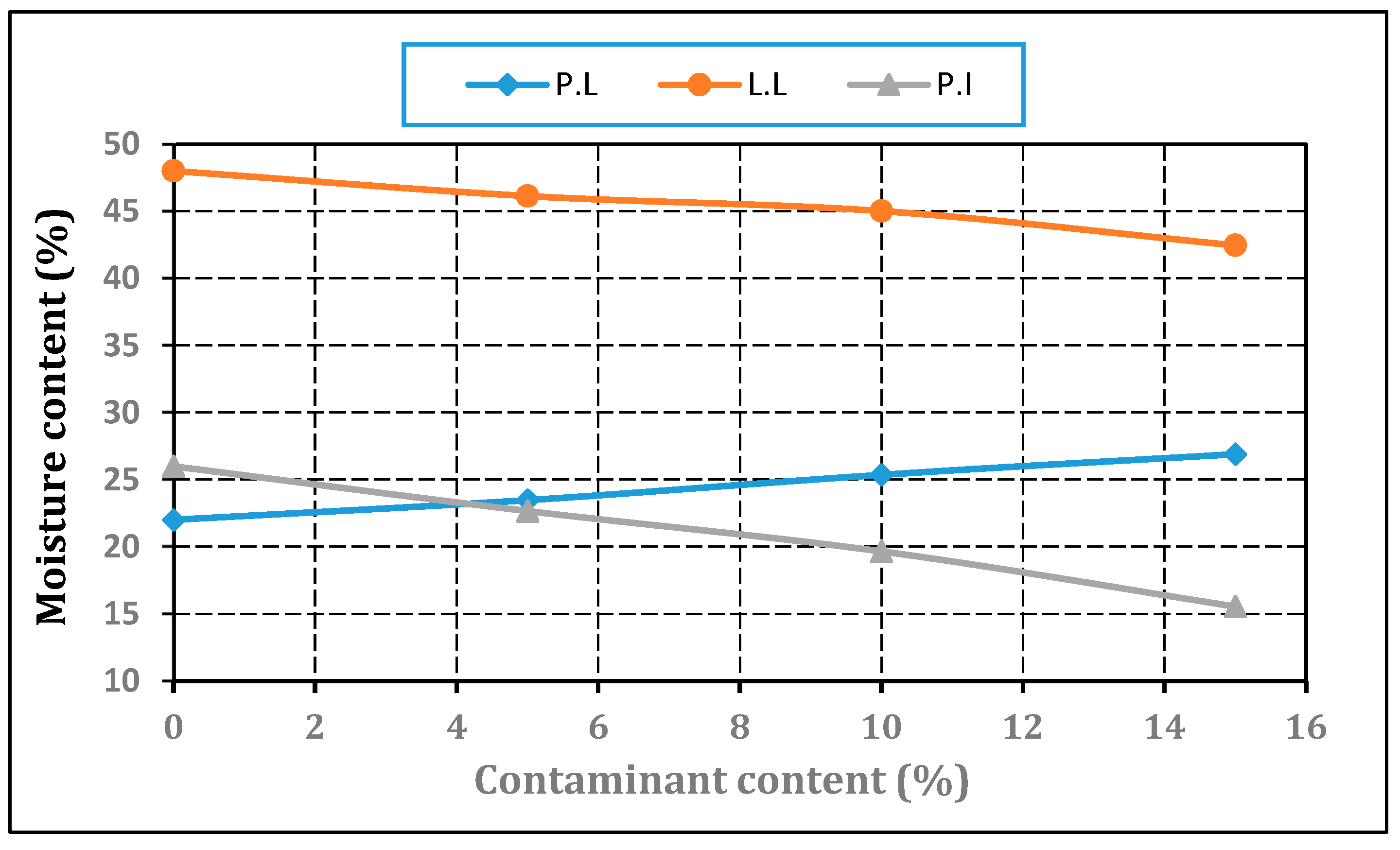

2.1. Atterberg Limits

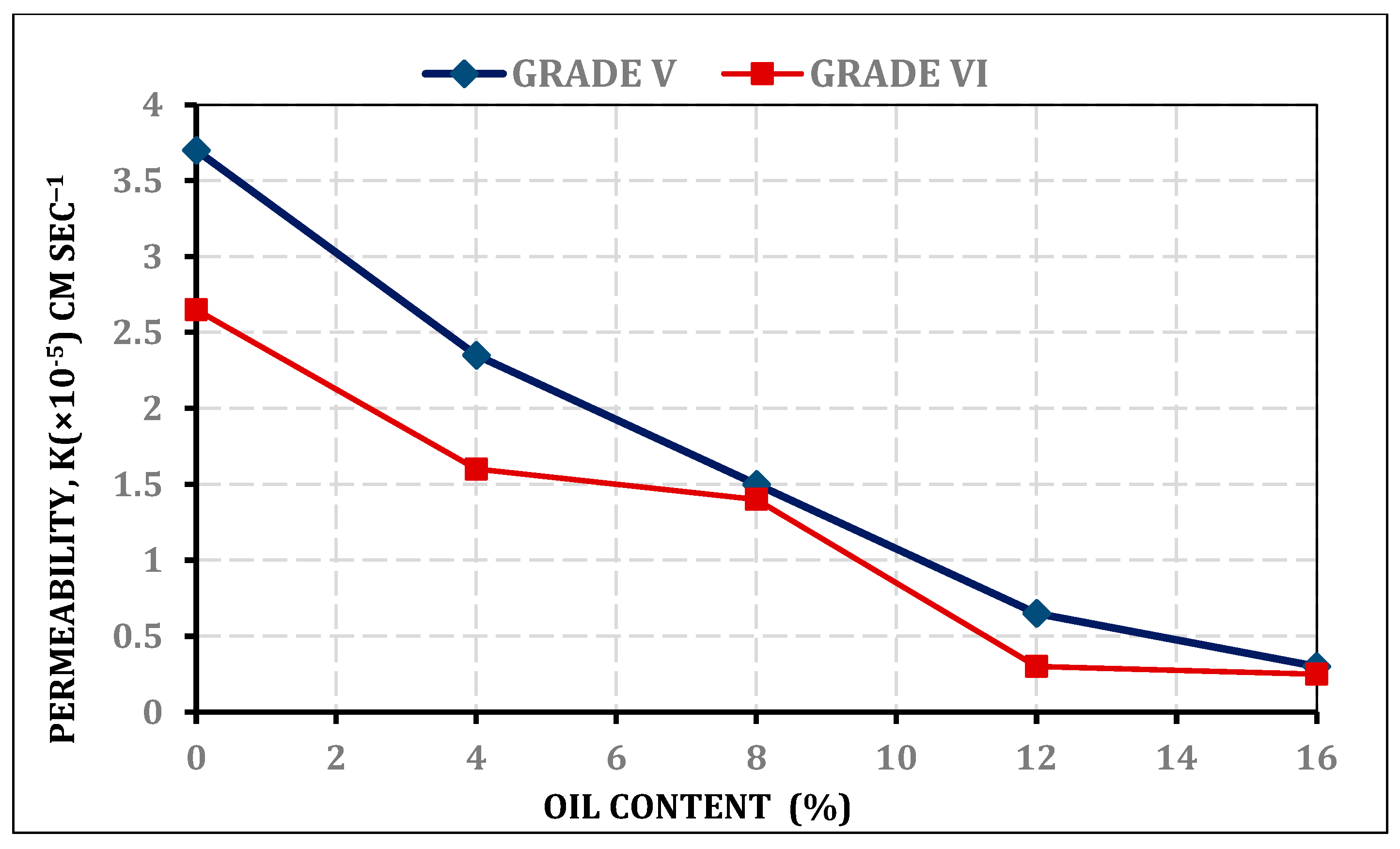

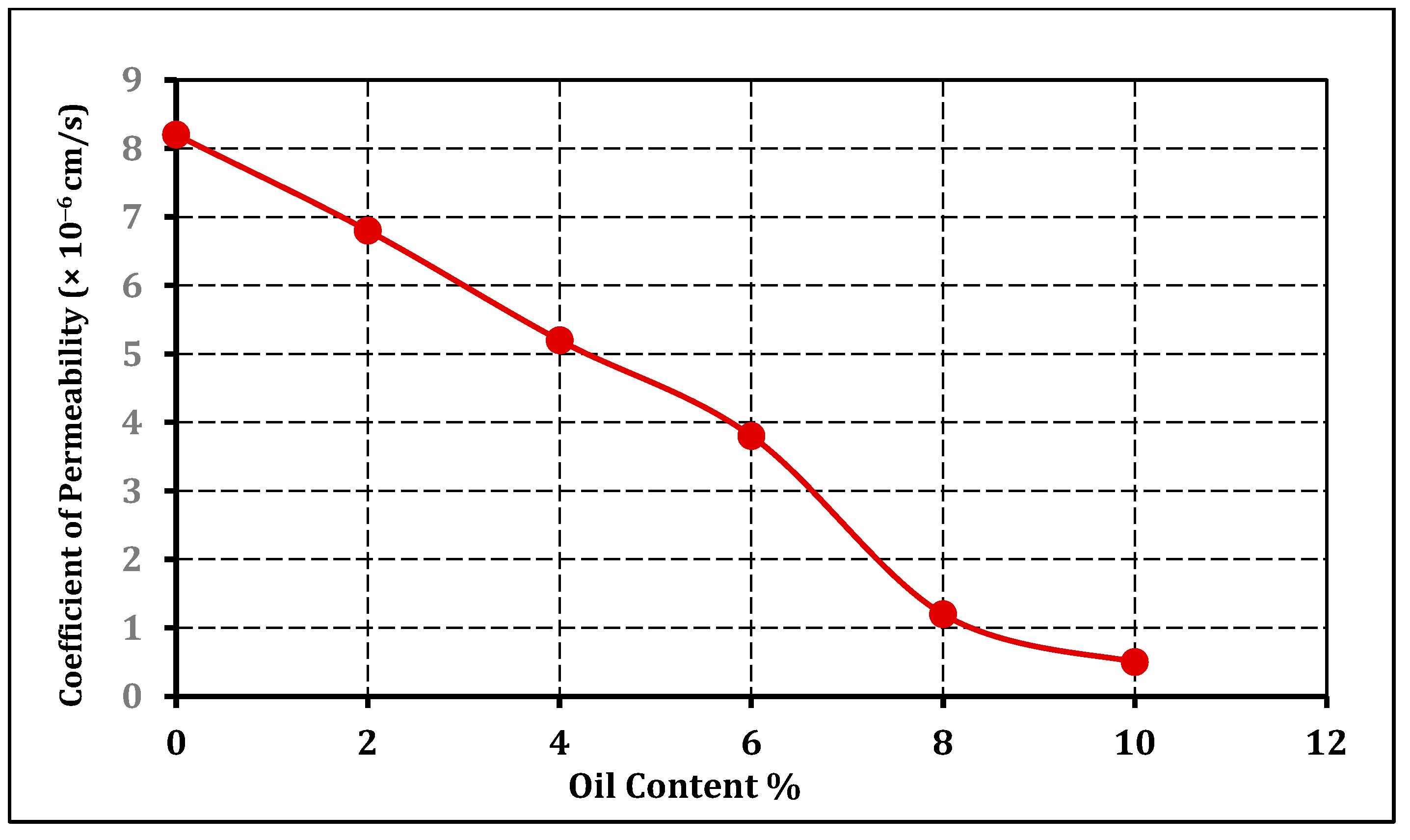

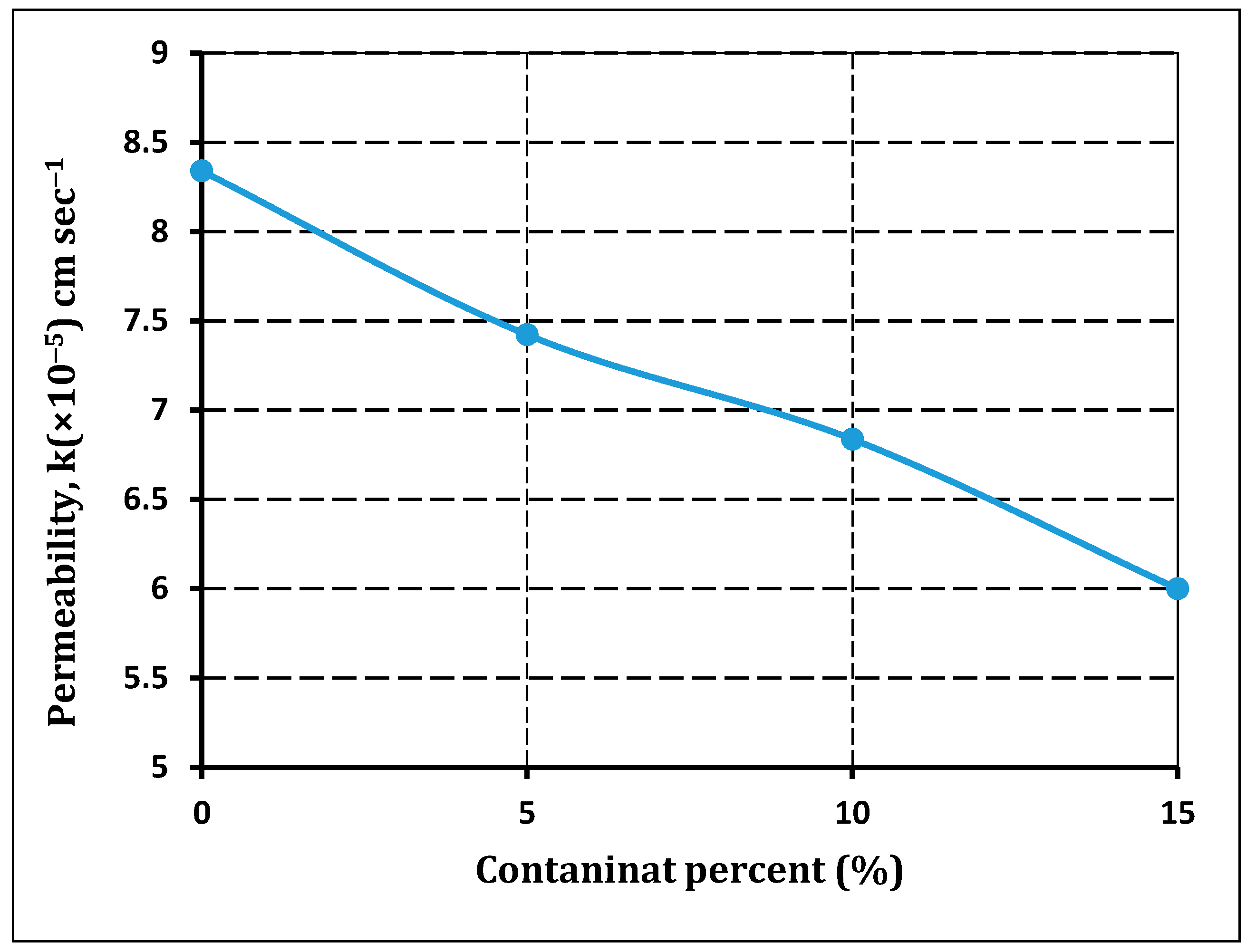

2.2. Permeability

Permeability of Lateritic Clay

3. Results and Discussion of the Current Study

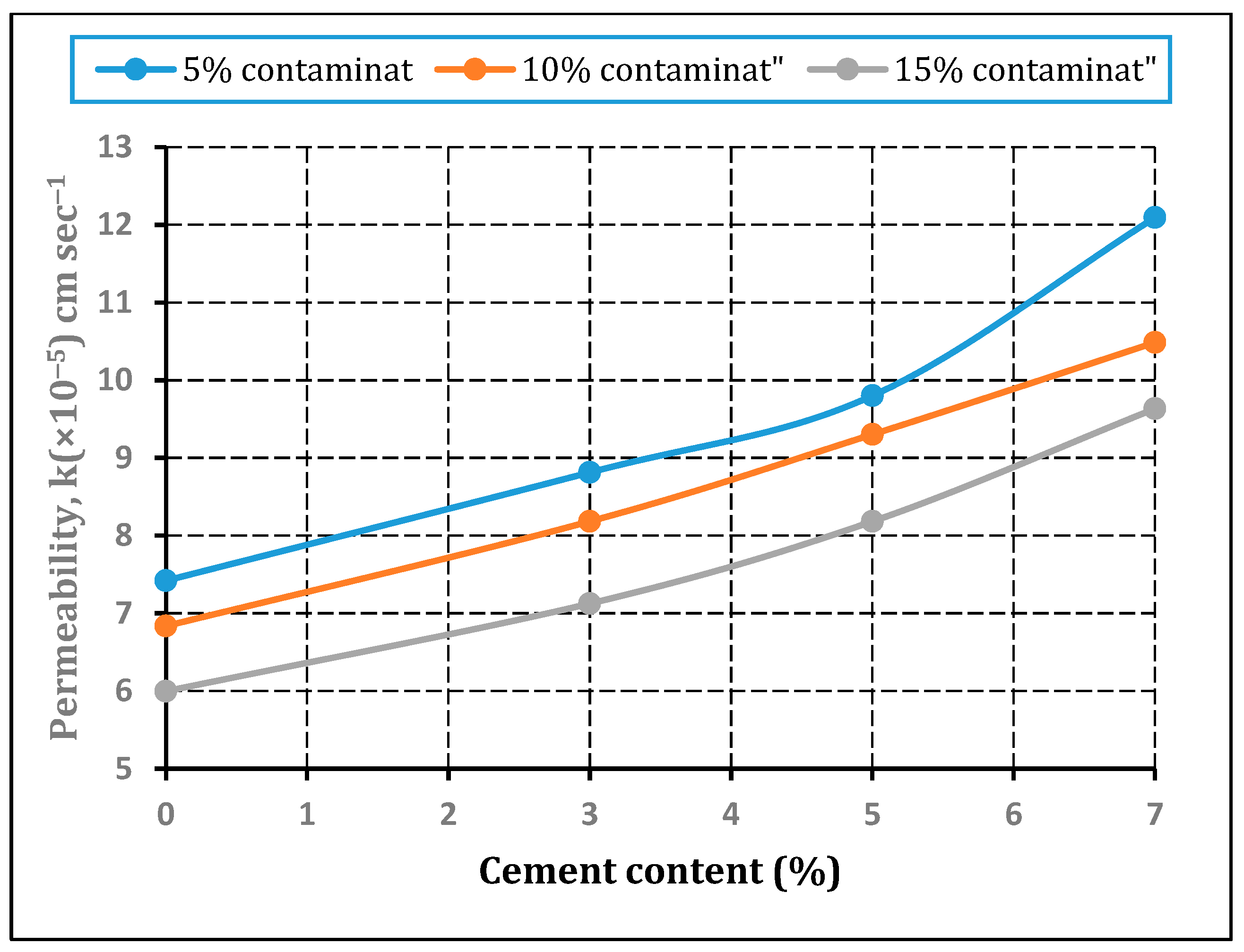

3.1. Effect of Cement Content on the Flow Characteristics of Soil

3.2. Effect of Cement Content on the Liquid and Plastic Limits of the Soil

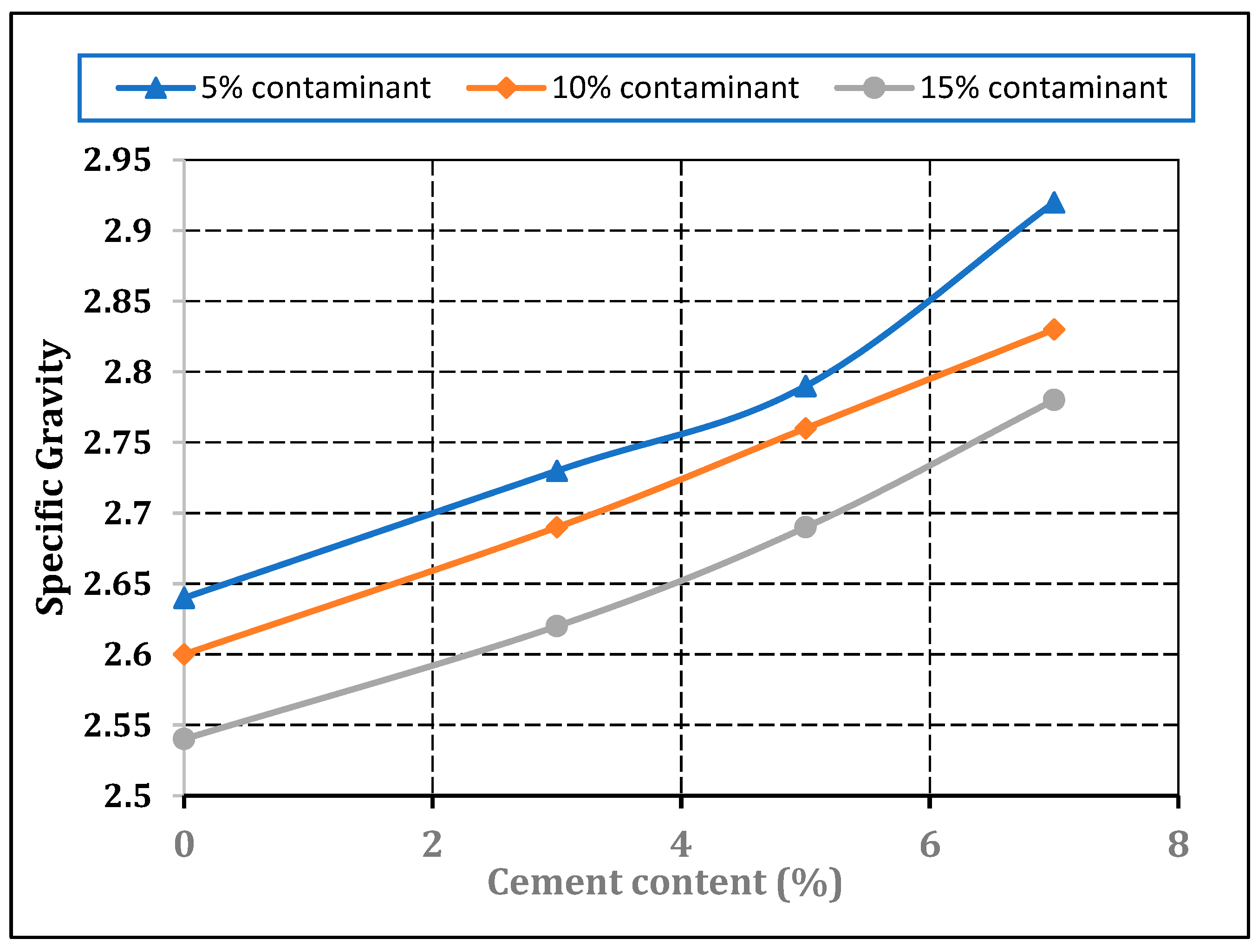

3.3. Effect of Cement Content on the Specific Gravity of Contaminated Soil

4. Process of Remediation for Oil-Contaminated Soil

4.1. Techniques for Biological Remediation

4.2. Techniques for Physical Remediation

4.2.1. Excavation

4.2.2. Incineration

4.3. Techniques for Chemistry Remediation

4.3.1. Oxidation

4.3.2. Photochemistry

5. Conclusions

- Considering the Atterberg limits, there are two opinions: The first one is that oil reduced the moisture content of the liquid and plastic limits of the polluted soils; the plastic index rose with oil-polluted soils. This might be because the water about the charged mud molecules is changed with non-polarised oil solutions. The second one is that both values of the liquid and plastic limits increase, the plastic index drops, and the ore oil wraps mud molecules and prevents water particles from reaching double-layer water; therefore, plastic soil requires more water, which may explain the higher plastic limit, and water added to the soil will join the free-water layer if the oil orients the soil particles.

- Increasing oil contents reduce permeability values due to the oil blocking specific inter-particle gaps in the soil. A reverse proportion was noted between the permeability value and the amounts of cement added to the contaminated soil due to adsorption behaviour.

- The appropriate percentage of cement to modify the geotechnical properties of contaminated soil is 7% and affects the results evenly, irrespective of the contaminant content.

- Adding cement in amounts from 3 to 7% to the contaminated soil may convert the behaviour from fine-grained to coarse-grained soil, leading to a smaller dry unit weight at a higher water content.

- Bioremediation is a natural process that does not add secondary chemicals to the soil and can completely mineralise oil into the water and carbon dioxide. Furthermore, photocatalysis mitigation may assist in smashing long-chain hydrocarbon portions of oil into primary forms that microorganisms can naturally break. As a result, the time required to restore polluted ground or soil was reduced.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hyman, M.; Dupont, R.R. Groundwater and Soil Remediation: Process Design and Cost Estimating of Proven Technologies; ASCE Press: Reston, VA, USA, 2001. [Google Scholar]

- Gavrilescu, M.; Pavel, V.L.; Cretescu, I. Characterisation and remediation of soils contaminated with uranium. J. Hazard. Mater. 2008, 163, 475–510. [Google Scholar] [CrossRef]

- Albuquerque, M.T.D.; Gerassis, S.; Sierra, C.; Taboada, J.; Martin, J.E.; Antunes, I.M.H.R.; Gallego, J.R. Developing a new Bayesian Risk Index for risk evaluation of soil contamination. Sci. Total Environ. 2017, 603–604, 167–177. [Google Scholar] [CrossRef] [PubMed]

- Rizzardini, C.B.; Goi, D. Sustainability of domestic sewage sludge disposal. Sustainability 2014, 6, 2424–2434. [Google Scholar] [CrossRef] [Green Version]

- Nadia, N.S.; Alabdraba, W.M.; Mohamed, G.H.; Mohammed, Z.B. Water Quality Monitoring of Tigris River by Using (GIS)-Based Physicochemical Parameters in Baghdad, Iraq. Int. J. Eng. Technol. 2018, 7, 57–62. [Google Scholar] [CrossRef]

- Al-Hamadani, Y.A.; Salal, A.M.; Mohammed, Z.B.; Assi, L.N.; Resheq, A.S. WQ Assessment of Water Treatment Plants Using Environmental and Statistical Indicators within Baghdad City. Period. Eng. Nat. Sci. 2022, 10, 427–436. [Google Scholar] [CrossRef]

- Harrison, R.M. An Introduction to Pollution Science; Royal Society of Chemistry: London, UK, 2006. [Google Scholar]

- Harrison, R.M. Pollution: Causes, Effects and Control; Royal Society of Chemistry (RSC): London, UK, 2001. [Google Scholar]

- Calabrese, E.J.; Kostecki, P.T.; Dragun, J. Contaminated Soils, Sediments and Water Volume 10: Successes and Challenges; Springer Science & Business Media: New York, NY, USA, 2006; Volume 10. [Google Scholar]

- Fine, P.; Graber, E.R.; Yaron, B. Soil interactions with petroleum hydrocarbons: Abiotic processes. Soil Technol. 1997, 10, 133–153. [Google Scholar] [CrossRef]

- Shin, E.C.; Das, B.M. Bearing capacity of unsaturated oil-contaminated sand. Int. J. Offshore Polar Eng. 2001, 11, 220–226. [Google Scholar]

- Ezeji, U.; Anyadoh, S.O.; Ibekwe, V.I. Cleanup of crude oil-contaminated soil. Terr. Aquat. Environ. Toxicol. 2007, 1, 54–59. [Google Scholar]

- Dos Santos, J.J.; Maranho, L.T. Rhizospheric microorganisms as a solution for recovering soils contaminated by petroleum: A review. J. Environ. Manag. 2018, 210, 104–113. [Google Scholar] [CrossRef]

- Westlake, D.W.S.; Jobson, A.; Phillippe, R.; Cook, F.D. Biodegradability and crude oil composition. Can. J. Microbiol. 1974, 20, 915–928. [Google Scholar] [CrossRef]

- Pampanin, D.; Sydnes, M. Polycyclic aromatic hydrocarbons a constituent of petroleum: Presence and influence in the aquatic environment. Hydrocarbon 2013, 5, 83–118. [Google Scholar]

- Ahmed, H.-U.-R.; Abduljauwad, S.N.; Akram, T. Geotechnical behavior of oil-contaminated fine grained soils. Electron. J. Geotech. Eng. 2007, 12, 1–12. [Google Scholar]

- Talukda, D.K.; Saika, B.D. Effect of crude oil on some consolidation properties of clay soil. Int. J. Eng. Technol. Adv. Eng. 2013, 3, 117–120. [Google Scholar]

- Aislabie, J.M.; Balks, M.R.; Foght, J.M.; Waterhouse, E.J. Hydrocarbon spills on Antarctic soils: Effects and management. Environ. Sci. Technol. 2004, 38, 1265–1274. [Google Scholar] [CrossRef] [PubMed]

- Han, J.C. Introduction to Land Engineering; Science Press: Beijing, China, 2013; pp. 188–191. (In Chinese) [Google Scholar]

- Ilyushin, Y.V.; Fetisov, V. Experience of virtual commissioning of a process control system for the production of high-paraffin oil. Sci. Rep. 2022, 12, 18415. [Google Scholar] [CrossRef] [PubMed]

- Potseshkovskaya, I.V.; Soroka, A.N. Revitalisation of Urban Industrial Areas Based on Sustainable Development Principles. E3S Web Conf. 2021, 266, 08012. [Google Scholar] [CrossRef]

- Khamehchiyan, M.; Charkhabi, A.H.; Tajik, M. Effects of crude oil contamination on geotechnical properties of clayey and sandy soils. Eng. Geol. 2007, 89, 220–229. [Google Scholar] [CrossRef]

- Shah, S.J.; Shroff, A.V.; Patel, J.V.; Tiwari, K.C.; Ramakrishnan, D. Stabilisation of fuel oil contaminated soil—A case study. Geotech. Geol. Eng. 2003, 21, 415–427. [Google Scholar] [CrossRef]

- Kermani, M.; Ebadi, T. The effect of oil contamination on the geotechnical properties of fine-grained soils. Soil Sediment Contam. Int. J. 2012, 21, 655–671. [Google Scholar] [CrossRef]

- Salih, M.M.; Jawad, F.W.; Al-Ameri, A.F.; Abdulhameed, A.A. Geotechnical Correlations of Soil Properties in Hilla City – Iraq. Open Eng. 2022, 12, 729–742. [Google Scholar] [CrossRef]

- Rahman, Z.A.; Hamzah, U.; Taha, M.R.; Ithnain, N.S.; Ahmad, N. Influence of oil contamination on geotechnical properties of basaltic residual soil. Am. J. Appl. Sci. 2010, 7, 954. [Google Scholar] [CrossRef] [Green Version]

- Akinwumi, I.I.; Diwa, D.; Obianigwe, N. Effects of crude oil contamination on the index properties, strength and permeability of lateritic clay. Int. J. Appl. Sci. Eng. Res. 2014, 3, 816–824. [Google Scholar]

- Abdulhamid, S.N.; Hasan, A.M.; Aziz, S.Q. Solidification/Stabilisation of Contaminated Soil in a South Station of the Khurmala Oil Field in Kurdistan Region, Iraq. Appl. Sci. 2021, 11, 7474. [Google Scholar] [CrossRef]

- Atlas, R.M.; Stoeckel, D.M.; Faith, S.A.; Minard-Smith, A.; Thorn, J.R.; Benotti, M.J. Oil Biodegradation and Oil-Degrading Microbial Populations in Marsh Sediments Impacted by Oil from the Deepwater Horizon Well Blowout. Environ. Sci. Technol. 2015, 49, 8356–8366. [Google Scholar] [CrossRef]

- Mustafa, Y.A.; Abdul-Hameed, H.M.; Abdul Razak, Z. Bioremediation of Soil Contaminated with 2,4-D Herbicide Using Bioslurry Reactor. J. Eng. 2023, 20, 109–128. [Google Scholar] [CrossRef]

- Karkush, M.O.; Ziboon, A.T.; Hussien, H.M. Studying the Effects of Contamination on Soil Properties Using Remote Sensing. J. Eng. 2023, 20, 78–90. [Google Scholar] [CrossRef]

- Zhang, H.; Yuan, X.; Xiong, T.; Wang, H.; Jiang, L. Bioremediation of co-contaminated soil with heavy metals and pesticides: Influence factors, mechanisms and evaluation methods. Chem. Eng. J. 2020, 398, 125657. [Google Scholar] [CrossRef]

- Varjani, S.J.; Rana, D.P.; Jain, A.K.; Bateja, S.; Upasani, V.N. Synergistic ex-situ biodegradation of crude oil by halotolerant bacterial consortium of indigenous strains isolated from on shore sites of Gujarat, India. Int. Biodeterior. Biodegrad. 2015, 103, 116–124. [Google Scholar] [CrossRef]

- Zhu, H.; Aitken, M.D. Surfactant-enhanced desorption and biodegradation of polycyclic aromatic hydrocarbons in contaminated soil. Environ. Sci. Technol. 2010, 44, 7260–7265. [Google Scholar] [CrossRef] [Green Version]

- Achugasim, D.; Osuji, L.; Ojinnaka, C. Use of activated persulfate in the removal of petroleum hydrocarbons from crude oil polluted soils. Res. J. Chem. Sci. 2011, 1, 57–67. [Google Scholar]

- Falciglia, P.P.; Giustra, M.G.; Vagliasindi, F.G.A. Lowtemperature thermal desorption of diesel polluted soil: Influence of temperature and soil texture on contaminant removal kinetics. J. Hazard. Mater. 2011, 185, 392–400. [Google Scholar] [CrossRef]

- Effendi, A.J.; Aminati, T. Enhancing Bioremediation of Crude Oil Contaminated Soil by Combining with Photocatalytic Process Using TiO2 as Catalyst. Int. J. Geomate 2019, 17, 100–107. [Google Scholar] [CrossRef]

- Ahmad, A.A.; Muhammad, I.; Shah, T.; Kalwar, Q.; Zhang, J.; Liang, Z.; Mei, D.; Juanshan, Z.; Yan, P.; Zhi, D.X.; et al. Remediation methods of crude oil contaminated soil. World J. Agric. Soil Sci. 2020, 4, 8. [Google Scholar]

- Diphare, M.; Muzenda, E. Remediation of Oil Contaminated Soils: A review. In Proceedings of the Integrated Waste Management & Environmental Engineering (ICCIWEE’2014), Johannesburg, South Africa, 15–16 April 2014; pp. 180–184. [Google Scholar]

- Adipah, S. Remediation of Petroleum Hydrocarbons Contaminated Soil by Fenton’s Oxidation. J. Environ. Sci. Public Health 2018, 2, 168–178. [Google Scholar] [CrossRef] [Green Version]

- Ogunkeyede, A.O. Conventional and Microwave Pyrolysis Remediation of Crude Oil Contaminated Soil. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2016; 223p. [Google Scholar]

- Xiang, Q.; Yu, J.; Wong, P.K. Quantitative characterisation of hydroxyl radicals produced by various photocatalysts. J. Colloid Interface Sci. 2011, 357, 163–167. [Google Scholar] [CrossRef] [PubMed]

- Brame, J.A.; Hong, S.W.; Lee, J.; Lee, S.H.; Alvarez, P.J.J. Photocatalytic pre-treatment with food-grade TiO2 increases the bioavailability and bioremediation potential of weathered oil from the Deepwater Horizon oil spill in the Gulf of Mexico. Chemosphere 2013, 90, 2315–2319. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Javed, H.; Zhang, D.; Li, D.; Kamath, R.; McVey, K.; Sra, K.; Alvarez, P.J.J. Merits and limitations of TiO2-based photocatalytic pretreatment of soils impacted by crude oil for expediting bioremediation. Front. Chem. Sci. Eng. 2017, 11, 387–394. [Google Scholar] [CrossRef]

| Soil Properties | Uncontaminated Soil | Contaminated Soil | ||

|---|---|---|---|---|

| Mean | S.D | Mean | S.D | |

| Natural moisture content (%) | 14 | 1.56 | 10.5 | 2.43 |

| In situ density (kg/m3) | 1360 | 0.16 | 1080 | 1.87 |

| Liquid limit (%) | 38 | 0.86 | 42 | 1.77 |

| Liquid limit (%) (exp. results) | - | - | 46.71 | 1.44 |

| Plastic limit (%) | 17.42 | 1.95 | 22.9 | 2.84 |

| Plastic limit (%) (exp. results) | - | - | 26.17 | 2.96 |

| Plasticity index (%) | 0.58 | 1.91 | 19.1 | 2.37 |

| Plasticity index (%) (exp. results) | - | - | 20.54 | 3.91 |

| Flow index (%) | 8.58 | 0.67 | 10.5 | 0.84 |

| Maximum dry | 1750 | 1.25 | 1680 | 0.11 |

| Density (kg/m3) | - | - | 1450 | 0.15 |

| OMC (%) | 16.48 | 1.53 | 12.5 | 1.05 |

| OMC (%) (exp. results) | - | - | 15.52 | 0.89 |

| UCS (kPa) (average of three tests) | 0.58 | - | 0.38 | - |

| Cohesion (kPa) (average of three tests) | 0.63 | - | 0.2 | - |

| The angle of internal friction (average of three tests) | 18 | - | 14 | - |

| Additives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lime | Fly Ash | Cement | |||||||||

| Atterberg Limits | Polluted Soil/ (Exp. Results) | Polluted Soil/ (Exp. Results) | 5% | 10% | 20% | 5% | 10% | 20% | 5% | 10% | 20% |

| Liquid limit (%) | 42 | 46.71 | 42.22 | 41.80 | 40.64 | 37.30 | 36.80 | 35.50 | 38.50 | 37.90 | 36.60 |

| Plastic limit (% | 22.9 | 26.17 | 25.80 | 23.70 | 19.44 | 19.00 | 18.70 | 17.90 | 19.28 | 18.50 | 17.80 |

| Plasticity index (%) | 19.1 | 20.54 | 16.42 | 19.10 | 21.20 | 18.30 | 18.10 | 17.60 | 19.22 | 19.40 | 18.80 |

| Additives | LL (%) | PL (%) | PI (%) | UCS in (kPa) |

|---|---|---|---|---|

| 10% lime + 10% fly ash | 42.84 | 23.11 | 19.73 | 109.44 (294%) |

| 10% cement + 10% fly ash | 38.46 | 18.45 | 19.96 | 87.28 (234%) |

| 15% lime + 5% fly ash | 40.73 | 22.38 | 18.35 | 122.58 (328%) |

| 10% lime + 5% fly ash + 5% cement | 25.59 | 19.87 | 5.72 | 138.28 (371%) |

| Parameter | Quantity |

|---|---|

| Clay, Silt, Sand, and Gravel (M.I.T. Categorization) | 3%, 89%, 7%, 1% |

| L.L., P.L., PI | 23.9, 45.5, 21.6 |

| Water Content | 3.90% |

| Organic Material Content | 3.64% |

| P.H. (in 27 °C) | 8–8.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mekkiyah, H.M.; Al-Hamadani, Y.A.J.; Abdulhameed, A.A.; Resheq, A.S.; Mohammed, Z.B. Effect of Crude Oil on the Geotechnical Properties of Various Soils and the Developed Remediation Methods. Appl. Sci. 2023, 13, 9103. https://doi.org/10.3390/app13169103

Mekkiyah HM, Al-Hamadani YAJ, Abdulhameed AA, Resheq AS, Mohammed ZB. Effect of Crude Oil on the Geotechnical Properties of Various Soils and the Developed Remediation Methods. Applied Sciences. 2023; 13(16):9103. https://doi.org/10.3390/app13169103

Chicago/Turabian StyleMekkiyah, Haider M., Yasir A. J. Al-Hamadani, Ali A. Abdulhameed, Ali S. Resheq, and Zainab B. Mohammed. 2023. "Effect of Crude Oil on the Geotechnical Properties of Various Soils and the Developed Remediation Methods" Applied Sciences 13, no. 16: 9103. https://doi.org/10.3390/app13169103