2.2. Data Preprocessing

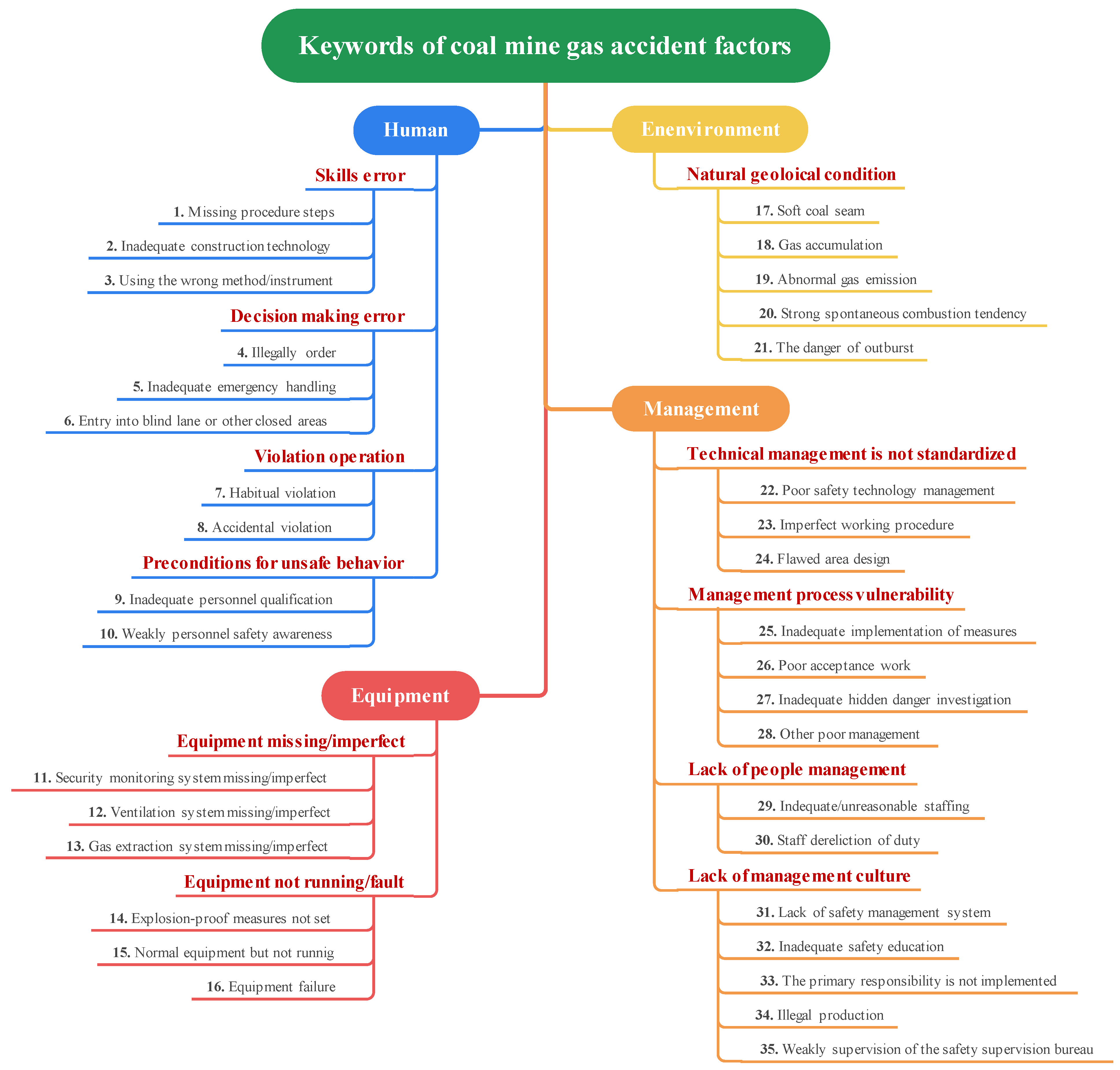

The causes of coal mine gas accidents are complex and changeable, and the identification of important factors leading to the occurrence of accidents can effectively prevent the occurrence of accidents [

15]. This paper adopts the idea of data-driven methods, extracts the key factors in the coal mine gas accident investigation report, and counts the frequency of each keyword. This paper also summarizes the causes comprehensively from the four aspects of human, equipment, environment, and management. Based on the statistical results of the frequency of the occurrence of keywords, combined with the existing literature and objective facts, 35 keywords with relatively high frequency are selected as research elements. As shown in

Figure 2.

- (1)

Human factors

The HFACS causation theory model divides human factors into four levels: unsafe behaviors, preconditions of unsafe behaviors, unsafe supervision, and organizational influence [

16]. According to the specific accident causes in the coal mine gas accident investigation report, this paper classifies human factors into three unsafe behaviors including skills error, decision-making error, and violation operation, as well as the preconditions of unsafe behaviors, and then divides them into different specific manifestations according to keywords. In order to avoid subjective factors affecting the classification process, the classification of factors in

Figure 2 is defined and explained as follows:

This refers to the “Missing procedures steps”, “Using inadequate construction technology”, “Using wrong methods/instruments”, etc. The missing procedures steps include failure to take anti-outburst measures, failure to test the effect of anti-outburst, blind operation without eliminating the risk of outburst, failure to measure the gas content in advance, etc. The construction technology is not in place, including the construction strength which is not in place, is not in accordance with the provisions of the design and construction, and equipment (facilities) installation is not reasonable. The use of wrong methods/instruments includes the use of wrong measuring tools, coal mining methods, gas extraction methods, etc.

- B.

Decision-making error

This refers to the situation of incomplete understanding and wrong judgment of emergency situations due to the lack of on-site experience or training of personnel, including “Illegally order”, “Inadequate emergency handling”, and “Illegal entry into blind lane and other closed areas”.

- C.

Violation operation

This refers to the behavior that the personnel do not abide by the rules and regulations subjectively, which is divided into habitual violation and accidental violation. Habitual violations often occur underground and are often condoned by managers, while operators are accustomed to natural violations, such as failure to carry or wear safety protection equipment, illegal shooting, illegal modification/use of equipment, falsified data parameters, and cross-operation of multiple types of underground work.

- (2)

Equipment factor

The objects in underground coal mine are mainly all kinds of working equipment and machines. With the progress and development of coal mining technology in China, the types and quantities of equipment and machines in underground coal mines are gradually increasing, and the unsafe state factors of objects are also increasing. In the process of sorting out and classifying all the equipment factors in the accident investigation report, it was found that there are various equipment factors involved in the specific content of the coal mine gas accident investigation report, and there are many fault types. The machine factors leading to accidents can be divided into missing or damaged parts of the equipment itself, working equipment is not in normal operation state, etc. This article is divided into two categories: “Equipment missing/imperfect” and “Equipment not running/failure”.

- A.

Security monitoring system missing/imperfect

This includes insufficient sensor types or quantity, insufficient gas monitor, and damaged safety monitoring equipment.

- B.

Gas extraction system missing/imperfect

Including: the ground gas extraction system has not been established, gas extraction drilling construction is not in place, and gas extraction time is not enough. The gas extraction system here includes equipment factors before and during the work, among which, insufficient gas extraction time can be a design defect, but from the overall situation, it should be classified as an imperfect gas extraction system.

- C.

Equipment failure

This refers to the long-term and occasional faults of all downhole equipment, such as short circuit, device detonation, cable damage, protection device does not move in time, gas data cannot be uploaded, etc.

- (3)

Environmental factors

Environmental factors include: coal mining geology is complicated, geological structure properties are different and so on. Environmental factors will indirectly lead to coal mine gas accidents [

17,

18,

19]. For example, if the spontaneous combustion of coal is strong, coal mines are prone to gas combustion accidents. This is because there is air leakage in the goaf or closed area, and the coal seam will come into contact with oxygen, resulting in spontaneous combustion [

20,

21]. It is easy to oxidize the coal body and cause gas combustion accidents [

22].

Secondly, the working environment of underground coal mine is another influencing factor causing coal mine gas accidents [

23,

24]. For example, the high noise in underground coal mines can easily affect the psychological state of operators, which may lead to operators making operation errors and to coal mine gas accidents [

25]. However, according to the specific content of the coal mine gas accident investigation report, there are few records of accidents caused by the poor working environment. Therefore, this paper mainly analyzes the natural geological conditions.

- (4)

Management factors

Management factors refer to the factors that cause safety accidents due to wrong or inadequate decision-making at the management level of coal mine safety production enterprises, which is the essential cause of the occurrence of coal mine safety accidents. The article classifies the management factors that appear in the accident investigation report as follows:

Poor safety technology management

Including no safety technical measures and safety technical measures are not perfect.

Flawed area design

The ventilation partition design is insufficient, the regional anti-penetration design is unreasonable, and the mining and excavation deployment is unreasonable.

Inadequate implementation of measures

The implementation of gas control measures is not in place, the implementation of blasting system is not in place, and the implementation of anti-intrusion measures is not in place.

2.3. Data Analysis Method

2.3.1. Accident Statistical Method

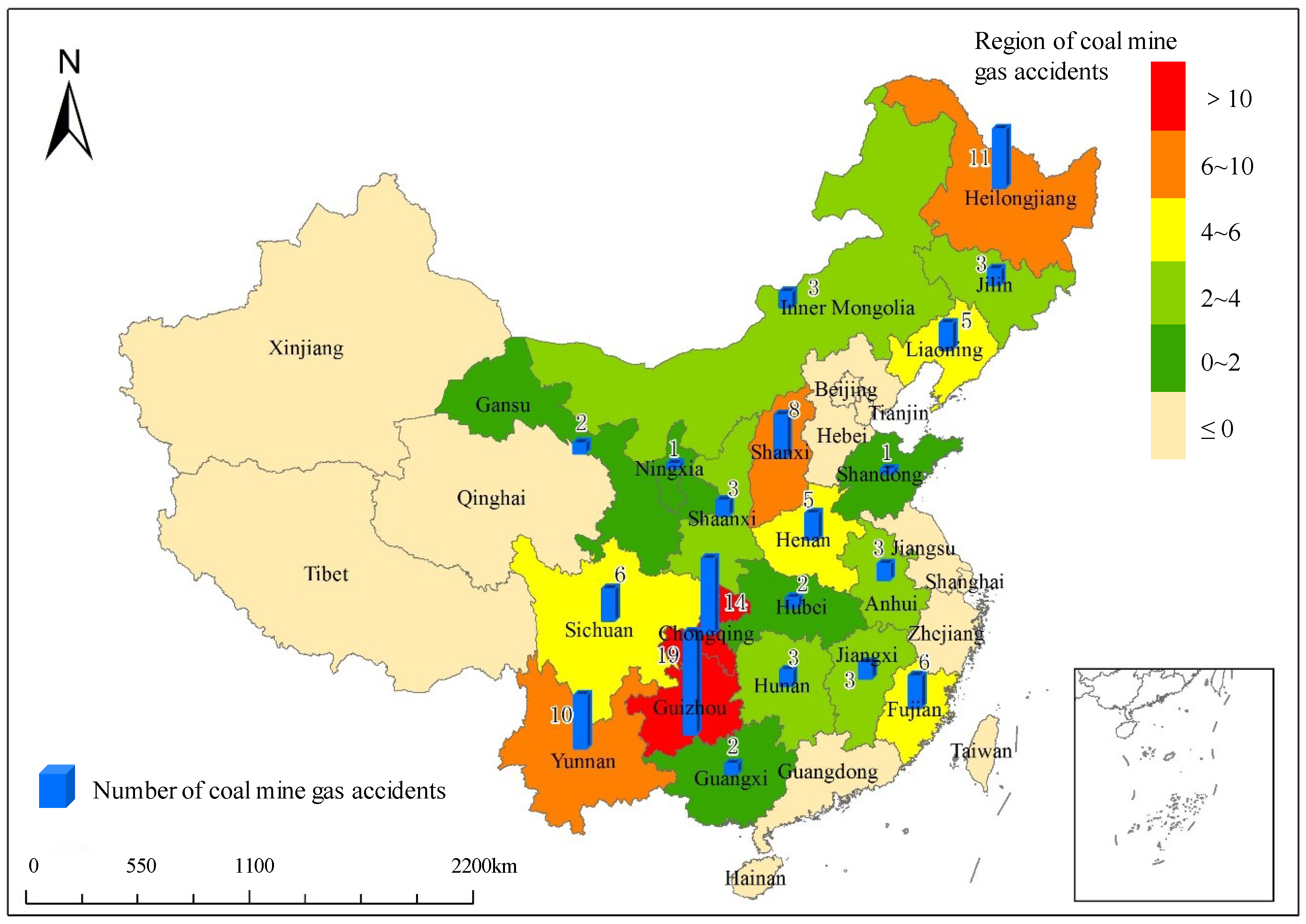

The samples of 110 coal mine gas accidents are comprehensively counted from three aspects of regional distribution, accident type, and accident grade, and the occurrence regularity of accidents is preliminarily explored.

2.3.2. Association Rule Method

The factors in coal mine gas accident are discrete data, and the occurrence frequency and frequency of factors are not enough to obtain the potential information from them. In order to get the relationship between each factor, the association rule method was selected as a data mining method for analysis.

- (1)

Association rule principle

The association rule data mining method is a means to discover potential connections hidden in a large amount of data. These potential connections can reveal the relationship between data, which is more conducive to discovering the occurrence mechanism of events [

26].

I for the item set, I = {, … }, where called the item, each transaction T is a subset of item set I. All T term sets, like X→Y (X,Y ⊆ I, X ∩ Y = ø) is the implied expression of the association rule.

- A.

Support:

This refers to the probability that transaction

X and transaction

Y occur simultaneously in the item set. In the application of the association rule method, the most important thing is to select the support threshold. The support threshold needs to be set reasonably according to the data situation. If the calculated support is lower than the threshold, it indicates that the occurrence times of the item set {

X,

Y} in the total item set are too few. Otherwise, subsequent analysis can be carried out. Support is expressed as:

- B.

Confidence:

This refers to the probability of transaction

Y occurring if transaction

X has already occurred. More important is the choice of confidence threshold, which reflects the ability of the occurrence of transaction

X to affect the occurrence of transaction

Y. Confidence is expressed as:

- C.

Frequent item sets:

The frequent item set refers to the set of all transactions whose support is greater than or equal to the support threshold. If the support of item set I meets the selected minimum support threshold, item set I is the frequent item set.

- D.

Association rules:

The association rules that meet the minimum support threshold and minimum confidence threshold are those selected to be mined.

- (2)

Apriori algorithm

Apriori algorithm is a data mining algorithm for mining frequent item sets and association rules. Its purpose is to carry out the two steps of association and mining continuously to find the association rules that meet the threshold of support and confidence.

Firstly, by scanning the database, the count of each item is accumulated and the items that meet the minimum support threshold are collected to find the set of frequent item set 1, denoted as . Then, use to find of frequent item set 2, use I to find , and so on until frequent k item set can no longer be found. A full scan of the database is required for each found.

- (3)

Analysis steps

The frequent item set in this paper is a combination of frequently occurring factors that lead to coal mine gas accidents. The mining results of frequent item sets are closely related to the selection of support threshold. If the support threshold is set too large, there will be too few causes in frequent item sets, which is not conducive to the generation of association rule results. However, if the support threshold is set too small, the number of frequent item sets generated will be too large, and it is not easy to determine the root cause of coal mine gas accidents. In order to prevent improper selection of the support threshold from affecting the conclusion of association rules, this paper determines the most appropriate support degree by comparing frequent item sets obtained from different support degrees. Four support degrees of 0.2, 0.15, 0.1, and 0.05 were selected, and 0.05 was selected as the frequent item set of minimum support mining after comparison of results.

After the frequent item set is obtained, the Apriori algorithm is used to mine association rules. According to the comparison of experience and results, the confidence degree is set as 0.4. One factor in the frequent item set is taken as the front term of association rules, and the other factors are taken as the back term, respectively.

2.3.3. Accident Cause Chains Method

The occurrence of coal mine gas accidents is the result of the interaction and joint action of various factors. According to association rules, a more intuitive cause chain of coal mine gas accidents is constructed, from which three cause chains are extracted for analysis and countermeasures and suggestions are put forward.