Abstract

Existing research on integrated innovation primarily focuses on the integration of product functions or technologies in the engineering field, with limited exploration of cross-domain integration of biological knowledge. Various organisms exhibit various advantageous biological characteristics, and the multi-biological knowledge embedded within these characteristics can inspire designers to implement product integrated innovation. Biologically Inspired Design (BID) is a method that seeks inspiration from nature to achieve innovation in the engineering field. However, existing BID processes mainly apply the features of a single biological prototype. Against this background, this paper emphasizes how to achieve cross-domain integrated innovation through multi-biological knowledge. First, a method for generating integrated innovation ideas is proposed, achieved through obtaining biological prototypes and analyzing biological performance. Second, by obtaining the principal solution through the three mapping methods of biological effects, behaviors, and structures, a method for building the conceptual structure of integrated innovation is proposed. Finally, in conjunction with the Theory of Inventive Problem Solving (TRIZ), a product-integrated innovation design process model based on biological inspiration is constructed. The method is validated with an example of a six-legged firefighting robot.

1. Introduction

With the shortening of product life cycles and the increase in market uncertainty, rapid identification and resolution of product problems can help companies gain advantageous positions in the market. Integrated innovation is the process of effectively integrating various elements in the product design process based on existing resources and developing new products that meet the needs of users [1]. Current research on integrated innovation mainly focuses on the integration of functions or technologies of products in the engineering field. Knowledge in the biological field can provide designers with innovation inspiration. By fully leveraging advantageous biological characteristics and integrating the biological knowledge embedded in these characteristics into products, it is possible to create new products that satisfy user needs. However, there is currently less research on applying biological knowledge to achieve the cross-domain integrated innovation of products.

Biologically Inspired Design (BID) is a method that applies biological knowledge to achieve innovation [2]. This method advocates seeking inspiration and potential solutions from the biological field to solve design problems in the engineering field [3,4,5]. In the process of BID, some scholars have employed bio-inspired topology optimization methods to achieve specific functionalities and enhance system compactness and structural compliance of robots, aiming for optimal designs [6,7]. In nature, the multi-biological knowledge possessed by different organisms can provide inspiration for designers to carry out product-integrated innovation. However, the current BID process focuses on applying the feature of a single biological prototype, and there is a need to seek an innovative design approach that integrates multi-biological features to solve the design problem of a product.

In summary, this paper draws on biological coupling theory to study the mechanism of product-integrated innovation based on biological inspiration. The study uses the Asknature biological knowledge base to search and perform a similarity analysis to obtain similar biological prototypes. Through the evaluation of the advantageous performance of biological prototypes and the judgment of the contribution degree of biological features, an integrated innovation idea generation method based on biological inspiration is proposed. By obtaining principal solutions through three mapping methods of biological effects, biological behaviors, and biological structures, an integrated innovation conceptual structure construction method based on biological feature mapping is proposed. Subsequently, a product-integrated innovation design method based on biological inspiration is generated.

The rest of this paper is arranged as follows. Section 2 introduces the development status of BID and integrated innovation. Section 3 introduces the proposed method and product-integrated innovation design process, including the generation of innovative ideas and the construction of product concept structures. Section 4 uses a six-legged firefighting robot as an example to validate the proposed method.

2. Related Research

2.1. Integrated Innovation

The concept of Integrated Innovation originates from the innovation theory proposed by Schumpeter [8]. Schumpeter proposed that innovation involves the “establishment of a new production function”, essentially implying a novel combination of factors and conditions of production. Integrated innovation during the product design process can effectively amalgamate various innovative elements to optimize the product. Researchers have studied integrated innovation from different perspectives.

From the perspective of product technology, Liu et al. [9] defined technology hybridization as the process of recombining technological bases to achieve integration between product technology properties. They validated this using an example of a traditional Chinese medicine dropping pills defatting machine. Zhang [10] divided the product innovation of technology integration into three stages: technology development, technology integration, and productization. This work suggests that the process of achieving product innovation through technology integration is a dynamic and cyclical evolution.

From the perspective of product function, Teng [11] studied the method of functional integration and analyzed the fire rescue drone, proposing the design process of an intelligent fire rescue drone based on function integration. Through functional analysis and the integration of functional elements, the fire rescue drone achieved functions such as automatic startup, quick charging, and smart capabilities. Chen [12] researched the theory and characteristics of integrated innovation and designed the urban main battle fire truck with integrated innovation, which realized the innovation in the whole vehicle shape, control system, and human–machine interaction. Klaiber et al. [13] described four generic strategies of functional integration derived gradually from differential designs. This study used different strategies to generate solutions in a systematic way. Moreover, these strategies were proposed to save weight, cost, and time for assembly and gain more installation space. Furthermore, scholars have investigated functional integration from several aspects including function fusion, function sharing, and function combination. In the aspect of function fusion, Ding [14] executed a design of function fusion for the fan mechanism and the body structure of a street sweeper truck. After optimization, finite element analysis and modal analysis were performed on the updated structure. The result was a lighter overall vehicle weight, while the performance requirements were still satisfied. Based on the function-oriented search for obtaining knowledge from multiple domains, Liu [15] established a functional design model rooted in the fusion of multi-domain knowledge, which was then employed for function fusion design and structure fusion design. Further, leveraging multi-domain knowledge fusion, Liu proposed a global idealized design method. When this method was applied to the design of an emergency cup that could desalinate seawater, a highly idealized product solution was achieved. In relation to function sharing, Kalyanasundaram et al. [16] proposed a function-based product integration approach. A function-sharing matrix and a component-sharing matrix were created based on the reconfigurable principle to identify the shared functions and components of two products. After that, a new product was obtained by combining the functional structure of the integrated product. The approach focused on assessing the feasibility of integrating two existing single-state products to produce a new reconfigurable or multifunctional product. Frohlic et al. [17] proposed a design method for multi-functional products, which can achieve different functions through a single structure. In terms of function combination, Liu et al. [18] analyzed the evolution process of product functional systems and proposed that implementing function combination must satisfy two principles: function complementarity and technology sharing. They established a model for the product-integrated innovation design process based on function combination and the Theory of Inventive Problem Solving (TRIZ). The feasibility of this model was verified through an innovative design instance that integrated straighteners and curlers into one product. Jiang et al. [19] presented the establishment of a functional combination matrix to innovatively form various products and enrich the product system through the combination and collocation of functions. Cao et al. [20] proposed a design process for function combination. They analyzed the combination relationship between each sub-function by decomposing the function of the product technology system and selected a function combination solution according to the market demand. Lu et al. [21] proposed a method for product function combination based on the functional structure and design matrix. This approach integrates multiple product functions into a single product.

From a biological perspective, Hou et al. [22] summarized different function combination patterns including, chain-like, tree-like, and cyclic based on multi-biological effects, and proposed a product design method based on function combination. This method was used to design a tent that could collect fresh water. Liu et al. [23] drew on the concept of biological gene recombination to research a product gene model suitable for product function hybridization, as well as a product gene recombination method, and then established a product functional hybridization design process model.

Most existing research on integrated innovation primarily generates integrated ideas by leveraging knowledge from the engineering field, with a focus on the integration of functions or technologies within products. Organisms have excellent biological features after hundreds of millions of years of evolutionary history. By introducing these biological features into product design and integrating them with the product, this approach has the potential to improve existing systems to form new products. It also provides new ideas and directions for solving complex design problems. However, fewer studies are available on the application of biological knowledge to achieve the cross-domain integration of products.

2.2. Biologically Inspired Design

An analogy, a cognitive process rooted in the similarity between two objects, facilitates the transfer of knowledge from the source to the target, thereby effectively guiding and nurturing creative potential [24]. Analogical design is a method that applies analogical thinking to product design. Moreno [25] argued that analogical design is a process that assists designers in identifying relevant cases, scenarios, and experiences to solve problems. Liu [26] suggested that research on analogical design has mainly focused on three aspects: the representation of analogical knowledge, retrieval of design analogies, and the transfer of analogical knowledge. Broadly speaking, analogical design can be divided into intra-domain analogical design and cross-domain analogical design [27]. In cross-domain analogical design, where the source of the analogy and the design target originate from different fields, innovation efficiency can be significantly enhanced, and the level of innovation elevated [28,29].

BID represents a method of cross-domain analogical design, stressing the emphasis on innovative design over mere imitation and replication of biological phenomena [30]. Existing research categorizes BID into two types: single-source analogy and multi-source compound analogy. Single-source analogy generates solutions based on a single biological prototype, while multi-source composite analogy generates solutions based on multiple biological prototypes.

In terms of single-source analogy, Wang [31] combined bionics with reconfiguration design and established a product innovation design process model. The biological prototype with the highest similarity was selected, and through a transformation model, the features of the biological prototype (including function, strategy, behavior, and structure) were transferred layer by layer to the product technology system. This process enhances the practicality and applicability of the design method. Liu [32] proposed a biological coupled function extension tree model, leveraging extenics and coupled bionics. The biological coupling elements were transferred by calculating their contribution, and the cicada wing with the highest similarity was used as a bionic example to solve some problems with the radiation well horizontal drilling machine. This underscores the practical effectiveness of applying biological prototypes to engineering problem-solving. Ji [33] mapped from the functional level to transfer the biological problem solution to the engineering field, and the problem of the poor portability of helmets was solved using an armadillo shell structure as an example. This method highlights the process of transforming biological features into practical product advantages. Liu [34] used bionics, extenics, and BioTRIZ for product innovation design, creating an extension model for the product and the biological prototype with the greatest similarity to the product. The transfer of coupled elements was carried out through conflict matrix resolution and the importance judgement of biological coupled elements. This approach emphasizes the importance of integrating multidisciplinary methods in product innovation. Chen et al. [35] selected the biological prototype with the highest similarity to the product as the biomimetic object. Utilizing the biological system database, the product system database, and the collaborative middleware database, they mapped the technology system from four levels of the biological system (function, principle, action, and structure). By integrating the inherent relationships across various levels of the technology system, they were able to derive product solutions. This study highlights the inspiration of integrating information from multiple sources in the design process. Liu et al. [36] utilized multi-biological effects for functional problem-solving. Through the effect transformation method of biological prototypes, they rapidly converted the biological prototype with the highest similarity into a product that met market demand, highlighting the potential of single-source analogy in enhancing product functionality.

In terms of multi-source compound analogy, Goel [37] provided a process description for compound analogy design, utilizing the analysis of various BID process instances. In the process of problem-solving, if the problem can be decomposed, the problem can be divided into sub-problems. Assuming the problem decomposes along the function, the designers identified similar biological instances by searching for each sub-function, thereby obtaining a solution for each sub-function. These solutions were then combined to generate an overall engineering solution. When the problem is not decomposable, a solution is directly formulated by searching for biological instances that resemble the problem itself. Liu et al. [38] performed feature clustering for the main functions of the target product. The corresponding multi-biological effects were obtained by retrieving each feature term, and the optimal biological effect was selected for the solution of the product problem to obtain the technical solution. Hou [39] proposed a breakthrough innovation design approach based on multi-biological effects. The general function of the product was decomposed to the functional element, and the functional elements were searched in the multi-biological effect knowledge base to obtain corresponding biological prototypes and multi-biological effect principal diagrams. Finally, the principal solution of the product was obtained through screening and combination. This approach utilizes multiple biological effects to deconstruct product functions, search for biological prototypes, and combine them to drive breakthrough innovation in product design. Liu et al. [40] proposed a bionic design strategy based on the function combination. They combined the new functions generated by various bionic design methods with each other to enhance the quality of the product. This highlights the substantial influence of multi-source compound analogies on function innovation. Bhasin et al. [41] introduced a tool for BID, termed as the Reduced Function-Means (RF-M) tree. The RF-M tree could illustrate the interactions among functions, behaviors, and structures in biological systems. They also proposed a problem-driven BID method. This method combined RF-M trees from multiple biological prototypes to achieve function sharing. This study provides a robust method for supporting problem-driven biomimetic design.

BID introduces novel solutions to product design by leveraging cross-domain knowledge analogies. In the BID process, most designers use a single biological prototype feature with the highest similarity for analogical transfer when solving sub-functions or functional elements. However, reliance on a single biological prototype may fail to fully exploit the diversity of organisms, which could lead to unresolved design issues, or the solution put forth by the single biological prototype might not represent the optimal choice.

2.3. Summary of the Literature Review

In summary, BID applies biological knowledge to address engineering challenges, whereas integrated innovation amalgamates solutions from various fields to foster innovation. By intertwining BID with integrated innovation, cross-domain knowledge can be utilized to rectify product issues, consequently enhancing product performance. Additionally, this amalgamation can further optimize resource utilization, fostering the development of more innovative products. The focal point of this article lies in implementing cross-domain integrated innovation through the application of multi-biological knowledge. Specifically, the generation of integrated innovative concepts and the establishment of an integrated innovation conceptual framework are paramount to the entire innovation design process.

3. Proposed Methods

3.1. Integrated Innovation Mechanism Based on Biological Inspiration

3.1.1. Acquire Problem Performance of Products Based on Root Cause Analysis

A product, as a technological system, exhibits specific performance. Performance is characterized by the technical attributes of the system during function implementation [42,43], stemming from functional objects, functional carriers, or their interactions. The performance of the product influences customer satisfaction. In this study, the term ‘problem performance’ is used to describe the aspect of a product’s performance that fails to meet user needs.

Using the problem performance of a product as a bridge for analogical design, it is essential to seek biological prototypes in the biological field that have advantageous performance opposite to the problem performance. The advantageous features inherent to the biological prototype are transferred to the engineering domain to solve problem functional elements. Identifying the problem performance of the product allows designers to gain a precise understanding of the issue, serving as the foundation for obtaining the appropriate biological prototype.

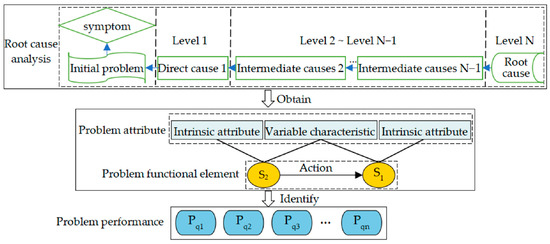

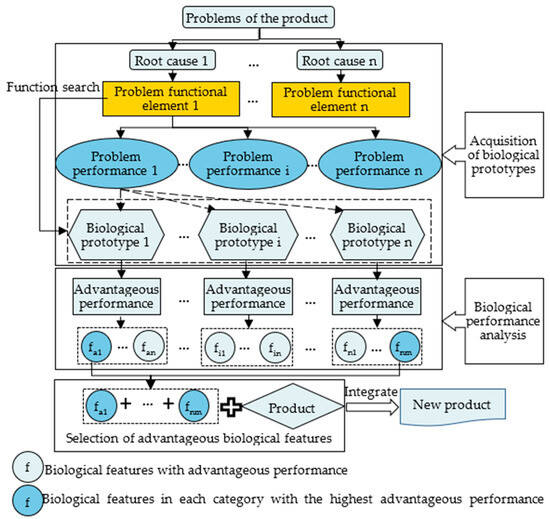

In this study, root cause analysis tools were employed to identify the components causing the issue and their corresponding problem attributes, thus leading to the identification of the problem performance of the product. Problem attributes comprise the intrinsic attributes and the variable characteristics of components or supersystems [44]. The process of identifying the problem performance of the product is illustrated in Figure 1.

Figure 1.

The process of identifying product problem performance.

3.1.2. Biological Coupling Analysis

Through extended evolutionary processes, organisms have refined their capacity to adapt to environmental changes. They exhibit outstanding biological characteristics that enable the achievement of functional elements akin to those of the product, thus displaying advantageous performance [45]. The advantageous performance exhibited by biological prototypes is a result of their unique biological features. For example, black thick-tail scorpions live in desert environments and have evolved unique biological features enabling them to resist erosion from wind-blown sand [46], thereby exhibiting advantageous anti-erosion performance. Different biological prototypes display varying degrees of advantageous performance while accomplishing the same function. Additionally, the impact of the biological features on actualizing the advantageous performance of the biological prototype varies. The extent of this impact depends on the degree of contribution of the biological features toward achieving that function.

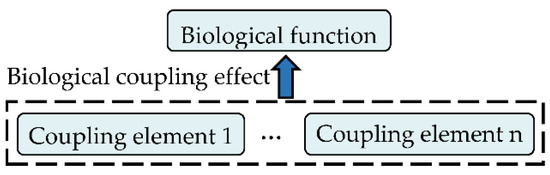

The realization of biological functions is seldom accomplished by a single part of an organism or a single factor but is the result of the synergistic interaction of two or more different parts of an organism or the coupling of different factors, and this coupling phenomenon is prevalent in biology [47], as shown in Figure 2. Biological coupling elements are various factors that contribute to biological functions and are the basic units that constitute biological coupling [48]. This study employs the biological coupling analysis method to examine the biological features inherent in biological prototypes that display advantageous performance and assess the degree of contribution of biological features. These biological features encompass biological effects, behaviors, and structures (including structural distribution, morphology, constituent materials, and inter-structural relationships).

Figure 2.

Realization model of biological function.

3.1.3. Integrated Innovation Mechanism Based on Multi-Biological Knowledge Inspiration

The integrated innovation mechanism inspired by multi-biological knowledge is an innovation process that integrates multi-biological features with products. This process commences with the existing issues of the product, selects advantageous biological features via acquiring biological prototypes and analyzing biological performance, and then integrates the selected multi-biological features into the product to form a new product. Its implementation principle is shown in Figure 3, and the specific process is as follows.

Figure 3.

Realization model of biological function.

First, the process starts with the problems of the product. Problem functional elements and their attributes are identified through root cause analysis, culminating in the discernment of the product’s problem performance. Utilizing the biological knowledge base to search for the problem function element, multiple biological prototypes are obtained. Subsequently, the degree of advantageous performance displayed by these biological prototypes is assessed. The biological features inherent to the prototypes that display advantageous performance, along with the contribution of these features, are analyzed using the biological coupling analysis method. Furthermore, the extent to which the biological features influence the advantageous performance is analyzed. If the features possessed by different biological prototypes exhibiting advantageous performance belong to the same category—for example, if they all belong to the morphological category—then the value of the degree of influence of this feature on the advantageous performance of these biological prototypes, i.e., the advantageous performance impact value, is not necessarily the same. The higher the value of the biological feature, the more effective it is for solving the problems of the product and has the potential to further improve the performance of the product. Ultimately, the biological feature in each category with the highest advantageous performance impact value is selected and integrated with the product to solve the problem functional element.

3.2. Method of Generating Integrated Innovation Ideas Based on Biological Inspiration

3.2.1. Acquire Similar Biological Prototypes

Functional similarities exist between the biological prototype and the product. Upon identifying the problem functional element through root cause analysis, this paper utilized the Asknature biological knowledge base to search for related functions and thus acquire biological prototypes. Based on this, a similarity analysis was conducted for the biological prototypes. The similarity between the biological prototypes and the product was categorized into three levels: level I, level II, and level III, where level I represents the highest level of similarity, as shown in Table 1. The impact on the product varies when integrating the biological features, depending on the level of similarity.

Table 1.

Similarity classification.

The similarity of the functional elements and the similarity of the behavioral elements were evaluated by calculating the similarity values of the similar elements. Here, the similar element is represented as ui, and the similarity value is determined by calculating Sim(ui), as shown in Equation (1), where ωj denotes the weight of the evaluation index, and Gra(kj) is the similarity value between two similar indexes. The calculation formula for Gra(kj) is shown in Equation (2), where v ∈ {0.1, 0.2, …, 0.9}. Elements are considered similar if Sim(ui) ≥ 0.6.

The similar functional element is represented as ui(Fp, Fbi), evaluated through 10 indicators: functional carrier, action, functional object, input energy, input substance, input signal, output energy, output substance, output signal, and environment. The weight attributed to each indicator is represented by ωA, where, ωA = {ω1,…,ωi,…,ω10}. The similar behavior element is represented as ui(Bp, Bbi), evaluated through 8 indicators: dominant object, actuated object, action, accepting object, pre-dominance state and post-dominance state of the dominant object, and pre-acceptance state and post-acceptance state of the accepting object. The weight assigned to each of these indicators is represented by ωB, where ωB = {ω1,…,ωi,…,ω8}.

In order to better integrate this method into industrial design, this paper provided the fundamental factors for evaluating the similarity values of functional similarity indicators, as shown in Table 2, as well as the fundamental factors for evaluating the similarity values of behavioral similarity indicators, as shown in Table 3. When applying this method to industrial design, it is crucial to ensure that the data are standardized and normalized initially. This enhances comparability among different data sets, making weight calculations more accurate and rational. Furthermore, during the early stages of design, models or simulations can be employed to validate the results of similarity assessments. By fabricating design prototypes or testing them within virtual environments, the accuracy of evaluation data can be verified, and necessary adjustments made. Additionally, close collaboration with domain experts is essential to ensure the validity and practical applicability of assessment data.

Table 2.

Fundamental factors for evaluating the similarity values of functional similarity indicators.

Table 3.

Fundamental factors for evaluating the similarity values of behavioral similarity indicators.

3.2.2. Method of Generating Integrated Innovation Ideas Based on Biological Performance Analysis

- Evaluate advantageous performance of biological prototypes

Various biological prototypes exhibit different degrees of advantageous performance in performing the same function. The advantageous performance of a biological prototype is influenced by the intrinsic attributes of the functional carrier, action, and functional object. An advantageous performance value evaluation index based on these attributes was established, as shown in Table 4. Performance values have been categorized into five ascending levels: 1, 3, 5, 7, and 9.

Table 4.

Advantageous performance value evaluation index based on attributes.

- 2.

- Judge the contribution degree of biological features

The advantageous performance exhibited by an organism when carrying out a function is the result of multi-biological features working in concert. However, the contribution of each biological feature toward realizing that function varies. Determining the contribution degree of biological features is a prerequisite for calculating the advantageous performance impact value. In this study, the analytic hierarchy process (AHP) [49,50] was employed to determine the contribution degree of biological features, and the steps are as follows:

Step 1: Establish the set X = {x1, x2,…xn} of each biological feature that contributes to the realization of the function of the biological prototype, where n denotes the number of biological features.

Step 2: Analyze the biological features and list the judgment matrix A. The element xij in matrix A indicates the importance degree of biological feature xi (1 ≤ i ≤ n) relative to biological feature xj (1 ≤ j ≤ n). Its value ranges from 1 to 9. xij is assigned a value depending on the varying degrees of importance, with the value increasing as the importance difference between two biological features grows. Here, 1 indicates that two biological features share equal importance, while 9 signifies that one biological feature is of extreme importance relative to the other. If the biological feature xi is compared with xj to get xij, then the biological feature xj is compared with xi to obtain xji = 1/xij.

Step 3: Compute the maximum eigenvalue λmax of matrix A and its corresponding eigenvector G and perform a consistency check. Normalize the eigenvector to obtain the contribution value of the biological features. The steps for consistency check are as follows:

1. Calculate the consistency index (CI), as shown in Equation (3).

where λmax is the maximum eigenvalue of the judgment matrix and n is the order of the judgment matrix.

2. The mean random consistency index (RI) is obtained by looking up the table. The values of the 1~10 order judgment matrices are shown in Table 5.

Table 5.

Mean random consistency index.

3. Calculate the consistency ratio (CR), as shown in Equation (4).

When CR < 0.1, it is generally believed that the consistency of the judgment matrix is acceptable; otherwise, the judgment matrix should be appropriately corrected.

- 3.

- Generate integrated ideas

After assessing the advantageous performance of the biological prototype and appraising the contribution degree of its features, the advantageous performance impact value of the biological features was calculated. This study then integrated the biological features from different prototypes, which possess the highest advantageous performance impact value in each type of feature, to form the integration idea. The specific steps are as follows:

Step 1: Utilizing the root cause analysis tool, the current product issues were analyzed to determine the root causes. After identifying the root causes, this study analyzed the problem performance when the product accomplishes its functional elements. The problem performance may be caused by a functional carrier, action, or functional object.

Step 2: Assess the advantageous performance of the biological prototype. Each biological prototype exhibits advantageous performance in achieving similar functions as opposed to problem performance, and the degree of advantageous performance differs among prototypes. The advantageous performance caused by the functional carrier, action or functional object of the biological prototype, was scored according to Table 2.

Step 3: Analyze the biological features that the biological prototype possesses when exhibiting advantageous performance in implementing similar functions. Make judgments on the contribution degree of these features and establish a score table for the contribution degree of biological features.

Step 4: Establish a score table for the advantageous performance impact value of the biological features. The advantageous performance impact value of the biological feature is denoted as Vi, the advantageous performance value of the biological prototype is denoted as Vp, and the contribution degree of the biological feature is denoted as Dc. Calculate the Vi, as shown in Equation (5).

Step 5: Generate integration ideas. For a single problem functional element, the integratable biological features from biological prototypes exhibit variability across different similarity levels. The difference between similarity level I and the other two levels resides in the effect. Therefore, the obtained biological prototypes are classified based on their effect. Within prototypes with the same effect, the features with the highest advantageous performance impact value are chosen from each feature category to be integrated with the product. If the highest level of similarity is I, multiple integrated ideas with different effects can be generated. If the highest level of similarity is II, multiple integrated ideas with different behaviors can be generated. If the highest level of similarity is III, multiple integrated ideas with different structures can be generated. If the root cause corresponds to multiple problem functional elements, establish a morphological matrix corresponding to the integrated ideas.

- 4.

- Select integrated idea

The practical degree parameter (Pdi) is used to select the integration idea, as shown in Equation (6). When solving product problems, the higher the overall performance (Poi) of the product and the smaller the degree of change (Cdi) of the product, the larger the parameter value and thus the greater the practical degree. In the morphological matrix corresponding to multiple problem function elements, the integration idea with the highest value of practical degree parameter in each problem function element is selected to solve the problem.

The calculation of the overall performance value of the product is based on the assumption that the integrated idea can be realized. It is the total score obtained by adding the advantageous performance impact values of each biological feature in the integrated idea.

The degree of change of the product is evaluated under the assumption that the integrated idea can be implemented. It can be divided into five categories: relatively small, small, moderate, relatively large, and large, as shown in Table 6. Scores can be assigned considering three aspects: structure (form, material, and distribution), behavior (direction of movement), and effect. The greater the degree of change, the higher the score.

Table 6.

Scoring table of degree of change.

3.3. Method of Establishing Integrated Innovation Concept Structure Based on Biological Feature Mapping

3.3.1. The Conversion Process from Integrated Innovation Ideas to Concept Structure

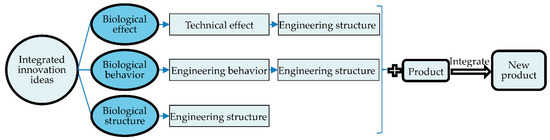

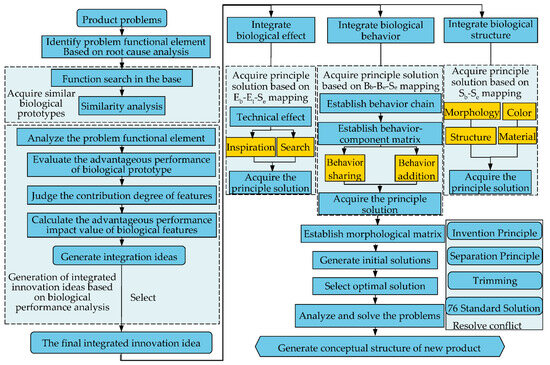

The integrated innovation idea involves integrating biological effects (Eb), biological behaviors (Bb), or biological structures (Sb) with a product. These biological features are individually mapped onto the engineering field and subsequently integrated with the product to build conceptual structure. The transformation process from integrated innovation idea to concept structure is shown in Figure 4.

Figure 4.

Conversion process from integrated innovation idea to conceptual structure based on biological feature mapping.

In the obtained integrated innovation ideas, if the element to be integrated is a biological effect, the biological effect is mapped to the engineering field to obtain a corresponding technical effect (Et). Then, the structure in the engineering field corresponding to the technical effect is identified, thereby forming a principal solution based on the Eb-Et-Se mapping. If the element to be integrated is a biological behavior, the biological behavior is mapped to the engineering field to obtain a corresponding engineering behavior (Be). Subsequently, the structure in the engineering field corresponding to the engineering behavior is identified, thereby generating a principal solution based on the Bb-Be-Se mapping. If the element to be integrated is a biological structure, the biological structure is mapped to the engineering field. The engineering structure is found or imitated from the biological structure, thereby generating a principal solution based on the Sb-Se mapping. The principal solutions are then gathered to build the conceptual structure.

3.3.2. Acquire Principal Solution Based on Eb-Et-Se Mapping

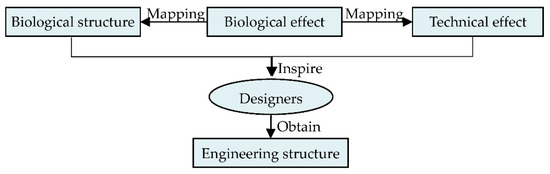

If the integrated innovation idea includes the integration of biological effects with the product, the engineering structure can be identified through two methods: inspiration or search.

- (1)

- Inspiration. Researchers study the biological structure that implements a function similar to the problem functional element through the biological effect and seek the corresponding technical effect of the biological effect in the engineering field. Through technical effects and biological structures, designers derive inspiration to identify engineering structures that can achieve similar functions. The process of obtaining the principal solution through inspiration is shown in Figure 5.

Figure 5. Process of obtaining the principal solution by means of inspiration.

Figure 5. Process of obtaining the principal solution by means of inspiration.

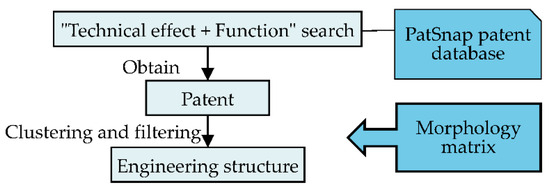

- (2)

- Search. In the engineering field, researchers search for the technical effect corresponding to the biological effect. The technical effect and the problem functional element are expanded using synonyms, near synonyms, or related words, which form the search formula “technical effect + function” in the PatSnap patent database. The obtained patents are clustered and filtered based on design experience to identify engineering structures. During the clustering and filtering process, several different patents are obtained. Taking into account that different patents may correspond to different sub-functions when implementing functions through the same technical effect. In this regard, a morphological matrix is established to obtain the engineering structures that realize the sub-functions. The process of obtaining a principal solution through this search method is shown in Figure 6.

Figure 6. Process of obtaining the principal solution by means of search.

Figure 6. Process of obtaining the principal solution by means of search.

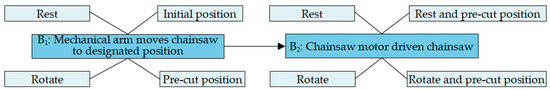

3.3.3. Acquire Principal Solution Based on Bb-Be-Se Mapping

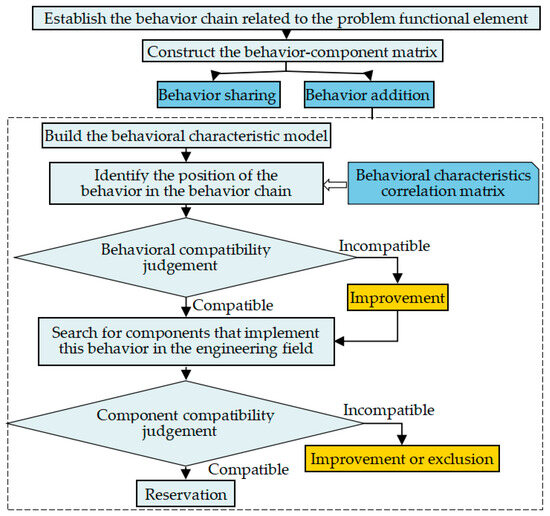

If the integrated innovation idea includes the integration of biological behaviors with the product, the engineering structure can be identified through two forms of integration: behavior sharing and behavior addition. Behavior sharing refers to a single component that can perform multiple behaviors. It is determined whether there are components in the product that can perform the behavior to be integrated, and if so, behavior sharing can be achieved. Behavior addition involves adding the behavior to be integrated to the behavior chain to solve product problems. The process of obtaining the principal solution based on Bb-Be-Se mapping is shown in Figure 7, and the specific steps are as follows:

Figure 7.

Process of obtaining principal solution based on Bb-Be-Se mapping.

Step 1: Establish the behavior chain and the behavior-component matrix associated with the problem functional element.

Step 2: Perform behavior sharing. Determine whether the product component can share the behavior to be integrated, and if there is a component in the behavior-component matrix that can implement the behavior, then the sharing is completed.

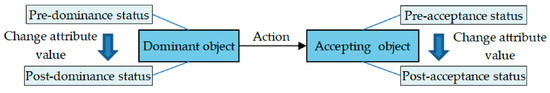

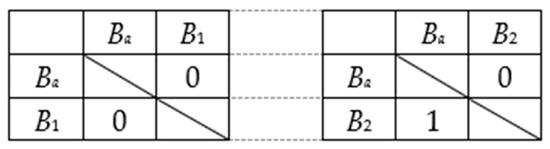

Step 3: Perform behavior addition. First, establish the behavioral characteristic model for the behaviors to be integrated, as shown in Figure 8. The dominant object changes the attribute value of the accepting object through its actions, thereby changing the pre-acceptance state and post-acceptance state of the accepting object.

Figure 8.

Behavior characteristics model.

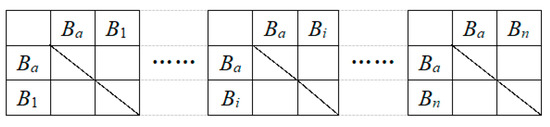

Second, determine the position of the behaviors to be integrated in the behavior chain. Considering that the Design Structure Matrix (DSM) is a mathematical tool for describing the complex relationships, interdependencies, and constraints among various design factors (such as design parameters, design activities, etc.) [51], this study established the behavior association matrix with the help of the DSM. The position of the behavior, which is to be integrated, within the behavior chain is determined by comparing the consistency between the pre-dominance and post-dominance status of the dominant object, or the pre-acceptance and post-acceptance status of the accepting object. The behavior association matrix of the behavior to be integrated and the n behavior elements in the behavior chain are shown in Figure 9. In the matrix, Ba represents the behavior to be added, and Bi (i = 1~n) represents the behavior elements in the related behavior chain. In the figure, ‘1’ below the diagonal line indicates a forward contact, ‘1’ above the diagonal line indicates a reverse contact, and ‘blank’ indicates that there is no connection between the behaviors.

Figure 9.

Behavior incidence matrix.

If both positions above and below the diagonal line are ‘blank’, it indicates that the behaviors are incompatible. If both above and below the diagonal line are ‘1’, it indicates that the behaviors are coupled. If ‘1’ is below the diagonal line and ‘0’ is above, it indicates a forward series connection of behaviors, represented as Bi→Ba. If ‘1’ is above the diagonal line and ‘0’ is below, it indicates a reverse series connection of behaviors, represented as Ba→Bi. The subsequent step is to assess the compatibility of the behavior. If the behavior is compatible, components that can implement this behavior in the engineering domain are sought, followed by an evaluation of component compatibility. If it is not compatible, auxiliary behaviors are added, or the behavior attribute values are modified.

3.3.4. Acquire Principal Solution Based on Sb-Se Mapping

If the integrated innovation idea includes the integration of biological structures with the product, the principal solutions are procured through structural integration. Structural integration refers to the transference of features such as the morphology, structure, color, and material of biology to the engineering field and then integrated with the product. The process of procuring principal solutions based on Sb-Se mapping is shown in Table 7.

Table 7.

The process of obtaining the principal solution based on Sb-Se mapping.

In the methodology proposed in this paper, the conversion of biological features into engineering structures stands as a pivotal stage in the construction of conceptual frameworks. Taking into consideration that within the natural realm, a single biological feature might serve diverse biological functions, integrating this attribute into BID can lead to streamlined system architectures and enhanced operational efficiency. In light of this, the present study introduced a design strategy for incorporating multifunctional shared components in the BID process. The specific steps are as follows:

Step 1: Feature combination analysis. Analyze the distinct characteristics of engineering structures to identify which features can mutually support and enhance each other in a multifunctional shared context.

Step 2: Function correlation analysis. Perform a functional correlation analysis on the engineering structures obtained through mapping and transformation, assessing the mutual influence of different features across various functions. Identify engineering structures suitable for function sharing.

Step 3: Modular design. Based on the characteristics of the engineering structure, conduct modular design by decomposing components of different functions into modules, ensuring each module can effectively achieve specific functionalities.

Step 4: Interaction analysis. Consider information exchange, energy transfer, and potential interference among the modules. Analyze the interactions between different modules to ensure their collaborative operation without conflicts.

Step 5: System integration. Integrate different modules into the overall system, ensuring connectivity and coordination between modules, enabling multi-functional shared components to perform within the entire system.

Step 6: Experimental validation and simulation. Employ experimental validation and simulation methods to verify the performance and stability of components under multi-functional shared conditions.

3.4. Process Model of Product-Integrated Innovation Design Based on Biological Inspiration

The whole design process starts from the problem of the product. Through the acquisition of biological prototypes and biological performance analysis, the features of the biological prototype with the highest advantageous performance impact value are integrated with the product to form integrated innovation ideas. The principal solutions are then obtained through three mapping methods: biological effects, biological behavior, and biological structure, converting the integrated innovation idea into a conceptual structure. The specific steps are as follows:

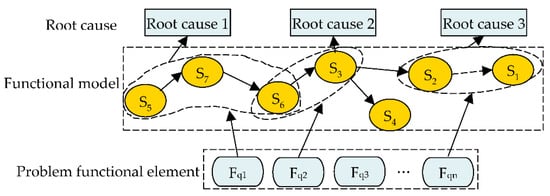

Step 1: Establish a functional model and identify the root cause of the problem through root cause analysis. On this basis, determine the conflict area where the root cause is located and further determine the problem functional element, as shown in Figure 10.

Figure 10.

Process of acquiring problem function elements.

Step 2: Acquire similar biological prototypes.

1. Search for biological prototypes based on the problem functional element and establish a search list. In the Asknature biological knowledge base, the problem functional element is searched using two methods: biomimicry taxonomy and keyword search. If the function belongs to insufficient or excessive function, search for this function or similar functions. If the function is harmful, search for the opposite function.

2. Analyze the functional similarity between the biological prototype and the problem functional element of the product, as well as the behavioral similarity of the behavior corresponding to the realization of the function. Functional similarity is analyzed to determine whether the effect of the biological prototype to achieve this function is the same as that of the product and then to build a list of similarity classification of the biological prototype.

Step 3: Generation of integrated innovation ideas based on biological performance analysis. By evaluating the advantageous performance of similar biological prototypes and judging the contribution degree of biological features, the advantageous performance impact value of biological features is calculated. Integrate the features of the biological prototype with the highest advantageous performance impact value in each category to obtain integrated ideas.

Step 4: Select an integrated innovation idea based on Pdi.

Step 5: Acquire the principal solution based on biological feature mapping.

Step 6: Summarize the obtained principal solutions, build the morphological matrix, and obtain the preliminary solutions.

Step 7: The method of ‘Entropy Weight Method-Grey Relational Analysis’ is used to evaluate the preliminary solutions, resulting in the optimal solution.

The entropy weight method is an objective weighting method, which determines the weight of each index according to the amount of information transmitted by each index. The magnitude of the weight reflects the relative competition intensity among the indexes [52]. In this paper, the weights of evaluation indexes were calculated by the entropy weight method, and the specific steps are as follows:

- Construct the evaluation index matrix. Assume that in the evaluation system with n evaluation indicators and m evaluated objects, the matrix formed by all evaluation scores is denoted as X = (xij)n×m, where xij (i = 1, 2, …, n; j = 1, 2, …, m) is the score of the j-th evaluated object under the i-th evaluation indicator, as shown in Equation (7).

- 2.

- Calculate the weight pij of the j-th evaluated object under the i-th evaluation indicator, as shown in Equation (8).

- 3.

- Calculate the entropy value ei (i = 1,2,…,n) of each indicator, as shown in Equation (9).

- 4.

- Calculate the redundancy di of the information entropy for each indicator, as shown in Equation (10).

- 5.

- Calculate the weight ωi for each indicator, as shown in Equation (11).

Grey relational analysis is a method that determines the correlation between curves by comparing the geometric similarity of the comparison sequence curve and the reference sequence curve. The higher the geometric similarity of the two curves, the greater the correlation. Grey relational analysis can also be used for scheme evaluation by calculating the correlation coefficients of different schemes to obtain the correlation degree values and then sorting the values to obtain the optimal scheme [53,54,55]. Based on the entropy weight method to calculate the weights of evaluation indexes, this article determined the optimal scheme through grey relational analysis, and the specific steps are as follows:

- Establish the initial decision matrix Y, which involves n samples characterized by m criteria.

- 2.

- Standardize the data.

If the maximum value is optimal, standardize the data as shown in Equation (13).

If the minimum value is optimal, standardize the data as shown in Equation (14).

- 3.

- Construct a standardized matrix by replacing each element in the initial decision matrix Y with the calculation result of y’ij. Calculate the maximum standardized value yo’(j) for each evaluation indicator, as shown in Equation (15), and use it as the reference value for the j-th evaluation indicator.

- 4.

- The difference value ∆oi(j) between each standardized value and its reference value is calculated, as shown in Equation (16).

A difference matrix ∆ is created, as shown in Equation (17).

- Calculate the grey relational coefficient roi(j) for each element, as shown in Equation (18), to obtain the matrix R.

- 2.

- Calculate the grey relational degree Γoi of the scheme, which represents the magnitude of the correlation, as shown in Equation (19). Here, ω(j) is the weight of the evaluation index obtained by the entropy weight method.

Step 8: Problem-solving and evaluation of the new concept structure.

Problem-solving and evaluation are performed by applying the optimal solution to establish the new concept structure. Whether there are problems in the new product concept structure is judged. If the answer is yes, the problems are solved according to TRIZ problem-solving tools [56,57,58]. Then, the improved product concept structure is established.

The process model of product-integrated innovation design based on biological inspiration is shown in Figure 11.

Figure 11.

Process model of product-integrated innovation design based on biological inspiration.

4. Case Study

Bio-inspired design has emerged as a transformative approach in the field of robotics, drawing inspiration from natural biological systems to develop innovative and efficient robotic solutions [59]. This methodology leverages millions of years of evolution and adaptation to create robots that possess enhanced capabilities and functionalities. By mimicking the intricate designs and behaviors found in nature, bio-inspired robotics has brought about a paradigm shift, enabling the development of robots that can excel in complex and dynamic environments.

Bio-inspired robots, founded upon the interplay between information and physical processes, have the capacity to imbue robots with the adaptivity, robustness, versatility, and agility demonstrated by biological organisms [60,61]. Applying these attributes in scenarios such as search-and-rescue missions enables the full utilization of the advantages of bio-inspired robots.

Forest fires possess characteristics of complexity and diversity, resulting in certain limitations for traditional firefighting methods. The application of firefighting robots can address these shortcomings, enhancing the capacity to respond to forest fires and improving firefighting efficiency. Additionally, it can mitigate safety risks for firefighters, presenting significant potential for application.

Forest firefighting robots need to possess the ability to navigate complex terrains and environments, including traversing ravines and thickets, climbing slopes, and clearing obstacles. They can be classified into three mobility modes: wheeled, tracked, and legged [62]. Among these, legged forest firefighting robots are developed based on bio-inspired design, incorporating the stability, coordination, and flexibility observed in the locomotion of crawling animals, thus holding crucial application prospects [63].

Analysis of the relevant literature [64,65,66] indicates that addressing forest fires with water-extinguishing methods may encounter challenges in terms of water sourcing. The use of chemical agents, such as dry powder for firefighting, may cause certain forest damage and add excessive payload to robots. Furthermore, forests often contain dense undergrowth, requiring obstacle clearance. Failure to clear obstacles in a timely manner could lead to missing the optimal firefighting window. Therefore, the purpose of this case study analysis was to overcome existing technological deficiencies and provide a forest firefighting robot solution that reduces environmental impact while enhancing firefighting efficiency.

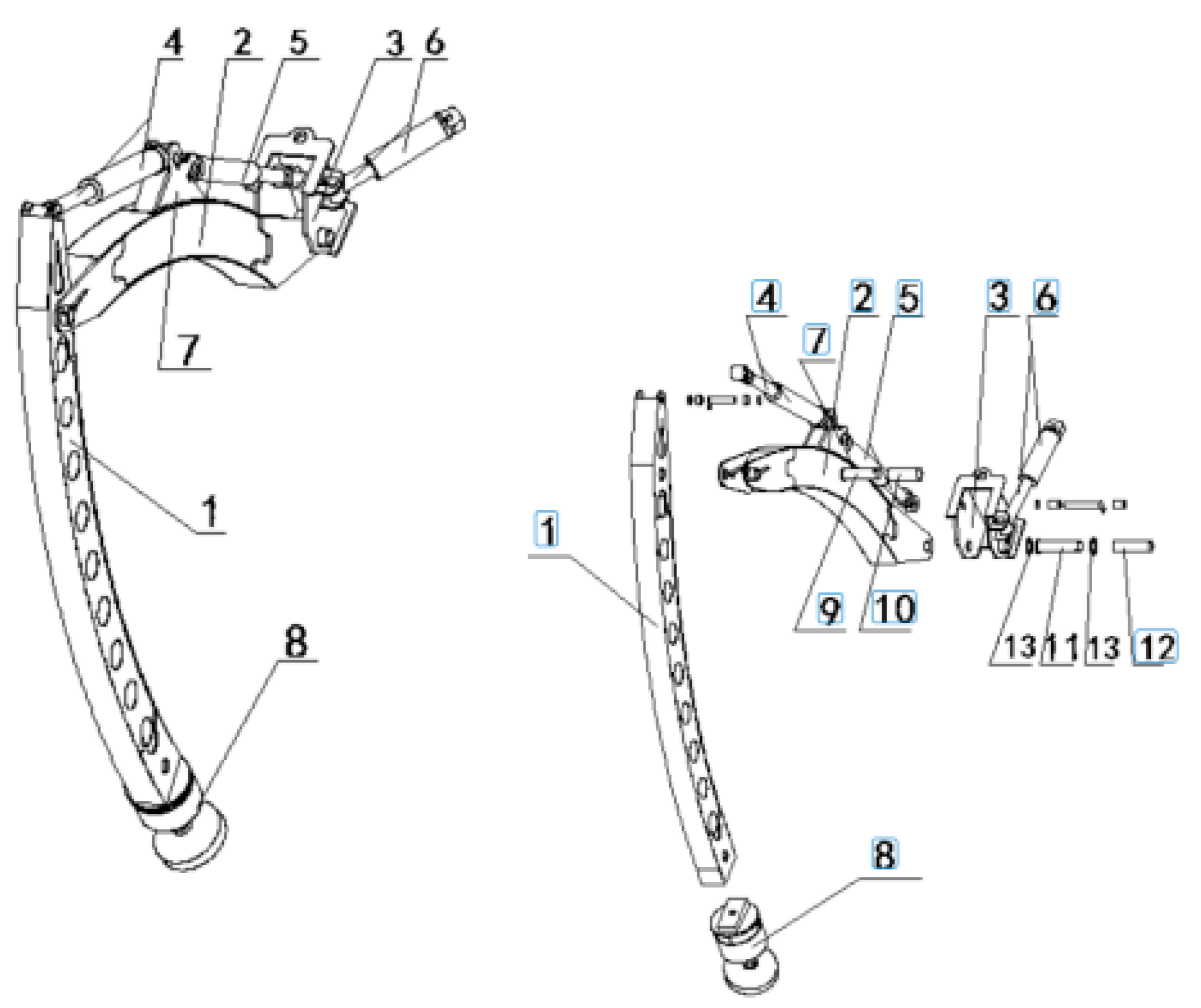

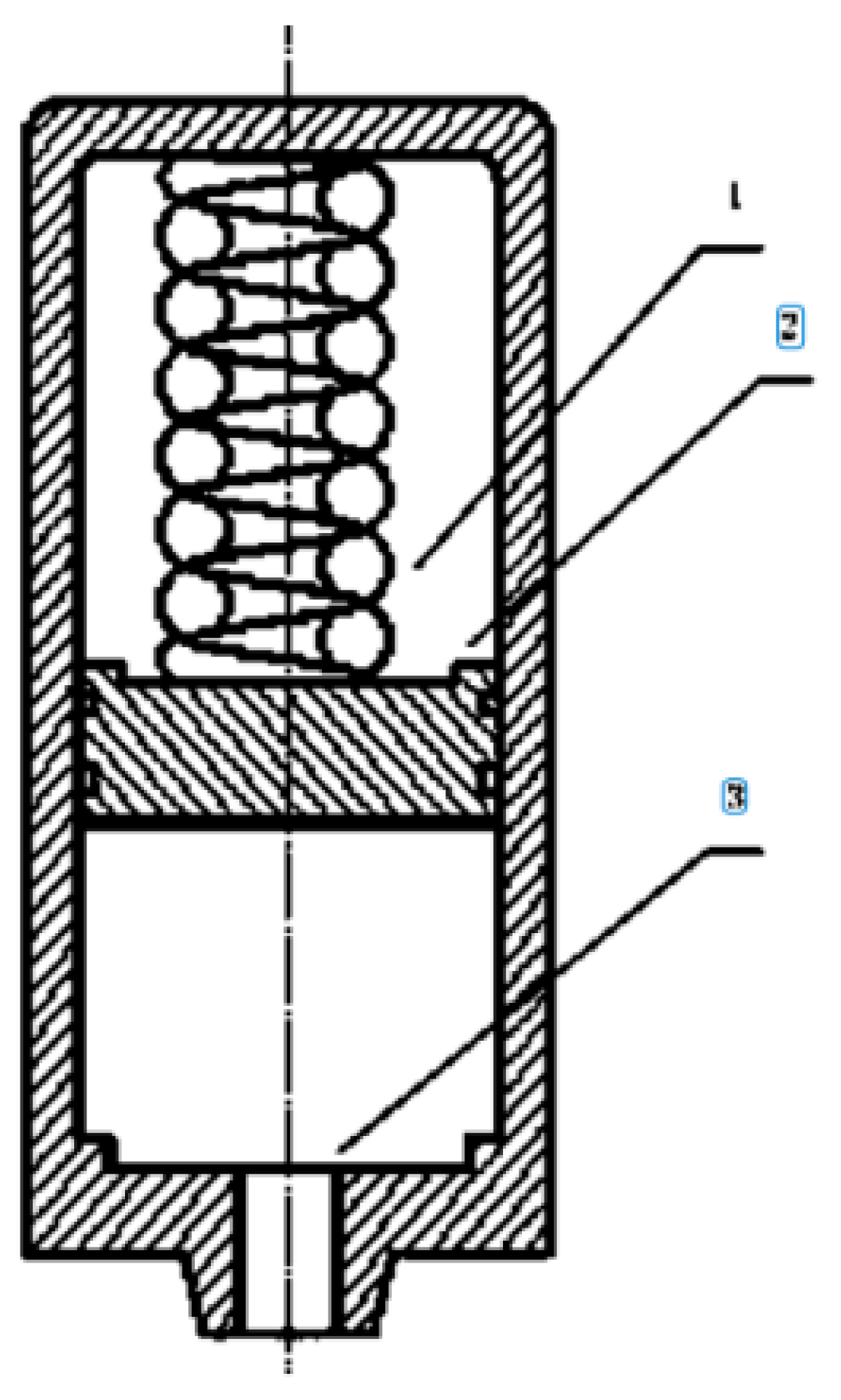

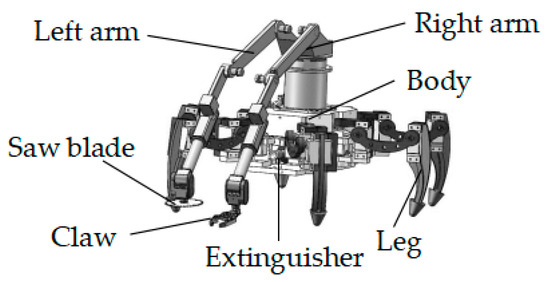

An existing six-legged fire-fighting robot includes legs, a left arm, a right arm, a body, and a fire extinguisher, as shown in Figure 12. During firefighting operations, the robot has problems such as slow clearance and low efficiency of firefighting. In this section, the aforementioned model is applied to solve the problem of low working efficiency of this six-legged fire-fighting robot.

Figure 12.

A six-legged fire-fighting robot.

Step 1: Identify problem functional elements based on root cause analysis.

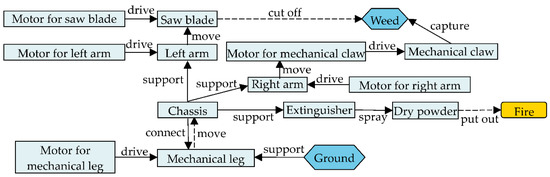

- The technical system of the product was decomposed, and a functional model was established, as shown in Figure 13.

Figure 13. Functional model.

Figure 13. Functional model.

- 2.

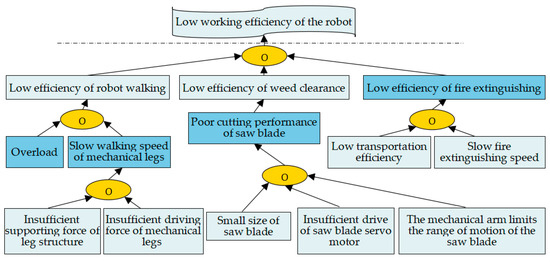

- A causal chain analysis is conducted to address the issue of the robot’s low working efficiency, as shown in Figure 14. The root causes of the problem are obtained, and the relationship between the root cause and the problem functional element is identified. The overload and slow walking speed of mechanical legs correspond to the problem functional element of ‘mechanical legs move chassis’, the poor cutting performance of the saw blade corresponds to the problem functional element of ‘saw blades cut weeds’, and the low efficiency of fire extinguishing corresponds to the problem functional element of ‘dry powder fire extinguishing’.

Figure 14. Causal chain analysis.

Figure 14. Causal chain analysis.

Step 2: Acquire similar biological prototypes.

- All the functions completed by the above problem functional elements belong to the insufficient function. Search for these functions or similar functions in the Asknature biological knowledge base, and a search list of problem functional elements and biological prototypes is established, as shown in Table 8.

Table 8. Search list of problem function elements and biology prototypes.

Table 8. Search list of problem function elements and biology prototypes.

- 2.

- A list of similarity levels of the biological prototypes is built. Take the problem functional element of ‘mechanical legs move chassis’ as an example for analysis. First, analyze the similar elements of the similar functional elements, as shown in Table 9. Obtain the similar value of similar function elements about similar indexes, as shown in Table 10.

Table 9. Similar index of similar functional elements.

Table 9. Similar index of similar functional elements. Table 10. Similar value of similar function element about the similar index.

Table 10. Similar value of similar function element about the similar index.

Using the spider as an example, the functional similarity value between ‘mechanical legs move chassis’ and ‘spider’s legs move body’ is calculated, as shown in Equation (20).

When the functional similarity value is ≥ 0.6, the functions implemented by ‘mechanical legs move chassis’ and ‘spider’s legs move body’ are similar. A list of functional similarity values of the biological prototypes is then established, as shown in Table 11.

Table 11.

List of functional similarity values of biology prototypes.

Second, the behavior corresponding to ‘mechanical legs move chassis’ is ‘motor drives the mechanical leg.’ Calculate the behavioral similarity value between ‘motor drives the mechanical leg’ and the behavior corresponding to the realization of the function by the biological prototype. A list of behavioral similarity values of biological prototypes is established, as shown in Table 12.

Table 12.

List of behavioral similarity values of biology prototypes.

Finally, a list of similarity levels between the biological prototypes and the problem functional element ‘mechanical legs move chassis’ is established, as shown in Table 13. In the same way, obtain the similarity levels between the remaining two problem functional elements and their corresponding biological prototypes.

Table 13.

List of similarity levels of biology prototypes.

Step 3: Generate integrated innovation ideas.

Based on the results of the root cause analysis, determine the problem functional elements of the product and the corresponding problem performances. An analysis list of problem functional elements is created, as shown in Table 14.

Table 14.

Analysis list of problem function elements.

For the problem functional element of ‘mechanical legs move chassis,’ the integrated idea is obtained by calculating the advantageous performance impact value of biological features. The process is as follows:

- According to Table 4, score the advantageous performance caused by the functional carrier, action, or functional object of the biological prototype, as shown in Table 15. Assuming that the volumes of these biological prototypes are similar, the magnitude of the structural support force is judged according to the density of the functional object, and the greater the density of the functional object, the greater the performance value. The magnitude of the driving force is determined based on the variable characteristics of the functional carrier. The weight of the load is determined by the density of the functional object, and the smaller the density of the functional object, the higher the advantage performance value.

Table 15. Advantageous performance values of biology prototypes.

Table 15. Advantageous performance values of biology prototypes. - Analyze the biological features that the biological prototype possesses when exhibiting advantageous performance in implementing a similar function and establish a list of biological characteristics, as shown in Table 16.

Table 16. List of biological features.

Table 16. List of biological features. - Taking the salamander as an example, calculate the contribution of biological features using the AHP. First, calculate the contribution of biological features for the function carrier of the salamander. The steps are as follows:

Step 1: Determine the composition of biological features. The set of biological features that contribute to the advantageous performance due to the functional carrier is denoted as X, where X = {irregular shape, structure distributed throughout the body, elastic properties}.

Step 2: Analyze the biological features and list the judgment matrix A.

Step 3: Calculate the maximum eigenvalue of matrix A, λmax = 3.0291. Normalize the obtained eigenvector G, resulting in the contribution value of the biological features, denoted as V, where V = (0.0629, 0.6716, 0.2654).

The steps for consistency check are as follows:

① Calculate the consistency index (CI).

② The table is checked to obtain the random index (RI).

③ Calculate the consistency ratio (CR).

When CR < 0.1, it is considered that the consistency of the judgment matrix is acceptable.

As the number of biological features contributing to the advantageous performance induced by both the functional action and the functional object of the salamander is 1, the contribution value of the features is therefore 1. In a similar way, calculate the contribution of features for other biological prototypes. Build a score table of the contribution of biological features for the problem functional element, ‘mechanical legs move chassis,’ as shown in Table 17.

Table 17.

Score table of contribution of biological features for ‘mechanical legs move chassis’.

- 4.

- Calculate the advantageous performance impact value of the biological features, as shown in Table 18.

Table 18. Score of advantageous performance impact value for ‘mechanical legs move chassis’.

Table 18. Score of advantageous performance impact value for ‘mechanical legs move chassis’.

Within biological prototypes with the same effect, select and integrate the features from the prototypes with the highest advantageous performance impact value in each category into the product. A total of four integrated ideas are obtained.

In a similar way, the integrated ideas of the problem functional element of ‘saw blades cut weeds’ and the problem functional element of ‘dry powder fire extinguishing’ can be obtained. A morphological matrix of multiple problem functional elements is established, as shown in Table 19. The integrated idea with the highest value of practical degree parameter in each problem function element is selected to solve the problem.

Table 19.

Analysis list of problem function elements.

Step 4: Select integrated innovation idea based on Pdi.

For the problem functional element of ‘mechanical legs move chassis,’ the value of Pdi of the integrated idea is calculated by Equation (6). The calculation process is shown in Table 20. The integrated idea 1, which has the highest value of Pdi, was selected as the final solution.

Table 20.

Calculation process of Pdi for ‘mechanical legs move chassis’.

In a similar way, for the problem functional element of ‘saw blades cut weeds,’ integrated idea 3 was selected as the final solution. For the problem functional element of ‘dry powder fire extinguishing,’ integrated idea 4 was selected as the final solution.

Step 5: Obtain the principal solution based on biological feature mapping.

- Solve the problem functional element of ‘mechanical legs move chassis’.

This integrated innovation idea includes the integration of morphology, structural distribution, characteristics, effects, and materials. Regarding effects, principal solutions are obtained based on the Eb-Et-Se mapping. For morphology, structural distribution, characteristics, and materials, principal solutions are obtained based on the Sb-Se mapping.

- (1)

- Acquire the principal solution based on Eb-Et-Se mapping.

Inspiration. The underside of the femur, patella, and tibia-metatarsal joints of the spider is filled with hemlymphatic fluid, which fills the spaces between muscle fibers. This fluid exerts pressure on the rippled structure, causing the legs to lengthen. Inspired by the muscle contraction effect and hydraulic effect, designers can draw insights for applying these principles in the engineering field, resulting in structures such as excavator mechanical arms, carousel lifting devices, tricycle self-dumping buckets, and hydraulic lifting platforms.

Search. Integrating the muscle contraction effect and hydraulic effect of spider legs, the movement of the mechanical leg applied the muscle contraction effect. By expanding synonyms, near synonyms, or related words for hydraulic effect, movement function, and mechanical leg, the search formula is TAC:(“walking” OR “walking mechanism” OR “walking device” OR “walking drive”) AND TAC:(“hydraulic” OR “hydraulic type” OR “hydraulic device” OR “hydraulic drive” OR “hydraulic mechanism”) AND TAC:(“mechanical leg” OR “ Leg mechanism” OR “Leg device”). The patents were clustered and screened based on experience, and the resulting patents are shown in Table 21.

Table 21.

Patent list for solving the problem functional element of ‘mechanical legs move chassis’.

Based on experience, all the structures obtained above were analyzed, and three engineering structures were selected: hydraulic auxiliary series mechanical leg with energy storage device, as shown in Z2. Hydraulic cylinders were connected in parallel as mechanical legs, and the hydraulic cylinder was equipped with an energy storage device, as shown in Z3. Hydraulic cylinders were connected in series as a mechanical leg, and the hydraulic cylinder was equipped with an energy storage device, as shown in Z4.

- (2)

- Acquire principal solution based on Sb-Se mapping.

For morphology, the mechanical leg already has the feature of the slender shape of the ostrich leg, and no improvement was needed. For structural distribution, the mechanical leg already has the feature of the spider leg in series, and no improvement was needed. For structure and foot material, the hole structure of the horse was applied to the design of the mechanical leg. A high-carbon alloy steel material with high hardness was searched for in the engineering field, and the material was replaced with the raw material used for the foot of the mechanical leg, with nylon on the outside and high-carbon alloy steel on the inside. For the body, in order to reduce the load, low-density aluminum alloy material was used.

- 2.

- Solve the problem functional element of ‘saw blades cut weeds’.

This integrated innovation idea includes the integration of morphology, structural distribution, characteristics, and behavior. For morphology, structural distribution, and characteristics, based on the principal solution of Sb-Se mapping acquisition, an electric chainsaw can be obtained.

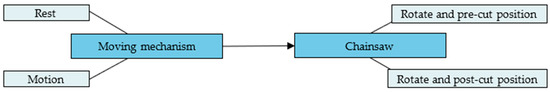

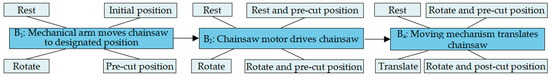

Regarding behaviors, principal solutions are obtained based on the Bb-Be-Se mapping. Integrate the behavior of the limpet moving its radula, the weevil moving its mouthpart, and the sawfish swinging its serrated nose with the product. For the product, it involves integrating the behavior of a translating chainsaw mechanism to achieve weed cutting. Establish a behavioral chain related to weed cutting functionality, as shown in Figure 15.

Figure 15.

Behavior chains related to the function of cutting weeds.

Perform behavior sharing and establish a behavior-component matrix, as shown in Table 22. The mechanical arm can be used as the moving mechanism to achieve the translation of the chainsaw. Therefore, a solution combining the mechanical arm and the chainsaw is obtained. However, using the mechanical arm directly would complicate the control and operation.

Table 22.

Behavior-component matrix.

Perform behavior addition by integrating the behavior of the moving mechanism with the chainsaw into the product. The specific steps are as follows:

① Establish the behavior feature model of the moving mechanism with the chainsaw, as shown in Figure 16. When the moving mechanism translates the chainsaw, the chainsaw itself rotates to cut branches and weeds.

Figure 16.

Behavior characteristics model of translating the chainsaw with the moving mechanism.

② Create a behavior correlation matrix, as shown in Figure 17. The receiving state of chainsaw B2, driven by the chainsaw motor, is the same as the pre-acceptance state of the moving mechanism with the chainsaw Ba. Therefore, Ba is placed after B2. Make appropriate adjustments to obtain an improved behavior chain, as shown in Figure 18.

Figure 17.

Behavior incidence matrix of translating chain saws with moving mechanism.

Figure 18.

Improved behavior chain.

③ Determine the compatibility of behaviors. The behavior of the translating chainsaw mechanism converts electrical energy into mechanical energy. The mechanical energy input for weed cutting comes from two sources: the chainsaw motor and the translating mechanism. Increasing the behavior of the translating mechanism in moving the chainsaw reduces the proportion of energy output from the previous behavior, resulting in an increase in mechanical efficiency for cutting weeds. Since no changes are made to the substance or signal, the behavior of the translating chainsaw mechanism is compatible with the previous behavior.

④ Search for components in the engineering field to implement this behavior. The movement of the limpet’s radula, the weevil’s mouthparts, or the sawfish’s swinging saw-like nose is achieved through muscle contraction. Therefore, the driving device for the translating mechanism can be an electric motor or a hydraulic motor. Furthermore, options for the translating mechanism include crank-slider mechanisms, cam mechanisms, gear-rack mechanisms, sliding table hydraulic cylinders, and ball screw mechanisms.

⑤ Component compatibility assessment. The crank-slider mechanism, cam mechanism, gear-rack mechanism, sliding table hydraulic cylinder, and ball screw mechanism are the components to be added, which have a connection relationship with the robotic arm and the chainsaw motor, satisfying component compatibility. These components will be securely attached to the end of the robotic arm, while the chainsaw motor will be positioned on the slider, connecting rod, rack, or sliding table structure of these components.

Step 6: Acquire preliminary solution.

Summarize the structures obtained from the aforementioned three problem functional elements and establish a morphological matrix, as shown in Table 23.

Table 23.

Morphological matrix.

Based on the compatibility of various structures, five initial schemes with higher feasibility were obtained through matching, as shown in Table 24.

Table 24.

Initial schemes.

Use the method of ‘Entropy Weight Method-Grey Relational Analysis’ to evaluate the five preliminary schemes. Combined with the needs of users and the development strategies of technicians, five evaluation indicators were proposed: fire extinguishing efficiency, economy, novelty, ease of manufacture, and space occupancy rate. Experts were invited to score the five indicators (full score of 10 points, which are positive integers) to obtain the score list, as shown in Table 25.

Table 25.

Score list.

Step 7: Program evaluation.

(1) Determine the weights.

The weights of the evaluation indicators were calculated according to the entropy weight method. The specific calculation steps are as follows:

1. Construct the evaluation index matrix. There are five evaluation indicators and five evaluation objects in the evaluation system. The evaluation index matrix X is constructed based on the score sheet.

2. Calculate the weight pij of the j-th evaluation object under the i-th evaluation indicator according to Equation (8) (i = 1,2,3,4,5; j = 1,2,3,4,5), forming the matrix P.

3. Calculate the entropy value of each indicator ei (i = 1,2,3,4,5) according to Equation (9), and form the matrix E.

4. Calculate the information entropy redundancy di (i = 1,2,3,4,5) of each indicator according to Equation (10), and calculate the weight ωi (i = 1,2,3,4,5) of each indicator according to Equation (11) to form the matrix W.

(2) Evaluation of schemes.

1. Construct the initial decision matrix Y, which involves five evaluation indicators and five evaluation objects.

2. Standardization of the data. Among these evaluation criteria, the largest data value is considered the best, and y’ij was obtained according to Equation (13), which constitutes the standardization matrix Y’, while yo’(j) was obtained according to Equation (15), yo’(1) = yo’(2) = yo’(3) = yo’(4) = yo’(5) = 1.0000.

3. Calculate the difference between each normalized term and its reference value and build the difference matrix Δ.

4. Calculate the gray correlation coefficient roi(j) for each item to form the matrix R.

5. Calculate the gray correlation Γoi. The gray correlation values are shown in Table 26.

Table 26.

Grey correlation degree value.

Therefore, scheme 4 has the largest grey correlation degree value, and scheme 4 is the optimal scheme.

Step 8: Problem analysis and solution.

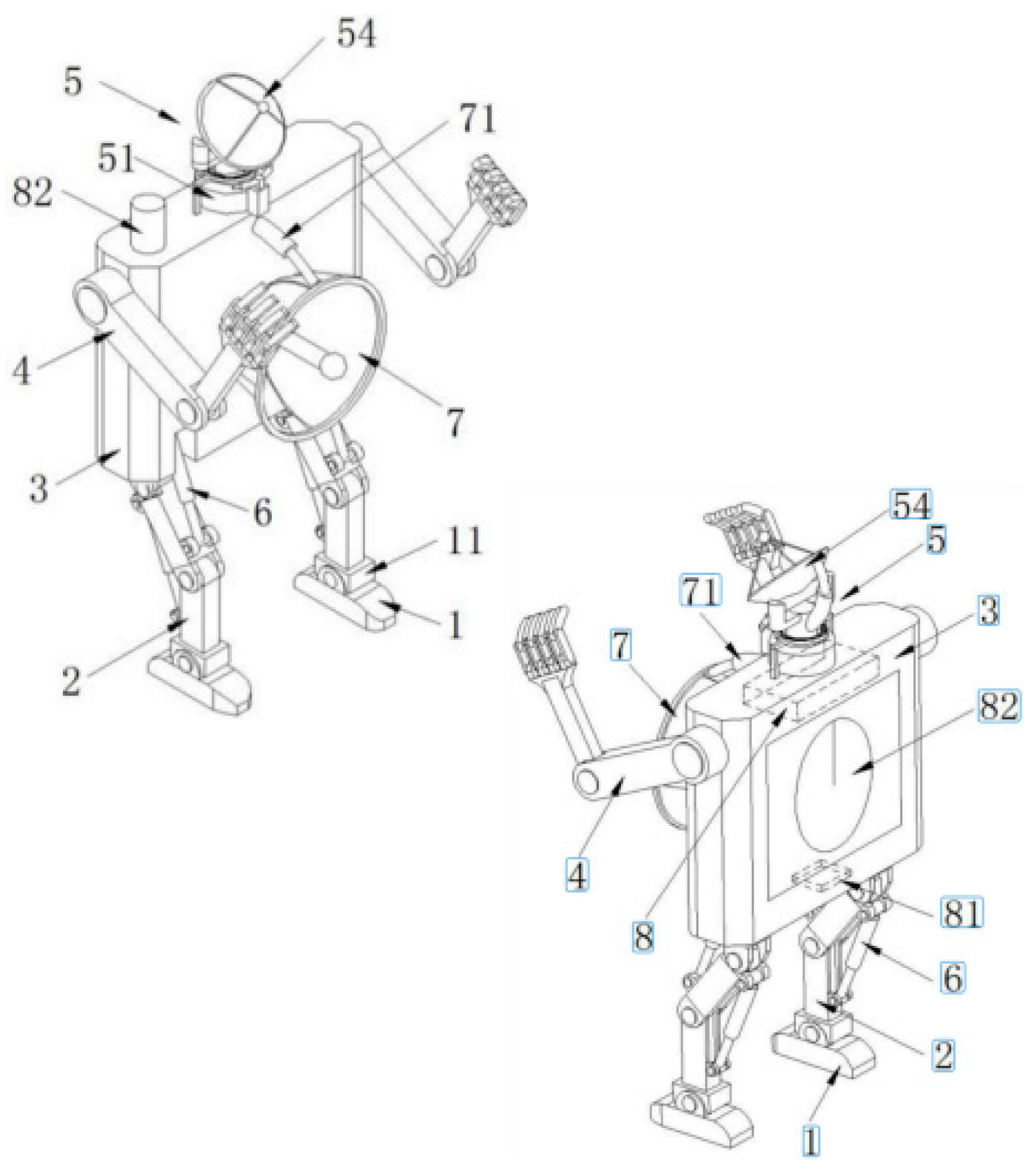

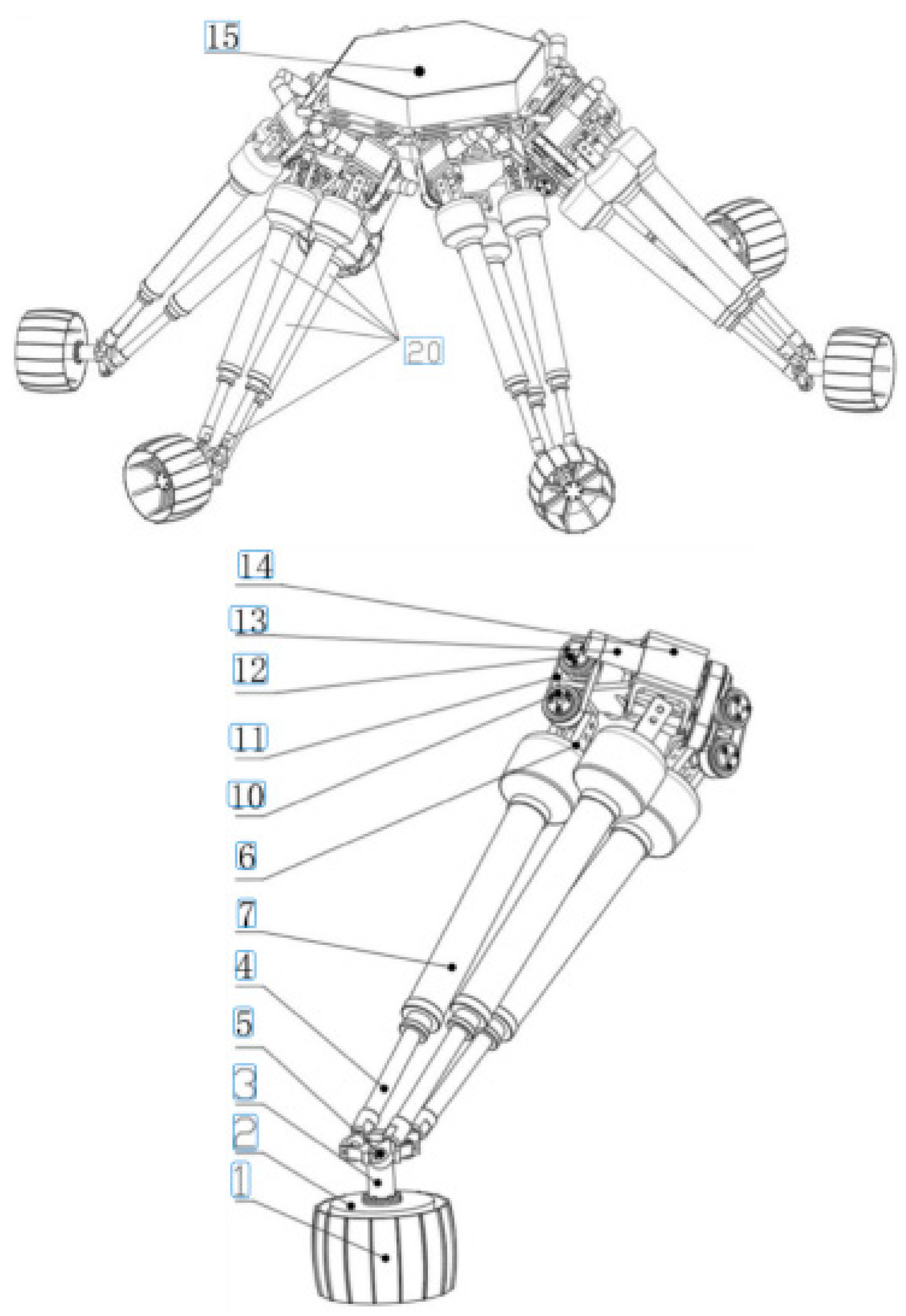

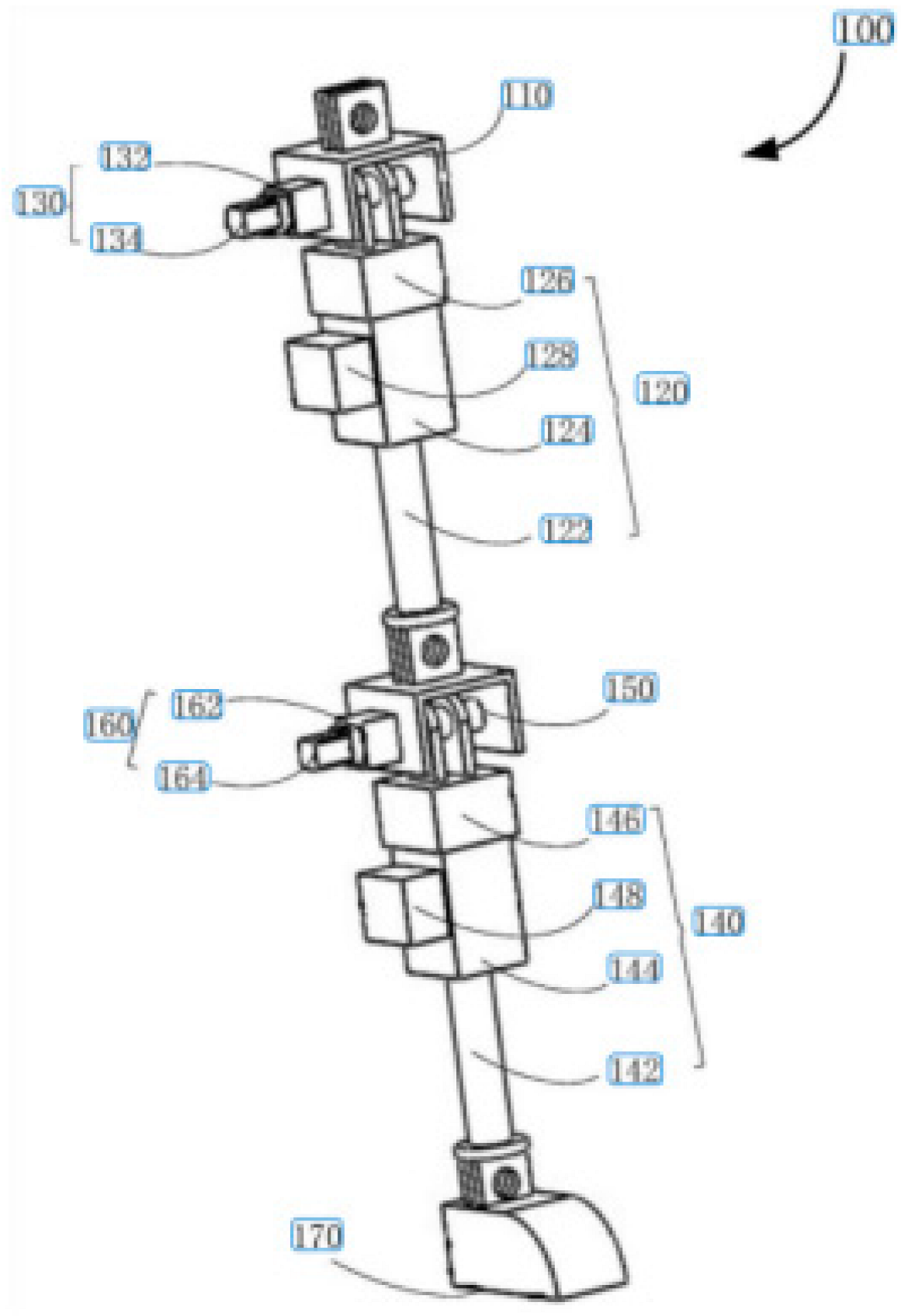

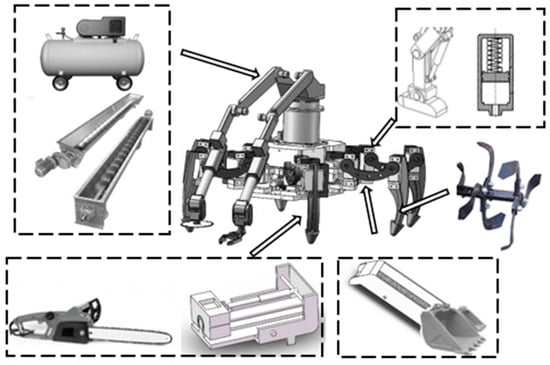

Improvements were made to the six-legged firefighting robot according to scheme 4, as illustrated in Figure 19. The upper segments of the mechanical legs, akin to ‘thighs’ in human anatomy, employed tandem mechanical legs aided by hydraulics, with accumulators featured in the hydraulic devices. The lower segments of the mechanical legs, comparable to ‘calves’ remained unchanged, being driven by motors. The robot’s left and right ‘arms’ were replaced by mechanical legs. The hydraulic cylinders for the sliding platform and the electric chainsaw were situated on the lower segments of the four mechanical legs that were oriented toward the front and back, respectively. Furthermore, the electric chainsaw was affixed to the sliding platform. The rotation of the chainsaw grinds down obstacles, while the outward sliding of the hydraulic cylinder of the sliding platform enables the chainsaw to cut through obstacles. Cutting turntables and soil-crushing rollers were installed on the lower segments of the two middle mechanical legs, with the rotation of the cutting turntable driving the soil-crushing rollers to break down the soil. In addition, a conveyor shovel with a screen was incorporated. The conveyor shovel was placed on the upper segments of the two middle mechanical legs, with a bucket hinged to the rear of the conveyor shovel for shoveling soil. The conveyor shovel with the screen facilitates soil transport and filtering. A screw conveyor was integrated into the body of the robot to transport soil, and an air compressor, located above the screw conveyor, was used to elevate the soil.

Figure 19.

Improvement process diagram of the firefighting robot.

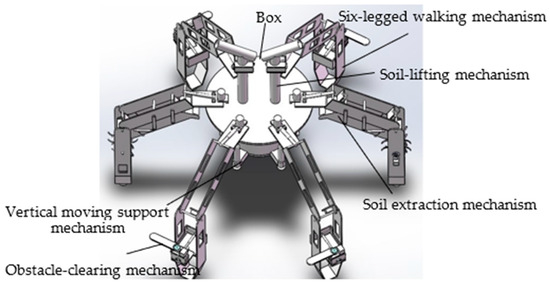

By further adjusting the structure of the robot, the initial product concept structure was achieved, as depicted in Figure 20. The robot comprised a box, a six-legged walking mechanism, two soil extraction mechanisms, two soil-lifting mechanisms, four obstacle-clearing mechanisms, and four vertical moving support mechanisms.

Figure 20.

Improvement process diagram of the firefighting robot.

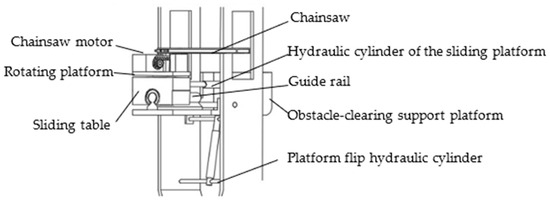

When building the conceptual structure, the obstacle-clearing mechanism was positioned at the lower segment of the mechanical leg to enhance the range of obstacle clearance, but this interfered with the robot’s mobility. To solve this problem, the TRIZ theory was applied to resolve the technical conflict. A solution was found: a platform flip hydraulic cylinder was installed under the obstacle-clearing support platform, and a rotating platform was set up between the sliding platform and the chainsaw motor, as shown in Figure 21. After the obstacle was cleared, the hydraulic cylinder of the sliding platform contracted, moving the sliding platform to its inner limit position. The rotating platform then pivoted, causing the chainsaw motor and chainsaw to rotate 90° clockwise. Subsequently, the platform flip hydraulic cylinder extended, causing the obstacle-clearing support platform to tilt inward, thus retracting the obstacle-clearing mechanism. After incorporating the platform flip hydraulic cylinder and the rotating platform, the final product concept structure was obtained, i.e., a soil-lifting six-legged firefighting robot.

Figure 21.

Improvement process diagram of the firefighting robot.

5. Discussion and Conclusions

Integrated innovation aids in enhancing an enterprise’s independent innovative ability, helping it to hold a dominant position in the market. Multi-biological knowledge can spark innovative thoughts among designers, providing them with fresh inspirations. The key to realizing product-integrated innovation lies in how to generate integrated innovation ideas based on multi-biological knowledge and how to construct product conceptual structures through the transfer and integration of cross-domain biological knowledge. Based on the BID process, this study explored the integrated innovation mechanism based on biological inspiration. It proposed a method of generating integrated innovation ideas based on biological inspiration, as well as a method of establishing integrated innovation concept structure based on biological feature mapping, ultimately presenting a process model of product-integrated innovation design based on biological inspiration. This process effectively guides designers in achieving integrated innovation through multi-biological knowledge inspiration. The method proposed in this paper offers a novel approach to industrial design.