Numerical Assessment of Standard Firebrand Accumulation Curve When Transferring Temperature to Contact Surfaces

Abstract

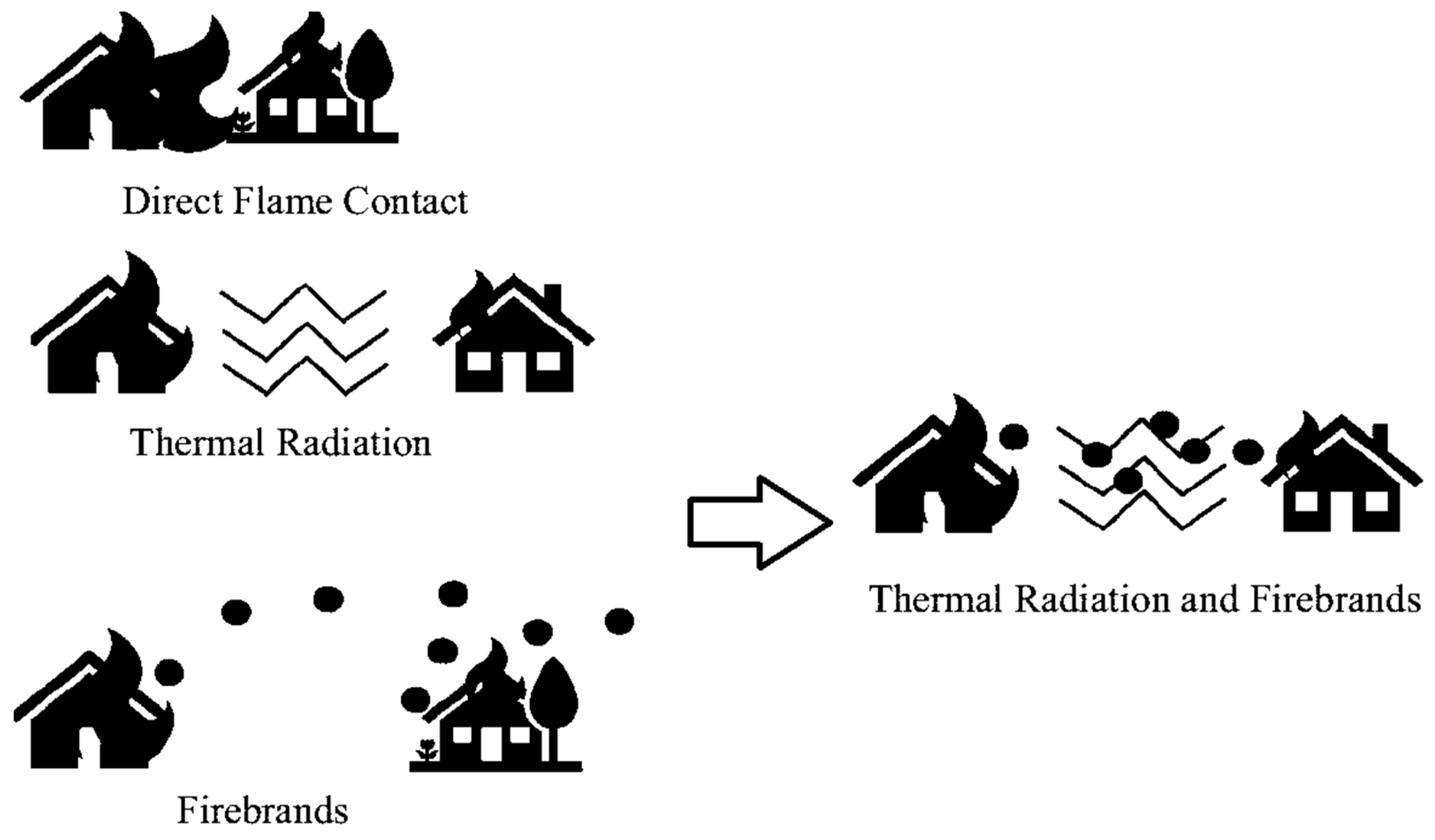

:1. Introduction

1.1. Research Significance

1.2. Objectives

2. Previous Experimental Campaign for Firebrand Accumulation

3. Standard Firebrand Accumulation Temperature Curve

4. Validation of the Numerical Model

4.1. Previous Experimental Campaign by Cantor et al. [38]

4.1.1. Geometry and Type of Analysis

4.1.2. Materials and Methods

4.1.3. Boundary Conditions

4.1.4. Adopted Mesh

4.1.5. Results

4.2. Previous Experimental Campaign by Mueller et al. [37]

4.2.1. Geometry and Type of Analysis

4.2.2. Materials and Methods

4.2.3. Boundary Conditions and Adopted Mesh

4.2.4. Results

5. Case Study of Firebrand Accumulation

Results

6. Final Remarks

6.1. Future Developments

6.2. Limitations of the Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Caton, S.E.; Hakes, R.S.; Gorham, D.J.; Zhou, A.; Gollner, M.J. Review of Pathways for Building Fire Spread in the Wildland Urban Interface Part I: Exposure Conditions. Fire Technol. 2017, 53, 429–473. [Google Scholar] [CrossRef]

- Hakes, R.S.; Caton, S.E.; Gorham, D.J.; Gollner, M.J. A Review of Pathways for Building Fire Spread in the Wildland Urban Interface Part II: Response of Components and Systems and Mitigation Strategies in the United States. Fire Technol. 2017, 53, 475–515. [Google Scholar] [CrossRef]

- Firefighter, W. Thousands Flee South Korea Wildfire. Available online: https://www.wildlandfirefighter.com/2019/04/05/thousands-flee-south-korea-wildfire/#gref (accessed on 19 October 2022).

- Marlon, J.R.; Bartlein, P.J.; Gavin, D.G.; Long, C.J.; Anderson, R.S.; Briles, C.E.; Brown, K.J.; Colombaroli, D.; Hallett, D.J.; Power, M.J.; et al. Long-term perspective on wildfires in the western USA. Proc. Natl. Acad. Sci. USA 2012, 109, E535–E543. [Google Scholar] [CrossRef]

- Calfire. 2018 Incident Archive. Available online: https://www.fire.ca.gov/incidents/2018/ (accessed on 19 October 2022).

- Syifa, M.; Panahi, M.; Lee, C.-W. Mapping of Post-Wildfire Burned Area Using a Hybrid Algorithm and Satellite Data: The Case of the Camp Fire Wildfire in California, USA. Remote Sens. 2020, 12, 623. [Google Scholar] [CrossRef]

- Guerreiro, J.; Fonseca, C.; Salgueiro, A.; Fernandes, P.; Lopez, I.E.; de Neufville, R.; Mateus, F.; Castellnou, R.M.; Sande, S.J.; Moura, J.M.; et al. Avaliação dos Incêndios Ocorridos Entre 14 e 16 de Outubro de 2017 em Portugal Continental. 2018. Available online: https://www.portugal.gov.pt/pt/gc21/comunicacao/documento?i=avaliacao-dos-incendios-ocorridos-entre-14-e-16-de-outubro-de-2017-em-portugal-continental (accessed on 19 July 2023).

- Viegas, D.X.; Almeida, M.F.; Ribeiro, L.M.; Raposo, J.M.T.V.; Oliveira, R.; Alves, D.; Pinto, C.; Jorge, A.R.H.; Lucas, D.; Lopes, S.; et al. O Complexo de Incêndios de Pedrógão Grande e Concelhos Limítrofes, Iniciado a 17 de Junho de 2017. 2017. Available online: https://www.portugal.gov.pt/pt/gc21/comunicacao/documento?i=o-complexo-de-incendios-de-pedrogao-grande-e-concelhos-limitrofes-iniciado-a-17-de-junho-de-2017 (accessed on 19 July 2023).

- Cantor, P.; Arruda, M.R.T.; Firmo, J.; Branco, F. Proposal of Standard Wildfire Curves for the Design Protection of Dwellings against Wildland Fire. J. Hazard. Toxic Radioact. Waste 2022, 26, 04022021. [Google Scholar] [CrossRef]

- Manzello, S.L.; Suzuki, S. Experimental investigation of wood decking assemblies exposed to firebrand showers. Fire Saf. J. 2017, 92, 122–131. [Google Scholar] [CrossRef]

- Manzello, S.L.; Cleary, T.G.; Shields, J.R.; Maranghides, A.; Mell, W.; Yang, J.C. Experimental investigation of firebrands: Generation and ignition of fuel beds. Fire Saf. J. 2008, 43, 226–233. [Google Scholar] [CrossRef]

- Manzello, S.L.; Park, S.-H.; Cleary, T.G. Investigation on the ability of glowing firebrands deposited within crevices to ignite common building materials. Fire Saf. J. 2009, 44, 894–900. [Google Scholar] [CrossRef]

- Warey, A. Influence of thermal contact on heat transfer from glowing firebrands. Case Stud. Therm. Eng. 2018, 12, 301–311. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Investigating Coupled Effect of Radiative Heat Flux and Firebrand Showers on Ignition of Fuel Beds. Fire Technol. 2021, 57, 683–697. [Google Scholar] [CrossRef]

- Jack, D.; Cohen, R.D.S. Home Destruction Examination: Grass Valley Fire; United State Department of Agriculture: Lake Arrowhead, CA, USA, 2008; p. 26.

- Maranghides, D.M.A.; Vihnanek, R.; Restaino, J.; Leland, C. A Case Study of a Community Affected by the Waldo Fire Event Timeline and Defensive Actions; National Institute of Standards and Technology: Gaithersburg, MA, USA, 2015.

- Mell, W.E.; Manzello, S.L.; Maranghides, A.; Butry, D.; Rehm, R.G. The wildlandurban interface fire problem current approaches and research needs. Int. J. Wildland Fire 2010, 19, 238–251. [Google Scholar] [CrossRef]

- Tarifa, C.S.; Del Notario, P.P.; Moreno, F.G. On the flight paths and lifetimes of burning particles of wood. Symp. Int. Combust. 1965, 10, 1021–1037. [Google Scholar] [CrossRef]

- Woycheese, J.P.; Pagni, P.J.; Liepmann, D. Brand Propagation from Large-Scale Fires. J. Fire Prot. Eng. 1999, 10, 32–44. [Google Scholar] [CrossRef]

- Wadhwani, R.; Sullivan, C.; Wickramasinghe, A.; Kyng, M.; Khan, N.; Moinuddin, K. A review of firebrand studies on generation and transport. Fire Saf. J. 2022, 134, 103674. [Google Scholar] [CrossRef]

- Usda, F.A.A. Transport of Firebrands by Line Thermals. Combust. Sci. Technol. 1983, 32, 277–288. [Google Scholar] [CrossRef]

- Matvienko, O.V.; Fil’kov, A.I.; Grishin, A.M. Computational Investigation of the Transport of Burning Particles. J. Eng. Phys. Thermophys. 2016, 89, 1315–1324. [Google Scholar] [CrossRef]

- Wang, H.-H. Analysis on Downwind Distribution of Firebrands Sourced from a Wildland Fire. Fire Technol. 2011, 47, 321–340. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Characteristics of Firebrands Collected from Actual Urban Fires. Fire Technol. 2018, 54, 1533–1546. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L.; Lage, M.; Laing, G. Firebrand generation data obtained from a full-scale structure burn. Int. J. Wildland Fire 2012, 21, 961–968. [Google Scholar] [CrossRef]

- Manzello, S.L.; Maranghides, A.; Mell, W.E. Firebrand generation from burning vegetation. Int. J. Wildland Fire 2007, 16, 458–462. [Google Scholar] [CrossRef]

- Hakes, R.S.P.; Salehizadeh, H.; Weston-Dawkes, M.J.; Gollner, M.J. Thermal characterization of firebrand piles. Fire Saf. J. 2019, 104, 34–42. [Google Scholar] [CrossRef]

- Manzello, S.L.; Suzuki, S. Experimentally Simulating Wind Driven Firebrand Showers in Wildland-urban Interface (WUI) Fires: Overview of the NIST Firebrand Generator (NIST Dragon) Technology. Procedia Eng. 2013, 62, 91–102. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Initial study on thatched roofing assembly ignition vulnerabilities to firebrand showers. Fire Saf. J. 2019, 103, 34–37. [Google Scholar] [CrossRef]

- Kasymov, D.; Paletsky, A. Effect of a fire retardant on the ignition of pine wood exposed to smoldering particles of pine bark. EPJ Web Conf. 2017, 159, 00026. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L. Firebrand production from building components fitted with siding treatments. Fire Saf. J. 2016, 80, 64–70. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, S.; Manzello, S.L. Garnering understanding into complex firebrand generation processes from large outdoor fires using simplistic laboratory-scale experimental methodologies. Fuel 2020, 267, 117154. [Google Scholar] [CrossRef]

- Suzuki, S.; Manzello, S.L.; Hayashi, Y. The size and mass distribution of firebrands collected from ignited building components exposed to wind. Proc. Combust. Inst. 2013, 34, 2479–2485. [Google Scholar] [CrossRef]

- Kasymov, D.P.; Tarakanova, V.A.; Martynov, P.S.; Agafontsev, M.V. Studying firebrands interaction with flat surface of various wood construction materials in laboratory conditions. J. Phys. Conf. Ser. 2019, 1359, 012092. [Google Scholar] [CrossRef]

- Salehizadeh, H.; Hakes, R.S.P.; Gollner, M.J. Critical Ignition Conditions of Wood by Cylindrical Firebrands. Front. Mech. Eng. 2021, 7, 17. [Google Scholar] [CrossRef]

- Manzello, S.L.; Suzuki, S.; Naruse, T. Quantifying wind-driven firebrand production from roofing assembly combustion. Fire Mater. 2019, 43, 3–7. [Google Scholar] [CrossRef]

- Thomas, J.C.; Mueller, E.; Hadden, R.M. Estimating net heat flux from surrogate firebrand accumulations using an inverse heat transfer approach. In Advances in Forest Fire Research; University of Coimbra: Coimbra, Portugal, 2018; pp. 769–779. [Google Scholar] [CrossRef]

- Cantor, P.; Arruda, M.R.T.; Firmo, J.; Branco, F. Development of a standard firebrand accumulation temperature curve for residential wildfire protection system. Results Eng. 2023, 17, 100935. [Google Scholar] [CrossRef]

- Jones, J.C.; Raj, S.C. The self-heating and ignition of vegetation debris. Fuel 1988, 67, 1208–1210. [Google Scholar] [CrossRef]

- Jones, J.C.; Rahmati, H. The self-heating and ignition of vegetation debris. 2. Authentic litter samples. Fuel 1990, 69, 253–255. [Google Scholar] [CrossRef]

- Jones, J.C.; Ramahti, H.; Fowler, D.; Vorasurayakarnt, J.; Bridges, R.G. The Self-Heating and Thermal Ignition Propensity of Forest Floor Litter. J. Fire Sci. 1990, 8, 207–223. [Google Scholar] [CrossRef]

- Jones, J.C. Predictive Calculations of the Effect of an Accidental Heat Source on a Bed of Forest Litter. J. Fire Sci. 1993, 11, 80–86. [Google Scholar] [CrossRef]

- Jones, J.C. Further Calculations Regarding the Accidental Supply of Heat to a Bed of Forest Material. J. Fire Sci. 1994, 12, 502–505. [Google Scholar] [CrossRef]

- Jones, J.C. Improved Calculations Concerning the Ignition of Forest Litter by Hot Particle Ingress. J. Fire Sci. 1995, 13, 350–356. [Google Scholar] [CrossRef]

- Grishin, A.M.; Dolgov, A.A.; Zima, V.P.; Kryuchkov, D.A.; Reino, V.V.; Subbotin, A.N.; Tsvyk, R.S. Ignition of a layer of combustible forest materials. Combust. Explos. Shock. Waves 1998, 34, 613–620. [Google Scholar] [CrossRef]

- Bearinger, E.D.; Hodges, J.L.; Yang, F.; Rippe, C.M.; Lattimer, B.Y. Localized heat transfer from firebrands to surfaces. Fire Saf. J. 2021, 120, 103037. [Google Scholar] [CrossRef]

- California Building Code. Chapter 7A [SFM] Materials and Construction Methods for Exterior Wildfire Exposure. 2010. Available online: https://up.codes/viewer/california/ca-building-code-2016/chapter/7A/sfm-materials-and-construction-methods-for-exterior-wildfire-exposure#7A (accessed on 19 July 2023).

- Arruda, M.R.T.; Tenreiro, T.; Branco, F. Rethinking How to Protect Dwellings against Wildfires. J. Perform. Constr. Facil. 2021, 35, 06021004. [Google Scholar] [CrossRef]

- El Houssami, M.; Mueller, E.; Filkov, A.; Thomas, J.C.; Skowronski, N.; Gallagher, M.R.; Clark, K.; Kremens, R.; Simeoni, A. Experimental Procedures Characterising Firebrand Generation in Wildland Fires. Fire Technol. 2016, 52, 731–751. [Google Scholar] [CrossRef]

- EN 1990:2002; Eurocode 0—Basis of Structural Design. Comité Européen de Normalisation: Brussels, Belgium, 2002.

- Dassault Systemes Simulia Corporation. ABAQUS v.2018; Dassault Systèmes: Johnston, RI, USA, 2018; Available online: https://www.3ds.com/products-services/simulia/products/abaqus/ (accessed on 19 July 2023).

- EN 1991-1-2:2002; Eurocode 1: Actions on Structures—Part 1–2: General Actions—Actions on Structures Exposed to Fire. Comité Européen de Normalisation: Brussels, Belgium, 2002.

- Thomas, H.R.; Zhou, Z. Minimum time-step size for diffusion problem in FEM analysis. Int. J. Numer. Methods Eng. 1997, 40, 3865–3880. [Google Scholar] [CrossRef]

- EN 1994-1-2:2005; Eurocode 4: Design of Composite Steel and Concrete Structures—Part 1–2: General Rules—Structural Fire Design. Comité Européen de Normalisation: Brussels, Belgium, 2005.

- Hottel, H.C. Radiant Heat Transmission Between Surfaces Separated by Non-Absorbing Media. Trans. Am. Soc. Mech. Eng. 2023, 53, 265–271. [Google Scholar] [CrossRef]

- Morgado, T.M.R. Thermal and Structural Response of Pultruded GFRP Profiles under Fire Exposure. Ph.D. Thesis, Universidade de Lisboa, Lisboa, Portugal, 2018. [Google Scholar]

- Mazzuca, P. Fire Behaviour of GFRP Sandwich Panels for the Rehabilitation of Building Floors. Ph.D. Thesis, Universita’ Della Calabria, Rende, Italy, 2022. [Google Scholar]

- EN 1995-1-2:2004; Eurocode 5: Design of Timber Structures—Part 1–2: General—Structural Fire Design. Comité Européen de Normalisation: Brussels, Belgium, 2004.

- Assis, E.B.; Neto, J.M. Analysis of heat transfer mechanisms on hollow concrete masonry units under standardized fire conditions. Proceedings of XLI Ibero-Latin-American Congress on Computational Methods in Engineering, Foz do Iguaçu, Brazil, 16–19 November 2020; Available online: https://cilamce.com.br/anais/arearestrita/apresentacoes/194/7822.pdf (accessed on 19 July 2023).

- Wickström, U. Temperature Calculation in Fire Safety Engineering, 1st ed.; Springer: Cham, Switzerland, 2016; 243p. [Google Scholar] [CrossRef]

- Bergman, T.; Lavine, A.; Incropera, F.; Dewitt, D. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bicelli, A.R.; Cantor, P.; Arruda, M.R.; Tiago, C.; Bernardes de Assis, E.; Branco, F. Numerical Assessment of Standard Firebrand Accumulation Curve When Transferring Temperature to Contact Surfaces. Appl. Sci. 2023, 13, 9657. https://doi.org/10.3390/app13179657

Bicelli AR, Cantor P, Arruda MR, Tiago C, Bernardes de Assis E, Branco F. Numerical Assessment of Standard Firebrand Accumulation Curve When Transferring Temperature to Contact Surfaces. Applied Sciences. 2023; 13(17):9657. https://doi.org/10.3390/app13179657

Chicago/Turabian StyleBicelli, Antonio Renato, Pedro Cantor, Mário Rui Arruda, Carlos Tiago, Ellon Bernardes de Assis, and Fernando Branco. 2023. "Numerical Assessment of Standard Firebrand Accumulation Curve When Transferring Temperature to Contact Surfaces" Applied Sciences 13, no. 17: 9657. https://doi.org/10.3390/app13179657